Craftsman 113232240 Owner’s Manual

f Save This Manual -_

For Future Reference

ModeJ No.

113,232240

Jointer/Planer

with Legs and Motor

Serial

Number

Model and serial numbers

may be found on the back of

the jointer base.

You should record both model

and serial number in a safe

place for future use.

YOU

SAFETY

READ ALL

INSTRUCTIONS

CAREFULLY

Sears, Roebuck and Co., Hoffman Estates, IL. 60179 U.S.A.

Part No, SP5971

CONTRACTOR ES

6-1/8 I

JOmNTEPJPLANER

• assembly

. operating

• repair parts

J

Printed inTaiwar_

!:i! !ii!i i¸I!!ii/! i ill! !

H

YEAR WARRANTY ON CRAFTSMAN STATIONARY TOOL

ie toa defect in material or workmanship within one year from the date

purchasei CONTACT THE NEAREST SEARS SERVICE CENTER iN THE UNITED STATES and

: Sears will repair it, free of charge,

This warranty applies only while this prodUct is in the United States.

this jointer/planer is used for commercial or rental purposes, this warranty will apply for ninety

days from the date of purchases.

This warranty gives you specific legal rights, and you may also have other rights which vary from

state to statei

Sears, Roebuck and Co., D/817 WA Hoffman Estates, IL 60179

Safety instructions For Jointer/Planer ....

Safety is a combination of common sense, staying alert and knowing how your jointer/planer works. Read this manual

to understand this tool.

J ±J ..... -==-..-Juu--=__ i_ _ iiiii, i

Safety Signal Words WARNING: means if the safety information is not followed

DANGER: means if the safety information is not followed someone could be seriously injured or killed.

someone will be seriously injured or killed. CAUTION: means if the safety information is not followed

someone may be injured.

Before Using the Jointer/Pianer

WARNING: To avoid mistakes that could cause

serious, permanent injury, do not plug the jointer/

planer in until the following steps have been satis-

factorily completed.

Know and Understand the JointertPlaner

* Completely assemble and align jointer/planer.

. Learn the use and function of the ON-OFF switch, _.

fence slide locking handle, cutter guard; depth of cut

hand wheel. Iocks and stops, fence bevel lock handle,

outfeed table, infeed table and hold-down/push-blocks. <_

• Review and understand all safety instruCtions and

operating procedures in this manual.

• Review the maintenance methods for this jointed

planer.

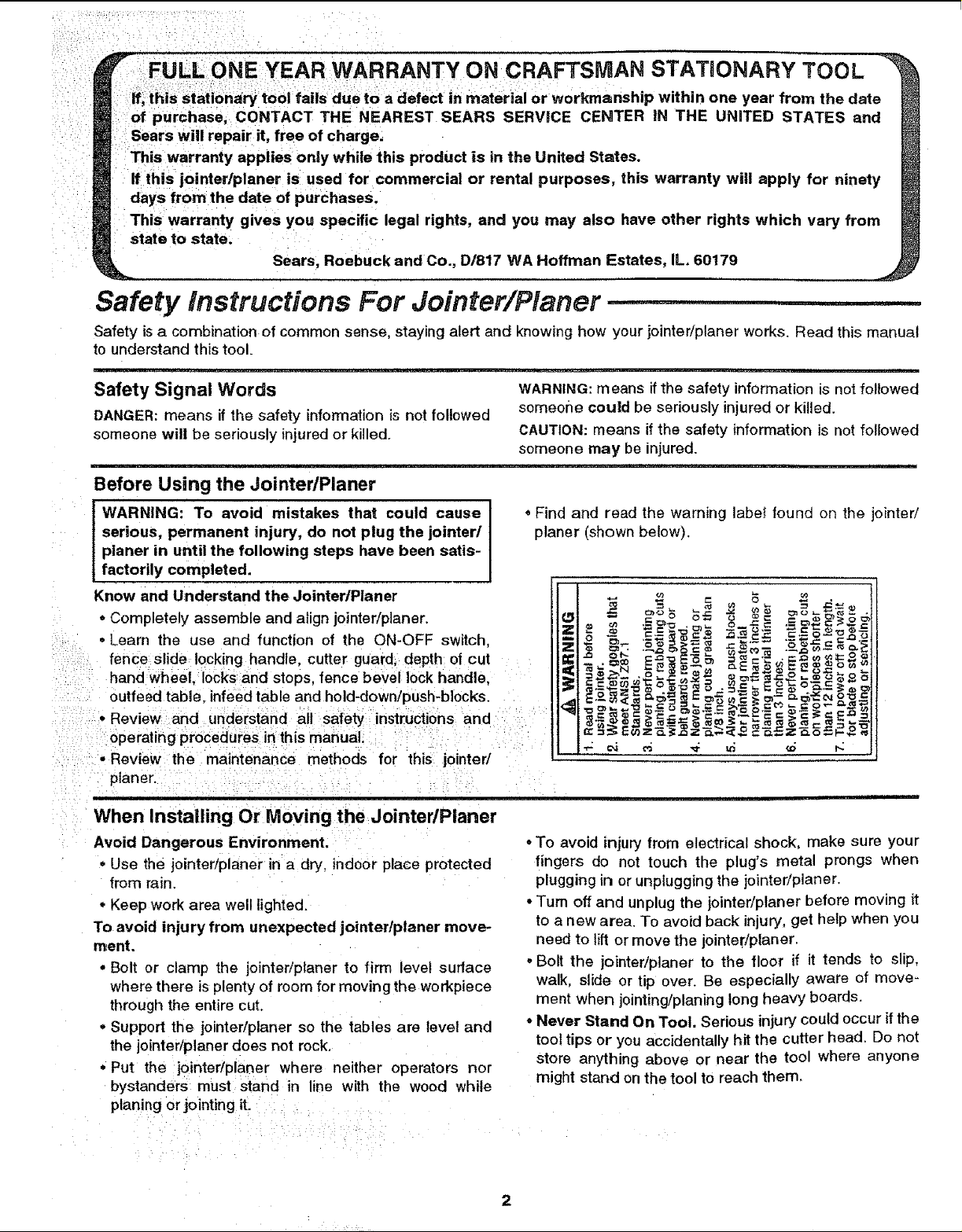

, Find and read the warning label found on the jointeri

planer (shown below).

Z

'.....

, u .......

When Installing Or Moving the Jointer/Pianer

Avoid Dangerous Environment.

• Use the jointer/planer in a dry, indoor place protected

from rain

° Keep work area well lighted.

To avoid injury from unexpected jointer/planer move-

ment.

• Bolt or clamp the jointeriplaner to firm level surlace

where there is plenty of room for moving the workpiece

through the entire cut.

- Support the jointer/planer so the tables are level and

the jointer/planer does not rock.

• Put the iointer/planer where neither operators nor

bystanders must stand in line with the wood while

planing or jointing it.

-To avoid injury from electrical shock, make sure your

fingers do not touch the plug's metal prongs when

plugging in or unplugg{ng the jointer/planer.

• Turn off and unplug the jointer/planer before moving it

to a new area. To avoid back injury, get help when you

need to lift or move the jointedplaner.

-Bolt the jointer/planer to the floor if it tends to slip,

walk slide or tip over. Be especially aware of move-

ment when jointing/planing long heavy boards.

° Never Stand On Tool. Serious injury could occur if the

tool tips or you accidentally hit the cutter head. Do not

store anything above or near the tool where anyone

might stand on the tool to reach them,

2

Before Each Use

Inspect your jointer/ptaner.

WARNING: The 2-1/2 inch jointer/planer pulley and

the 3-112 inch motor pulley furnished will run the

cutter head at about 5000 RPM when used with a

3450 RPM motor. Use of different types of pulleys

or motors will change this speed and could cause

jamming, binding, kickback, thrown knives or

other dangers,

. To avoid injury from accidental starting, turn the switch

off, unplug the saw, and remove the switch key before

moving the cutter head guard, changing the blades,

changing the setup, or adjusting anything.

• Check for alignment of moving parts, binding of mov-

ing parts, breakage of parts, unit stability, and any

other conditions that may affect the way the jointed

planer works.

