Page 1

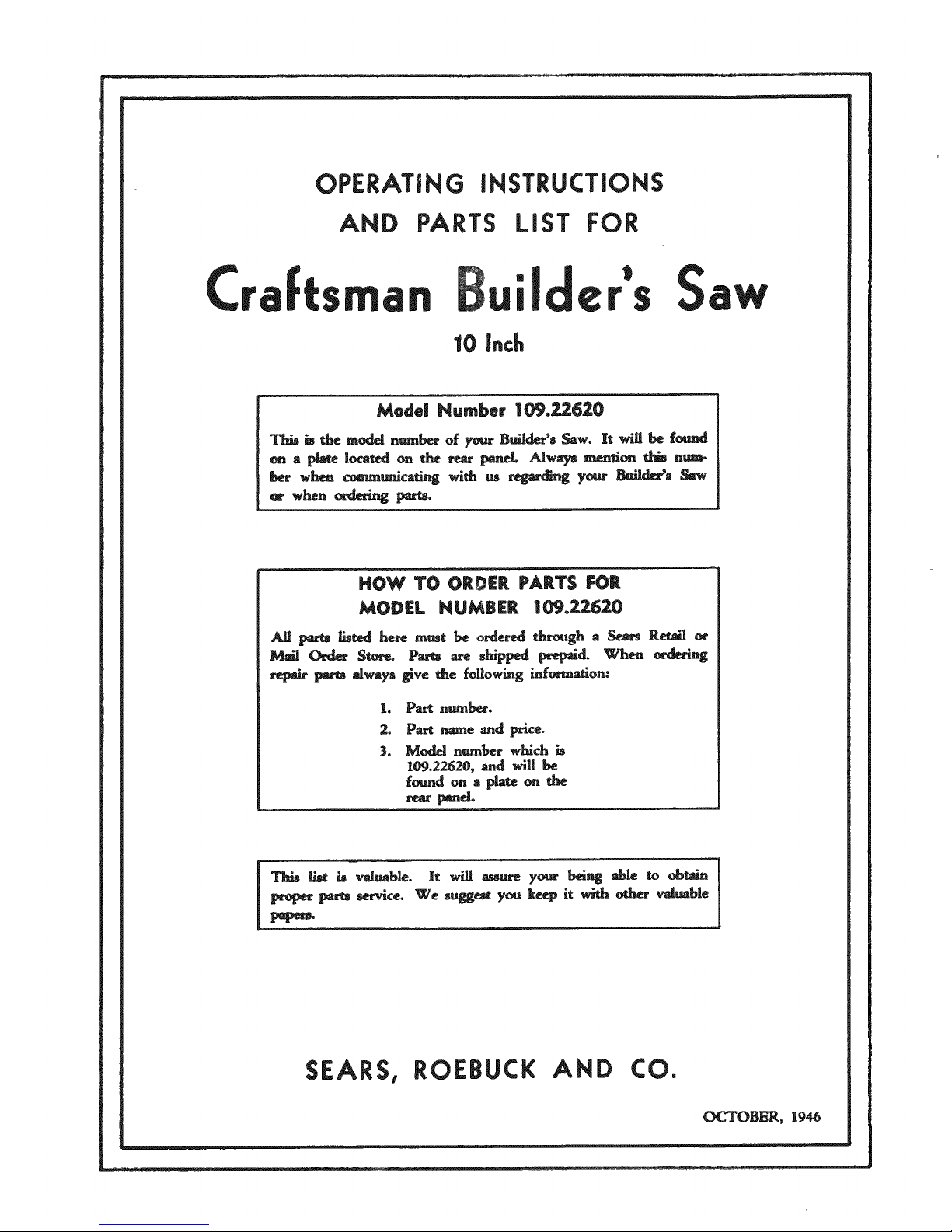

OPERATING iNSTRUCTIONS

AND PARTS LiST FOR

CrBftsrnan

Model Number 109.22620

This is the medal number of your Bufilder'sSaw. It wiU be Eomld

on a plate located on the rear pand. Always numtion _ num-

b_ when communicating with us regarding your Build_s Saw

when orating p_.

HOW TO ORDER PARTS FOR

MODEL HUMBER 109.22620

AU parts listed here mint be ordered throtlgh a Sears Ret_ or

M_ Order Store° Parts are shipped p_Lvald° When

parts always give the following information:

le

2.

3.

Part number°

Part name and price.

