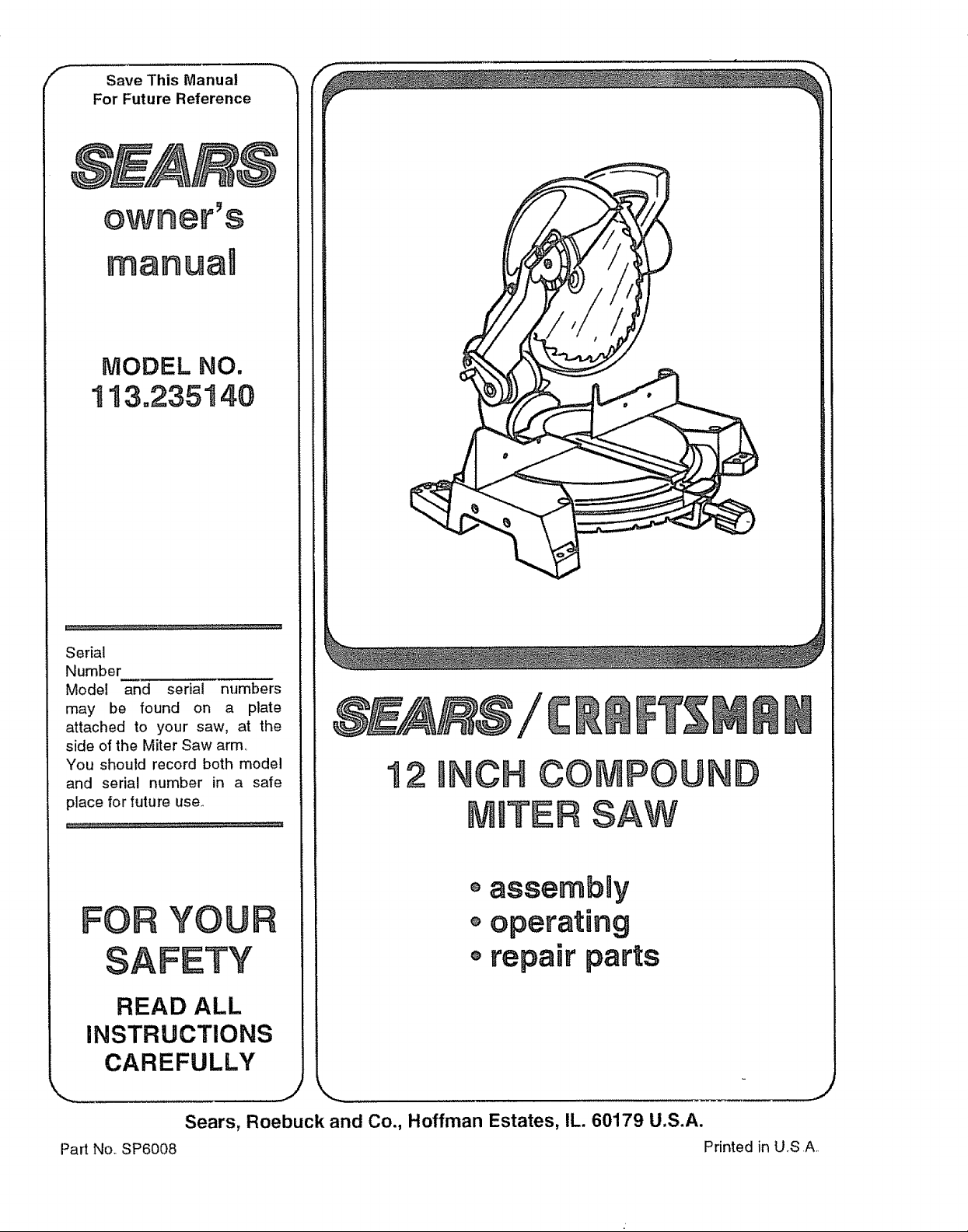

Craftsman 113235140 Owner’s Manual

F

Save This Manual

For Future Reference

owner's

manua

NODEL NO.

t 13.235140

Serial

Number

Modal and serial numbers

may be found on a plata

attached to your saw, at the

side of the Miter Saw arm,,

You should record both model

and seria! number in a safe

place for future use_

FOR YOUF

READ ALL

INSTRUCTIONS

CAREFULLY

oassembny

ooperating

orepair parts

J

Part No, SP6008

Sears, Roebuck and Co., Hoffman Estates, IL. 60179 U.S.A.

Printed in U.S A.

FULL ONE YEAR WARRANTY ON CRAFTSMAN BENCHTOP TOOLS

If this miter saw fails due to a defect in material or' workmanship within one year' from the date of

purchase, RETURN IT TO THE NEAREST SEARS SERVICE CENTER IN THE UNITED STATES, and

Sears will repair it, free of charge°

If this miter' saw is used for' commercial or rental purposes, this warranty will apply for ninety days

from the date of purchase.

This warranty applies only while this product is in the United States.

This warranty gives you specific legal rights, and you may also have other rights which vary from

state to state.

Sears, Roebuck and Co,, D/817 Wa Hoffman Estates, IL. 60179

Safety instructions For Miter Saw ................................

Safety is a combination of common sense, staying alert and knowing how your miter saw works. Read this manual to

understand this miter' saw

Safety Signal Words

DANGER: means ifthe safety information is not followed

someone will be seriously injured or killed.

....i 1,1,,11 ,,,]1,_1,1 i i ,,i,,,,111¸ ,, i,,,,,,,,,,,11,_

L_.....

Before Using The Saw

WARNING: To avoid mistakes that could cause

serious, permanent injury, do not plug the miter

saw in until the following steps have been satisfac-

torily completed.

° Completely assemble and align saw. (See "Assembly"

and "Alignment" sections within _)

