Craftsman 113236090 Owner’s Manual

Save This Manual

For Future Reference

owner's

manual

Model No.

113.236090

Serial

Number

Model and serial num-

bers may be found

attached to the right

side of arm housing.

You should record both

model and serial num-

bers in a safe place for

future use,

====1=

FOR YOUR

SAFETY

READ ALL

INSTRUCTIONS

CAREFULLY

r

®

16 iNCH VARIABLE

SPEED SCROLL SAW

- assembly

• operating

° repair parts

Sears, Roebuck and Coo, Hoffman Estates, IL 60179 U.S.A.

Part No SP5837 Printed in USA,

_FULi-ONF YEAR WARRANTY ON CRAFTSMAN BENCHTOP TOOLS

If this Scroll Saw fails due to a defect in material or workmanship,

within one year from the date of purchase, RETURN IT TO THE NEAR=

EST SEARS SERVICE CENTER IN THE UNITED STATES, and Sears will

repair it, free of Charge.

If this Scroll Saw is used for commercial or rental purposes, warranty

will apply for ninety days from the date of purchase.

This warranty applies only while this product is in the United States.

This warranty gives you specific legal rights and you may also have

other rights which vary from state to state.

Sears, Roebuck and Co., D817 WA Hoffman Estates, IL. 60179

b_

Safety Instructions for Scroll Saw

Safety is a combination of common your scroll saw works. Read this manual

sense, staying alert and knowing how to understand this saw.

Safety Signal Words

DANGER: means if the safety informa- seriously injured or killed.

tion is not followed someone will be seri- CAUTION: means if the safety informa-

ous]y injured or killed, tion is not followed someone might be

WARNING: means if the safety informa- njured.

tion is not followed someone could be

Before Using The Saw

WARNING: To avoid mistakes

that could cause serious perma-

nent injury, do not plug the saw in

until the following steps are com-

pleted.

• Completely assemble and align saw

(see "Assembly and Alignment" sec-

tions w_hin).

• Learn the use and function of the

speed control ON-OFF knob, bevel lock

knob blade holders, blade support,

hold down, tension knob, and blade

guard. (See "Getting to Know Your

Scroll Saw" section.)

* Review and understand all safety

instructions and operating procedures

in this manual.

* Review the maintenance methods for

this saw. (See "Maintenance" section.)

- Read the warning label below, found on

the base of the saw.

1. Readmanual before usingsaw,

2. Wearsafely goggleslhet meet ANStZ87.1 S_ndards,

3. Besere blade is inslalladwlthteeth pointing down.

4, Properlyadjusthelddow_,

S.' Keepfingersaway hem the movingblade.

S. DOnotronleve is_mme_tcutoffpiaces_untitblade has stopped.

7. Mnlntnlnp_per adiustznunt Ofblade tensio_.

8. Holdwed(piece fimlly _llales4 Ibe table.

9. Turnpower off a_dwait for bladeto st_pbefere adlu_ng orservicinlD.

50_t700 RPM 1 PHASE 120 VOLT AC ONLY 60 HZ L2 AMPS

..... L ...... . _ ,

When Installing or Moving The Saw

Avoid Dangerous Environment. Use

the saw in a dry indoor place, protected

from rain. Keep work area wel! lighted.

To avoid injury from unexpected saw

movement:

oTurn saw off and unplug cord before

moving the saw.

- Place the saw on a firm level surface

where there is plenty of room for han-

dling and properly supporting the work-

piece.

. Support the saw so the table is level

and the saw does not rock.

o Bott the saw to the work surface if it

tends to slip, walk, or slide during oper-

ations like cutting long heavy boards, or

when using an auxiliarytabte.

° Never Stand On Tool. Serious injury

Before Each Use

Inspect your saw.

Disconnect The Saw. To avoid injury

from accidental starting, unplug the saw,

turn the switch off and lock out the switch

before changing the setup, removing

covers, guards or blade.

Check For Damaged Parts. Check for:

• Alignment of moving parts,

- Binding of moving parts.

° Broken parts,

• Stable mounting.

° Any other conditions that may affect the

way the saw works.