Model number which is

109.22620, and will be

found on a plate on the

rear pand.

Th_ llst is valuable. It wW assure your being ab|e to dbtain

proper part, service. We su_t yon keep it with other valuab|e

papa_.

SEARS, ROEBUCK AND CO.

OCTOBER, 1946

Page 2

Page 3

Page 4

Page 5

Instructions for Assembling

Un©rafing

Your C_man Bu_der's Saw is shipped complete

(less motor) in one crate, with a carton for miscellaneous

parts inside the crate. Remove nails around sides 'at

bottom d crate. The top and sldes can then be lihed

off. Remove bol_ in legs from bottom of the crate

and lift saw off. h_tructlous for removing are also

printed on the crate. The carton between the legs cou-

talns the rip fence, lah-hand miter, right-hand miter,

saw guard_ splitter, dust bag, switch, pulleys and bdu,

and an envdope with the necessary small parts such as

nu_, etc., needed for assembly.

Assembly

Your Builder's Saw has been assembled, operated,

and inspected at the factory. The saw carriage has been

fastened securely for shipment. There is a pin attached

with a chain to the leh-hand side d the carriage that

locks the carriage for ripping and dado purpeees at

three points. The carriage Is now locked and fastened.

Open side door removing pin and fastening, so car-

riage can be moved. Mount your motor on the motor

support plate with the motor shah and saw spindle

lined up so that the saw is turning TOWARD the

operator. We have supplied slots in the motor support

plate that will accommodate the holes in most motor

bases. However if they do not fit your motor base,

use the ones that do agree and drill any others that

are necessary° For efficient operation use a 3450 R.PoM.

motor of not less than _ HiP. Any difference in the_

R.P.M. of your motor can be taken care of by usingr

different slz_ of pulleys in accordance with the fol-

lowing table:

Saw Spin_© Motor Motor Appl_ox.

Dia. PuUcy PuUcy R.P,M. Spin.g.P.M.

8 2V2 3gz 3450 48O0

8 2½ 6_ 1750 48O0

10 2V2 3 3450 4200

I0 2_/2 6 1750 42O0

-- --- 7

SRW

Travel

17Y2

17Yz

15½

15½

2¼

2¼

3¼

3¼

Motor should have a _/_-inch shaft with a 3/16-inch key-

way. After mounting the motor, fasten the 3-inch or

doublesheavepulleyson themotor shaftand puton the

two brits.Ifthebritsfurnishedarenotthe fightlength

you can probablyget the lengthyou need at your

nearest Sears Retail or Mail Order Store. Length of

belt is determined by measuring over the OUTSIDE

diameter of the pulley after iustallation. An adjustment

for tightening brits will be found at the rear of the

motor support plate. Do not have the balls too tight.

The switch is mounted with two screws to the front

panel. The following data should be followed for de.

retraining the size of wire recommended for the proper

operation d motor:

MOTOR

H.P.

1

1

1½

MOTOR

VOLTAGE

115

230

115

230

115

230

D]STANCE FROM OUTLET

TO MOTOR

50-feet

No. 14

No. 14

No. 14

No. 14

No. 12.

