Craftsman 113235500 Owner’s Manual

Save This Manua! For

Futu re Reference

MO L O.

113.235500

Serial

Number

Model and serial number may be

found attached to the underside of

the worktable.

You should record both model and

serial number in a safe place for

future use.

FOR YOUR

SAFETY:

Read ALL

INSTRUCTIONS

carefully

Sold by SEARS, ROEBUCK AND CO., Chicago, IL 60684 U.S.A.

!61 CH SCROLL SAW

, assembly

. operating

. repair parts

Part No. SP5639 Printed in USA

IAN SCROLL SAW

i Saw fails due to a defect In

RETURNING THE CRAFTSMAN SCROLL SAW

SERVICE CENTER/DEPARTMENT IN THE

APPLIES ONLY WHILE THIS PRODUCT IS USED IN THE UNITED STATES.

Th_s:Wttrranty gives you specific tegat: rights and you may also have other rights which vary from

state to state.

SEARS, ROEBUCK AND CO., D817 WA HOFFMAN ESTATES, IL 60195

safety instructions for scroll saw

Safety is a combination of common sense, stay!ng

alert and knowing how your scroll saw works.

Read this manual to understand this saw.

BEFORE USING THE SAW

WARNING: To avoid mistakes that could

cause serious permanent Injury, do not pl_ug

the saw in until the following steps are

completed.

Assembly and alignment. (See pages 7 -12)

- Learn the use and function of the speed control

ON-OFF knob, bevel lock knob, blade homders,

blade support, hold down, tension knob, and

blade guard. (See pages 13 -14)

Review and understand all safety instructions and

operating procedures in this manual.:

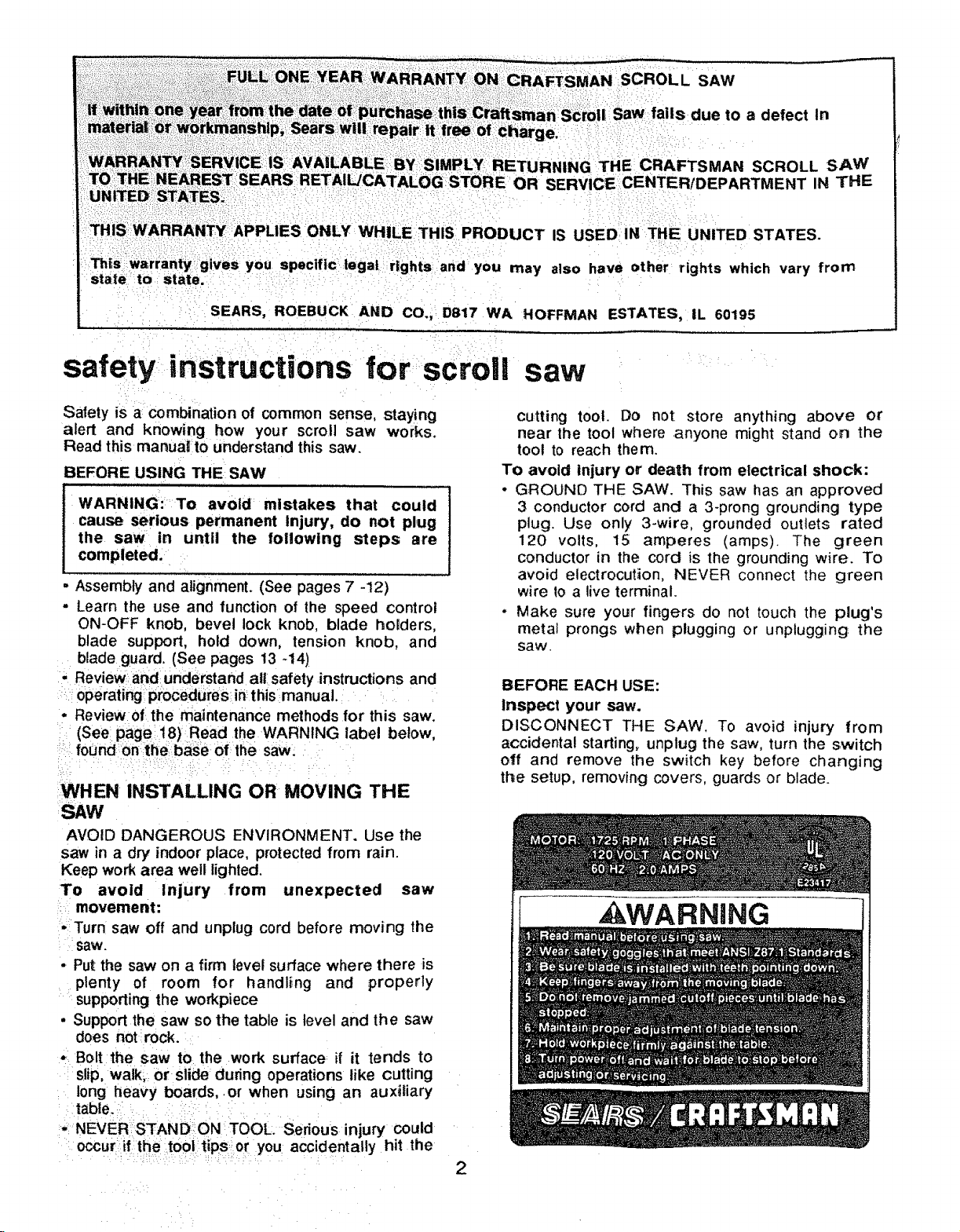

- Review of the maintenance methods for this saw.

