Craftsman 113234650 Owner’s Manual

f'_ Save ThisManual

For Future Reference

owner's

manual

MODEL NO.

113.234650

I 0" CONTRACTOR

MITER SAW

Serial

Number

Model and serial numbers

may be found at the side of

the miler saw arm.

You should record both

model and serial number in

a safe place for future use.

CAUTION:

READ ALL

INSTRUCTIONS

CAREFULLY

CRRFTSMRN

10-1NCH CONTRACTOR

MITER SAW

• assembly

• operating

• repair parts

J J

Sold by SEARS, ROEBUCK AND CO., Chicago, IL 60684 U.S.A.

Part No. SP5229 Printed in Taiwan.

FULL ONE YEAR WARRANTY ON CRAFTSMAN MITER SAW

If within one year from the date of purchase, this Craftsman Miter Saw fails due to a defect

in material or workmanship, Sears will repair it, free of charge.

WARRANTY SERVICE iS AVAILABLE BY SIMPLY CONTACTING THE NEAREST SEARS SER-

VICE CENTER/DEPARTMENT THROUGHOUT THE UNITED STATES.

This warranty applies only while this product is used in the United States.

This warranty gives you specific legal rights, and you may also have other rights which

vary from state to state.

SEARS, ROEBUCK AND CO., Dept. 698/731A, Sears Tower, Chicago, IL 60684

GENERAL SAFETY INSTRUCTIONS FOR POWER TOOLS

1. KNOW YOUR POWER TOOL

Read and understand the owner's manual and

labels affixed to the tool. Learn its application and

limitations as well as the specific potential hazards

peculiar to this tool.

2. This tool is DOUBLE INSULATED to give you

added protection. Double insulation does not take

the place of normal safety precautions when

operating this tool. When servicing this double insu-

lated tool, use only identical parts.

3. KEEP GUARDS IN PLACE

In working order, and in proper adjustment and

alignment.

4. REMOVE ADJUSTING KEYS AND WRENCHES

Form habit of checking to see that keys and adjust-

ing wrenches are removed from tool before turning

it on.

5. KEEP WORK AREA CLEAN

Cluttered areas and benches invite accidents. Floor

must not be slippery due to wax or sawdust.

6. AVOID DANGEROUS ENVIRONMENT

Don't use power tools in damp or wet locations or

expose them to rain. Keep work area well lighted.

Provide adequate surrounding work space.

7. KEEP CHILDREN AWAY

All visitors should be kept a safe distance from

work area.

8. MAKE WORKSHOP CHILD-PROOF

With padlocks, master switches, by removing star-

ter keys, or storing tools where children can't get

them.

9. DON'T FORCE TOOL

It wil! do the job better and safer at the rate for

which it was designed.

10, USE RIGHTTOOL

Don't force tools or attachment to do a job it was

not designed for.

11. WEAR PROPER APPAREL

Do not wear loose clothing, gloves, neckties, or

jewelry (rings, wrist watches) to get caught in mov-

ing parts. NONSLIP footwear is recommended.

Wear protective hair covering to contain long hair.

Roll long sleeves above the elbow.

12. USE SAFETY GOGGLES (HEAD PROTECTION)

Wear safety goggles (must comply with ANSI

Z87.1) at all times. Everyday eyeglassess are not

safety glasses. They only have impact resistant

lenses. Also, use face or dust mask if cutting oper-

ation is dusty, and ear protectors (plugs or muffs)

during extended periods of operation.

13. SECURE WORK

Use clamps or a vise to hold work when practical.

It frees both hands to operate tool.

14. DON'T OVERREACH

Keep proper footing and balance at all times.

15. MAINTAIN TOOLS WITH CARE

Keep tools sharp and clean for best and safest

performance. Follow instructions for lubricating and

changing accessories.

16. DISCONNECT TOOLS

Before servicing; when changing accessories such

as blades, bits. cutters, etc.

17. AVOID ACCIDENTAL STARTING

Make sure switch is in "OFF" position before plug-

ging in.

18. USE RECOMMENDED ACCESSORIES

Consult the owner's manual for recommended ac-

cessories. Follow the instructions that accompany

the accessories. The use of improper accessories

may cause hazards.

19. NEVER STAND ON TOOL OR ITS STAND

Serious injury could occur if the tool is tipped or if

the cutting tool is accidentally contacted. Do not

store materials above or near the tool such that it

_s necessary to stand on the tool or its stand to

reach them.

20. CHECK DAMAGED PARTS

Before further use of the tool, a guard or other part

that is damaged should be carefully checked to

ensure that it will operate properly and perform its

intended function. Check for alignment of moving

parts, binding or moving parts, breakage of parts,

mounting, and any other conditions that may affect

its operation. A guard or other part that is damaged

should be properly repaired or replaced.

21. NEVER LEAVETOOL RUNNING UNATTENDED

Turn power off. Don't leave tool until it comes to a

complete stop.

additional safety instructions for miter saw

Safety is a combination of common sense, staying alert

and knowing how your miter saw works.

BEFORE USING THE SAW:

WARNING: TO AVOID MISTAKES THAT COULD

CAUSE SERIOUS, PERMANENT INJURY, DO NOT

PLUG THE SAW IN UNTIL THE FOLLOWING STEPS

HAVE BEEN SATISFACTORILY COMPLETED.

1. Assembly and alignment.

2. Learn the function and proper use of:

a. The on-off switch.

b. The upper and lower blade guards.

c. The arbor lock and handle latch.

d. The bevel clamp, fence clamps, and miter lock

handle.

3. Read and understand all safety instructions and

operating procedures throughout the manual.

4. Read the following label on the miter saw:

WHEN INSTALLING OR MOVINGTHE SAW:

1. To avoid injury from unexpected saw movement:

a. Place the saw on a firm level surface where there

is plenty of room for handling and properly sup-

porting the workpiece.

b. Support the saw so the table is level and the saw

does not rock.

c. Bolt or clamp the saw to its support.

2. Before moving the saw, lock the miter, bevel and

power-head positions. Unplug electric cord.

3. To avoid back injury, get help when you need to lift

the saw more than 10 inches. Hold the tool close to

your body. Bend your knees so you can lift with your

legs, not your back. Lift by using the hand-hold areas

at "the bottom of the base. Never carry the tool by

the cord or power head handle. Damage to insulation

could cause an electric shock. Damage to wire con-

nections could cause a fire.

4. Place the saw so others will stay out from behind it.

Thrown debris could injure people in its path.

BEFORE EACH USE:

1. Inspect your saw. If any part of this miter saw is

missing, or bent, or has failed in any way, or any

electrical parts don't work properly, turn the saw off

and unplug the saw. Replace damaged, missing, or

failed parts before using the saw again.

