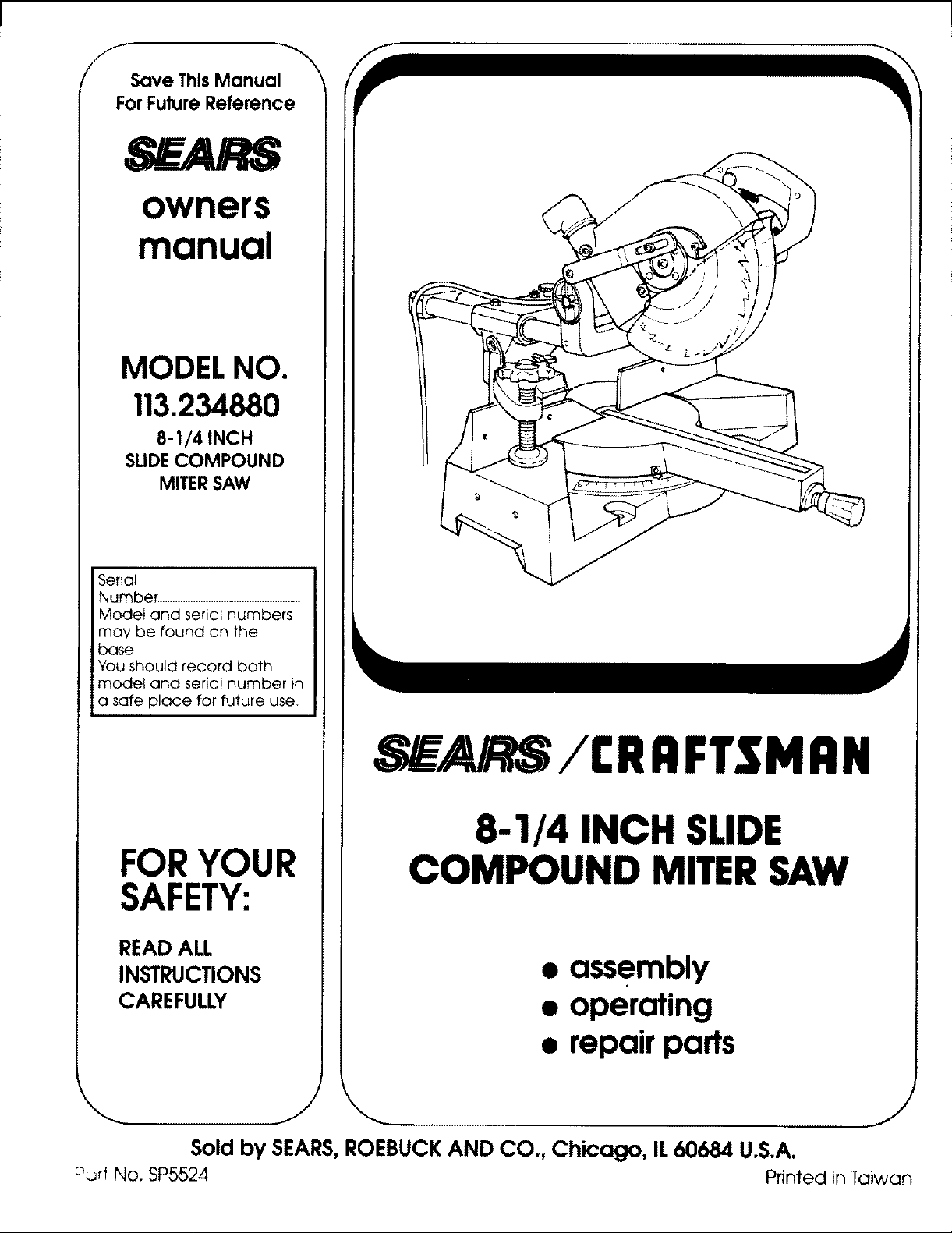

Craftsman 113234880 Owner’s Manual

Save This Manual

For Future Reference

S_r_ARS

owners

manual

MODEL NO.

113.234880

8- I/4 INCH

SLIDECOMPOUND

MITER SAW

Serial

Number_

Model and serial numbers

may be found on the

base

You should record both

model and serial number in

a safe place for future use.

FORYOUR

SAFETY:

READ ALL

INSTRUCTIONS

CAREFULLY

,__AIRS / r.RRFT._H RN

8-1/4 INCH SLIDE

COMPOUND MITERSAW

• assembly

• operating

• repair parts

Sold by SEARS, ROEBUCK AND CO., Chicago, IL60684 U.S.A.

P_rt No. SP5524 Printed in Taiwan

FULL ONE YEAR WARRANTY ON CRAFTSMAN SLIDE COMPOUND MITER SAW •

if within one year from the date of purchase, this Craftsman Slide Compound Miter Saw fails

due to a defect in material or workmanship, Sears will repair it, free of charge.

WARRANTY SERVICE IS AVAILABLE BY SIMPLY CONTACTING THE NEAREST SEARS SERV-

ICE CENTER/DEPARTMENT THROUGHOUT THE UNITED STATES.

This warranty applies only while this product is used in the United States.

This warranty gives you specific legal rights, and you may also have other rights which vary

from state to state.

SEARS, ROEBUCK AND CO., D/817 WA Hoffman Estates, IL 60195

Safety Instruction for Slide Compound Miter Saw

Safety is a combination of common sense, staying alert

and knowing how your slide compound miter saw

works. Read this manual to understand this saw.

SAFETY SIGNAL WORDS

_1, DANGER: means if the safety information is not

followed someone will be seriously injured or kilted.

A_ WARNING: means if the safety information is not

followed someone could be seriously injured or

killed.

'& CAUTION: means if the safety information is not

followed someone might be injured.

BEFORE USING THE SLIDE

COMPOUND MITER SAW:

serious, permanent injury, do not plug the saw

WARNING: To avoid mistakes that could cause

in until the following steps are completed.

F _ \_ i

!

/

• Assembly and alignment. (See pages 9-13).

• Learn the use and function of:

(a) the ON-OFF switch,

(b) upper and lower blade guards,

(c) handle latch,

(d) bevel lock handle,

(e) cover plate screw.

(f) depth adjustment bolt,

(g) carriage lock knob,

(h) miter lock handle, and

(i) saw handle.

• Review and understand all safety instructions and

operating procedures in this manual.

