Craftsman 107280340 Owner’s Manual

Operator's anual

®

Rear Engine Riding Mower with Electric Start

Model No.

107.280340 (12.5HP Briggs & Stratton Engine with 28" Mower Deck)

For answers to your questions about this

product, call:

1°800°659°5917

Sears Craftsman HeUp Line

5 am o5 pm, Mort oSat

Sears, Roebuck and Co., Hoffman Estates, IL 60179

Visit our Craftsman website: www.sears.com/craftsman

U.S.A.

7103268

Revision B

Thank You for purchasing this quality-built Craftsman product. We're pXeased that you placed

your confidence in our brand. When operated and maintained according to the instructions in this

manual, your Craftsman product will provide many years of dependable service.

This manuaU contains safety information to make you aware of the hazards and risks associated

with the machine and how to avoid them. This machine is designed and intended onJy for finish

cutting of established lawns and is not intended for any other purpose. It is important that you read

and understand these instructions thoroughJy before attempting to start or operate this equipment.

Save these instructions for future reference.

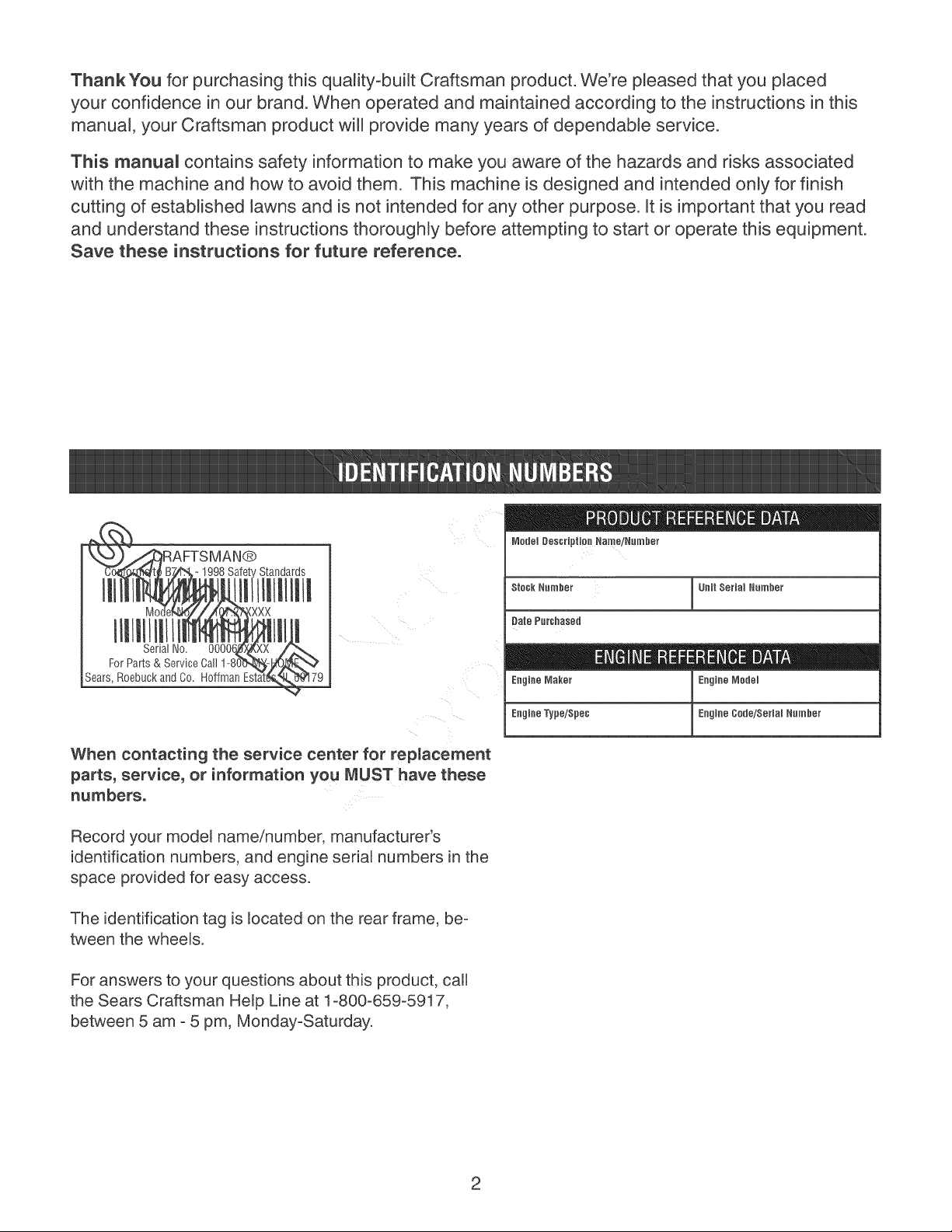

__RAFTSMAN®

siii i iiiiii iim

tlmt i[im xxxImi

When contacting the service center for replacement

parts, service, or information you MUST have these

numbers.

Record your model name/number, manufacturer's

identification numbers, and engine serial numbers in the

space provided for easy access.

The identification tag is located on the rear frame, be-

tween the wheels.

For answers to your questions about this product, call

the Sears Craftsman Help Line at 1-800-659-5917,

between 5 am - 5 pm, Monday-Saturday.

Mede_Description NameiNamber

Stock Nnmber Unit Serial Nnmber

Date Pnrchased

EngineMaker EngineMeae_

EngineType/Spec EngineCode/SeHaJtlnrnber

2

Identification Numbers

Warranty Statement

Emissions Statement

Operator Safety

Features and Controls

Operation

CRAFTSMAN FULL WARRANTY

When operated and maintained according to aH supplied instructions, if any non-expendable part of this riding equip-

ment fails due to a defect in material or workmanship within two years from the date or purchase, call 1-800-659-5917 to

arrange for free in-home repair.

The frame and front axle will be repaired free of charge for five years from the date of purchase if defective in material or

workmanship.

All of the above warranty coverage applies for only 90 days from the date of purchase if this riding equipment is ever

used for commercial or rental purposes.