• Ifany part is missing, bent or broken in any way, or any

electrical part does not work property, turn the jointed

planer off and unplug the jointedplaner.

= Replace damaged, missing or failed parts before using

the jointer/planer again.

• Make sure the cutter guard works properly. With the

........................................................ ii i, iii iiiii

switch off and key removed, pull the cutter guard open

and let go. tf the guard doesn't smoothly swing closed,

contact Sears Service Department.

• Make sure the cutter head turns in the right direction.

The top should move toward the infeed table. If the

cutter head turns the wrong direction, contact Sears

Service Department.

• Keep Jointer/Planer interior free of wood chips and

dust buildup around motor and switch box.

• Keep knives sharp. Dull or nicked knives tend to

"pound" and chew at the'wood, causing kickbacks.

° To avoid injury from unsafe accessories, use only rec-

ommended accessories.

Use Recommended Accessories.

° To avoid injury from unsafe accessories, use only rec-

ommended accessories.

Consult the owners manual for recommended accessories.

• Follow the instructionsthat accompany the accessories.

WARNING: Use only accessories recommended

for this jointer/planer. (Using other accessories

I may be dangerous.)

To Avoid Injury From Jams, Slips Or Thrown Pieces (Kickbacks Or Throwbacks)

° Use this jointer/planer to cut oniy wood.

• Plan your hand placement so your fingers will not be

anywhere a sudden slip could cause them to slide or

fall into the cutter head. When using onty one hold-

down/push-block to feed the wood, do not put your

other hand on the jointer/planer, workpiece, or hold-

down/push-block.

° To avoid injury from thrown pieces, make sure the

knives are sharp, properly installed and the cutter

knives wedge screws are tight.

• Make sure the clamps and {ocks are tight and there is

not excessive play in any parts.

° Adjust the depth of cut to between 1/32 and 1/16 of an

inch for best results in most operations. A deep cut

makes feeding the wood harder and can cause the

wood to kickback. To be sure you will make a depth of

i ii iiii

cut you planned, always lower the infeed table slightly

farther than you wanted then, raise the table to the

desired depth.

oUse The Right Tool. Don't force toot or attachment to

do a job it was not designed for.

Inspect your work area.

° Keep work area clean.

• Cluttered areas and benches invite accidents.

• Floor must not be slippery from wax or sawdust.

° To avoid bums or other fire damage, never use the

jointer/planer near flammable liquids, vapors or gases.

=Before using the jointer/ptaner, clear the table of aH

objects not needed to feed the workpiece.

• To avoid injury, don't do any layout, assembly, or

setup work on the jointer/ptaner bed.

Plan Ahead To Protect Your Eyes, Hands, Face and Ears

Avoid Accidental Starting.

oMake sure switch is "OFF" before plugging jointed

planer into a power outlet.

Dress for safety.

• Do not wear loose clothing, gloves, neckties or jewelry

(r_ngs,wrist watches), They can get caught and draw

you into moving parts,

• Wear nonslip footwear.

• Tie back long hair.

=Roll long sleeves above the elbow.

• Noise levels vary widely. To avoid possible hearing

damage, wear ear plugs or muffs when using jointed

planer for hours at a time.

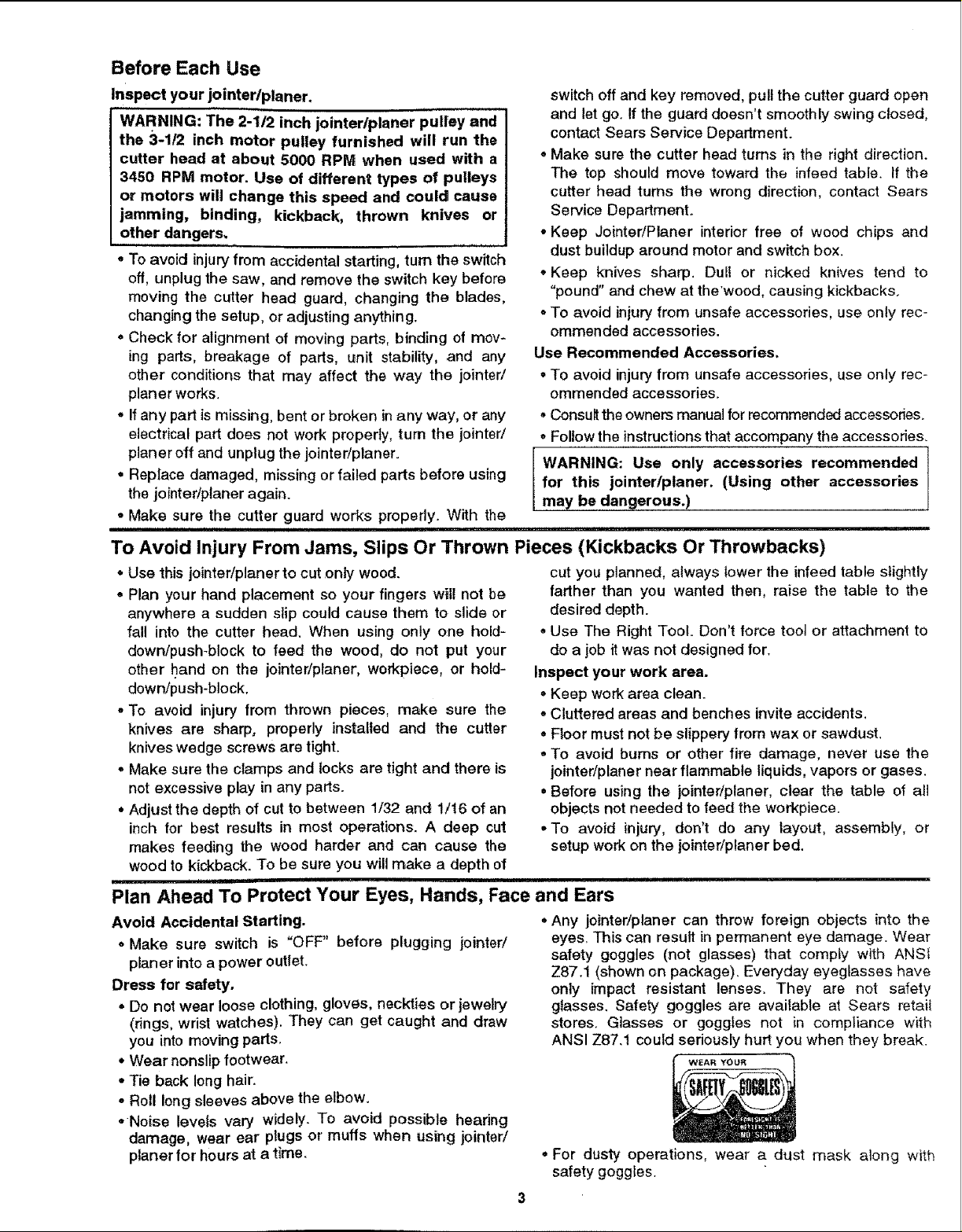

• Any jointer/planer can throw foreign objects into the

eyes. This can result in permanent eye damage. Wear

safety goggles (not glasses) that comply with ANSI

Z87,1 (shown on package). Everyday eyeglasses have

only impact resistant lenses. They are not safety

glasses. Safety goggles are available at Sears retail

stores. Glasses or goggles not in compliance with

ANSI Z87.1 could seriously hurt you when they break.

WEAR YOUR

• For dusty operations, wear a dust mask along with

safety goggles.

Safety tnstructions For Jointer/Planer (contin,

Inspect your wotkpiece.

• Make sure there are no nails or foreign objects in the

part of the workpiece to be cut.

Plan your cut.

° Small or thin workpieces can kickback when they tip

over on the tables or into the cutter head. To avoid

head contact or workpiece kickback:

- Never joint, plane or bevel workpieces shorter than

12 inches.

° When jointing, beveling or rabbeting:

- Never joint or bevel workpieces less than 3/4 inch

wide or 1/4 inch thick.

