Craftsman 113235110, 113235221 Owner’s Manual

_FSave This Manual "_

or Future Reference

SEARS

owner's

manual

MODEL NO.

113.235221

COMPOUND MITER SAW

MODEL NO.

113.235110

NON-COMPOUND

MITER SAW

Serial

Number

Model and serial number

may be found on a plate

attached to your saw, at

the side of the Miter Saw

arm,

You should record both

model and serial number in

a safe place for future use.

FOR YOUR

SAFETY'.

READ ALL

INSTRUCTIONS

CAREFULLY

CRRFTSMRN

10 INCH MITERSAW

• assembly

• operating

• repair parts

Sears, Roebuck and Co., Hoffman Estates, IL 60179 U.S.A.

Part No, SP5992 Form No, SP5992-2 Printed in USA 4/97

FULL ONE YEAR WARRANTY ON CRAt- iSMAN BENCH TOP TOOLS

If this miter saw fails due to a defect in material or workmanship within one year from the date

of purchase, RETURN IT TO THE NEAREST SEARS SERVICE CENTER IN THE UNITED

STATES, and Sears will repair it, free of charge.

If this miter saw is used for commercial or rental purposes, this warranty will apply for ninety

days from the date of purchase.

This warranty applies only while this product is in the United States.

This warranty gives you specific legal rights, and you may also have other rights which vary

from state to state.

Sears, Roebuck and Co., D/817 WA Hoffman Estates, IL 60179

Safety Instructions for Miter Saw

Safety is a combination of common sense, staying alert and knowing how your miter saw works. Read this manual to

understand this miter saw.

SAFETY SIGNAL WORDS

DANGER: If the safety information is not followed,

someone Will be seriously injured or killed.

Before Using The Saw

WARNING: To avoid mistakes that could cause

serious, permanent injury, do not plug the miter

saw in until the following steps have been satis-

factorily completed.

• Assembly and alignment. (See "Alignment/

Adjustment" section.)

• Learn the use and function of the ON-OFF switch,

upper and lower blade guards, handle latch, bevel

clamp, cover plate stop screw, and fence clamps.

(See "Getting to Know Your Miter Saw'' section).

• Review and understand all safety instructions and

operating procedures in this manual.

• Review the maintenance methods for this miter saw.

(See "Maintenance and Lubrication" section).

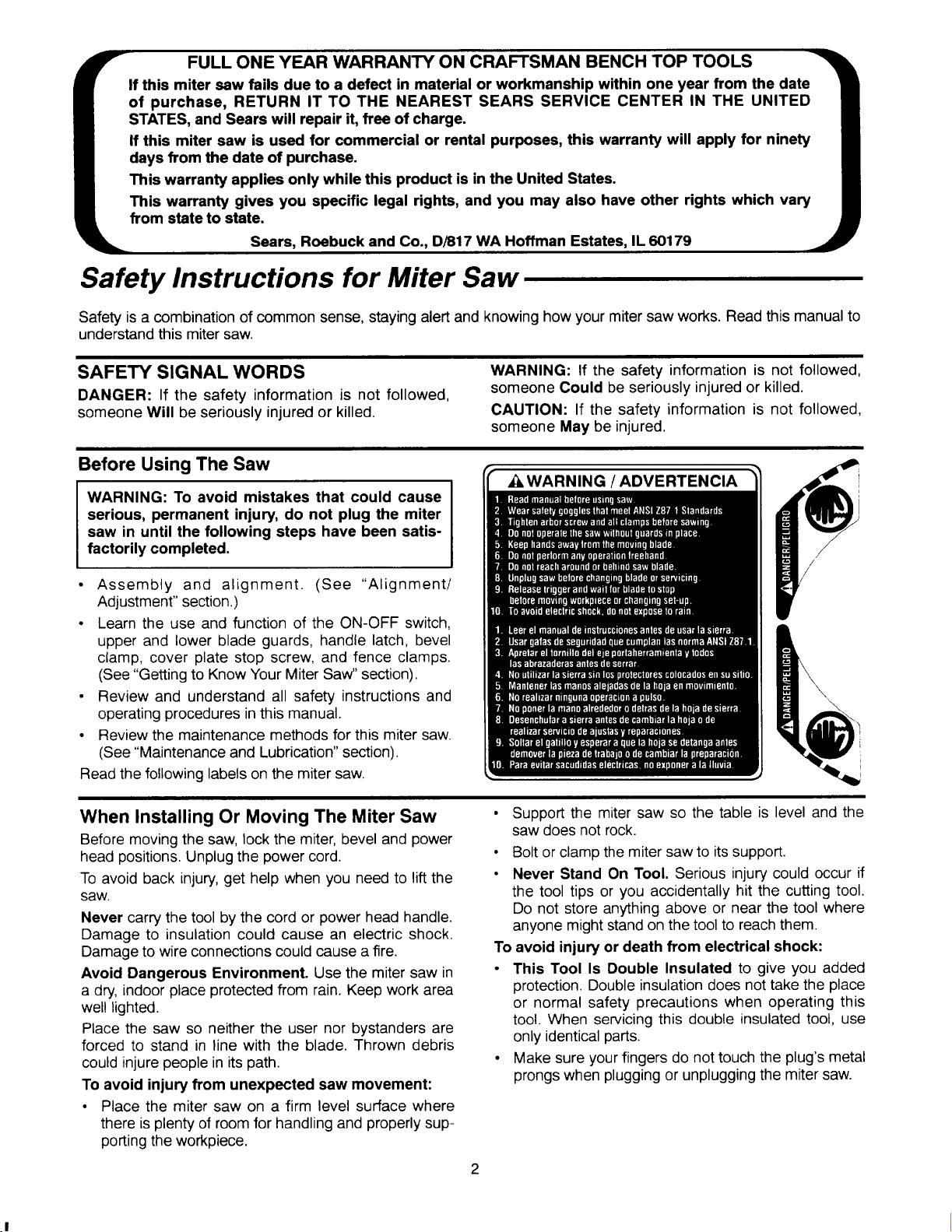

Read the following labels on the miter saw.

When Installing Or Moving The Miter Saw

Before moving the saw, lock the miter, bevel and power

head positions. Unplug the power cord.

To avoid back injury, get help when you need to lift the

saw.

Never carry the tool by the cord or power head handle.

Damage to insulation could cause an electric shock.

Damage to wire connections could cause a fire.

Avoid Dangerous Environment. Use the miter saw in

a dry, indoor place protected from rain. Keep work area

wel! lighted.

Place the saw so neither the user nor bystanders are

forced to stand in line with the blade. Thrown debris

could injure people in its path.

To avoid injury from unexpected saw movement:

• Place the miter saw on a firm level surface where

there is plenty of room for handling and properly sup-

porting the workpiece.

WARNING: If the safety information is not followed,

someone Could be seriously injured or killed.

CAUTION: If the safety information is not followed,

someone May be injured.

WARNING / ADVERTENCIA

/

/

• Support the miter saw so the table is level and the

saw does not rock.

• Bolt or clamp the miter saw to its support.

• Never Stand On Tool. Serious injury could occur if

the tool tips or you accidentally hit the cutting tool.

Do not store anything above or near the tool where

anyone might stand on the tool to reach them.

To avoid injury or death from electrical shock:

• This Tool Is Double Insulated to give you added

protection. Double insulation does not take the place

or normal safety precautions when operating this

tool. When servicing this double insulated tool, use

only identical parts.

• Make sure your fingers do not touch the plug's metal

prongs when plugging or unplugging the miter saw.

Before Each Use

Inspect your miter saw.

Disconnect The Miter Saw. To avoid injury from acci-

dental starting, unplug the saw, before changing the

setup, changing the blade or adjusting anything.

