Craftsman 113226431 Owner’s Manual

l!lll ii i i i

Save This Manual For

Future Reference

BELT AND DiSC

SANDER

Serial

Number

Model and serial number may be

found onthe back side ofthe base

You shouldrecordboth modeland

serial number in a safe place for

future use.

ll,.i.i., i ,.i.H,,, i i i

FOR YOUR

SAFETY:

READ ALL

iNSTRUCTiONS

CAREFULLY

SoRd by SEARS, ROEBUCK AND CO., Chicago, IL. 60684 U°S.A.

SF_ARS/CRA

BEI_T AND DISC

SANDER

• assembly

• operating

• repair parts

P_,n.... in ChEr;aPart No, SP5632 _ *_ '

FULL ONEYEAR WARRANTY ON CRAFTSMAN BELT AND DISC SANDER

ifwithin one yearfromthe dateofpurchase, this Craftsman BeItandDiscSander failsdueto adetect Inmaterial

orworkmanship, Sears will repairit, free of charge.

WARRANTY SERVICE IS AVAILABLE BY SIMPLY CONTACTING THE NEAREST SEARS SERVICE CENTER/

DEPARTMENTTHROUGHOUT THEUNITED STATES.

THISWARRANTY APPLIES ONLYWHILE THIS PRODUCTIS USED IN THE UNITED STATES.

Thiswarranty gives youspecific legalrighta,andyou may alsohaveotherrightswhichvary from stateto state.

SEARS, ROEBUCK AND CO., D/817 WA Hoffman Estates, IL 60195

safety instructions for

Safety isa combination of common sense, staying alert

and knowinghowyourbelt anddisc sanderworks. Read

this manual to understand this sander.

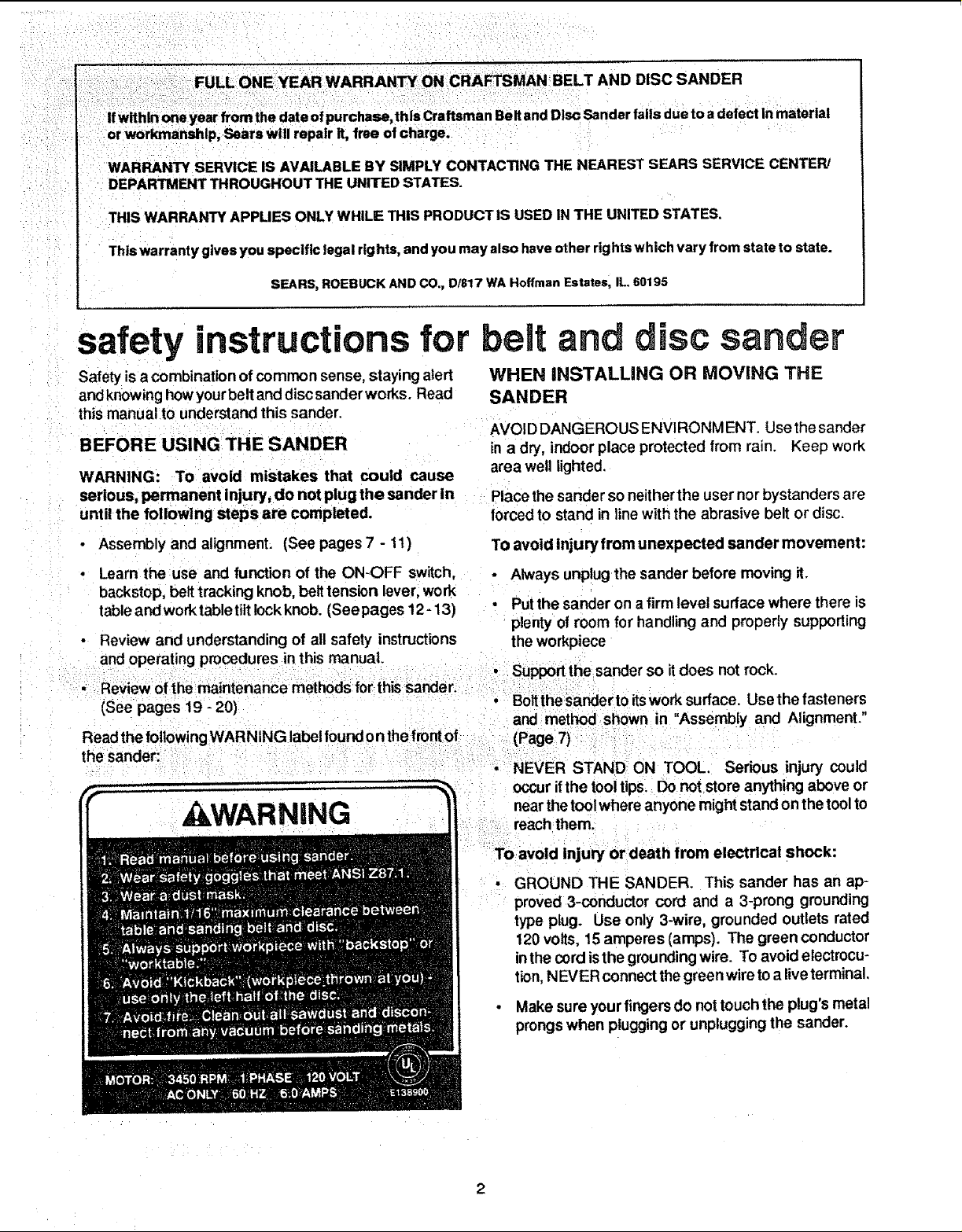

BEFORE USING THE SANDER

WARNING: TO avoid mistakes that could cause

serious, permanent injury, do not plug the sander in

until the following steps are completed.