- Always use the hold-down/push-blocks when jointing

or beveling wood narrower than 3 inches.

-When rabbeting, always make cuts in 1/8" incre-

ments or less.

o When planing:

- Never plane wood thinner than 1/2 inch.

-Always use hold-down/push-blocks when planing

wood thinner than 3 inches.

Whenever JointedPlaner is Running:

WARNING: Don't allow familiarity (gained from fre-

quent use of your jointerlplaner) cause a careless

mistake. Always remember that a careless fraction

of a second is enough to cause a severe injury.

- Before actually cutting with the jointer/planer, let it run

for a while. If it makes an unfamiliar noise or vibrates a

lot, stop immediately. Turn the jointer/planer off.

Unplug the jointedplaner. Do not restart until finding

oKeep atl visitors a safe distance from the jointedplaner.

- Make Sure bystanders are clear of the jointer/planer

and workpiece.

- Never cut Freehand, Guide your workpiece solidly

against the fence and table top.

- Make sure there's no debris between the workpiece

and its supports.

Use extra caution with large, very small or awkward

workpieces.

• Use extr_ supports (tables, saw horses, blocks, etc.)

for any workpiece large enough to tip when not held

down to the table top. Never use another person as

additional support or to help feed, support or pull the

workpiece.

- Never cut more than one workpiece at a time.

o Never turn your jointer/planer "ON" before clearing

everything except the workpiece and related support

devices offthe table.

oBefore trying a new or little used operation, carefully

plan your hand placement. Make sure you have proper

hold-down/push-blocks, jigs, fixtures, steps, etc. ready

to use.

Don't Force Tool.

° Let the cutter head reach full speed before cutting.

* Feed the workpiece into the jointer/planer only fast

enough to let the tool cut without bogging down or

binding.

Before freeing jammed material.

, Turn switch "OFF'.

oWait for all moving parts to stop.

=Unplug the jointer/planer.

- Check knives for sharpness and nicks before starting

again.

Before Leaving the Jointer/Planer.

=Turnthe jointer/planer off. oMake workshop child-proof. Lock the shop. Disconnect

• Wait for knives to come to a complete stop. master switches. Remove the yellow switch key. Store

- Unplug the jointedplaner, the tool.

Glossary of Terms for Woodworking ........

Bed

The combination of infeed and outfeed table surfaces

which support the workpiece during a cutting operation.

Bevel!Chamfer

Removing wood along the edge of a board to make that

edge straight, smooth and angled to the board face which

is against the fence.

Cutter Guard :

Spring loaded guardo_ ishie!d c0vering the cutter head.

it away from children and others not qualified to use

n

Cutter Head

The cutter head is a rotating piece with three adjustable

knives. The cutter head removes material from the work-

piece

Depth of cut

Aterm used to indicate how deep into the workpiece the

cutter knives will cut.

Fence

The fence is attached to the jointer/planer base. The

fence helps support and guide the workpiece as it is

pushed across the cutter head.

Freehand

Using the tool without holding the workpiece firmly

against the fence and table. This can let the workpiece

twist and kick back and must never be attempted.

Gum

A sticky, sap based residue from wood products.

Hold.Down/Push-Blocks

They are required for your own safety. They are used to

hold your wo_pieces against the table and fence when

planing, rabbeting or jointing.

infeed Table

The section of the jointer bed upon which the workpiece

is placed before being pushed into the cutter head.

Infeed table height is adjustable which allows the opera-

tor to select the depth of cut.

Jointing

The removal of wood along the edge of a board so as to

make that edge straight, smooth and square to the board

face which is against the fence.

Kickback

An uncontrolled grabbing and throwing of the workpiece

back toward the operator by the rotating cutter head.

Leading End

The end of the workpiece which is pushed into the cutter

head first.

Ouffeed Table

The section of a jointer bed which supports the workpiece

after itpasses over the cutter head.

Planing

Removing wood from the widest surface or face of a

board so as to make it flat and smooth.

Rabbet

A notch cut into the edge ofworkpiece.

Resin

A sticky, sap based substance that has hardened.

Revolutions Per Minute (RPM)

The number of turns completed by a spinning object in

one minute.

Throw-Back

Throwing of pieces in a manner similar to a kickback.

Trailing End

The workpiece end last cut by the knives.

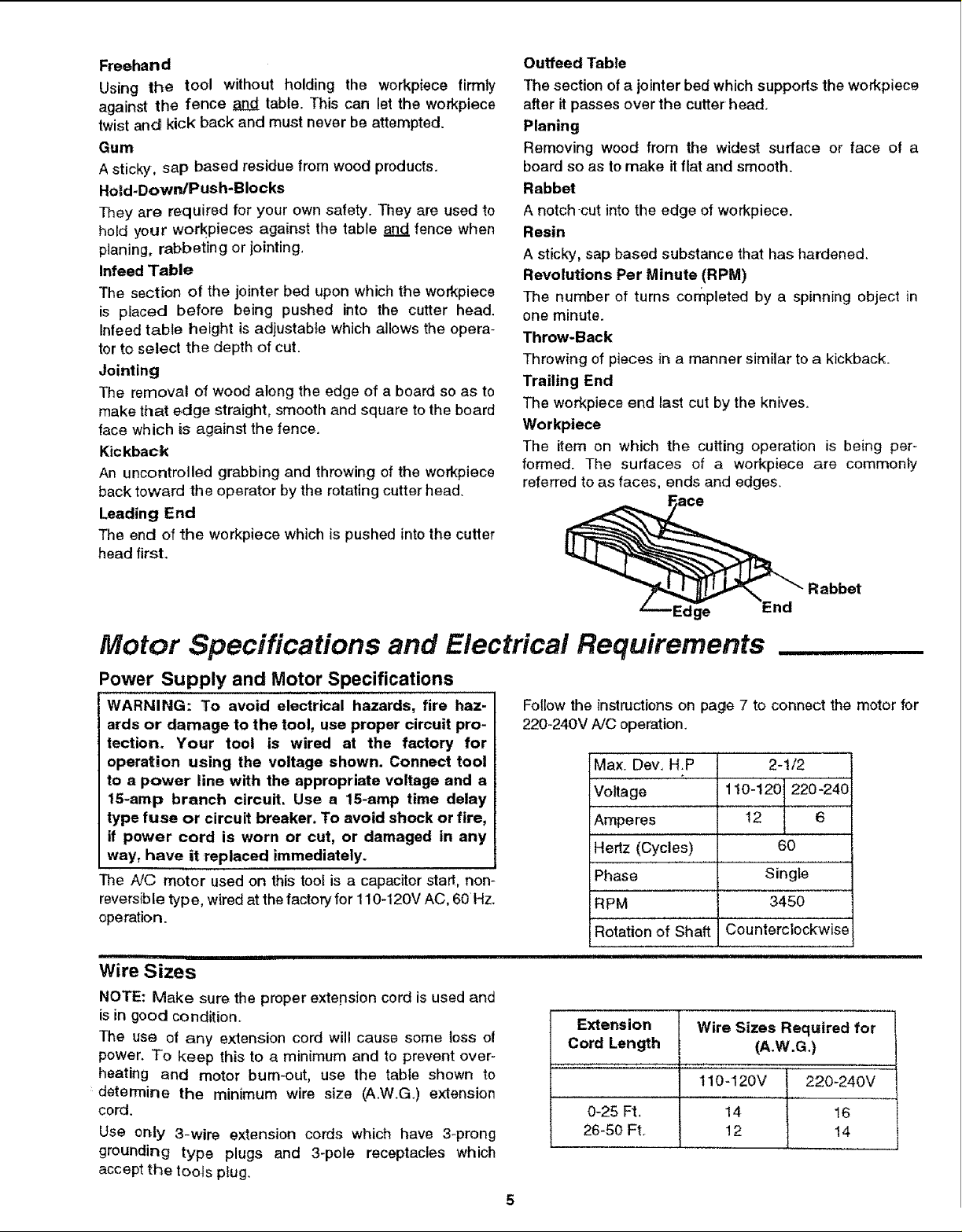

Workpiece

The item on which the cutting operation is being per-

formed. The surfaces of a workpiece are commonly

referred to as faces, ends and edges.