. Learn the use and function of the ON-OFF switch,

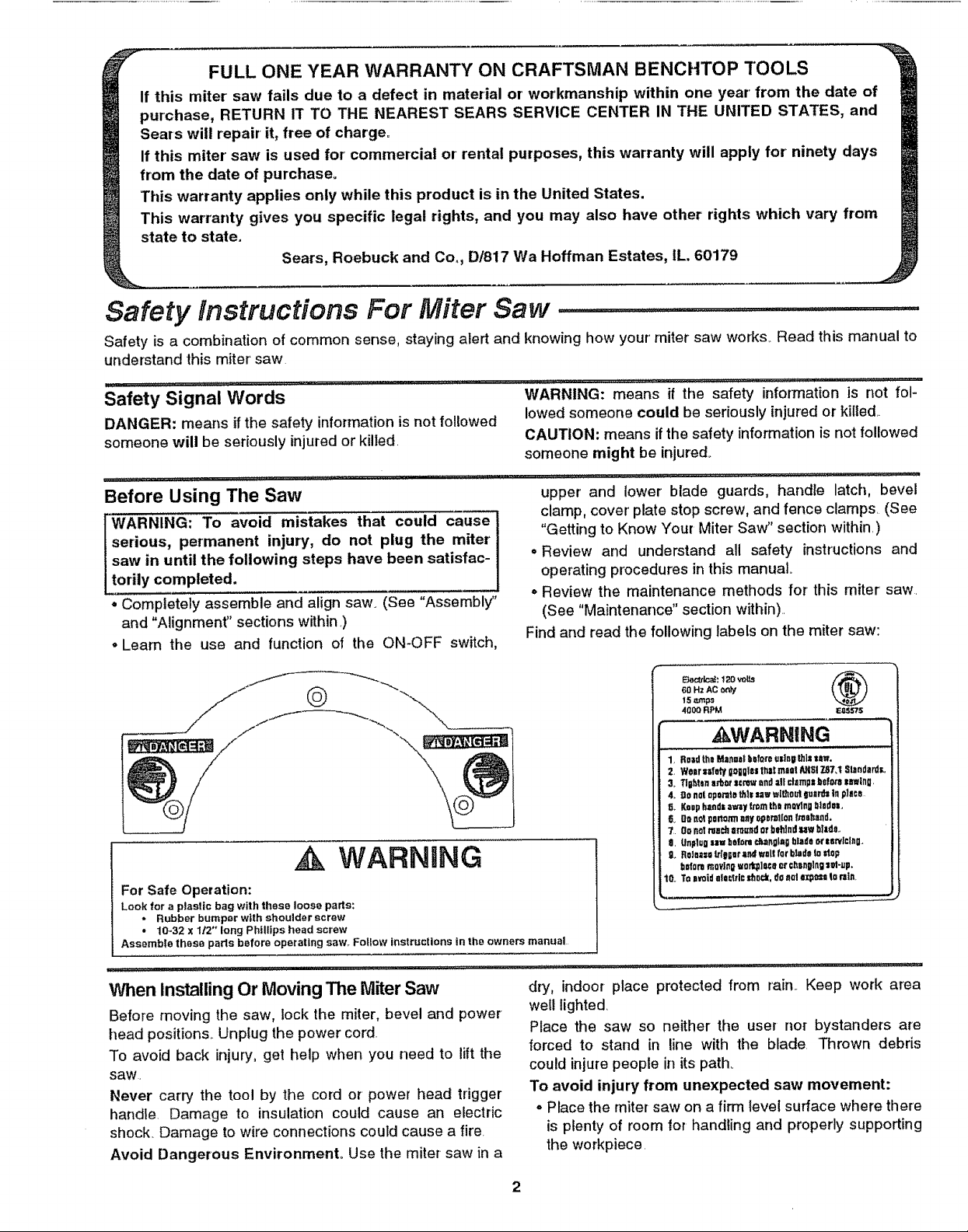

WARNING

For Safe Operation:

Look for a plastic bag with these loose pads:

• Rubber bumper with shouldsrscrsw

• 10-32 x 1/2" long Phillips head screw

Assemble these parts before operating saw,. Follow instructions in the owners manual

WARNING: means if the safebJ information is not fol-

lowed someone could be seriously injured or killed

CAUTION: means if the safety information is not followed

someone might be injured,.

......... , :,:: :::. .... , ,....

upper' and lower blade guards, handle latch, bevel

clamp, cover' plate stop screw, and fence clamps. (See

"Getting to Know Your Miter Saw" section within)

° Review and understand all safety instructions and

operating procedures in this manual

° Review the maintenance methods for this miter saw.

(See "Maintenance" section within).

Find and read the following labels on the miter saw:

60HzACon_f

15 m"nps

4O00 RPM E_S

, WARNING

1. RoadtheManna|baforaudnBthissaw.

2, Wear=sfdy gagglasthatn_aatAHSIT-87.tSlandsrd=,.

3_ TlltMsnarborscrewandallutazTIplbeforesawinliI.

4. _onatoparatathissawwithoutousrdstflplace

[i, K_ophandsawaytmx:rlt_llmovlngbtados,

6_ Dosatponotrnsay opsral[anfmohatid.

7,, Donotroacharn_r_or behindsawblade,,

9, {lnPlsOmawbot_tod_al_gtagbladoorservicing..

9.. Rolna=n_tEar al_ waltlot bladatoIdop

botsramay]figwo_plase_r €._angtngsot-,p.

10. Toavoidhill€trioshack,doaut axp0saIs rain_

When Installing Or Moving The Miter Saw

Before moving the saw, lock the miter, bevel and power

head positions.. Unplug the power cord.

To avoid back injury, get help when you need to lift the

saw.

Never carry the tool by the cord or power head trigger

handle. Damage to insulation could cause an electric

shock. Damage to wire connections could cause a fire.

Avoid Dangerous Environment° Use the miter-saw in a

dry, indoor place protected from rain.. Keep work area

well lighted

Place the saw so neither the user nor bystanders are

forced to stand in line with the blade. Thrown debris

could injure people in its path.

To avoid injury from unexpected saw movement:

• Place the miter saw on a firm level surface where there

is plenty of room for handling and properly supporting

the workplace.

2

°Supportthemitersawsothetableis levelandthesaw

doesnotrock,.

• Bolt or clamp the saw to its support.

o Never Stand On Tool. Serious injury could occur if the

tool tips or you accidentally hit the cutting tool.. Do not

store anything above or near the tool where anyone

might stand on the tool to reach them.

To avoid injury or death from electrical shock:

° Make sure your fingers do not touch the plug's metal

prongs when plugging or unplugging the miter saw..

Before Each Use

Inspect your miter saw.

Disconnect The Miter Saw,, To avoid injury from acci-

dental starting, unplug the saw, before changing the

setup, changing the blade or adjusting anything.

Compare the direction of rotation arrow on the guard to

the direction arrow on the blade.. The blade teeth should

always point downward at the front of the saw

Tighten the arbor screw.

Tighten the cover plate stop screw.

Check For Damaged Parts. Check for:

° Proper Alignment of moving pads,

° Damaged electric cords,

. Binding of moving parts,

° Broken parts,

° Stable mounting,

• Function of arm return spring and lower guard: Push before turning it on.

To Avoid Injury From Jams, Slips Or Thrown

Pieces

• Use Only Recommended Accessories. (See "Acces-

sory" section within) Consult this Owner's manual for

recommended accessories. Follow the instructions

that come with the accessoriesr The use of improper

accessories may cause risk of injury to persons..

° Choose the right 12-inch diameter blade for the mate-

rial and the type of cutting you plan to don

. Make sure the blade is sharp, undamaged and prop-

erly aligned.. With the saw unplugged, push the power-

head all the way down Hand spin the blade and check

for clearance, Tilt the power-head to 45 degree bevel

and repeat the check. If the blade hits anything, make

Plan Ahead To Protect Your Eyes, Hands,

Face, Ears.

Know Your Miter Saw. Read and understand the

owner's manual and labels affixed to the tool Learn its

applications and limitations as well as the specific poten-

tial hazards peculiar to this tool,

To avoid injury from accidental contact with moving parts,

don't do layout, assembly, or setup work on the miter saw

while any parts are moving,

Avoid Accidental Starting. Make sure switch is "OFF"

before plugging miter saw into a power outlet

Plan your work,

Use The Right Tool. Don't force tool or attachment to do

a job it was not designed to do..Use a different tool for

any workpiece that can't be held in a solidly braced, fixed

position.

the arm all the way down, then let it rise up until it

stops by itself.. Check the lower guard to see if it closed

fully.. If it did not, follow the instructions in the Trouble

Shooting section,.

° Other conditions that may affect the way the miter saw

works

If any part of this miter saw is missing, bent, or broken in

any way, or any electrical parts don't work, turn the saw

off and unplug it. Replace damaged, missing, or failed

parts before using the saw again

Keep Guards In Place, in working order, and in proper

adjustment..

Maintain Tools With Care, Keep the miter saw clean for

best and safest performance. Follow instructions for lubri-

cating_ DON'T put lubricants on the blade while it's spin-

ning,.

Remove Adjusting Keys And Wrenches from tool

,, ,,,_rl_ H,'"i'll ....... _1_'_"±'I I

the adjustments shown in the Maintaining Maximum

Cutting Capacity section.

° Make sure the blade and arbor collars are clean.

° Make sure the collars' recessed sides are facing the

blade..

• Using the 1/4" hex end of combination wrench (sup-

plied) or a 1/2-inch box end wrench, make sure the

arbor cap screw is firmly hand tightened

° Make sure all clamps and locks are tight and there is

no excessive play in any parts.

o Keep Work Area Clean. Cluttered areas and benches

invite accidents. Floor must not be slippery_

To avoid burns or other fire damage, never use the saw

near flammable liquids, vapors or gases..

CAUTION: This machine is not designed for cutting

ferrous metals (steel, iron and iron based metals).

Use this miter saw to cut only wood, wood like

products or soft metals like aluminum. Other mate-

rial may shatter, bind on the blade, or create other

dangers.

CAUTION: When cutting any metals, sparks or hot

fragments could cause afire. To avoid this, discon-

nect any dust collecting bag or hose from the miter

saw, and remove all traces of wood dust from

inside dust traps in the miter saw.

............ ;:.... ,,,,, .............

Safety Instructions fen"Miter Saws (continued) ....................................

Dress For Safety

WEAR YOUR

Any power miter saw can throw foreign objects into the

eyes. This can result in permanent eye damage.. Wear

safety goggles (not glasses) that comply with ANSI Z87 1

(shown on package). Everyday eyeglasses have only

impact resistant lenses.. They are not safety glasses

Safety goggles are available at Sears retail stores

Glasses or goggles not in compliance with ANSI Z87_1

could seriously hurt you when they break=

............. ........ ,L................ ,, ,,, ............. , ........................ , ,...... ,, ,:.............. , ........ _..........