Assembly and alignment. (See pages 7 - 11)

Learn the use and function of the ON-OFF switch,

backstop, belt tracking knob,belt tension lever,work

table andwork table titt lock knob. (Seepages 12-13)

Review and understanding of all safety instructions

and operating procedures in this manual.

Review of the maintenance methods for this sander.

(See pages 19 - 20)

Readthe followingWARNING abelfoundonthefrontof (Page 7)

the sander:

belt and disc sander

WHEN INSTALLING OR MOVING THE

SANDER

AVOID DANGEROUS ENVIRONMENT. Usethe sander

in a dry, indoor place protected from rain. Keep work

area well lighted.

Place the sander so neither the user nor bystanders are

forced to stand in line with the abrasive belt or disc.

To avoid Injury from unexpected sander movement:

Always unplugthe sander before moving it.

Putthe sander on a firm level surface where there is

plenty of room for handling and properly supporting

the workpiece

• Support the sander so it does not rock.

• Boltthe sanderto itswork surface, Use the fasteners

and method shown in "Assembly and Alignment."

• NEVER STAND ON TOOL, Serious injury could

occur ifthe tool tips. Do not store anything above or

ILWAR,,l"'ING near thetool where anyone might stand on thetoolto

GROUND THE SANDER. This sander has an ap-

proved 3-conductor cord and a 3-prong grounding

type plug. Use only 3-wire, grounded outlets rated

120 volts, 15amperes (amps). The green conductor

in the cord isthe grounding wire. To avoid electrocu-

tion, NEVER connect the green wire to alive terminal,

Make sure your fingers do not touch the plug's metal

prongs when plugging or unplugging the sander.

BEFORE EACH USE:

inspect your sander.

PLAN AHEAD TO PROTECT YOUR EYES,

HANDS, FACE, EARS.

DISCONNECT THE SANDER. To avoid injury from

accidental starting, unplugthe sander, turnthe switchoff

and remove the switch key before changing the setup,

sanding disc or belt or adjusting anything.

CHECK DAMAGED PARTS. Check for:

. alignment of moving parts,

. binding of moving parts,

° broken parts,

• workpartsthatcauseagaplargerthan 1/16"between

work support and sanding surface,

° sanding belt narrowerthan 4 inches. Narrower belts

uncover parts that could trap your fingers,

- worn or damaged electric cords,

• stable mounting, and

• any other conditions that may affect the way the

sander works.

If any part is missing, bent, or broken inany way, or any

electrical parts don't work properly, turn the sander off

and unplug the sander. REPLACE damaged, missing,

or failed parts before using the sander again.

MAINTAIN TOOLS WITH CARE. Keep the sander

clean for best and safest performance. Follow instruc-

tions for lubricating.

REMOVE ADJUSTING KEYS AND WRENCHES from

tool before turning iton.

KNOW YOUR SANDER. Read and understand the

owner's manual and labels affixed to the tool. Learn its

application and limitations as well as the specific poten-

tial hazards peculiar to this tool.

To avoid injury from accidental contact with moving

pads:

, KEEP GUARDS IN PLACE and in working order.

Don't do layout, assembly, or setup work on the

sander while any parts are moving.

AVOIDACCIDENTALSTARTtNG. Make sure switch

is "OFF" before plugging sander into a power outlet.

Plan your work.

USE THE RIGHT TOOL. Don't force tool or attachment

to do a job it was not designed to do.

CAUTION: This machine is not designed for heavy

deburring operations. When finishing metals, sparks

or hot fragments could cause a fire, To avoid this:

• Disconnect any dust collecting hose from the

sander.

• Remove all traces of wood dust from inside the

sander.

. Remove all traces of metal dust from Inside the

sander before sanding wood again.