• Review the maintenance methods for this slide

compound miter saw. (See page 21)

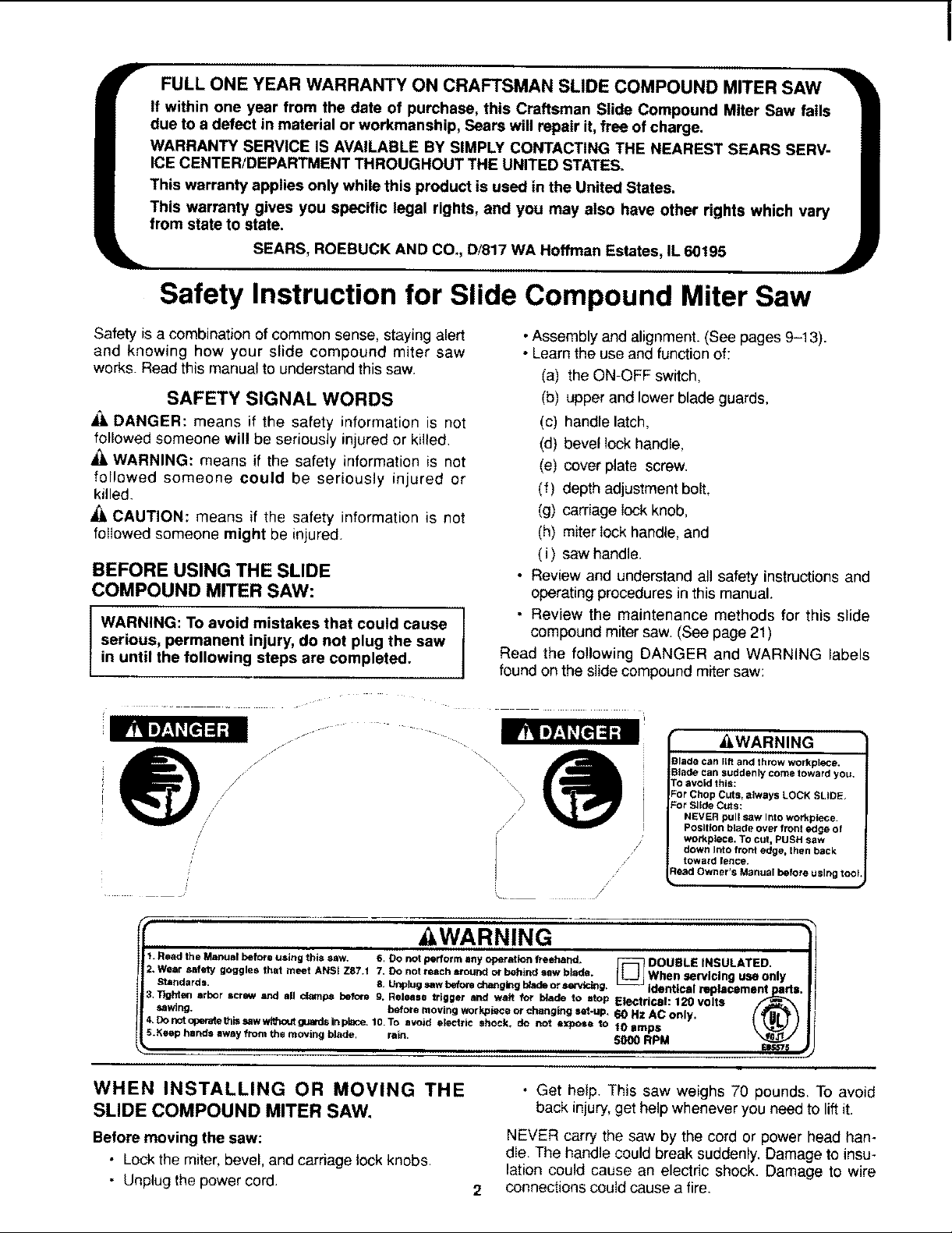

Read the following DANGER and WARNING labels

found on the slide compound miter saw:

m.,LtA1 =[:l

•\\

For Slide Cuts:

Read Owner's Manual before using tool

_WARNING

3lade can lift and throw wo_plece.

3Jade can suddenly come toward you.

ro avoid this:

'or Chop Cuts, _lways LOCK SLIDE.

NEVER pull saw Into workplace.

Position blade over front edge of

workplace. To cut, PUSH saw

down Into front edge, then back

toward fence.

&WARNING

f* Read the Manual before using this saw. 6, Do nor perform any operation freehand. I_ DOUBLE INSULATED

Z.Wear safety goggles that meet ANSI Z87.1 7. Do not reach around or behind saw blade, fL-.J JWhen servicing use only

Standards. 8. Unplug saw before changing blade or secvtc_g. _ identical mn_Rmmnt nactm

3,Tighten_ arbor screw and all clamps beforB g. Release trigger end ,waft for blade to stop Electncs" I-. 120 vo'-rts........ "_-

sawing, before moving wor kpmce or changing set.up. 60 Hz AC only ( _l,_' \

4.Donotoperatethissawwifftoutguardsinplace. 10.To avoid electric shock_ do not oxpose to |n= m "' _ _.UL,J ./

5.Keep hands away from the moving blade, rain• S000 _M

WHEN INSTALLING OR MOVING THE

SLIDE COMPOUND MITER SAW.

Before moving the sew:

• Lock the miter, bevel, and carriage lock knobs.

• Unplug the power cord.

IEWo-/5

• Get help. This saw weighs 70 pounds. To avoid

back injury, get help whenever you need to lift it.

NEVER carry the saw by the cord or power head han-

dle. The handle could break suddenly. Damage to insu-

lation could cause an electric shock. Damage to wire

connections could cause a fire.

2

AVOIDDANGEROUSENVIRONMENT.Usetheslide

compoundmitersawinadry,indoorplaceprotected

fromrain.Keepworkareawelllighted.

Placetheslidecompoundmitersawsoneithertheuser

orbystandersareforcedtostandinlinewiththeblade.

Throwndebriscouldinjurepeopleinitspath.

Toavoid injury from unexpected saw movement:

• Put the slide compound miter saw on a firm level

surface where there is plenty of room for handling

and properly supporting the workpiece.

• Support the slide compound miter saw so the table

is level and the saw does not rock.

Bolt or clamp the saw to its support.

NEVER STAND ON TOOL. Serious injury could

occur if the tool tips or you accidentally hit the cut-

ting tool. Do not store anything above or near the

tool where anyone might stand on the tool to reach

them.

To avoid injury or death from electrical shock:

• THIS TOOL IS DOUBLE INSULATED to give you

added protection. Double insulation does not take

the place of normal safety precautions when oper-

ating this tool. When servicing this double insulat-

ed tool, use only identical parts.

• Make sure your fingers do not touch the plug's

metal prongs when plugging or unplugging the

slide compound miter saw.

BEFORE EACH USE:

Inspect your slide compound miter saw.

DISCONNECT THE SAW. To avoid injury from acci-

dental starting, unplug the saw, before changing the

setup, changing the blade or adjusting anything.