If any part is missing, bent or broken in

any way, or any electrical parts don't

work properly, turn the saw off and

unplug the saw. Replace damaged,

missing or failed parts before using the

saw again. Keep Guard In Place and in

working order,

Maintain Tools with Care. Keep the saw

clean for best and safest performance,

Follow instructions for lubricating.

Remove adjusting keys and wrenches

from tool before turning it on.

To avoid injury from jams, slips or

thrown pieces

° Use Only Recommended Accesso-

ries. (See "Recommended Accesso-

ries" section), Consult this owners

manual for recommended accessories.

could occur Jfthe tool tips or you acci-

dentally hit the cutting toot. Do not store

any item above or near the tool where

anyone might stand on the scroll saw to

reach that item.

To avoid injury or death from electri-

cal shock:

• Ground the saw. This saw has an

approved 3 conductor cord and a 3-

prong grounding type plug. Use only 3-

wire, grounded outlets rated 120 volts,

15 amperes (amps). The green con-

ductor inthe cord is the grounding wire.

To avoid electrocution, NEVER con-

nect the green wire to a live terminal.

oMake sure your fingers do not touch

the plug's metal prongs when plugging

or unplugging the saw.

Follow the instructions that come with

the accessories. The use of improper

accessories may cause risk of injury to

person.

• Choose the right size and style blade

for the material and the type of cutting

you plan to do.

° Make sure the blade teeth point down-

ward, toward the table.

• Make surethe blade tension is properly

adjusted,

• Keep Work Area Clean. Cluttered

areas and benches invite accidents.

Floor must not be slippery.

To avoid burns or other fire damage,

never use the saw near flammable liq-

uids, vapors or gases,

• Know Your Saw. Read and under-

stand the owners manual and labels

affixed to the tool, Learn its application

and limitations as well as the specific

potential hazards peculiar to this tool.

° To avoid injury from accidental contact

with moving parts, don't do _ayout,

assembly, or setup work on the saw

while any parts are moving.

• Avoid Accidental Starting. Make sure

switch is "OFF" before plugging saw

into a power outlet.

Safety Instructions for Scroll Saw (continued)

Plan Your Work.

- Use The Right Tool. Don't force tool or

attachment to do a job it was not

designed to do.

• Use this scroll saw to cut only wood,

woodlike products, plastics and nonfer-

rous metals.

Plan Ahead To Protect Your Eyes, Hands, Face and Ears

Any power saw can throw foreign objects

into the eyes. This can cause permanent

eye damage. Wear safety goggles (not

glasses) that comply with ANSi Z87.1

(shown on package). Everyday eye-

glasses have only impact resistanl

lenses. They are not safety glasses.

Safety goggles are available at Sears

Retail Stores. Glasses or goggles not in

compltance with ANSI Z87.1 could seri-

ously hurt you when they break.

WEAR YOUR

Dress for safety

• Do not wear bose clothing, gloves,

neckties or jewelry (rings, wrist-

watches). They can get caught aria

draw you into moving parts.

oWear nonslip footwear.

oTie back long hair.

oRoll long sleeves above the elbow.

° Noise levels vary wide!y.To avoid pos-

sible hearing damage, wear ear plugs

or muffs when using saw for hours ata

time.

• For dusty operations, Wear a dust mask

along with the safety gogg lee

CAUTION: This saw is NOT

designed for cutting ferrous metals

like iron or steel. When cutting

nonferrous metals (brass, copper

and aluminum, etc.), metal shav-

ings can react with wood dust and

start a fire. To avoid this:

- Remove all traces of wood dust

from on and around the saw.

- Remove all metal shavings from

on or around the saw before saw-

ing wood again.

Inspect Your Workpiece.

Make sure there are no nails or foreign

objects in the part of the workpiece to be

cut.

Use extra caution with large, very

small or awkward workpieces

* Never use this tool to finish pieces too

small to hold by hand.

° Use extra supports (tables, saw horses,

blocks, ezc.)for any workpieces large

enough to tip when not held down to

the table top.

. Never use another person as a substi-

tute for a table extension, or as addi-

tional support for a workpiece or to hetp

feed. support or pull the workpiece.

