Craftsman 113221620 Owner’s Manual

f

Save This Manual

For Future Reference

,__AIRS

owners

manual

MODEL NO.

113.221620

Serial

Number

Model and serial numLxzrs

may be found at the

left-hand side of the base.

You should record both

model and serial number

in a safe place for future

Use,

FOR YOUR

_'__AIRS/ CRRFTSMRN

8 INCH DIRECT DRIVE

TABLE SA W

• assembly

SAFETY

READ ALL

INSTRUCTIONS

CAREFULLY

Part No. SP5311

• operating

• repair parts

J

Sears, Roebuck and Co., Hoffman Estates, IL. 60179 U.S.A.

Printed in U.S.A.

FULL ONE YEAR WARRANTY ON CRAFTSMAN TABLE SAW

If within one year from the date of purchase, this Craftsman Table Saw fails due to a defect in

material or workmanship, Sears wil! repair it, free of charge.

WARRANTY SERVICE IS AVAILABLE BY SIMPLY CONTACTING THE NEAREST SEARS

SERVICE CENTER/DEPARTMENT THROUGHOUT THE UNITED STATES.

This warranty applies only while this product is in use in the United States.

This warranty gives you specific legal rights, and you may also have other rights which vary

from state to state.

Sears, Roebuck and Co., D/817 WA Hoffman Estates, IL. 60179

SAFETY INSTRUCTIONS FOR TABLE SAW

Safety is a combination of common sense, staying

alert and knowing how your table saw works. Read

this manual to understand this saw.

BEFORE USING THE SAW:

WARNING: TO AVOID MISTAKES THAT COULD

CAUSE SERIOUS, PERMANENT INJURY, DO NOT

PLUG THE SAW IN UNTIL THE FOLLOWING STEPS

HAVE BEEN SATISFACTORILY COMPLETED.

1. Assembly and alignment (See pages 8-20).

2 Learn the use and function of the ON-OFF switch,

guard, spreader, anti-kickback device, miter gauge,

fence, table insert and blade elevation and bevel

controls. (See page 21).

3. Review and understanding of all safety instructions

and operating procedures in this manual.

4. Review of the maintenance methods for this saw.

(See page 32).

Read the following DANGER label found on the

front of the saw:

_tEAD AND UNDERSTAND OWNERS MANUAL BEFORE OPERATING MALJHIN[

JS[ %A_SLAD[ _,_ AAD _ )_ T_4L, SAW_, 2 _ roc, _(]," PERF_IA_I OPFRATIONS _q_[H#,NC,

Ii [ DANGER ] FORYOUROWN SAFETY:

_tP"_DS _'J' ;_ PA'_'F SAWB_AO_ ' NEvEeREA, H m£OUND ;a_,VER',&_B_Ar)E

WHEN INSTALLING OR MOVING THE SAW:

1. AVOID DANGEROUS ENVIRONMENT. Use the

saw in adry place protected from rain Keep work

area well righted.

2. To avoid injury from unexpected saw movement:

a. Put the saw on a firm level surface where there

is plenty of room for handling and properly

supporting the workp_ece.

b. Support the saw so the table is level and the

saw does not rock.

c Bolt the saw to the floor if it tends to siip, walk,

or slide during normal use.

d. When us=ngtabre extensions over 24" wide on

any side of the saw, bolt the saw to the floor or

prop up the outer end of the extension from

the floor to keep the saw from tipping.

3 Put the saw where neither operators or bystand-

ers must stand in line with the saw blade.

4 GROUND THE SAW- This saw has an approved

3-conductor cord and a 3-prong grounding type

pt,Jg. The plug fits grounding type outlets design-

ed for 120 volt 15 amp circuits. The green

conductor in the cord is the grounding wire. To

avoid electrocution, NEVER connect the green

wire to a live terminal.

5. To avoid injury from electrical shock, make sure

your fingers do not touch the plug's met31 prongs

when plugging in or unplugging the saw.

6. To avoid back injury, get help or use recom-

mended casters when you need to move the saw.

Always get help if you need to lift the saw. Hold

the saw close to your body. Bend your knees so

you can lift with your legs, not your back.

7. NEVER STAND ON TOOL. Serious injury could

occur if the tool tips or you accidentally hit the

cutting tool. Do not store anything above or near

the tool where anyone might stand on the tool to

reach them.

BEFORE EACH USE:

1. Inspect your saw.

a. To avoid injury from accidental starting, unplug

the saw, turn the switch off and remove the

switch key before raising or removing the

guard, changing the cutting tool, changing

the setup or adjusting anything.

b. Check for alignment of moving parts, binding

of moving parts, breakage of parts, mounting,

and any other conditions that may affect the

way it works. If any part is missing, bent, or

broken in any way, or any electrical parts don't

work properly, turn the saw off and unplug the

saw.

c. Replace damaged, missing, or failed parts

before using the saw again

d. Use the sawblade guard, spreader, and anti-

kickback pawls for any thru-sawing (whenever

the blade comes through the top of the work-

p,ece). Make sure the pawls work properly.

Make sure the spreader is in line with the

sawblade.

e. REM©VE ADJUSTING KEYS AND

WRENCHES. Form habit of checking for and

removing keys and adiusting wrenches from

toot before turning it on.

f. To avoid injury from jams. slips or thrown pieces

(kickback and throwback):

1. USE ONLY RECOMMENDED ACCESSO-

RIES. Follow the instructions that come with

the accessories. Consult the owner's manual

for recommended accessories. The use of

improper accessories may cause risk of injury

to persons.

2. Choose the right blade or cutting accessory

for the material and the type of cutting you

plan to do.

3. Never use grinding wheels, abrasive cut-off

wheels, friction wheels (metal slitting

blades) wire wheels or buffing wheel. They

can fly apart explosively.

4. Choose and inspect your cutting tool carefully.

a. To avoid cutting tool failure and thrown

shrapnel (broken pieces of blade), use only

8" or smaller blades or other cutting tools

marked for speeds of 3450 rpm or higher.

b. Always use unbroken, balanced blades

designed to fit this saw's 5/8" arbor.

c. When thru-sawing, (making cuts where the

blade comes through the workpiece top)

always use a 8" diameter blade. This keeps

the spreader in closest to the blade.

d. Do not overtighten arbor nut. Use arbor

wrenches to "snug" it securely.

e. Use only sharp blades with properly set

teeth. Consult a professional blade shar-

pener when in doubt.

f. Keep blades clean of gum and resin.

5. Adjust table inserts flush with the table top.

NEVER use the saw without the proper insert.

6. Make sure all clamps and locks are tight and no

parts have any excessive play.

2. KEEP WORK AREA CLEAN

a. Cluttered areas and benches invite accidents.

Floor must not be slippery from wax or

sawdust.

b. To avoid burns or other fire damage, never use

the saw near flammable liquids, vapors or

gases.

Plan ahead to protect your eyes, hands, face,

ears.

a. To avoid injury, don't do layout, assembly, or

setup work on the table while the blade is

spinning. It could cut or throw anything hitting

the blade.

AVOID ACCIDENTAL STARTING - Make sure

switch is "OFF" before plugging saw in.

Plan your work

1. USE THE RIGHT TOOL - Don't force tool or

attachment to do a job it was not designed for.

2. Dress for safety:

- Do not wear loose clothing, gloves, neckties

or jewelry (rings, wrist watches). They can get

caught and draw you into moving parts.

- Wear nonslip footwear.

- Tie back long hair.

- Roll long sleeves above the elbow

Noise levels vary widely. To avoid possible

hearing damage, wear ear plugs or muffs

when using saw for long periods of time.