Inspect Your Workpiece

• Make sure there are no nails or foreign objects in the

part of the workpiece to be cut

Plan your work to avoid thrown pieces caused when

the workpiece binds on the blade and is torn from

your hands.

Plan the way you will hold the workpiece from start to fin_

ish..

Avoid awkward operations and hand positions where a

sudden slip could cause fingers or hand to move into the

blade.

Don't Overreach. Keep good footing and balance

Keep your face and body to one side of sawblade, out of

line with a possible thrown piece.

• Cut only one workpiece at a time

Never cut Freehand:

° Brace your workpiece solidly against the fence and

table top so it wil! not rock or'twist during the cut.,

° Make sure there's no debris between the workpiece

and its supports.

oMake sure no gaps between the workpiece, fence and

table will let the workpiece shift after' it is cut in two..

° Keep the cut off piece free to move sideways after it's

cut off.. Otherwise, it could get wedged against the

blade and thrown violently_

° Clear everything except the workpiece and related

support devices off the table before turning the miter

saw on.

° Secure Work. Use clamps or a vise to help hold the

work when it's practical

oDo not wear loose clothing, gloves, neckties or' jewelry

(rings, wrist watches) They can get caught and draw

you into moving parts.

• Wear nonslip footwear.

• Tie back long hair_

• Roll long sleeves above the elbow.

° Noise levels vary widely,. To avoid possible hearing

damage, wear' ear plugs or muffs when using miter

saw for hours at a time.

o For dusty operations, wear a dust mask along with

safety goggles,

Use extra caution with large, very small or awkward

workpieces:

° Use extra supports (tables, saw horses, blocks, etc.,)

for any workpieces large enough to tip when not held

down to the table top.

° Never use another person as a substitute for a table

extension, or as additional support for a workpiece that

is longer or wider than the basic miter saw table or to

help feed, support or' pull the workpiece.

° Do not use this saw to cut pieces too small to let you

easily hold the work while you keep the thumb side of

your index (pointer) finger against the outside edge of

the fence..

° When cutting irregularly shaped workpieces, plan your'

work so it will not slip and pinch the blade and be tom

from your hands.. A piece of molding, for example,

must tieflat or be held by a fixture or jig that will notj,_et

it twist, rock or slip while being cut..

° Properly support round material such as dowel rods, or

tubing. They have a tendency to roll while being cut,

causing the blade to "bite." To avoid this, always use a

fixture designed to properly hold your' workpiece.

WARNING: If planning to cut aluminum or' other

non-ferrous metals: Under adverse conditions, the

blade can grab and throw the workpiece suddenly

and unexpectedly. To avoid injury, follow all applica-

ble safety instructions, as you normally would, and:

oUse only sawblades specifically recommended

for non-ferrous metal cutting,

o Do not cut metal workpieces that must be hand

held. Use auxiliary clamps or other equipment as

needed.

oCut non-ferrous metals only if you are experi-

enced or under the supervision of an experienced

person,

Whenever Saw is Running

WARNING: Don't allow familiarity (gained from fre-

quent use of your miter saw) cause a careless mis-

take. A careless fraction of a second is enough to

cause a severe injury.

Before starting your cut, watch the miter saw while it

runs. Ifit makes an unfamiliar noise or vibrates a lot, stop

immediately° Turn the saw off. Unplug the saw Do net

restart until finding and correcting the problem.

Keep Children Away,. Keep all visitors a safe distance

from the miter saw. Make sure bystanders are clear of

the miter saw and workpiece

Never confine the piece being cut off. Never hold it,

clamp it, touch it, or use length stops against it while the

blade is spinning. It must be free to move sideways on its

own. if confined, it could get wedged against the blade

and be thrown violently.

Let the blade reach full speed before cutting. This will

help avoid thrown workpieces

Don't Force Tool. It will do the job better and safer at its

designed rate. Feed the saw into the workpiece only fast

enough to let the blade cut without bogging down or binding..

Before freeing jammed material:

• Turn miter saw "OFF" by releasing trigger switch

° Wait for all moving parts to stop.

° Unplug the miter saw

After finishing a cut:

° Keep holding the power head down..

° Release the switch, and wait for all moving parts to

stop before moving your hands or raising power head

° If blade doesn't stop within 6 seconds, unplug the saw

and follow the instructions in the Trouble Shooting sec-

tion for fixing the blade brake before using the saw

again..

Before Leaving The Saw the hole provided in the trigger to prevent unauthorized

Never Leave Tool Running Unattended,Turn power usage., Lock the shop. Disconnect master switches. Store

off. Wait for all moving parts to stop., the tool,

Make Workshop Child Proof. Install a padlock through

tool away from children and others not qualified to use

Glossary of Terms for Woodworking

Arbor

The shaft on which a cutting tool is mounted.

Bevel Cut

An angle cutting operation made through the face of the

workpiece.

Compound Cut

A simultaneous bevel and miter cutting operation.

Crosscut

A cutting operation made across the width of the work-

piece.

Freehand

Doing a cut without holding the workpiece against both

the table and fence. Most workpieces can be held down

with your hand Large or wide pieces should be clamped

to the fence or table.

Gum

A sticky, sap based residue from wood products..

Heel

Misalignment of the blade

Kerr

The amount of material removed by the blade in a

through cut or the slot produced by the blade in a non-

through or partial cut

Miter Cut

An angle cutting operation made across the width of the

workpiece._

Resin

A sticky, sap based substance that has hardened.

Revolutions Per Minute (RPM)

The number of turns completed by a spinning object in

one minute.

Sawblade Path

The area of the workpiece or table top directly in line with

either the travel of the blade or the part of the workpiece

which will be, or has been, cut by the blade

Set

The distance that the tip of the sawblade tooth is bent (or

set) outward from the face of the blade..

