Craftsman 113228162 Owner’s Manual

Save This Manual

For Future Reference

MODEL NO.

313.228362

LATHE WITH MOTOR

[serial

! Number

Model and serial

number may be found

under belt guard.

You should record both

model and serial number

in a safe place for

future use.

CAUTION.

Read GENERAL and

O

!2-INCH

WOOO-TURNING [A THE

* assembly

, operating

ADDITIONAL SAFETY

INSTRUCTIONS

cerefully

Sold by SEARS, ROEBUCK AND CO., Chicago, IL. 60684 U.S.A.

t No. SP4938 _e_ ,'<_

®repair parts

" FULL ONE YEAR WARRANTY ON CRAFTSMAN WOOD LATHE

if within One year from the date of purchsse, this Craftsman Wood L_the fails due to a defect in material or

workmanship. Sears will repair it, free of cha rge.

WARRANTY SERVICE IS AVAILABLE BY SIMPLY CONTACTING THE NEAREST SEARS SERVICE

CENTER/DEPARTMENT THROUGHOUT THE UNITED STATES.

THIS wARRANTY APPLtES ONLY WHILE THIS PRODUCT IS iN USE'IN THE UNITED STATES.

This warranty gives you =pecifi0 legal rights, and you may atso have other rights which vary from state to state.

: SEARS, ROEBUCK AND CO., D/817 WA HOFFMAN ESTATES, IL 60195

general safety instructions for

1. KNOW. YOUR LATHE 13.

Read and understand owner's manual and labels affixed to

the tool, Learn its apphcation and imitations as well as _ts

specific Potential hazards peculiar to this tool. 14.

2. GROUND THE LATHE

This Lathe is equipped wi_h an approved 3-conductor 15.

cord and a 3-prong grounding type plug to fit the proper

grounding type receptacle. The green conductor in the

cord is the grounding wire, Never connect the green wire

to a live terminal.

3. KEEP GUARDS IN PLACE

=n working order, and in proper adjustment and align- 16,

mort,

4. REMOVE ADJUSTING KEYS AND WRENCHES

Form habt of checking to see that keys and adjusting 17.

wrenches are removed from toot before turning =t on.

5, KEEP WORK AREACLEAN

Cluttered areas and benches nvite accidents. Flour must

not be slippery due to wax Or sawdust.

6. AVOID DANGEROUS ENVIRONMENT

Don't use power tools in damp or wet locations or expose

them to rain. Keep work area well lighted, Provide ade-

quate surround ng work space: 19.

7. KEEP CHILDREN AWAY

All visitors should be kept a safe distance from Work area.

8. MAKE WORKSHOP CHILD-PROOF

- with padlocks, master switches, or by removing starter

keys. 20.

9. USE PROPER SPEED

The Lathe will do the job better and safer when ooerated

at the proper speed.

10. USE RIGHT TOOL

Don't force toot or attachment to do a job for which it

was not designed.

11. WEAR PROPER APPAREL

DO not wear loose clothing, gloves, neckties or jewelry

(rings; wristwatches) to get caught i_ moving parts. 21,

NONSLIP footwear is recommended. Wear protective

hair covering to contain tong hair. Roll long sleeves

above the elbow.

12. USE SAFETY GOGGLES (Head Protection) 22.

Wear safety goggles (must comply with ANSI Z87.1) at all

times. Everyday eyeglasses only have impact resistant len-

ses, they are NOT safety glasses. Also, use face or dust

mask if cutting operation is dusty, and ear protectors

(plugs or muffs) du ring extended periods of operation.

18.

power tools

SECURE WORKPIECE

Vlount workpiece secureIv between centers.

DON'T OVERREACH

Kee3 proper footing ann balance at all times.

MAINTAIN TOOLS WITH CARE

Keep tools sharp and clean for best and safest perform-

ance. Follow instructions for ubricating and changing

accessori as.

DISCONNECT YOUR LATHE

before servicing; when changing accessories or attach-

ments.

AVOID ACCIDENTAL STARTING

Make sure switch is m "OFF" position before plugging

n.

USE RECOMM ENDED ACC ESSORIES

Consult this owner'smanua for recommended accessories.

Follow the instructions that accompany the accessories.

The use of improper accessories may cause hazards.

NEVER STAND ON LATHE

Serious injury could occur if the Lathe tips over.

Do not store materials such that it is necessary to stand

on the tool to reach them.

CHECK DAMAGED PARTS

Before further use of the Lathe, a guard or other part that

s damaged should be carefully checked to ensure that it

wilt operate properly and perform its intended functiom

Check for alignment of moving oarts, binding.of moving

parts, breakage of parts, mounting, and any other con-

ditions that may affect its operation, A guard or other

part that is damaged should be properly repaired or

replaced.

DIRECTION OF FEED

Apply cutting tool to the workpJece against the direction

of sDindl%rotation.

NEVER LEAVE LATHE RUNNING

ATTENDED

Turn power "OFF" Don't leave Lathe until it comes to a

complete stop.

Safety is a combination of operator common sense and

alertness at all times when the Lathe is being used.

j. Never operate the Lathe with protective cover on

the unused shaft end of the motor removed,

WARNING: FOR YOUR OWN SAFETY, DO

NOT ATTEMPT TO OPERATE YOUR LATHE

UNTIL iT iS COMPLETELY ASSEMBLED AND

INSTALLED ACCORDING TO THE INSTRUC-

TIONS . . . AND UNTIL YOU HAVE READ

AND UNDERSTAND THE FOLLOWING:

PAG E

1. General Safety Instructions .................. 2

2. Getting to Know Your Lathe .................. 11

3, Basic Lathe Operation ....................... 13

4, Maintenance .............................. 30

5. The Lathe and motor must be bolted down to a stand

or workbench for stability.

6. Protection: Eyes, Hands, Face, Ears, Body

a. Wear safety goggles that comply with ANSI Z87.t-

1968, and a face shield if operation is dusty. Wear

ear plugs or muffs during extended periods of

operation.

b. When turning between centers or on the faceplate,

always rough-out "out of round" workpieces at

stow speed. Running the Lathe too fast, so that it

vibrates, could cause the workpiece to be thrown

from the Lathe. _ , or the turning tool to be jerked

from your hands,

c. Always revolve the workpiece by hand before turn-

ing on the motor. If the workpiece strikes the too!

rest, it could split and be thrown out of the Lathe.

d. Do not allow the turning tool to "bite" into the

workpiece which could result in splitting of the

workpiece or the workpiece being thrown from the

Lathe. Always position the tool rest above the

centedine of the Lathe for spindle turning. Do not

apply the turning tool to the workpiece below the

level of the toot rest.

e. Do not run the Lathe in the wrong direction. This

could cause the turning tool to be thrown from

your hands. The Lathe must run in a direction so

that the workpiece turns toward you.

f. Before attaching a workpiece to the faceplate al-

ways "rough it out" to as "true round" as possible.

This will minimize vibration while turning.

Always fasten the workpiece securely to the face-

plate.

Failure to perform these set-up operations could

cause the workpiece to be thrown from the Lathe,

g. Avoid awkward hand positions, where a sudden

slip could cause a hand to move into the workpiece.

h. Remove all loose knots before installing workpiece

between centers or on the faceplate.

i. Never leave the Lathe work area with the power on

before the Lathe has come to a complete stop, or

without removing and storing the switch key.

Hang your turning tools on the wall toward the tail-

stock end of the Lathe. Do not lay them on the bench

so that you must reach over the revolving workpiece

to select them.

8. Keep firm hold and control of the turning toot at aH

times. Speciat caution must be exercised when knots or

voids are exposed to the turning tool.