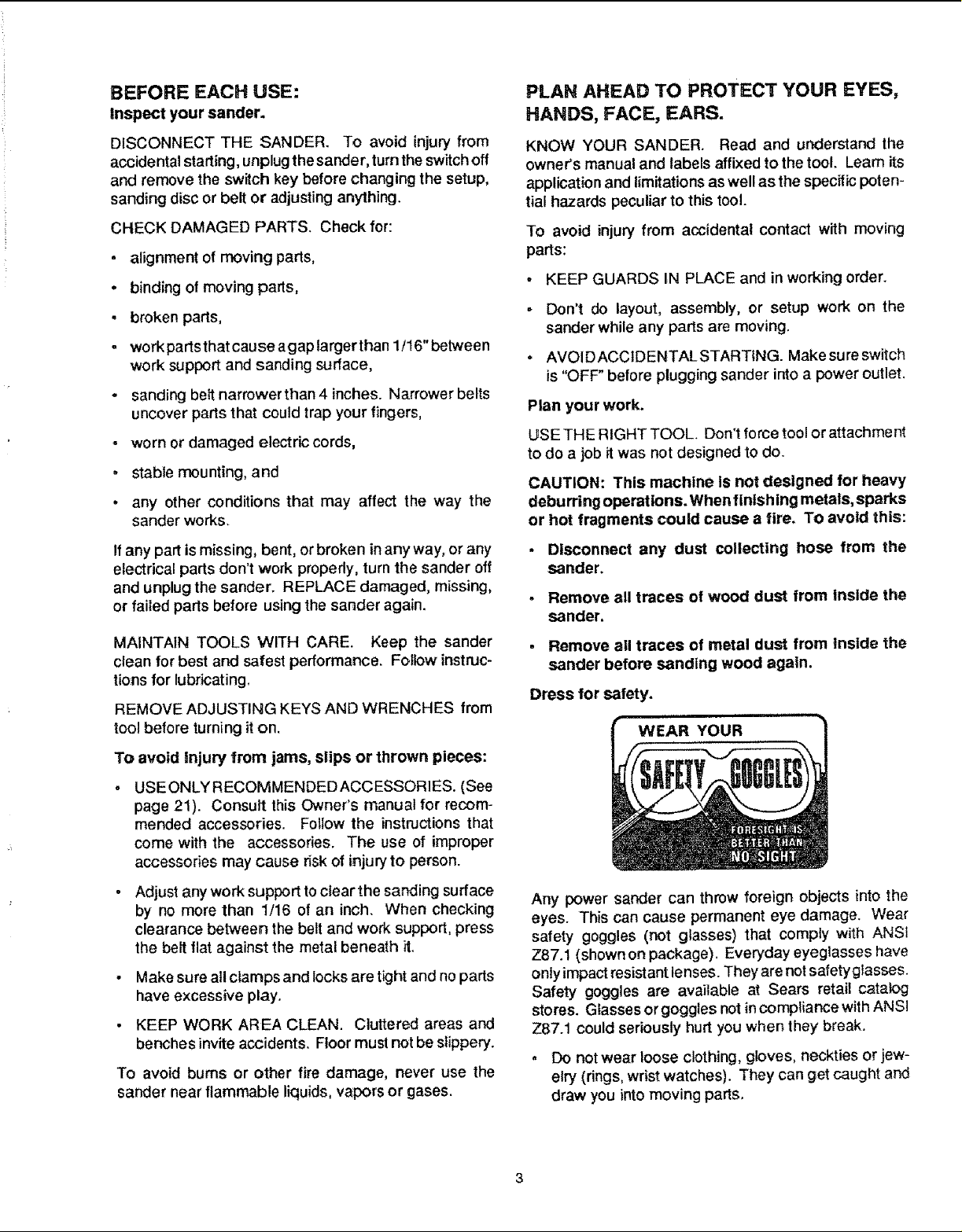

Dress for safety.

To avoid Injury from jams, slips or thrown pieces:

, USEONLYRECOMMENDEDACCESSORIES. (See

page 21). Consult this Owner's manual for recom-

mended accessories. Follow the instructions that

come with the accessories. The use of improper

accessories may cause r_skof injury to person.

• Adjust any work support to clear the sanding surface

by no more than 1/16 of an inch. When checking

clearance between the belt and work support, press

the belt flat against the metal beneath it.

• Make sure ait clamps and locks are tight and no parts

have excessive play.

• KEEP WORK AREA CLEAN. Cluttered areas and

benches inviteaccidents. Floor must not be slippery.

To avoid bums or other fire damage, never use the

sander near flammable liquids, vapors or gases.

Any power sander can throw foreign objects into the

eyes. This can cause permanent eye damage. Wear

safety goggles (not glasses) that comply with ANSI

Z87.1 (shown on package). Everyday eyeglasses have

onlyimpact resistant lenses. They are not safetyglasses.

Safety goggles are available at Sears retail catalog

stores. Glasses or goggles not incompliance with ANSI

Z87°1 could seriously hurt you when they break.

, Do notwear loose clothing, gloves, neckties or jew-

elry (rings, wrist watches). They can get caught and

draw you into moving parts,

disc sander

Plan the way you will hold the workplece from start

w

• To avoid possible headng sandingsudace. Keepfingersawayfromwherethebelt

muffs wl_en using sander" goes into the dust trap.

to finish.

Avoid awkward operations and hand positions where a

sudden slip could cause fingers or hand to move intoa

DON'TOVERREACH. Keepgoodfooting and balance.

mask along with the safety goggles.

Inspect your workplece

Make sure there are no nails orforeign objectsinthe part

of the workpiece to be sanded.

Plan your work to avoid THROWBACKS. when the

workplece catches on the sanding belt or disc and Is

torn from your hands.

- Make sure there's no debris between the workpiece

and its supports.

- When sanding irregularly shaped workpieces, plan

yourwork support so itwill not slipand be pulled from

your hands.

Use extra caution with large, very small or awkward

workpieces.

Never usethis tool to finishpieces too small to hold by

hand.

- Use extra supports (tables, saw horses, blocks, etc.)

for any wor_moieceslarge enough totip when not held

down tO the table top.

- NEVER use anotherpe_son as a substitute fora table

extension, or as additiona! support for a workpiece

that is longer or wider than the basic sander table, or

to help feed, support or pull the workpiece.

• When finishing on the disc, always press the work-

piece against the "Down" side of the disc, Sanding

against the side coming up from under the table could

damage the work by making it "chatter," or tear the

work from your hands and throw it.

*J

Sand onlyone workpiece at a time,

w

Clear everything except the workpiece and related

support devices off thetable before turningthe sander

on.