2. Plan Your Work to protect your eyes, hands,

face, ears.

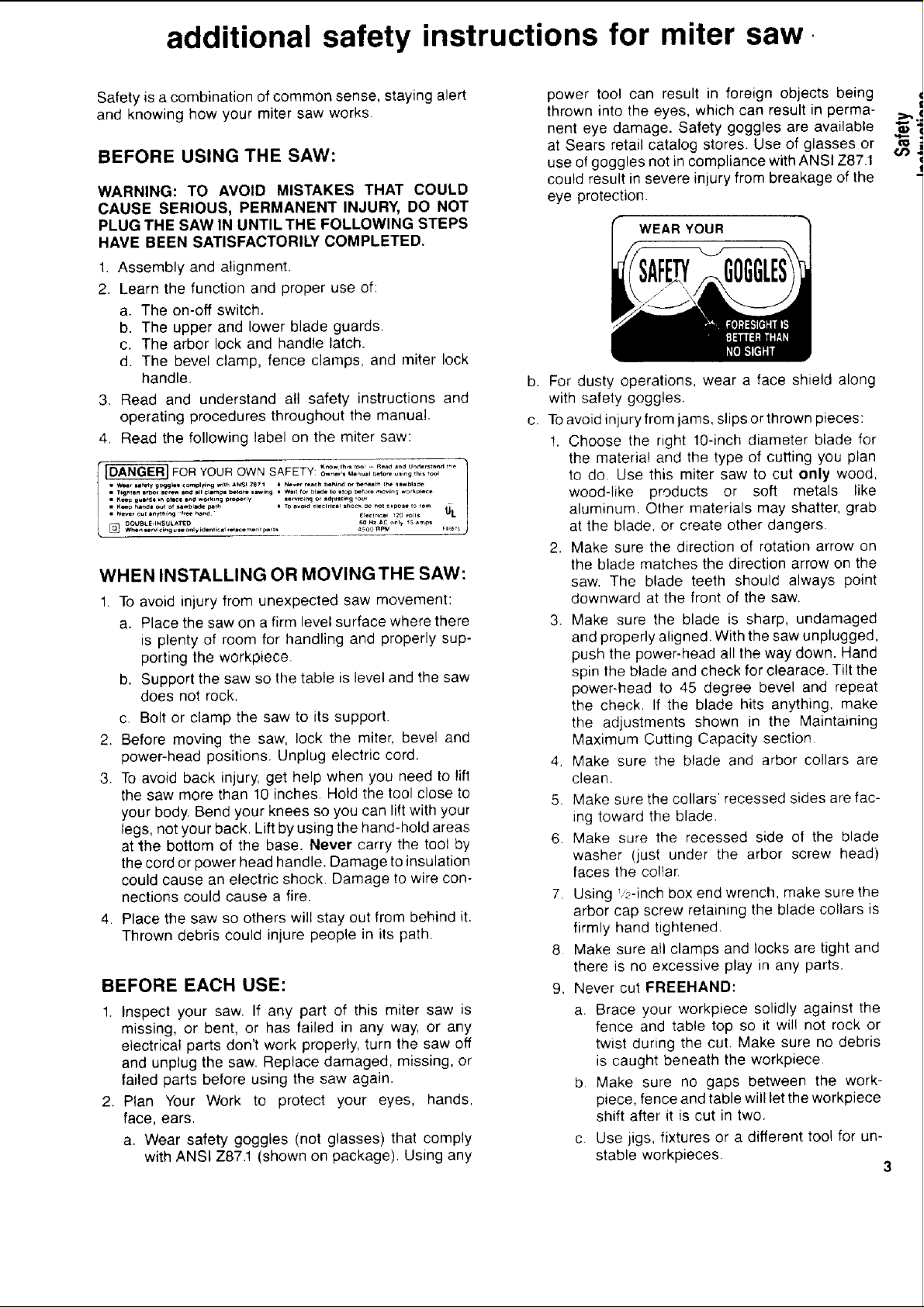

a. Wear safety goggles (not glasses) that comply

with ANSI Z87.1 (shown on package). Using any

power tool can result in foreign objects being

thrown into the eyes, which can result in perma-

nent eye damage. Safety goggles are available

at Sears retail catalog stores. Use of glasses or

use of goggles not in compliance with ANSI Z87.t

could result in severe injury from breakage of the

eye protection.

WEAR YOUR

b. For dusty operations, wear a face shield along

with safety goggles.

c. To avoid injury from jams, slips or thrown pieces:

t. Choose the right 10-inch diameter blade for

the material and the type of cutting you plan

to do. Use this miter saw to cut only wood,

wood-like products or soft metals like

aluminum. Other materials may shatter, grab

at the blade, or create other dangers.

2, Make sure the direction of rotation arrow on

the blade matches the direction arrow on the

saw. The blade teeth should always point

downward at the front of the saw.

3. Make sure the blade is sharp, undamaged

and properly aligned. With the saw unplugged,

push the power-head all the way down. Hand

spin the blade and check for clearace. Tilt the

power-head to 45 degree bevel and repeat

the check. If the blade hits anything, make

the adjustments shown in the Maintaining

Maximum Cutting Capacity section.

4. Make sure the blade and arbor collars are

clean,

5. Make sure the collars' recessed sides are fac-

ing toward the blade.

6. Make sure the recessed side of the blade

washer (just under the arbor screw head)

faces the collar.

7. Using l_._-inch box end wrench, make sure the

arbor cap screw retaining the blade collars is

firmly hand tightened

8 Make sure all clamps and locks are tight and

there is no excessive play in any parts.

9. Never cut FREEHAND:

a Brace your workpiece solidly against the

fence and table top so it wil! not rock or

twist during the cut. Make sure no debris

is caught beneath the workpiece.

b Make sure no gaps between the work-

piece, fence and table will let the workpiece

shift after it is cut in two.

c Use jigs, fixtures or a different tool for un-

stable workpieces.

3

10. Never cut more than one workpiece at a time,

11. Make sure the cut off piece can move side-

ways after it's cut off, Otherwise, it could

get wedged against the blade and thrown

violently.

12. Use extra caution with large, very small or

awkward workpieces:

a. Use extra supports (tables, saw horses,

block& etc.) for any workpieces large

enough to tip when not held down to the

table top.

b. Do not use this saw to cut pieces too

small to let you easily hold the work while

you keep the thumb side of your index

(pointer) finger against the outside edge

of the fence.

c. When cutting irregularly shaped work-

pieces, plan your work so it will not slip

and pinch the blade. A piece of molding,

for example, must lie flat or be held by a

fixture or jig that will not let it twist, rock

or slip while being cut.

d. Properly support round material such as

dowel rods, or tubing. They have a ten-

dency to roll while being cut. causing the

blade to "bite." To avoid this, always use

a fixture designed to properly hold your

work piece.