9. Note the following DANGER label which appears on

the front of the belt guard.

DANGER

FOR YOUR OWN SAFETY:

READ AND UNDERSTAND THE OWNER'S

MANUAL BEFORE OPERATING MACHINE;

1. WEAR SAFETY GOGGLES PER ANSI Z87.1

AND FACE SHIELD IF OPERATION iS

DUSTY.

2. DO NOT WEAR GLOVES, NECKTIES, OR

LOOSE CLOTHING. TIE BACK LONG HAIR.

3. BE POSITIVE ALL LOCKS ARE TIGHT BE-

FORE OPERATING MACHINE,

4. TURN WORKPIECE BY HAND BEFORE

APPLYING POWER TO DETERMINE IF IT

CLEARS THE TOOL REST OR OTHER MA-

CHINE PARTS.

5. ROUGH OUT FACEPLATE WORKPIECES

BEFORE INSTALLING ON FACEPLATE TO

AVOID EXCESSIVE VIBRATION AND POS-

SIBLE INJURY,

6. DO NOT MOUNT SPLIT OR CHECKED

WORKP|ECE OR ONE CONTAINING KNOT.

7. ALWAYS USE LOWEST SPEED WHEN

STARTING A NEW WORKPIECE, USING

FACEPLATE OR TURNING BETWEEN CEN-

TERS, TO MINIMIZE POTENTIAL iNJURY.

t0. Think Safety,

11. Complete hand sanding of between-centers or

faceplate mounted workpieces BEFORE removing

from the lathe. Do not exceed the speed used for the

last cutting operation performed on the workpiece, in

accordance with the speed chart.

12. NEVER attempt to remount a faceptate turning to

the faceplate for any reason. NEVER attempt to

remount a between-centers turning if the original

centers in the turning have been altered or removed.

BE POSITIVE the lathe _s set at the lowest speed if

remounting a between-centers turning with

non-altered original centers.

t3. Use extra caution in mounting a between-centers or

spindle turning to the faceplate, or a faceplate turning

to between-centers, for subsequent operations. BE

POSITIVE the lathe is set at the _owest speed before

turning ON.

14, NEVER mount a workpiece that contains any splits,

checks, or loose knots to a faceplate or between

centers.

15. Do not perform any operation when hand holding the

workpiece. Do not mount a reamer, mHIing cutter,

wire wheeI, buffing wheel, or a drill bit to the

headstock spindie.

16. Use the drill chuck accessory in the tai! stock o_,_y,

Do not mount any dri_I that extends more than 6

inches beyond chuck jaws.

WARNING: DO NOT ALLOW FAMaUARITY (GAINED WARNING: THE FOUR STEP LATHE AND MOTOR

FROM FREO_ENT USE OF YOUR MACHINE) TO BE- PULLEYS FURNISHED ARE DESIGNED TO RUN THE

COME COMMONPLACE. ALWAYS REMEMBER THAT LATHEATTHECORRECTSPEEDSWHENUSEDWnTH

ACARELESSFRACTIONOFASECOND ISSUFFICIENT A 1725 R.PoM. MOTOR. DO NOT USE A 3450 R.P.M.

T01NFUCTSEVERE INJURY. MOTOR TO INCREASE THE SPEED BECAUSE IT

COULD BE DANGEROUS.

The operation of any power tool can result in foreign

objects being thrown into the eyes, which can result in

severe eye damage. Always wear safety gogg|escomplying

with ANSI Z87.1 (shown on Package) before commencing

power tool operation. Safety Gogglesare available at Sears

retail or catalog stores.

CONTENTS

GENERAL SAFETY INSTRUCTIONS FOR POWER TOOLS .... 2

ADDITIONAL SAFETY INSTRUCTIONS FOR WOOD TURNING

LATHE ....................................... 3

MOTOR SPECIFICATIONS AND ELECTRICAL

REQUIREMENTS ............................... 4

UNPACKING AND CHECKING CONTENTS ............... 5

ASSEMBLY . ; ................................... 6

Mounting Lathe and Motor on Workbench ........... 7

Spur and Cup/Center Installation ................. 9

Om0ff Switch ............................... I0

Check Motor Rotation ......................... 11

GETTING TO KNOW YOUR WOO D LATHE ............. 11

Belt Guard Lock ............................. 1t

Index Pin .................................. 11

Spindle Lock Hole .. ; ......................... 1t

Tool Rest Bracket Lock ........................ 11

Tool Rest Lock ............................... 11

To0t Rest Base Lock .......................... 1t

Handwheel .................................. 11

TailstockRam Lock ........................... 11

TailstockLock ............................... 11

Spur Center and Cup Center {Aligning Centers) ...... 12

Tailstock ................................... 12

SpeedChart ................................ 13

BASIC LATHE OPERATIONS ....................... 13

ChangingSpeeds ............................ 13

SpindleTurning ............................. 14

Indexing................................... 15

HOW TOUSE YOURCRAFTSMANWOOD-LATHE ........ 16

Woodworking Chisels and How to Use Them ........ 16

Making Standard Cuts ......................... 20

How to Handle Spindle Turnings ................. 22

Miscellaneous Operations ...................... 24

Faceplate and Chuck Turnings ................... 25

How to Make Fancy Faceplate Turnings ............ 26

How to Turn Plastics .......................... 28

Sanding, Buffing and Polishing .................. 29

MAINTENANCE ................................. 30

LUBRICATION .................................. 30

RECOMMENDED ACCESSORIES .................... 31

TROUBLESHOOTING ............................. 31

REPAIR PARTS ................................. 33

On*Off Switch .............................. 1t

motor specifications and

This Lathe is designed to use a 1725 RPM motor only. Do

not use any motor that runs faster than 1725 RPM. It is

wired for operation on 110.120 volts, 60 Hz., alternating

current, IT MUST NOT BE CONVERTED TO OPERATE

ON 230VOLTS. EVEN THOUGH SOME OF THE RE-

COMMENDED MOTORS ARE DUAL VOLTAGE.

THESE MOTORS HAVE BEEN FOUND TO BE

ACCEPTABLE FOR USE ON THIS TOOL,

HP RPM VOLTS CATALOG NO,

1/3 1725 110-120 1282

t/2 1725 110-120 1278

;/2 1725 110-120 1279

1/2 1725 1t0-120 1289

CAUTION: Do not use blower or washing machine motors

or any motor with an automatic resezoverload protector

astheir usemay be hazardous.

CONNECTING TO POWER SOURCE OUTLET

This machine must be grounded while in useto protect the

operator from electric shock.

Plug power cord into a 110-120V properly grounded type

outlet protected by a 15-amp. dual element time deiay or

Circuit-Saver fuse or circuit breaker,

If you are not sure that you r outlet is properly grounded,

have it checked by s qualified electrician.

WARNING: DO NOT PERMIT FINGERS TO TOUCH

THE TERMINALS OF PLUGS WHEN INSTALLING OR

REMOVING THE PLUG TO OR FROM THE OUTLET.

WARNING: IF NOT PROPERLY GROUNDED THIS

POWER TOOL CAN INCUR THE POTENTIAL HAZARD

OF ELECTRICAL SHOCK. PARTICULARLY WHEN

USED IN DAMP LOCATIONS IN PROXIMITY TO

PLUMBING. IF AN ELECTRICAL SHOCK OCCURS

THERE IS THE POTENTIAL OF A SECONDARY HAZ-

eJectrica requirements

ARD SUCH AS YOUR HANDS CONTACTING THE

CUTTING TOOL.

If power cord is worn or cut. or damaged in any way,

have it replaced immediately.