Keep your face and body to one side, out ol line with a

possible throwback.

WHENEVER SANDERIS RUNNING

WARNING: Don't let familiarity (gained from fre-

quent use of your belt and disc sander) cause a

careless mistake, A careless fraction of a second is

enough to cause a severe Injury,

Beforestarting your work,watch thesander while itruns.

If it makes an unfamiliar noise or vibrates a lot, stop

immediately. Turn the sander off. Unplug the sander.

Do not restartuntil finding and correcting the problem.

Make sure the sanding disc turns counterclockwise

before using the sander.

KEEP CHILDREN AWAY. Keep all visitors a safe

distance from the sander. Make sure bystanders are

clear of the sander and workpiece.

DON'T FORCE TOOL, Itwill do thejob better and safer

at its designed rate. Press the workpiece against the

sanding material only hard enough to let it sand without

bogging down or binding.

Before freetng any jammed material:

• Tum switch "OFF."

Unplug the sander.

Wait for all moving parts to stop.

BEFORE LEAVING THE SANDER:

NEVER LEAVE TOOL RUNNING UNATTENDED.

TURN POWER OFF. Don't leave tool until it comes to

a complete stop.

MAKE WORKSHOP CHILD-PROOF. Lock the shop.

Disconnect master switches. Remove the yellow switch

key. Store it awayfrom childrenand others not qualified

to use the tool.

motor specifications

requirements

electricam

This machine is designed to use, and is equipped with,

a 3450 RPM motor. It iswired for operation on 120 volts,

60 Hz., alternating currentL

WARNING: To avoid electrocution or fire, tool must

not be converted to operate on 240 volts.

For replacement motor, refer to parts list in this manual.

CONNECTING TO POWER SUPPLY

OUTLET

This machine must be grounded while in use to protect

the operator from electric shock.

In the event of a malfunction or breakdown, grounding

provides a pathof least resistance for electric current to

reduce the risk of electric shock.

Plug power cord into a 120V properly grounded type

outlet protected by a 15 amp fuse or circuit breaker.

WARNING: To avoid electrocution: Do not let fin-

gem touch the terminals of plugs when Insta!ling or

removing the plug tO or lrom the outlet.

WARNING: it not properly grounded, this power tool

can cause an electrical shock, particularly when

used tn damp locations close to plumbing. If an

electrical shock occurs there is the potential of a

secondary hazard, such as your hands contacUng

the sanding surface.

WARNING: To avoid electrocution or tire, if power

cord is worn or cut, or damaged In any way, have it

replaced Immediately.