:ii: (See page 18)_Readth e WARNING label below,

found::0n the:baSe of: the saw: : i

::WHEN INSTALLING OR MOVING THE

:SAW

AVOID DANGEROUS ENVIRONMENT. Use the

saw in a dry indoor place, protected from rain.

Keep work area welt lighted.

To avoid Injury from unexpected saw

_ movement:

:'Turn saw off and unplug cord before moving the

i saw.

• Put the saw on a firm level surface where there is

plenty of room for handling and properly

supporting the workpiece

• Support the saw so the table is level and the saw

does not rock.

, Bolt the saw to the work surface if it tends to

slip, walki, or slide during operations like cutting

long heavy boards, ,or when using an auxiliary

table._:_ :iii .. :

i; NEVER IISTAND ON OOL. Serious injury could

occur:if the tooi tips:or you accidentally hit the

cutting tool. Do not store anything above or

near the tool where anyone might stand on the

tool to reach them.

To avoid injury or death from electrical shock:

• GROUND THE SAW. This saw has an approved

3 conductor cord and a 3-prong grounding type

plug. Use only 3-wire, grounded outlets rated

120 volts, 15 amperes (amps). The green

conductor in the cord is the grounding wire. To

avoid electrocution, NEVER connect the green

wire to a live terminal.

• Make sure your fingers do not touch the plug's

metal prongs when plugging or unplugging the

saw,

BEFORE EACH USE:

Inspect your saw.

DISCONNECT THE SAW. To avoid injury from

accidental starting, unplug the saw, turn the switch

off and remove the switch key before changing

the setup, removing covers, guards or blade.

2

CHECK DAMAGED PARTS. Check for:

• Alignment of moving parts.

• Binding of moving parts.

• Broken pads.

• Stable mounting.

• Any other conditions that may affect the way

the saw works.

If any part is missing, bent or broken in any way,

or any electrical parts don't work properly, turn the

saw off and unplug the saw. REPLACE damaged,

missing or failed parts before using the saw again.

KEEP GUARD IN PLACE and in working order.

MAINTAIN TOOLS WITH CARE. Keep the saw

clean for best and safest pedormance. Follow

instructions for lubricating.

REMOVE ADJUSTING KEYS AND WRENCHES

from tool before turning it on.

To avoid injury from jams, slips or thrown

pieces:

• Choose the right size and style blade for the

material and the type of cutting you plan to do.

• USE ONLY RECOMMENDED ACCESSORIES.

(See page 19). Consult this owneCs manual for

recommended accessories. Follow the instruc-

tions that come with the accessories. The use of

improper accessories may cause risk of injury to

person.

• Make sure the blade teeth point downward,

toward the table.

o Make sure the blade tension is propedy adjusted.

° Make sure the bevel lock knob is tight and no

parts have excessive play,

, To avoid accidental blade contact, minimize blade

breakage and provide maximum blade support,

always adjust the blade hold down and blade

guard to just clear the workpiece.

. KEEP WORK AREA CLEAN. Cluttered areas

and benches invite accidents. Floor must not be

slippery.

To avoid burns or other fire damage, never use the

saw near flammable liquids, vapors or gases.

PLAN AHEAD TO PROTECT YOUR EYES,

HANDS, FACE, EARS.

KNOW YOUR SAW. Read and understand the

owner's manual and labels affixed to the tool. Learn

its application and limitations as well as the specific

potential hazards peculiar to this tool.

To avoid injury from accidental contact with moving

parts, don't do layout, assembly, or setup work on

the saw while any parts are moving.

AVOID ACCIDENTAL STARTING. Make sure switch

is "OFF" before plugging saw into a power outlet.

Plan your work.

. USE THE RIGHT TOOL. Don't force tool or

attachment to do a job it was not designed 1o do.

• Use this scroll saw to cut only wood, woodqike

products, plastics and nomferrous metals.

CAUTION: This saw is NOT designed for

cutting ferrous metals like iron or steel. When

cutting non-ferrous metals (brass, copper and

aluminum, etc.), metal shavings can react with

wood dust and start a fire. To avoid this:

° Disconnect any type of dust collecting

hose from the saw.

• Remove all traces of wood dust

from on and around the saw.

• Remove a,tl meta! shavings from on

or around the saw before sawing

wood again.