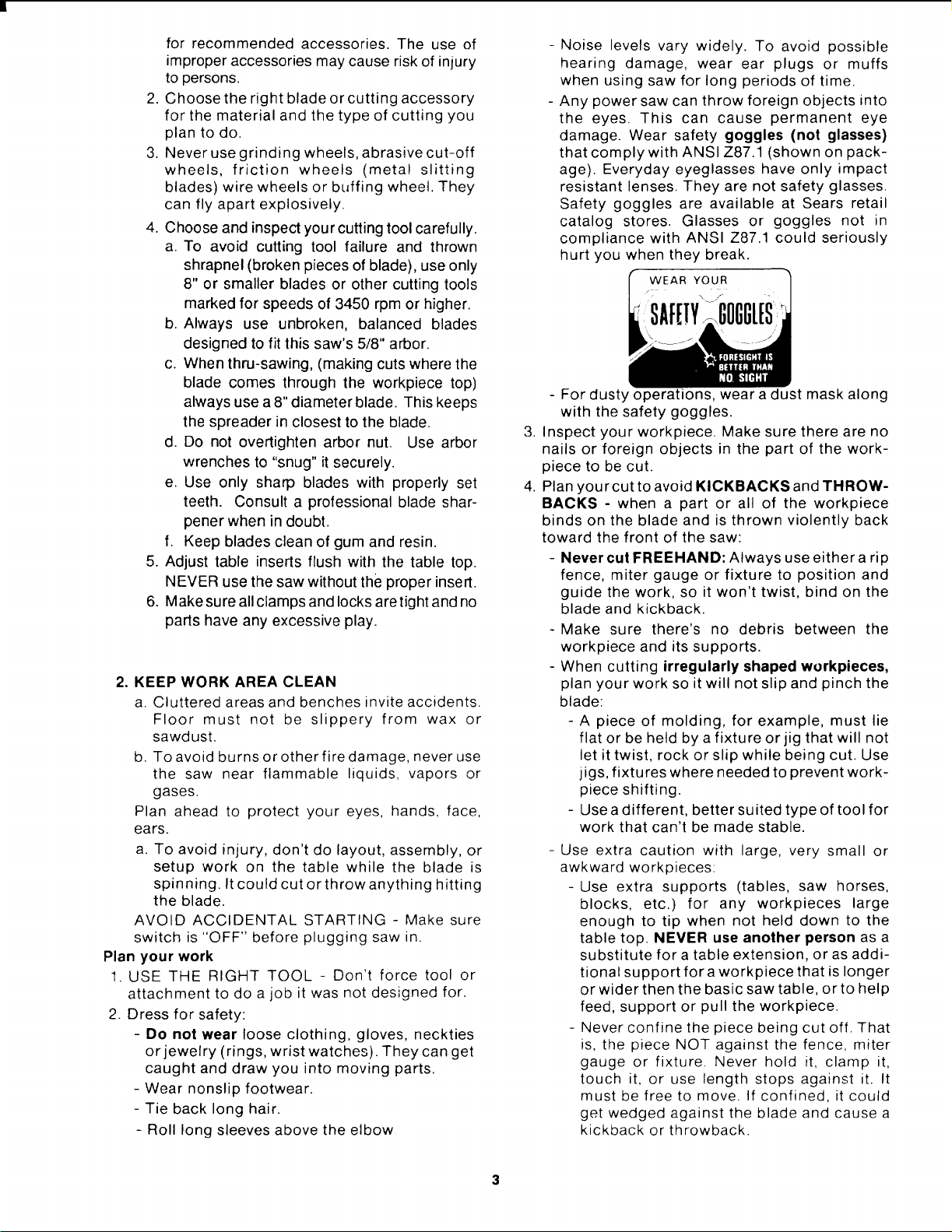

Any power saw can throw foreign objects into

the eyes. This can cause permanent eye

damage. Wear safety goggles (not glasses)

that comply with ANSI Z87.1 (shown on pack-

age). Everyday eyeglasses have only impact

resistant lenses. They are not safety glasses.

Safety goggles are available at Sears retail

catalog stores. Glasses or goggles not in

compliance with ANSI Z87.1 could seriously

hurt you when they break.

WEAR YOUR

- For dusty operations, wear a dust mask along

with the safety goggles.

3. Inspect your workpiece. Make sure there are no

nails or foreign objects in the part of the work-

piece to be cut.

4. Plan yourcut to avoid KICKBACKS and THROW-

BACKS - when a part or all of the workpiece

binds on the blade and is thrown violently back

toward the front of the saw:

- Never cut FREEHAND: Always use either a rip

fence, miter gauge or fixture to position and

guide the work, so it won't twist, bind on the

blade and kickback.

-Make sure there's no debris between the

workpiece and its supports.

- When cutting irregularly shaped workpieces,

plan your work so it will not slip and pinch the

blade:

- A piece of molding, for example, must lie

flat or be held by a fixture or jig that will not

let it twist, rock or slip while being cut. Use

jigs, fixtures where needed to prevent work-

piece shifting.

- Use a different, better suited type of tool for

work that can't be made stable.

- Use extra caution with large, very small or

awkward workpieces:

-Use extra supports (tables, saw horses,

blocks, etc.) for any workpieces large

enough to tip when not held down to the

table top. NEVER use another person as a

substitute for a table extension, or as addi-

tional support for a workpiece that is longer

or wider then the basic saw table, or to help

feed, support or pull the workpiece.

- Never confine the piece being cut off. That

is, the piece NOT against the fence, miter

gauge or fixture. Never hold it, clamp it,

touch it, or use length stops against it. It

must be free to move. If confined, it could

get wedged against the blade and cause a

kickback or throwback.

- Nevercut morethan oneworkpieceat a

time.

-Never turn your table saw "ON" before

clearingeverythingexcepttheworkpiece

andrelatedsupportdevicesoffthetable,

Plan the way you will push the workpiece through.

- NEVER pull the workpiece through. Start and

finish the cut from the front of the table saw.

- NEVER put your fingers or hands in the path of

the sawblade or other cutting tool.

- NEVER reach in back of the cutting tool with

either hand to hold down or support the work-

piece, remove wood scraps, or for any other

reason.

- Avoid hand positions where a sudden slip could

cause fingers or hand to move into asawblade or

other cutting tool.

- DON'T OVERREACH. Always keep good footing

and balance.

- Push the workpiece against the rotation of the

blade. NEVER feed material into the cutting tool

from the rear of the saw.

- Always push the workpiece all the way past the

sawb/ade.

- As much as possible, keep your face and body to

one side of the sawblade, out of line with a

possible kickback or throwback.

- NEVER turn the saw "ON" before clearing the

table of all tools, wood scraps, etc., except the

workpiece and related feed or support devices

for the cut planned.

WHENEVER SAW IS RUNNING

WARNING: DON'T LET FAMILIARITY (GAINED

FROM FREQUENT USE OF YOUR TABLE SAW)

CAUSE A CARELESS MISTAKE. ALWAYS

REMEMBER THAT A CARELESS FRACTION OF A

SECOND IS ENOUGH TO CAUSE A SEVERE

INJURY.

1. Before actually cutting with the saw, watch it

while it runs for a short while. If it makes an

unfamiliar noise or vibrates a lot, stop immedi-

ately. Turn the saw off. Unplug the saw. Do not

restart until finding and fixing the problem.

2. Make sure the top of the arbor or cutting tool

turns toward the front of the saw.

3. Set the cutting tool as low as possible for the cut

you're planning.

4. KEEP CHILDREN AWAY. All visitors should be

kept a safe distance from work. Make sure

bystanders are clear of the saw and workpiece.

5. Let the blade reach full speed before cutting.

6. DON'T FORCE TOOL. It will do the job better

and safer at its designed rate. Feed the workpiece

into the blade only fast enough to let it cut

without bogging down or binding.

7. Before freeing any jammed material:

a. Turn switch "OFF".

b. Unplug the saw.

c. Wait for all moving parts to stop.

d. Check blade, spreader and fence for proper

alignment before starting, again.

8. To avoid throwback of small, cut off pieces:

a. Use the guard assembly.

b. Push loose pieces off the table with a long

stick before starting another cut.

c. To remove pieces trapped inside the guard:

1. Turn saw off.

2. Remove switch key.

3. Unplug saw.

4. Wait for blade to stop before lifting the

guard.

additional instructions for

RIP TYPE CUTS

NEVER use the miter gauge when ripping.

Use a push stick whenever the fence is 2 to 6

inches from the blade. Use an auxiliary fence and

push block whenever the fence must be within 2

inches of the blade. (See "Basic Saw Operation

Using The Rip Fence" section.)

Never rip anything shorter than 10" long.

When using a push stick or push block, the

trailing end of the board must be square. A push

stick or block against an uneven end could slip

off or push the work away from the fence.