13, Make sure there are no nails or foreign ob-

jects in the part of the workpiece to be cut.

14. Make sure bystanders are clear of the tool

and workpiece Keep them clear of the area

behind the saw where debris wilt be thrown.

15. Never turn your miter saw "ON" before clear-

ing everything except the workpiece and

related support devices off the table.

d. To avoid risk of hearing damage, wear ear plugs

or muffs during extended periods of operation.

e. To avoid being suddenly pulled into the blade:

1. Do not wear gloves.

2. Remove all jewelry and loose clothing.

3. Tie back long hair.

4. Roll long sleeves above the elbow.

f. To avoid injury from accidental starting, always

unplug saw before disconnecting the guard, in-

stalling or removing any blade, accessory or

attachment, or making any adjustments.

g, To avoid an electrical shock, make sure your

fingers do not touch the metal prongs on the plug

when inserting or remowng the ptug to or from

a live outlet.

h. Never put lubricants on the blade while it's

spinning,

i. To avoid burns or other fire damage, never use

the saw near flammable liquids, vapors or gases.

j. To avoid injury from unsafe accessories, use only

accessories shown on the recommended acces-

sories list in this manual.

WHENEVER SAW IS RUNNING:

WARNING: DON'T ALLOW FAMILIARITY (GAINED

FROM FREQUENT USE OF YOUR MITER SAW) TO

CAUSE A CARELESS MISTAKE. ALWAYS RE-

MEM BER THAT A CARELESS FRACTION OF A SEC-

OND IS ENOUGH TO CAUSE A SEVERE INJURY.

1. Before actually cutting with the saw, let it run for a

while. If your saw makes an unfamiliar noise or if it

vibrates excessively, stop immediately.Turn the saw

off. Unplug the saw. Do not restart until finding and

correcting the problem.

2, Never confine the piece being cut off. Never hold it,

ctamp it, touch it, or use length stops against it. It

must be free to move sideways If confined, it could

get wedged against the blade and thrown violently.

3. Avoid awkward hand positions where a sudden slip

could cause a hand to move into the blade.

4. Let the blade reach full speed before cutting.

5. Feed the saw into the workpiece only fast enough

to letthe blade cut without bogging down or binding.

6. Before freeing jammed material, release switch and

unplug the saw. Wait for all moving parts to stop,

7. After finishing a cut. keep holding the power-head

down, release the switch, and wait for all moving

parts to stop before moving your hands.

glossary of terms for woodworking

Arbor

The shaft on which a cutting tool is mounted

Bevel Cut

An angle cutting operation made through the face of

the work piece.

Compound Cut

A simultaneous bevel and miter cutting operation.

Crosscut

A cutting operation made across the width of the work-

piece.

Freehand

Performing a cut without the use of fence (guide), hold

down or other proper device to prevent the workpiece

from twisting during the cutting operation. Twisting of

the workpiece can cause it to be thrown.

Gum

A sticky, sap based residue from wood products.

Heel

Misalignment of the blade.

Kerr

The amount of material removed by the blade in a

through cut or the slot produced by the blade in a non-

through or partial cut.

Miter Cut

An angle cutting operation made across the width of

the work piece.

Resin

A sticky, sap based substance that has hardened.

Revolutions Per Minute (RPM)

The number of turns completed by a spinning object in

one minute.

Sawblade Path

The area of the workpiece or table top directly in line

with either the travel of the blade or the part of the

workpiece which will be, or has been, cut by the blade.

Set

The distance that the tip of the sawblade tooth is bent

(or set) outward from the face of the blade.