2 Maintenance 17

3 Storage 21

4 Troubleshooting 22

5 Specifications 24

10 Service Parts PTS-1

11

In alUcases, if repair proves impossible, the riding equipment will be replaced free of charge with the same or an equiva-

lent model.

The battery will be replaced free of charge for 90 days from the date of purchase if defective in material or workmanship

(or testing proves that it will not hold a charge).

This warranty covers ONLY defects in materia_and workmanship. Sears will NOT pay for:

o Expendable items that become worn during normal use. including but not limited to blades, spark plugs, air cleaners,

belts, and oil filters.

o Standard maintenance servicing, oil changes, or tune-ups.

o Tire replacement or repair caused by punctures from outside objects, such as nails, thorns, stumps, or glass.

o Tire or whee_ replacement or repair resuking from normal wear. accident, or improper operation or maintenance.

o Repairs necessary because of operator abuse, including but not limited to damage caused by towing objects beyond

the capability of the riding equipment, impacting objects that bend the frame or crankshaft, or over-speeding the

engine.

o Repairs necessary because of operator negligence, including but not limited to, e_ectrical and mechanical damage

caused by improper storage, failure to use the proper grade and amount of engine oil, failure to keep the deck clear

of flammable debris, or failure to maintain the riding equipment according to the instructions contained in the opera-

tot's manual.

o Engine (fuel system) cleaning or repairs caused by fuel determined to be contaminated or oxidized (stale). In general,

fuel should be used within 30 days of its purchase date.

o Normal deterioration and wear of the exterior finishes, or product label replacement.

This warranty applies only while this product is within the United States.

This warranty gives you specific legal rights, and you may also have other rights which vary from state to state.

Sears, Roebuck and Co., Hoffman Estates, IL 60179

3

Emissions Control SystemWarranty Statement

California, United States and Canada Emissions Contrn! Defects Warranty

Statement

TheCaliforniaAirResourceBoard(CAR6),U.S.EPAadn6&Sarepleasedto explainthe

EmissionsControlSystemWarrantyonyour smalloff-roadengine(SORE).InCalifor-

nai,newsmalloff=roadenginesmodelyear2006andlatermustbedesigned,builtand

equippedtomeettheState'sstdgentanti=smogstandards.ElsewhereintheUnitedStates,

newnon=road,spark-ignitionenginescertifiedfor modelyear1997andlatermust meet

similarstandardssetforth bythe U.S.EPA.B&Smustwarranttheemissionscontrolsys=

temon yourenginefor theperiodsof timelistedbelow,providedtherehasbeennoabuse,

neglectorimpropermaintenanceofyoursmalloff-roadengine.

Youremissionscontrolsystemincludespartssuchasthecarburetor,aircleaner,ignition

system,fuelline,mufflerandcatalyticconverter.Alsoincludedmaybeconnectorsand

otheremissionsrelatedassemblies.

Whereawarrantableconditionexists,B&Swillrepairyoursmalloff-roadengineat no

costto youincludingdiagnosis,partsandlabor.

Bfiggs & Stratton Emissions Centre! Defects Warranty Coverage

Smalloff=roadenginesarewarrantedrelativetoemissionscontrol partsdefectsfor a

periodof two years,subiectto provisionssetforth below.If anycoveredparton your

engineis defective,the partwill berepairedor replacedby B&S.

Thefollowing arespecificprovisions relativeto your EmissionsControlDefectsWarrantyCoverage.It is in additionto the B&Senginewarrantyfor non°regulatedenginesfound

in the Operatingand MaintenanceInstructions.

1.WarrantedParts

Coverageunderthis warrantyextendsonlyto the paris s_eobelow the emissions

control systemsparts)to the extent these partswere oresenron me engne

purchased.

a. FuelMeteringSystem

• Coldstartenrichmentsystem(soft choke)

• Carburetorandinternalparts

Fuelpump 4.

• Fuelline,fuel linefittings, clamps

• Fueltank, capandtether

• Carboncanister

b. Air inductionSystem

• Air cleaner

• intake manifold

• Purgeandvent line

c. IgnitionSystem 5.

• Sparkplug(s)

• Magnetoignition system

d. CatalystSystem

• Catalyticconverter

• Exhaustmanifold

• Air injectionsystemor pulsevalve

e. MiscellaneousItems Usedin AboveSystems

• Vacuum,temperature,position,time sensitivevalvesandswitches

• Connectorsandassemblies

2.Lengthof Coverage

6&S warrantstothe initialownerand eachsubsequentpurchaserthatthe Warranted 6.

Partsshall befreefrom defectsin materialsandworkmanshipwhich causedthe

failureof theWarrantedpartsfor a periodof twoyearsfrom the datetheengineis

deliveredto a retailpurchaser.

Owner's Warranty Respnnsibitity

Asthesmalloff-madengineowner,you areresponsiblefor the performanceoftherequired

maintenancelistedinyour OperatingandMaintenanceInstructions.B&Srecommends

thatyouretainallyour receiptscoveringmaintenanceonyoursmalloff-roadengine,but

B&Scannotdenywarrantysolelyfor thelackof receiptsor foryour failureto ensurethe

performanceof allscheduledmaintenance.

Asthesmalloff-madengineowner,you shouldhoweverbeawarethat6&Smaydenyyou

warrantycoverageifyour smalloff-roadengineor aparthasfaileddueto abuse,neglect,

impropermaintenanceor unapprovedmodifications.

Youareresponsiblefor presentingyoursmalloff-roadengineto anAuthorized6&S Service

Dealerassoonasaproblemexists.Theundisputedwarrantyrepairsshouldbecompleted

ina reasonableamountoftime,notto exceed30 days.

if you haveanyquestionsregardingyour warrantyrightsandresponsibilities,you should

contactaB&SServiceRepresentativeat(414)259-5262.

Theemissionswarrantyis a defectswarranty.Defectsarejudgedon normalengineperfor=

mance.Thewarrantyis not relatedto anin=useemissionstest.