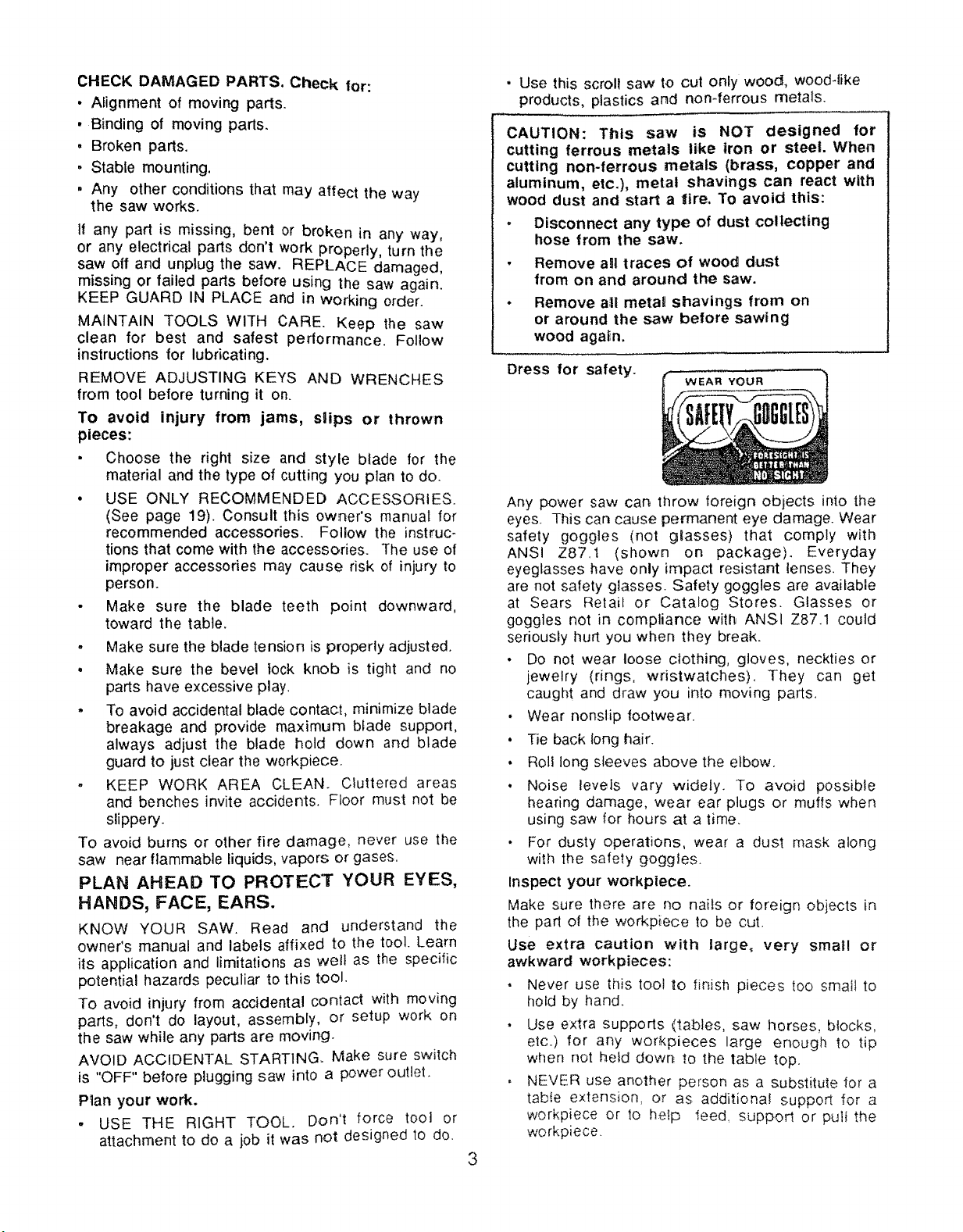

Dress for safety.

WEAR YOUR

Any power saw can throw foreign objects into the

eyes. This can cause permanent eye damage. Wear

safety goggles (not gtasses) that comply with

ANSI Z87_1 (shown on package). Everyday

eyeglasses have only impact resistant lenses. They

are not safety glasses. Safety goggles are available

at Sears Retail or Catalog Stores. Glasses or

goggles not in compliance with ANSI Z87.1 could

seriously hurt you when they break.

• Do not wear loose clothing, gloves, neckties or

jewelry (rings, wristwatches), They can get

caught and draw you into moving parts.

• Wear nonstip footwear.

• Tie back long hair.

• Roll long sleeves above the elbow.

• Noise levels vary widely. To avoid possible

hearing damage, wear ear plugs or muffs when

using saw for hours at a lime.

• For dusty operations, wear a dust mask along

with the safety goggles.

Inspect your workpiece.

Make sure there are no nails or foreign objects in

the par1 of the workpiece to be cut.

Use extra caution with large, very small or

awkward workpieces:

• Never use this toot to finish pieces too smatl to

hold by hand.

Use extra supports (tables, saw horses, blocks,

etc.) for any workpieces large enough to tip

when not held down to the table top.