electrical connections

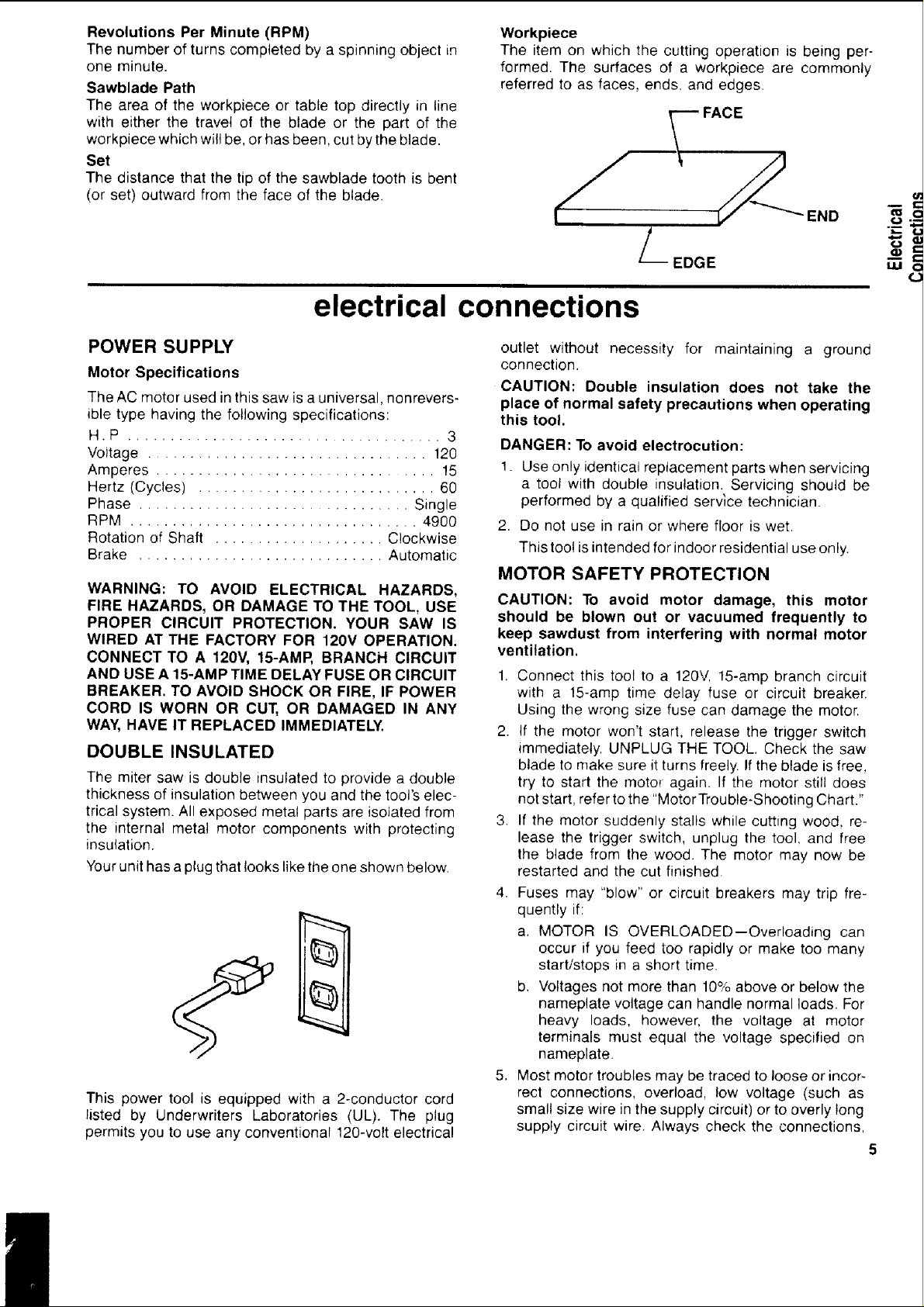

Workpiece

The item on which the cutting operation is being per-

formed. The surfaces of a workpiece are commonly

referred to as faces, ends, and edges.

END

LEDGE

_=_,c

€1)

_J

POWER SUPPLY

Motor Specifications

The AC motor used in this saw is a universal, nonrevers-

ible type having the following specifications:

H.P .................................... 3

Voltage ................................. 120

Amperes ................................ 15

Hertz (Cycles) ............................ 60

Phase ................................ Single

RPM .................................. 4900

Rotation of Shaft .................... Clockwise

Brake ............................. Automatic

WARNING: TO AVOID ELECTRICAL HAZARDS,

FIRE HAZARDS, OR DAMAGE TO THE TOOL, USE

PROPER CIRCUIT PROTECTION. YOUR SAW IS

WIRED AT THE FACTORY FOR 120V OPERATION.

CONNECT TO A 120V, 15-AMP, BRANCH CIRCUIT

AND USE A 15-AMP TIME DELAY FUSE OR CIRCUIT

BREAKER. TO AVOID SHOCK OR FIRE, IF POWER

CORD IS WORN OR CUT, OR DAMAGED IN ANY

WAY, HAVE IT REPLACED IMMEDIATELY.

DOUBLE INSULATED

The miter saw is double insulated to provide a double

thickness of insulation between you and the tool's elec-

trical system. All exposed metal parts are isolated from

the internal metal motor components with protecting

insulation.

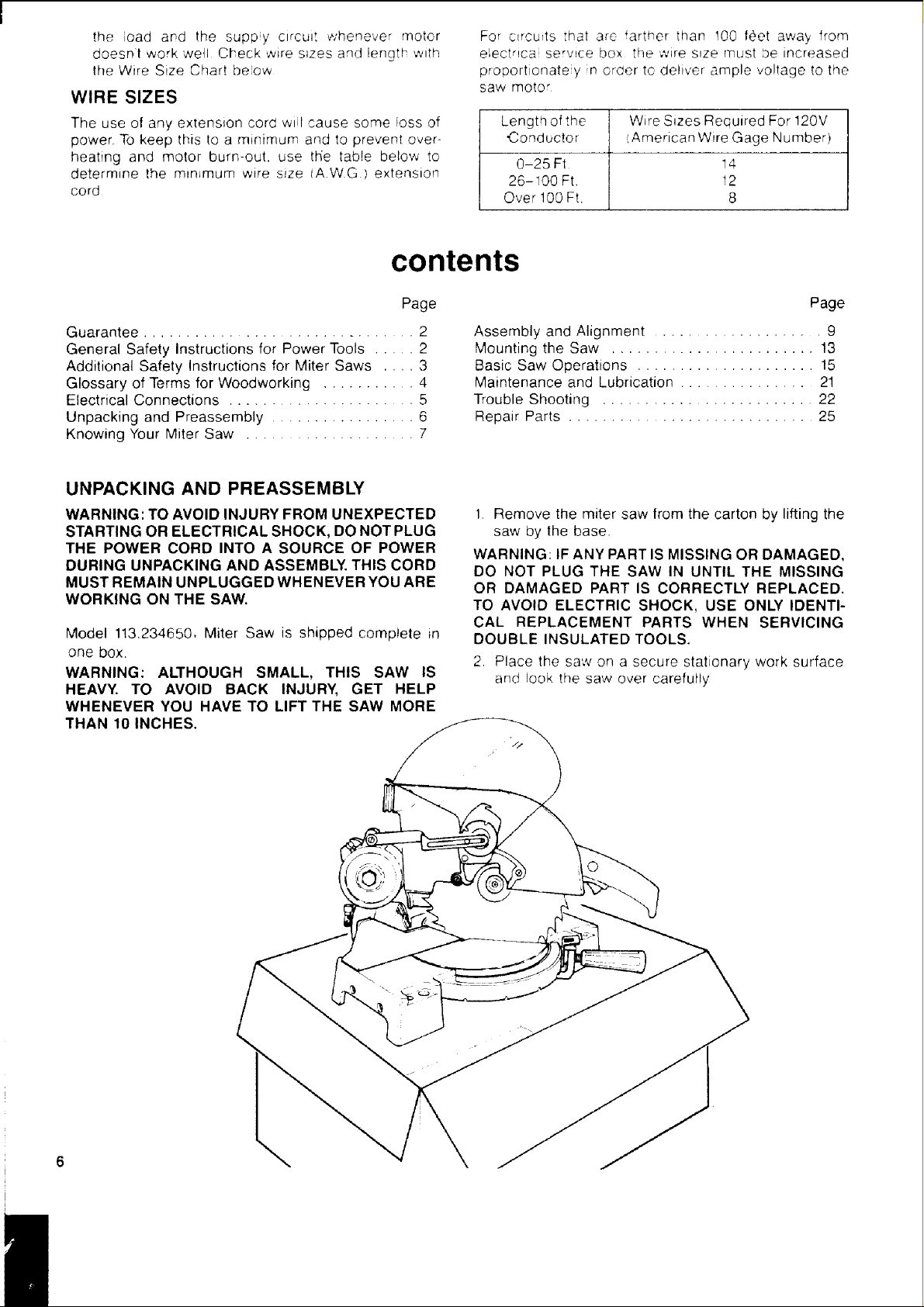

Your unit has a plug that looks like the one shown below.

This power tool is equipped with a 2-conductor cord

listed by Underwriters Laboratories (UL). The plug

permits you to use any conventional 120-volt electrical

outlet without necessity for maintaining a ground

connection.

CAUTION: Double insulation does not take the

place of normal safety precautions when operating

this tool.