'Edge End

Motor Specifications and Electrical Requirements

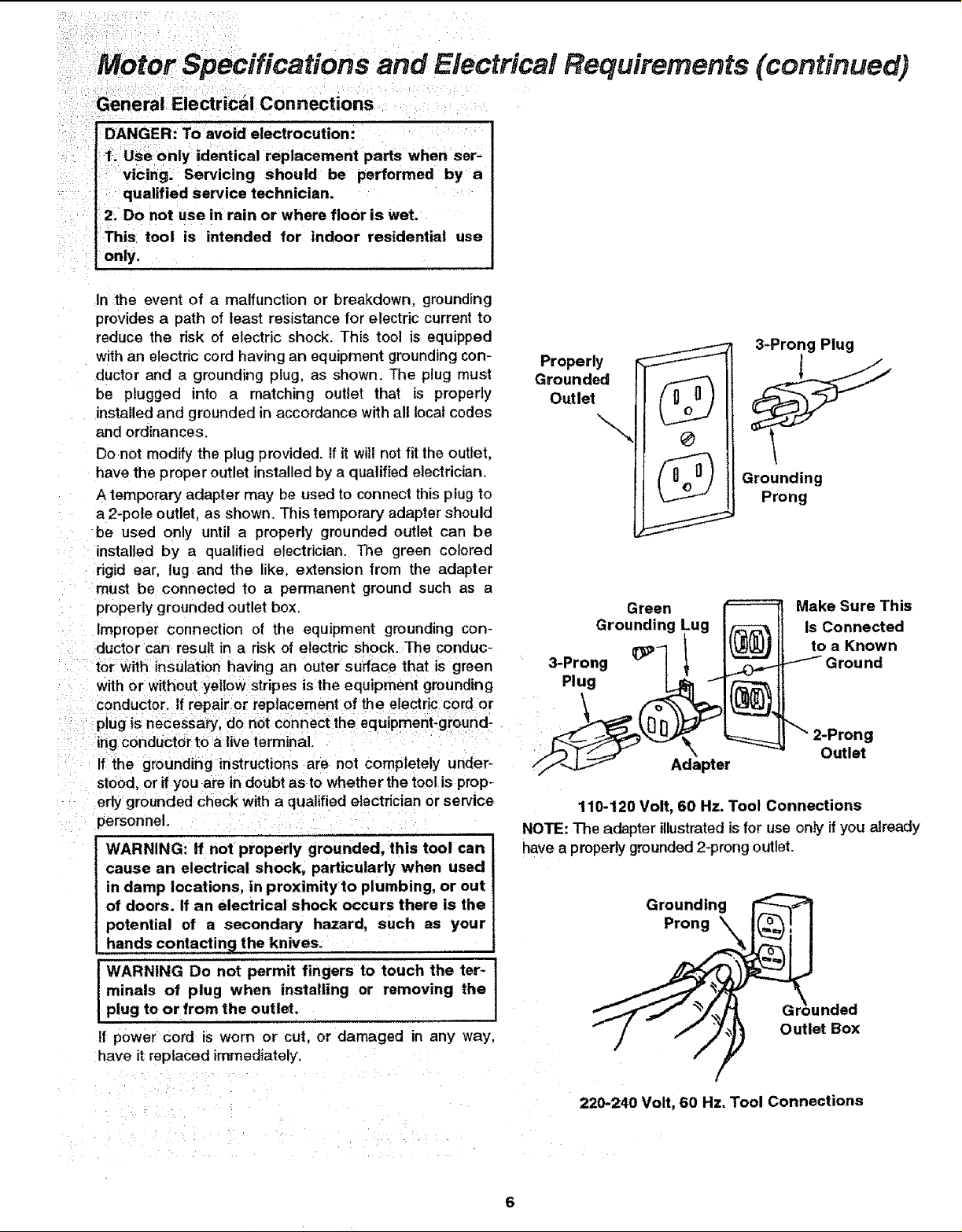

Power Supply and Motor Specifications

WARNING: To avoid electrical hazards, fire haz-

ards or damage to the tool, use proper circuit pro-

tection. Your tool is wired at the factory for

operation using the voltage shown. Connect tool

to a power line with the appropriate voltage and a

15-amp branch circuit. Use a 15-amp time delay

type fuse or circuit breaker. To avoid shock or fire,

if power cord is worn or cut, or damaged in any

way, have it replaced immediately.

The A!© motor used on this tool is a capacitor start, non-

reversible typ e, wired at the factory for 110-120V AC, 60 Hz.

operation.

ii !nllllH Ul

Wire Sizes

NOTE: Make sure the proper extepsion cord is used and

is in good condition.

The use ot any extension cord will cause some toss o!

power. To keep this to a minimum and to prevent over-

heating and motor bum-out, use the tabte shown to

determine the minimum wire size (A.W.G.) extension

cord.

Use or_ty 3-wire extension cords which have 3_prong

grounding type plugs and 3-pole receptacles which

accept the tools ptug.

Follow the instructions on page 7 to connect the motor for

220-240V A/C operation.

Max. Dev, H.P

Voltage

Amperes

Hertz (Cycles)

Phase

110"120 220-24-0

RPM

Rotation of Shaft Counterclockwise

Extension

Wire Sizes Required for |

Cord Length (A.W.G.) /

........... , .......,.......... ,.... !

110-120V 220_240V

0-25 Ft, 14 16

26-50 Ft. 12 14

2-1/2

12 6

60

Single

3450

q

Motor Speclfic.tions and Eiectr, cat Requirements (continued)

i : i DANGER: To aVoid electrocution: _ ;_

; I U_e only identical replacement parts when ser-

vicing! Servicing should be performed by a

qualified service technician.

2i Do not use in rain or where floor is wet.

This tool is intended for indoor residential use

;: :only.