3. NoCharge

Repairor replacementofanyWarrantedPartwill beperformed at nochargeto the

owner, nc_umngdiagnosticlabor which leadsto thedeterminationthat aWar-

rame_Partis defecttive,if the diagnosticworkis performedat an AuthorizedB&S

ServiceDealeras listedin the"YellowPages"under "Engines,Gasoline,""Gasoline

Engnee.""LawnMowers,"or similarcategory.

ClaimsandCoverageExclusions

Warrantyclaims shallbefiled inaccordancewith the provisionsofthe B&S Engine

WarrantyPolicy.Warrantycoverageshallbeexcludedfor failures ofWarrantedParts

whicharenot original 6&Spartsor becauseof abuse,neglector impropermain=

renanceassetforth inthe B&S EngineWarrantyPolicy.B&Sis notliableto cover

failuresof WarrantedPartscausedbythe useof add-on, non-original,or modified

E_/[[S.

Maintenance

AnyWarrantedPartwhich is notscheduledfor replacementasrequiredmaintenance

or whichis scheduledonlyfor regularinspectionto the effect of "repairor replaceas

necessary"shallbewarrantedasto defectsfor thewarranty period. AnyWarranted

Partwhichis scheduledfor replacementasrequired maintenanceshallbewarranted

asto defectsonlyfor the periodoftime up tothefirst scheduledreplacementfor

that part.Any replacementpartthat is equivalentinperformanceanddurabilitymay

beusedin theperformanceof anymaintenanceor repairs.Theowner is responsible

for theperformanceof all requiredmaintenance,asdefinedin theB&S Operating

andMaintenanceinstructions.

ConsequentialCoverage

Coveragehereundershallextendto thefailure ofany enginecomponentscausedby

thefailure ofanyWarrantedPartstill underwarranty.

Enginesthatarecertified to meettheCaliforniaAirResourcesBoard(CAR6)Emiso

sions Standardmust displayinformationregardingthe EmissionsDurabilityperiod

andthe Air Index.Bdggs& Stratton makesthis informationavailabletothe con-

sumer on our emissions labels.Theengineemissionslabelwill indicatecertification

information.

TheEmissions Durability Perioddescribesthe numberof hoursof actual running

time forwhich the engineis certifiedto beemissionscompliant,assumingproper

maintenancein accordancewihtthe OperatingandMaintenanceinstructions. The

following categoriesareused:

Nlederate:

Engineis certifiedto be emissionscompfiantfor 125hoursof actual runningtime.

Intermediate:

Engineis certifiedto be emissionscompliantfor 256hours ofactualrunningtime.

Extended:

Engineis certifiedto be emissionscompliantfor 566 hoursof actualenginerunningtime.

Forexample,atypicalwalk-behindlawn moweris used20 to 25 hoursperyear.There°

fore, theEmiseieesDurability Period ofan enginewith anintermediate rating would

equateto 10to 12years.

6riggs & Strattonenginesarecertifiedto meetthe UnitedStatesEnvironmentalProteco

tion Agency(ESEPA)Phase2emissionsstandards.ForPhase2 certifiedengines,the

EmissionsCompliancePeriodreferredto on the EmissionsCompliancelabel indicatesthe

numberof operatinghours forwhichthe enginehasbeenshownto meetFederalemis-

sions requirements.

Forengineslessthan 225cc displacement.

CategoryC=125 hours,CategoryB=250 hours,CategoryA=500 hours

Forenginesof 225ccor moredisplacement.