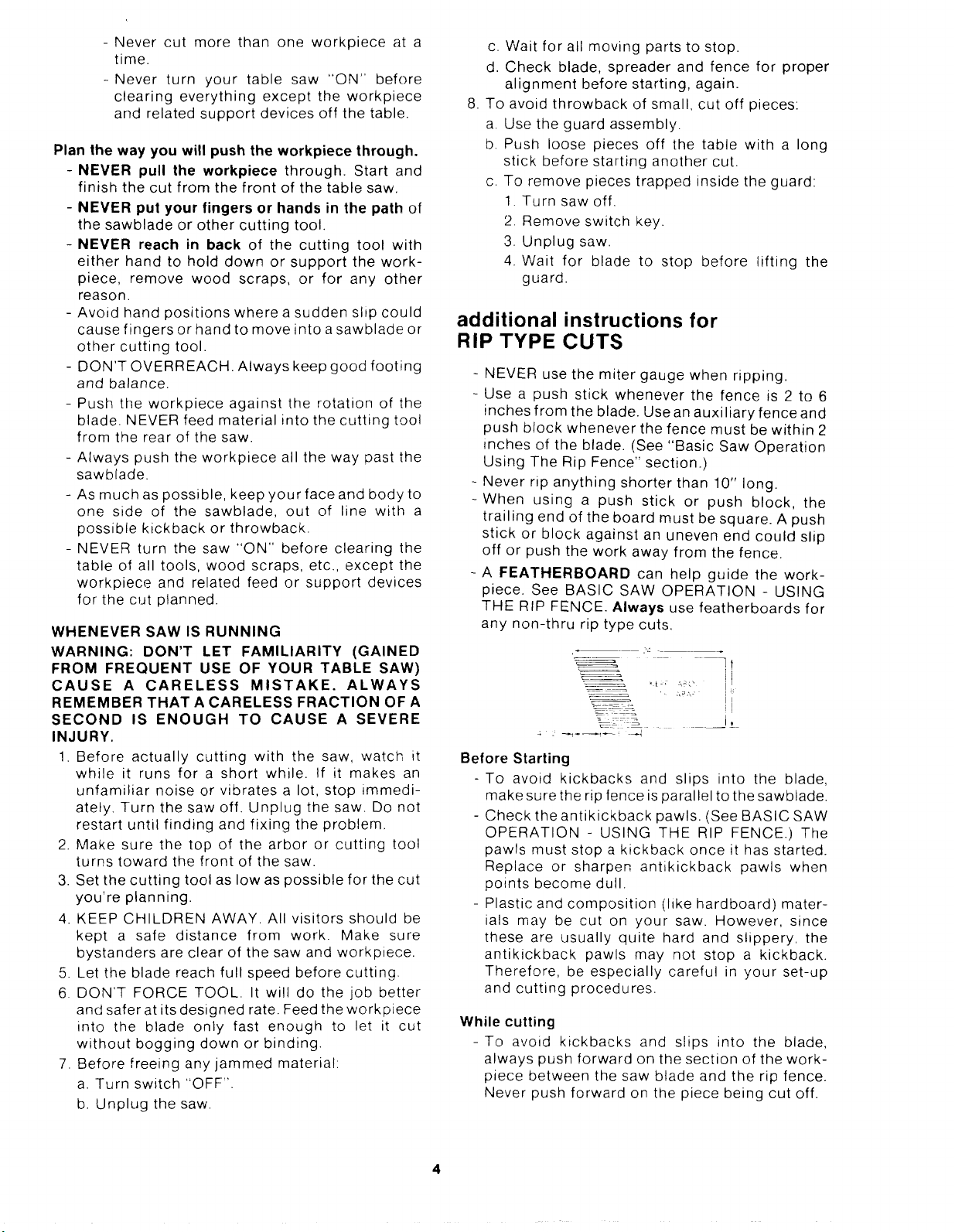

A FEATHERBOARD can help guide the work-

piece. See BASIC SAW OPERATION - USING

THE RIP FENCE. Always use featherboards for

any non-thru rip type cuts.

,_ 2'I

I I

Before Starling

-To avoid kickbacks and slips into the blade,

make sure the rip fence is parallel to the sawblade.

- Check theantikickback pawls. (See BASlCSAW

OPERATION - USING THE RIP FENCE.) The

pawls must stop a kickback once it has started.

Replace or sharpen antikickback pawls when

points become dull.

- Plastic and composition (like hardboard) mater-

ials may be cut on your saw. However, since

these are usually quite hard and slippery, the

antikickback pawls may not stop a kickback.

Therefore, be especially careful in your set-up

and cutting procedures.

While cutting

-To avoid kickbacks and slips into the blade,

always push forward on the section of the work-

piece between the saw blade and the rip fence.

Never push forward on the piece being cut off.

4

additional instructions for

CROSS CUT TYPE CUTS

Before starting

- NEVER use the rip fence when crosscutting.

- An auxiliary wood facing attached to the miter

gauge can help prevent workpiece twisting and

throwbacks. Attach it to the holes provided.

Make the facing long enough and big enough to

support your work. Make sure, however, it will

not interfere with the sawblade guard.

- Use jigs or fixtures to help hold any piece too

small to extend across the full length of the miter

gauge face during the cut. This lets you properly

hold the miter gauge and workpiece and helps

keep your hands away from the blade.

GLOSSARY OF TERMS FOR WOODWORKING

While cutting

-To avoid blade contact, always hold the miter

gauge as shown in the BASIC SAW OPERA-

TIONS - USING THE MITER GAUGE.

BEFORE LEAVING THE SAW

1. Turn the saw off.

2. Wait for blade to stop spinning.

3. Make workshop child-proof. Lock the shop. Dis-

connect master switches. Remove the yellow

switch key. Store it away from children and

others not qualified to use the tool.

4. Unplug the saw.

Anti-Kickback Pawls (AKB)

Device which, when properly maintained, is design-

ed to stop the workpiece from being kicked back at

the operator during ripping operations.

Arbor

The shaft on which a cutting tool is mounted.

Crosscut

A cutting or shaping operation made across the

width of the workpiece.

Dado

A non-through cut which produces a square sided

notch or trough in the workpiece.

Featherboard

A device which can help guide workpieces during rip

type operations.

Freehand

Performing a cut without using a fence, miter gauge,

fixture, hold down or other proper device to keep the

workpiece from twisting during the cut.

Gum

A sticky, sap based residue from wood products.

Heel

Misalignment of the blade.

Kerf

The amount of material removed by the blade in a

through cut or the slot produced by the blade in a

non-through or partial cut.

Kickback

An uncontrolled grabbing and throwing of the work-

piece back toward the front of the saw during a rip

type operation.

Leading End

The end of the workpiece which, during a rip type

operation, is pushed into the cutting tool first.

Molding

A non-through cut which produces a special shape

in the workpiece used for joining or decoration.

Push Stick

A device used to feed the workpiece through the saw

during narrow ripping type operations and help

keep the operator's hands well away from the blade.

Push Block

A device used for ripping type operations too narrow

to allow use of a push stick.

Rabbet

A notch in the edge of a workpiece.

Resin

A sticky, sap base substance that has hardened.

Ripping

A cutting operation along the length of the work-

piece.

Revolutions Per Minute (RPM)

The numberofturnscompleted by a spinning object

in one minute.

Sawblade Path

The area of the workpiece or table top directly in line

with the part of the workpiece which will be, or has

been, cut by the blade.

Set

The distance that the tip of the sawblade tooth is

bent (or set) outward from the face of the blade.

Throw-Back

Throwing of pieces in a manner similar to a kickback.

Thru-Sawing

Any cutting operation where the blade extends

completely through the thickness of the workpiece.

Trailing End

The workpiece end last cut by the blade in a ripping

operation.

Workpiece

The item on which the cutting operation is being

done. The surfaces of a workpiece are commonly

referred to as faces, ends, and edges.