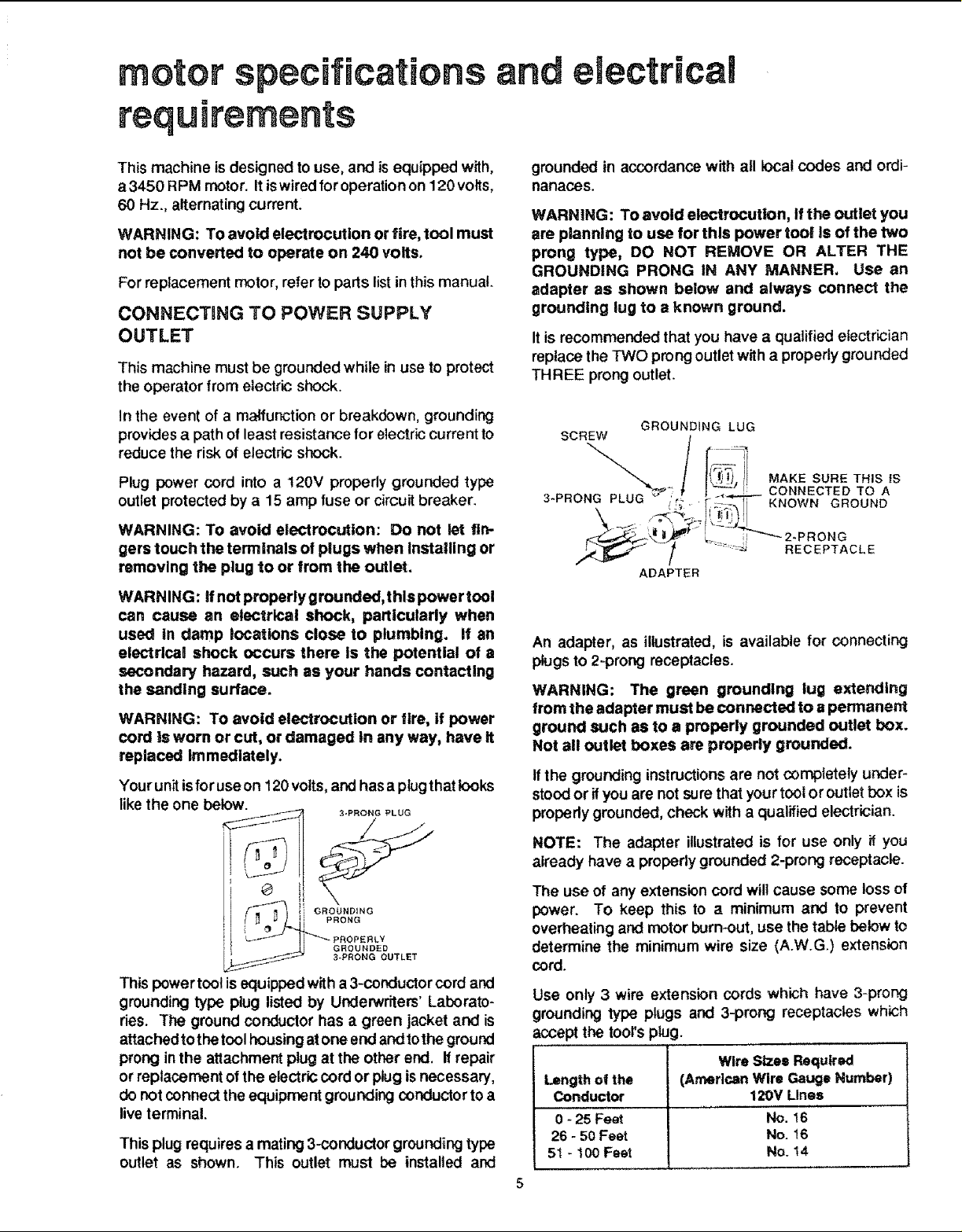

Your unitis for use on 120 volts, and has aplug that looks

like the one below, j

3-PRONG PLUG

grounded in accordance with afl local codes and ordi-

nanaces.

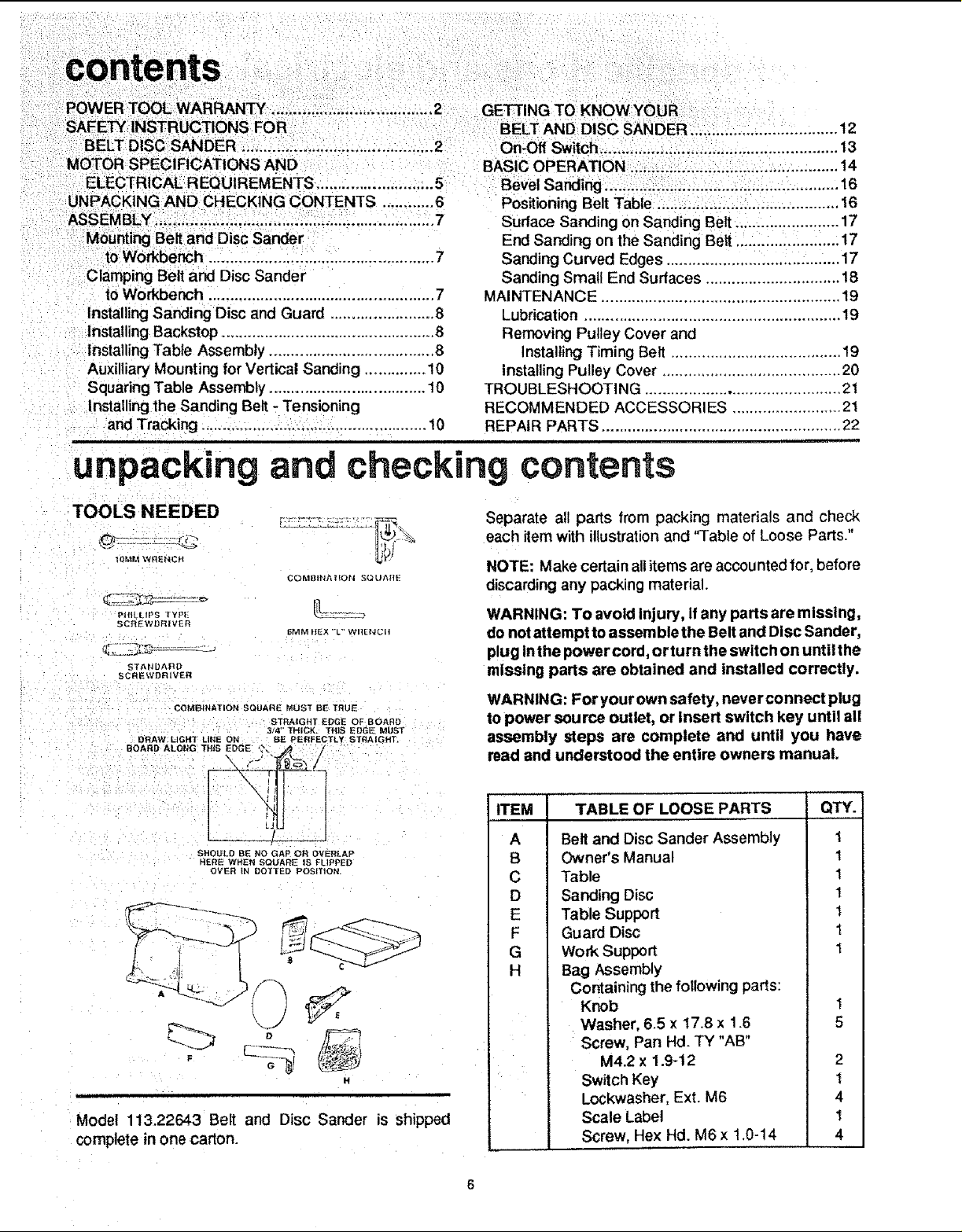

WARNING: To avoid electrocution, if the outlet you

are planning to use for this power tool is of the two

prong type, DO NOT REMOVE OR ALTER THE

GROUNDING PRONG IN ANY MANNER, Use an

adapter as shown below and always connect the

grounding lug to a known ground.

It is recommended that you have a qualified electrician

replace the TWO prong outlet with a properly grounded

THREE prong outlet.

