Craftsman 113228360 Owner’s Manual

Save Thls Manual _'X

or Future Reference

• SF RS

owner's

manual

MODEL NO.

113.228360

WOOD LATHE

it i liiii ,ii lul

Serial

Number

Model and serialnumber

may be found on back of

headstock assembly.

You shouldrecordboth

model and serialnumber in

a safeplace forfutureuse.

FOR YOUR

SAFETY'.

READ ALL

INSTRUCTIONS

CAREFULLY

CRAFTSMAN

12-INCH

WOOD LATHE

• assembly

• operating

• repair parts

J

Sears, Roebuck and Co., Hoffman Estates, IL60179 U.S.A.

Part No, SP5110 Printed in U.S,A. 5195

FULL ONE YEAR WARRANTY ON CRAFTSMAN WOOD LATHE

Ifwithin one year from the date of purchase, this Craftsman Wood Lathe fails due to a defect

in material or workmanship, Sears will repair it, free of charge.

WARRANTY SERVICE IS AVAILABLE BY SIMPLY CONTACTING THE NEAREST SEARS SERV-

ICE CENTER/DEPARTMENT THROUGHOUT THE UNITED STATES.

This warranty applies only while this product is used in the United States.

This warranty gives you specific legal fights, and you may also have other rights which

vary from state to state.

Sears, Roebuck and Co., D/817 WA Hoffman Estates, IL 60179 U.S.A.

illll ,ill i ii ii , i,i i ii i

=

GENERAL SAFETY INSTRUCTIONS FOR POWER TOOLS

1, KNOW YOURTOOL

Read and understandowner'smanual and labels

affixed to the tool. Learn its application and limita-

tions as wellas its specific potential hazards pecul-

iar to this tool.

2. GROUND THE TOOL

Thistool is equippedwithan approved3-condu ctor

cord and a 3.prong grounding type plug to fit the

proper grounding type receptac[e. The green con-

ductor in the cord is the grounding wire, Never

connect the green wire to a live terminal.

3. KEEP GUARDS IN PLACE

- in working order, and Lnproper adjustment and

alignment.

4. REMOVE ADJUSTING KEYS AND WRENCHES

Formhabit of checking to seethat keys and adjust-

ingwrenches are removedfromtoolbefore turning

it on.

5. KEEP WORK AREA CLEAN

Clutteredareasandbenches inviteaccidents, Floor

must not be slippery due to wax or sawdust.

6, AVOID DANGEROUS ENVIRONMENT

Don't use power toolsin damp orwet locations or

exposethemto rain. Keep work area well lighted,

Provide adequate surrounding work space,

7. KEEP CHILDREN AWAY

NI visitors should be kept a safe distance from

work area,

8, MAKE WORKSHOP CHILD-PROOF

- withpadlocks, master switches, or by removing

starter keys,

9. USE PROPER SPEED

This toolwilldo thejob betterand safer when op-

eratedat the properspeed,

10,

USE RIGHT TOOL

Don'tforce toolorattachment to doa job for which

itwas not designed.

11.

WEAR PROPER APPAREL

Do not wear loose clothing, gloves, neckties or

jewelry (rings, wristwatches) to get caught in mov-

ing parts. Non-slipfootwear isrecommended, Wear

protective hair coveringto contain long hair. Roll

long sleeves above the elbow.

12,

USE SAFETY GOGGLES (Head Protection)

Wear safety qoqqtes (must comply with ANSI

Z87.1) at all times. Everyday eyeglasses only have

impact resistant lenses, they are NOT safety glass.

es. Also, use face or dust mask if cutting operation

is dusty, and ear protectors (plugs or muffs) during

extended periods of operation.

13, SECURE WORKPIECE

Mount workpiece securely between centers.

14. DON'T OVERREACH

Keep proper footing and balance at all times.

15. MAINTAIN TOOLS WITH CARE

Keep tools sharp and clean for best and safest

performance. Follow instructions for lubricating and

changing accessories.

16. DISCONNECT TOOLS

Before servicing, when changing accessories or

attachments.

17, AVOID ACCIDENTAL STARTING

Make sure switch is in "OFF" pos[tion before plug.

sing in,

18. USE RECOMMENDED ACCESSORIES

Consult the owner's manual for recommended ac-

cessorles. Follow the instructions that accompany

the accessories. The use of improper accessories

may cause hazards.

t9, NEVER STAND ON TOOL

Serious injury could occur if the tool tips over.

Do not store materials such that it is necessary to

stand on the tool to reach them.

20. CHECK DAMAGED PARTS

Before further use of the tool, a guard or other part

that is damaged should be carefully checked to

ensure that it will operate properly and perform its

intended function. Check for alignment of moving

parts, binding of moving parts, breakage of parts,

mounting, and any other conditions that may affect

its operation. A guard or other part that isdamaged

should be properly repaired or replaced.

21, DIRECTION OF FEED

Apply cutting tool to the workpiece against the direc-

tion of spindle rotation.

22, NEVER LEAVE TOOL RUNNING

UNATTENDED

Turn power "OFF". Don't leave Lathe until It comes

to a complete stop.

additional safety instructions for wood turning lathes

Safety is a combination of common sense, staying alert

and knowing how your lathe works.

BEFORE USING THE LATHE:

WARNING: To avoid mistakes that could result in

serious, permanent injury, do not connect power

cord until the following steps have been satisfac-

torily completed:

1. Assembly, mounting and alignment.

2. Learn the function and proper use of the on-off

switch, head stock, tail stock, tool rest, spur center,

cup center, tail stock ram lock, tool rest locks, index

pin, face plate and bed.

3. Read and understand all safety instructions and

operating procedures throughout the manual.