5

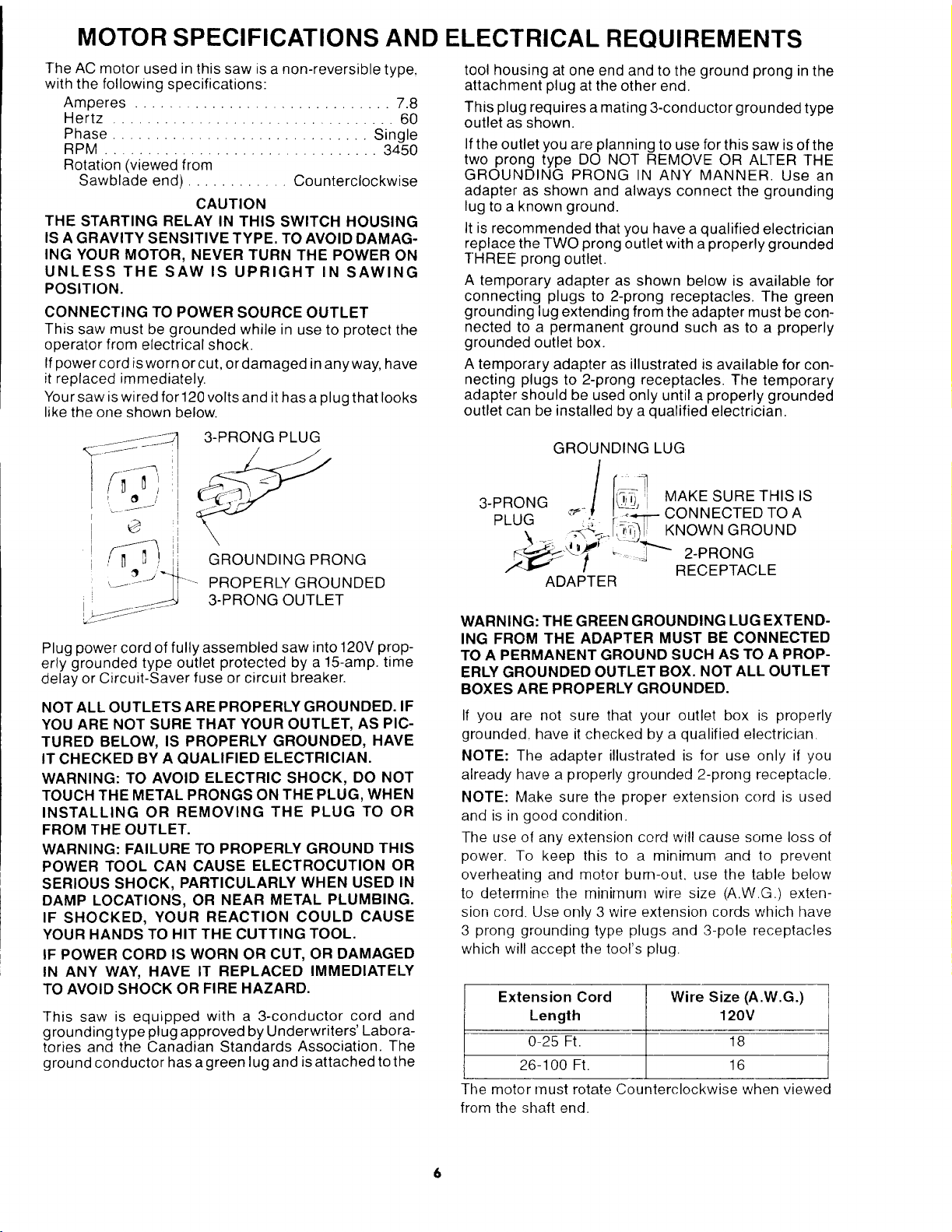

MOTOR SPECIFICATIONS AND ELECTRICAL REQUIREMENTS

The AC motor used in this saw is a non-reversible type,

with the following specifications:

Amperes .............................. 7.8

Hertz ................................. 60

Phase .............................. Single

RPM ................................ 3450

Rotation (viewed from

Sawblade end) ............ Counterclockwise

CAUTION

THE STARTING RELAY IN THIS SWITCH HOUSING

IS A GRAVITY SENSITIVE TYPE. TO AVOID DAMAG-

ING YOUR MOTOR, NEVER TURN THE POWER ON

UNLESS THE SAW IS UPRIGHT IN SAWING

POSITION.

CONNECTING TO POWER SOURCE OUTLET

This saw must be grounded while in use to protect the

operator from electrical shock.

Ifpower cord is worn or cut, or damaged in any way, have

it replaced immediately.

Your saw is wired for 120 volts and ithas a plug that looks

like the one shown below.

3-PRONG PLUG

GROUNDING PRONG

PROPERLY GROUNDED

3-PRONG OUTLET

Plug power cord of fully assembled saw into 120V prop-

erly grounded type outlet protected by a 15-amp. time

delay or Circuit-Saver fuse or circuit breaker.

NOT ALL OUTLETS ARE PROPERLY GROUNDED. IF

YOU ARE NOT SURE THAT YOUR OUTLET, AS PIC-

TURED BELOW, IS PROPERLY GROUNDED, HAVE

IT CHECKED BY A QUALIFIED ELECTRICIAN.

WARNING: TO AVOID ELECTRIC SHOCK, DO NOT

TOUCH THE METAL PRONGS ON THE PLUG, WHEN

INSTALLING OR REMOVING THE PLUG TO OR

FROM THE OUTLET.

WARNING: FAILURE TO PROPERLY GROUND THIS

POWER TOOL CAN CAUSE ELECTROCUTION OR

SERIOUS SHOCK, PARTICULARLY WHEN USED IN

DAMP LOCATIONS, OR NEAR METAL PLUMBING.

IF SHOCKED, YOUR REACTION COULD CAUSE

YOUR HANDS TO HIT THE CUTTING TOOL.

IF POWER CORD IS WORN OR CUT, OR DAMAGED

IN ANY WAY, HAVE IT REPLACED IMMEDIATELY

TO AVOID SHOCK OR FIRE HAZARD.

This saw is equipped with a 3-conductor cord and

grounding type plug approved by Underwriters' Labora-

tories and the Canadian Standards Association. The

ground conductor has a green lug and is attached to the

tool housing at one end and to the ground prong in the

attachment plug at the other end.

This plug requires amating 3-conductor grounded type

outlet as shown.

If the outlet you are planning to use for this saw is of the

two prong type DO NOT REMOVE OR ALTER THE

GROUNDING PRONG IN ANY MANNER. Use an

adapter as shown and always connect the grounding

lug to a known ground.

It is recommended that you have a qualified electrician

replace the TWO prong outlet with aproperly grounded

THREE prong outlet.

A temporary adapter as shown below is available for

connecting plugs to 2-prong receptacles. The green

grounding lug extending from the adapter must be con-

nected to a permanent ground such as to a properly

grounded outlet box.

A temporary adapter as illustrated is available for con-

necting plugs to 2-prong receptacles. The temporary

adapter should be used only until a properly grounded

outlet can be installed by a qualified electrician.

GROUNDING LUG

3-PRONG

PLUG

_- CONNECTED TO A

ADAPTER

MAKE SURE THIS IS

KNOWN GROUND

2-PRONG

RECEPTACLE

WARNING: THE GREEN GROUNDING LUG EXTEND-

ING FROM THE ADAPTER MUST BE CONNECTED

TO A PERMANENT GROUND SUCH AS TO A PROP-

ERLY GROUNDED OUTLET BOX. NOT ALL OUTLET

BOXES ARE PROPERLY GROUNDED.

If you are not sure that your outlet box is properly

grounded, have it checked by a qualified electrician.

NOTE: The adapter illustrated is for use only if you

already have a properly grounded 2-prong receptacle.

NOTE: Make sure the proper extension cord is used

and is in good condition.

The use of any extension cord will cause some loss of

power. To keep this to a minimum and to prevent

overheating and motor burn-out, use the table below

to determine the minimum wire size (A.W.G.) exten-

sion cord. Use only 3 wire extension cords which have

3 prong grounding type plugs and 3-pole receptacles

which will accept the too!'s plug.

Extension Cord Wire Size (A.W.G.)

Length 120V

0-25 Ft. 18

26-100 Ft. 16

The motor must rotate Counterclockwise when viewed

from the shaft end.