NEVER use another person as a substitute for a

tabte extension, or as additionaf support for a

workpiece or to help 1eed supporl or puli the

workpiece.

3

safety instru cti0ns, for scro ml

shaped workpieces; plan

!:_/;;y0ur_workso;iitwiil_-_Ot_pinch: the :blad& A piece Of

:::::_':_iiolding;for examplei rnust :lay flat orbe heid by a

et ittwisL rock or slip whi e

being'cut, i:i.

* ilProperly supp6rt'round material such as dowel

= i:ods or tubing. They have a tendency to rollduring

acuL causing the blade to bite.

o Cut only one worl_iece at atime:

,_ Clear everything except the workpiece and related

support devices off the table before turning the

saw On.

Plan the way you will hold the workpiece

from start to finish.

Do not hand hold pieces so small that your fingers will

go under the blade guard. Use jigs or fixtures to hold

the work and keep your hands away from the blade.

SECURE WORK. Use clamps to hold work when

practical, tt'soften safer than using your hand and

frees both hands to operate the tool.

Avoid awkward operations and hand positions where

a sudden slip could cause fingers or hand to move

into the blade.

DON'T OVERREACH. Keep good footing and

balance.

Keep your face and body toone side of the blade,

out of line with a possibte thrown piece _fthe blade

should break.

WHENEVER SAW IS _RUNNING: ....

SSIW

When backing up the workpiece, the blade

may bind in the kerf (cut), This is usually

Caused by sawdust clogging up the kerr. If

this happens:

" Turn switch "OFF".

° Remove switch key.

" Unplug the saw.

* Wait for all moving parts to stop.

° With a flat blade screwdriver, turn motor shaft by

hand, by inserting into the slotted end of motor

shaft located at the center of the motor :housing.

Do this while backing up the workpiece.

Before removing loose pieces from the

table, turn saw off and wait for a!! moving

parts to stop.

BEFORE LEAVING THE SAW:

Wait for all moving parts to stop,

MAKE WORKSHOP CHILD-PROOF. Unplug the saw,

Lock the shop or ON!OFF knob. Store the key away

from children and others not qualified to use the tool.

Safety Signal Words

DANGER: means if the safety information is not

followed someone will be seriously injured or killed.

WARNING: means if the safety information is not

foltowed someone could be seriously injured or

killecl.

CAUTION: means if the safety information is not

followed someone might be injured.

WARNING: Don!t:let familiarity (gained=fr0m !

frequent use of your scroll:: Sa_v): :cause:a

careless: mistake. A careless :fraction of a

second is enough to Cause::a severe injury.

_fore starting your cut, watch the sawwhile it runs, If

it makes an unfamiliar noise or vibrates a lot; stop

immediately. Turn the saw off. Unplug the saw. Do not

restart until finding and correcting the problem,

KEEP CHILDREN AWAY. Keep all visitors a safe

distance from the saw. Make sure bystanders are clear

of the saw and workpiece.

DON'T FORCE TOOL. It will do the job better and

safer at its designed rate. Feed the workpiece into the

saw blade only fast enough to let it cut without

bogging down or binding.

Before freeing any jammed material:

• Turn switch "OFF"

• Remove switch key.

• Unplug the saw.

• Wait for all moving parts to stop.

:.:.:.:_ ._ : _.:

!

4

motor specifications and electricaJ requirements

This machine is equipped with, a 1725 RPM motor.

It is wired for operation on 120V, 60Hz,

alternating current.

For replacement motor, refer to parts list in this

manual.

CONNECTING TO POWER SUPPLY

OUTLET

if power cord is worn or cut, or damaged in any

way, have it replaced immediately.

WARNING: tf not properly grounded, this

power tool can cause an electrical shock,

particularly when used in damp locations

close to plumbing, if an electrical shock

occurs there is potential of a secondary

hazard, such as your hands contacting the

saw blade.

WARNING: Do not permit fingers to touch the

terminals of pJug when installing or removing

the plug to or from the outlet.

Plug power cord into a 120V properly grounded

type outlet.

if the outlet you are p_anning to use for the power

tooJis of the 2-prong type, DO NOT REMOVE OR

ALTER THE GROUNDING PRONG IN ANY

MANNER. Use an adapter as shown below and

always connect the grounding lug to known

ground,

It is recommended that you have a qualilied

electrician replace the TWO prong outlet with a

properly grounded THREE prong outlet.