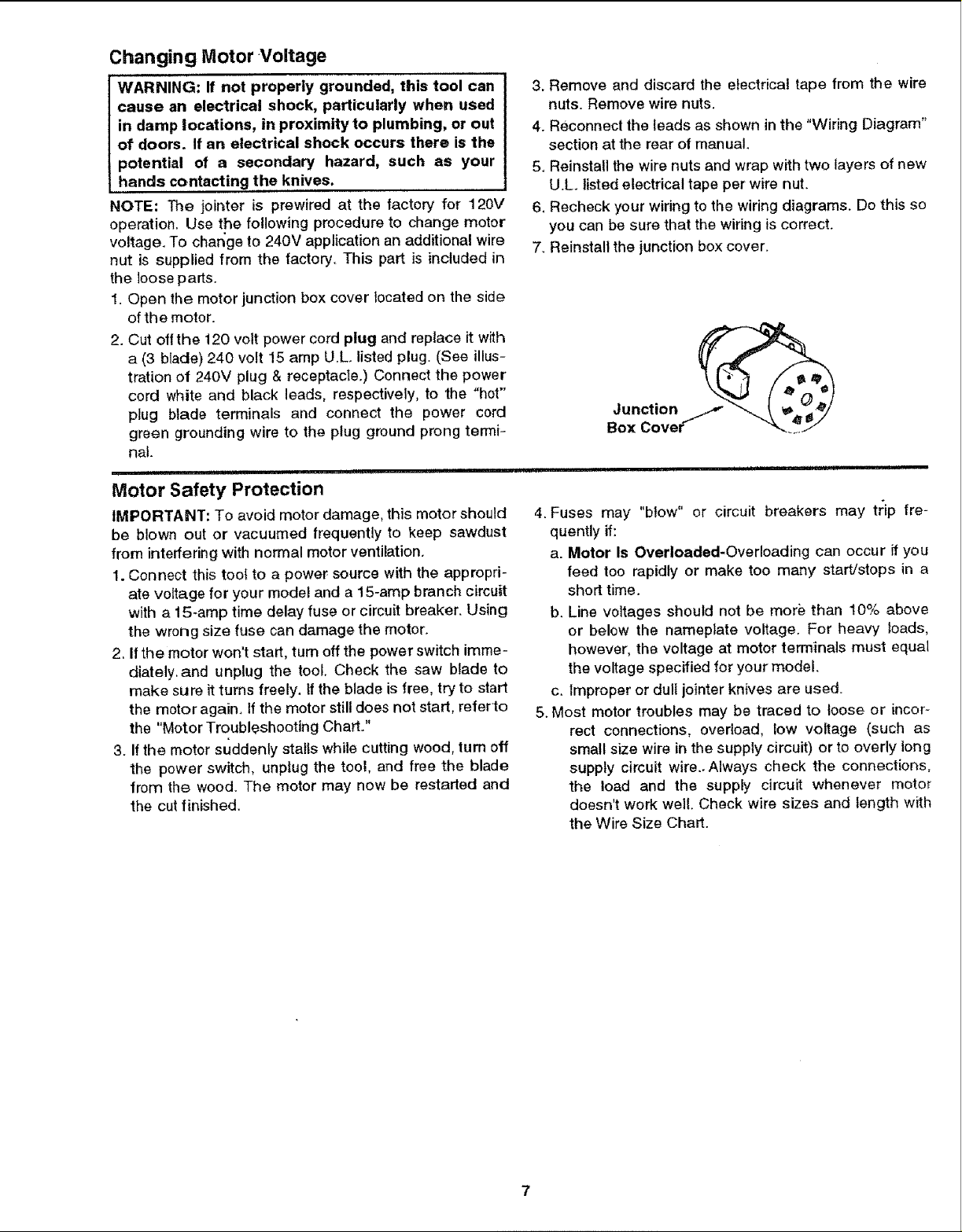

,In _he event of a malfunction or breakdown, grounding

provides a path of least resistance for electric current to

reduce the risk of electric shock. This tool is equipped

with an electric cord having an equipment grounding con-

ductor and a grounding plug, as shown. The plug must

be plugged into a matching outlet that is properly

installed and grounded in accordance with all local codes

and ordinances.

Donot modify the plug provided. If it wittnot fit the outlet,

have the proper outlet installed by a qualified electrician.

A temporary adapter may be used to connect this plug to

a 2-pole outlet, as shown. This temporary adapter should

be used only until a properly grounded outlet can be

installed by a qualified electrician. The green colored

rigid ear, lug land the like, extension from the adapter

must be connected to a permanent ground such as a

properly grounded outlet box.

Improper connection of the equipment grounding con- Grounding ug I__ Is Connected

duct0r Can result in a risk Of electric shock. The conduc- €l"l_ _ to a Known

:i tbr:With insulation having an outer surface that is green 3-Prong v | _ _ Ground

:: Withor without yelloWstripes isthe equipment grounding Plug C ll "_"

: C0nduct0i'. if repairor replacement of the electric cord or \ /'_ _ _,_]_g.J_

plug _s necessary; do not connect the equlpment_ground- _._'_" !_ _ ,]

Properly r_

Green _ Make Sure This

3-Prong Plug

Grounding

Prong

2-Prong

:: If;the grounding instructions are not completely under- ff'_ Adapter Outlet

sto0d, or if you are in doubt as to whether the tool is prop-

erly groundedbheck with a qualified electrician Or service

personnel. : :_

.... , ,,,,

WARNING: If not properly grounded, this tool can

cause an electrical shock_ particularly when used

in damp locations, in proximity to plumbing, or out

of doors. If an electrical shock occurs there is the

potential of a secondary hazard, such as your

hands contacting the knives.

NOTE: The adapter illustratedis for use only if you already

havea propedy grounded2-prong outlet.

110-120 Volt, 60 Hz. Tool Connections

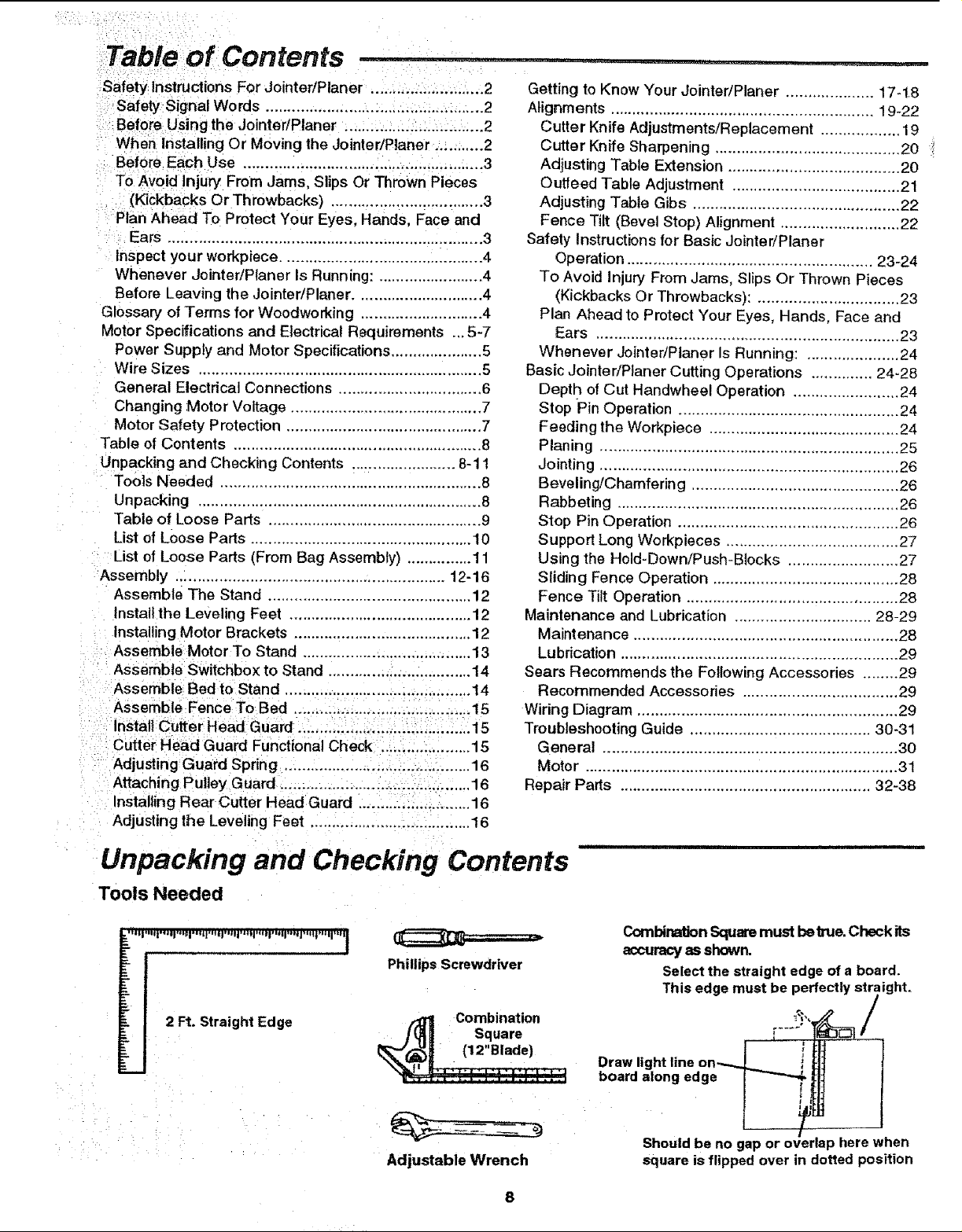

Grounding

Prong

WARNING Do not permit fingers to touch the ter-

minals of plug when installing or removing the

plug to or from the outlet.

If power cord is worn or cut, or damaged in any way,

have it replaced immediately.

nded

Outlet Box

220-240 Volt, 60 Hz. Tool Connections

Changing Motor Voltage

WARNING: If not properly grounded, this tool can

cause an electrical shock, particularly when used

in damp locations, in proximity to plumbing, or out

of doors. If an electrical shock occurs there is the

potential of a secondary hazard, such as your

hands contacting the knives.