Compare the direction of rotation arrow on the guard to

the direction arrow on the blade. The blade teeth

should always point downward at the front of the saw.

lqghten the arbor screw,

lqghten the cover plate stop screw.

Check For Damaged Parts. Check for:

• Alignment of moving parts,

• Damaged electric cords,

• Binding of moving parts,

• Broken parts,

• Stable mounting,

• Function of arm return spring and lower guard: Push

Keep Guards In Place, in working order, and in proper

adjustment.

If any part of this miter saw is missing, bent, or broken

in any way, or any electrical parts don't work, turn the

saw off and unplug it. Replace damaged, missing, or

failed parts before using the saw again.

Maintain Tools With Care, Keep the miter saw clean

for best and safest performance. Follow instructions for

lubricating. DON'T put lubricants on the blade while it's

spinning.

Remove Adjusting Keys And Wrench from tool

before turning it on.

To Avoid Injury From Jams, Slips Or Thrown Pieces

the arm all the way down, then let it rise up until it

stops by itself. Check the lower guard to see if it

closed fully. If it did not, follow the instructions in the

"Trouble Shooting" section.

Other conditions that may affect the way the miter

saw works.

• Use Only Recommended Accessories. (See

"Sears Recommends The Following Accessories"

section.) Consult this Owner's manual for recom-

mended accessories. Follow the instructions that

come with the accessories. The use of improper

accessories may cause risk of injury to persons.

• Choose the right 10-inch diameter blade for the

material and the type of cutting you plan to do.

• Make sure the blade is sharp, undamaged and prop-

erly aligned. With the saw unplugged, push the

power-head all the way down. Hand spin the blade

and check for clearance. Tilt the power-head to 45

degree bevel and repeat the check. If the blade hits

anything, make the adjustments shown in the

Maintaining Maximum Cutting Capacity section.

• Make sure the blade and arbor collars are clean.

• Make sure the collars' recessed sides are facing the

blade.

• Using 1/2-inch box end wrench, make sure the arbor

cap screw is firmly hand tightened.

• Make sure all clamps and locks are tight and there is

no excessive play in any parts.

• Keep Work Area Clean Cluttered areas and

benches invite accidents. Floor must not be slippery.

To avoid burns or other fire damage, never use the saw

near flammable liquids, vapors or gases.

Plan Ahead To Protect Your Eyes, Hands, Face, Ears

Know Your Miter Saw. Read and understand the

owner's manual and labels affixed to the tool. Learn its

applications and limitations as well as the specific

potential hazards peculiar to this tool.

To avoid injury from accidental contact with moving

parts, don't do layout, assembly, or setup work on the

miter saw while any parts are moving.

Avoid Accidental Starting. Make sure switch is "OFF"

before plugging miter saw into a power outlet.

Plan your work.

Use The Right Tool. Don't force tool or attachment to

do a job it was not designed to do. Use a different tool

for any workpiece that can't be held in a solidly braced,

fixed position.

CAUTION: When cutting any metals, sparks or

hot fragments could cause a fire. To avoid this,

disconnect any dust collecting bag or hose from

the miter saw, and remove all traces of wood

dust from inside dust traps in the miter saw.

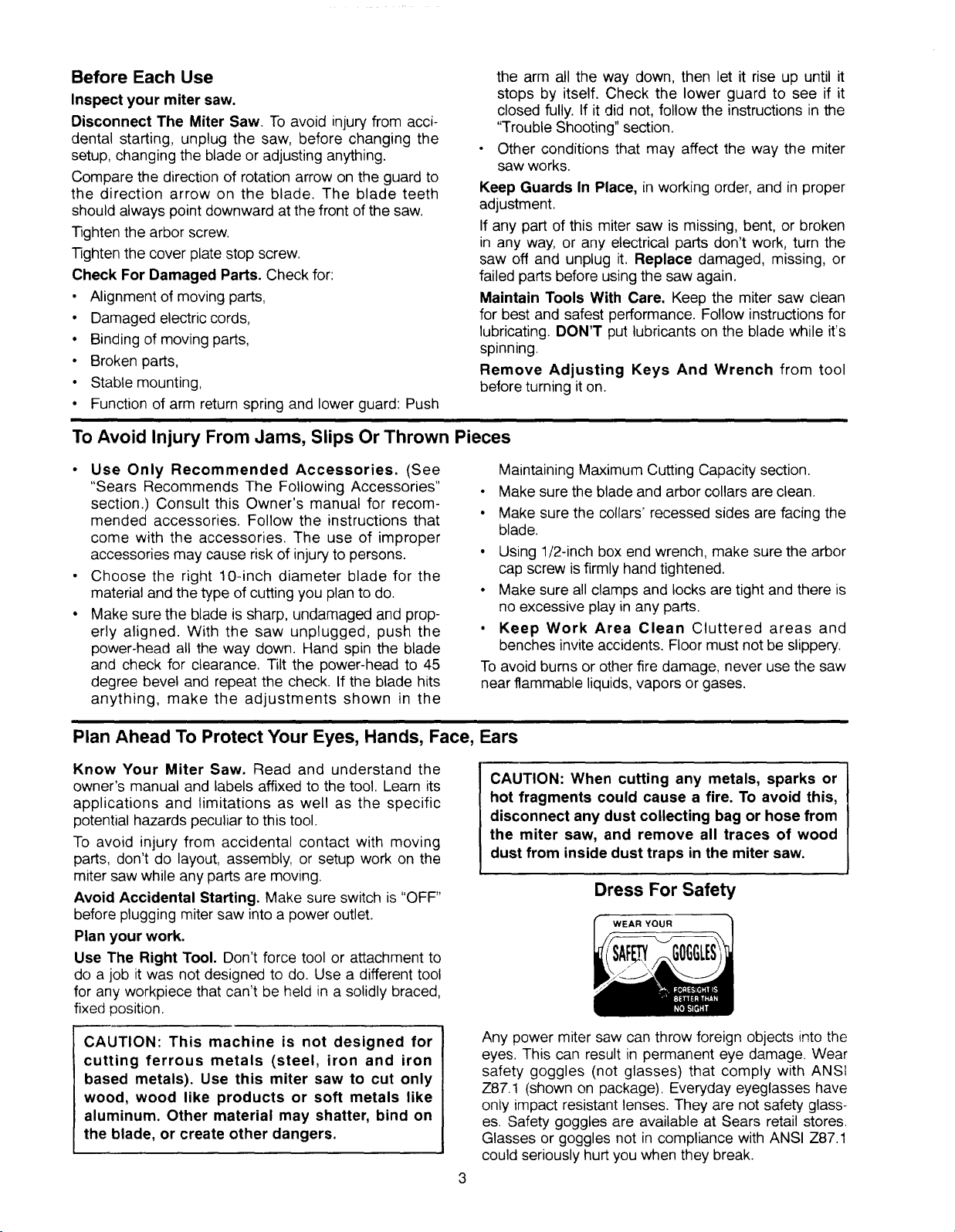

Dress For Safety

WEAR YOUR

CAUTION: This machine is not designed for

cutting ferrous metals (steel, iron and iron

based metals). Use this miter saw to cut only

wood, wood like products or soft metals like

aluminum. Other material may shatter, bind on

the blade, or create other dangers.

Any power miter saw can throw foreign objects into the

eyes. This can result in permanent eye damage. Wear

safety goggles (not glasses) that comply with ANSI

Z87.1 (shown on package). Everyday eyeglasses have

only impact resistant lenses. They are not safety glass-

es. Safety goggles are available at Sears retail stores.

Glasses or goggles not in compliance with ANSI Z87.1

could seriously hurt you when they break.

3

Safety Instructions For Miter Saws (continued)

- Do not wear loose clothing, gloves, neckties or jew-

elry (rings, wrist watches) They can get caught and

draw you into moving parts.