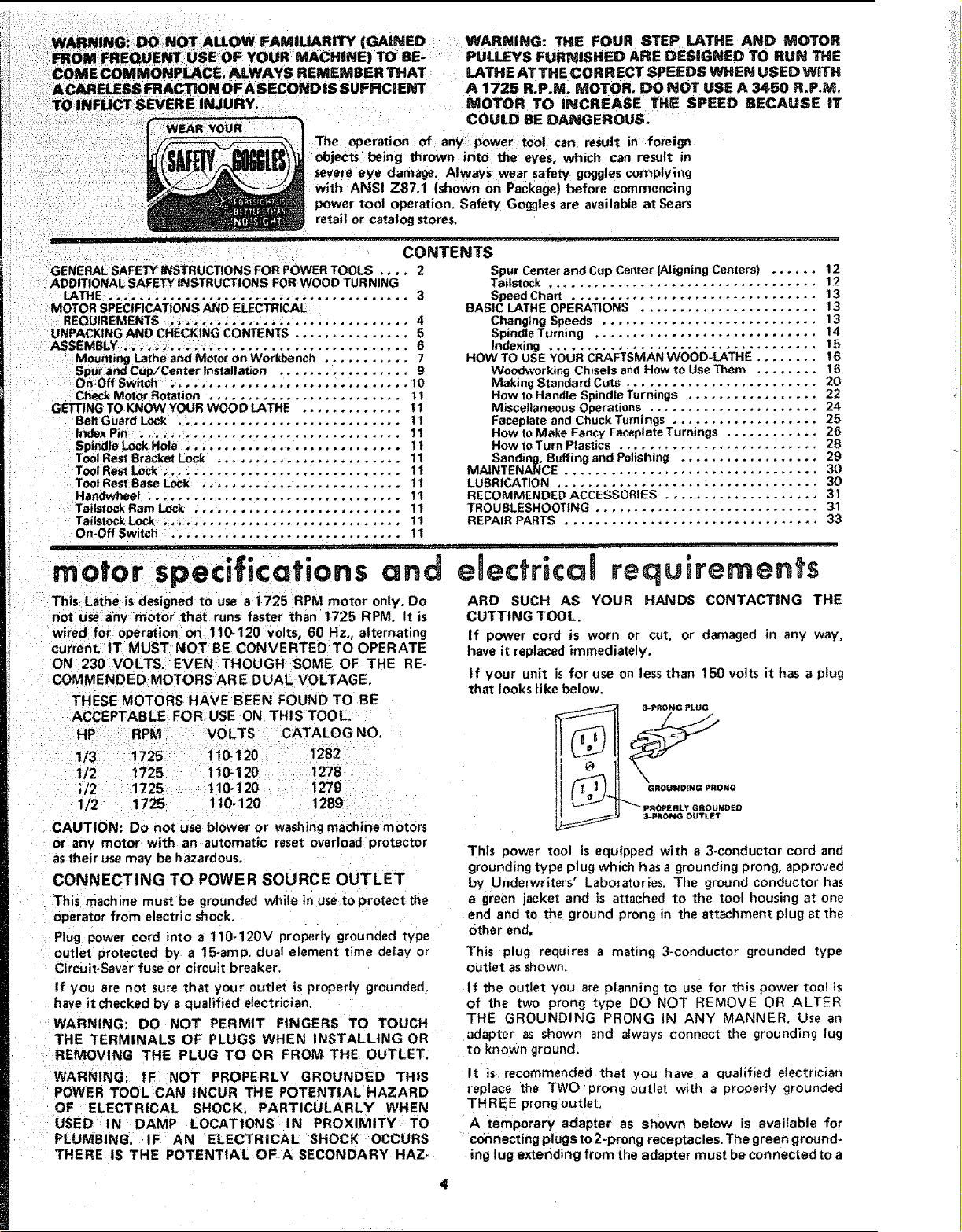

tf your unit is for use on less than t50 volts it has a plug

that looks like below.

_ _3"PROI_G PLUG

PROPERLY GROUNDED

_ GROUNOfNG P_tONG

This power tool is equipped with a 3-conductor cord and

grounding type plug which hasa grounding prong, approved

by Underwriters' Laboratories, The ground conductor has

a green jacket and is attached to the tool housing at one

end and to the ground prong in the attachment plug at the

other end.

This plug requires a mating 3-conductor grounded type

outlet as shown.

If the outlet you are planning to use for this power tool is

of the two prong type DO NOT REMOVE OR ALTER

THE GROUNDING PRONG IN ANY MANNER. Use an

adapter as shown and always connect the groundir_g lug

to known ground.

It is recommended that you have a qualified electrician

replace the TWO prong outlet with a properJy grounded

THRE_E prong Outlet.

A temporary adapter as shown below is available for

connecting plugs to 2-prong receptacles. Thegreen ground-

ing lug extending from the adapter must be connected to a

3-PltONG OUTLET

permanentgroundsuchastoapropertygroundedoutlet

box.

Atemporaryadapterasillustrated isavailable forconnecting

plugs to 2 -pro ngreceptecles, The temporary adapter shouId

be used only until a properly grounded outlet can be

installed bya qualified electrician,

GROUNDING LUG

i _ MAKE SURE THIS IS

3-PRONG _'_ [-._-_-_-_--CONNECTED TO A

_,_-._ _N_ L_ Jt_'_- 2-PRONG

,_,_ / _'-_J_ RECEPTACLE

ADAPTER

NOTE: The adapter illustrated is for use only if you already

have a properly grounded 2-prong receptacle.

The use of any extension cord will cause some loss of

power. To keep this to a minimum and to prevent over-

heating and motor burn-out, use the table below to deter-

NowNGROUND

i , !l,i , _1

assembly procedure

mine the minimum wire size (A,W.G.} extension cord, Use

only 3 wire extension cords which have 3-prong grounding

type plugs and 3-pole receptacles which accept the tools

plug,

Extension Cord Length Wire Size A.W.G.

Up to 100 Ft. t6

t00- 200 Ft. 14

200- 400 Ft. 10

CHECK MOTOR ROTATION

Place the motor on your workbench or on the floor.

Standing clear of the motor shaft, plug the motor cord into a

properly grounded outlet. Notice the rotation of the shaft,

As you look directly at the motor shaft it should be turning in

the clockwise direction _ . If the motor shaft is turning

clockwise, remove the plug from the power outlet and

continue the assembly procedures, If the motor is turning

counterclockwise, remove the plug from the power outlet

and contact your Sears Store immediately.

!, !,,,,i , , ...... •.....