Compare the direction of rotation arrow on the guard to

the direction arrow on the blade. The blade teeth

should always point downward at the front of the saw,

Tighten the arbor screw.

Tighten the cover plate stop screw.

CHECK DAMAGED PARTS. Check for:

Alignment of moving parts,

Damaged electric cords.

Binding of moving parts,

Broken parts,

Stable mounting,

Function of arm return spring and lower guard:

Push the arm all the way down, then let it rise up

until it stops by itself. Check the lower guard to see

if it closed fully, If it did not, follow the instructionsin

the Trouble Shooting section.

Smooth, solid movement of sliding assembly,

Other conditions that may affect the way the slide

compound miter saw works.

KEEP GUARDS IN PLACE, in working order, and in

proper adjustment.

If any part is missing, bent, or broken in any way, or any

electrical parts don't work, turn the saw off and unplug

it. REPLACE damaged, missing, or failed parts before

using the saw again.

MAINTAIN TOOLS WITH CARE Keep the slide com-

pound miter saw clean for best and safest performance

Follow instructions for lubricating. DON'T put lubricants

on the blade while it's spinning.

REMOVE ADJUSTING KEYS AND WRENCHES from

toolbefore turning it on.

To avoid injury from jams, slips or thrown pieces:

• Choose the right 8-1/4 inch diameter blade for the

material and the typeof cuttingyouplan to do.

• Make sure the blade is sharp, undamaged and

properly aligned. With the saw unplugged, push

the power-head all the way down and back. Hand

spin the blade and check for clearance. Tilt the

power-head to 45 degree bevel and repeat the

check. If the blade hits anything, make the adjust-

ments shown in the Assembly and Alignment

section. (page 9)

• Make sure the blade and arbor collars are clean.

• Make sure the arbor collars' recessed sides are

facing the blade.

• Using the provided arbor wrench or other 1/2"

wrench, make sure the arbor cap screw is firmly

hand tightened.

° Make sure all clamps and looks are tight and no

parts have excessive play.

• KEEP WORK AREA CLEAN. Cluttered areas and

benches invite accidents. Floor must not be slippery.

To avoid burns or other fire damage, never use the

slide compound miter saw near flammable liquids,

vapors or gasses.

Plan ahead to protect your eyes, hands,

face, ears.

KNOW YOUR SLIDE COMPOUND MITER SAW.

Read and understand the owner's manual and labels

affixed to the toot. Learn its application and limitations

as well as the specific potential hazards peculiarto this

tool.

To avoid injury from accidental contact with moving

parts, don't do layout, assembly, or setup work on the

slide compound miter saw while any parts are moving.

AVOID ACCIDENTAL STARTING. Make sure switch is

"OFF" before plugging slide compound miter saw into a

power outlet.

Plan your work.

USE THE RIGHT TOOL. Don't force tool or attachment

to do a job it was not designed to do. Use a different

tool for any workpiece that can't be held in a solidly

braced, fixed position.

CAUTION: This machine is not designed for

cutting metals. Use this slide compound miter

saw to cut only wood, and wood like products.

Other materials may shatter, bind on the blade,

start fires or create other dangers.

Dress for safety. WEARYOUR

Any power slide compound miter saw can throw foreign

objects into the eyes. This can cause permanent eye

damage. Wear safety goggles (not glasses) that comply

with ANSI Z87.1 (shown on package). Everyday eye-

glasses have only impact resistant lenses. They are not

safety glasses. Safety goggles are available at Sears

retail catalog stores, Glasses or goggles not in compliance

with ANSI Z87.1 could seriously hurt you when they

break.

• Do not wear loose clothing, gloves, neckties or

jewelry (rings, wrist watches) They can get caught

and draw you into moving parts.

• Wear nonslip footwear.

• lqe back long hair.

• Roll long sleeves above the elbow

• Noise levels vary widely. To avoid possible hearing

damage, wear ear plugs or muffs when using slide

compound miter saw for hours at a time.

• For dusty operations wear a dust mask along with

the safety goggles.

Inspect your workpieee.

Make sure there are no nails or foreign objects in the

part of the workpiece to be cut.

Plan your work to avoid the spinning blade and

keep the workpiece from binding on the blade and

flying out of your hands:

Plan how you will make the cut. Always:

• Make sure the blade is not spinning.

• Raise the blade.

• Slide the saw out above the front edge of the work-

piece before starting it, and

• Push the saw blade down on top of the wood and

then away from you to make the cut.

during a cut. The blade can suddenly climb up

on top of the workpiece and force itself

I DANGER: NEVER pull the saw toward you

toward you.

Never cut FREEHAND:

• Brace your workpiece solidly against the fence and

table top so ,t will not rock or twist during the cut

• Make sure there's no debris between the work

piece and its supports

• Make sure no gaps between the workpiece fence

and table wilr let the workpiece shill after it is cut _n

two.

• Never cut more than one workppece at a time

• Keep the cut off piece free to move sideways after

it's cut off Otherwise. it could get wedged against

the blade and thrown violently

• Clear everything except the workpiece and related

support devices off t,_e table before turning the

slide compound miter saw on

• SECURE WORK. Use clamps or a vise to help

hold the work when irs practical

Use extra caution with large, very small or awk-

ward workpieces:

• Use extra supports (tables saw horses, blocks.

e[c.i for any workpieces large enough to tip when

not hetd down to the table top.

• NEVER use another persoH as a substitute for a

table ex_er'.so "_, or as additiona_ sn,ooort for a

workplece

• Do nol use tn,s saw to :,,,' pieces too small [o let

you easily i-old the ,.vo_kwniie you keep the thumb

side of your flt_/ poetic,, _'_'g_ against the out-

sideeag_ _ n. !ercd.

• When cutting {rregu_auy shapeo workp_eces, plan

your work support so =twlti not Shp Dncn Th_biaoe .

and be torn [rum ,,.u. , __ A pLece of molding,

for example nc, b[ ,o iL_f_r be heid by a fixture or

j_gthat wiii not let [ r_,,_/ _ock or slip while being

cut.

• Properly support round material such as dowel

rods. They have a tendency to roll while being cut

causing the blade to "bite" To avoid this, always

use a fixture designed to properly hold your work-

piece

WHENEVER SAW BLADE IS SPINNING.

WARNING: Don't let familiarity (gained from

frequent use of your slide compound miter

saw) cause a careless mistake. A careless

fraction of a second is enough to cause

a severe injury.

Plan the way you will hold the workpiece from start to

finish:

Avoid awkward operations and hand positions where a

sudden slip could cause fingers or hand to move into

the blade.