• Wear nonslip footwear.

• Tie back long hair.

• Rol! long sleeves above the elbow.

• Noise levels vary widely. To avoid possible hearing

damage, wear ear plugs or muffs when using miter

saw for hours at atime.

• For dusty operations, wear a dust mask along with

safety goggles.

Inspect your workpiece

• Make sure there are no nails or foreign objects in the

part of the workpiece to be cut.

Plan your work to avoid THROWBACKS - when the

workpiece binds on the blade and is torn from your

hands.

Plan the way you will hold the workpiece from start to

finish:

Avoid awkward operations and hand positions where a

sudden slip could cause fingers or hand to move into

the blade.

Don't Overreach. Keep good footing and balance.

Keep your face and body to one side of saw blade, out

of line with a possible throwback.

Never cut Freehand

• Cut only one workpiece at a time.

• Brace your workpiece solidly against the fence and

table top so it will not rock or twist during the cut.

• Make sure there's no debris between the workpiece

and its supports.

• Make sure no gaps between the workpiece, fence

and table will let the workpiece shift after it is cut in

two,

• Keep the cut off piece free to move sideways after

it's cut off. Otherwise it could get wedged against the

blade and could be thrown violently.

• Clear everything except the workpiece and related

support devices off the table before turning the miter

saw On.

• Secure Work. Use clamps or a vise to help hold the

work when it's practical.

Use extra caution with large, very small or awkward

workpieces:

• Use extra supports (tables, saw horses, blocks, etc.)

for any workpiece large enough to tip when not held

Whenever Saw Is Running

WARNING: Don't allow familiarity (gained from

frequent use of your miter saw) cause a care-

less mistake. A careless fraction of a second is

enough to cause a severe injury.

Before starting your cut, watch the miter saw while it

runs. If it makes an unfamiliar noise or vibrates a lot,

stop immediately. Turn the saw off. Unplug the saw. Do

not restart until finding and correcting the problem.

Keep Children Away. Keep all visitors a safe distance

from the miter saw. Make sure bystanders are clear of

down to the table top.

• Never use another person as a substitute for a table

extension, or as additional support for a workpiece

that is longer or wider than the basic miter saw table

or to help feed, support or pull the workpiece.

• Do not use this saw to cut pieces too small to let you

easily hold the work while you keep the thumb side

of your index (pointer) finger against the outside

edge of the fence.

• When cutting irregularly shaped workpieces, plan

your work so it will not slip and pinch the blade and

be torn from your hands. A piece of molding, for

example, must lie flat or be held by a fixture or jig

that will not let it twist, rock or slip while being cut.

• Properly support round material such as dowel rods,

or tubing. They have a tendency to roll while being

cut, causing the blade to "bite." To avoid this, always

use a fixture designed to properly hold your work-

piece.

WARNING: If planning to cut aluminum or other

non-ferrous metals: Under adverse conditions,

the blade can grab and throw the workpiece

suddenly and unexpectedly. To avoid injury,

follow all applicable safety instructions, as you

normally would, and:

• Use only sawblades specifically recom-

mended for non-ferrous metal cutting.

• Do not cut metal workpieces that must be

hand held. Use auxiliary clamps or other

equipment as needed.

° Cut non-ferrous metals only if you are expe-

rienced or under the supervision of an expe-

rienced person.

the miter saw and workpiece.

Never confine the piece being cut off. Never hold it,

clamp it, touch it, or use length stops against it while the

blade is spinning. It must be free to move sideways on

its own. If confined, it could get wedged against the

blade and thrown violently.

Let the blade reach full speed before cutting.

Don't Force Tool. It will do the job better and safer at

its designed rate. Feed the saw into the workpiece only

fast enough to let the blade cut without bogging down

or binding.

4

Before freeing jammed material

• Turn switch"OFF".

• Unplug the miter saw.

• Wait for all moving parts to stop.

After finishing a cut

• Keep holding the power head down.

Release the switch, and wait for all moving parts to

stop before moving your hands.

If blade doesn't stop within 6 seconds, unplug the

saw and follow the instructions in the "Trouble

Shooting" section for fixing the blade brake before

using the saw again,

Before Leaving The Saw:

Never Leave Tool Running Unattended. Turn power

off. Wait for all moving parts to stop.

Make workshop child-proof. Lock the shop.

Disconnect master switches. Store tool away from chil-

dren and others not qualified to use the tool.

Glossary of Terms for Woodworking

Arbor

The shaft on which a cutting tool is mouHted.

Bevel Cut

An angle cutting operation made through the face of the

workpiece.

Compound Cut

A simultaneous bevel and miter cutting operations.

Crosscut

A cutting operation made across the width of the work-

piece.

Freehand

Performing a cut without the use a fence (guide), hold

down or other proper device to prevent the workpiece

from twisting during the cutting operation. Twisting of

the workpiece can cause itto be thrown.

Gum

A sticky, sap based residue from wood products.

Heel

Misalignment of the blade.

Kerr

The amount of material removed by the blade in a

through cut or the slot produced by the blade in a non-

through or partial cut.

Miter Cut

An angle cutting operation made across the width of the

workpiece.

Resin

A sticky, sap based substance tI=athas hardened.

Revolutions Per Minute (RPM)

The number of turns completed by a spinning object in

one minute.

Sawblade Path

The area of the workpiece or table top directly in line

with either the travel of the blade or the part of the work-

piece which wilt be, or has been, cut by the blade.

Set

The distance that tp_etip of the sawblade tooth is bent

(or set) outward from the face of the blade.