No. 14

100-f_ 150-feet

No. 12 No. 10

No, 14, No. 14

No. I0 No. 8

No. 14 No. 12

No. 8 No. 6

No. 14 No. 12

and Operatin8 Your Saw

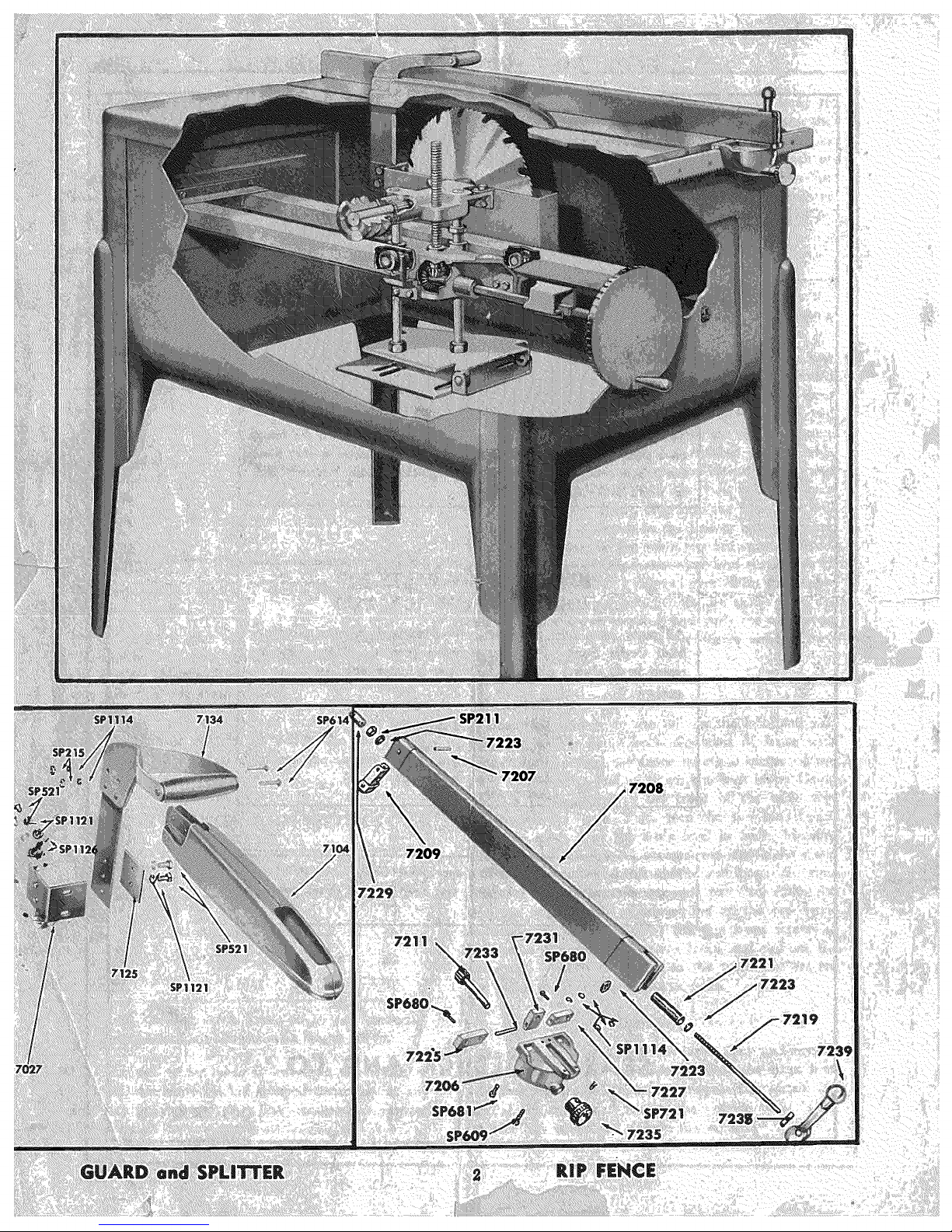

Bolt the splitter angle bracket part No. 7027 to the rear

of the dust chute. Drop the splitter blade, with handl_

over the saw, through the saw slot in the top of the

table. Bolt it with the splitter retaining plate part No.

7125 to the angle bracket part No. 7027. The splitter

blade must be directly in llne with the saw blade. Bolt

guard to the spliRerblade.

The six-inch hand wheel at the front will raise and

lowerthe entire assembly, consisting of saw blade, split°

ter, guard, and handle, to the required height above the

table. The guard should not be more than _ inch

above the work passing _gh saw blade.

The fence guide bar part No. 7121 should be checked

to be sure it has not ja_ed out of llne in shipment. If

so,line up paralidwiththe tabletopand tightenthe

sk mounting screws. For attaching the rip _ence to the

table top, pull out on the small pinion gear knob No.

7235, and slide the fence overthe gmda bar. The fence

may now be moved back and forth by hand. For fin_

adjus_nent engage the piniongear with fence guide bar

by pushing in the knob. The fence can be locked _ront

and back by pushing down on lever No. 7239. If clamp-

ing action is not as tight as desired it may be adjusted

by the jam nuts on the rear end of the tie rod that

runs through the complete fence.

Cumin9 Capa¢i

The depth of cut is controlled by raising and lower-

ing the saw blade using the hand wheel located on

the front panel. The saw can be set to cut thicknesses

from "0" to 3¼ inches. The maximum saw carriage

t_avd is 15_ inches.

Lubrication

Greesin_

The spindle bearings are lubricated at the [ac_

and will' give you approximately 1000 hours of use be-

fore they need to be lubricated. In the housing

the spindlebearings there is a Zerk type fitting which

may be reached from the lab-hand door. Use a ha_

type grease gun, with any high-pressure chassis gun

grease. Do not PACK bearings.