NOTE: The joir_ter is prewired at the factory for 120V

operation. Use the following procedure to change motor

voltage. To char_ge to 240V application an additional wire

nut is supplied from the factory. This part is included in

the loose pads.

1. Open the motor junction box cover located on the side

of the motor.

2. Cut off the 120 volt power cord plug and replace it with

a (3 blade) 240 volt 15 amp U.L. listed plug. (See illus-

tration of 240V plug & receptacle.) Connect the power

cord white and black leads, respectively, to the "hot"

plug blade terminals and connect the power cord

green grounding wire to the plug ground prong termi-

nal.

,, _ ii i i,!l i,

Motor Safety Protection

IMPORTANT: To avoid motor damage, this motor should

be blown out or vacuumed frequently to keep sawdust

from interfering with normal motor ventilation.

1. Connect this toot to a power source with the appropri-

ate voltage for your model and a 15-amp branch circuit

with a 15-amp time delay fuse or circuit breaker. Using

the wrong size fuse can damage the motor.

2. If the motor won't start, turn off the power switch imme-

diately,and unplug the tool. Check the saw blade to

make sure it turns freely. If the blade is free, try to start

the motor again, If the motor still does not start, referto

the "Motor Troubleshooting Chart."

3. If the motor suddenly stalls while cutting wood, turn off

the power switch, unplug the tool, and free the blade

from the wood. The motor may now be restarted and

the cut finished.

3. Remove and discard the electrical tape from the wire

nuts. Remove wire nuts.

4. Reconnect the leads as shown in the "Wiring Diagram"

section at the rear of manual.

5, Reinstall the wire nuts and wrap with two layers of new

U.L. listed electrical tape per wire nut.

6, Recheck your wiring to the wiring diagrams. Do this so

you can be sure that the wiring is correct.

7. Reinstall the junction box cover.

JoU:Cctio_i_

4. Fuses may "blow" or circuit breakers may trip fre-

quently it:

a. Motor Is Overloaded-Overloading can occur if you

feed too rapidly or make too many start/stops in a

short time.

b. Line voltages should not be more than 10% above

or below the nameplate voltage. For heavy loads,

however, the voltage at motor terminals must equal

the voltage specified for your model.

c. Improper or dull jointer knives are used.

5. Most motor troubles may be traced to loose or incor-

rect connections, overload, low voltage (such as

small size wire in the supply circuit) or to overly tong

supply circuit wire.. Always check the connections,

the load and the supply circuit whenever motor

doesn't work well. Check wire sizes and length with

the Wire Size Chart.

7

Table of Contents

Safety Instructions For Jointer/Planer .......................... 2

Safety Signal Words ....................... :................... _......2

Before Using the JointedPlaner ................. ;.............. 2

When Installing Or Moving the Jointer/Planer. .......... 2

Before Each Use ....................................................... 3

: To Avoid Injury' From Jams, Slips Or Thrown Pieces

• (Kickbacks Or Throwbacks) ................................... 3

Plan Ahead To Protect Your Eyes, Hands, Face and

Ears ........................................................................ 3

Inspect your workpiece .............................................. 4

Whenever Jointer/Planer Is Running: ........................ 4

Before Leaving the Jointer/Planer ............................ 4

Glossary of Terms for Woodworking ........................... 4

Motor Specifications and Electrical Requirements ...5-7

Power Supply and Motor Specifications ..................... 5

Wire Sizes ................................................................. 5

General Electrical Connections ................................. 6

Changing Motor Voltage ............................................ 7

Motor Safety Protection ............................................. 7

Table of Contents ......................................................... 8

Unpacking and Checking Contents ....................... 8-11

Tools Needed ............................................................ 8

Unpacking ................................................................. 8

Table of Loose Parts ................................................. 9

List of Loose Parts ................................................... 10

List of Loose Parts (From Bag Assembly) ............... 11

Assembly .............................................................. 12-16

Assemble The Stand ............................................... 12

Install the Leveling Feet .......................................... 12

Installing Motor Brackets ......................................... 12

Assemble Motor To Stand ....................................... 13

Assemble Switchbox to Stand ................................. 14

Assemble Bed to Stand ........................................... 14

Assemble Fence To Bed ......................................... 15

Install Cutter Head Guard ........................................ 15

Cutter Head Guard Functional Check ..................... 15

Adjusting Guard Spring .......................................... 16

Attaching Pulley Guard ............................................ 16

Installing Rear Cutter Head Guard .......................... 16

Adjusting the Leveling Feet ..................................... 16

Unpacking and Checking Contents

Tools Needed

Getting to Know Your JointedPlaner .................... 17-18

Alignments ............................................................ 19-22

Safety Instructionsfor Basic Jointer/Planer

Basic Jointer/Ptaner Cutting Operations .............. 24-28

Maintenance and Lubrication ............................... 28-29

Sears Recommends the Following Accessories ........ 29

Wiring Diagram ........................................................... 29

Troubleshooting Guide ......................................... 30-31

Repair Parts ......................................................... 32-38

Cutter Knife Adjustments/Replacement .................. 19

Cutter Knife Sharpening .......................................... 20

Adjusting Table Extension ....................................... 20

Outfeed Table Adjustment ...................................... 21

Adjusting Table Gibs ............................................... 22

Fence Tilt (Bevel Stop) Alignment ........................... 22

Operation ........................................................ 23-24

To Avoid Injury From Jams, Slips Or Thrown Pieces

(Kickbacks Or Throwbacks): ................................ 23

Plan Ahead to Protect Your Eyes, Hands, Face and

Ears ..................................................................... 23

Whenever JointedPtaner Is Running: ..................... 24

Depth of Cut Handwhee! Operation ........................ 24

Stop Pin Operation .................................................. 24

Feedin g the Workpiece ........................................... 24

Planing .................................................................... 25

Jointing .................................................................... 26

Beveling/Chamfering ............................................... 26

Rabbeting ................................................................ 26

Stop Pin Operation .................................................. 26

Support Long Workpieces ....................................... 27

Using the Hold-Down/Push-Blocks ......................... 27

Sliding Fence Operation .......................................... 28

Fence Tilt Operation ................................................ 28

Maintenance ............................................................ 28

Lubrication ............................................................... 29

Recommended Accessories ................................... 29

General ................................................................... 30

Motor ...................................................................... 31

...... i ,i ii

2 Ft. Straight Edge

Phillips Screwdriver

Combination

Square

Adjustable Wrench

CombinationSquaremust betrue. Check its

accuracyasshown.

Selectthe straight edge of a board.

erfectly straight.

This edge must be _, _/

.... t

Draw light line on---. _ i

board along edge _ I

t

Should be no gap or overlap here when

square is flipped over in dotted position

Unpacking

WARNING: To avoid injury from unexpected starl-

ing or electrical shock, do not plug the power cord

into a power source outlet during Unpacking, until

all assembly steps are complete, and you have

read and understand the safety and operating

instructions.

WARNING: Although compact, this tool is heavy.

To avoid back injury, get help whenever you have

to lift the tool.

Your jointer/planer is shipped complete in one carton and

includessteel legs,

1. Clear yourself a large work area. Remove the jointed

planer and parts from the carton. Lift-the tool at the

bottom of the base.

2. Place the tool on a secure, stationary work surface and

look it over carefully.

3. Separate all parts from packing materiels and check

each one with the "Table of Loose Parts" and the "List

of Loose Parts" to make certain all items are

accounted for before discarding any packing material.

If you are missing any parts, chect_ packing material for

those items.

WARNING: if any parts are missing, do not attempt

to assemble the jointerlplaner. Do not plug in the

power cord or turn the switch on until the missing

parts are obtained and are installed correctly.

4. Contact your Sears Service Center to get the missing

parts. Use the "Repair Parts" pages at the end of this

manual to identify the part number of the missing parts

after completing the "Unpacking and Checking Con-

tents section.

5. Remove the protective oil that is applied to all

unpainted sudaces. Use any ordinary household type

grease and spot remover,

I WARNING: To avoid fire or health hazard, never use t

. gasoline, naptha, or similar highly volatile solvents.

6_Apply coat of paste wax to the tables and fence.