° When cutting irregularly shaped work*

;31eces,plan your work so it wilt not

pinch the b_ade.A piece of molding, for

example, must fay flat or be held by a

fixture or jig that will net let it twist, rock

or slip while being cut.

• Properly support round material such

as dowel rods or tubing. They have a

tendency to roll during a cut, causing

the blade to "bite". To avoid this,

always use "V" blocks.

oCut only one workpiece at a time.

° Clear everything except the workpiece

and related support devices off the

table before turning the saw on.

i

4

Plan the way you will hold the work-

piece from start to finish.

* Do not hand hold pieces so smatl that

your fingers will go under the blade

guard. Use jigs or fixtures to hold the

work and keep your hands away from

the blade.

° Avoid awkward operations and hand

Whenever Saw Is Running

WARNING: Don't let familiarity

(gained from frequent use of your

scroll saw) cause a careless mis-

take. A careless fraction of a sec-

ond is enough to cause a severe

injury.

oBefore starting your cut, watch the saw

while it runs. If it makes an unfamiliar

noise or vibrates excessively, stop

immediately. Turn the saw off. Unplug

the saw. Do not restart untif finding and

correcting the problem.

* Keep Children Away. Keep all visitors

a safe distance from the saw. Make

sure bystanders are clear of the saw

and workpiece.

* Don't Force Tool. It will do the job bet-

ter and safer at its designed rate, Feed

the workpiece into the saw blade only

fast enough to let it cut without bogging

down or binding.

positions where a sudden slip could

cause fingers or hand to move into the

blade.

• Don't Overreach, Keep good footing

and balance,

° Keep your face and body to one side of

the blade, out of line with a possible

thrown piece if the blade s_eutd break.

Before Freeing Any Jammed Material.

* Turn switch "OFF"

oWait for all moving parts to stop.

- Unplug the saw,

When backing up the workpiece, the

blade may bind in the kerf (cut). This

is usually caused by sawdust clog-

ging up the kerr. If this happens:

- Turn switch "OFF".

- Wait for all moving parts to stop.

. Unplug the saw.

. With a flat blade screwdriver, turn

motor shaft by hand. Insert the screw-

driver into the slotted end of motor

shaft located at the center of the motor

housing. Do this while backing up the

workpiece.

Before removing loose pieces from

the table, turn saw off and wait for all

moving parts to stop.

Before Leaving the Saw

• Wait for all moving parts to stop,

• Make Workshop Child-proof. Unplug

the saw, Lock the workshop and ON/

OFF knob on the saw, Store the key

away from children and others not qual-

ified to use the tool,

Glossary of Terms for Woodworking ......

Kerf -the slot cut by the blade.

Leading Edge - the edge of the work-

piece which is pushed into the blade

first.

Sawbtade Path - the area of the work-

piece directly in line with and moving

toward the sawblade edge,

Bevel - the ability to slant the table to

make angle cuts, An angle cutting opera-

tion through the face of the board,

Blade Tooth Set - the distance that the

edge of the sawblade tooth is bent (or

set) outward from the side of the blade,

Trailing Edge - the workpiece edge last

cut by the sawblade.