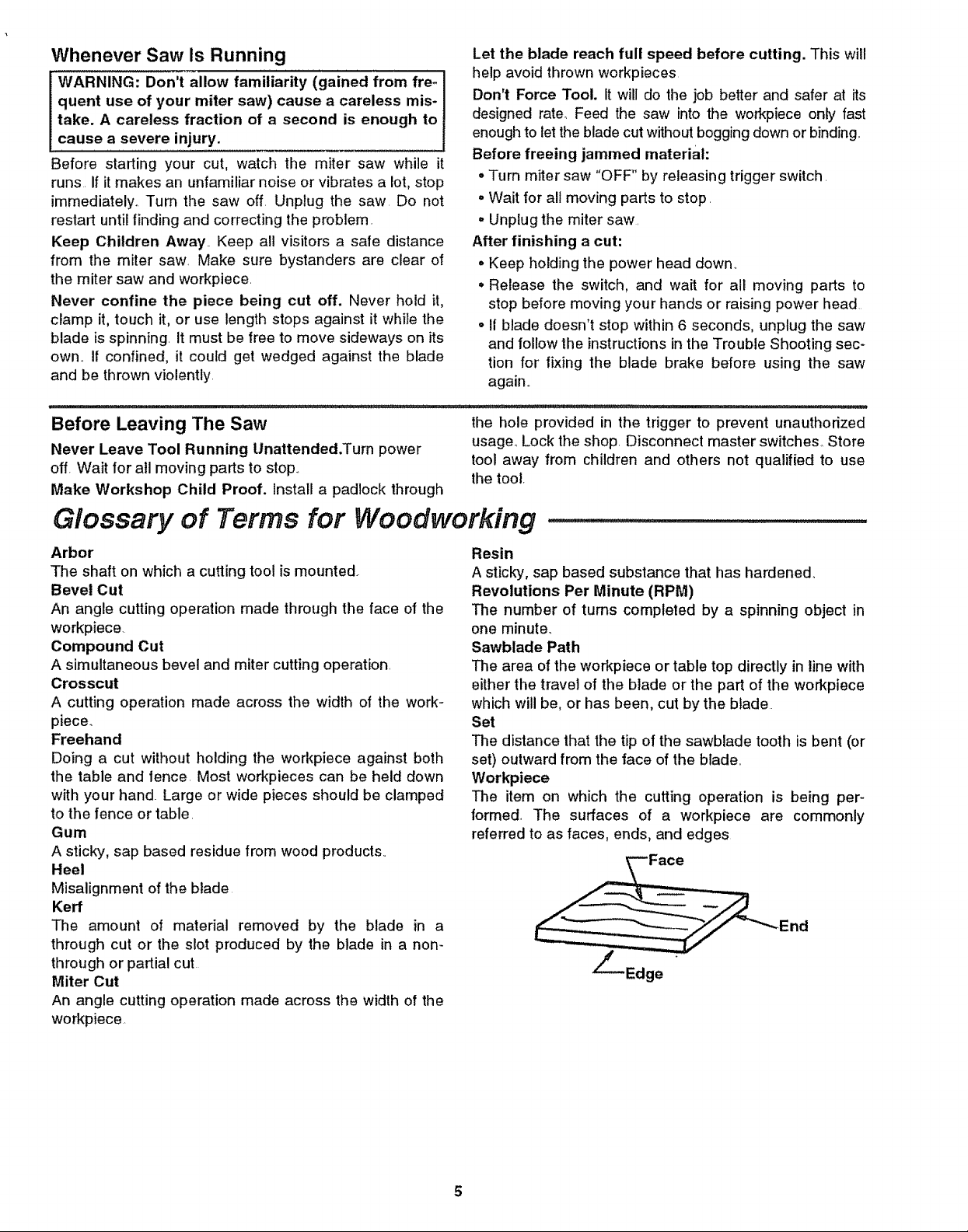

Workpiece

The item on which the cutting operation is being per-

formed, The surfaces of a workpiece are commonly

referred to as faces, ends, and edges

Motor Specifications and Electrical Requirements

Power Supply and Motor Specifications

WARNING: To avoid electrical hazards, fire haz-

ards or' damage to the tool, use proper circuit pro-

tection. Your tool is wired at the factory for

operation using the voltage shown. Connect tool

to a power line with the appropriate voltage and a

15-amp branch circuit° Use a 15-amp time delay

type fuse or circuit breaker° To avoid shock or fire,

if power' cord is worn or cut, or damaged in any

way, have it replaced immediately.

General Electrical Connections

DANGER: To avoid electrocution:

1. Use only identical replacement parts when ser-

vicing. Servicing should be performed by a

qualified service technician°

2. Do not use in rain or where floor is wet.

This tool is intended for' indoor residential use

only.

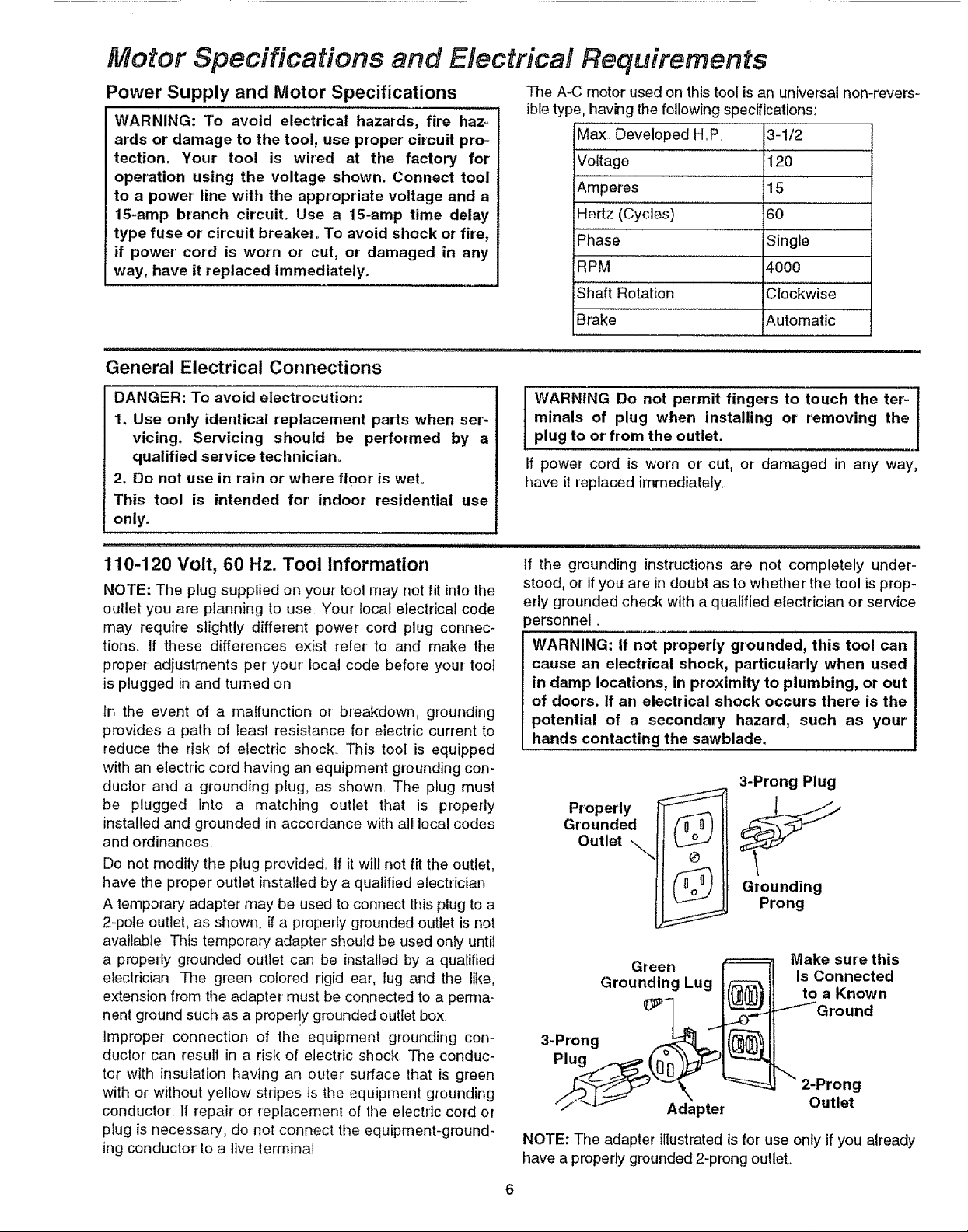

The ArC motor used on this tool isan universal non-revers-

ible type, having the following specifications:

Max Developed H_P, 3-1/2

Voltage 120

Amperes ......................1"5.....

Hertz (Cycles) 60

Phase Single

RPM 4OOO

Shaft Rotation Clockwise

Brake Automatic

minals of plug when installing or removing the

J WARNtNG Do not permit fingers to touch the ter- 1

If power cord is worn or cut, or damaged in any way,

have it replaced immediately..

lplug to or from the outlet.

110-120 Volt, 60 Hz. Tool Information

NOTE: The plug supplied on your tool may not fit into the

outlet you are planning to use.. Your local electrical code

may require slightly different power cord plug connec-

tions.. If these differences exist refer to and make the

proper adjustments per your local code before your toot

is plugged in and turned on

In the event of a malfunction or breakdown, grounding

provides a path of least resistance for electric current to

reduce the risk of electric shock.. This tool is equipped

with an efectric cord having an equipment grounding con-

ductor and a grounding plug, as shown. The plug must

be plugged into a matching outlet that is properly

installed and grounded in accordance with air local codes

and ordinances

Do not modify the plug provided.. If itwilJnot fit the outlet,

have the proper outlet installed by a qualified electrician.

A temporary adapter may be used to connect this plugto a

2-pote outlet, as shown, if a properly grounded outlet is not

available This temporary adapter should be used only until

a proper_y grounded outlet can be installed by a qualified

electrician The green colored rigid ear, lug and the like,

extension from the adapter must be connected to a pemla-

nent ground such as a proper!y grounded outlet box

improper connection of the equipment grounding con-

ductor can resutt in a risk of electric shock The conduc-

tor with insulation having an outer surface that is green

with or without yellow stripes is the equipment grounding

conductor tf repair or replacement of the electric cord or

plug is necessary, do not connect tt_e equipment-ground-

ing conductor to a live terminal

If the grounding instructions are not completely under-

stood, or ifyou are in doubt as to whether the tool is prop-

erly grounded check with a qualified electrician or service

_ersonnel.

WARNING: If not properly grounded, this tool can

cause an electrical shock, particularly when used

in damp locations, in proximity to plumbing, or out

of doors. If an electrical shock occurs there is the

potential of a secondary hazard, such as your

hands contacting the sawblade.