TOOLS NEEDED

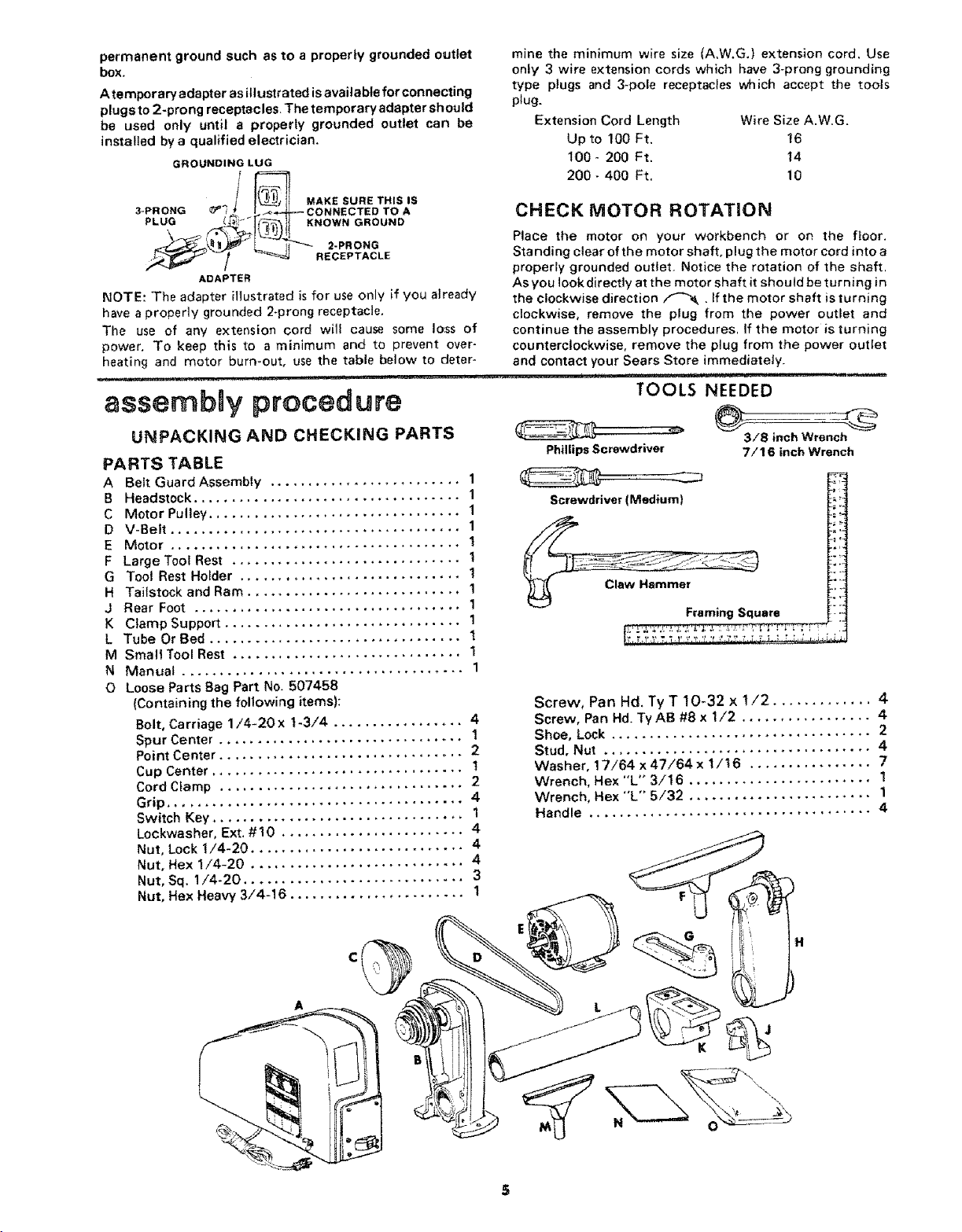

UNPACKING AND CHECKING PARTS

PARTS TABLE

A Belt Guard Assembly ......................... 1

B Headstock ................................... 1

C Motor Pulley ................................. 1

D V-Belt ...................................... 1

E Motor ...................................... 1

F Large Toot Rest .............................. !

G Tool Rest Holder ............................. 1

H Tailstock and Ram ............................ 1

J Rear Foot ................................... 1

K Clamp Support ............................... 1

L Tube Or Bed ................................. 1

M Small Tool Rest .............................. 1

N Manual ..................................... 1

0 Loose Parts Bag Part No. 507458

(Containing the following items):

Bolt, Carriage 1/4-20x 1-3/4 ................. 4

Spur Center ................................ 1

Point Center ................................ 2

Cup Center ................................. I

Cord Clamp ................................ 2

Grip ....................................... 4

Switch Key ................................. 1

Lookwasher, Ext, #10 ........................ 4

Nut, Lock !/4-20 ............................ 4

Nut, Hex 1/4-20 ............................ 4

Nut, Sq. 1/4-20 ............................. 3

Nut, Hex Heavy 3/4-16 ....................... 1

Phillips Screwdriver

Screwdriver (Medium)

Framing Square

3/8 inch Wrench

7/16 inch Wrench

Screw, Pan Hd. Ty T 10-32 x !/2 ............. 4

Screw, Pan Hd. Ty AB #8 x 1/2 ................. 4

Shoe, Lock .................................. 2

Stud, Nut ................................... 4

Washer, 17/64 x 47/64 x 1/16 ................ 7

Wrench, Hex "L'" 3/16 ........................ 1

Wrench, Hex "'L" 5/32 ........................ 1

Handle ..................................... 4

A

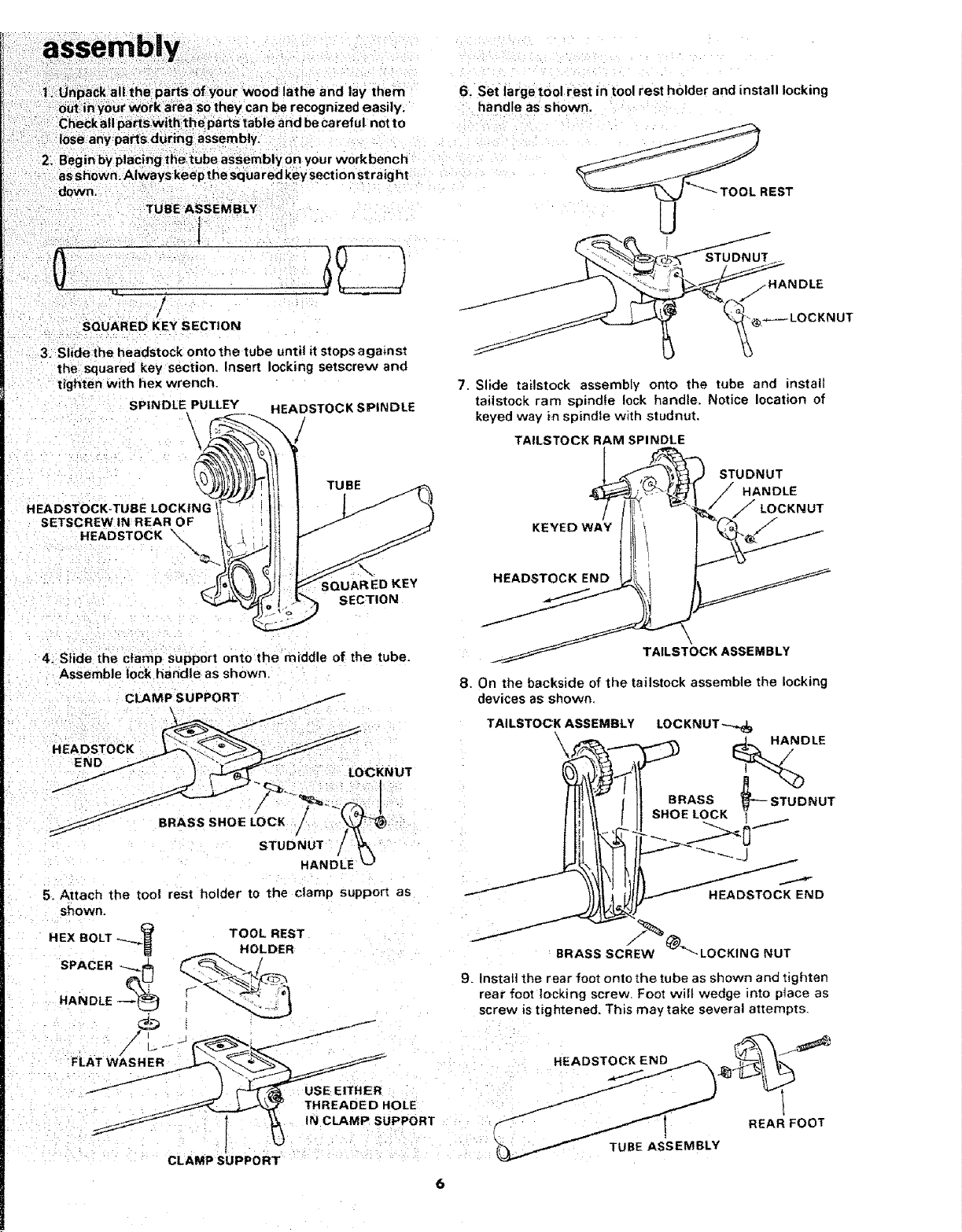

assembly

1. UnpaCk all the part_ of your wood lathe and lay them

0ut in your work area so they can be recognized easily.