GROUNDING LUG

SCREW / i_, ij_t_ _N_) N_v_?T_ERDcTT_DAI

3 PRO _

_-\_ ,j_'_,• _ , 2-PRONG

/ ..... REOEP,AO,E

ADAPTER

An adapter, as illustrated, is available for connecting

plugs to 2-prong receptacles.

WARNING: The green grounding lug extending

from the adapter must be connected to a permanent

ground such as to a properly grounded outlet box.

Not all outlet boxes are properly grounded.

If the grounding instructionsare not completely under-

stood or if you are not sure that your tool or outlet box is

properly grounded, check with a qualified electrician.

®

! PRONG

_j_ GROUNDING

i _ PROPERLY

i l GROUNDED

_ 3-PRONG OUTLET

Thispowertoolisequippedwitha3-conductorcordand

groundingtypepluglistedby Underwriters'Laborato-

ries.The ground conductorhas a green jacketand is

attachedtothetoolhousingatoneend andtotheground

prong inthe attachment plug at the other end, It repair

or replacement of the electric cord or plug is necessary,

do not connect the equipment grounding conductor to a

live terminal.

This plug requires a mating 3-conductor grounding type

outlet as shown. This outlet must be installed and

NOTE: The adapter illustrated is for use only if you

already have a properly grounded 2-prong receptacle.

The use of any extension cord will cause some loss of

power. To keep this to a minimum and to prevent

overheating and motor burn-out, use the table below to

determine the minimum wire size (A.W.G.) extension

cord.

Use only 3 wire extension cords which have 3-prong

grounding type plugs and 3-prong receptacles which

accept the tool's plug.

Wire Sizes Required

Length of the (American Wire Gauge Number)

Conductor 120V Lines

0 -25 Feet No.I6

26 - 50Feet No. 16

51 - 100Feet No. 14

ClampingBeltand Disc Sander

to Workbench .................................................... 7

Installing Sanding Disc and Guard ........................ 8

Installing Backstop ................................................. 8

Installing Table Assembly ...................................... 8

Auxilliary Mounting for Vertical Sanding .............. 10

Squaring Table Assembly .................................... 10

Installing the Sanding Belt - Tensioning

and Tracking .................................................... 10

GETTING TO KNOW YOUR

BELT AND DISC SANDER....: .............................. 12

on-off Switch ....................................................... 13

BASIC OPERATION. ............................................... 14

Bevel Sanding ...................................................... 16

Positioning Belt Table .......................................... 16

Surface Sanding on Sanding Belt ........................ 17

End Sanding on the Sanding Belt ............. ........... 17

Sanding Curved Edges ....................................... 17

Sanding Small End Surfaces ............................... !8

MAINTENANCE ...................................................... !9

Lubrication ........................................................... 19

Removing Pulley Cover and

Installing Timing Belt ....................................... 19

Installing Pulley Cover ......................................... 20

TROUBLESHOOTING ............................................. 21

RECOMMENDED ACCESSORIES ......................... 21

REPAIR PARTS ....................................................... 22

, L I Ill,

unpacking

and checking contents

TOOLS NEEDED

10f, fM WRENCH

CC'MBIHA ,_$OH SQ [ JAf;,|_

Pt||k LIPS IYP[ _

SCREWDRIVER

STAfJDARD

SCREWDRIVER

COMBINAI'ION SQUARE MUST BE TRUE

DRAW LIGHT LINE OH BE PERFECTLY STRAIGHT.

BOARD ALONG "rHtB EDGE *_'.,

SHOL_LD BE NO GAP OR OVENLAP

HERE WH]EN SQUARE IS FLIPPED

OVER EN DO*il'ED POSITION.

gMM HEX "L" VV_I[14CIt

STRAIGHT EDGE OF BOARD

3/4" THICK_ THIS EDGE MUST

E T.N

N

Model 113.22643 Belt and Disc Sander is shipped

complete in one carton.

Separate all parts from packing materials and check

each item with illustration and 'q-able of Loose Parts."

NOTE: Make certain allitems are accounted for, before

discarding any packing material.

WARNING: To avoid Injury, if any parts are misslng,

do not attempt to assemble the Belt and Disc Sander,

plug Inthe power cord, or turn the switch on until the

missing parts are obtained and installed correctly.

WARNING: For your own safety, never connect plug

to power source outlet, or Insert switch key until all

assembly steps are complete and until you have

read and understood the entire owners manual.

ITEM TABLE OF LOOSE PARTS QTY.

A Belt and Disc Sander Assembly 1

B Owner's Manual 1

C Table 1

D Sanding Disc 1

E Table Support 1

F Guard Disc 1

G Work Support 1

H Bag Assembly

Containing the following parts:

Knob 1

Washer, 6.5 x 17.8 x 1.6 5

Screw, Pan Hd. TY "AB"