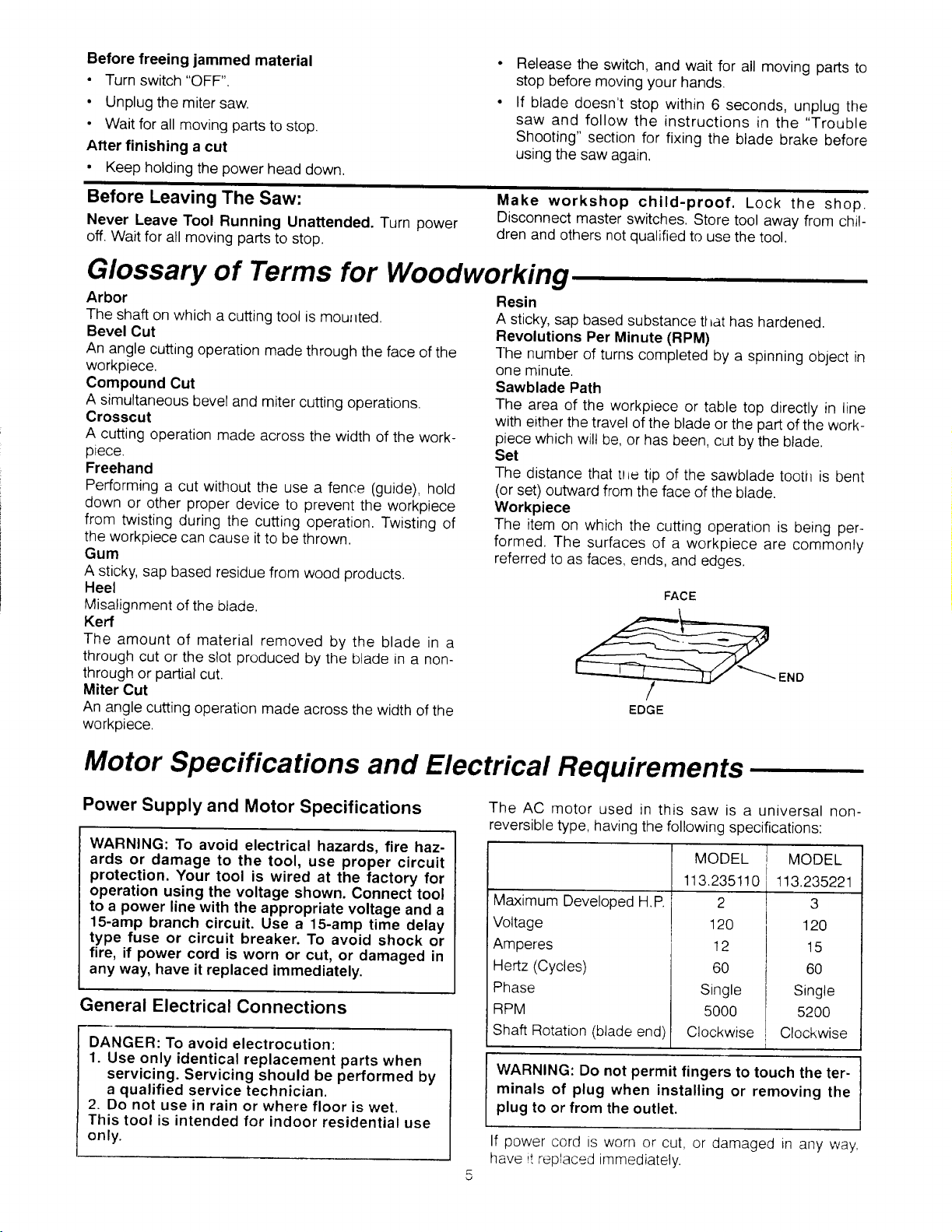

Workpiece

The item on which the cutting operation is being per-

formed. The surfaces of a workpiece are commonly

referred to as faces, ends, and edges.

FACE

_END

EDGE

Motor Specifications and Electrical Requirements

Power Supply and Motor Specifications

WARNING: To avoid electrical hazards, fire haz-

ards or damage to the tool, use proper circuit

protection. Your tool is wired at the factory for

operation using the voltage shown. Connect tool

to a power line with the appropriate voltage and a

15-amp branch circuit. Use a 15-amp time delay

type fuse or circuit breaker. To avoid shock or

fire, if power cord is worn or cut, or damaged in

any way, have it replaced immediately.

General Electrical Connections

DANGER: To avoid electrocution:

1. Use only identical replacement parts when

servicing. Servicing should be performed by

a qualified service technician.

2. Do not use in rain or where floor is wet.

This tool is intended for indoor residential use

only.

The AC motor used in this saw is a universal non-

reversible type, having the following specifications:

MODEL ! MODEL

113.235110 1!3.235221

Maximum Developed H.P. 2 3

Voltage

Amperes

Hertz (Cycles)

Phase

RPM

Shaft Rotation (blade end) Clockwise Clockwise

WARNING: Do not permit fingers to touch the ter-

minals of plug when installing or removing the

plug to or from the outlet.

If power cord is worn or cut, or damaged in any way,

have rtreplaced immediately.

120 120

12 15

60 60

Single Single

5000 5200

I

Motor Specifications and Electrical Requirements (Continued)

110-120 Volt, 60 Hz. Tool Information

Double Insulated

The miter saw is double insulated to provide a double

thickness of insulation between you and the tool's elec-

trical system. All exposed metal parts are isolated from

the internal metal motor components with protecting

insulation.

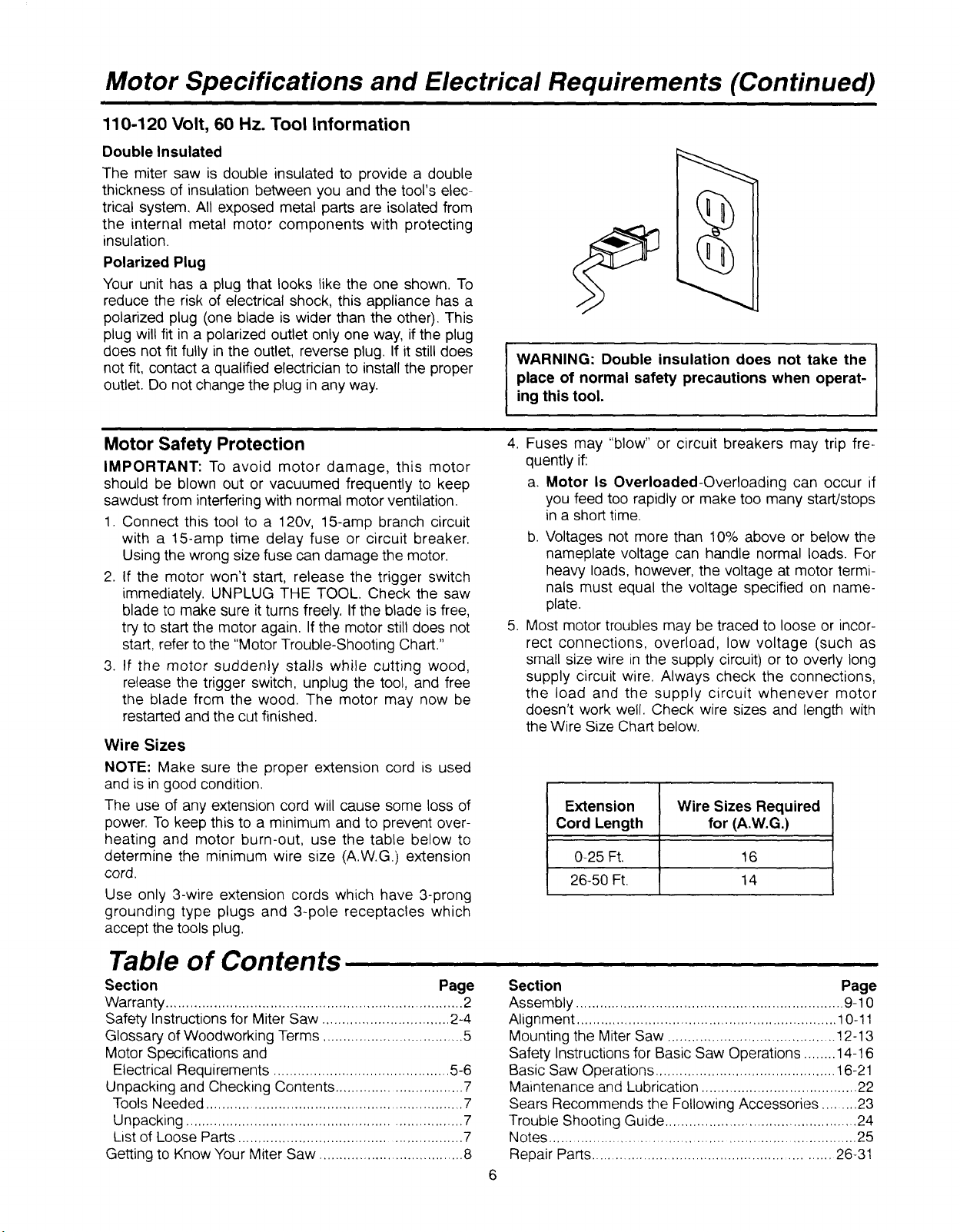

Polarized Plug

Your unit has a plug that looks like the one shown. To

reduce the risk of electrical shock, this appliance has a

polarized plug (one blade is wider than the other). This

plug will fit in a polarized outlet only one way, if the plug

does not fit fully in the outlet, reverse plug. If it still does

not fit, contact a qualified electrician to install the proper

outlet. Do not change the plug in any way.

ii

Motor Safety Protection

IMPORTANT: To avoid motor damage, this motor

should be blown out or vacuumed frequently to keep

sawdust from interfering with normal motor ventilation.

1. Connect this tool to a 120v, 15-amp branch circuit

with a 15-amp time delay fuse or circuit breaker.