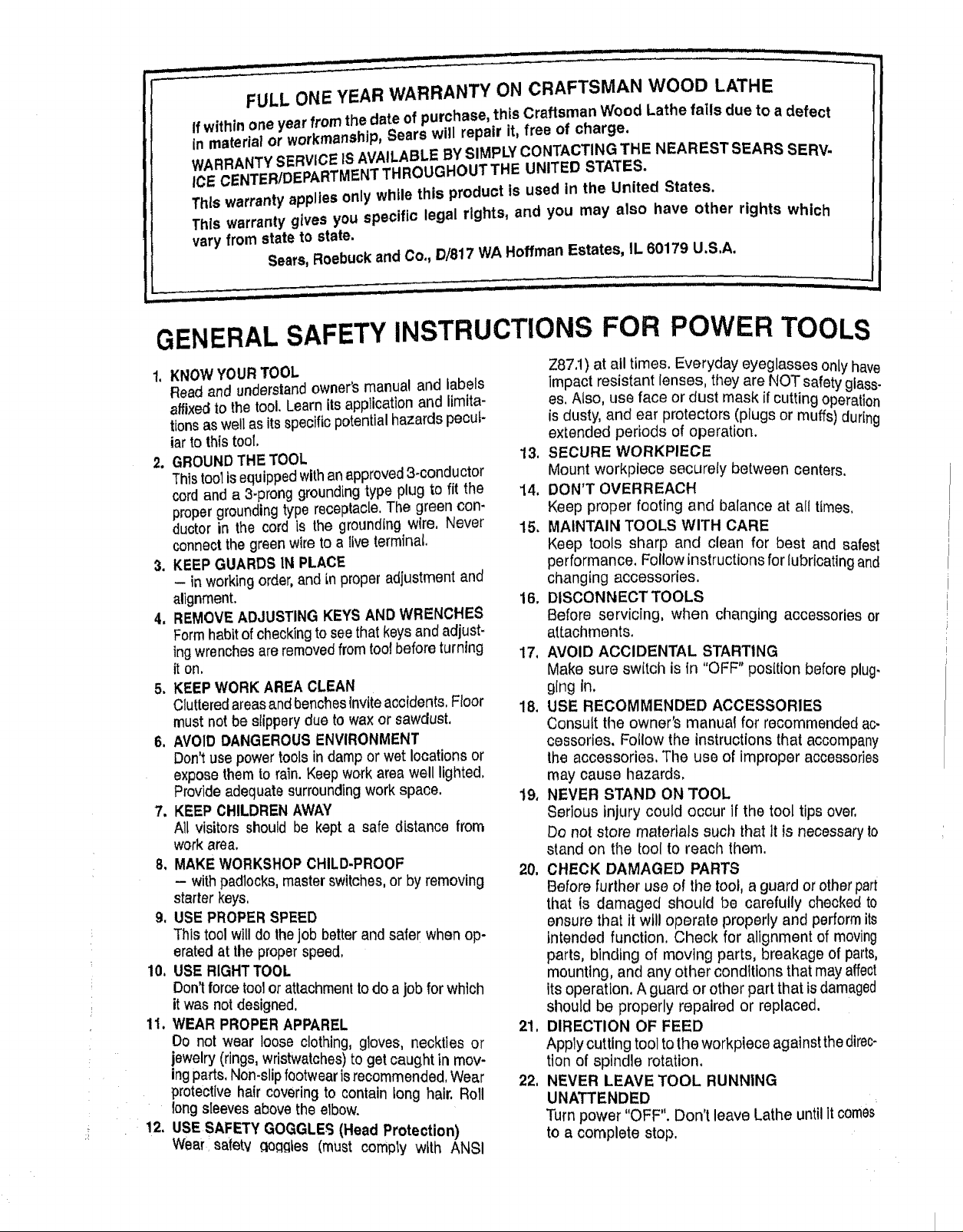

4. Read the following labels which appear on the front

and side of the lathe:

FOR YOUR OWN SAFETY:

Read _nd gnderltend Ihe Owner's

Manual before Opetaffng M1¢hlmt.

a AIwByl Welt lalely goeg(H p4"t ANSI

Z87.1.

aOa nat welt S)OVel, _eckUal or loose

r*lothln_, Tll blC_ long hair,

I TJgttlirt Ill lOCks befell lurnin w "on" lithe.

ITu(h wOr_ple¢:a by ha_l (p cheek arid see

_hl' the workplt¢l t_'llatl thll tool flail and

olhmr msohttte pllrts_

J aOu(Ih ovI laclplill WOlllplocea 2omll_

as ra_nd n posslb|e, I_fore Ill*¢hlng le

laoepllil.

a Hevl( mount w_pl_el ,hal rot, split,

©hocked _r h|ve kl_OtS-

mA)Wltyl ula Iowlst speed whQ_ Itlrtlt)g

ntw wGrkpl_¢e.

WHEN

INSTALLING OR MOVING THE

LATHE:

1. To

avoid injury from unexpected lathe movement:

Bolt the lathe to a stand or workbench that has

a.

a rigid, flat surface for stability.

b. Fasten the stand or bench to the floor to pre-

vent slipping, sliding, rocking or tipping during

operation.

c. Turn off lathe and unplug electrical cord before

moving the lathe to a new area.

,

Store and operate lathe indoors.

BEFORE EACH USE:

1. Inspect your lathe. If any parts of this lathe are

missing, bent, or fail in any way, or any electrical

components do not work properly, turn off the lathe,

remove switch key, and remove power supply cord

from power supply. Replace damaged, missing or

faired parts before using the lathe again.

2. Plan your work to protect your eyes, hands, face,

ears and body.

a. Turn switch "off" and remove switch key before

mounting workpiece in lathe.

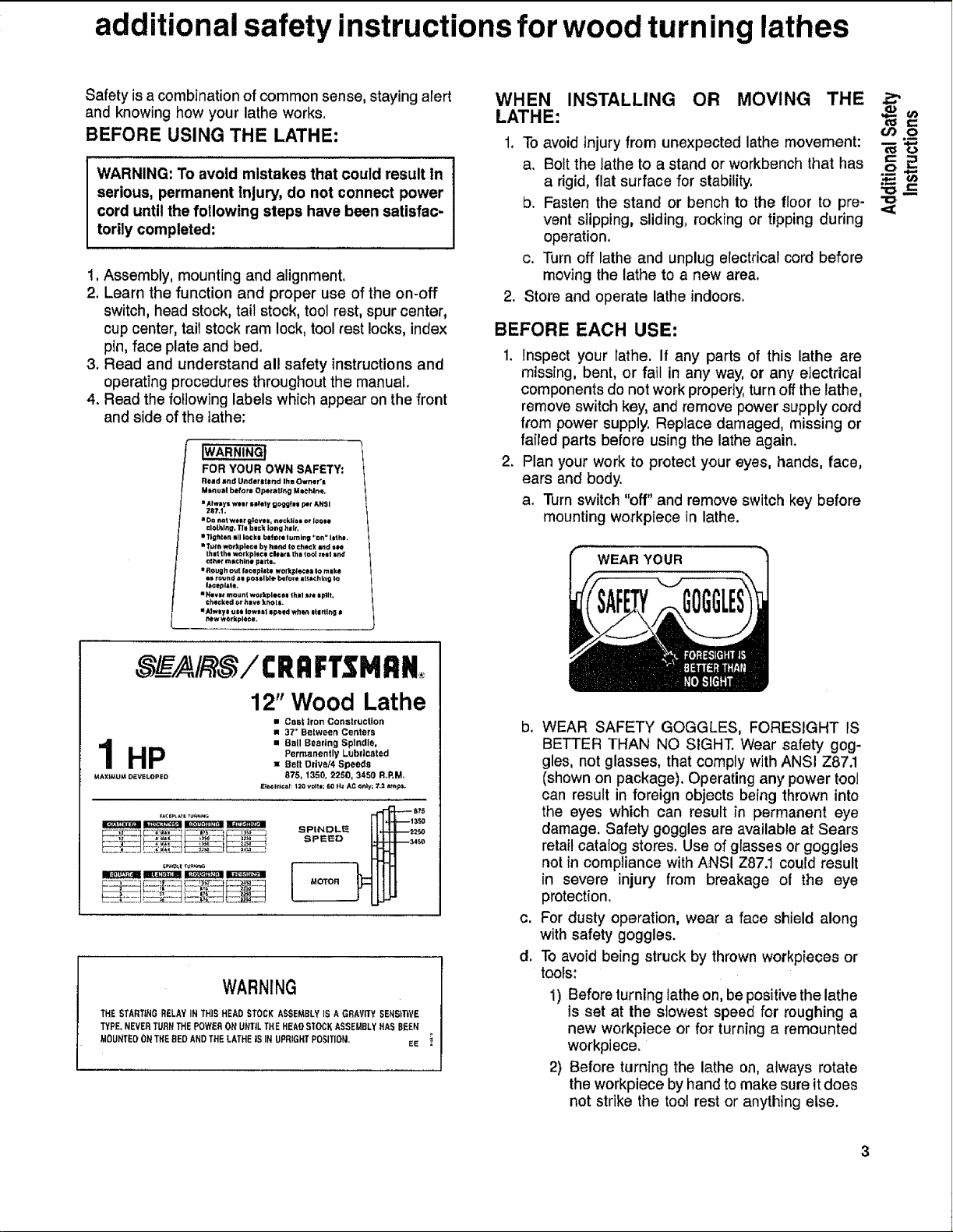

WEAR YOUR

O_ o

.i

._o

/ CRRFTSMRN

12" Wood Lathe

= Cast iron Construction

m 37" Between Centers

m Ball Bearing Spindle,

1HP

MAXIMUM D_VELOPED

O mnm_rm _ _t_,_rm_

WARNING

THESTARTINGRELAYINTHISHEADSTOCKASSEMBLYIS AGRAVITYSENStTtV[

TYPE,NEVERTURNTHEPOW;ERONUNTJLTHEHEAOSTOCKASSEMBLYHASBEEN

MOUNTEOONTHE,BEDANDTHE LATHEiSIN UPRIGHTPOSITION, EE

Permanently Lubricated

• Belt Drive/4 Speeds

875, 1350, 2250, 3450 R.P.M,

E_¢I_: 120 y_lt I; 60 HZ AC off)y; 7,,2 attiCS,

SPINDL_

SPEED

_*IOTOR

b. WEAR SAFETY GOGGLES, FORESIGHT IS

BETTER THAN NO SIGHT. Wear safety gog-

gles, not glasses, that comply with ANSI Z87.1

(shown on package). Operating any power tool

can result in foreign objects being thrown into

the eyes which can result in permanent eye

damage. Safety goggles are available at Sears

retail catalog stores. Use of glasses or goggles

not in compliance with ANSI Z87.1 could result

in severe injury from breakage of the eye

protection.

c. For dusty operation, wear a face shield along

with safety goggles.

d. To avoid being struck by thrown workpieces or

tools:

1) Before turning latheon, be positive the lathe

is set at the slowest speed for roughing a

new workpiece or for turning a remounted

workpiece.