DON'T OVERREACH. Keep good footing and balance.

Never reach behind or beneath the saw blade.

Keep your face and body to one side, out of line with a

possible throwback.

Before starting your cut watch the slide compuur'o

miter saw whiie it runs If it makes an unfarnil,at no_se

or vibrates a lot, stop _mmediately Turn the slide com-

pound miter saw off. Unplug the shde compound m_,

saw. Do not restart until finding and correcting the p_c_'

lem.

KEEP CHILDREN AWAY. Keep all visitors a safe dis-

tance from the slide compound miter saw. Make sure

bystanders are clear of the slide compound miter saw

and workp_ece

4

Never confine the piece being cut off. Never hold it,

clamp it, touch it, or use length stops against it while the

blade is spinning, tt must be free to move sideways on

its own. If confined, it could get wedged against the

blade and thrown violently.

Let the blade reach full speed before cutting.

DON'T FORCE TOOL. It will do the job better and safer

at its designed rate. Feed the blade into the workpiece

only fast enough to let it cut without bogging down or

binding.

Before freeing any jammed material:

• Turn switch "OFF"

• Unplug the slide compound miter saw.

• Wait for all moving parts to stop.

glossary of terms for woodworking

After finishing a cut:

• Keep holding the power head down,

• Release the switch, and wait for all moving parts to

stop before moving your hands.

• If blade doesn't stop within 6 seconds, unplug the

saw and follow the instructions in the Trouble

Shooting section for fixing the blade brake before

using the saw again,

BEFORE LEAVING THE SAW:

NEVER LEAVE TOOL RUNNING UNATTENDED. Turn

power off. Wait for all moving parts to stop.

Make workshop child-proof. Lock the shop. Disconnect

master switches. Store tool away from children and oth-

ers not qualified to use it.

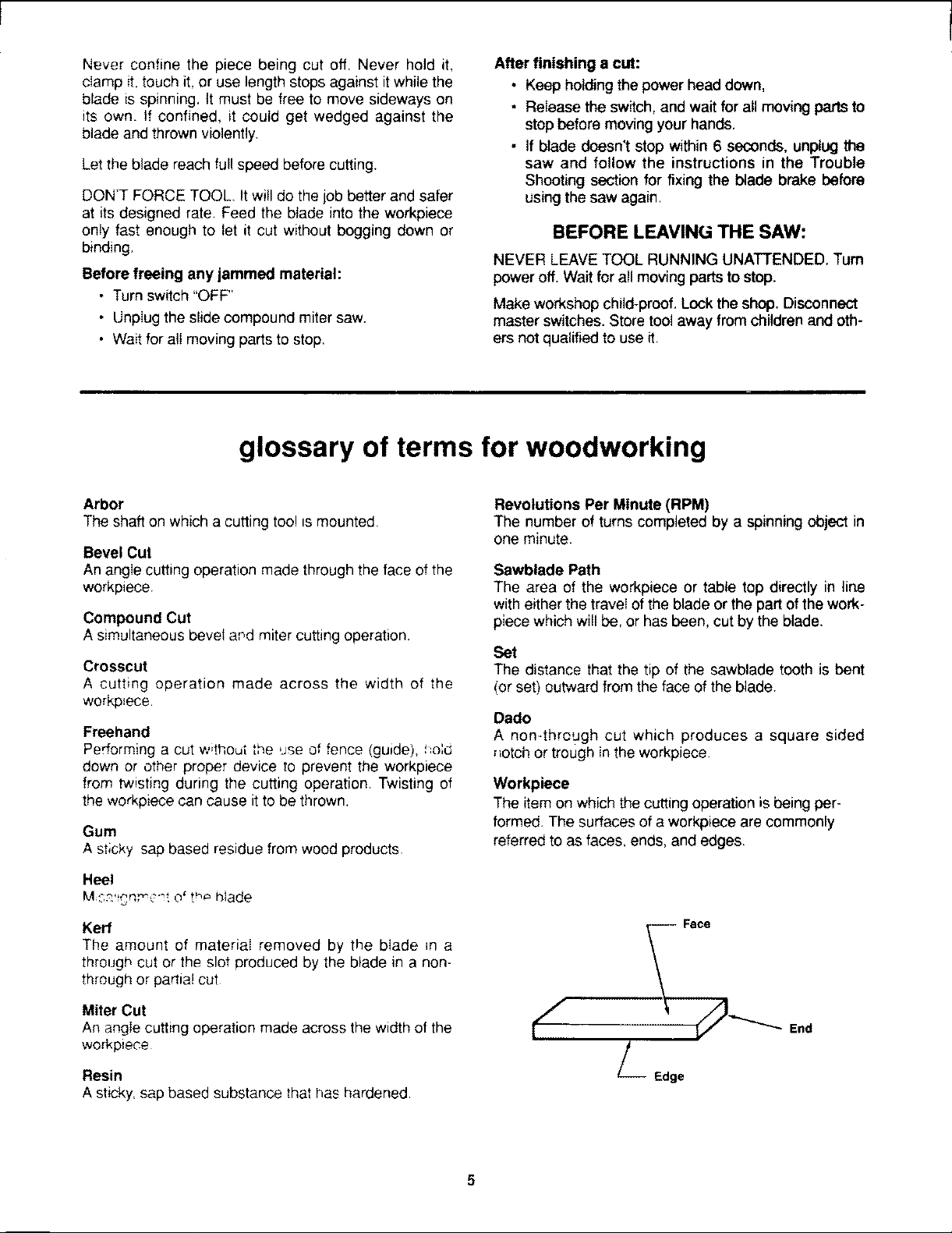

Arbor

The shaft on which a cutting too! is mounted

Bevel Cut

An angle cutting operation made through the face of the

workpiece.

Compound Cut

A simultaneous bevel and miter cutting operation.

Crosscut

A cutting operation made across the width of the

workp_ece,

Freehand

Performing a cut w,thout the use of fence (guide), hold

down or other proper device to prevent the workpiece

from _Jisting during the cutting operation. Twisting of

the workpiece can cause it to be thrown.

Gum

A st;cky sap based residue from wood products

Heel

M ';a'icnm(mt o_th_ nlade

Kerr

The amount of material removed by the blade _n a

through cut or the slot produced by the blade in a non-

through or partial cut

Revolutions Per Minute (RPM)

The number of turns completed by a spinning object in

one minute.

Sawblade Path

The area of the workpiece or table top directly in line

with either the travel of the blade or the part of the work-

piece which will be, or has been, cut by the blade.

Set

The distance that the tip of the sawblade tooth is bent

(or set) outward from the face of the blade.

Dado

A non-through cut which produces a square sided

_otch or trough in the workpiece.