CategoryC=250 hours,CategoryB=500 hours,CategoryA= 1000hours

4

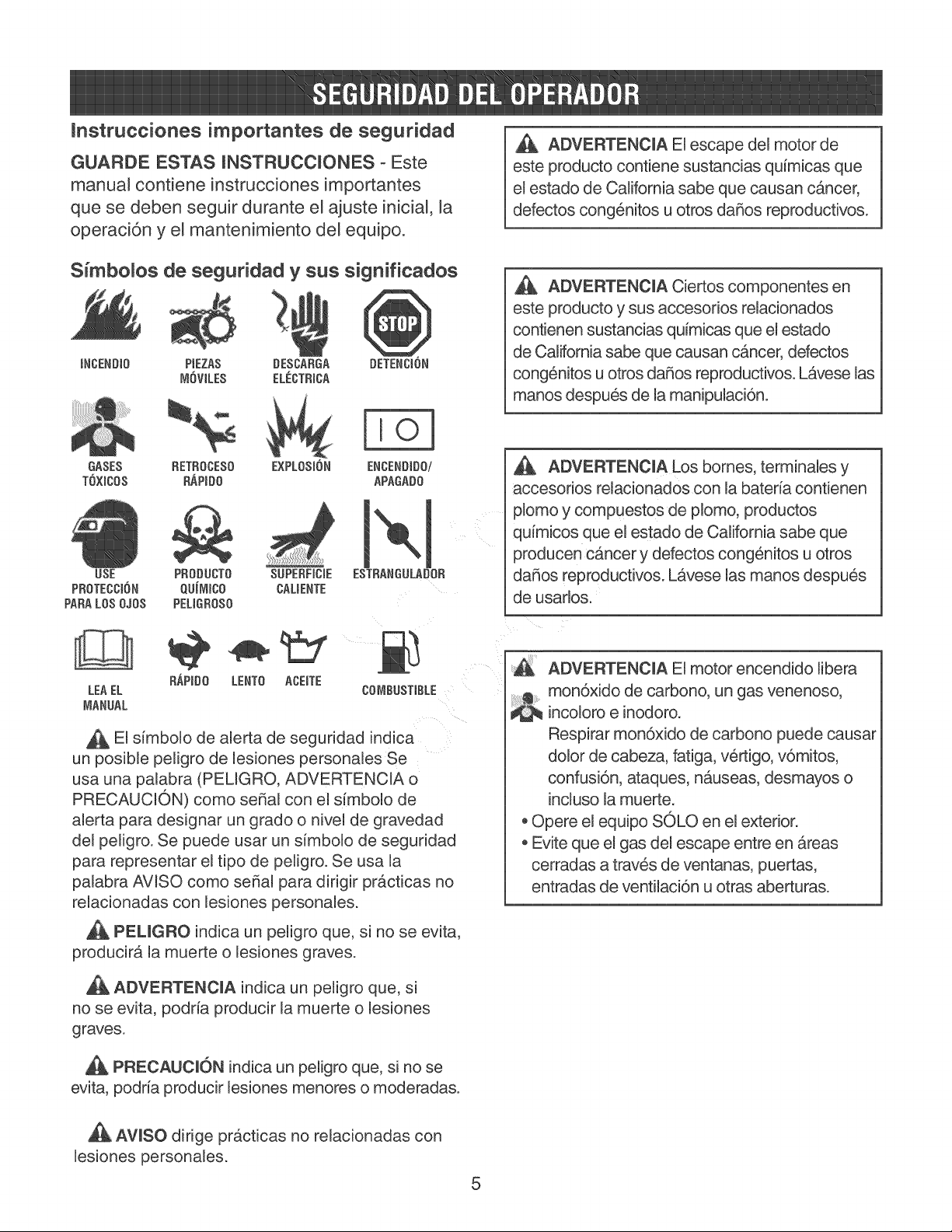

_mportant Safety _nstructions

SAVE THESE INSTRUCTIONS -This manua_ contains

important instructions that should be followed during the

initial set-up, the operation, and the maintenance of the

equipment.

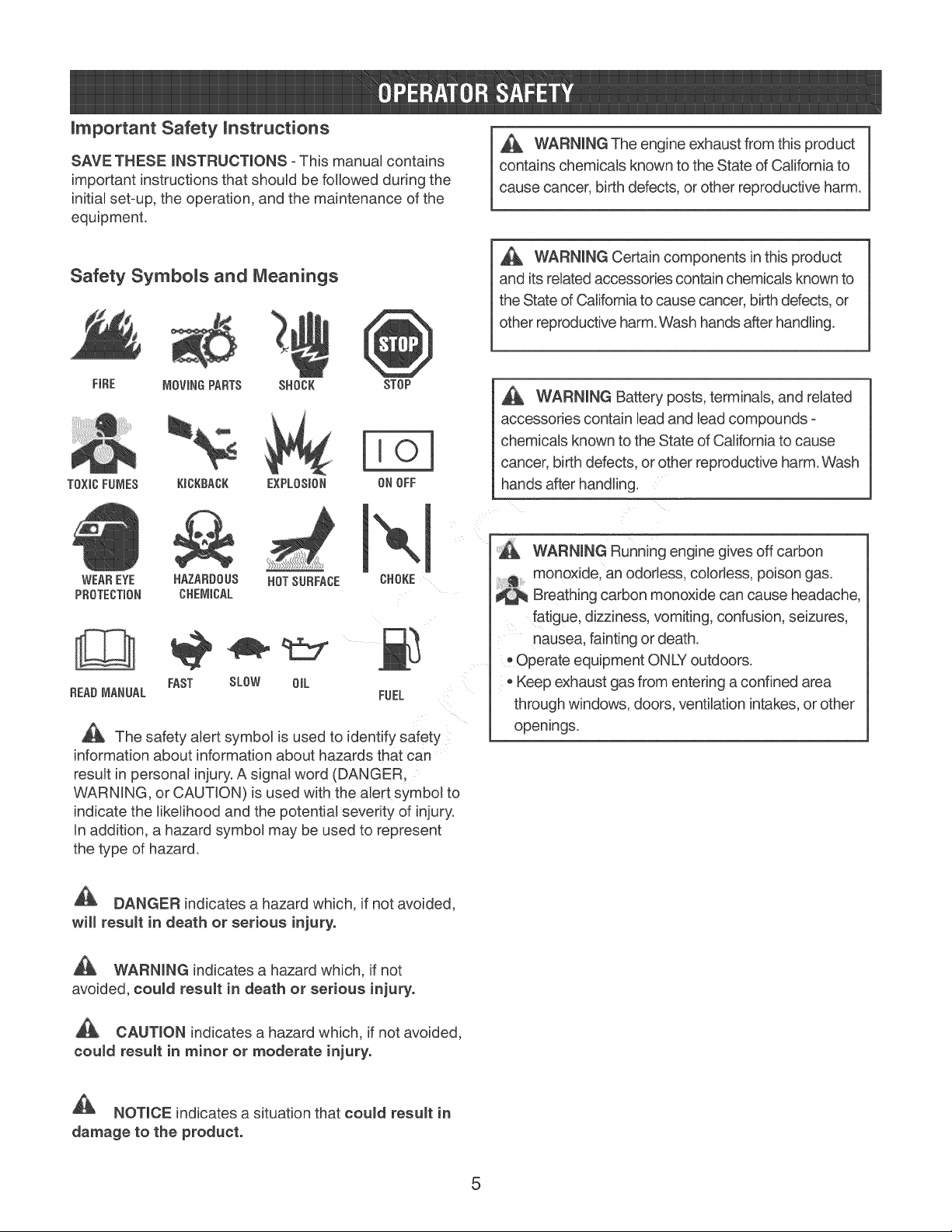

Safety SymboUs and Meanings

WARNmNGThe engine exhaust from this product

contains chemicals known to the State of California to

cause cancer, birth defects, or other reproductive harm.

WARNmNGCertain components in this product

and its related accessories contain chemicals known to

the State of California to cause cancer, birth defects, or

other reproductive harm. Wash hands after handling.

FiRE MOVJNGPARTS SHOCK STOP

i

TOXICFUMES KICKBACK EXPLOSION

WEAR EYE HAZARDOUS HOTSURFACE CHOKE

PROTECTION CHEMICAL

READMANUAL FUEl

The safety alert symbol is used to identify safety

information about information about hazards that can

result in personal injury. A signal word (DANGER,

WARNING, or CAUTION) is used with the alert symbol to

indicate the likelihood and the potential severity of injury.

In addition, a hazard symbol may be used to represent

the type of hazard.