2) Before turning the lathe on, always rotate

the workplace by hand to make sure itdoes

not strike the tool rest or anything else.

3

3) Make sure centers are aligned when

tailstock and ram are locked.

4) Make sure the spur center and cup center

are firmly seated against theworkpiece and

that the tail stock is locked in place for spin-

dle turnings.

5) Always center workpiece and use wood

free of checks, splits, cracks or knots. Use

lathe to turn wood and wood-like products

only.

6) Before mounting workpiece "rough it out"

to as "true round" as possible.

7) Always center and fasten the workpiece

securely to the face plate for face plate

turning.

8) Always position thetool rest above the cen-

terllne of the lathe for spindle turning and

lock in place.

9) Do not try any operation when hand holding

the workpiece or applying the turning tool

to the workpiece below the level of the tool

rest.

10) Never try to remount a face plate turning

to the face plate for any reason.

11) Never try to remount spindle turnings be-

tween centers if the original centers in the

turning have been altered or removed.

12) Keep firm hold and control of the turning

tool and do not let the tool "bite" into the

workpiece.

13) Make sure all clamps and locks are tight

and there is no sideplay,

14) Never use lathe to cut workpiece into two

pieces.

15) Before turning lathe on be sure motor cover

Esinstalled and slide closed,

16) Make sure headstock is securely attached

to bed.

e. To avoid being suddenly caught in the lathe:

1) Do not wear gloves, neckties or loose

clothing.

2) Tie back long hair.

3) Remove all jewelry.

4) Roll long sleeves above the elbow.

5) Keep motor cover in place.

6) Do not store turning tools where you must

reach over therevolving workpiece toselect

them.

f, To avoid iniury from accidental starting always

turn switch off, unplug power cord, and remove

switch key before removing the guard, installing

or removing the workpiece, accessory orattach-

ment, or making any adjustments:

g. Toavoidlosing control ofthe turning tool causing

Injury:

1) Use both hands spaced apart and keep a

firm hold of the turning toot.

2) Always support the turning tool directly on

the tool rest.

3) Always operate the lathe so that the top of

the workpiece turns toward you (clockwise

facing the left side of the lathe).

4) Keep turning tools sharp.

5) Never start a cut directly at the end where

it may catch the workpiece.

6) Always use both hands spaced apart along

turning tool for leverage and balance.

h,

Plan your hand placement so your hands will

not be where a sudden slip could cause them

to contact the workpiece.

To avoid an electrical shock, make sure your

fingers do not touch the metal prongs on the

plug when installing or removing the plug to or

from a live outlet.

Never turn your lathe "ON" before clearing the

area ofall objects (tools, scraps of wood, etc.).

3, WHENEVER LATHE IS RUNNING

WARNING: Don't let familiarity (gained from fre-

quent use of your wood lathe) cause a careless

mistake. Always remember that a careless frac.

tion of a second Is enough to cause severe Injury.

a, If your lathe makes an unfamiliar noise or if it

vibrates excessively, turn off the lathe im-

mediately. Remove switch key, Do not restart

until the problem is corrected,

b, Position turning tool so it will not chatter or

kickback,

c, Always stand to the side of the turning tool.

d, Never position your face over the turning tool.

e. Avoid awkward hand positions, where a sudden

slip could cause a hand to move into the

workpiece.

f, Complete hand sanding of spindle turnings

BEFORE removing from the lathe using the

same or slower turning speed,

g, Never leave the lathe work area without turning

the lathe off, removing the switch key and wait-

ing for the lathe to come to a complete stop.

4. To avoid injury use only recommended accessories

listed in the accessory section.

a, Do not mount and use a reamer, milling cutter,

wire wheel, buffing wheel or a drill bit on the

headstock spindle.

b, Use the drill chuck accessory on the tall stock

only.

c. Do not mount any drill that extends more than

6" beyond the chuck jaws.

4

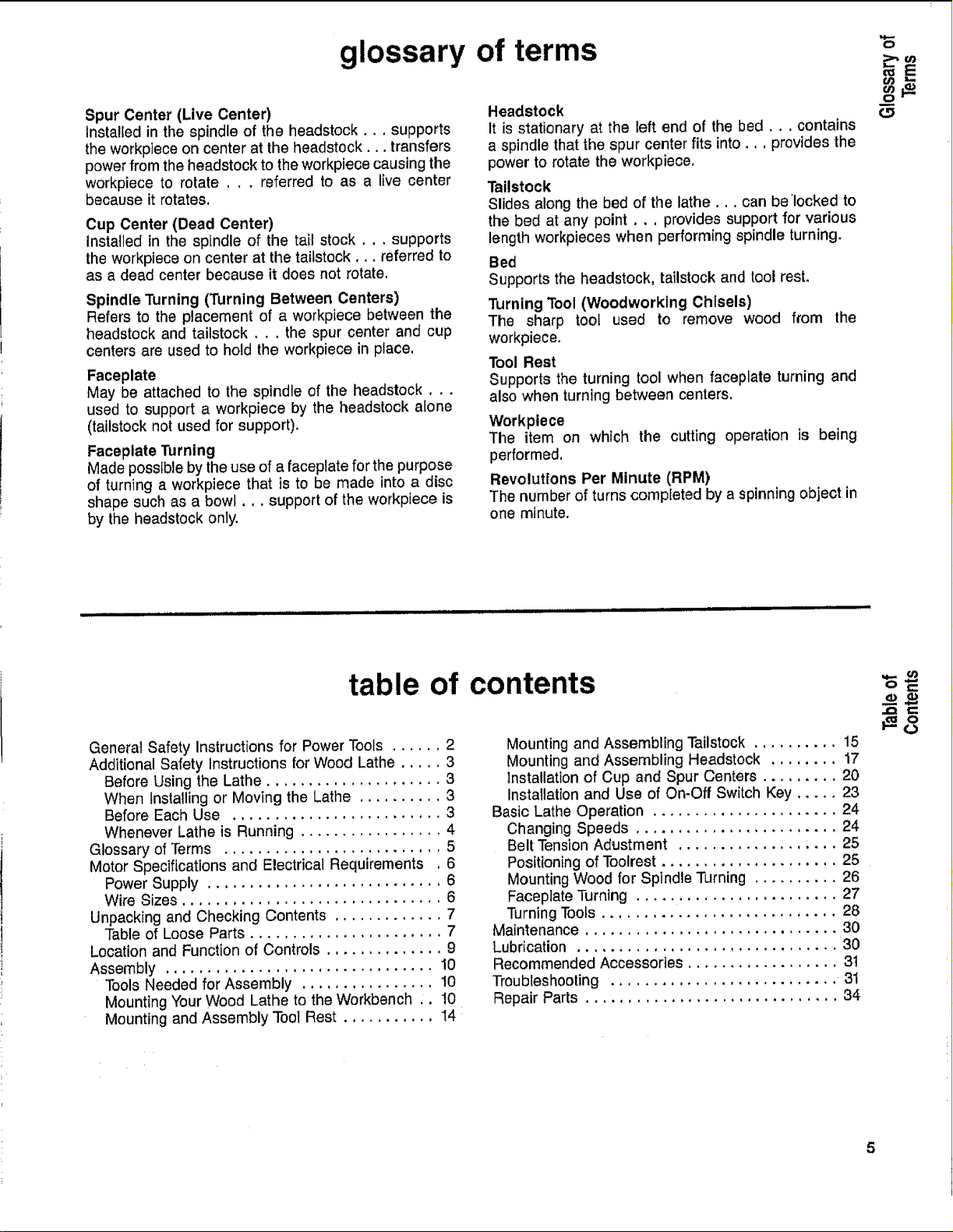

glossary of terms

O

ME

Spur Center (Live Center)

Installed in the spindle of the headstock.., supports

the workpiece on center at the headstock.., transfers

power from the headstock to the workpiece causing the

workpiece to rotate . , , referred to as a live center

because it rotates.