DANGER: To avoid electrocution:

1. Use only identical replacement parts when servicing

a tool with double insulation. Servicing should be

performed by a qualified service technician.

2. Do not use in rain or where floor is wet.

This tool isintended for indoor residential use only.

MOTOR SAFETY PROTECTION

CAUTION: To avoid motor damage, this motor

should be blown out or vacuumed frequently to

keep sawdust from interfering with normal motor

ventilation.

1. Connect this tool to a 120V, 15-amp branch circuit

with a 15-amp time delay fuse or circuit breaker.

Using the wrong size fuse can damage the motor.

2. If the motor won't start, release the trigger switch

immediately. UNPLUG THE TOOL. Check the saw

blade to make sure it turns freely. If the blade is free,

try to start the motor again. If the motor still does

not start, refer to the "MotorTrouble-Shooting Chart."

3. If the motor suddenly stalls while cutting wood, re-

lease the trigger switch, unplug the tool, and free

the blade from the wood. The motor may now be

restarted and the cut finished

4. Fuses may "blow" or circuit breakers may trip fre-

quently if:

a. MOTOR IS OVERLOADED--Overloading can

occur if you feed too rapidly or make too many

start/stops in a short time.

b. Voltages not more than 10% above or below the

nameplate voltage can handle normal loads. For

heavy loads, however, the voltage at motor

terminals must equal the voltage specified on

nameplate.

5. Most motor troubles may be traced to loose or incor-

rect connections, overload, tow voltage (such as

small size wire in the supply circuit) or to overly long

supply circuit wire. Always check the connections,

the load and the suppy c_rcu_t whenever motor

doesnt work well Check wire s_zes and length with

the Wire Size Chart below

WIRE SIZES

The use of any extension cord will cause some _oss of

power To keep this to a minimum and to prevent over-

heating and motor burn-out, use the table below to

determine the minimum wire s_ze iAWG) extension

cord

contents

For c_rcurts ',hat are farther than 100 f6et away from

electqca se'wce box the wire size rnust :)e increased

proportionatey n oraer to deliver ample voltage to the

saw motor

Length of the Wire Sizes Required For 120V

•Conductor ',American Wire Gage Number)

O-25 Ft 14

26-100 Ft. 12

Over 100 Ft 8

Page

Guarantee ............................... 2

General Safety Instructions for Power Tools ..... 2

Additional Safety Instructions for Miter Saws .... 3

Glossary of Terms for Woodworking ........... 4

Electrical Connections ...................... 5

Unpacking and Preassembly ................. 6

Knowing Your Miter Saw ................... 7

UNPACKING AND PREASSEMBLY

WARNING: TO AVOID INJURY FROM UNEXPECTED

STARTING OR ELECTRICAL SHOCK, DO NOT PLUG

THE POWER CORD INTO A SOURCE OF POWER

DURING UNPACKING AND ASSEMBLY, THIS CORD

MUST REMAIN UNPLUGGED WHENEVER YOU ARE

WORKING ON THE SAW.

Model 113.234650, Miter Saw is shipped complete in

one box.

WARNING: ALTHOUGH SMALL, THIS SAW IS

HEAVY. TO AVOID BACK INJURY, GET HELP

WHENEVER YOU HAVE TO LIFT THE SAW MORE

THAN 10 INCHES.

Page

Assembly and Alignment ................... 9

Mounting the Saw ........................ 13

Basic Saw Operations ..................... 15

Maintenance and Lubrication ............... 21

Trouble Shooting ......................... 22

Repair Parts ............................. 25

1. Remove the miter saw from the carton by lifting the

saw by the base.

WARNING: IF ANY PART IS MISSING OR DAMAGED,

DO NOT PLUG THE SAW IN UNTIL THE MISSING

OR DAMAGED PART IS CORRECTLY REPLACED.

TO AVOID ELECTRIC SHOCK, USE ONLY IDENTI-

CAL REPLACEMENT PARTS WHEN SERVICING

DOUBLE INSULATED TOOLS.