FAST

WARNING Battery posts, terminals, and related

accessories contain lead and lead compounds =

chemicals known to the State of California to cause

cancer, birth defects, or other reproductive harm. Wash

hands after handling.

WARNING Running engine gives off carbon

monoxide, an odorless, colorless, poison gas.

Breathing carbon monoxide can cause headache,

fatigue, dizziness, vomiting, confusion, seizures,

nausea, fainting or death.

• Operate equipment ONLY outdoors.

o Keep exhaust gas from entering a confined area

through windows, doors, ventilation intakes, or other

openmngs.

DANGER indicates a hazard which, if not avoided,

will result in death or serious injury.

WARNING indicates a hazard which, if not

avoided, could result in death or serious injury.

CAUTmON indicates a hazard which, if not avoided,

could result in minor or moderate injury,

NOTICE indicates a situation that could result in

damage to the product.

5

WARNING: This cutting machine is capable of amputating hands and feet and can throw objects that can

cause injury and damage! Failure to comply with the following SAFETY instructions could result in serious

injury or death to the operator or bystanders. The owner of the machine must understand these instructions

and must allow only persons who understand these instructions to operate machine. Each person operating

the machine must be of sound mind and body and must not be under the influence of any substance, which

might impair vision, dexterity or judgment.

Protection for Children

Tragic accidents can occur ifthe operator is not alert to

the presence of children. Children are often attracted to

the machine and the mowing activity. Never assume that

children will remain where you last saw them.

1. KEEP children out of the mowing area and under the

watchful care of a responsible adult.

2. DO NOT allow chi}dren or others to ride on machine,

attachments or towed equipment (even with the

blades OFF). They may fall and be seriously injured.

3. ALLOW only responsiMe adults & teenagers with

mature judgment under dose adult supervision to

operate machine.

4. DO NOT operate blades in reverse. STOP BLADES.

LOOK and SEE behind and down for children, pets

and hazards before and while backing.

5. USE EXTRA CARE when approaching blind corners.

shrubs, trees, or other objects that may obscure vi-

sion.

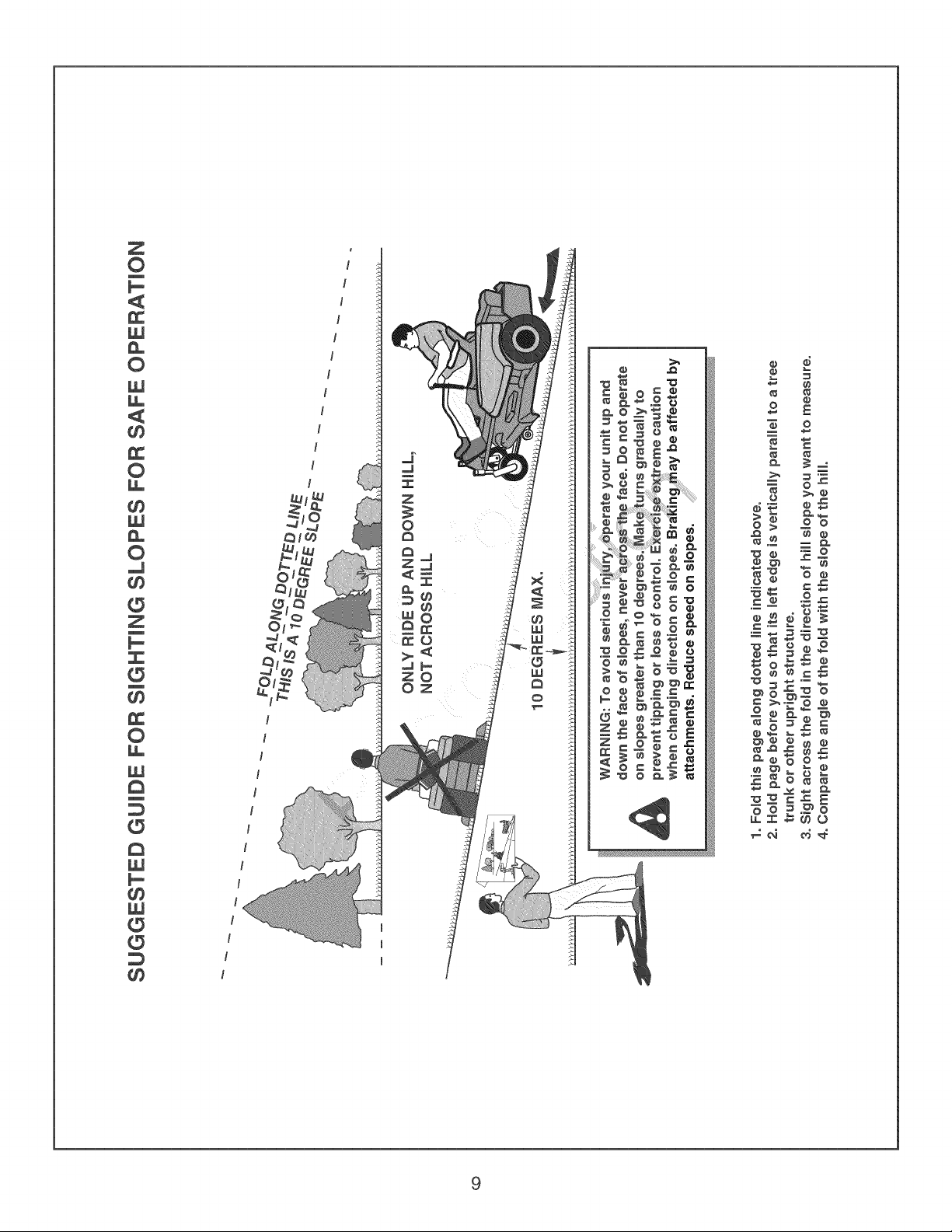

Protection against Tipovers

Slopes are a major factor related to loss-of-control and

tip-over accidents, which can result in severe injury or

death. All slopes require extra CAUTION. ff you cannot

back up the slope or if you feel uneasy on the slope. DO

NOT mow it. Use extra care with grass catchers or other

attachments; these affect the handling and the stability of

the machine. Refer to the Slope Guide at the end of this

section.