GROUNDING LUG

SCREW /

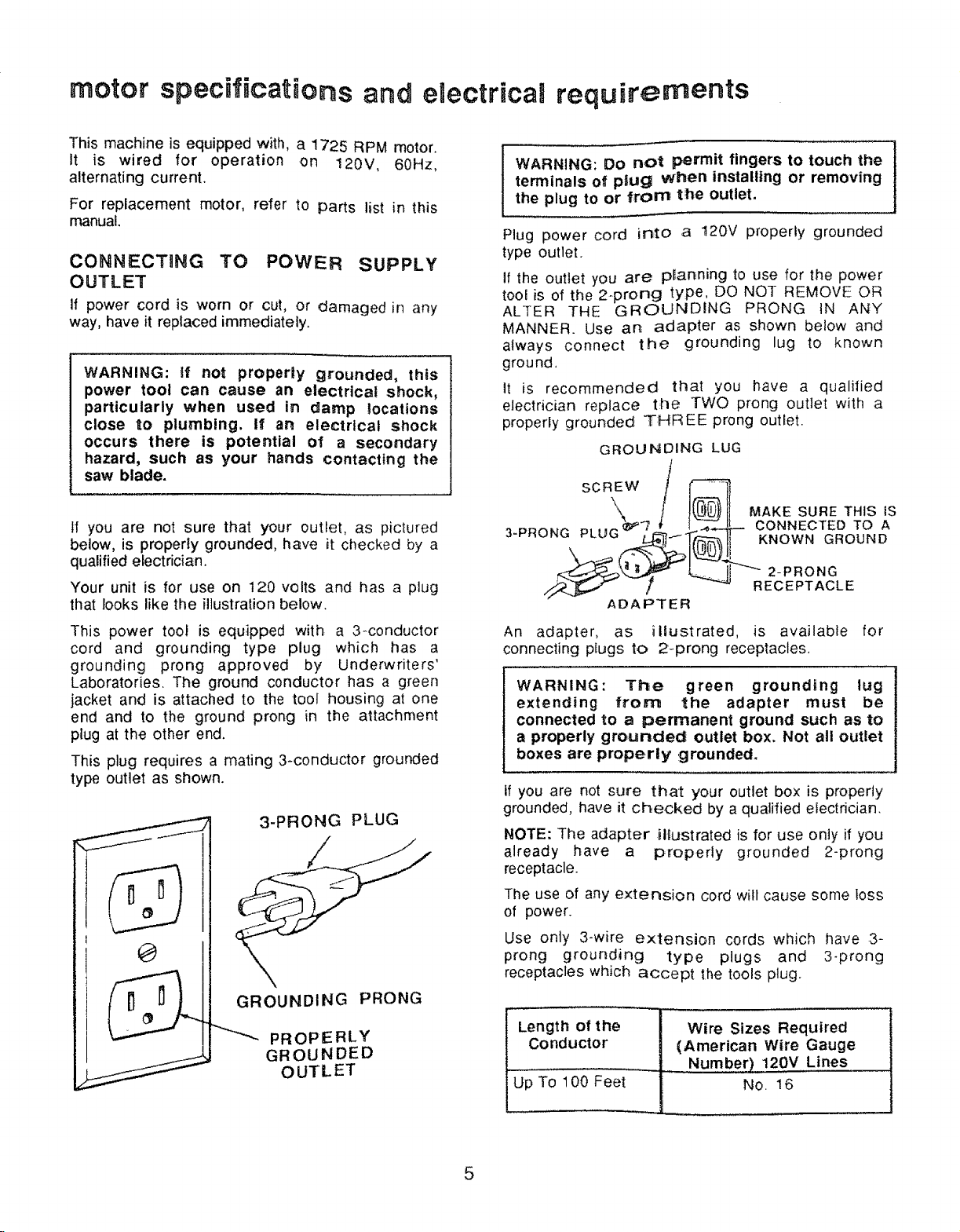

If you are not sure that your outlet, as pictured

below, is properly grounded, have it checked by a

qualified electrician.

Your unit is for use on t20 volts and has a plug

that looks like the illustration below.

This power tool is equipped with a 3-conductor

cord and grounding type plug which has a

grounding prong approved by Underwriters'

Laboratories. The ground conductor has a green

jacket and is attached to the tool housing at one

end and to the ground prong in the attachment

plug at the other end.

This plug requires a mating 3-conductor grounded

type outlet as shown.

3-PRONG PLUG

@

GROUNDING PRONG

p ........ _"7 t- I ._-- It CONNECTED TO A

" " KNOWNGROUND

Z ..... .EOE TAC E

ADAPTER

An adapter, as illustrated, is available for

connecting plugs to 2-prong receptacles,

WARNING: The green grounding lug

extending from the adapter must be

connected to a permanent ground such as to

a properly grounded outlet box. Not all outlet

boxes are properly grounded.

if you are not sure that your outlet box is properly

grounded, have it checked by a qualified electrician.

NOTE: The adapter illustrated is for use only if you

already have a properly grounded 2-prong

receptacle.

The use of any extension cord will cause some toss

of power.

Use only 3-wire extension cords which have 3-

prong grounding type plugs and 3-prong

receptacles which accept the tools plug.

_--'"_ PROPERLY

GROUNDED

OUTLET

Length of the

Conductor

uP To lOO Feet'

Wire Sizes Required

(American Wire Gauge

Number) 120V Lines

No. 16

glossary of terms

1. Kerr - the slot cut by the blade.

2.