2. Place the saw on a secure stationary work surface

and look the saw over carefully

/

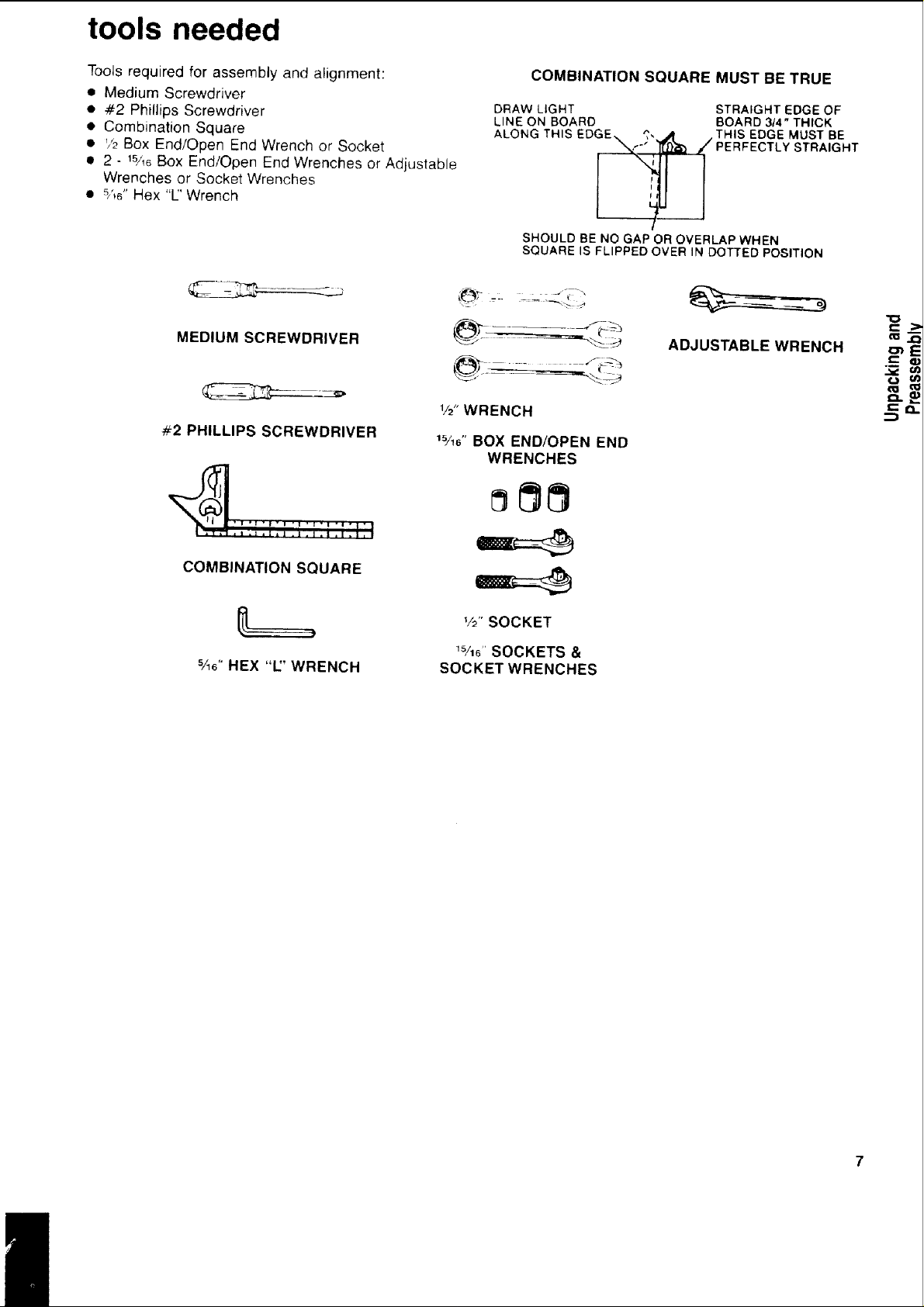

tools needed

Tools required for assembly and alignment:

• Medium Screwdriver

• #2 Phillips Screwdriver

• Combination Square

• '_ Box End/Open End Wrench or Socket

• 2 - ls/!6 Box End/Open End Wrenches or Adjustable

Wrenches or Socket Wrenches

• %6" Hex 't" Wrench

MEDIUM SCREWDRIVER

#2 PHILLIPS SCREWDRIVER

iii:iIi;1111111;:]:]

COMBINATION SQUARE MUST BE TRUE

DRAW LIGHT STRAIGHT EDGE OF

LINE ON BOARD BOARD 314" THICK

ALONG THIS EDGE-- C, ,m THIS EDGE MUST BE

SHOULD BE NO GAP OR OVERLAP WHEN

SQUARE IS FLIPPED OVER IN DOTTED POSITION

....... _: _

1/2"WRENCH

W16"BOX END/OPEN END

WRENCHES

"_.-'" "_)_:_ //PERFECTLY STRAIGHT

c

ADJUSTABLE WRENCH

=A-

COMBINATION SQUARE

5,46"HEX "1.:'WRENCH

'/2" SOCKET

1%6" SOCKETS &

SOCKET WRENCHES

/

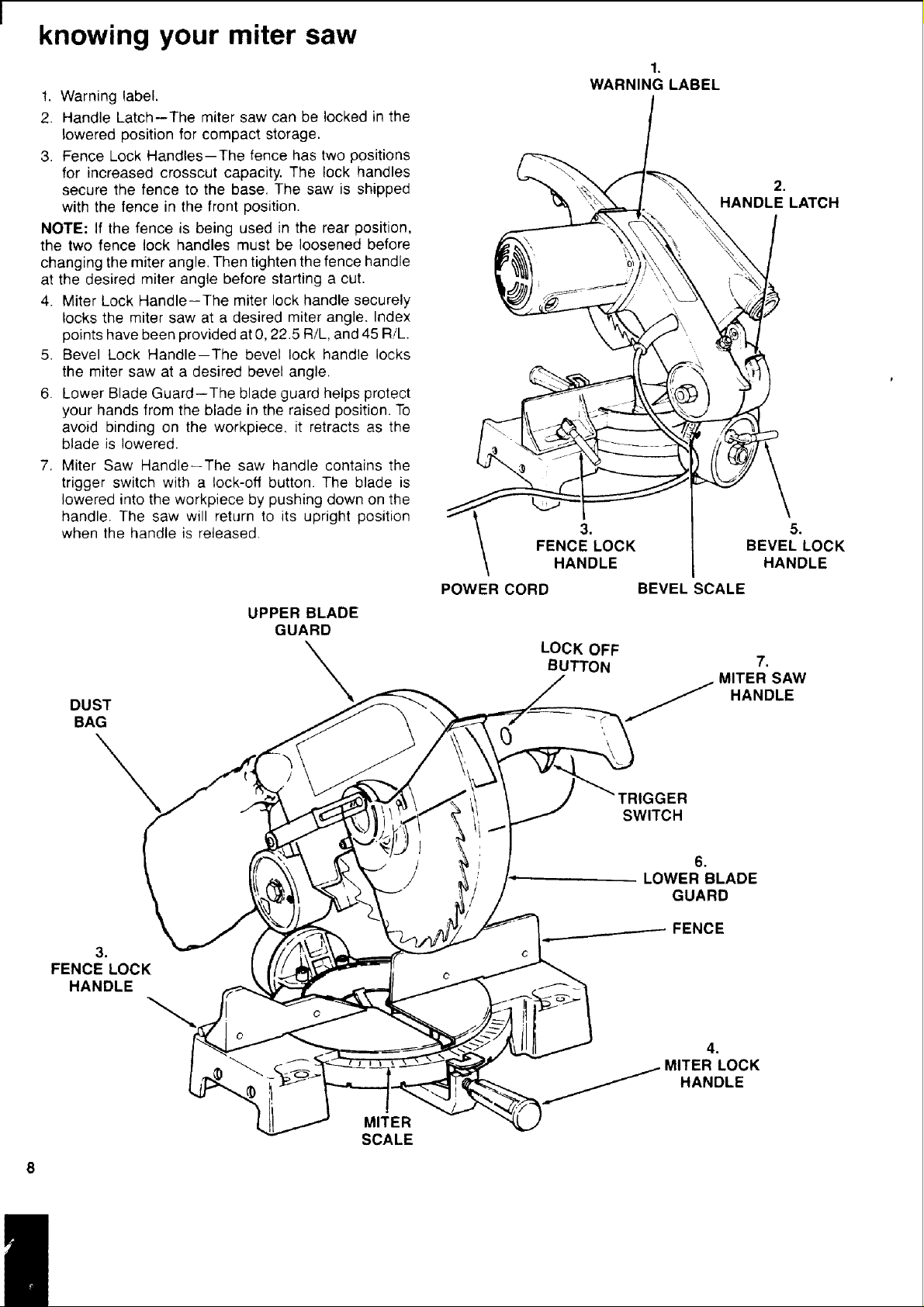

knowing your miter saw

1. Warning label,

2. Handle Latch--The miter saw can be locked in the

lowered position for compact storage.

3. Fence Lock Handles--The fence has two positions

for increased crosscut capacity. The lock handles

secure the fence to the base. The saw is shipped

with the fence in the front position.