Workpiece - the item on which the cut-

ting operation is being performed,

5

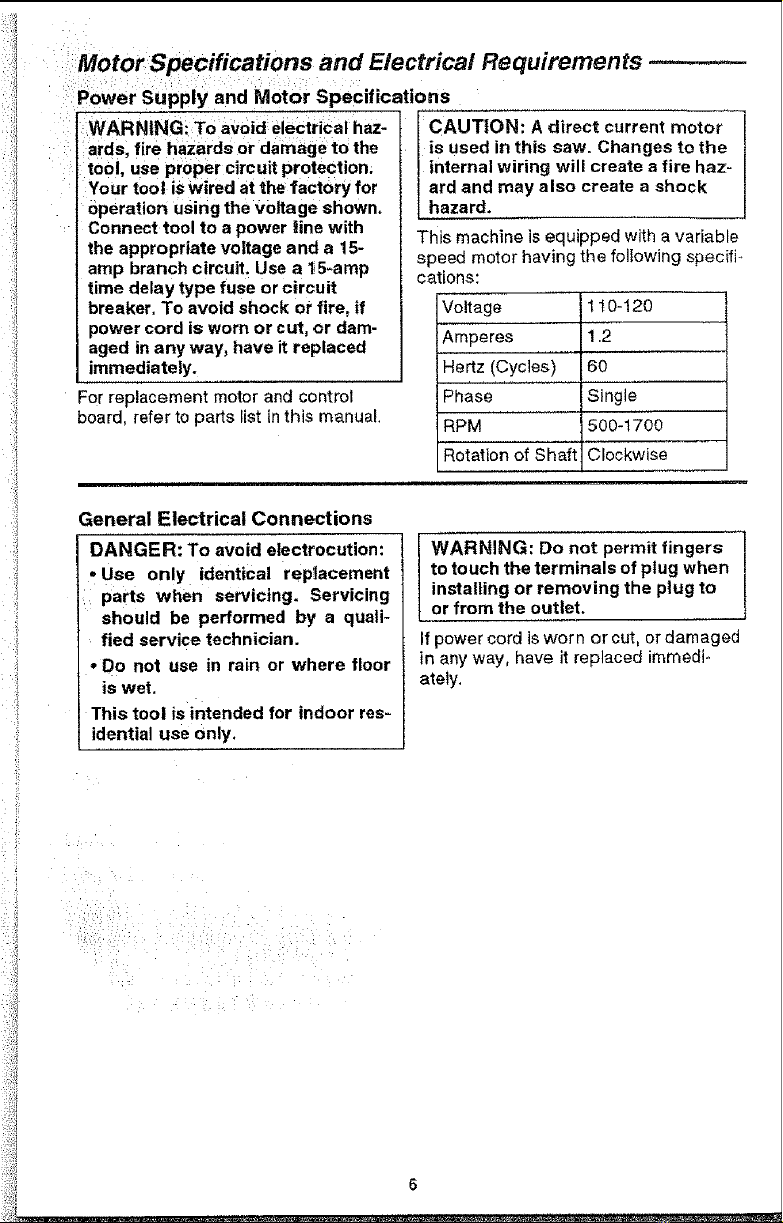

Motor Specifications and Electrical Requiremen ts

::p_o,,erS.ppiyand.otorSpecif cot ons

:i WARNINGI T0 avoid eiectri_al haz- _e_

:i : ards; fire hazards or damageto the I _n this saw. Changes to the t

;; Operation using the voltage shown, hazard.

;.=. __ . . ^__ speecl motor nawng me TOt ng specsfF

; amp branch c!rcult _Use a t5*_,qJ -. .

I time delay type fuse or circuit cations. , ,

i breaker To avoid shock or fire, if Voltage 1t0-120

i aged in any way, have it replaced Amperes ,

i immediately. Hertz (Cycles) 60

:t0oi, use proper circuit protection; _ internal wiring will create a fire haz- I

Your toot is Wired at the factory for Iard and may also create a shock I

Connect too to a power line with .....

,h ....... _,^, ^t, ..... ,4_ ! = This machine Is equipped w_tha variable

power cord is worn or cut, or dam- - .... 1 2

For replacement moto_ and contro-------_ Phase single

board, refer to parts list in this manual, RPM 500-1700

Rotation of Shaft Clockwise

uu m i,i i i,, ....

General Electrical Connections

DANGER: To avoid electrocution:

. Use only identical replacement

parts when servicing_ Servicing

should be performed by a quali-

fied service technician.

, Do not use in rain or where floor

is wet.

This tool is intended for indoor res-

idential use only.

to touch the terminals of plug when

installing or removing the plug to

I ARNING: Do not permit fingers

or from the outlet.

If power cord isworn or cut, or damaged

in any way, have it replaced immedi-

ately,

110-120Volt, 60 Hz. Tool

Information

NOTE: The plug supplied on your tool

may not fit into the outlet you are plan-

ning to use. Your local electrical code

may require slightly different power cord

plug connections, if these differences

exist refer to and make the proper

adjustments per your local code before

your too] is plugged in and turned on.