Leading Edge - the edge of the workpiece

which is pushed into the blade first.

.

Sawblade Path - the area of the workpiece

directly in line with and moving toward the

sawblade edge.

.

Bevel - the ability to slant the table to make

angle cuts. An angle cutting operation through

the face of the board.

for

woodworking

contents

Warranty Information ............................................. 2

Safety Instruction for Scroll Saws .......................... 2

Motor Specs and Electrical Information .................. 5

Glossary of Terms for Woodworking ...................... 6

Unpacking and Checking Contents ....................... 6

Assembly ................................................................ 7

Setting Table for Horizontal or Bevel Cutting... 8

Aligning the Bevel Indicator .............................. 8

Removing and Installing Blades ............................. 10

Mounting the Scroll Saw ....................................... 12

5, Blade Tooth Set -the distance that the edge

of the sawblade tooth is bent (or set) outward

from the side of the blade.

6. Trailing Edge - the workpiece edge last cut by

the sawblade.

7. Workpiece - the item on which the cutting

operation is bebng performed.

Getting to Know Your Scroll Saw ........ 13

Operation ..................................... 15

Making Interior Cuts ...... 17

Maintenance ................... 18

Wiring Dtagram .................. 18

Recommended Accessories ............ 19

Trouble Shooting 19

Repair Parts ........................ 20

Notes ................................ 22

Service Inlormation ............ 24

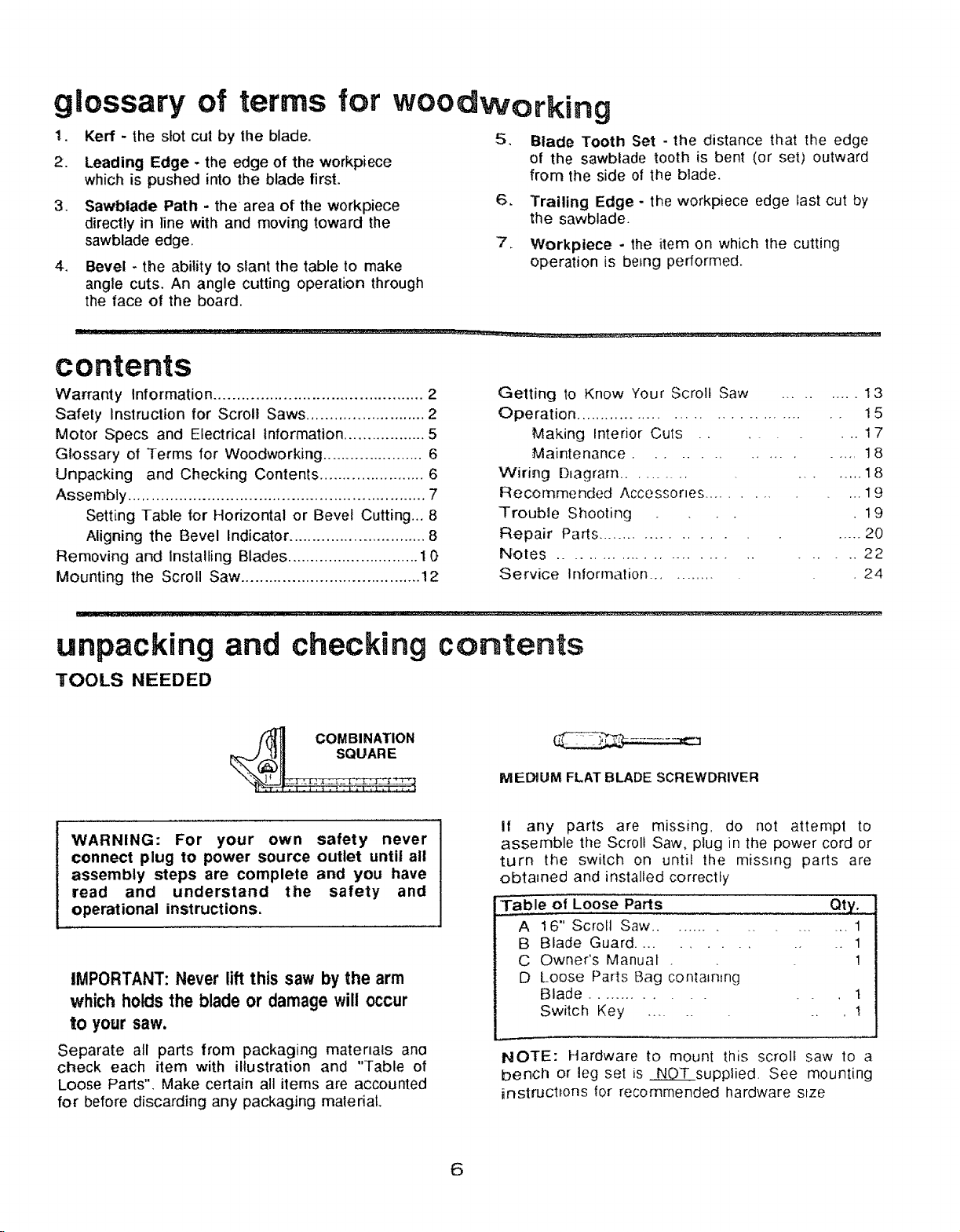

unpacking and checking contents

TOOLS NEEDED

COMBINATION

SQUARE

WARNING: For your own safety never

connect plug to power source outlet until all

assembly steps are complete and you have

read and understand the safety and

operational instructions.