Workpiece

The item on which the cutting operation is being per-

formed. The surfaces of a workpiece are commonly

referred to as faces, ends, and edges.

Miter Cut

An angle cutting operation made across the width of the

workp=ece

Resin

A sticky, sap based substance that has hardened.

End

Edge

electrical connections

POWER SUPPLY

Motor Specifications

The AC motor used in this saw is a universal, nonre-

versible type having the following specifications:

Maximum Developed H.P .......................................... 2

Voltage ................................................................... 120

Amperes .................................................................. 10

Hertz (Cycles) ......................................................... 60

Phase .............................................................. Single

RPM .................................................................... 5000

Rotation of Shaft ......................................... Clockwise

Brake ............................................................ Automatic

WARNING: To avoid electrical hazards, fire haz-

ards, or damage, or damage to the tool, use

proper circuit protection. Your saw is wired at

the factory for 120v operation. Connect to a

f20v, 15-amp branch circuit and use a 15-amp

time delay fuse or circuit breaker. To avoid

shock or fire, if power cord is worn or cut, or

damaged in any way, have it replaced immedi-

ately.

DOUBLE INSULATED

The slide compound miter saw is intended for residen-

tian use only. It is double insulated to provide a double

thickness of insulation between you and the tool's

electrical system. All exposed metal parts are isolated

from the internal metal motor components with pro-

tecting insulation.

Your unit has a plug that looks like the one shown

below..

WARNING: To reduce the risk of electrical

shock, this appliance has a polarized plug (one

blade is wider than the other). This plug will fit in

a polarized outlet only one way, f the p ug does

not fit fully in the outlet, reverse plug. If it still

does not fit, contact a qualified electrician to

install the proper outlet. Do not change the plug

in any way.

WARNING: Double insulation does not take the

place of normal safety precautions when operat-

ing this tool.

DANGER: To avoid electrocution:

1. Use only identical replacement parts when

servicing a tool with double insulation. Ser-

vicing should be performed by a qualified ser-

vice technician.

2. Do not use in rain or where floor is wet. This

tool is intended for indoor residual use only.

MOTOR SAFETY PROTECTION

CAUTION: To avoid motor damage, this motor

should be blown out or vacuumed frequently to

keep sawdust from interfering with normal

motor ventilation.

1. Connect this tool to a 120V, 15-amp branch circuit

with a 15-amp time delay fuse or circuit breaker.

Using the wrong size fuse can damage the motor.

2. If the motor won't start, release the trigger switch

immediately. UNPLUG THE TOOL Check the saw

blade to make sure it turns freely. If the blade is

free, try to start the motor again. If the motor still

does not start, refer to the "Motor Trouble-Shoot-

mg Chart."

3. If the motor suddenly stalls while cutting wood,

release the trigger switch, unplug the tool, and

free the blade from the wood. The motor may now

be restarted and the cut finished.

4. Fuses may "blow" or circuit breakers may trip fre-

quently if:

a. MOTOR IS OVERLOADED--Overloading can

occur if you feed too rapidly or make too many

start/stops in a short time.

b. Voltages net more than 10% above or below

the nameplate voltage can handle normal

loads. For heavy loads, however, the voltage at

motor terminals must equal the voltage speci-

fied on nameplate.

5. Most motor troubles may be traced to loose or

incorrect connections, overload, low voltage (such

as small size wire in the supply circuit) or to overly

tong supply circuit wire. Always check the connec-

tions, the load and the supply circuit whenever

motor doesn't work well. Check wire sizes and

length with the Wire Size Chart below,

WIRE SIZES

The use of any extension cord will cause some loss of

power. To keep this to a minimum and to prevent over-

heating and motor burn-out, use the table below to

determine the minimum wire size (A.W.G.) extension

cord.

6

For circuits that are farther than 100 feet away from

electrical service box, the wire size must be increased

proportionately in order to deliver ample voltage to the

saw motor,

contents

Guarantee .................................................................. 2

Safety Instructions for Slide Compound

Miter Saw ................................................................. 2

Glossary of Terms for Woodworking ............................ 5

Electrical Connections ................................................... 6

Unpacking and Preassembly ................................ 7

Knowing Your Miter Saw ................................................ 8

unpacking

Ampererati_g 0 50 51 100 107 i3 0 1:2! - 150

ton _)ameplate)

Ext Cord Length Wire Size iAmerican Wire Gauge}

25 Ft 18 18 l_ 14

50 Ft 18 16 16 14

75 F1 18 16 !4 14

!00 F_ 16 14 12 12

125 Ft 16 12 12 12

150 Ft 16 12 !2 -=

Assembiy and Alignment .......................................... 9

Mounting the Saw.......................................................... 13

Basic Saw Operations ....................................... 14

Maintenance and Lubrication ........................................ 21

Troubie Shooting ......................................................... 23

Repair Parts .............................................................. 26

WARNING: To avoid injury from unexpected

starting or electrical shock, do not plug the

power cord into a source of power during

unpacking and assembly. This cord must remain

unplugged whenever you are working on the

saw.