Cup Center (Dead Center)

Installed in the spindle of the tail stock.,, supports

the workplece on center at the tailstock.., referred to

as a dead center because it does not rotate.

Spindle Turning (Turning Between Centers)

Refers to the placement of a workpiece between the

headstock and tailstock,., the spur center and cup

centers are used to hold the workpiece in place.

Faceplate

May be attached to the spindle of the headstock...

used to support a workpiece by the headstock alone

(tailstock not used for support).

Faceplate Turning

Made possible by theuse of a faceplate for the purpose

of turning a workpiece that is to be made into a disc

shape such as a bowl.., support of the workpiece is

by the headstock only.

Headstock

It is stationary at the left end of the bed.., contains

a spindle that the spur center fits into.,, provides the

power to rotate the workpiece.

Tailstock

Slides along the bed of the lathe.., can be'locked to

the bed at any point.., provides support for various

length workpieces when performing spindle turning.

Bed

Supports the headstock, tailstock and tool rest,

Turning Tool (Woodworking Chisels)

The sharp toot used: to remove wood f_om the

workpiece.

Tool Rest

Supports the turning tool when faceplate turning and

also when turning between centers,

Workplece

The item on which the cutting operation is being

performed.

Revolutions Per Minute (RPM)

The number of turns completed by a spinning object in

one minute.

o

table of contents

General Safety Instructions for Power Tools ...... 2

Additional Safety Instructions for Wood Lathe ..... 3

Before Using the Lathe ..................... 3

When Installing or Moving the Lathe .......... 3

Before Each Use ......................... 3

Whenever Lathe is Running ................. 4

Glossary of Terms .......................... 5

Motor Specifications and Electrical Requirements . 6

Power Supply ............................ 6

Wire Sizes ............................... 6

Unpacking and Checking Contents ............. 7

Table of Loose Parts ....................... 7

Location and Function of Controls .............. 9

Assembly ................................ 10

Tools Needed for Assembly ................ 10

Mounting Your Wood Lathe to the Workbench .. 10

Mounting and Assembly Tool Rest ........... 14

O c

_o

Mounting and Assembling Tailstock .......... 15

Mounting and Assembling Headstock ........ 17

Installation of Cup and Spur Centers ......... 20

Installation and Use of On-Off Switch Key ..... 23

Basic Lathe Operation ...................... 24

Changing Speeds ........................ 24

Belt Tension Adustment ................... 25

Positioning of Toolrest ..................... 25

Mounting Wood for Spindle Turning .......... 26

Faceplate Turning ........................ 27

Turning Tools ......... ................... 28

Maintenance .............................. 30

Lubrication ............................... 30

Recommended Accessories .................. 31

Troubleshooting ........................... 31

Repair Parts ............................... 34

5

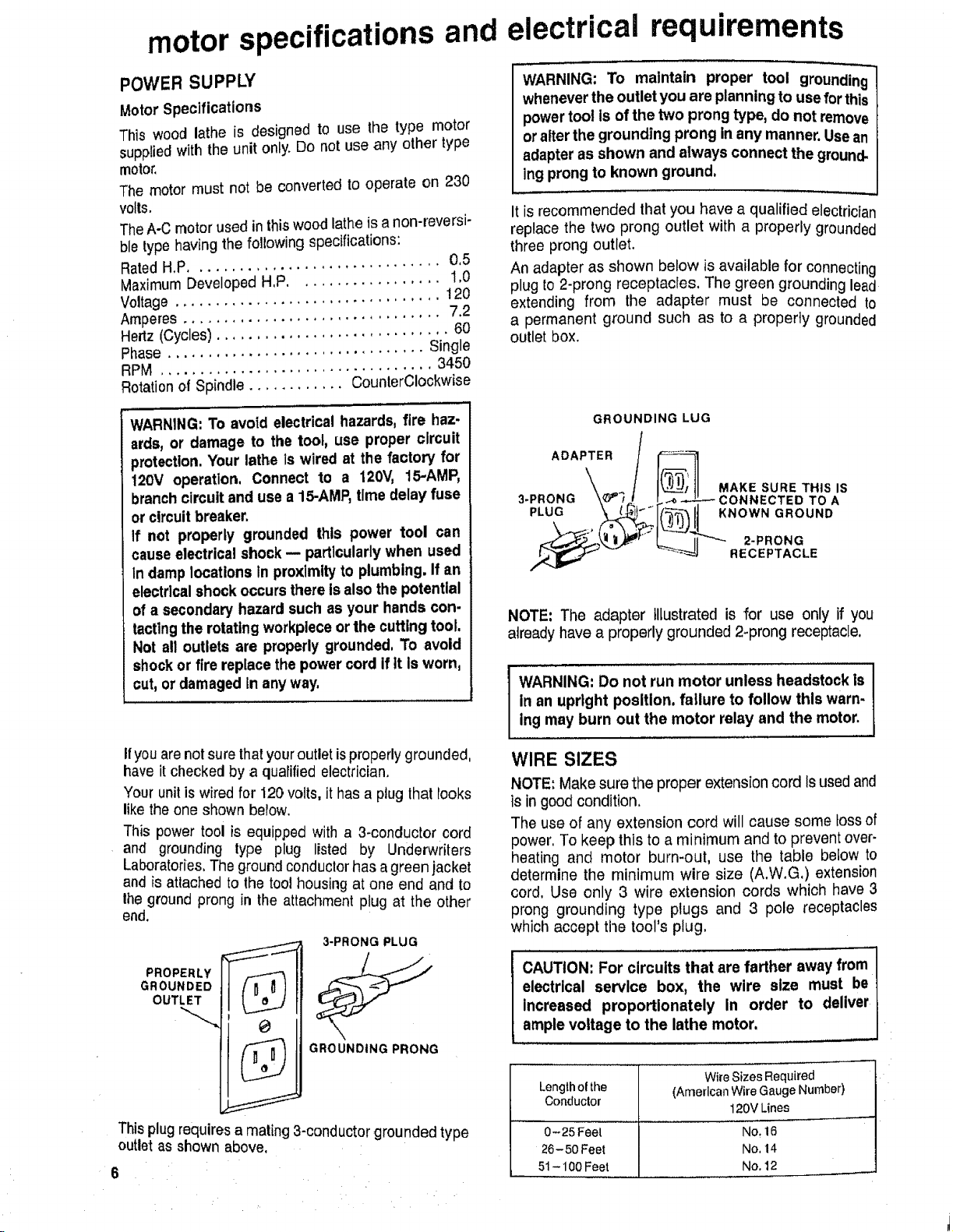

motor specifications and electrical requirements

POWER SUPPLY

Motor Specifications

This wood lathe is designed to use the type motor

supplied withthe unit only. Do not use any other lype

motor.

The motor must not be converted to operate on 230

volts.