IMPORTANT: Never lift this saw by the arm

which holds the blade or damage will occur

to your saw.

Separate all parts from packaging materials ano

check each item with illustration and "Table of

Loose Parts". Make certain all items are accounted

for before discarding any packaging material.

MEDIUM FLAT BLADE SCREWDRIVER

If any parts are missing, do not attempt to

assemble the Scroll Saw, plug in the power cord or

turn the switch on until the missing parts are

obta=ned and installed correctly

Table of Loose Parts

A 16" Scroll Sawll .........

B Blade Guard ..........

C Owner's Manual .

D Loose Parts Bag contalntng

Blade .............

Switch Key ......

NOTE: Hardware to mount this scroll saw to a

bench or leg set is _supplied. See mounting

instructions for recommended hardware s=ze

Qty,

1

!

1

. 1

6

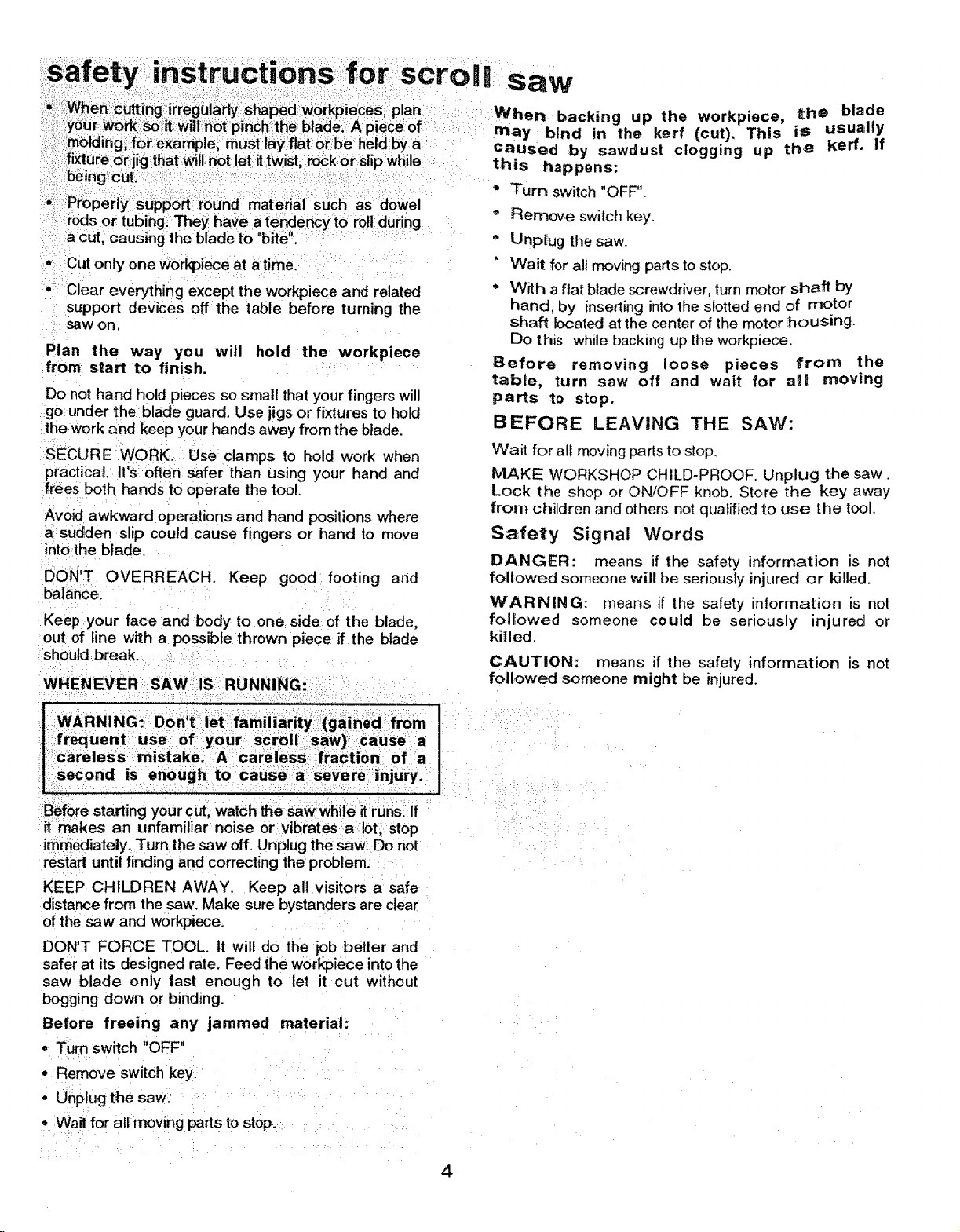

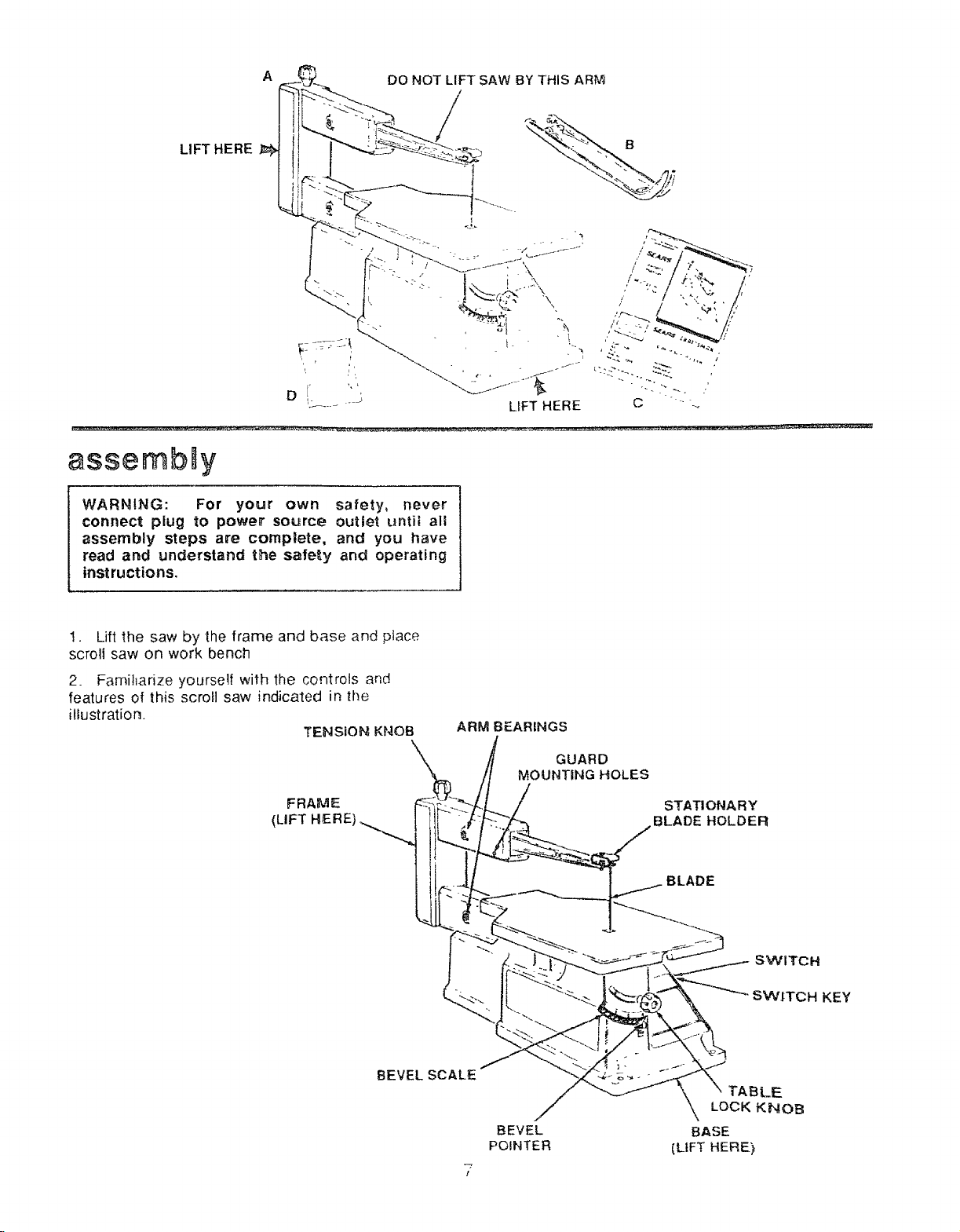

A DO NOT LIFT SAW BY ]'HIS ARM

LIFT HERE

assembly

WARNING: For your own safety, never

connect plug to power source outlet L_ntit all

assembly steps are complete, and you have

read and understand the safety and operating

instructions.

t. Lift the saw by the frame and base and place

scroll saw on work bench

2_ Famiharize yourse!f with the controls and

features of this scroll saw indicated in the

illustration.

TENSION KItOB

FRAME

(LIFT HERE)

BEVELSCALE

ARM BEARINGS

MOUNTING HOLES

BEVEL

POINTER

l"

GUARD

STA_ONARY

BLADE HOLDER

.BLADE

SWITCH

SW{TCH KEY

TABLE

LOCK KNOB

BASE

(LIFT HERE}

Loading...

Loading...