M4.2 x 1.9-t 2 2

Switch Key t

Lockwasher, Ext. M6 4

Scale Label 1

Screw, Hex Hd. M6 x 1.0-14 4

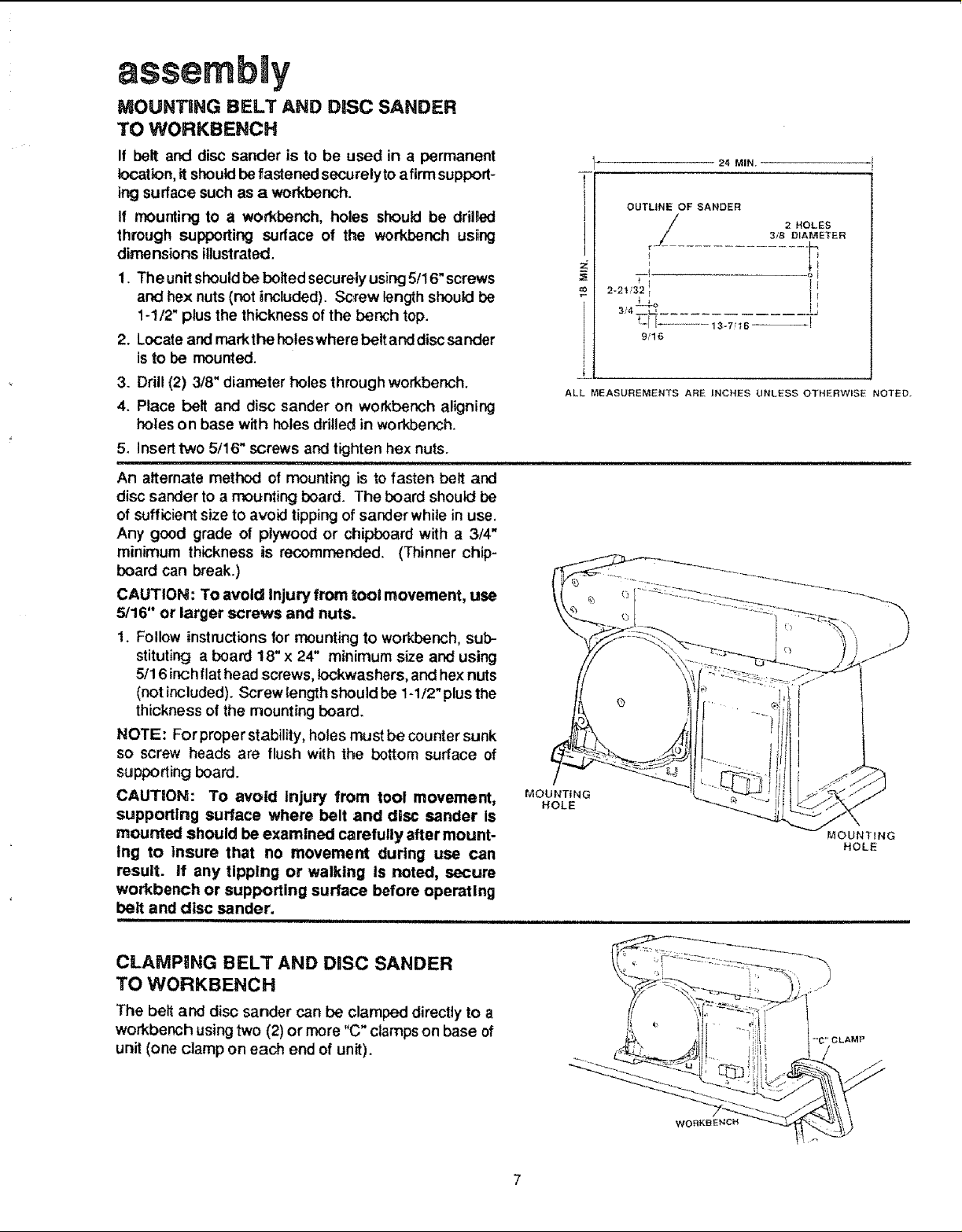

assembly

MOUNTBNG BELT AND DaSC SANDER

TO WORKBENCH

If belt and disc sander is to be used in a permanent

location, it shouldbe fastened securely to a firm supporl-

ing surface suchas a workbench.

If mounting to a workbench, holes should be drilled

through supporting surface of the workbench using

dimensions illustrated.

1. The unit should bebo{ted securely using 5/16" screws

and hex nuts (not included). Screw length should be

1-1/2" plus the thickness of the bench top.

2. Locate and markthe holes where belt and disc sander

is to be mounted.

3. Drill (2) 3/8" diameter holes through workbench.

4. Place belt and disc sander on workbench aligning

holes on base with holes drilled in workbench.

5, Insert two 5/16" screws and tighten hex nuts.

An alternate method of mounting is to fasten belt and

disc sander to a mounting board. The board should be

of sufficient size to avoid tipping of sanderwhile in use,

Any good grade of plywood or chipboard with a 3/4"

minimum thickness is recommended. (Thinner chip-

board can break.)

CAUTION: To avoid injury from tool movement, use

5/16" or larger screws and nuts.

1. Follow instructions for mounting to workbench, sub-

stituting a board 18" x 24" minimum size and using

5/16 inchflat head screws, !ockwashers, and hex nuts

(not included). Screw length should be 1-1/2" plusthe

thickness of the mounting board.

NOTE: For proper stability, holes must be counter sunk

so screw heads are flush with the bottom surface of

supporting board.

CAUTION: To avoid Injury from tool movement,

supporting surface where belt and disc sander Is

mou nted shou Id be examined carefully after mount-

lng to Insure that no movement during use can

result. If any tipping or walking is noted, secure

workbench or supporting surface before operating

belt and dlsc sander.