6

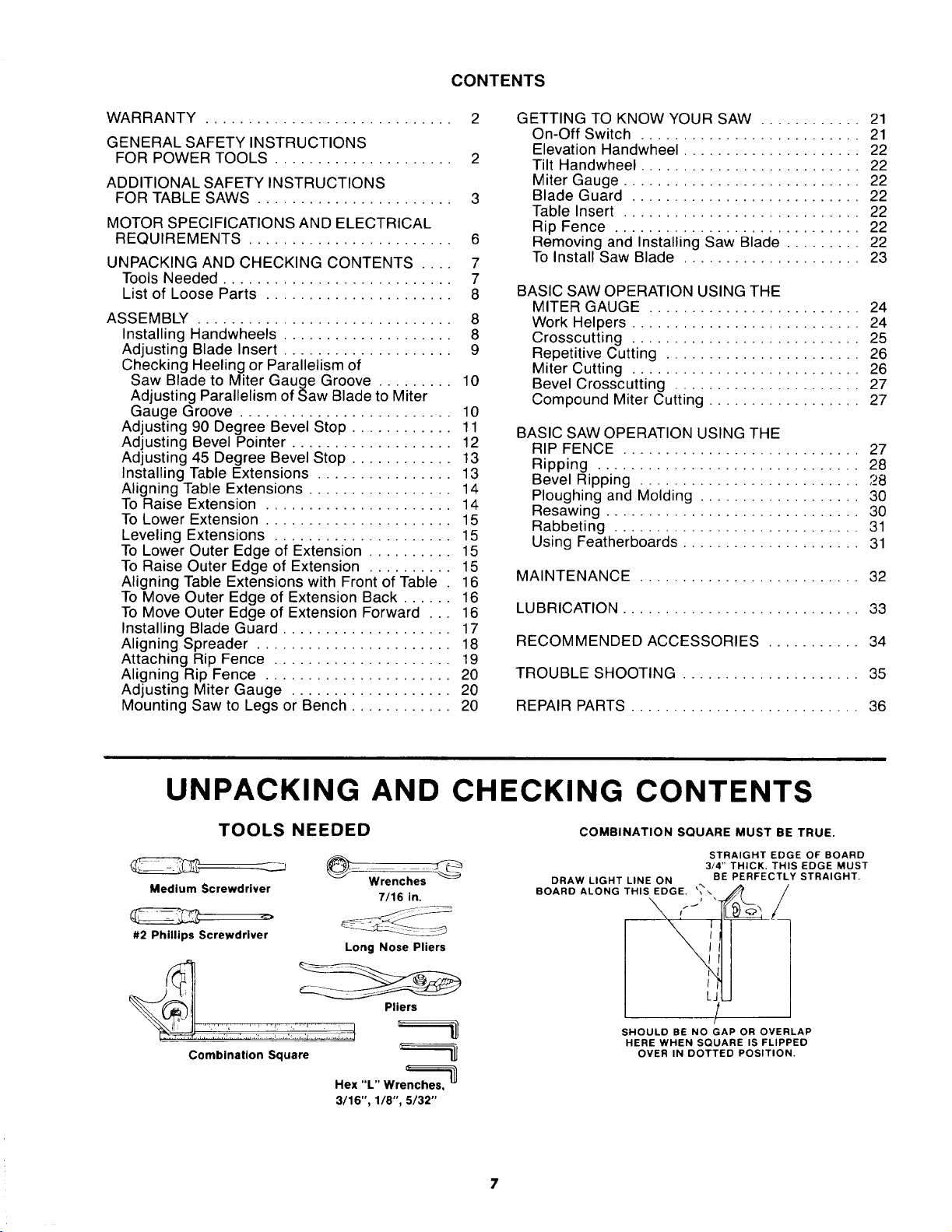

CONTENTS

WARRANTY ............................. 2

GENERAL SAFETY INSTRUCTIONS

FOR POWER TOOLS ..................... 2

ADDITIONAL SAFETY INSTRUCTIONS

FOR TABLE SAWS ....................... 3

MOTOR SPECIFICATIONS AND ELECTRICAL

REQUIREMENTS ........................ 6

UNPACKING AND CHECKING CONTENTS .... 7

Tools Needed ........................... 7

List of Loose Parts ...................... 8

ASSEMBLY .............................. 8

Installing Handwheels .................... 8

Adjusting Blade Insert .................... 9

Checking Heeling or Parallelism of

Saw Blade to Miter Gauge Groove ......... 10

Adjusting Parallelism of Saw Blade to Miter

Gauge Groove ......................... 10

Adjusting 90 Degree Bevel Stop ............ 11

Adjusting Bevel Pointer ................... 12

Adjusting 45 Degree Bevel Stop ............ 13

Installing Table Extensions ................ 13

Aligning Table Extensions ................. 14

To Raise Extension ...................... 14

To Lower Extension ...................... 15

Leveling Extensions ..................... 15

To Lower Outer Edge of Extension .......... 15

To Raise Outer Edge of Extension .......... 15

Aligning Table Extensions with Front of Table . 16

To Move Outer Edge of Extension Back ...... 16

To Move Outer Edge of Extension Forward ... 16

Installing Blade Guard .................... 17

Aligning Spreader ....................... 18

Attaching Rip Fence ..................... 19

Aligning Rip Fence ...................... 20

Adjusting Miter Gauge ................... 20

Mounting Saw to Legs or Bench ............ 20

GETTING TO KNOW YOUR SAW ............ 21

On-Off Switch .......................... 21

Elevation Handwheel ..................... 22

Tilt Handwheel .......................... 22

Miter Gauge ............................ 22

Blade Guard ........................... 22

Table Insert ............................ 22

Rip Fence ............................. 22

Removing and Installing Saw Blade ......... 22

To Install Saw Blade ..................... 23

BASIC SAW OPERATION USING THE

MITER GAUGE ......................... 24

Work Helpers ........................... 24

Crosscutting ........................... 25

Repetitive Cutting ....................... 26

Miter Cutting ........................... 26

Bevel Crosscutting ...................... 27

Compound Miter Cutting .................. 27

BASIC SAW OPERATION USING THE

RIP FENCE ............................ 27

Ripping ............................... 28

Bevel Ripping .......................... 28

Ploughing and Molding ................... 30

Resawing .............................. 30

Rabbeting ............................. 31

Using Featherboards ..................... 31

MAINTENANCE .......................... 32

LUBRICATION ............................ 33

RECOMMENDED ACCESSORIES ........... 34

TROUBLE SHOOTING ..................... 35

REPAIR PARTS ........................... 36

UNPACKING AND CHECKING CONTENTS

TOOLS NEEDED

Medium Screwdriver

#2 Phillips Screwdriver

Combination Square

-'-J _-- W renc-hes- _-_

7/16 in.

Long Nose Pliers

Hex "L" Wrench_es,

3/16", 1/8", 5/32"

COMBINATION SQUARE MUST BE TRUE.

DRAW LIGHT LINE ON BE PERFECTLY STRAIGHT.