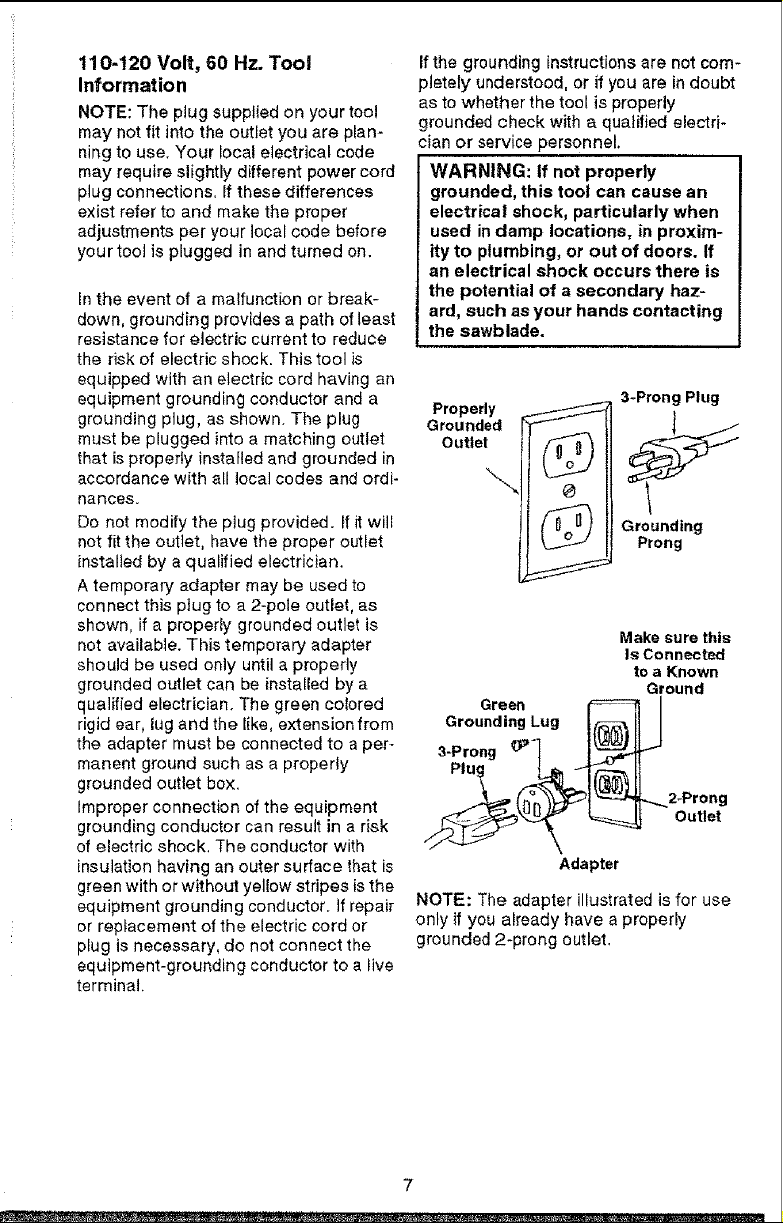

In the event of a malfunction or break-

down, grounding provides a path of least

resistance for electric current to reduce

the risk of electric shock This tool is

equipped with an electric cord having an

equipment grounding conductor and a

grounding plug, as shown. The plug

must be plugged into a matching outlet

that is properly installed and grounded in

accordance with all local codes and ordi-

nances.

Do not modify the plug provided, tfit will

not fit the outlet, have the proper outlet

installed by a qualified electrician.

A temporary adapter may be used to

connect this plug to a 2-pole outlet, as

shown, if a properly grounded outlet is

not available. This tempo[ary adapter

should be used only until a properly

grounded outlet can be installed by a

qualified electrician. The green colored

rigid ear, lug and the like, extension from

the adapter must be connected to a per-

manent ground such as a properly

grounded outlet box.

Improper connection of the equipment

grounding conductor can result in a risk

of electric shock, The conductor with

insulation having an outer surface that is

green with or without yellow stripes is the

equipment grounding conductor. ]f repair

or replacement of the electric cord or

plug is necessary, do not connect the

equipment-grounding conductor to a live

terminal.