7. Wipe al! parts thoroughly with a clean, dry cloth.

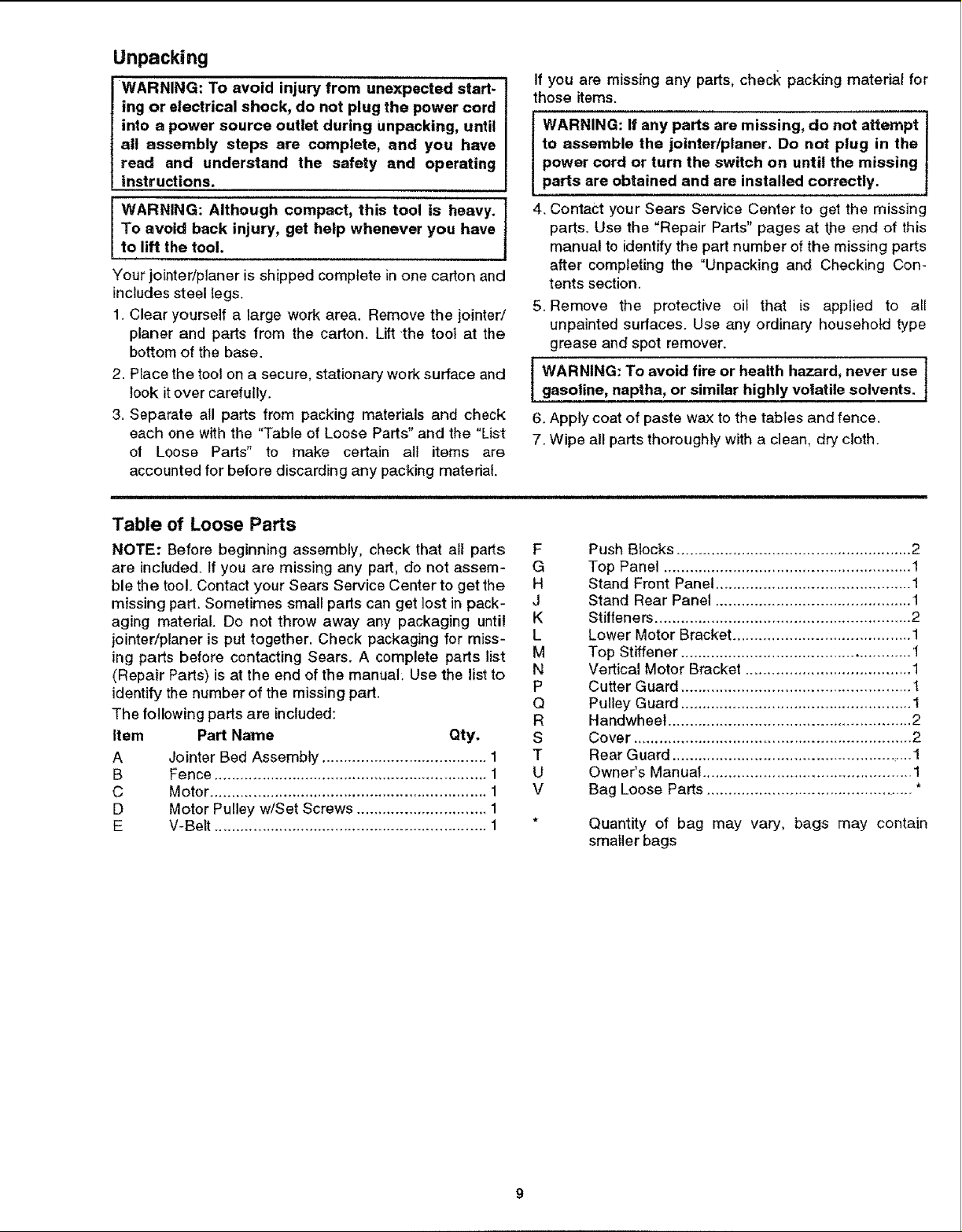

Table of Loose Parts

NOTE: Before beginning assembly, check that all parts F

are included. If you are missing any part, do not assem- G

ble the tool, Contact your Sears Service Center to get the H

missing part. Sometimes small parts can get lost in pack- J

aging material. Do not throw away any packaging until K

jointer/planer is put together. Check packaging for miss- L

ing parts before contacting Sears. A complete parts list M

(Repair Pads) is at the end of the manual: Use the list to N

identify the number of the missing part, P

The following parts are included: R

item Part Name Qty.

A Jointer Bed Assembly ...................................... 1

B Fence ............................................................... 1

C Motor ................................................................ 1

D Motor Pulley w/Set Screws .............................. 1

E V-Belt ............................................................... 1

Push Blocks ...................................................... 2

Top Panel ......................................................... 1

Stand Front Panel ............................................. 1

Stand Rear Panel ............................................. 1

Stiffeners ........................................................... 2

Lower Motor Bracket ......................................... 1

Top Stiffener ..................................................... 1

Vertical Motor Bracket ...................................... 1

Cutter Guard ..................................................... 1

Q

S

T

U

V

Pulley Guard ..................................................... 1

Handwheet ........................................................ 2

Cover ................................................................ 2

Rear Guard ........................................................ 1

Owner's Manual ................................................ 1

Bag Loose Parts ............................................... *

Quantity of bag may vary, bags may contain

smaller bags

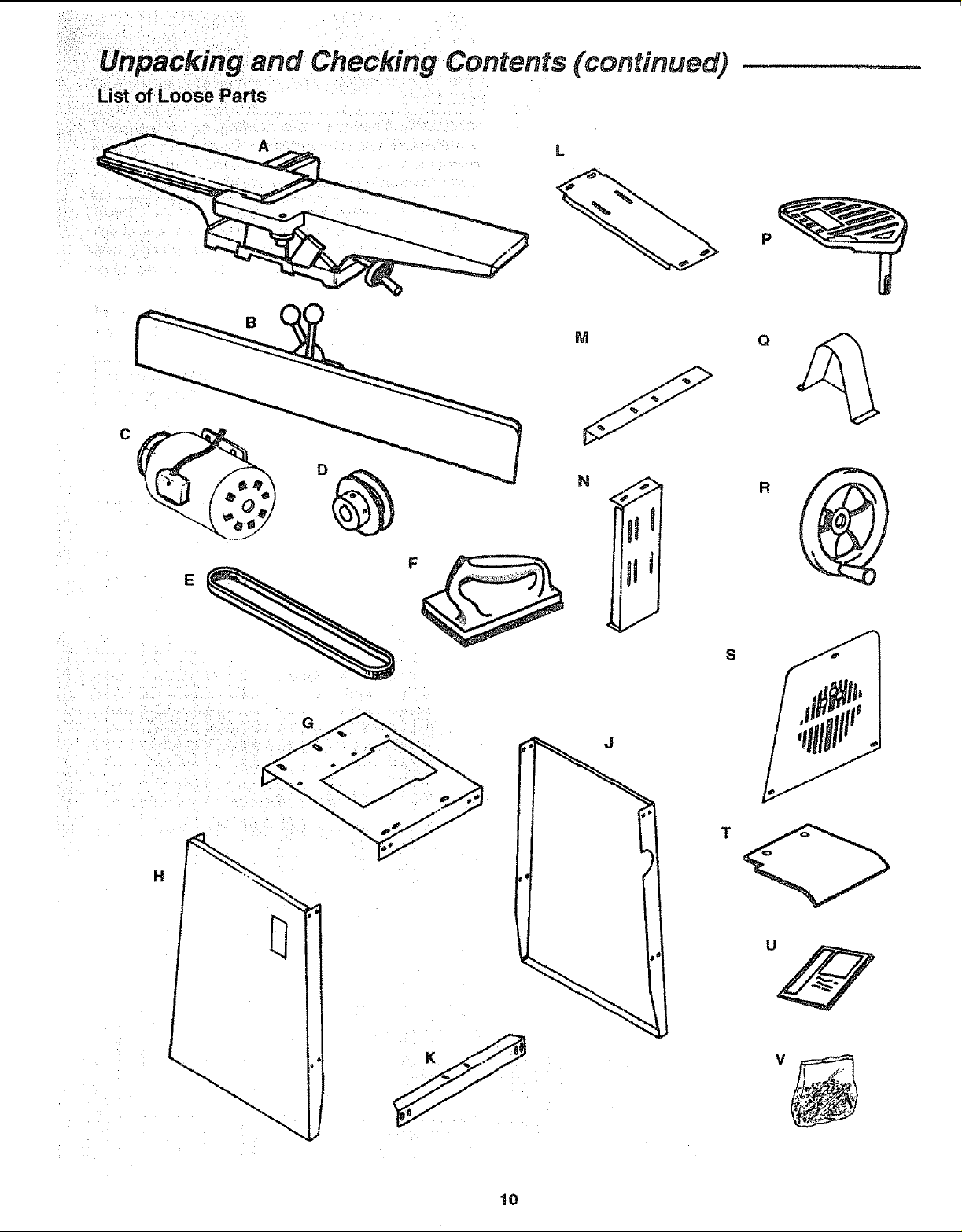

Unpacking and Checking =Contents Ccontinued) ....