Checkall partswith the parts table and be careful not to

" i lose any parts during assembly.

2_ Begin by placing thetUbe assembly on your workbench

as shown. Always keep the squa red key section straig ht

down.

TUBE ASSEMBLY

l

!

SQUARED KEY SECTION

. 3. Slide the headstock onto the tube until it stops against

the squared key section, Insert locking setscrew and

tighten with hex wrench.

HEADSTOCK-TUBE LOCKING

SETSCREW tN REAR OF

HEADSTOCK X

/

SPINDLE PULLEY

t

HEADSTOCK SPINDLE

TUBE

6. Set large tool rest in tool rest holder and install locking

handle as shown.

REST

Slide tailstock assembly onto the tube and install

tailstock ram spindle lock handle. Notice location of

keyed way i_ spindle with studnut,

TAILSTOCK RAM SPINDLE

STUDNUT

HANDLE

/ LOCKNUT

KEYED

_ED KEY

SECTION

4. Slide the clamp support onto the middle of the tube.

Assemble lock handle as shown.

5. Attach the tool rest bolder to the clamp supporl as

shown,

HEX BOLT _.__ TOOL REST

sPACE"

HANDLE _% : "_'_-2

HOLDER

HEADSTOCK END _

TAILSTOCK ASSEMBLY

8. On the backside of the tailstock asse ruble the locking

devices as shown.

TAILSTOCK ASSEMBLY LOCKNUT_

_._... ,.,....%% ,._ HANDLE

lllill t s.o2?0CKV---STUONOT

t!!.IIYI f- -----J

ND

BRASS SCREW @"_'-LOCKING NUT

9. Instal] the rear foot onto the tube as shown and tighten

rear foot to,cking screw, Foot wilt wedge into ptace as

screw is tightened. This may take several attempts,

LATWASHER @"a

_ THREADED HOLE

_ I _ IN CLAMP SUPPORT

CLAMP SUPPORT

"--..

HEADSTOCK END

I REAR FOOT

TUBE ASSEMBLY

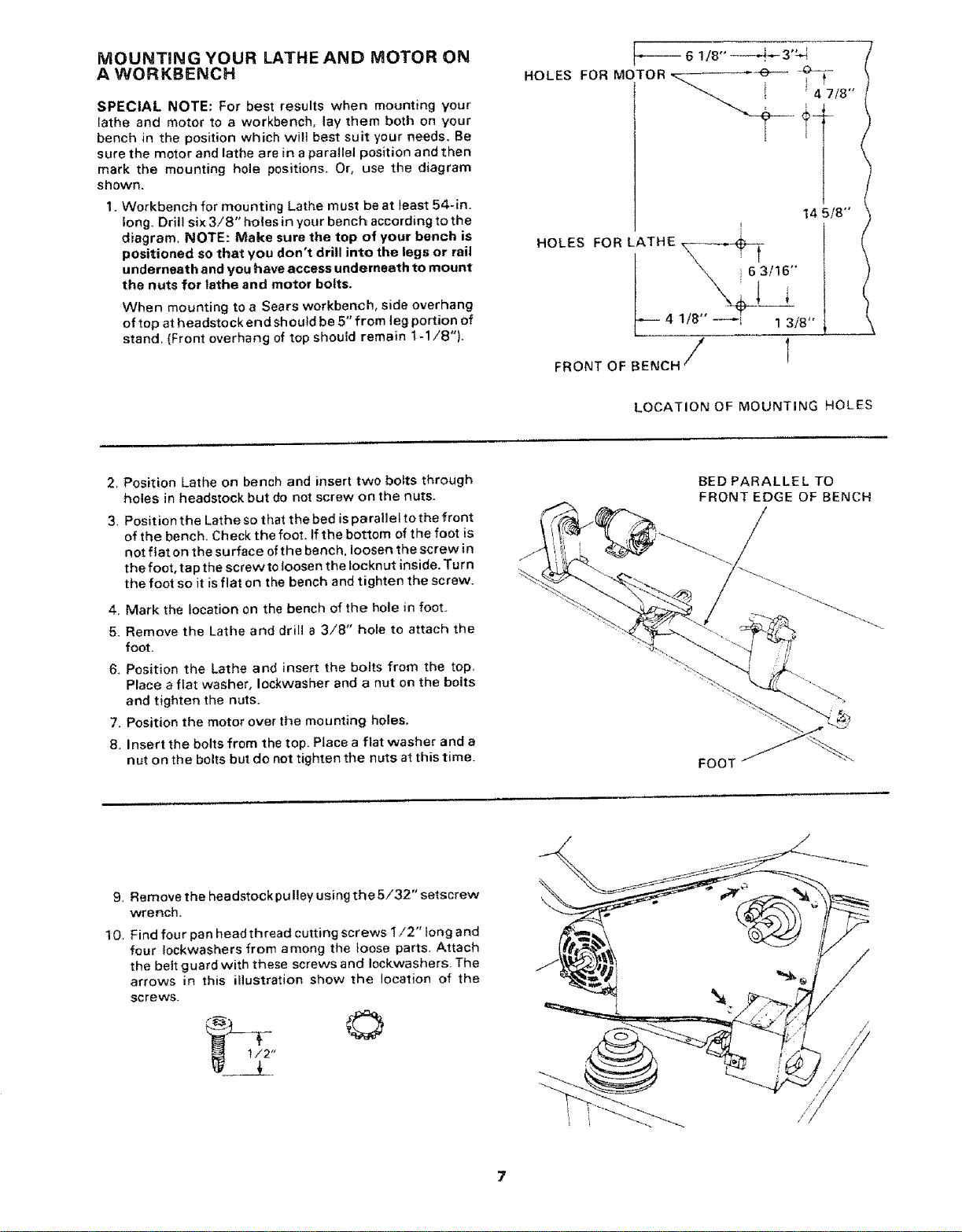

MOUNTING YOUR LATHE AND MOTOR ON

A WORKBENCH

SPECIAL NOTE: For best results when mounting your

lathe and motor to a workbench, lay them both on your

bench in the position which will best suit your needs. Be

sure the motor and lathe are in a parallel position andthen

mark the mounting hole positions. Or, use the diagram

shown.

1. Workbench for mounting Lathe must be at least 54-in.

long. Drill six 3/8" holes in your bench according to the

diagram, NOTE: Make sure the top of your bench is

positioned so that you don't drill into the legs or rail

underneath and you have access underneath to mount

the nuts for lathe and motor bolts.

When mounting to a Sears workbench, side overhang

of top at headstock end should be 5" from leg portion of

stand. (Front overhang of top should remain 1-1/8").

6 1t8' ----+--, 3'_

HOLES FOR MOTOR i 4f7/8 '"

14 5/8"

HOLES FOR LATHE,

6 3/16"

4 118" ---i 1 3/8"

FRONT OF BENCH E

LOCATION OF MOUNTING HOLES

/ ,

2. Position Lathe on bench and insert two bo_ts through

holes in headstock but do not screw on the nuts.