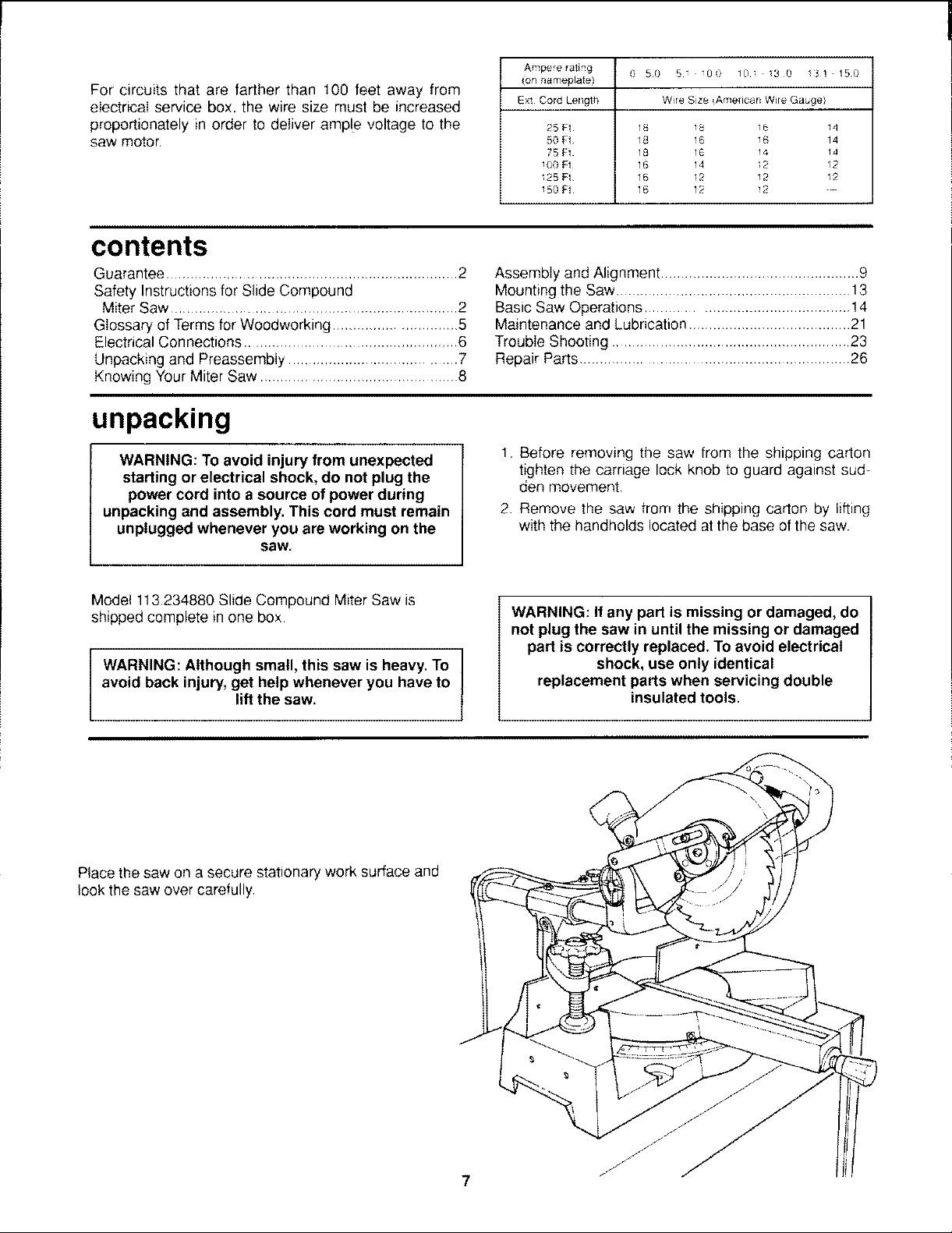

Model 113.234880 Slide Compound Miter Saw is

shipped complete in one box

WARNING: Although small, this saw is heavy. To J

avoid back injury, get help whenever you have to

lift the saw.

Place the saw on a secure stationary work surface and

look the saw over carefully.

1. Before removing the saw from the shipping carton

tighten the carriage lock knob to guard against sud-

den movement

2. Remove the saw from the shipping carton by lifting

with the handholds located at the base of the saw.

WARNING: It any part is missing or damaged, do

not plug the saw in until the missing or damaged

I

J

part is correctly replaced. To avoid electrical

shock, use only identical

replacement parts when servicing double

insulated tools.

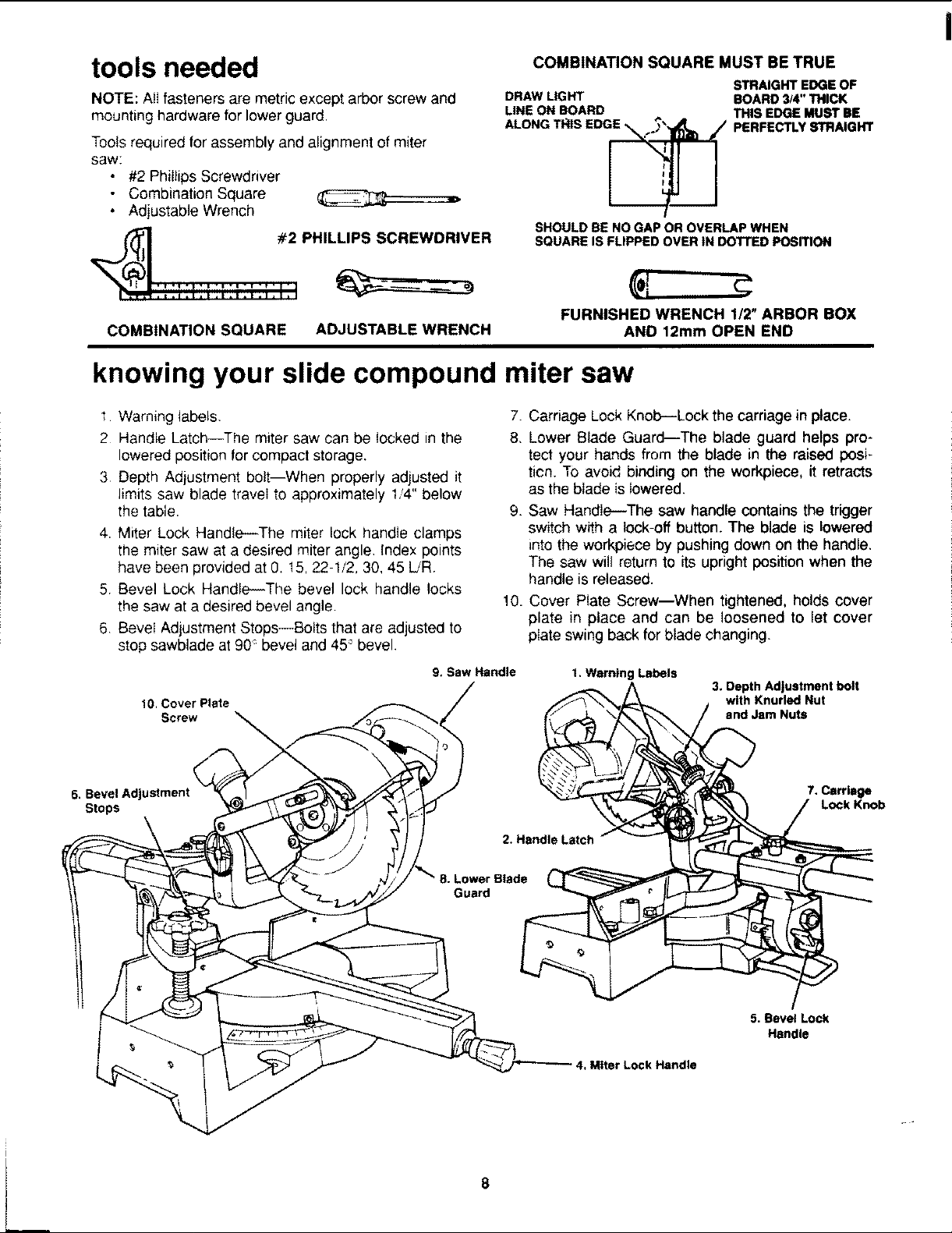

tools needed

NOTE: AII fasteners are metric except arbor screw and

mounting hardware for lower guard,

COMBINATION SQUARE MUST BE TRUE

DRAW LIGHT

LINE ON BOARD

Tools required for assembly and alignment of miter

saw:

• #2 Phillips Screwdriver

• Combination Square

ALONG TRIS EDG_.__

• Adjustable Wrench

SHOULD BE NO GAP OR OVERLAP WHEN

SQUARE IS FLIPPED OVER IN DOTTED PO61TION

_,_ #2 PHILLIPS SCREWDRIVER

FURNISHED WRENCH I12" ARBOR BOX

COMBINATION SQUARE ADJUSTABLE WRENCH

knowing your slide compound miter saw

STRAIGHT EDGEOF

BOARD 3/4" THICK

THIS EDGE MUST BE

PERFECTLYSTRAIGHT

AND 12mm OPEN END

I Warning labels.