Using the wrong size fuse can damage the motor.

2. If the motor won't start, release the trigger switch

immediately. UNPLUG THE TOOL. Check the saw

blade to make sure it turns freely, If the blade is free,

try to start the motor again. Ifthe motor still does not

start, refer to the "Motor Trouble-Shooting Chart."

3. If the motor suddenly stalls while cutting wood,

release the trigger switch, unplug the tool, and free

the blade from the wood. The motor may now be

restarted and the cut finished.

Wire Sizes

NOTE: Make sure the proper extension cord is used

and is in good condition.

The use of any extension cord will cause some loss of

power. To keep this to a minimum and to prevent over-

heating and motor burn-out, use the table below to

determine the minimum wire size (A.W.G) extension

cord.

Use only 3-wire extension cords which have 3-prong

grounding type plugs and 3-pole receptacles which

accept the tools plug.

WARNING: Double insulation does not take the

place of normal safety precautions when operat-

ing this tool.

4. Fuses may "blow" or circuit breakers may trip fre-

quently if:

a. Motor Is Overloaded-Overloading can occur if

you feed too rapidly or make too many start/stops

in a short time.

b. Voltages not more than 10% above or below the

nameplate voltage can handle normal loads. For

heavy loads, however, the voltage at motor termi-

nals must equal the voltage specified on name-

plate.

5. Most motor troubles may be traced to loose or incor-

rect connections, overload, low voltage (such as

small size wire in the supply circuit) or to overly long

supply circuit wire. Always check the connections,

the load and the supply circuit whenever motor

doesn't work well. Check wire sizes and length with

the Wire Size Chart below.

Extension Wire Sizes Required

Cord Length for (A.W.G.)

0-25 Ft. 16

26-50 Ft. 14

Table of Contents

Section Page

Warranty .......................................................................... 2

Safety Instructions for Miter Saw ................................ 2-4

Glossary of Woodworking Terms ................................... 5

Motor Specifications and

Electrical Requirements ............................................ 5-6

Unpacking and Checking Contents ............................... 7

Tools Needed ................................................................ 7

Unpacking .................................................................... 7

List of Loose Parts ....................................................... 7

Getting to Know Your Miter Saw .................................... 8

Section Page

Assembly ................................................................... 9-10

Alignment ................................................................. 10-11

Mounting the Miter Saw .......................................... ! 2-13

Safety Instructions for Basic Saw Operations ........ 14-16

Basic Saw Operations ............................................ 16-21

Maintenance and Lubrication ....................................... 22

Sears Recommends the Following Accessories ........ 23

Trouble Shooting Guide ................................................ 24

Notes ........................................................................... 25

Repair Parts ........................................................... 26-31

6

Unpacking and Checking Contents

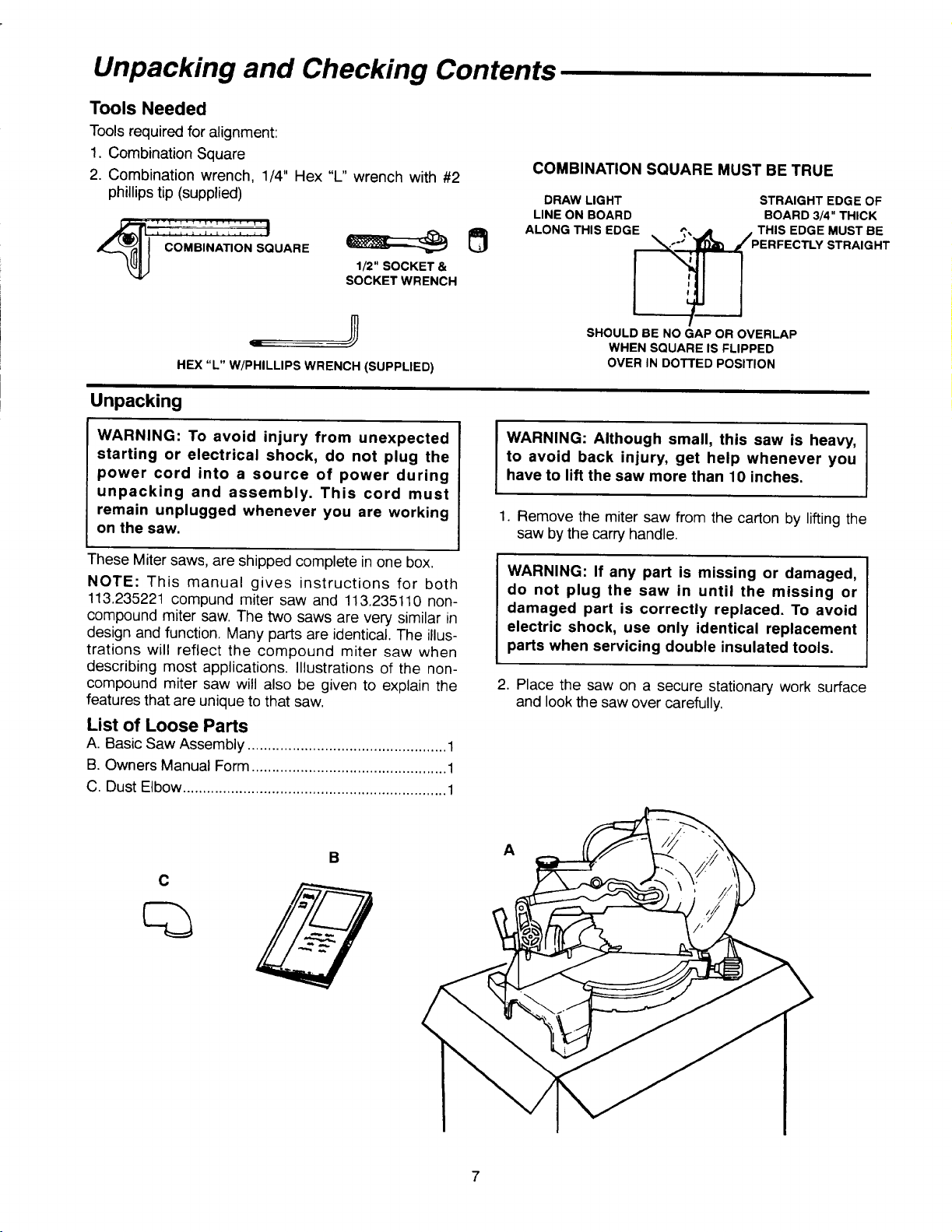

Tools Needed

Tools required for alignment:

1. Combination Square

2. Combination wrench, 1/4" Hex "L" wrench with #2

phillips tip (supplied)

COMBINATION SQUARE

1/2" SOCKET &

SOCKET WRENCH

COMBINATION SQUARE MUST BE TRUE

DRAW LIGHT

LINE ON BOARD

ALONG THIS EDGE _, ,m . THIS EDGE

STRAIGHT EDGE OF

BOARD 3/4" THICK

PERFECTLY

MUST BE

STRAIGHT

HEX "L" W/PHILLIPS WRENCH (SUPPLIED)

Unpacking

WARNING: To avoid injury from unexpected

starting or electrical shock, do not plug the

power cord into a source of power during

unpacking and assembly. This cord must

remain unplugged whenever you are working

on the saw.

These Miter saws, are shipped complete in one box.

NOTE: This manual gives instructions for both

113.235221 compund miter saw and 113.235110 non-

compound miter saw. The two saws are very similar in

design and function. Many parts are identical. The illus-

trations will reflect the compound miter saw when

describing most applications. Illustrations of the non-

compound miter saw will also be given to explain the

features that are unique to that saw.