Oi|in_

The followlng parts should be oiled frequently with

No. 20 or No. 30 _utomobile engine oil:

1. Saw raising screw and _,

2. The miter gear sha_ part No. 7063.

3. The hexagon sha_ part No. 7045.

4. Oil poin_ where there is f_ic_io_

between two ormore moving sm_ces

or when a slipfitisnec_sary such

as where the fence _lidas, etc.

To preventsaw table and saw from _th_g, keep

them covered with a film of oll when not in we a_

wipe off before using.

5

Page 6

Operating Instructiom---Continued

This saw is particularly designed for cutting long

pieces. Crosscutting plates, studding, perlim and joists

is fast and accurate, became the work is held against

the miter gage and the blade is pulled through. Mak-

ing the plumb cuts on common and principal rafters,

for roofs of any pitch, is accomplished by setting the

miter gage. The accompanying table shows the proper

miter gage setting for the more common roof pitches.

TABLE OF MITER GAGE SETTINGS FOR

CUTTING RAFTERS

Inches rise per

ft. of mn

6

7

8

9

10

11

12

Degrees to be set

on Miter Gage

63

60

/ 56

50

47zA

45

The same method applies to cutting the ends of raft-

ers for box coruiceL

Rough stair m_ngers are quickly cut by making all

the _ ms and then moving the miter gage 90 de-

gzees for all the tread cuts. Notching of rafters is

accomplished in the same manner.

Bridging is handled with one setting of the miter

gage. The various degrees at which the miter gage

is set for joists of different widths are shown in the

table.

TABLE OF MITER GAGE SETTINGS

FOR BRIDGING

Joist Size

Inches

2x 6

2x 8

2x 10

2x 12

Inches

13¼

16

17

18¼

Degrees on

MiterGage

73

68

62

57

The same methods as reed for roughing-in apply to

finishing. In cases where wide panels are to be cut, the

mit_ gage can be removed and the carriage locked on

the rails. The work can then be fed through, with or

without the rip fence, exactly as on a bench saw. For

dadoing across such parts as drawer fronts, the splitter

and guard can be removed and the carriage locked on

the rails.

Cross Cutting with Miter

The right-hand miter slides in the groove on the

rig_-hand side of the table and is reed for pmhing

the work through the saw.

The left-hand miter is used when pulling the saw

through the work. The table top has been provided

with two pivot positions to accommodate the left-hand

mi_er gage. Put pivot pin part No. 7407 in the keyed

hole closest to the operator. Then line up the double

end pointer with the angle line marked on the table

that is the dosast to the angle you intend cutting and

loosen knob part No. 7303. The two pins in clamp

assembly No. 7404 should drop into the holes that will

hdd the miter the closest to the line of cut you want.

The division lines on the table top are spaced 15 de-

apart. The scale on the miter arm represents 15

•_Tees, with markings 1 degree apart. With the double

_d pointer still in alignment, set the pointer on the

_i'__n scale at the end marking and push the arm along

until the pointer is on the exact degree needed_ then

tighten the handle.

Ripping

Lock the carriage to the rail on the left-hand side

_th the locking pin. Check alignment of fence with

the blade, by sliding the fence within 2 inches of the

blade and lock by pulling down the lock lever. Using

the saw tooth closest to the front of the table top,

measure to the fence. Then turn the saw blade until

the same tooth is at the table level in back. Measure

to the fence. The two measurements should be alike.

If not, take the fence off the table and loosen the four

screws under the front fence guide part No. 7206. Re-

turn the fence to the table and line up the saw fence

as mentioned above. Tighten the two front screws to

hold your adjustment. Remove fence and tighten the

other two. Attach the fence to the table and set for

the width of cut you propose to make.

Based on 1½ inch stock. Joists on 16-inch center.

One-quarter inch allowance on length for fit.

When the cut to be made is less than the width of

the board, the blade can be stopped accurately at any

point such as the end of a line because it is always

visible through the saw guarcL

Dadoing

To use a dedo head, take out insert plate and remove

the saw blade. Place one dndo blade on the arbor first,

_nd then theinsidechippersas requiredto obtain the

desired thickness, and finally, the outside dado blade.

Replace saw collar and tighten nut securely.

Loading...

Loading...