NOTE: If the fence is being used in the rear position,

the two fence lock handles must be loosened before

changing the miter angle. Then tighten the fence handle

at the desired miter angle before starting a cut.

4. Miter Lock Handle--The miter lock handle securely

locks the miter saw at a desired miter angle. Index

points have been provided at 0, 22.5 R/L, and 45 RiL.

5. Bevel Lock Handle--The bevel lock handle locks

the miter saw at a desired bevel angle.

6. Lower Blade Guard--The blade guard helps protect

your hands from the blade in the raised position. To

avoid binding on the workpiece, it retracts as the

blade is lowered.

7, Miter Saw Handle--The saw handle contains the

trigger switch with a lock-off button. The blade is

lowered into the workpiece by pushing down on the

handle. The saw will return to its upright position

when the handle is released.

UPPER BLADE

GUARD

DUST

BAG

POWER CORD

WARNING LABEL

3,

FENCE LOCK

HANDLE

LOCK OFF

BUTTON

2.

HANDLE LATCH

°

BEVEL LOCK

HANDLE

BEVEL SCALE

,

MITER SAW

HANDLE

,

FENCE LOCK

HANDLE

TRIGGER

SWITCH

°

LOWER BLADE

GUARD

FENCE

4°

MITER LOCK

HANDLE

MITER

SCALE

/

assembly and alignment

ASSEMBLY AND ALIGNMENT

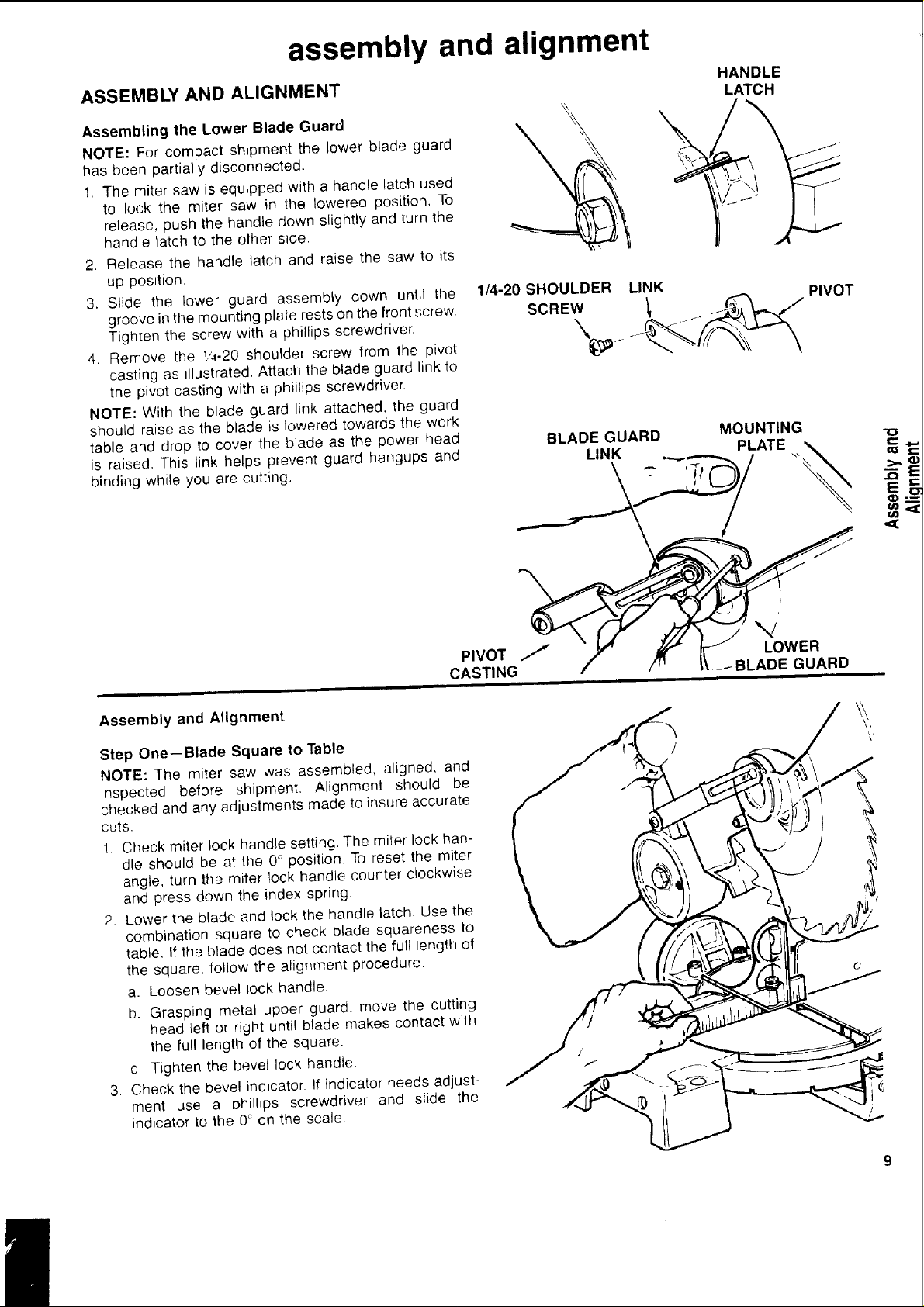

Assembling the Lower Blade Guard

NOTE: For compact shipment the lower blade guard

has been partially disconnected.

1. The miter saw is equipped with a handle latch used

to lock the miter saw in the lowered position. To

release, push the handle down slightly and turn the

handle latch to the other side.

2, Release the handle iatch and raise the saw to its

up position.

3. Slide the lower guard assembly down until the

groove in the mounting plate rests onthe front screw.

Tighten the screw with a phillips screwdriver,

4. Remove the v4.20 shoulder screw from the pivot

casting as illustrated, Attach the blade guard link to

the pivot casting with a phillips screwdriver.

NOTE: With the blade guard link attached, the guard

should raise as the blade is lowered towards the work

table and drop to cover the blade as the power head

is raised. This link helps prevent guard hangups and LINK ,--.-._.--,._ PLATE -.-

\

1/4-20 SHOULDER LINK

SCRE_;_, ____ PIVOT

BLADE GUARD

HANDLE

LATCH

MOUNTING

p.

8.'.'

Assembly and Alignment

Step One--Blade Square to Table

NOTE: The miter saw was assembled, aligned, and

inspected before shipment. Alignment should be

checked and any adjustments made to insure accurate

cuts.

1. Check miter lock handle setting, The miter lock han-

dle should be at the 0° position. To reset the miter

angle, turn the miter lock handle counter clockwise

and press down the index spring.