3, Position the Lathe so that the bed is paralleltothe front

of the bench. Check the foot, if the bottom of the foot is

not fiat on the surface of the bench, loosen the screw in

the foot, tap the screw to loosen the Iocknut inside. Turn

the foot so it is flat on the bench and tighten the screw,

4, Mark the location on the bench of the hole in foot.

5, Remove the Lathe and drill a 3/8" hole to attach the

foot.

6. Position the Lathe and insert the bolts from the top,

Place a flat washer, Iockwasher and a nut on the bolts

and tighten the nuts.

7. Position the motor over the mounting holes.

8. Insert the bolts from the top. Place a flat washer and a

nut on the bolts but do not tighten the nuts at this time.

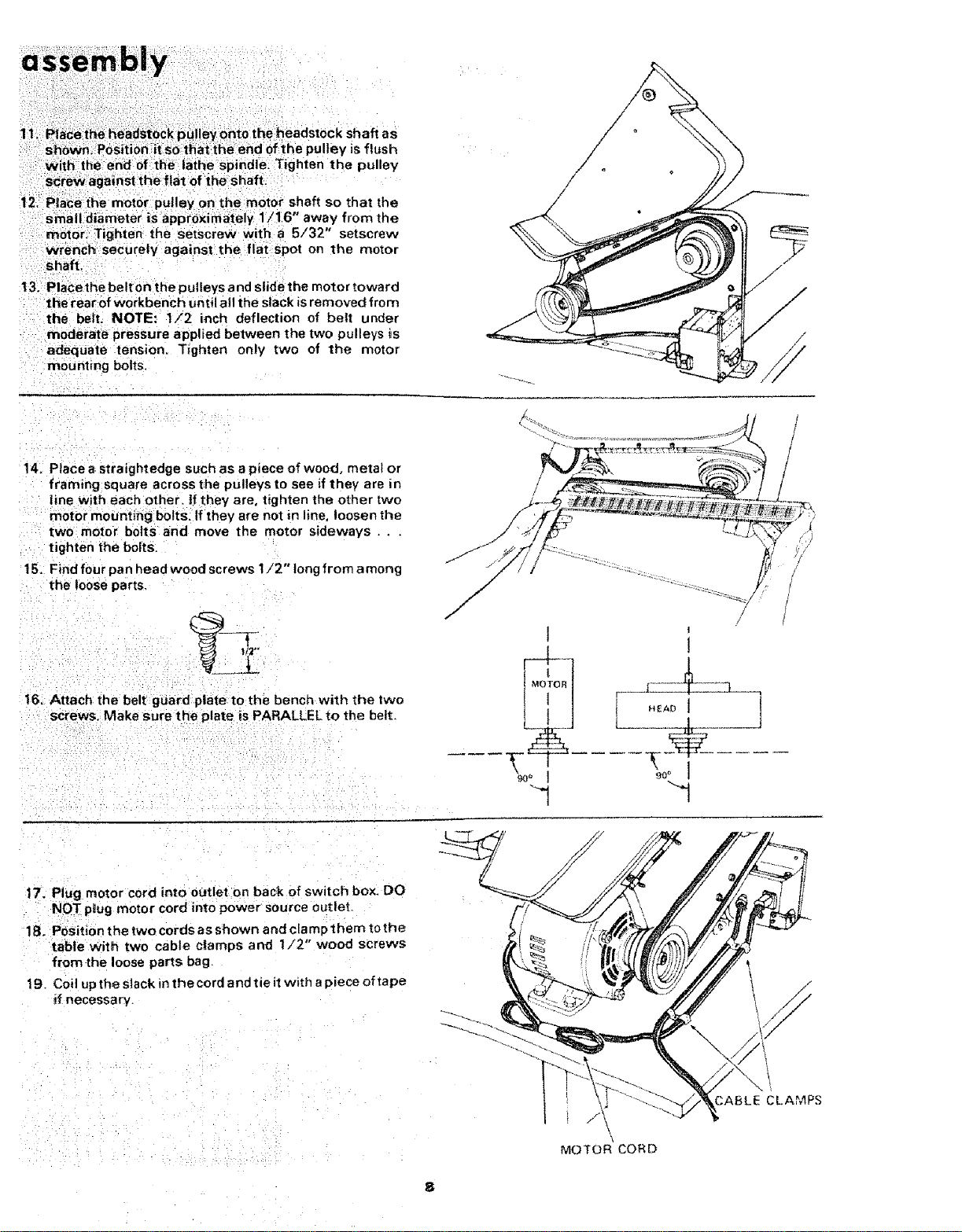

9, Removethe headstockpulleyusingtheS/32"setscrew

wrench.

10, Find four pan head thread cutting screws 1/2" tong and

four Iockwashers from among the loose parts. Attach

the bett guard with these screws and Iockwashers_ The

arrows in this illustration show the location of the

screws.

BED PARALLEL TO

FRONT EDGE OF BENCH

FOOT

/

With the end of the la{he spindle: Tighten the pulley

screw against the flat:of theshaft

12, P|ace the motor pulley on the motor shaft so that the

small diameter is approximately 1/16 away from the

motor. Tighten the setscrew with a 5/32" setscrew

wrench securety against the flat spot on the motor

shaft.

t3. Place the belt on the pulleys and slide the motor toward

the rear of workbench until all the slack isremoved from

the belt. NOTE: 1/2 inch deflection of belt under

moderate pressure applied between the two pulleys is

adequate tension. Tighten only two of the motor

mounting bolts.

14. Place a straightedge such as a piece of wood, metal or

framing square across the pulleys to see if they are in

line with each other, tf they are, tighten the other two

motor mounting bolts. If they are not in line, loosen the

two motor bolts and move the motor sideways .

tighten the boJts.

15. Find four pan head wood screws t/2" long from a mong

the loose parts

16, Attach the belt guard plate to the bench with the two

screws. Make sure the plate is PARALLEL to the belt.

17. Plug motor cord into outlet o n back of switch box. DO

NOT pJ4ugmotor cord into power source outlet

18. Position the twocordsasshown andclamp themtothe

table with two cable clamps and 1/2" wood screws

from the loose parts bag.

t9. Coil upthe stack in the cord and tie it with a piece oftape

if necessary.