BOARD ALONG

THIS EDGE, '_''T_

\ ILl /-

\i,11

SHOULD BE NO GAP OR OVERLAP

HERE WHEN SQUARE IS FLIPPED

OVER IN DOTTED POSITION,

STRAIGHT EDGE OF BOARD

3/4" THICK. THIS EDGE MUST

/

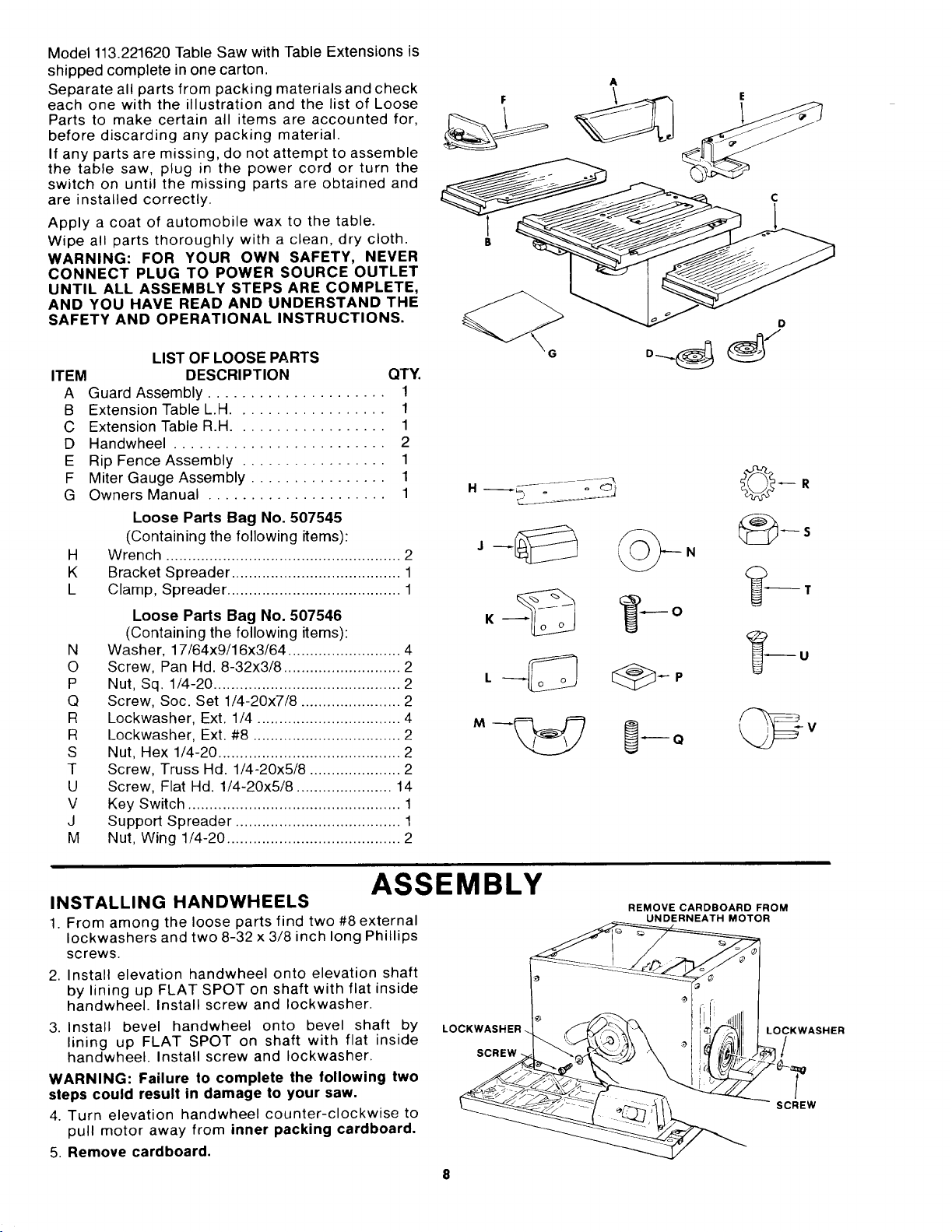

Model 113.221620 Table Saw with Table Extensions is

shipped complete in one carton.

Separate all parts from packing materials and check

each one with the illustration and the list of Loose

Parts to make certain all items are accounted for,

before discarding any packing material.

If any parts are missing, do not attempt to assemble

the table saw, plug in the power cord or turn the

switch on until the missing parts are obtained and

are installed correctly.

Apply a coat of automobile wax to the table.

Wipe all parts thoroughly with a clean, dry cloth.

WARNING: FOR YOUR OWN SAFETY, NEVER

CONNECT PLUG TO POWER SOURCE OUTLET

UNTIL ALL ASSEMBLY STEPS ARE COMPLETE,

AND YOU HAVE READ AND UNDERSTAND THE

SAFETY AND OPERATIONAL INSTRUCTIONS.

A

LIST OF LOOSE PARTS

ITEM

A

Guard Assembly ..................... 1

B

Extension Table L.H .................. 1

C

Extension Table R.H.................. 1

D

Handwheel ......................... 2

E

Rip Fence Assembly ................. 1

F

Miter Gauge Assembly ................ 1

G

Owners Manual ..................... 1

DESCRIPTION QTY.

Loose Parts Bag No. 507545

(Containing the following items):

H

Wrench ...................................................... 2

K

Bracket Spreader ....................................... 1

L

Clamp, Spreader ........................................ 1

Loose Parts Bag No. 507546

(Containing the following items):

N

Washer, 17/64x9/16x3/64 .......................... 4

O

Screw, Pan Hd. 8-32x3/8 ........................... 2

P

Nut, Sq. 1/4-20 ........................................... 2

Q

Screw, Soc. Set 1/4-20x7/8 ....................... 2

R

Lockwasher, Ext. 1/4 ................................. 4

R

Lockwasher, Ext. #8 .................................. 2

S

Nut, Hex 1/4-20 .......................................... 2

T

Screw, Truss Hd. 1/4-20x5/8 ..................... 2

U

Screw, Flat Hd. 1/4-20x5/8 ...................... 14

V

Key Switch ................................................. 1

J

Support Spreader ...................................... 1

M

Nut, Wing 1/4-20 ........................................ 2

o___@

N

ASSEMBLY

INSTALLING HANDWHEELS

1. From among the loose parts find two #8 external

Iockwashers and two 8-32 x 3/8 inch long Phillips

screws.

2. Install elevation handwheel onto elevation shaft

by lining up FLAT SPOT on shaft with flat inside

handwheel. Install screw and Iockwasher.

3. Install bevel handwheel onto bevel shaft by

lining up FLAT SPOT on shaft with flat inside

handwheel. Install screw and Iockwasher. SCREW

WARNING: Failure to complete the following two

steps could result in damage to your saw.

4. Turn elevation handwheel counter-clockwise to

pull motor away from inner packing cardboard.

5. Remove cardboard.

REMOVE CARDBOARD FROM

UNDERNEATH MOTOR

LOCKWASHER

/

SCREW

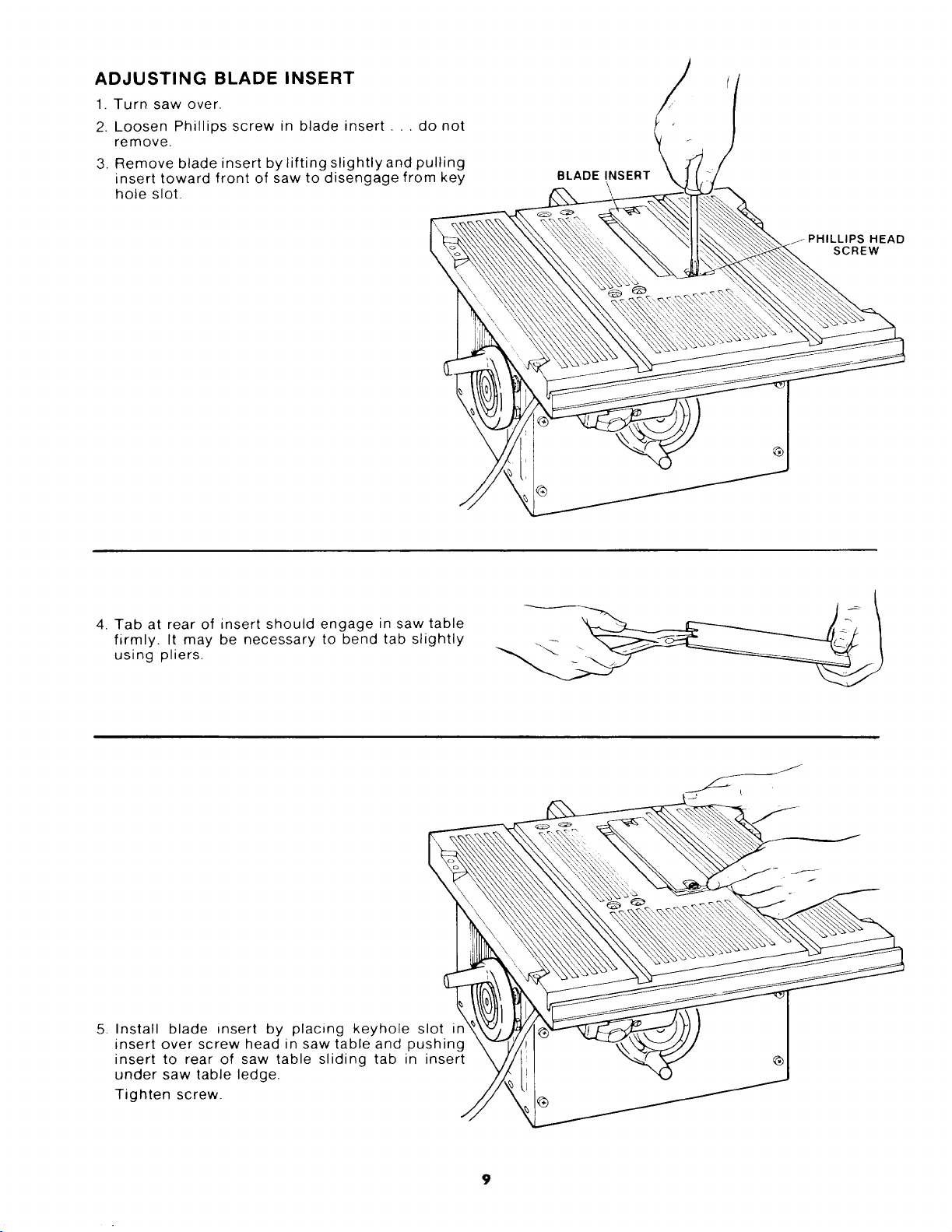

ADJUSTING BLADE INSERT

1. Turn saw over.

2. Loosen Phillips screw in blade insert.., do not

remove.