3-Prong Plug

Properly

Grounded

Outlet _,,

Grounding

Prong

Green

Grounding Lug ({_(_._

Make sure this

is Connected

to a Known

1_'Ground

a-Prong

Plug .__ (n_ _P_

2-Prong

ter

NOTE: The adapter illustrated isfOrruse only if you already

have a properly grounded 2-prong outlet.

Outlet

Motor Safety Protection

1. Connect this tool to a 120v, 15-amp branch circuit with

a 15-amp time delay fuse or circuit breaker Using the

wrong size fuse can damage the motor.

2. If the motor won't start, release the trigger switch

immediately.. Unplug The Tool. Check the saw blade

to make sure it turns freely, tf the blade is tree, try to

start the motor again. If the motor still does not start,

refer to the "Motor Trouble-Shooting Chart."

3oIf the motor suddenly stalls while cutting wood, release

the trigger switch, unplug the tool, and free the blade

from the wood The motor may now be restarted and

the cut finished

4oFuses may "blow" or circuit breakers may trip fie-

quently if:

a..Motor Is Overloaded-Overloading can occur if you

feed too rapidly or make too many start/stops in a

short time.

b..Line voltages are more than 10% above or below the

nameplate voltage. For heavy loads, however, the

voltage at motor terminals must equal the voltage

specified on nameplate..

c. Improper or dult saw blades are used

5,.Most motor troubles may be traced to loose or incor-

rect connections, overload, low voltage (such as small

size wire in the supply circuit) or to overly long supply

circuit wire.. Always check the connections, the load

and the supply circuit whenever motor doesn't work

well Check wire sizes and length with the Wire Size

Chart below.

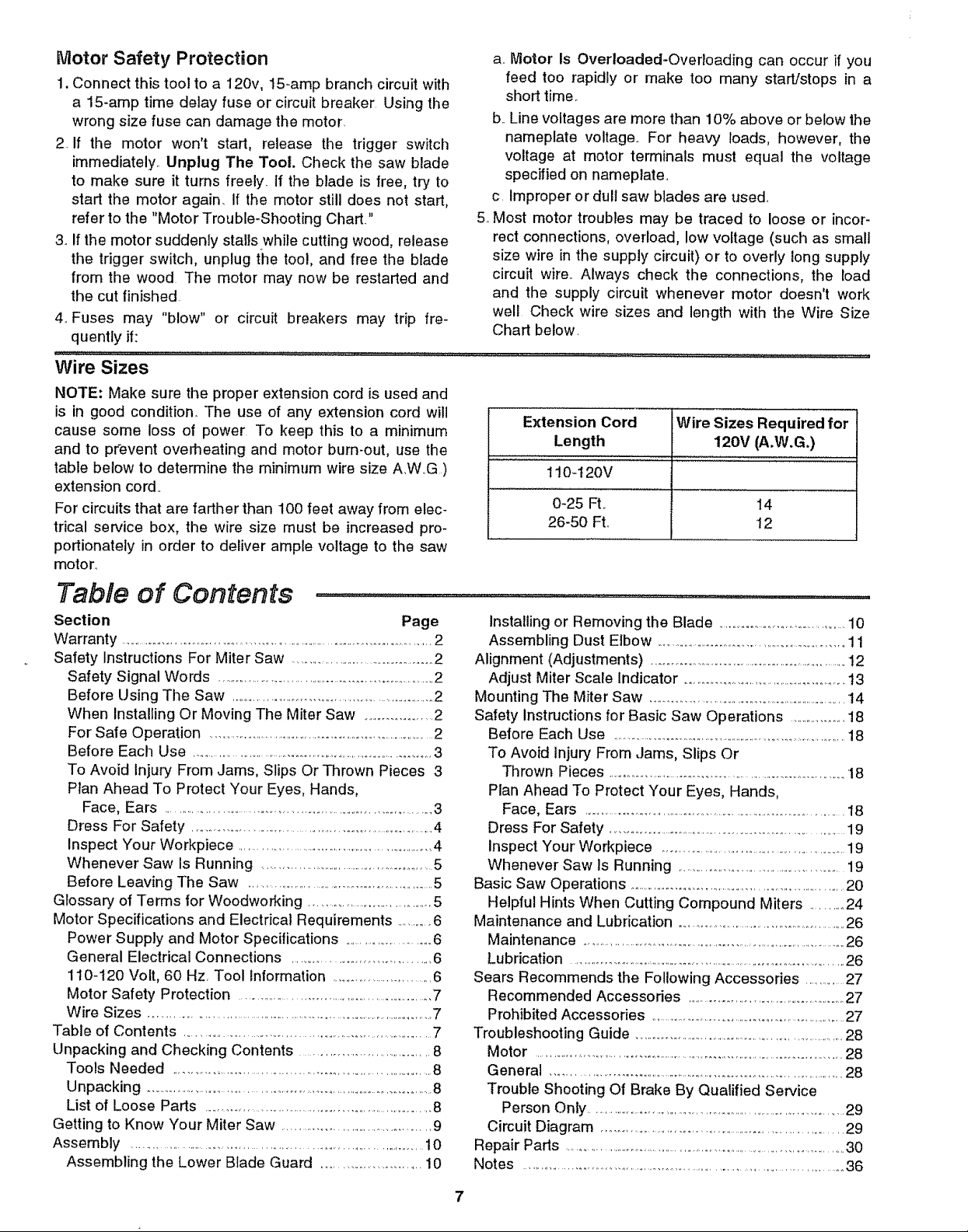

wire sizes .........................................

NOTE: Make sure the proper extension cord is used and

is in good condition. The use of any extension cord will

cause some loss of power To keep this to a minimum

and to prevent overheating and motor burn-out, use the

table below to determine the minimum wire size AW..G )

extension cord..

For circuits that are farther than 100 feet away from elec-

trical service box, the wire size must be increased pro-

portionately in order to deliver ample voltage to the saw

motor..

Extension Cord Wire Sizes Required for

Length 120V (A,W.G.)

110-t20V

0-25 It.. 14

26-5O Fto 12

Table of Contents .........

Section Page

Warranty ...............................................................................................2

Safety Instructions For Miter Saw ..............................................2

Safety Signal Words .........................................................................2

Before Using The Saw .....................................................................2

When Installing Or Moving The Miter Saw .....................2

For Safe Operation ................................................................................2

Before Each Use ...............................................................................3

To Avoid injury From Jams, Slips Or Thrown Pieces 3

Plan Ahead To Protect Your Eyes, Hands,

Face, Ears .....................................................................................3

Dress For Safety .........................................................................4

Inspect Your Workpiece ..................................................................4

Whenever Saw Is Running .........................................................5

Before Leaving The Saw .........................................................5

Glossary of Terms for Woodworking .....................................5

Motor Specifications and Electrical Requirements .............6

Power Supply and Motor Specifications ...........................6

General Electrical Connections ......................................6

1t0-120 Volt, 60 Hz. Tool Information ..............................6

Motor Safety Protection ..............................................................7

Wire Sizes ...............................................................................................7

Table of Contents .............................................................................7

Unpacking and Checking Contents .......................................8

Tools Needed ...........................................................................8

Unpacking ........................................................................................8

List of Loose Parts .....................................................................8

Getting to Know Your Miter Saw ..........................................9

Assembly ........................................................................................10

Assembling the Lower Blade Guard ...................................10

Installing or Removing the Blade ..........................................10

Assembling Dust Elbow .............................................................11

Alignment (Adjustments) .................................................................12

Adjust Miter Scale Indicator ......................................................t3

Mounting The Miter Saw ................................................................14

Safety instructions for Basic Saw Operations .................18

Before Each Use .................................................................................18

To Avoid Injury From ,Jams, Slips Or

Thrown Pieces ............................................................................18

Plan Ahead To Protect Your Eyes, Hands,

Face, Ears ....................................................................................18

Dress For Safety .................................................................................19

Inspect Your Workpiece ..............................................................19

Whenever Saw ls Running ......................................................19

Basic Saw Operations ........................................................................20

Helpful Hints When Cutting Compound Miters .........24

Maintenance and Lubrication ......................................................26

Maintenance ..........................................................................................26

Lubrication .........................................................................................26

Sears Recommends the Following Accessories ..............27

Recommended Accessories ..................................................27

Prohibited Accessories ..................................................................27

Troubleshooting Guide ......................................................................28