CABLE CLAMPS

MOTOR CORD

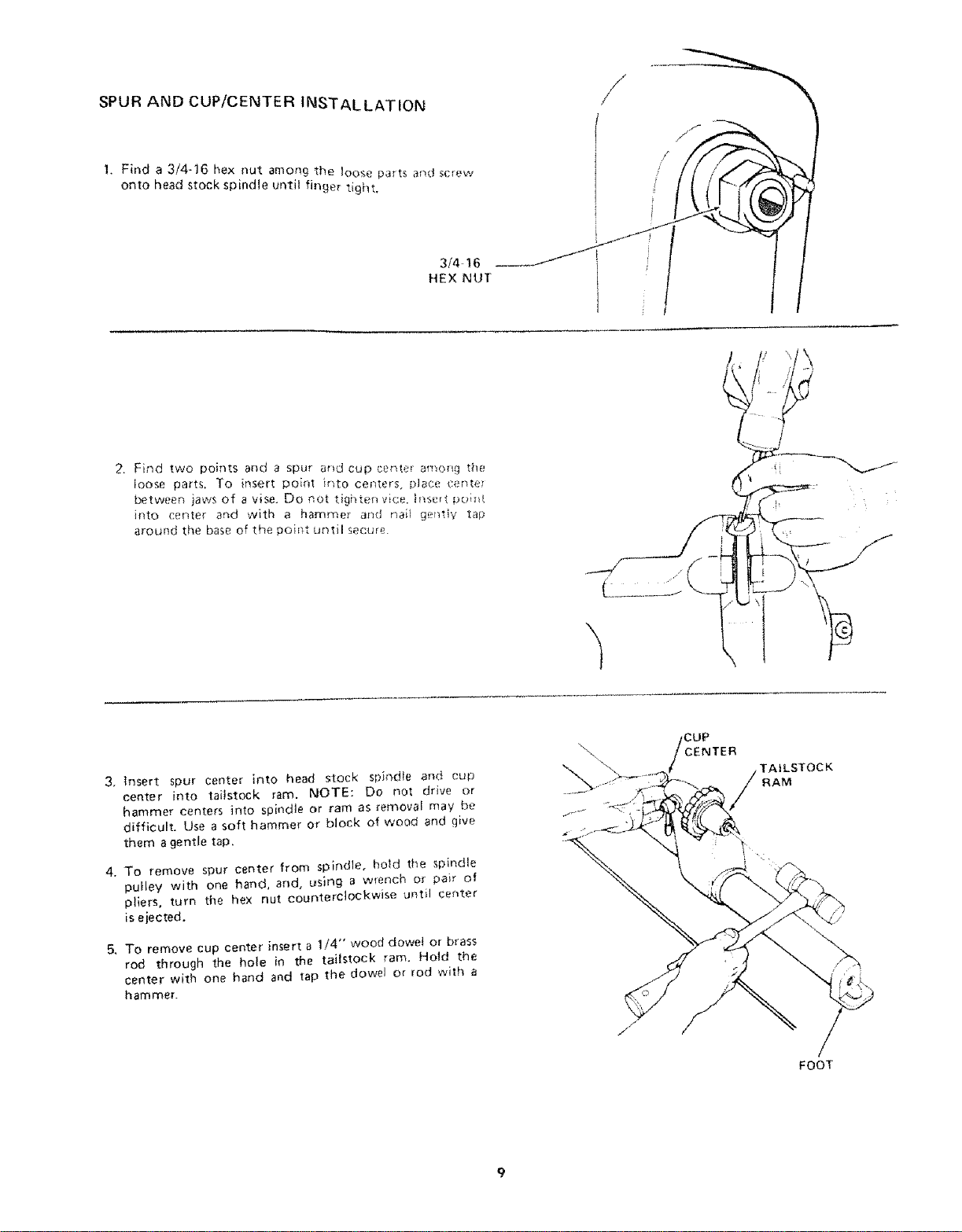

SPUR AND CUP/CENTER 1NSTALLATIOt_

1, Find a 3/4-16 hex nut among the loose parts and scr(_w

onto head stock spindle until finger tight,

3/4 16

HEX NUT

2. Find two points and a spur ahd cup ct.m_er amo_g the

loose parts. To insert poir_t ir_to cer_ters, _)Jace cente_

between jaws of a vise. Do not ti£hte[_vice h_seq p[_i_

into center and with a hammer and r_ai_ ger_tly tap

around the base of the poh_t until secure

/

i!. |

J

f

3, Insert spur center into head stock spir_dle and cup

center into tai;stock ram. NOTE: Do not drive or

hammer centers into spindte or ram as removal may be

difficult, Use a soft hammer or block of wood and give

them a gentle tap,

4. To remove spur center from spindle, hen the spindle

pulley with one hand, and, using a wrench or pair of

pliers, turn the hex nut counterclockwise until center

is ejected.

& To remove cup center insert a 1/4" wood dowe_ or brass

rod through the hole in the tailstock ram. Ho{d the

center with one hand and tap the dowet or rod with a

hammer.

\

CENTER

TAILSTOCK

RAM

FOOT

assemblly

WARNING:OONT CONNECTPOWERCOROTO

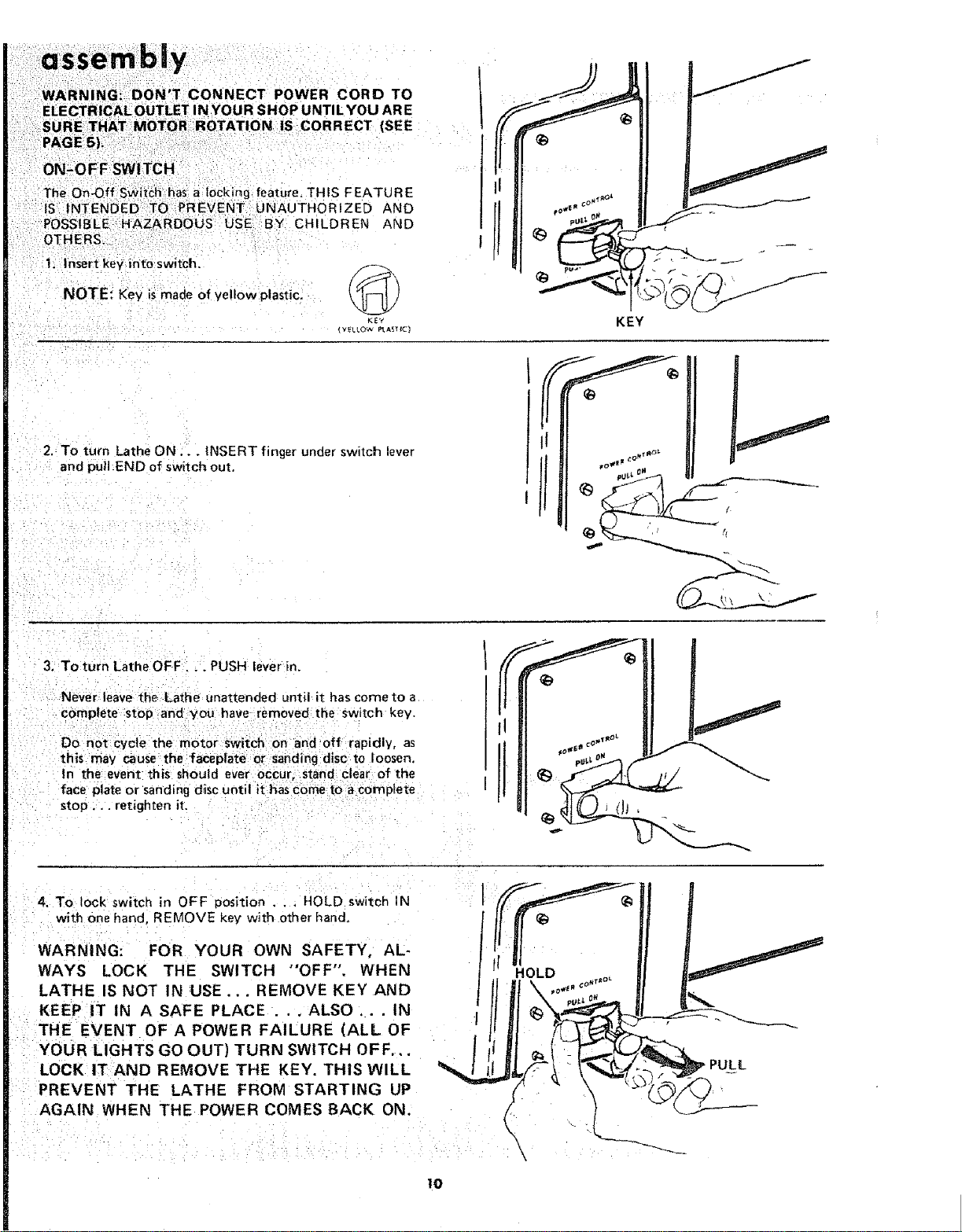

ON-OFF SWITCH

The On-Off Switch has a locking feature. THIS FEATURE

IS INTENDED TO PREVENT UNAUTHORIZED AND

POSSIBLE =HAZARDOUS USE BY CHILDREN AND

OTHERS.