Ifthe grounding instructions are not com-

pletely understood, or if you are in doubt

as to whether the tool is properly

grounded check with a qualified electri-

cian or service personnel.

WARNING: If not properly

grounded, this tool can cause an

electrical shock, particularly when

used indamp locations, in proxim-

ity to plumbing, or out of doors, tf

an electrical shock occurs there is

the potential of a secondary haz=

ard, such as your hands contacting

the sawblade.

Properly

Grounded

Outlet

\

Green i_"_ I

J_

/flu}

/n u_

3-Prong Plug

0

Grounding

Prong

Make sure this

Is Connected

toa Known

Ground

Gro0n0,°gLo, I lll

a-Prong _1_'] i_._-

Plug %, li

Adapter

NOTE: The adapter illustrated is for use

only if you already have a properly

grounded 2-prong outlet.

7

Motor Specifications and Electrical Requirements (continued)

Wire Sizes

NOTE: Make sure the proper extension

cord is used and is in good condition.

The use of any extension cord will cause

some loss of power. To keepthis to a

minimum and to prevent overheating

and motor bum-out, use the table shown

to determine the minimum wire size

(A.W,G.) extension cord

Use only 3-wire extension cords which

have 3-prong grounding type plugs and

3-pote receptacles which accept the

tools plug.

Cord Length , .for (A.W.G.)

0-25 Ft. 18

26-50 Ft, 16

Wire Sizes Required

110-120V

Table of Contents

Safety Instructions for Scroll Saw ........ 2

Safety Signal Words ......................... 2

Before Using The Saw ..................... 2

When Installing or Moving The Saw .3

Before Each Use: ............................. 3

Safety Instructions for Scroll Saw ........4

Plan Ahead To Protect Your Eyes,

Hands, Face and Ears: ................... 4

Whenever Saw Is Running: .............. 5

Before Leaving the Saw: ................. 5

Giossary of Terms for Woodworking .... 5

Motor Specifications and Electrical

Requirements .................................. 6

Power Supply and Motor

Specifications,....._ ............................ 6

General Electrical Connections ........ 6

110-120 Volt, 60 Hz. Tool

Information :....... ,:............................. 7

Wire Sizes .........:............. :................ 8

Table of Contents ................................. 8

Unpacking and Checking Contents ...... 9

Tools Needed L;................................ 9

Unpacking ........................................ 9

List of Loose Parts .,_....................... 9

Getting to Know your Scroll Saw ....... 10

Align ment (Adjustments) .................... 12

Changing the Table Bevel Angle ....12

To Align the Bevel Indicator ............ 12

Adjusting Work Hold-down ............. 13

Over Tensioning Or Under Tensioning

Blade ............................................. 13

Removing Pin End Blades ............. 14

Installing Pin End Blades ............... 15

Removing Plain End Blades .......... 16

installing Plain End Blades ............ 17

Dust Blower .................................... 18

Blade Guard ................................... !8

Mounting the Scroll Saw .................... 18

Workbench Applications ................ I8

Leg Set Applications ....................... 18

Safety Instructions for Basic Saw

Operations .................................... 19

Before Each Use: ........................... 19

Plan Ahead To Protect Your Eyes,

Hands, Face And Ears: ................. 20

Whenever Saw Is Running: ........... 20

Before Leaving The Saw: ............... 21

Basic Saw Operations ....................... 2!

General Instructions ....................... 2t

Making Interior Scroll Cuts ............. 22

Choice of Blade and Speed ........... 22

Maintenance ...................................... 23

Sears Recommends the Following

Accessories .................................. 23

Recommended Accessories .......... 23

Troubleshooting ................................. 24

Wiring Diagram .................................. 25

Repair Parts ....................................... 26

ii'i 8

Unpacking and Checking Contents ..............