List of Loose Parts

A. BasicSaw Assembly ................................................. 1

B. Owners Manual Form................................................ 1

C. Dust Elbow ................................................................. 1

SHOULD BE NO GAP OR OVERLAP

WHEN SQUARE IS FLIPPED

OVER IN DOTTED POSITION

I

WARNING: Although small, this saw is heavy,

to avoid back injury, get help whenever you

have to lift the saw more than 10 inches.

1. Remove the miter saw from the carton by lifting the

saw by the carry handle.

WARNING: If any part is missing or damaged,

do not plug the saw in until the missing or

damaged part is correctly replaced. To avoid

electric shock, use only identical replacement

parts when servicing double insulated tools.

2. Place the saw on a secure stationary work surface

and look the saw over carefully.

B

A

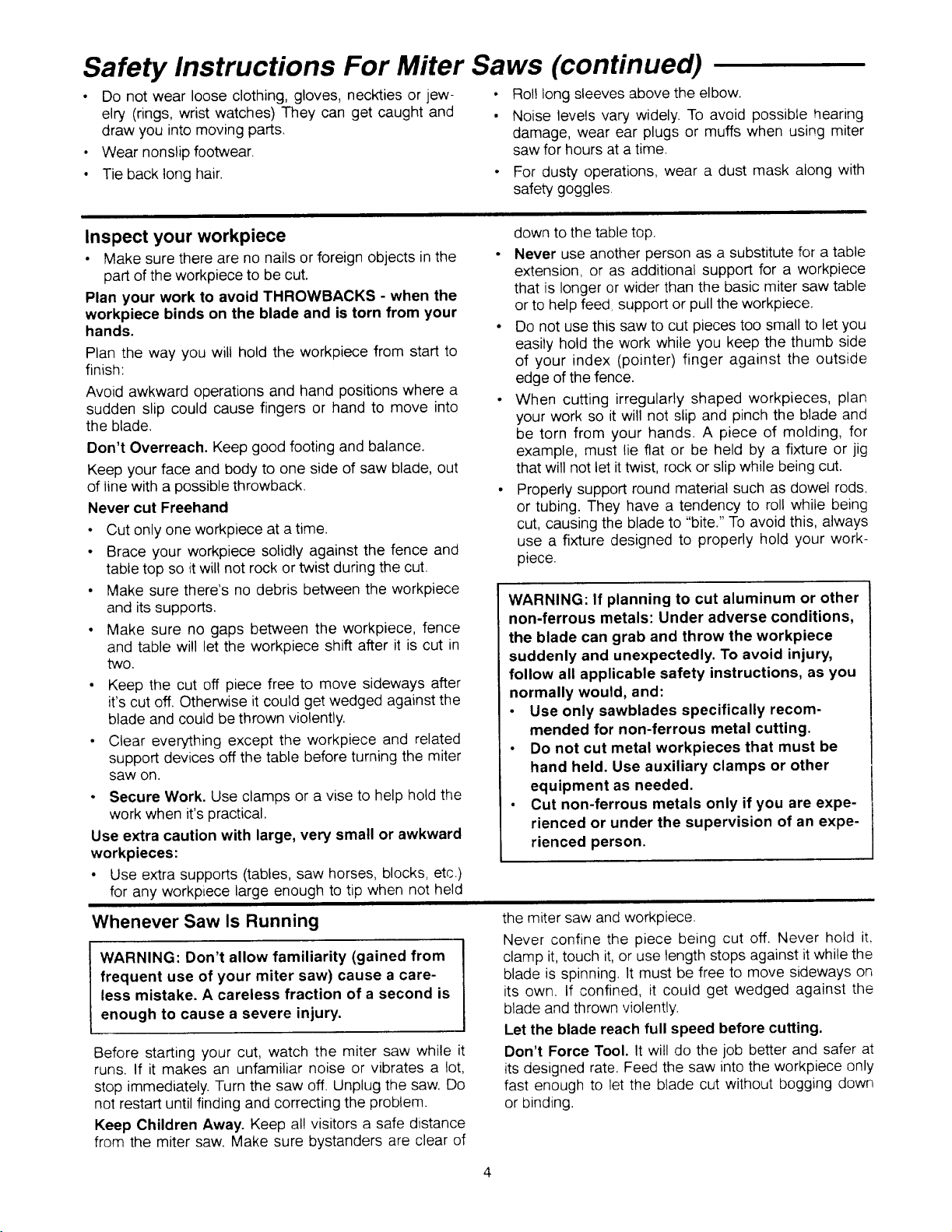

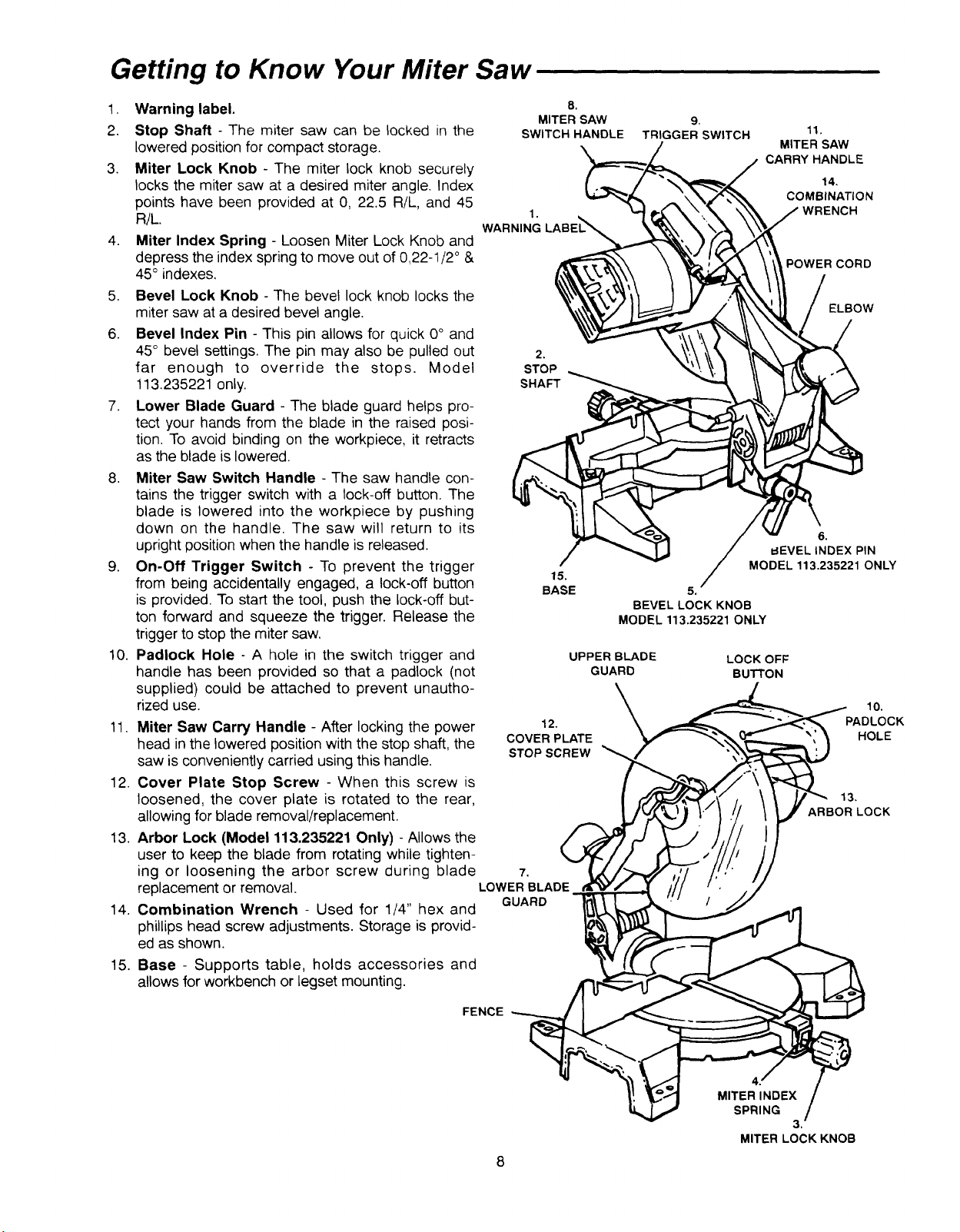

Getting to Know Your Miter Saw

1. Warning label.

2. Stop Shaft - The miter saw can be locked in the

lowered position for compact storage.