1. DO NOT operate machine on slopes exceeding 10

degrees, which is 3.5 feet (1.1 m) vertically for every

20 feet (6.1 m) horizontally.

2. Turn blades OFF when traveling uphill. Use a slow

speed and avoid sudden or sharp turns.

3. DO NOT operate machine back and forth across face

of slopes. Operate up and down. Practice on slopes

with blades off.

4. AVOID starting, stopping or turning on slopes, ff

machine stops going uphill or tires lose traction, turn

blades OFF and back slowly straight down the slope.

5. STAYALERT for holes and other hidden hazards. Tall

grass can hide obstacles. Keep away from ditches,

washouts, culverts, fences and protruding objects.

6. KEEP A SAFE DISTANCE of at least 3 feet (.9 meters)

away from edge of ditches and other drop offs. The

machine could turn over if an edge caves in.

7. Always begin forward motion slowly and with caution.

8. Use weights or a weighted load carrier in accordance

with instructions supplied with a grass catcher. DO

NOT operate machine on slopes exceeding 10 de-

grees.

9. DO NOT put your foot on the ground to try to stabilize

the machine.

10. DO NOT operate machine on wet grass. Reduced

traction could cause sliding.

11. Choose a low enough speed setting so that you will

not have to stop or shift on a slope. Tires may lose

traction on slopes even though the brakes are func-

tioning properly.

12. DO NOT operate machine under any condition where

traction, steering or stability is doubtful.

13. Always keep the machine in gear when going down

slopes. DO NOT shift to neutral (or actuate hydro roll

release) and coast downhill.

Before Mowing

1= Read, understand, and follow instructionsand warm

ings in this manual and on the machine, engine and

attachments. Know the controls and the proper use of

the machine before starting.

2. Only mature, responsible persons shall operate the

machine and only after proper instruction.

3. Data indicates that operators age 60 and above,

are involved in a large percentage of mower=related

injuries. These operators should evaluate their ability

to operate the mower safely enough to protect them-

selves and others from serious injury.

4. Handle fuel with extra care. Fuels are flammable

and vapors are explosive. Use only an approved fuel

container. DO NOT remove fuel cap or add fuel with

engine running. Add fuel outdoors only with engine

stopped and cool. Clean spilled fuel from machine. DO

NOT smoke.

5. Practice operation of machine with BLADES OFF to

learn controls and develop skills.

6. Check the area to be mowed and remove all objects

such as toys, wire, rocks, limbs and other objects that

could cause injury ifthrown by blade or interfere with

mowing.

7. Keep people and pets out of mowing area. Immedi-

ately STOP blades, STOP engine, and STOP machine

ifanyone enters the area.

8. Check shields, deflectors, switches, blade controls

and other safety devices frequently for proper opera-

tion and location.

9. Make sure aHsafety decals are clearly legible. Re-

place if damaged.

10. Protect yourself when mowing by wearing safety

glasses, a dust mask, long pants and substantial

footwear.

6

11. Know how to STOP blades and engine quickly in

preparation for emergencies.

12. Use extra care when loading or unloading the ma-

chine into a trailer or truck.

13. Check grass catcher components frequently for signs

of wear or deterioration and replace as needed to

prevent injury from thrown objects going through weak

or worn spots.

Safe Handling of Gasoline

To avoid personal injury or property damage, use ex-

treme care in handling gasoline. Gasoline is extremely

flammable and the vapors are explosive.

1. Extinguish all cigarettes, cigars, pipes and other

sources of ignition.

2. Use only an approved fuel container.

3. DO NOT remove fuel cap or add fuel with the engine

running. Allow the engine to cool before refueling.

4. DO NOT refuel the machine indoors.

5. DO NOT store the machine or fuel container inside

where there is an open flame, spark or pilot light such

as on a water heater or other appliances.

6. DO NOT fill fuel containers inside a vehicle or on a

truck or trailer bed with a plastic liner. Always place the

containers on the ground away from the vehicle before

filling.

7. Remove gas-powered equipment from the vehicle or

trailer and refuel it on the ground. If this is not possi-

ble, then refuel equipment using a portable container.

rather than a gasoline dispenser nozzle.

8. DO NOT start gas powered equipment in enclosed

vehicles or trailers.

9. Keep the nozzle in contact with the rim of the fuel tank

or container opening at all times until fueling is com-

plete. DO NOT use a nozzle lock-open device

10. If fuel is spilled on clothing, change clothing immedi-

ately.

11. Never overfill a fuel tank. Replace fuel cap and tighten

securely.

Genera_ Operating Safety

1. Mount and dismount machine from left side. Keep

clear of discharge opening at all times.

2. Start engine from operator's seat. Make sure blades

are OFF and parking brake is set.

3. DO NOT leave machine with engine running. STOP

engine, STOP blades, SET brake, and Remove key

before leaving operators position of any reason.

4. DO NOT operate machine unless properly seated with

feet on rests or pedal(s).

5. STOP BLADES and ENGINE and make sure blades

have stopped before removing grass catcher or un-

clogging mower to prevent loss of fingers or hand.

6. Blades must be OFF except when cutting grass. Set

blades in highest position when mowing over rough

ground.

7. Keep hands and feet away from rotating blades un-

derneath deck. DO NOT place foot on ground while

BLADES are ON or machine is in motion.

8. DO NOT operate machine without entire grass

catcher or guards in place and working. DO NOT point

discharge at people, passing cars, windows or doors.

9. Slow down before turning.

10. Watch out for traffic when near or crossing roadways.

11. STOP engine immediately after striking an obstruc-

tion. Inspect machine and repair damage before

resuming operation.

12. Operate machine only in daylight or with good artifi-

cial light.

13. Move joystick (if equipped) SLOWLY to maintain con-

tro_during speed and directional changes.

14. DO NOT operate engine in enclosed areas. Engine

exhaust gases contain carbon monoxide, a deadly

poison.

15. DO NOT discharge material against a wall or obstruc-

tion. Material may ricochet back towards the operator.