Tools Needed

Medium Standard Screwdriver

Combination Square

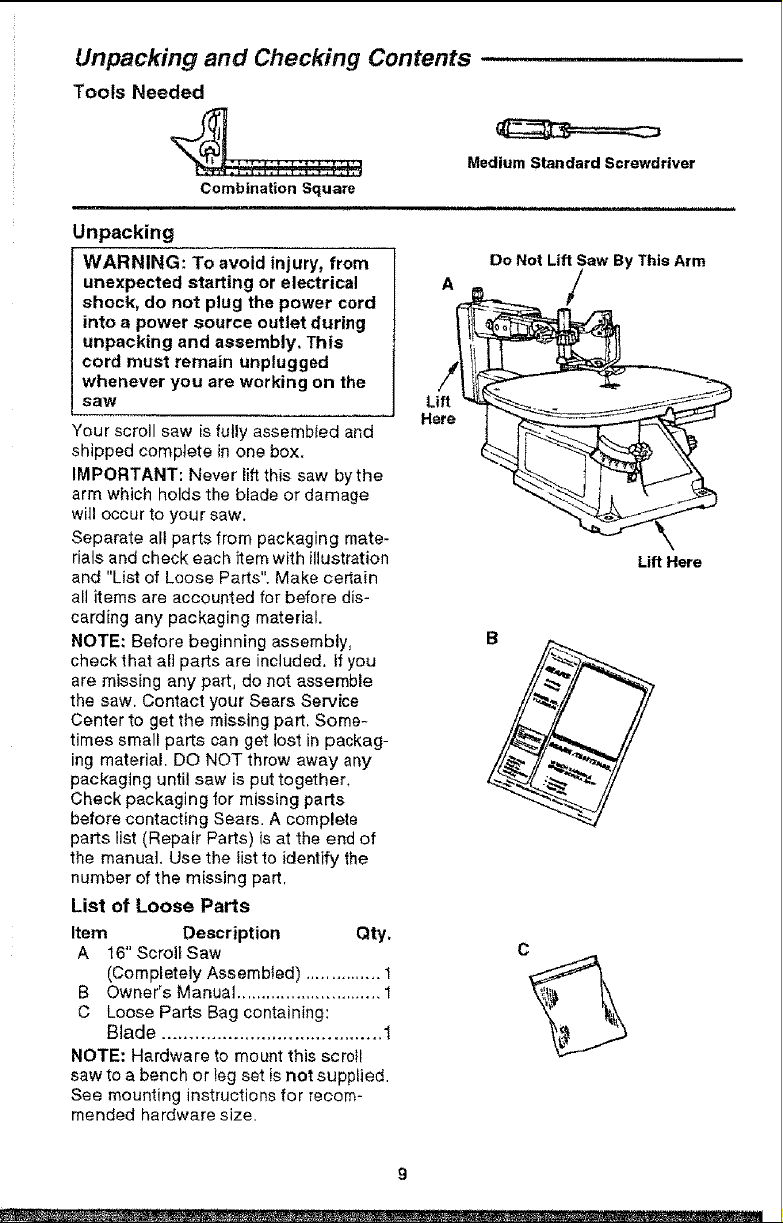

Unpacking

WARNING: To avoid injury, from

unexpected starting or electrical

shock, do not plug the power cord

into a power source outlet during

unpacking and assembly, This

cord must remain unplugged

whenever you are working on the

saw

Here

Your scroll saw is fully assembled and

shipped complete in one box.

IMPORTANT: Never lift this saw bythe

arm which holds the blade or damage

will occur to your saw.

Separate all parts from packaging mate-

rials and check each item with illustration

and "List of Loose Parts". Make certain

all items are accounted for before dis-

carding any packaging material.

NOTE: Before beginning assembly,

check that al] parts are included, ifyou

are missing any part, do not assemble

the saw, Contact your Sears Service

Center to get the missing part. Some-

times small parts can get lest in packag-

ing material. DO NOT throw away any

packaging until saw is put together,

Check packaging for missing parts

before contacting Sears, A complete

parts list (Repair Parts) is at the end of

the manual Use the list to identify the

number of the missing part.

List of Loose Parts

Item Description Qty.

A 16" Scroll Saw

(Completely Assembled) ............... 1

B Owner's Manual ............................. 1

C Loose Parts Bag containing:

Blade ........................................ 1

NOTE: Hardware to mount this scroll

sawto a bench or _egset is not supplied.

See mounting instructions for recom-

mended hardware size.

Do Not LiftSaw By This Arm

C

Lift Here

9

Loading...

Loading...