3. Miter Lock Knob - The miter lock knob securely

locks the miter saw at a desired miter angle. Index

points have been provided at 0, 22.5 R/L, and 45

R/L.

4. Miter Index Spring - Loosen Miter Lock Knob and

depress the index spring to move out of 0,22-1/2 ° &

45° indexes,

5. Bevel Lock Knob - The bevel lock knob locks the

miter saw at a desired bevel angle.

6. Bevel Index Pin - This pin allows for quick 0° and

45° bevel settings. The pin may also be pulled out

far enough to override the stops. Model

113.235221 only.

7. Lower Blade Guard - The blade guard helps pro-

tect your hands from the blade in the raised posi-

tion. To avoid binding on the workpiece, it retracts

as the blade is lowered.

8. Miter Saw Switch Handle - The saw handle con-

tains the trigger switch with a lock-off button. The

blade is lowered into the workpiece by pushing

down on the handle. The saw will return to its

upright position when the handle is released.

9. On-Off Trigger Switch - To prevent the trigger

from being accidentally engaged, a lock-off button

is provided. To start the tool, push the lock-off but-

ton forward and squeeze the trigger. Release the

trigger to stop the miter saw.

10. Padlock Hole - A hole in the switch trigger and

handle has been provided so that a padlock (not

supplied) could be attached to prevent unautho-

rized use.

11. Miter Saw Carry Handle - After locking the power

head in the lowered position with the stop shaft, the

saw is conveniently carried using this handle.

12 Cover Plate Stop Screw - When this screw is

loosened, the cover plate is rotated to the rear,

allowing for blade removal/replacement.

13. Arbor Lock (Model 113.235221 Only) - Allows the

user to keep the blade from rotating while tighten-

ing or loosening the arbor screw during blade

replacement or removal.

14. Combination Wrench - Used for 1/4" hex and

phillips head screw adjustments. Storage is provid-

ed as shown.

15. Base - Supports table, holds accessories and

allows for workbench or legset mounting.

8,

MITER SAW 9.

SWITCH HANDLE TRIGGER SWITCH

1,

WARNING

2,

STOP

SHAFT

15.

BASE

BEVEL LOCK KNOB

MODEL 113.235221 ONLY

UPPER BLADE

GUARD

12,

COVER PLATE

STOP SCREW

7,

LOWER BLADE

GUARD

11.

MITER SAW

CARRY HANDLE

14.

COMBINATION

POWER CORD

ELBOW

6.

I=IEVEL INDEX PIN

MODEL 113.235221 ONLY

5,

LOCK OFF

BUTTON

10.

PADLOCK

HOLE

13,

ARBORLOCK

FENCE

MITER INDEX

SPRING

3.

MITER LOCK KNOB

Assembly

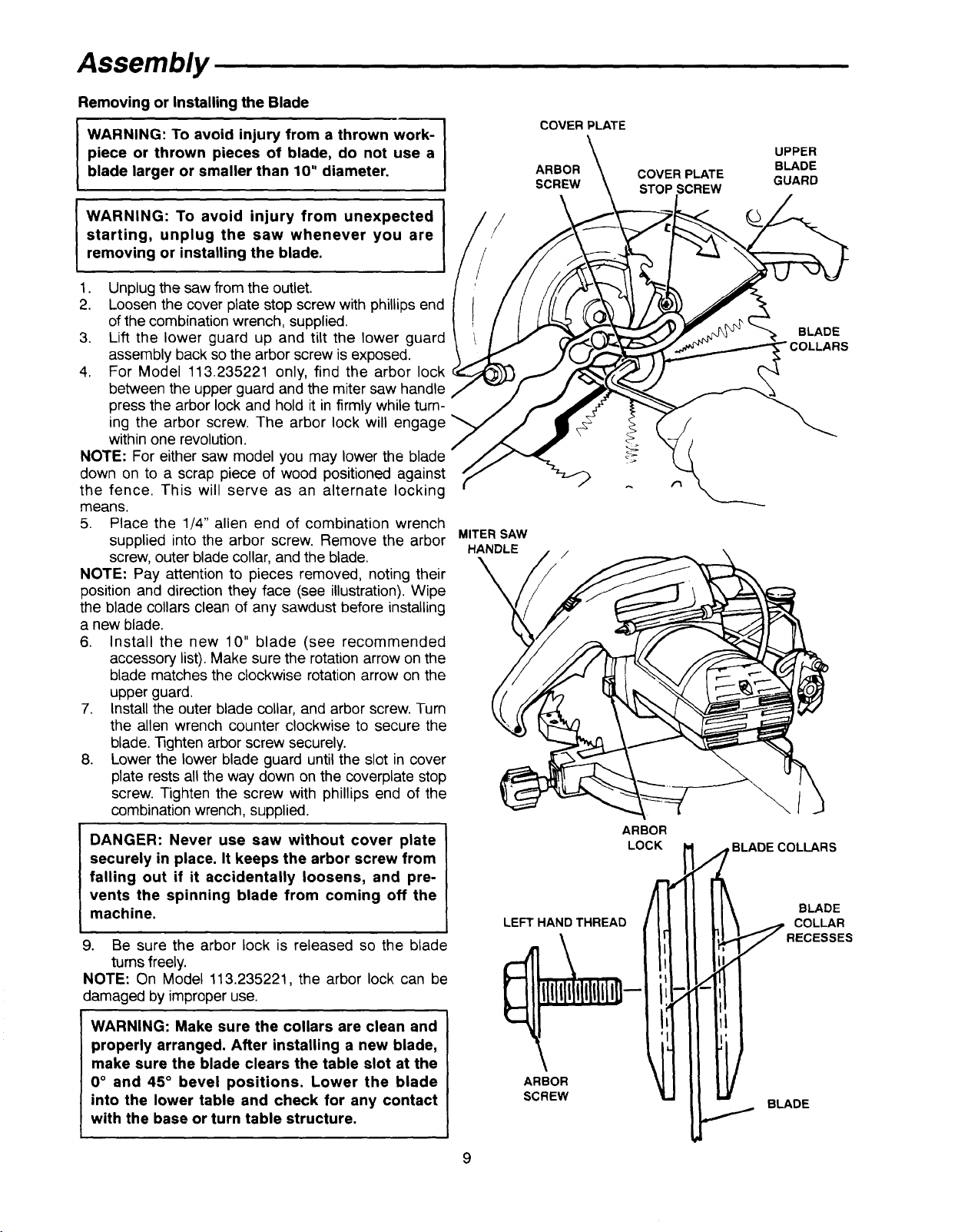

Removing or Installing the Blade

WARNING: To avoid injury from a thrown work-

piece or thrown pieces of blade, do not use a

blade larger or smaller than 10" diameter.

starting, unplug the saw whenever you are

I WARNING: To avoid injury from unexpected

removing or installing the blade.

1. Unplug the saw from the outlet.

2. Loosen the cover plate stop screw with phillips end

of the combination wrench, supplied.

3. Lift the lower guard up and tilt the lower guard

assembly back so the arbor screw is exposed.