16. Only use accessories approved by the manufacturer.

See manufacturer's instructions for proper operation

and installation of accessories.

7

Towing

1. Tow only with a machine that has a hitch designed for

towing. DO NOT attach towed equipment except at the

hitch point,

2. Follow the manufacturer's recommendation for weight

limits for towed equipment and towing on slopes.

3. DO NOT allow children or others on towed equipment.

4. On slopes, the weight of the towed equipment may

cause loss of traction and loss of control.

5. Travel slowly and allow extra distance to stop.

6. Exercise CAUTION when pulling loads. Limit loads to

those you can safely control and attach loads to hitch

plate as specified in the attachment instructions.

Maintenance Safety

1. DO NOT store machine or fuel container inside where

fumes may reach an open flame, spark or pilot light

such as in a water heater, furnace, clothes dryer or

other gas appliance. Allow engine to cool before stor-

ing machine in an enclosure. Store fuel container out

of the reach of children in a well ventilated, unoccu-

pied building.

2. Keep engine free of grass, leaves or excess grease to

reduce fire hazard and engine overheating.

3. When draining fuel tank, drain fuel into an approved

container outdoors and away from open flame.

4. Always provide adequate ventilation when running

engine. Exhaust gases contain carbon monoxide, an

odorless and deadly poison.

5. Disconnect negative (black) cable from battery before

performing maintenance or service. Cranking engine

could cause injury.

6. DO NOT work under machine without safety blocks.

7. Service engine and make adjustments only when em

gine is stopped. Remove spark plug wire(s) from spark

plug(s) and secure wire(s) away from spark plug(s).

8. DO NOT change engine governor speed settings or

overspeed engine.

9. Mower blades are sharp and can cut. Wrap the blades

or wear heavy leather gloves and use CAUTION when

handling them.

10. DO NOT test for spark by grounding spark plug next

to spark plug hole; spark plug could ignite gas exiting

engine.

11. Maintain or replace safety and instruction labels as

necessary.

8

0

i

<

W

_L

0

W

U.

_ E

@

0

U.

W

_L

0

.J

7

i

:E

G

i

0

U.

W

i

W

W

_>, =_

p,s

_ 0 _-_

9

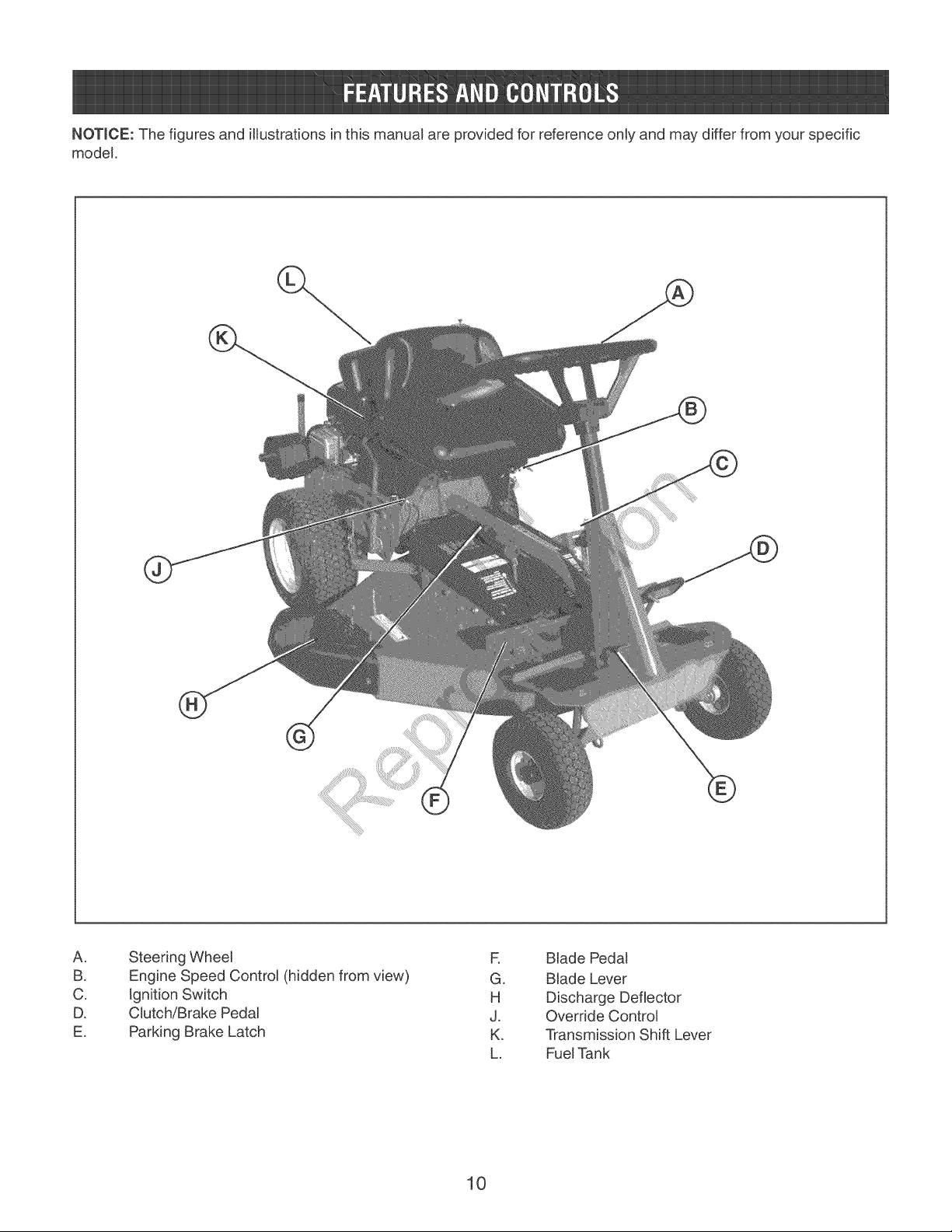

NOTmCE:The figures and illustrations in this manual are provided for reference only and may differ from your specific

model.