H,IIII IIH, I ,i,ii

If

OUTLINE OF SANDER

2"2_/3T2 i [r

24 MIN.

2 HOLES

3/8 DIAMETER

Lrl ............. 13-7_B

9/16

ALL MEASUREMENTS ARE JNCHES UNLESS OTHERWISE NOTED.

i!IIi

/

MOUNTING

HOLE

MOUNTING

HOLE

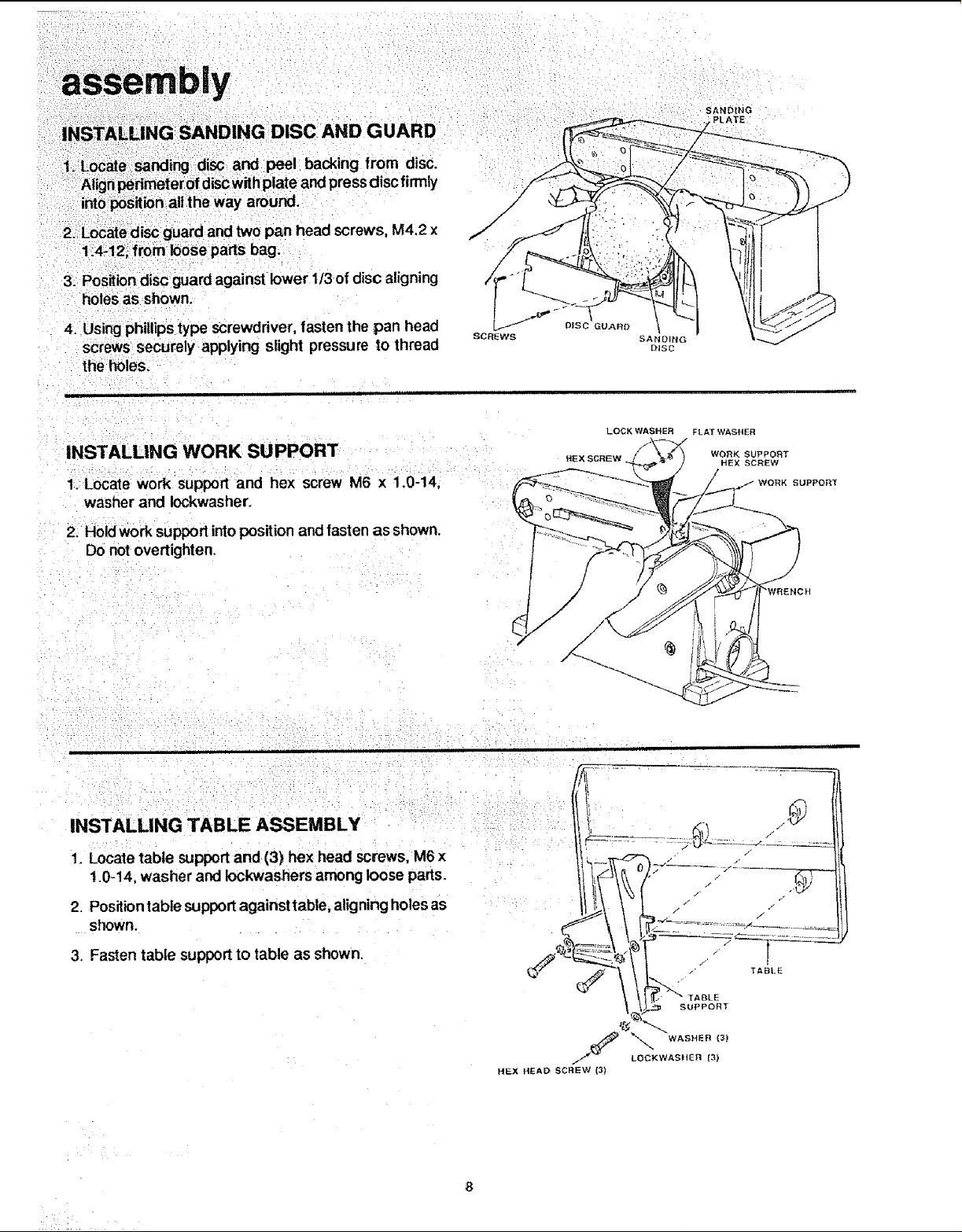

CLAiVIPING BELT AND DISC SANDER

TO WORKBENCH

The belt and disc sander can be clamped directly to a

workbench using two (2) or more "C" clamps on base of

unit (one clamp on each end of unit).

2• Locate disc guard and two pan head screws, M4.2 x

1.4-12i from loose parts bag.

3. Position disc guardagainst lower 1/3 of disc aligning

holes as shown.

4• Using phillips type screwdriver, fasten the pan head

screws securely applying slight pressure to thread

the holes.

INSTALLING WORK SUPPORT

1. Locate work support and hex screw M6 x 1.0-14,

washer and Iockwasher.

2, Hold work supportintoposition and fasten as shown.

Do not overtighten.

SANDING

LOCK WASHER FLAT WASHER

........ z/F_X_ WORK SUPPORT

INSTALLING TABLE ASSEMBLY

1. Locate table support and (3) hex head screws, M6 x

1•0-14, washer and Iockwashers among loose parts.

2. Positiontable support againsttable, aligning holes as

shown•

3. Fasten table support to table as shown.

HEX HEAD SCREW (3)

J

L

TABLE

SUPPORT

_ WASHER (3)

LOC:KWASH ER [3)

Loading...

Loading...