Motor ...............................................................................................28

General ..............................................................................................28

Trouble Shooting Of Brake By Qualified Service

Person Only ...................................................................................29

Circuit Diagram ........................................................................29

Repair Parts ..........................................................................................30

Notes ...................................................................................................36

7

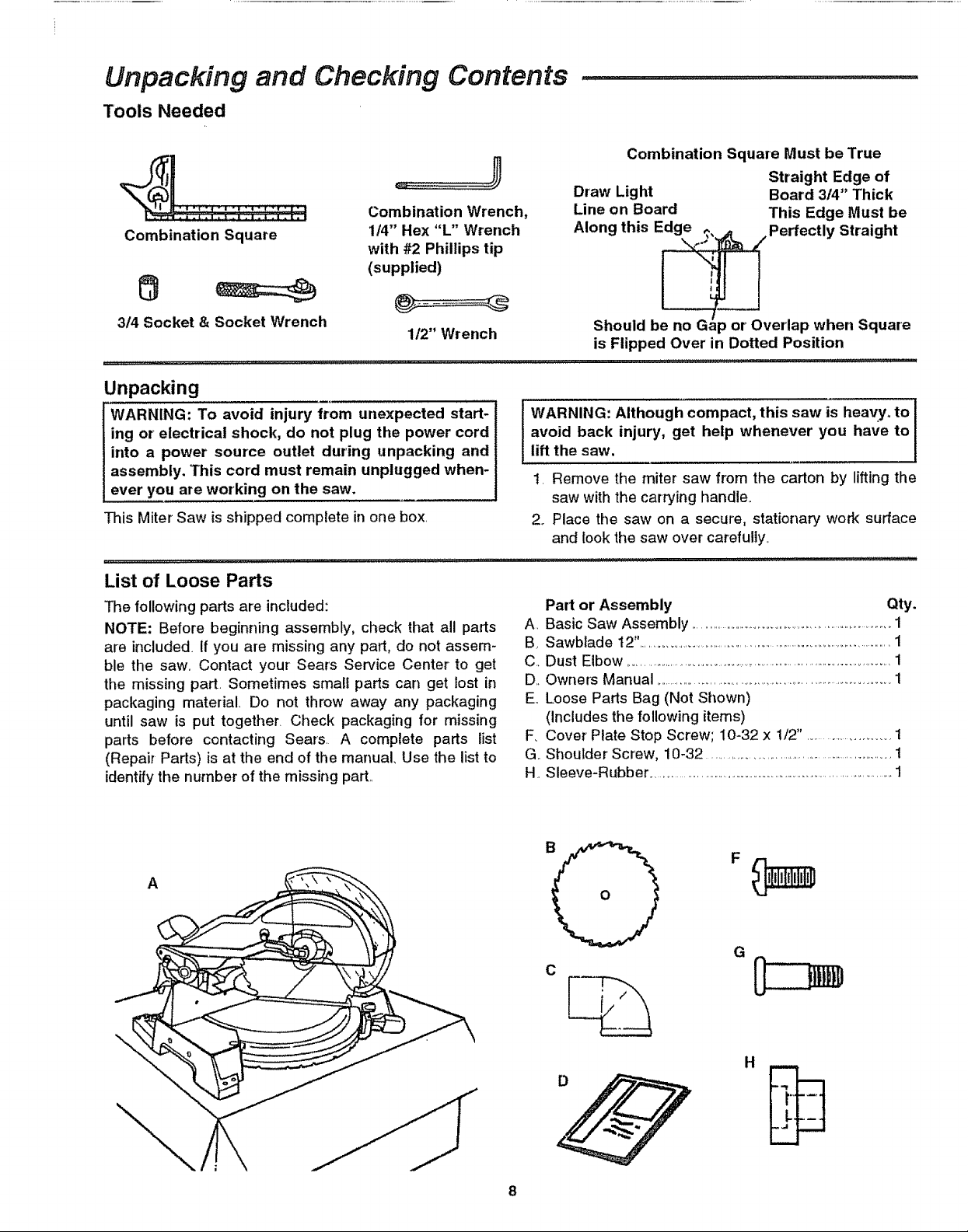

Unpacking and Checking Contents

Tools Needed

Combination Wrench,

Combination Square

1/4" Hex "L" Wrench

with #2 Phillips tip

(supplied)

Combination Square Must be True

Straight Edge of

Draw Light Board 314" Thick

Line on Board This Edge Must be

Along this i_i. _ PI rfectly Straight

314 Socket & Socket Wrench

112"Wrench

Unpacking

WARNING: To avoid injury from unexpected start-

ing or electrical shock, do not plug the power cord

into a power source outlet during unpacking and

assembly. This cord must remain unplugged when-

ever you are working on the saw.

This Miter Saw is shipped complete in one box.

' ii,i,,, ,_,,,_11,,,,i : ....

List of Loose Parts

The following parts are included:

NOTE: Before beginning assembly, check that all parts

are included. If you are missing any part, do not assem-

ble the saw.+ Contact your Sears Service Center to get

the missing part. Sometimes small parts can get lost in

packaging material. Do not throw away any packaging

until saw is put together. Check packaging for missing

parts before contacting Sears. A complete parts list

(Repair Parts) is at the end of the manual. Use the list to

identify the number of the missing part..

Should be no L_apor uverlap when Square

is Flipped Over in Dotted Position

............ I i i l!l _ _ I_II_IIL _ii : :

WARNING: Although compact, this saw is heavy+ to

avoid back injury, get help whenever you have to

lift the saw.

1. Remove the miter saw from the carton by lifting the

saw with the car+vyinghandle.

2 Place the saw on a secure, stationary work surface

and look the saw over carefully+

Part or Assembly Qty.

A Basic Saw Assembly ........................................................................1

B. Sawblade t2".............................................................................................1

C+Dust Elbow ..........................................................................................1

D+Owners Manual ...........................................................................1

E. Loose Parts Bag (Not Shown)

(Includes the following items)

F. Cover Plate Stop Screw; 10-32 x t/2". ..........................1

G.,Shoulder Screw, 10-32 .............................................................1