2. Lower the blade and lock the handle latch. Use the

combination square to check blade squareness to

table. If the blade does not contact the full length of

the square, follow the alignment procedure.

a. Loosen bevel lock handle.

b. Grasping metal upper guard, move the cutting

head left or right until blade makes contact with

the full length of the square.

c. Tighten the bevel IocX handle.

3, Check the bevel indicator. If indicator needs adjust-

ment use a phi/lips screwdriver and slide the

indicator to the 0° on the scale.

.,vo. Y--" .ow .

CASTING f /71 _JBLADE GUARD

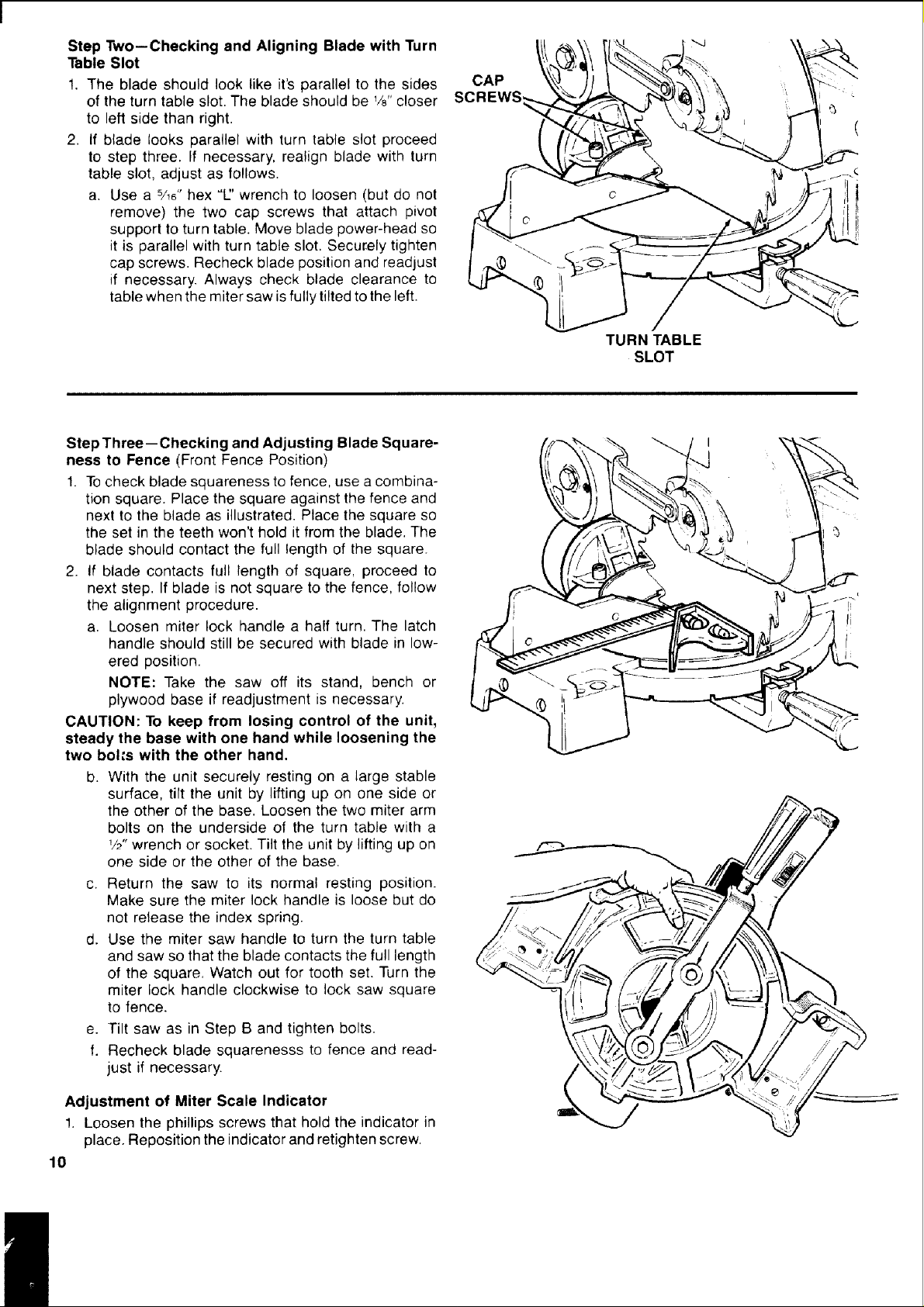

Step Two--Checking and Aligning Blade with Turn

Table Slot

1. The blade should look like it's parallel to the sides

of the turn table slot. The blade should be W' closer

to left side than right.

2. If blade looks parallel with turn table slot proceed

to step three. If necessary, realign blade with turn

table slot, adjust as follows.

a. Use a 5/16"hex "U' wrench to loosen (but do not

remove) the two cap screws that attach pivot

support to turn table. Move blade power-head so

it is parallel with turn table slot. Securely tighten

cap screws. Recheck blade position and readjust

if necessary. Always check blade clearance to

table when the miter saw isfully tilted to the left.

Step Three-- Checking and Adjusting Blade Square-

ness to Fence (Front Fence Position)

1. Tocheck blade squareness to fence, use a combina-

tion square. Place the square against the fence and

next to the blade as illustrated. Place the square so

the set in the teeth won't hold it from the blade. The

blade should contact the full length of the square.

2. If blade contacts full length of square, proceed to

next step. If blade is not square to the fence, follow

the alignment procedure.

a. Loosen miter lock handle a half turn. The latch

handle should still be secured with blade in low-

ered position.

NOTE: Take the saw off its stand, bench or

plywood base if readjustment is necessary.

CAUTION: To keep from losing control of the unit,

steady the base with one hand while loosening the

two bolt.s with the other hand.

b. With the unit securely resting on a large stable

surface, tilt the unit by lifting up on one side or

the other of the base. Loosen the two miter arm

bolts on the underside of the turn table with a

W' wrench or socket. Tilt the unit by lifting up on

one side or the other of the base.

c. Return the saw to its normal resting position.

Make sure the miter lock handle is loose but do

not release the index spring.

d. Use the miter saw handle to turn the turn table

and saw so that the blade contacts the full length

of the square, Watch out for tooth set. Turn the

miter lock handle clockwise to lock saw square

to fence.

e. Tilt saw as in Step B and tighten bolts.

f. Recheck blade squarenesss to fence and read-

just if necessary.

CAP

TURN TABLE

SLOT

/

Adjustment of Miter Scale Indicator

1. Loosen the phillips screws that hold the indicator in

place. Reposition the indicator and retighten screw.

10

Loading...

Loading...