4. For Model 113.235221 only, find the arbor lock

between the upper guard and the miter saw handle

press the arbor lock and hold it in firmly while turn-

ing the arbor screw. The arbor lock will engage

within one revolution.

NOTE: For either saw model you may lower the blade

down on to a scrap piece of wood positioned against

the fence. This will serve as an alternate locking

means.

5. Place the 1/4" allen end of combination wrench

supplied into the arbor screw. Remove the arbor

screw, outer blade collar, and the blade.

NOTE: Pay attention to pieces removed, noting their

position and direction they face (see illustration). Wipe

the blade collars clean of any sawdust before installing

a new blade.

6. Install the new 10" blade (see recommended

accessory list). Make sure the rotation arrow on the

blade matches the clockwise rotation arrow on the

upper guard.

7. Install the outer blade collar, and arbor screw. Turn

the allen wrench counter clockwise to secure the

blade. Tighten arbor screw securely.

8. Lower the lower blade guard until the slot in cover

plate rests all the way down on the coverplate stop

screw. Tighten the screw with phillips end of the

combination wrench, supplied.

DANGER: Never use saw without cover plate

securely in place. It keeps the arbor screw from

falling out if it accidentally loosens, and pre-

vents the spinning blade from coming off the

machine.

9. Be sure the arbor lock is released so the blade

turns freely.

NOTE: On Model 113.235221, the arbor lock can be

damaged by improper use.

/

/

MITER SAW

HANDLE /

\

LEFT HAND THREAD

COVER PLATE

ARBOR

SCREW

COVER PLATE

STOP SCREW

ARBOR

LOCK

UPPER

BLADE

GUARD

BLADE

;OLLARS

\

,BLADE COLLARS

BLADE

WARNING: Make sure the collars are clean and

properly arranged. After installing a new blade,

make sure the blade clears the table slot at the

0° and 45 ° bevel positions. Lower the blade

into the lower table and check for any contact

with the base or turn table structure.

ARBOR

SCREW

BLADE

Assembly (continued)

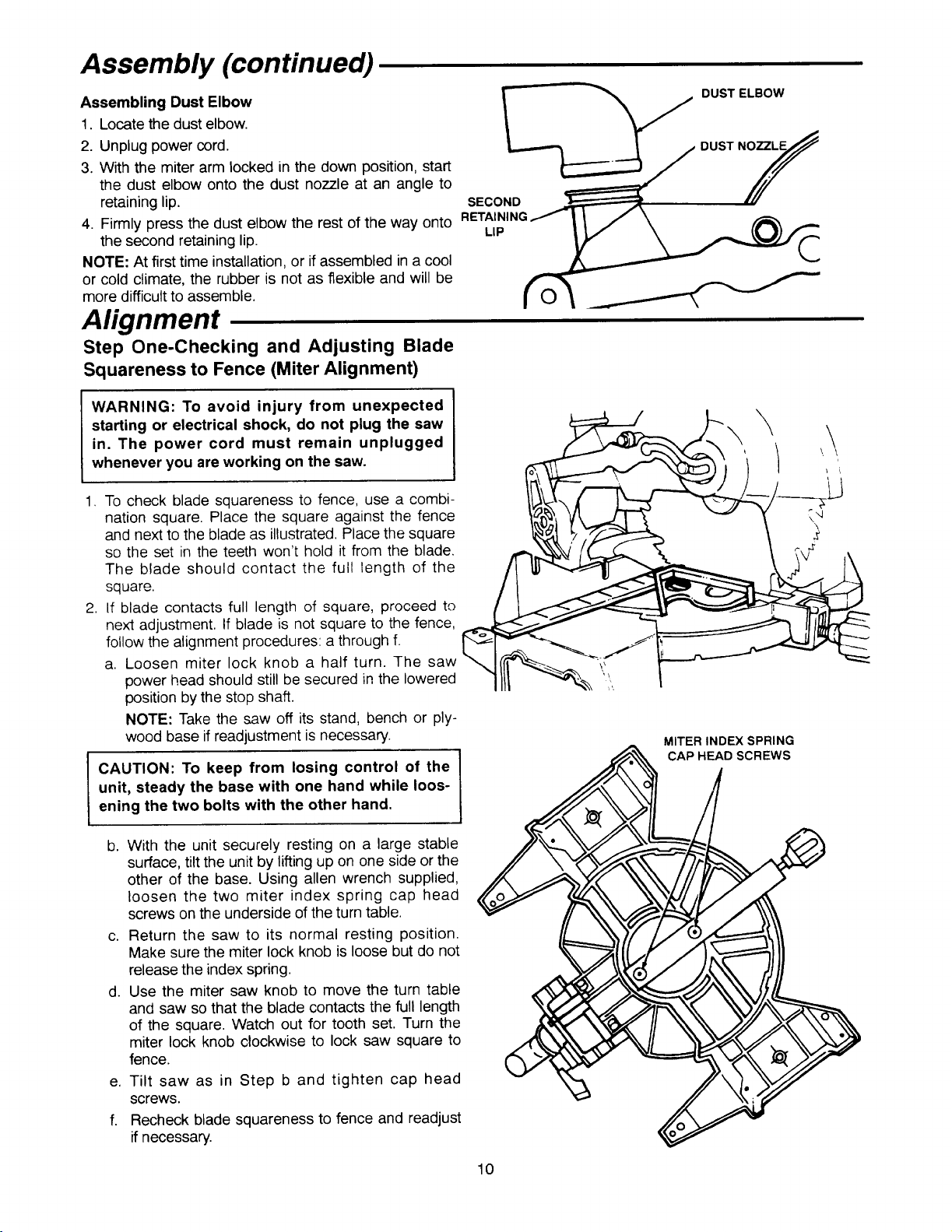

Assembling Dust Elbow

1. Locate the dust elbow.

2. Unplug power cord.

3. With the miter arm locked in the down position, start

the dust elbow onto the dust nozzle at an angle to

retaining lip. SECOND

4. Firmly press the dust elbow the rest of the way onto RETAINING

the second retaining lip. LIP

NOTE: At first time installation, or if assembled in a cool

or cold climate, the rubber is not as flexible and will be

more difficult to assemble.

Alignment

Step One-Checking and Adjusting Blade

Squareness to Fence (Miter Alignment)

WARNING: To avoid injury from unexpected

starting or electrical shock, do not plug the saw

in. The power cord must remain unplugged

whenever you are working on the saw.

1. To check blade squareness to fence, use a combi-

nation square. Place the square against the fence

and next to the blade as illustrated. Place the square

so the set in the teeth won't hold it from the blade.

The blade should contact the full length of the

square.

2. If blade contacts full length of square, proceed to

next adjustment. If blade is not square to the fence,

follow the alignment procedures: a through f.

a. Loosen miter lock knob a half turn. The saw

power head should still be secured in the lowered

position by the stop shaft.

NOTE: Take the saw off its stand, bench or ply-

wood base if readjustment is necessary.

CAUTION: To keep from losing control of the

unit, steady the base with one hand while loos-

ening the two bolts with the other hand.

DUST ELBOW

DUST NF

\

MITER INDEX SPRING

CAP HEAD SCREWS

b. With the unit securely resting on a large stable

surface, tilt the unit by lifting up on one side or the

other of the base. Using allen wrench supplied,

loosen the two miter index spring cap head

screws on the underside of the turn table.

c. Return the saw to its normal resting position.

Make sure the miter lock knob is loose but do not

release the index spring.

d. Use the miter saw knob to move the turn table

and saw so that the blade contacts the full length

of the square. Watch out for tooth set. Turn the

miter lock knob clockwise to lock saw square to

fence.

e. Tilt saw as in Step b and tighten cap head

screws.

f. Recheck blade squareness to fence and readjust

if necessary.

10

Loading...

Loading...