H. Sleeve-Rubber ...........................................................................1

A

G

H

D

Getting to Know Your Miter Saw

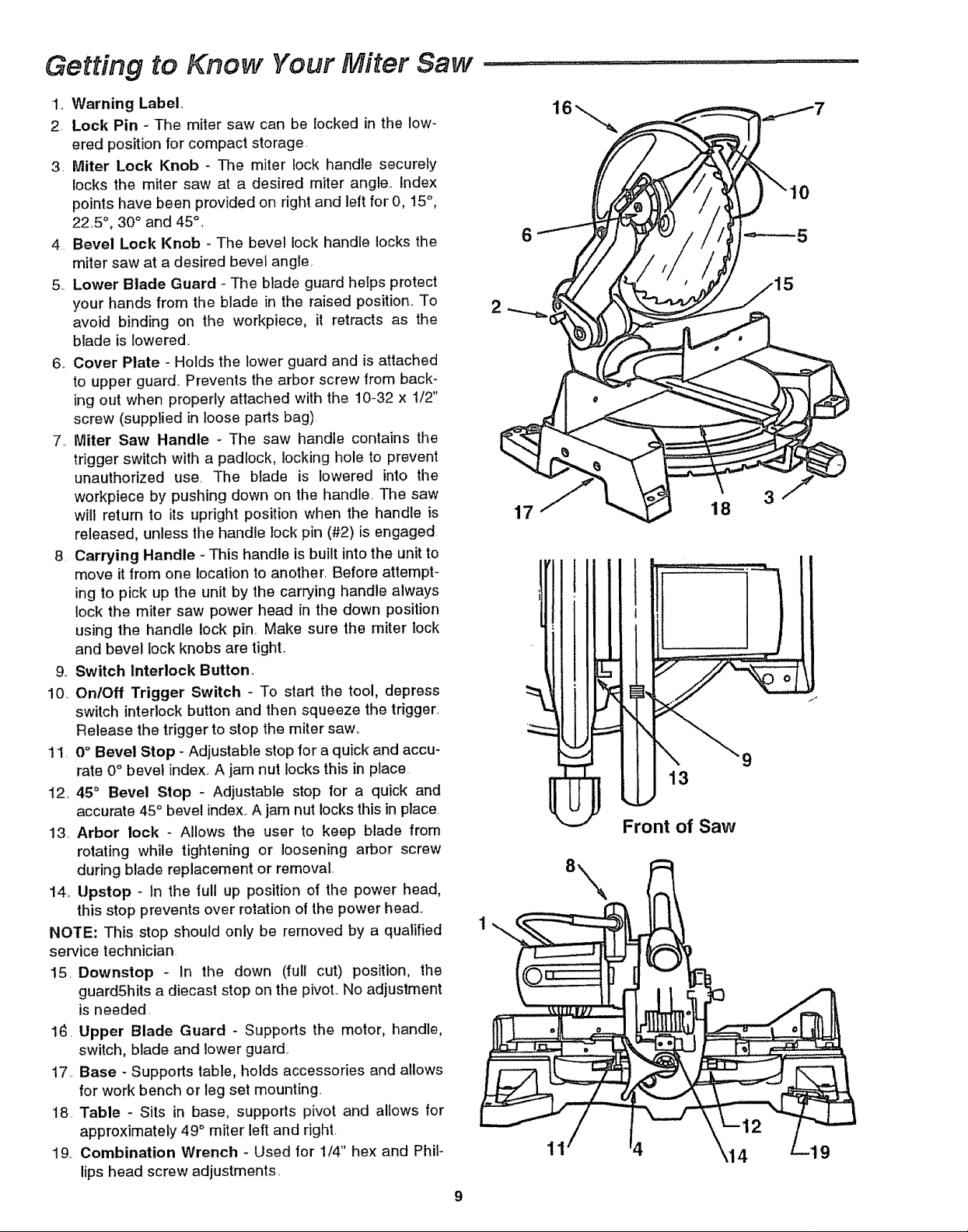

1,, Warning Label,

2. Lock Pin - The miter saw can be locked in the low-

ered position tor compact storage.

3. Miter Lock Knob - The miter lock handle securely

locks the miter saw at a desired miter angle, Index

points have been provided on right and left for 0, 15°,

225 °, 30° and 45°,

4 Bevel Lock Knob - The bevel lock handle locks the

miter saw at a desired bevel angle,

5.. Lower Blade Guard - The blade guard helps protect

your hands from the blade in the raised position.,To

avoid binding on the workpiece, it retracts as the

blade is lowered..

6. Cover Plate - Holds the lower guard and is attached

to upper guard.. Prevents the arbor screw from back-

ing out when properly attached with the 10-32 x 1/2"

screw (supplied in loose parts bag)

7., Miter Saw Handle - The saw handle contains the

trigger switch with a padlock, locking hole to prevent

unauthorized use, The blade is lowered into the

workpiece by pushing down on the handle. The saw

will return to its upright position when the handle is

released, unless the handle lock pin (#2) is engaged.

8. Carrying Handle - This handle is built into the unit to

move it from one location to another, Before attempt-

ing to pick up the unit by the carrying handle always

lock the miter saw power head in the down position

using the handle lock pin. Make sure the miter lock

and bevel lock knobs are tight°

9_ Switch Interlock Button,

10.. On/Off Trigger Switch - To start the tool, depress

switch interlock button and then squeeze the trigger.,

Release the trigger to stop the miter saw,,

11. 0° Bevel Stop - Adjustable stop for a quick and accu-

rate 0° bevel index_A jam nut locks this in place

12, 45° Bevel Stop - Adjustable stop for a quick and

accurate 45° bevel index..A jam nut locks this inplace.

13, Arbor lock - Allows the user to keep blade from

rotating while tightening or loosening arbor screw

during blade replacement or removal,

14., Upstop - tn the full up position of the power head,

this stop prevents over rotation of the power head..

NOTE: This stop should only be removed by a qualified

service technician

15. Downstop - In the down (full cut) position, the

guardShits a diecast stop on the pivot., No adjustment

is needed.

16. Upper Blade Guard - Supports the motor, handle,

switch, blade and lower guard.

17.. Base - Supports table, holds accessories and allows

for work bench or leg set mounting,

18. Table - Sits in base, supports pivot and allows for

approximately 49 ° miter left and right,

19.. Combination Wrench - Used for 1/4" hex and Phil-

lips head screw adjustments,

6

3

18

f_

11

Assembly

WARNING: For your own safety, never connect

plug to power' source outlet until all assembly

steps are complete, and you have read and under'-

stood the safety and operational instructions,

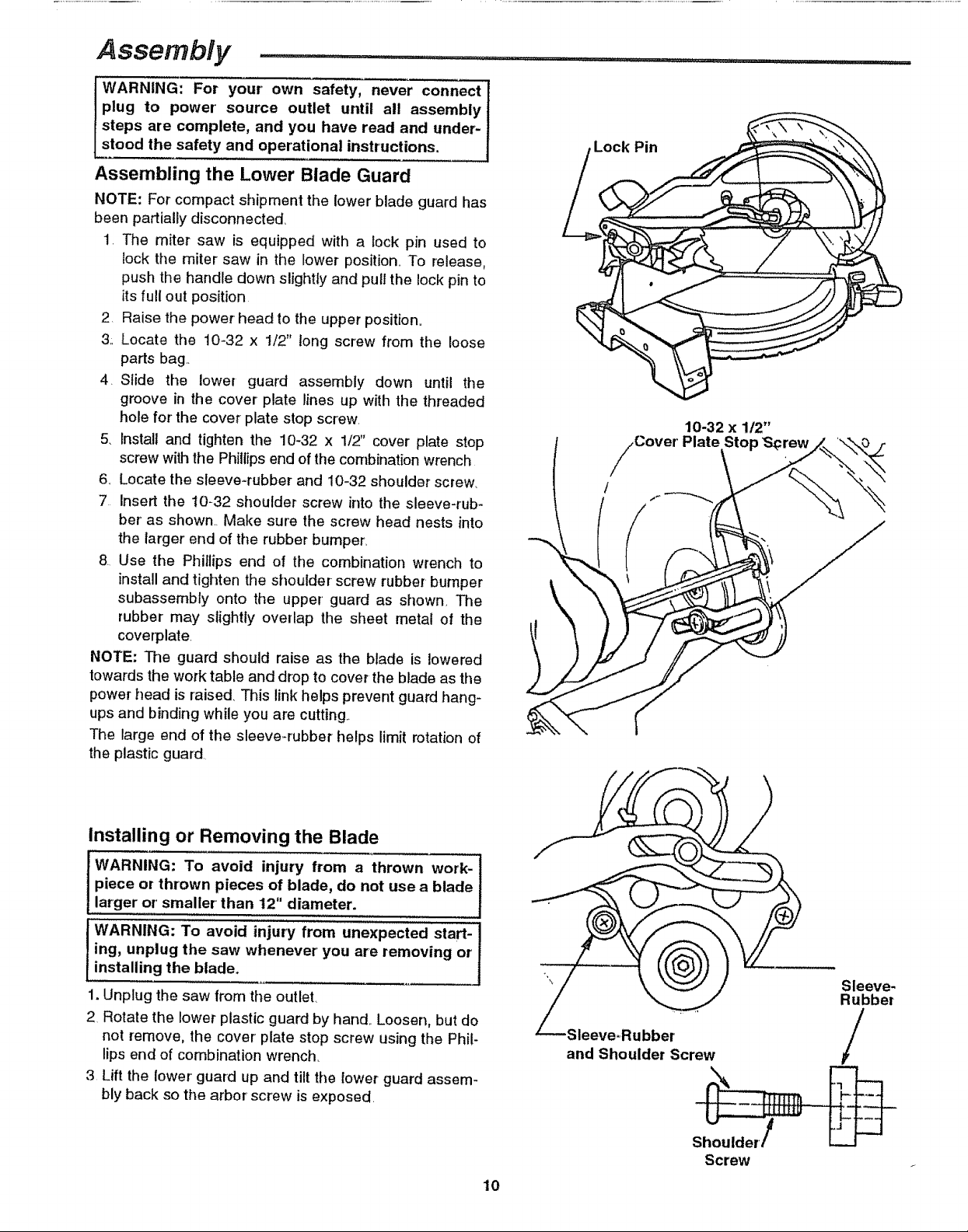

Assembling the Lower Blade Guard

NOTE: For compact shipment the lower blade guard has

been partially disconnected.