2 Handle Latch--The miter saw can be locked in the

lowered position for compact storage.

3 Depth Adjustment bolt--When properly adjusted it

limits saw blade travel to approximately 1/4" below

the table.

4. Miter Lock Handle--The miter lock handle clamps

the miter saw at a desired miter angle. Index points

have been provided at 0.15, 22-1/2, 30, 45 L/R.

5 Bevel Lock Handle_The bevel lock handle locks

the saw at a desired bevel angle.

6 Bevel Adjustment Stops--Bolts that are adjusted to

stop sawblade at 90_bevel and 45; bevel.

10. Cover Plate

Screw

6. Bevel Adju

Stops

9. Saw Handle

7. Carriage Lock Knob--Lock the carriage in place.

8. Lower Blade Guard-The blade guard helps pro-

tect your hands from the blade in the raised posi-

ticn. To avoid binding on the workpiece, it retracts

as the blade is lowered.

9. Saw Handle--The saw handle contains the trigger

switch with a lock-off button. The blade is bowered

into the workpiece by pushing down on the handle.

The saw will return to its upright position when the

handle is released.

!0. Cover Plate Screw--When tightened, holds cover

plate in place and can be loosened to let cover

plate swing back for blade changing.

1. Warning Labels

2. Handle Latch

3. Depth Adjustment bolt

with Knurled Nut

and Jam Nuts

7, Carriage

Lock Knob

8. Lower Blade

Guard

5. Bevel Lock

Handle

4_Miter Lock Handle

assembly and alignment

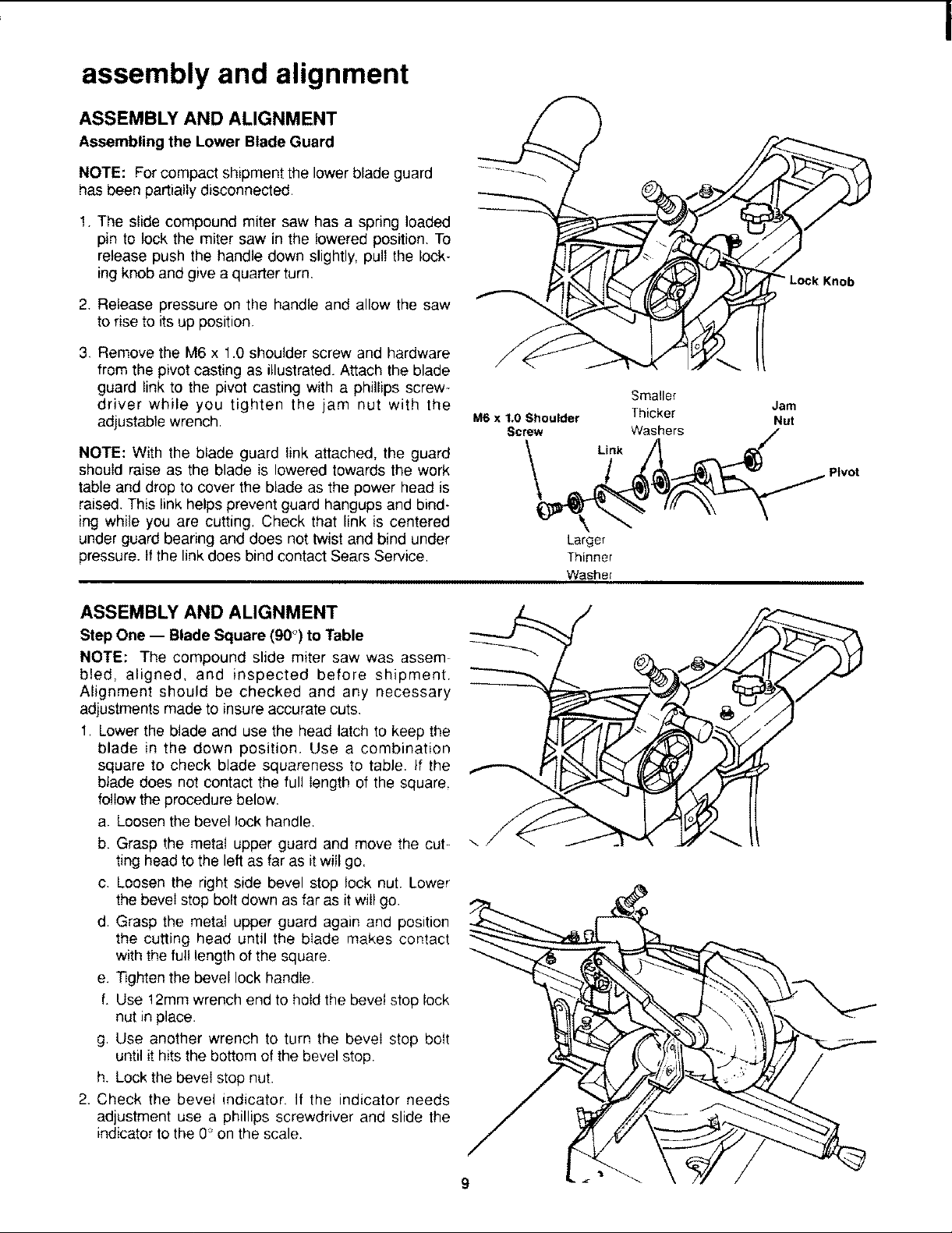

ASSEMBLY AND ALIGNMENT

Assembling the Lower Blade Guard

NOTE: For compact shipment the lower blade guard

has been partially disconnected.