TheA-C motorused in thiswood latheis a non-reversi-

ble type having the following specifications:

Rated H.P............................... 0,5

Maximum Developed H,P.................. 1,0

Voltage ................................. 120

Amperes ................................ 7.2

Hertz (Cycles) ............................. 60

Phase ................................ Single

RPM .................................. 3450

Rotation of Spindle ............ CounterClockwise

WARNING: To avoid electrical hazards, fire haz-

ards, or damage to the tool, use proper circuit

protection. Your lathe ls wired at the factory for

120V operation. Connect to a 120V, 1,_AMP,

branch circuit and use a 15-AMP, tlme delay fuse

or circuitbreaker.

If not properly grounded this power tool can

cause electrical shock -- particularly when used

In damp locations In proximity to plumbing. If an

electrical shock occurs there is also the potential

of a secondary hazard such as your hands con-

tactlngthe rotating workplece or the cutting tool.

Not all outlets are properly grounded. To avoid

shock or fire replace the power cord if tt Is worn,

cut, or damaged In any way.

WARNING: To maintain proper tool grounding

whenever the outlet you are planningto use forthis

power tool is of the two prong type, do not remove

or alterthe grounding prong in any manner. Use an

adapter as shown and always connect the ground.

ing prong to known ground.

It is recommended that you have a qualified electrician

replace the two prong outlet with a properly grounded

three prong outlet.

An adapter as shown below is available for connecting

plug to 2-prong receptacles, The green grounding lead

extending from the adapter must be connected to

a permanent g_'ound such as to a properly grounded

outlet box.

GROUNDING LUG

_ t I_f/tl MAKE SURE THIS IS

3-PRONG CONNECTEOTOA

PLUO KNOWNGROUND

NOTE; The adapter Illustrated is for use only if you

already have a properly grounded 2-prong receptacle,

WARNING: Do not run motor unless headstock ls

in an upright position, failure to follow this warn-

ing may burn out the motor relay and the motor.

If you arenotsure thatyour outlet isproperlygrounded,

have itcheckedby a qualified electrician.

Your unit is wired for 120 volts,it has a ptug lha! looks

like the one shown below.

This power tool is equipped with a 3-conductor cord

and grounding type plug listed by Underwriters

Laboratories, The ground conduclor has a green jacket

and is atlached to the toolhousing at one end and to

lhe ground prong in the attachment plug at the other

end,

3-PRONG PLUG

PROPERLY

GROUNDED

OUTLET

-.....

GROUNDING PRONG

Thisplug requires amating 3-conductor grounded type

outlet as shownabove.

6

WIRE SIZES

NOTE: Make sure the proper extension cord Is used and

isin good condition,

The use of any extension cord will cause some loss of

power, To keep this to a minimum and to prevent over-

heating and motor burn-out, use the table below to

determine the minimum wire size (A.W.G,) extension

cord, Use only 3 wire extension cords which have 3

prong grounding type plugs and 3 pole receptacles

which accept the tool's plug,

CAUTION: For circuits that are farther away from I

electrical service box, the wire size must be 1

Increased proportionately In order to deliver I

ample voltage to the lathe motor. I

Length o! the (American Wire Gauge Number)

Conductor

0-25 Feel No, 16

2.6-50 Feel No, 14

51- 100 Feet No. 12

Wire Sizes Required

120V Lines

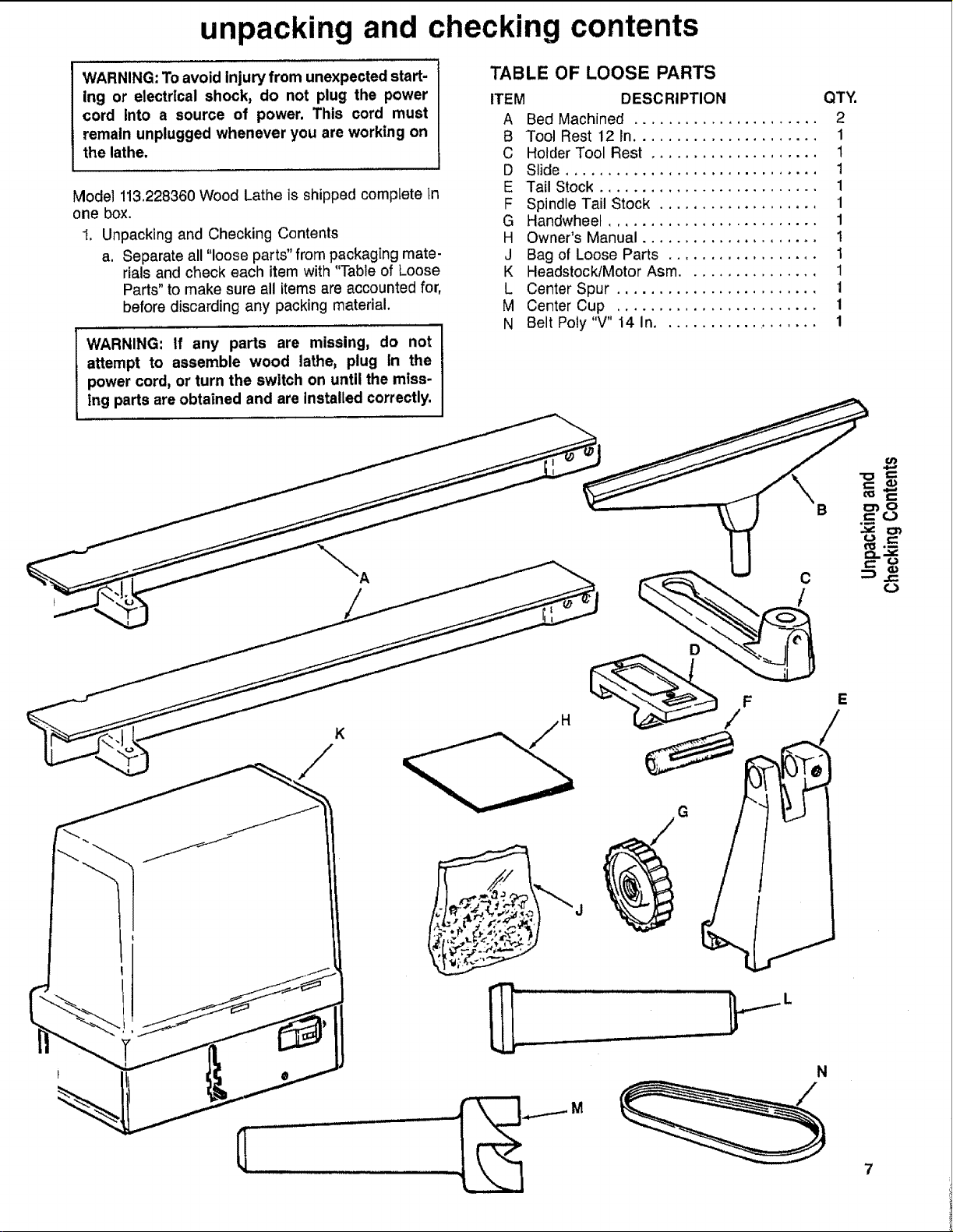

unpacking and checking contents

WARNING: To avoid injury from unexpected start-

Ing or electrical shock, do not plug the power

cord into a source of power. This cord must

remain unplugged whenever you are working on

the lathe.

Model 113.228360 Wood Lathe is shipped complete in

one box.

1, Unpacking and Checking Contents

a, Separate all "loose parts" from packaging mate-

rials and check each item with "Table of Loose

Parts" to make sure all items are accounted for,

before discarding any packing material.

WARNING: If any parts are missing, do not

attempt to assemble wood lathe, plug in the

power cord, or turn the switch on until the miss-

ing parts are obtained and are Installed correctly.