1. The miter saw is equipped with a lock pin used to

lock the miter saw in the lower position.. To release,

push the handle down slightly and pull the lockpin to

itsfull out position

2. Raise the power head to the upper position.

3.+Locate the 10-32 x 1/2" tong screw from the loose

parts bag.+

4+ Slide the lower guard assembly down until the

groove in the cover' plate lines up with the threaded

hole for the cover plate stop screw.

5. Install and tighten the 10-32 x 1/2" cover plate stop

screw withthe Phillips end of the combination wrench

6+ Locate the sleeve+rubber and 10-32 shoulder screw..

7 Insert the 10-32 shoulder screw into the sleeve-rub-

ber' as shown.. Make sure the screw head nests into

the larger end of the rubber bumper.

8. Use the Phillips end of the combination wrench to

install and tighten the shoulder +screw rubber bumper

subassembly onto the upper' guard as shown The

rubber may slightly overlap the sheet metal of the

coverplate

NOTE: Tlle guard should raise as the blade is lowered

towards the work table and drop to cover the blade as the

power head is raised This link helps prevent guard hang-

ups and binding while you are cutting..

The large end of the sleeve+rubber helps limit rotation of

the plastic guard

.Lock Pin

10-32 x 1/2"

Cover' Plate Stop S_rew

/

(

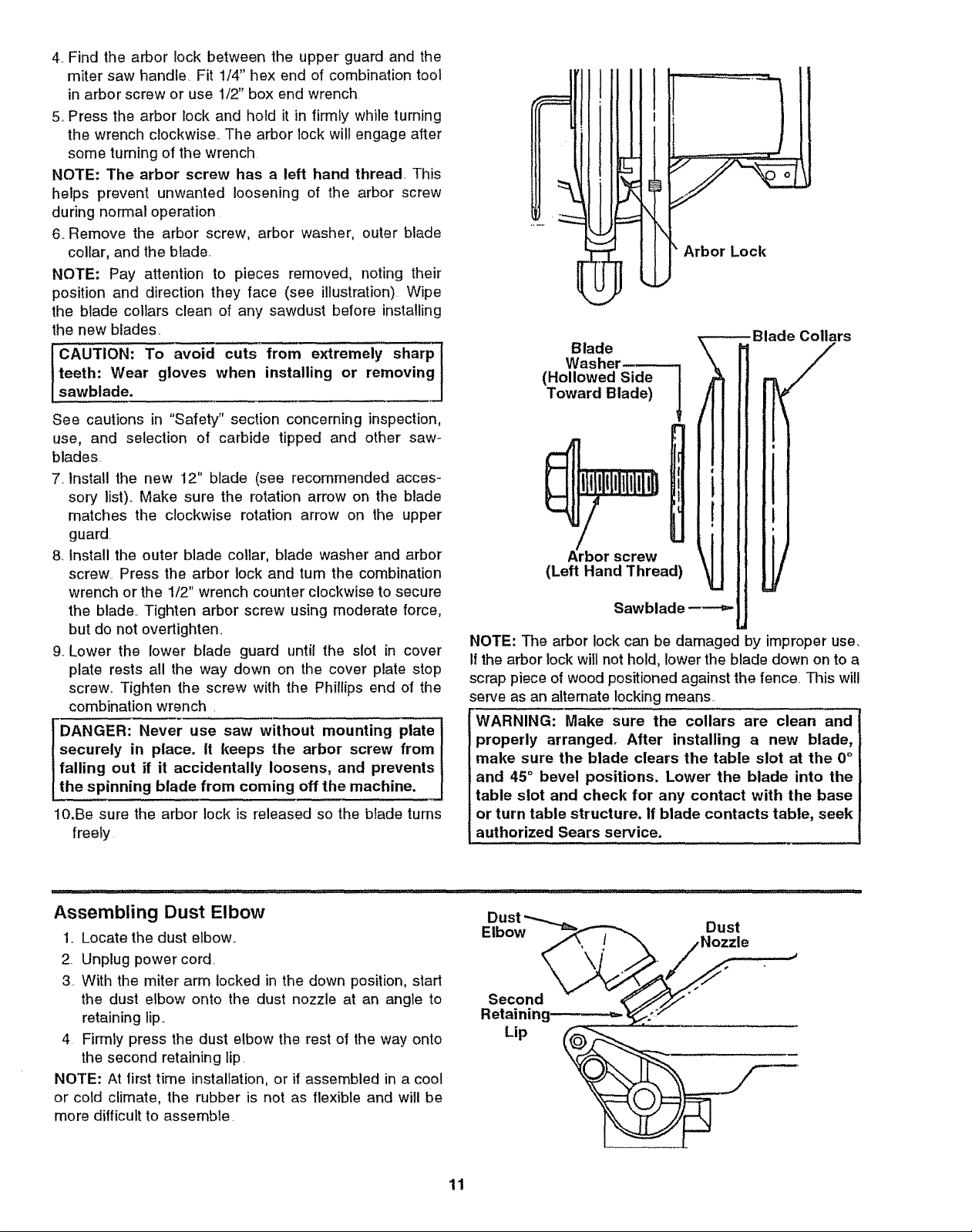

Installing or Removing the Blade

WARNING: To avoid injury from a thrown work-

piece or thrown pieces of blade, do not use a blade

larger or' smaller than t2" diameter.

WARNING: To avoid injury from unexpected start-

ing, unplug the saw whenever' you are removing or

installing the blade,

1.Unplug the saw from the outlet.

2 Rotate the lower plastic guard by hand.. Loosen, but do

not remove, the cover' plate stop screw using the Phil-

lips end of combination wrench_

3 Lift the lower guard up and tilt the lower guard assem-

bly back so the arbor screw is exposed.

10

and Shoulder Screw

Sleeve-

Rubber

/

Screw

4. Find the arbor lock between the upper guard and the

miter saw handle Fit 1/4" hex end of combination tool

in arbor screw or use 1/2" box end wrench

5.,Press the arbor lock and hold it in lirmfy while turning

the wrench clockwise.. The arbor lock will engage after

some turning of the wrench

NOTE: The arbor screw has a left hand thread, This

helps prevent unwanted loosening of the arbor screw

during normal operation

6. Remove the arbor screw, arbor washer, outer blade

collar, and the blade.

NOTE: Pay attention to pieces removed, noting their

position and direction they face (see illustration) Wipe

the blade collars clean of any sawdust before installing

the new blades.

teeth: Wear gloves when installing or removing

sawblade.

See cautions in "Safety" section concerning inspection,

use, and selection of carbide tipped and other saw-

blades

7. Install the new 12" blade (see recommended acces-

sory list)_ Make sure the rotation arrow on the blade

matches the clockwise rotation arrow on the upper

guard.

8_ Install the outer blade collar, blade washer and arbor

screw Press the arbor lock and tum the combination

wrench or the 1/2" wrench counter clockwise to secure

the blade.. Tighten arbor screw using moderate force,

but do not overtighten.

9. Lower the lower blade guard until the slot in cover

plate rests all the way down on the cover plate stop

screw° Tighten the screw with the Phillips end of the

combination wrench.

DANGER: Never use saw without mounting plate

securely in place, tt keeps the arbor screw from

falling out if it accidentally loosens, and prevents

the spinning blade from coming off the machine.

10.Be sure the arbor lock is released so the blade turns

freely

1

i

I

Arbor Lock

Collars

Blade

Washer----.--_

(Hollowed Side I

Toward Blade) 1

screw

(Left Hand Thread)

Sawblade -----_

NOTE: The arbor lock can be damaged by improper use,

If the arbor lock wilt not hold, lower the blade down on to a

scrap piece of wood positioned against the fence. This will

serve as an attemate locking means.

WARNING: Make sure the collars are clean and

properly arranged. After installing a new blade,

make sure the blade clears the table slot at the 0°

and 45 ° bevel positions. Lower the blade into the

table slot and check for any contact with the base

or turn table structure. If blade contacts table, seek

authorized Sears service.

Assembling Dust Elbow

1. Locate the dust elbow..

2. Unplug power cord.

3. With the miter arm locked in the down position, start

the dust elbow onto the dust nozzle at an angle to

retaining lip..

4 Firmly press the dust elbow the rest ol the way onto

the second retaining lip.

NOTE: At first time installation, or if assembled in a cool

or cold climate, the rubber is not as flexible and will be

more difficult to assemble.

..J

Lip

11

Loading...

Loading...