!. The slide compound miter saw has a spring loaded

pin to lock the miter saw in the !owered position. To

release push the handle down slightly, pull the lock-

ing knob and give a quarter turn,

2. Release pressure on the handle and allow the saw

to rise to its up position

3, Remove the M6 x 1.0 shoulder screw and hardware

from the pivot casting as illustrated. Attach the blade

guard link to the pivot casting with a phillips screw-

driver while you tighten the jam nut with the

adjustable wrench,

NOTE: With the blade guard link attached, the guard

should raise as the blade is lowered towards the work

table and drop to cover the blade as the power head is

raised. This link helps prevent guard hangups and bind-

ing while you are cutting, Check that link is centered

under guard bearing and does not twist and bind under

pressure, tfthe link does bind contact Sears Service,

Smaller

M6 x 1.0 Shoulder Thicker Nut

Screw Washers

Link

Larger

Thinner

Washel

Jam

Pivot

ASSEMBLY AND ALIGNMENT

Step One -- Blade Square (90°) to Table

NOTE: The compound slide miter saw was assem-

bled, aligned, and inspected before shipment.

Alignment should be checked and any necessary

adjustments made to insure accurate cuts.

1. Lower the blade and use the head latch to keep the

blade in the down position. Use a combination

square to check blade squareness to table. If the

blade does not contact the full length of the square.

follow the procedure below,

a. Loosen the bevel lock handle.

b. Grasp the metal upper guard and move the cut-

ting head to the left as far as it will go.

c. Loosen the right side bevel stop lock nut. Lower

the bevel stop bolt down as far as it will go.

d. Grasp the metal upper guard again and position

the cutting head until the blade makes contact

with the full length of the square.

e. Tighten the bevel lock handie

f. Use 12mm wrench end to hold the bevel stop lock

nut in place.

g Use another wrench to turn the bevel stop bolt

until it hits the bottom of the bevel stop.

h. Lock the bevel stop nut.

2. Check the bevel indicator, If the indicator needs

adjustment use a phillips screwdriver and slide the

indicator to the 0" on the scale.

9

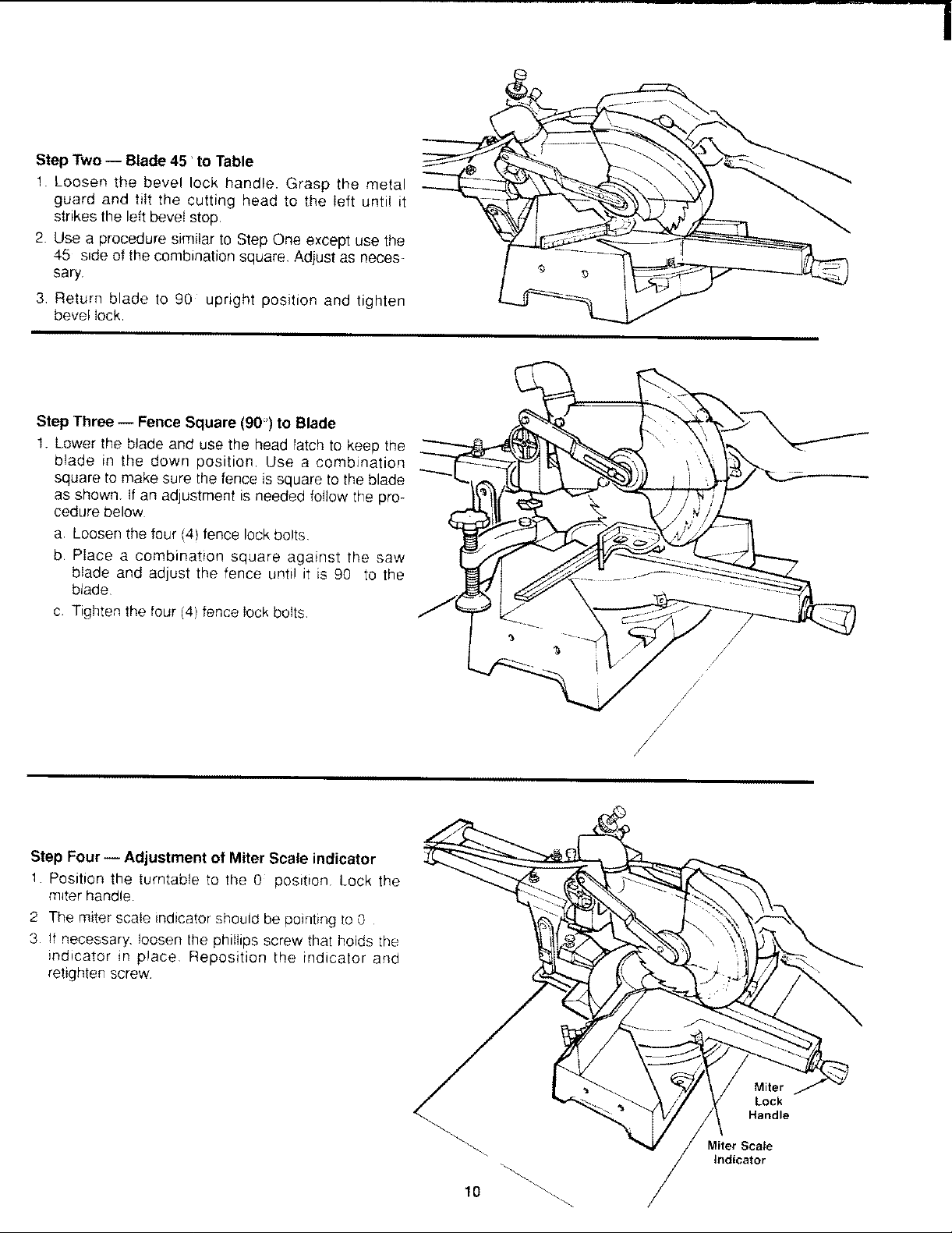

Step Two -- Blade 45 to Table

1. Loosen the bevel lock handle. Grasp the metal

guard and tiIt the cutting head to the Ieft until it

strikes the left bevel stop,

2. Use a procedure similar to Step One except use the

45 side of the combination square, Adjust as neces-

sary.

3. Return blade to 90 upright position and tighten

bevel lock

Step Three -- Fence Square (90') to Blade

1. Lower the blade and use the head latch to keep the

blade in the down position. Use a combination

square to make sure the fence is square to the blade

as shown. If an adjustment is needed follow the pro-

cedure below

a Loosen the four (4) fence lock bolts

b Piace a combination square against the saw

blade and adjust the fence until it is 90 to the

blade

c Tighten the four (4) fence lock bolts

Step Four- Adjustment of Miter Scale indicator

1 Position the turntable to the 0 position Lock the

m_terhandle

2 The miter scale indicator should be pointing to 0

3 !f necessary, loosen the phillips screw that holds the

indicator in place Reposition the indicator and

retighten screw

Miter

Lock

Handle

Miter Scale

Indicator

10 /

Loading...

Loading...