3. Remove blade insert by lifting slightly and pulling

insert toward front of saw to disengage from key

hole slot.

BLADE INSERT

\

PHILLIPS HEAD

SCREW

4. Tab at rear of insert should engage in saw table

firmly. It may be necessary to bend tab slightly

using pliers.

5. Install blade insert by placing keyhole slot in

insert over screw head in saw table and pushing

insert to rear of saw table sliding tab in insert

under saw table ledge.

Tighten screw.

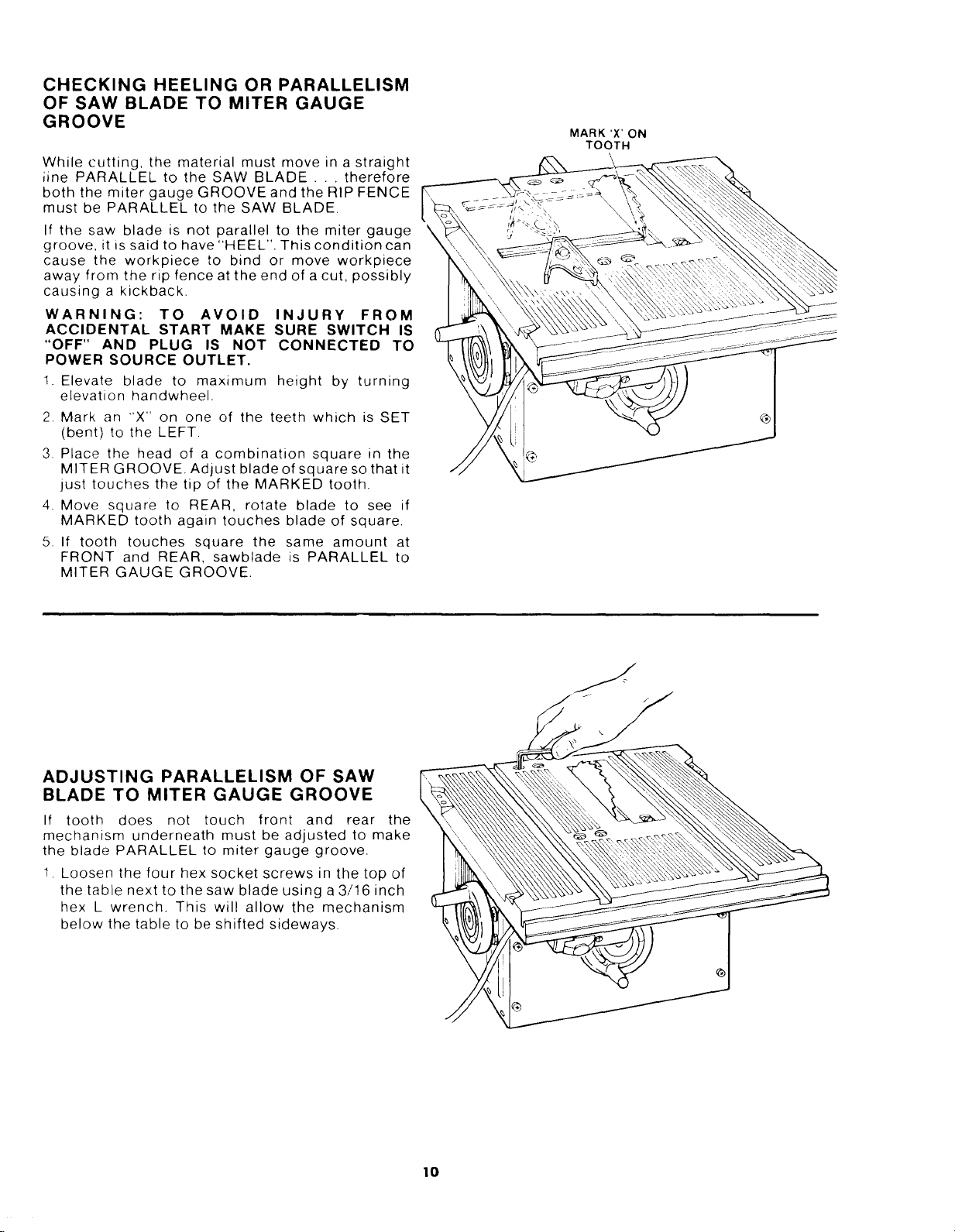

CHECKING HEELING OR PARALLELISM

OF SAW BLADE TO MITER GAUGE

GROOVE

While cutting, the material must move in a straight

line PARALLEL to the SAW BLADE . . . therefore

both the miter gauge GROOVE and the RIP FENCE

must be PARALLEL to the SAW BLADE.

If the saw blade is not parallel to the miter gauge

groove, it is said to have "HEEL". This condition can

cause the workpiece to bind or move workpiece

away from the rip fence at the end of a cut, possibly

causing a kickback.

WARNING: TO AVOID INJURY FROM

ACCIDENTAL START MAKE SURE SWITCH IS

"OFF" AND PLUG IS NOT CONNECTED TO

POWER SOURCE OUTLET.

1. Elevate blade to maximum height by turning

elevation handwheel.

2. Mark an "X" on one of the teeth which is SET

(bent) to the LEFT.

3. Place the head of a combination square in the

MITER GROOVE. Adjust blade of square so that it

just touches the tip of the MARKED tooth.

4. Move square to REAR, rotate blade to see if

MARKED tooth again touches blade of square.

5. If tooth touches square the same amount at

FRONT and REAR, sawblade is PARALLEL to

MITER GAUGE GROOVE.

MARK 'X' ON

TOOTH

\

ADJUSTING PARALLELISM OF SAW

BLADE TO MITER GAUGE GROOVE

If tooth does not touch front and rear the

mechanism underneath must be adjusted to make

the blade PARALLEL to miter gauge groove.

1. Loosen the four hex socket screws in the top of

the table next to the saw blade using a 3/16 inch

hex L wrench. This will allow the mechanism

below the table to be shifted sideways.