TABLE OF LOOSE PARTS

ITEM DESCRIPTION

A

Bed Machined ...................... 2

B

Tool Rest 12 In...................... 1

C

Holder Tool Rest .................... 1

D

Slide .............................. 1

E

Tail Stock .......................... 1

F

Spindle Tail Stock ................... 1

G

Handwheel ......................... 1

H

Owner's Manual ..................... 1

J

Bag of Loose Parts .................. 1

K

HeadstocktMotor Asm ................ 1

L

Center Spur ........................ 1

M

Center Cup ........................ 1

N

Belt Poly "V" 14 In .................... 1

QTY.

E

K

/

G

N

7

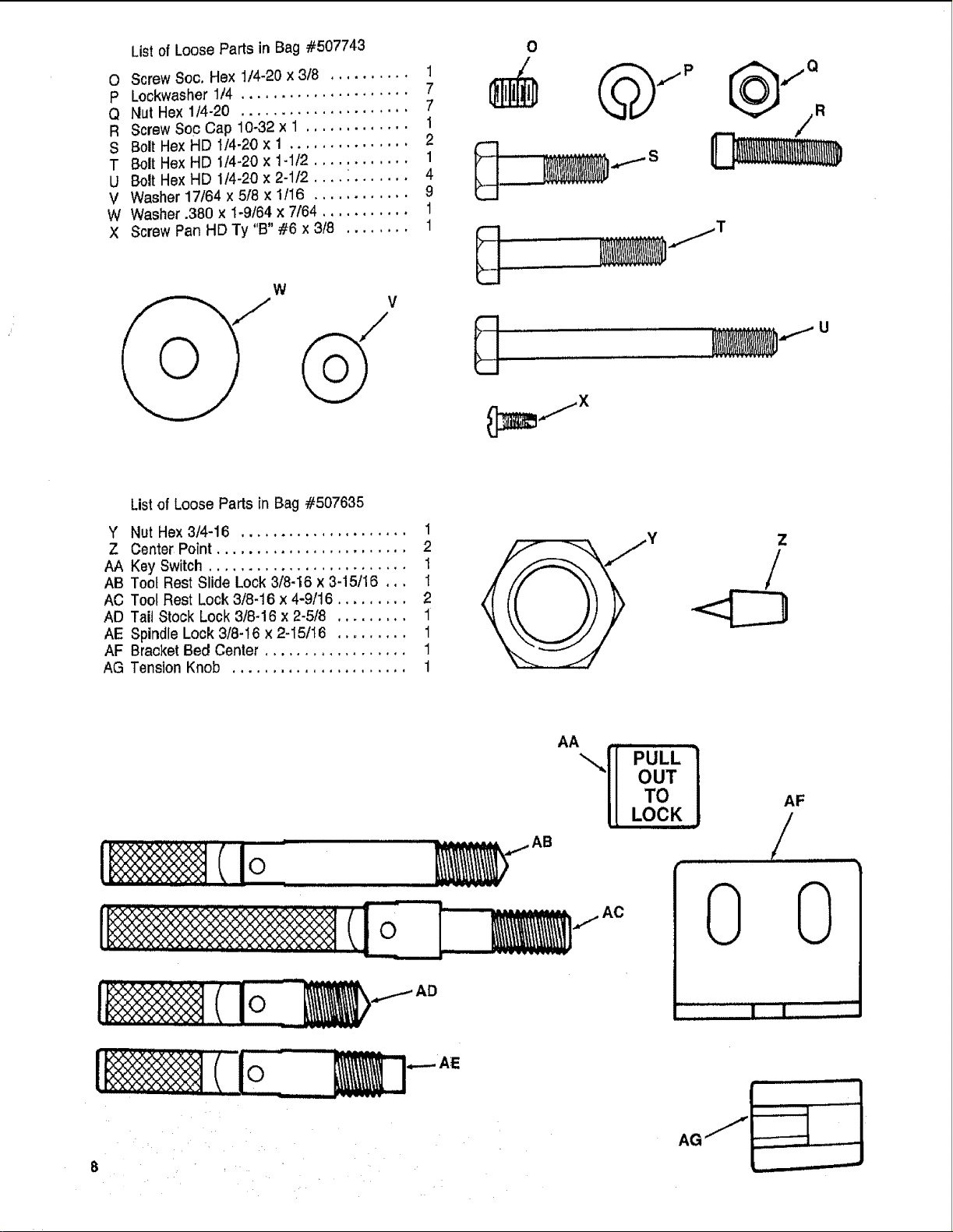

List of Loose Parts in Bag #507743

O Screw Soc. Hex 1/4-20 x 3/8 .......... 1

p Leckwasher 1/4 ..................... 7

Q Nut Hex 1/4-20 ..................... 7

R Screw Soc Cap 10o32 x 1 ............. 1

S Bolt Hex HD 1/4-20 x 1 ............... 2

T Bolt Hex HD 114-20x 1-1/2 .... : ....... 1

U Bolt Hex HD 1/4-20 x 2-1/2 ............ 4

V Washer 17/64 x 5/'8 x 1/I6 ............ 9

W Washer .380 x 1-9164x 7/64 ........... 1

X Screw Pan HD Ty "B" #6 x 3/8 ........ 1

W

O

P

_f u

List of Loose Parts in Bag #507635

Y Nut Hex 3/4-16 ..................... 1

Z Center Point ........................ 2

AA Key Switch ......................... 1 /

AB Toot Rest Slide Lock 3/8-16 x 3-15/16 ,.. I

AC Tool Rest Lock 3/8-16 x 4-9/16 ......... 2

AD Tait Stock Lock 3/8-16 x 2-5/6 ......... 1

AE Spindle Lock 3/8-16 x 2-15/16 ......... 1

AF Bracket Bed Center .................. 1

AG Tension Knob ...................... 1

AA

,,.,!I PULL

i_IIo

r o _._AC

I,WlL ,Imlll • - _vvw.v

......_iii_,o

Z

/

<EC3

IIou_

0 0

!_( 10-1_,_>f'°

l ilo

! Ii

location and function of controls

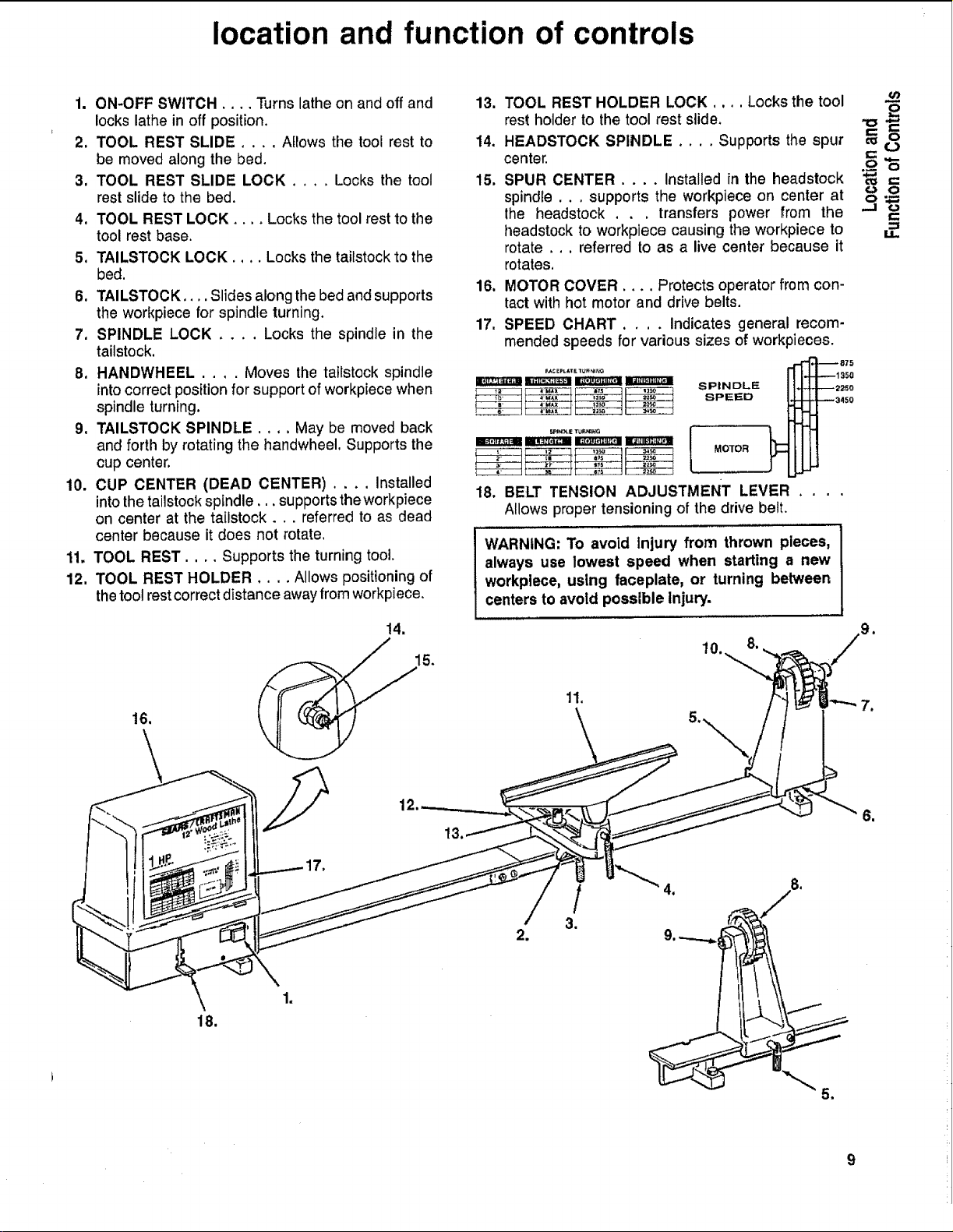

1. ON-OFF SWITCH .... Turns lathe on and off and

locks lathe in off position.

2. TOOL REST SLIDE .... Allows the tool rest to

be moved along the bed.

3. TOOL REST SLIDE LOCK .... Locks the tool

rest slide to the bed.