List of Loose Parts

B

M Q

F

E

H

U

10

List of Loose Parts (From Bag Assembly)

D

Rod-Knife Gauge

3ramHex-LWrench

Wrench 8mm/lOmm

Wrench 12mm/14mm

Gauge-Knife (2)

Switch Key (t)

Leveling Feet (4)

Q @

External Washer (8)

Lockwasher #8 (2) 1/4"

Screw Pan Head (2) Screw Pan Head (8)

8-32 x 5/8 1/4-20 x 1/2

Retaining Ring (4)

@

Lock'washer (3)

318"

@

Hex Jam Nut (8)

3/8-16

Wire Nut

@

Washer (34)

13132"

©

Lockwasher (30)

5/16"

@

Nut Hex (30)

5116-18

Hex Head Bolt (3)

318-16 x 3/4

11

Carriage Bolt (30)

5/16-18 x 3/4"

i_:¸ _ i ::i: :i • : •

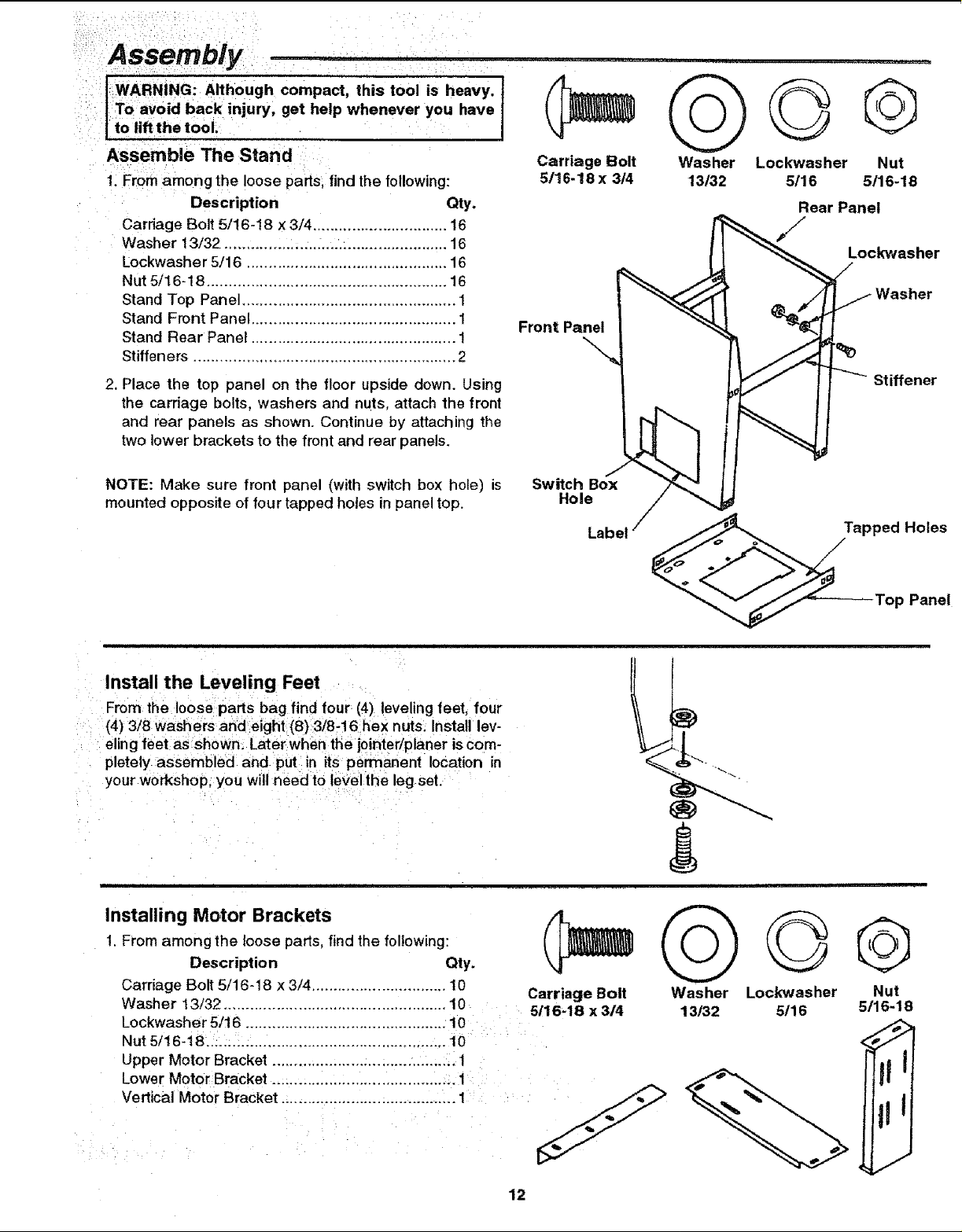

1WARNING: Although compact, this tool is heavy.

: l:To avoid back injury, get help whenever you have

: I to liftthe tool

Assemble The Stand

i

1. From among th e loose parts; find the following:

Description Qty.

Carriage Bolt 5/16-18 x 3/4 ............................... 16

Washer 13/32 ............ ,.._....: ............................. 16

Lockwasher 5/16 .............................................. 16

Nut 5/16-t8 ....................................................... 16

Stand Top Panel ................................................. 1

Stand Front Panel ............................................... 1

Stand Rear Panet ............................................... 1

Stiffeners ............................................................ 2

2. Place the top panel on the floor upside down. Using

the carriage bolts, washers and nuts, attach the front

and rear panels as shown. Continue by attaching the

two lower brackets to the front and rear panels.

Carriage Bolt

5/16-18 x 314

Front Panel

Washer Lockwasher Nut

13132 5/16 5/16-18

Rear Panel

Lockwasher

Stiffener

NOTE: Make sure front panel (with switch box hole) is

mounted opposite of four tapped holes in panel top.

i

Install the Leveling Feet

From the loose parts bag find four (4) teve ng feet, four

(4) 3/8 washers and eight (8)3/8_16hex nuts; Install lev-

iater when the jointer/pianer isCom-

pletely assembled and pUt:!n its pe_anent location in

your Workshop; you wi:li need t0 ieVel the leg set. '

IHIIII l!ll III II I I I I I I IIIIIIIII I' !

Installing Motor Brackets

1. From among the loose parts, find the following:

Description Qty.

Carriage Bolt 5/16-18 x 3/4 ............................... 10

Washer 13/32 ................................................... 10

Lockwasher 5/16 .............................................. 10

Nut 5/16-18..i.!:._i.: ............................................. i0

Upper Motor Bracket .............. :......_...:.........:.,:_i 1

Lower Motor Bracket .,_...,......, ...................... ::. ! :

Vertical Motor Bracket .;..................... _............. ,. 1 : '

Switch Box

Hole

Label

Carriage Bolt

5/16-18 x 3/4

Q

Washer

13/32

©

Lockwasher

5116

Tapped Holes

top Panel

©

Nut

5/16-18

II

i

12

Loading...

Loading...