10

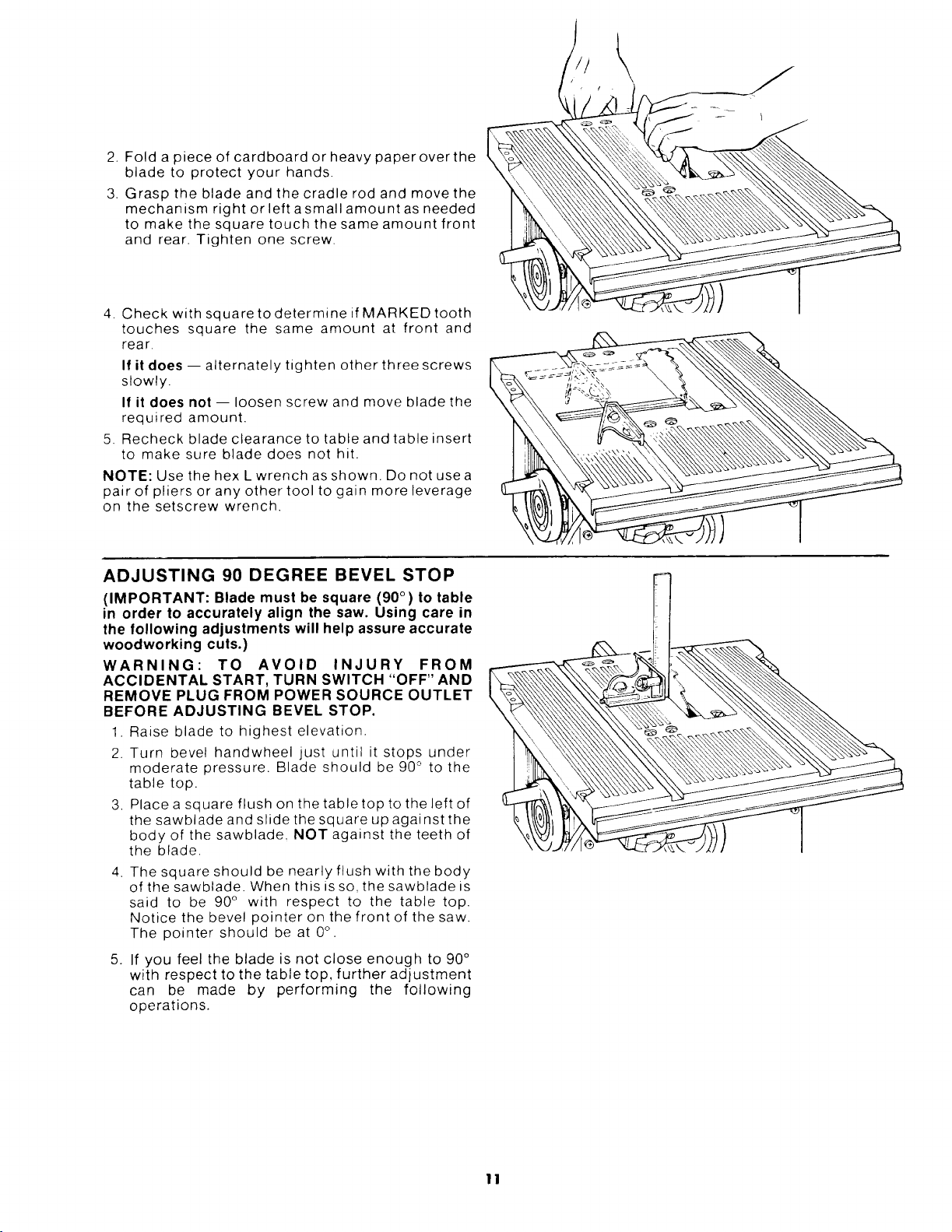

2.Foldapieceofcardboardorheavypaperoverthe

bladeto protectyourhands.

3.Graspthe bladeandthecradlerodandmovethe

mechanismrightorleftasmallamountasneeded

to makethesquaretouchthesameamountfront

andrear.Tightenonescrew.

4.CheckwithsquaretodetermineifMARKEDtooth

touchessquarethe sameamountatfront and

rear.

Ifit does-- alternatelytightenotherthreescrews

slowly.

Ifit doesnot-- loosenscrewandmovebladethe

requiredamount.

5.Recheckbladeclearancetotableandtableinsert

to makesurebladedoesnothit.

NOTE:UsethehexLwrenchasshown.Donotusea

pairofpliersoranyothertooltogainmoreleverage

onthesetscrewwrench.

ADJUSTING 90 DEGREE BEVEL STOP

(IMPORTANT: Blade must be square (90 ° ) to table

in order to accurately align the saw. Using care in

the following adjustments will help assure accurate

woodworking cuts.)

WARNING: TO AVOID INJURY FROM

ACCIDENTAL START, TURN SWITCH "OFF" AND

REMOVE PLUG FROM POWER SOURCE OUTLET

BEFORE ADJUSTING BEVEL STOP.

1. Raise blade to highest elevation.

2. Turn bevel handwheel just until it stops under

moderate pressure. Blade should be 90 ° to the

table top.

3. Place a square flush on the table top to the left of

the sawblade and slide the square up against the

body of the sawblade. NOT against the teeth of

the blade.

4. The square should be nearly flush with the body

of the sawblade. When this isso, the sawblade is

said to be 90° with respect to the table top.

Notice the bevel pointer on the front of the saw.

The pointer should be at 0°.

5. If you feel the blade is not close enough to 90 °

with respect to the table top, further adjustment

can be made by performing the following

operations.

!i

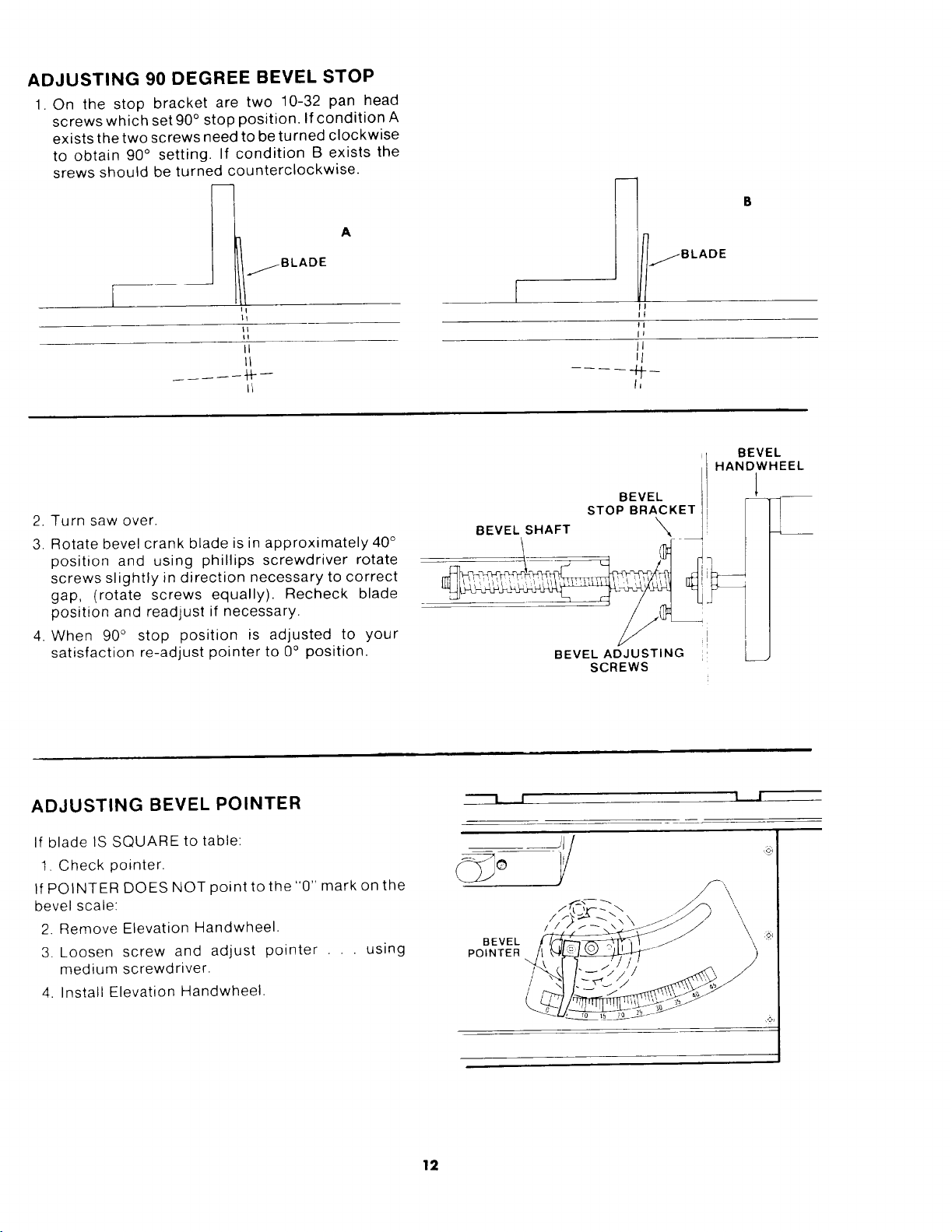

ADJUSTING 90 DEGREE BEVEL STOP

1. On the stop bracket are two 10-32 pan head

screws which set 90 ° stop position. If condition A

exists the two screws need to be turned clockwise

to obtain 90 ° setting. If condition B exists the

srews should be turned counterclockwise.

A

/

2. Turn saw over.

3. Rotate bevel crank blade is in approximately 40°

position and using phillips screwdriver rotate

screws slightly in direction necessary to correct

gap, (rotate screws equally). Recheck blade

position and readjust if necessary.

4. When 90 ° stop position is adjusted to your

satisfaction re-adjust pointer to 0° position.

IBLADE

/

Ii

Ii

tl

LL

LI

I

/BLADE

[

II

It

!1

II

I/

BEVEL

STOP BRACKET I

BEVELSHAFT X J

BEVEL ADJUSTING

SCREWS

B

BEVEL

HANDWHEEL

1

J

ADJUSTING BEVEL POINTER

If blade IS SQUARE to table:

1. Check pointer.

If POINTER DOES NOT point to the"0" mark on the

bevel scale:

2. Remove Elevation Handwheel.

3. Loosen screw and adjust pointer . . . using

medium screwdriver.

4. Install Elevation Handwheel.

12

"----I

BEVEL

POINTER

/

/

/

/

/

t

\

Loading...

Loading...