4, TOOL REST LOCK .... Locks the tool rest to the

tool rest base.

5. TAILSTOCK LOCK .... Locks the taitstock to the

bed.

6. TAILSTOCK .... Slides along the bed and supports

the workpiece for spindle turning.

7. SPINDLE LOCK .... Locks the spindle in the

tailstock.

8. HANDWHEEL .... Moves the tailstock spindle

into correct position for support of workpiece when

spindle turning.

9. TAILSTOCK SPINDLE .... May be moved back

and forth by rotating the handwheel, Supports the

cup center.

10, CUP CENTER (DEAD CENTER) .... Installed

into the tailstockspindle,., supports the workpiece

on center at the tailstock.., referred to as dead

center because it does not rotate.

11. TOOL REST .... Supports the turning tool.

12. TOOL REST HOLDER .... Allows positioning of

the tool rest correct distance away from workpiece.

13. TOOL REST HOLDER LOCK .... Locks the tool _o

rest holder to the tool rest slide. ,z_ -,_

14. HEADSTOCK SPINDLE Supports the spur _ o

center. '-

._o"_

15. SPUR CENTER .... Installed in the headstock "_ ,-

spindle.., supports the workpiece on center at _ -_

lhe headstock . . , transfers power from the -J

headstock to workpiece causing the workpiece to ,,-'

rotate.., referred to as a live center because it

rotates.

16, MOTOR COVER .... Protects operator from con-

tact with hot motor and drive belts.

17, SPEED CHART .... Indicates general recom-

mended speeds for various sizes of workpieces.

F*_£EPt _T £ TUR P_JJO _1 _5.l 1

_ __ SPINDLE --+2++o

SF_N_E T_

SPEED --_4so

--875

I MOTOR

18. BELT TENSION ADJUSTMENT LEVER ....

Allows proper tensioning of the drive belt.

WARNING: To avoid Injury from thrown pieces,

always use lowest speed when starting a new

workpiece, using faceplate, or turning between

centers to avoid possible Injury.

9

assembly

,,. J ,,,,

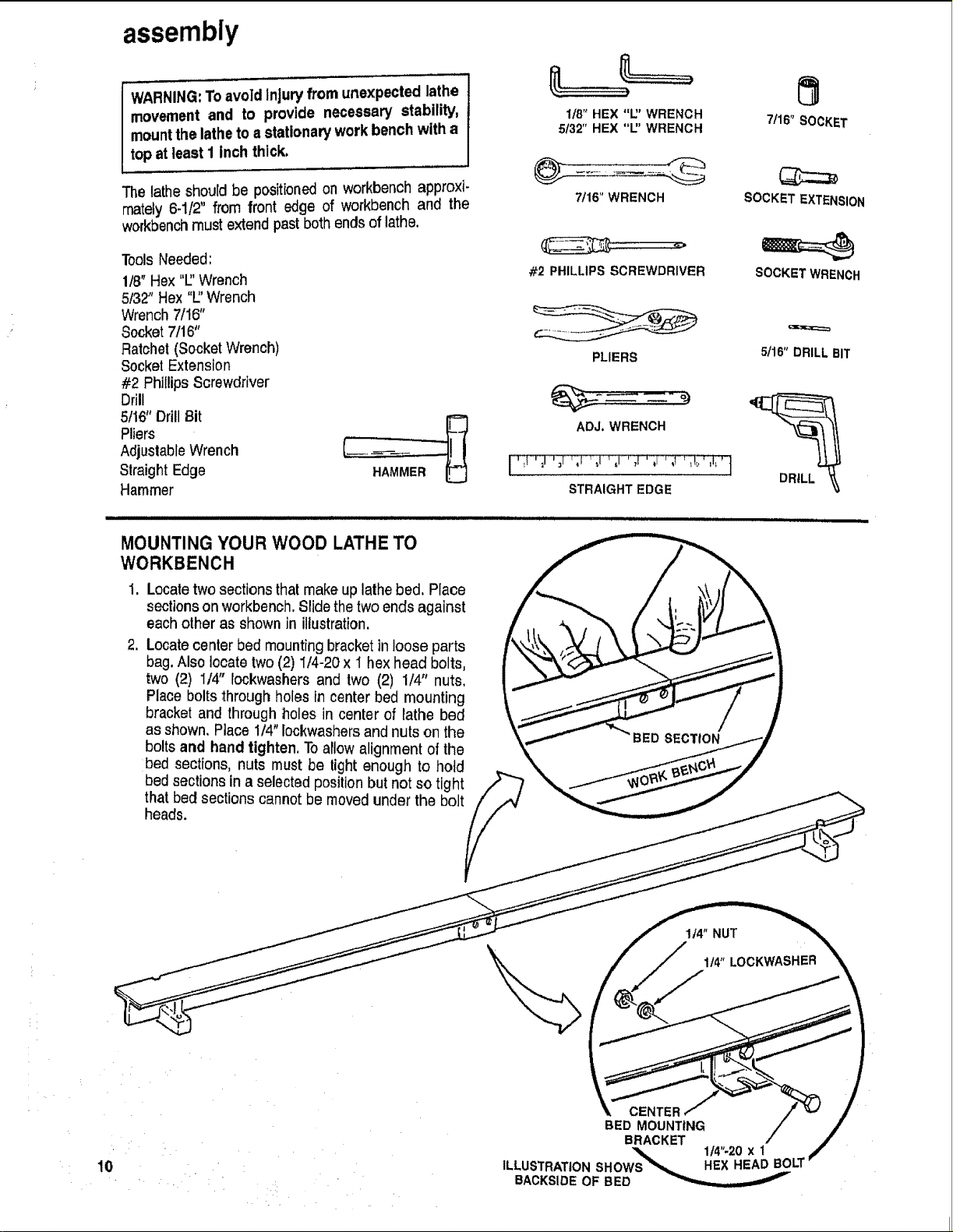

WARNING:To avoid Injuryfrom unexpected lathe

movement and to provide necessary stability,

mountthe lathe to a stationarywork bench with a

top at leasti Inch thick.