1, Insert key into switch.

NOTE: Key is made of yellow _lastic. _1;

K E Y

(YELtOW _AST It1

2. To turn Lathe ON,.. INSERT finger under switch lever

and pull END of switch out.

J

KEY

3.: To turn Lathe OFF... PUSH lever in,

Never leave the Lathe unattended until it has come to a

complete stop ant you have removed the switch key.

Do net cycle the motor switch on and off rapidly, as

this may cause the faceplate or sanding disc to loosen.

In the event this should ever occur, stand clear of the

face plate or sanding d_sc until it has come to a complete

stop, ,. retignten it.

4. To lock switch in OFF position . . . HOLD switch IN

with one hand, REMOVE key with other hand.

WARNING: FOR YOUR OWN SAFETY, AL-

WAYS LOCK THE SWITCH "OFF". WHEN

LATHE IS NOT IN USE ... REMOVE KEY AND

KEEP IT IN A SAFE PLACE . ALSO. IN

THE EVENT OF A POWER FAI'LURE (ALL'OF

YOUR LIGHTS GO OUT) TURN SWITCH OFF,,.

LOCK IT AND REMOVE THE KEY. THiS WILL

PREVENT THE LATHE FROM STARTING UP

AGAIN WHEN THE POWER COMES BACK ON.

_OLD

I

I

PULL

\

\

Io

ROTATION

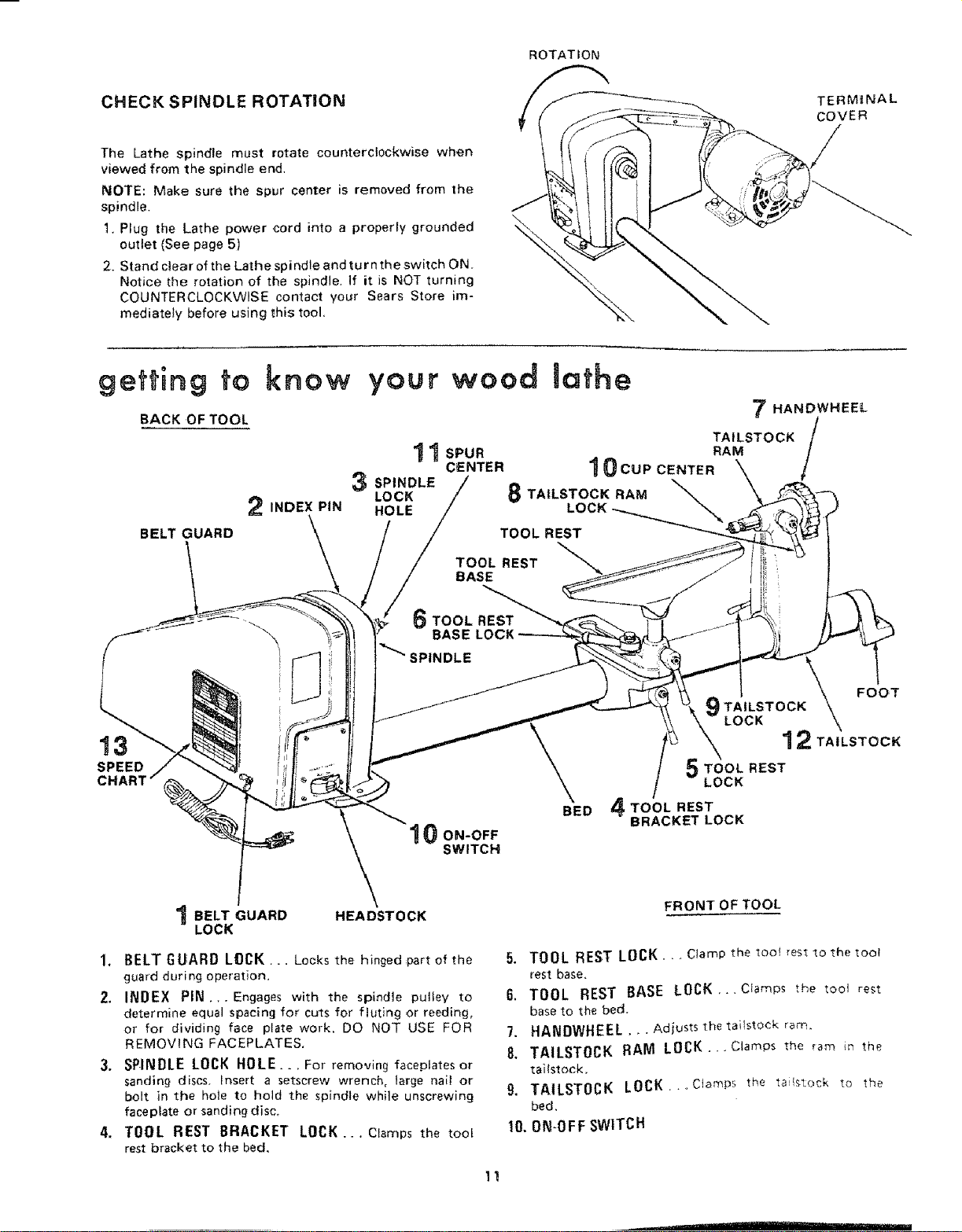

CHECK SPINDLE ROTATION

The Lathe spindle must rotate counterclockwise when

viewed from the spindle end,

NOTE: Make sure the spur center is removed from the

spindle.

1. Plug the Lathe power ,cord into a properly grounded

outlet (See page 5)

2. Stand clear of the Lathe spindle and tur n the switch ON.

Notice the rotation of the spindle. If it is NOT turning

COUNTERCLOCKWISE contact your Sears Store im-

mediately before using this tool,

getting to know

BACK OF TOOL

your b'VO Od

11spu.

CENTER

3 SPINDLE

2 INDEX PIN

BELT GUARD

LOCK

HOLE

lathe

1 0 CUP CENTER

8 TAILSTOCK RAM

TOOL REST

TERMINAL

coVER

7 HANDWHEEL

TAILSTOCKRAM /

TOOL REST

BASE LO¢

SPINDLE

!3

SPEED

SWITCH

1 0 ON-OFF

1 BELT GUARD

LOCK

I. BELT GUARD LOCK... Locks the hinged part of the

guard during operation.

2. INDEX PIN.,. Engages with the spindle pufley to

determine equal spacing for cuts for fluting or reeding,

or for dividing face plate work. DO NOT USE FOR

REMOVING FACEPLATES,

3. SPINDLE LOCK HOLE.., For removing faceplates or

sanding discs, insert a setscrew wrench, large na_I or

bolt in the hole to hold the spindle while unscrewing

faeep_ate or sanding disc,

4. TOOL REST BRACKET LOCK._. Clamps the tool

rest bracket to the bed,

HEADSTOCK

TOOL REST _"_

BASE

\

5. TOOL REST LOCK.., Clamp the too_rest to the tOOl

rest base.

6. TOOL REST BASE LOCK... Clamps the tool rest

base to the bed.

7. HANDWHEEL • . . Adjusts the tailstock ram.

8. TAILSTOCK RAM LOCK,.. Clamps the ram in the

taiistock,

9, TAILSTOCK LOCK.,-CIamPs the tailstock to the

bed,

10. 0N-0FF SWITCH

BED

)TAILSTOCK

FOOT

LOCK

12 TA,LSTOCK

TOOL REST

LOCK

4 TOOL REST

BRACKET LOCK

FRONT OF TOOL

11

,, °_--=1!--= ......... i

Loading...

Loading...