118"HEX%? WRENCH

5f32" HEX "It' WRENCH

7t16" SOCKET

The lathe should be positioned on workbench approxi-

mately 6-1/2" from front edge of workbench and the

7t16"WRENCH

SOCKETEXTENSION

workbenchmust extend past both ends of lathe.

Tools Needed:

1/8"Hex "E'Wrench

#2 PHILLIPS SCREWDRIVER

SOCKET WRENCH

5/32" Hex "U'Wrench

Wrench 7/16"

Socket7/16"

Ratchet (Socket Wrench)

Socket Extension

PLIERS

5t16"DRILLBIT

#2 Phillips Screwdriver

Drill

5116"Drill Bit

Pliers

ADJ. WRENCH

Adjustable Wrench

Straight Edge

Hammer

j ',I ',='iF ';i 'i_ ' ,I ',l' ,i ' ,__,p_'Tti_,]

STRAIGHT EDGE

MOUNTINGYOUR WOOD LATHE TO

WORKBENCH

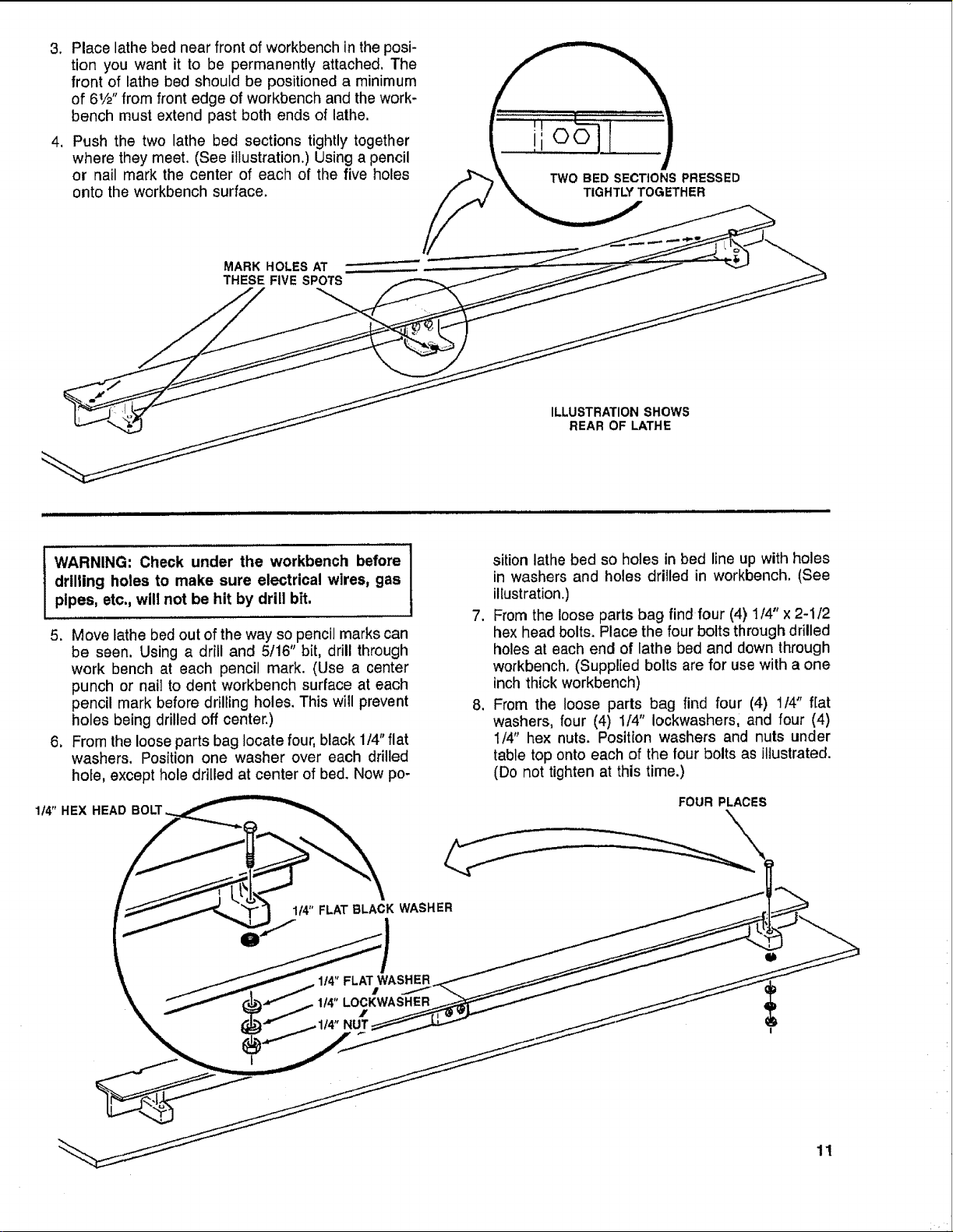

,

Locate two sections that make up lathe bed. Place

sections on workbench.Slide thetwo ends against

each other as shown in illustration.

2. Locate center bed mounting bracket inloose parts

bag.Also locate two (2) 1/4-20 x I hex head bolts,

two (2) 1/4" lockwashers and two (2) 1/4" nuts.

Place bolts through holes in center bed mounting

bracket and throughholes in center of lathe bed

as shown. Place 1/4"Iockwashers and nuts on the

bolts and hand tighten. To allow alignment of the

bed sections, nuts must be light enough to hold

bed sections in a selected position but not so tight _ A

that bed sections cannot be moved under the bolt / _ _ -_.,_

heads. / /

BED MOUNTING / J

BRACKET / ,/

' " "=_. 1/4"-20x 1 jr"

10 . ILLUSTRATION SHOWS'_ HEXHEAD BOLT-

- . .... ' BACKSIDEOF BED _1

,

Place lathe bed near front of workbench in the posi-

tion you want it to be permanently attached. The

front of lathe bed should be positioned a minimum

of 61/2" from front edge of workbench and the work-

bench must extend past both ends of lathe.

,

PtJsh the two lathe bed sections tightly together

where they meet. (See illustration.) Using a pencil

or nail mark the center of each of the five holes

onto the workbench surface.

MARK HOLES AT --

THESE FIVE SPOTS

TWO BED SECTIONS PRESSED

TIGHTLY TOGETHER

ILLUSTRATION SHOWS

REAR OF LATHE

i ii i ii i , i

WARNING: Check under the workbench before

drilling holes to make sure electrical wires, gas

pipes, etc., will not be hit by drill bit.

5. Move lathe bed out of the way so pencil marks can

be seen. Using a ddll and 5/16" bit, drill through

work bench at each pencil mark. (Use a center

punch or nai3to dent workbench surface at each

pencil mark before drilling holes. This will prevent

holes being drilled off center.)

6. From the loose parts bag locate four, black 114"flat

washers. Position one washer over each drilled

hole, except hole drilled at center of bed. Now po-

1t4" HEX HEAD

1/4" FLAT BLACK WASHER

sition lathe bed so holes in bed line up with holes

in washers and holes drilled in workbench. (See

illustration.)

,

From the loose parts bag find four (4) t/4" x 2-1/2

hex head bolts. Place the four bolts through drilled

holes at each end of lathe bed and down through

workbench, (Supplied bolts are for use with a one

inch thick workbench)

.

From the loose parts bag find four (4) 114"fiat

washers, four (4) 1/4'° Iockwashers, and four (4)

1/4" hex nuts. Position washers and nuts under

table top onto each of the four bolts as illustrated.

(Do not tighten at this time.)

FOUR PLACES

11

Loading...

Loading...