A. Steering Wheel R Blade Pedal

B. Engine Speed Control (hidden from view) G. Blade Lever

C. Ignition Switch H Discharge Deflector

D. Clutch/Brake Pedal J. Override Control

E. Parking Brake Latch K. Transmission Shift Lever

L. Fuel Tank

10

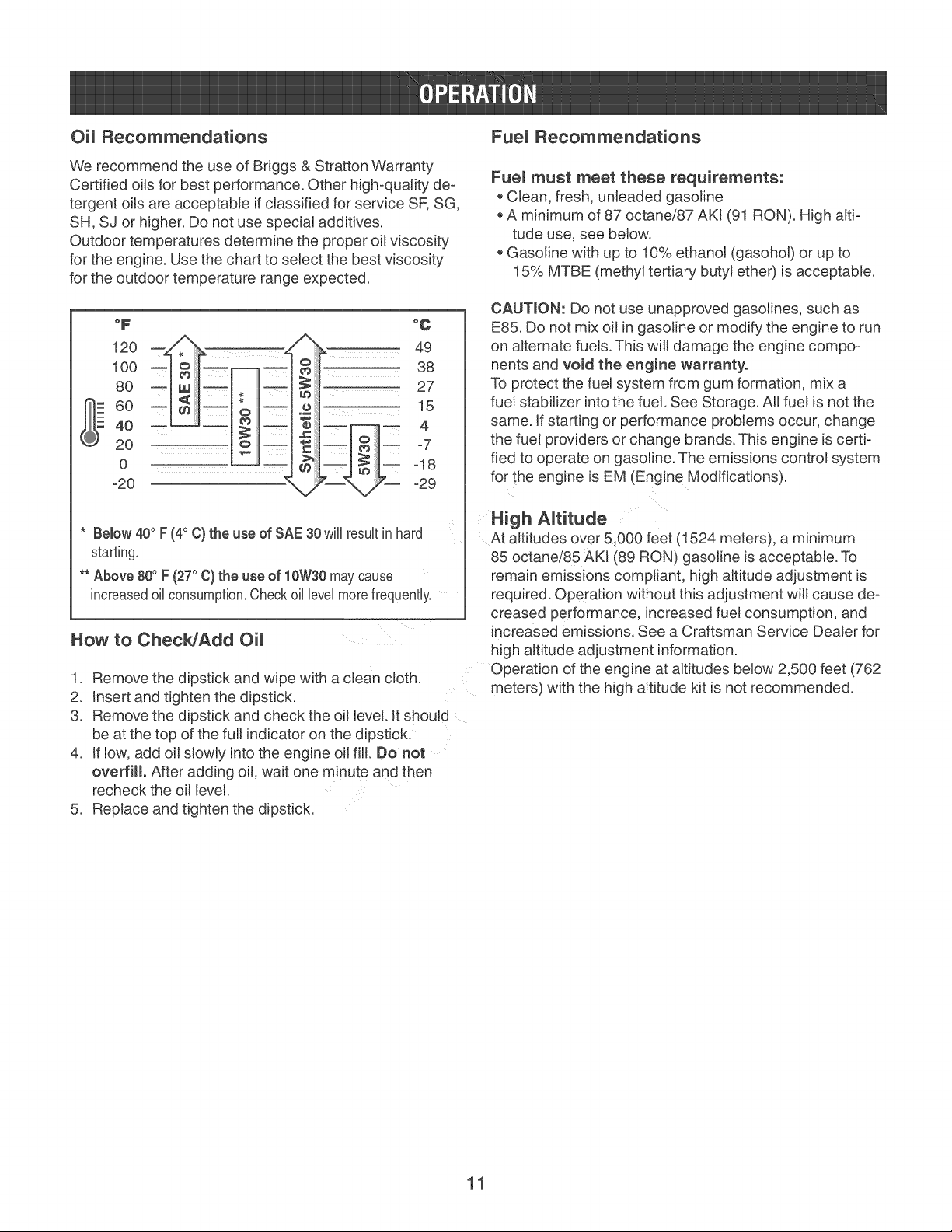

OiURecommendations

FueU Recommendations

We recommend the use of Bdggs & Stratton Warranty

Certified oils for best performance. Other high-qualky de-

tergent oils are acceptable if classified for service SF, SG,

SH, SJ or higher. Do not use special additives.

Outdoor temperatures determine the proper oil viscosity

for the engine. Use the chart to select the best viscosity

for the outdoor temperature range expected.

°F

120

100

8O

= 60

40

20

0

-20

* Below 400F(40C)the useof SAE 30wi resultin hard

starting.

** Above 800F(270C)the useof 10W30maycause

increasedoil consumption.Checkoil levelmorefrequently.

o 49

- 38

- 27

o - 15

¢ -- -- 4

-- -- -7

>' -18

°C

-29

How to Check/Add OiU

1. Remove the dipstick and wipe with a c_ean cloth.

2. Insert and tighten the dipstick.

3. Remove the dipstick and check the oil level It should

be at the top of the full indicator on the dipstick.

4. If low, add oil slowly into the engine oil fill. Do not

overfill After adding oil, wait one minute and then

recheck the oil _evel.

5. Replace and tighten the dipstick.

Fuem must meet these requirements:

o Clean, fresh, unleaded gasoline

oA minimum of 87 octane!87 AKI (91 RON). High alti-

tude use, see below.

o Gasoline with up to 10% ethanol (gasohol) or up to

15% MTBE (methyl tertiary butyl ether) is acceptable.

CAUTmON: Do not use unapproved gasolines, such as

E85. Do not mix oil in gasoline or modify the engine to run

on alternate fuels. This will damage the engine compo-

nents and void the engine warranty°

To protect the fuel system from gum formation, mix a

fuel stabilizer into the fuel. See Storage. AHfuel is not the

same. If starting or performance problems occur, change

the fuel providers or change brands. This engine is certi-

fied to operate on gasoline. The emissions control system

for the engine is EM (Engine Modifications).

High AUtitude

At altitudes over 5,000 feet (1524 meters), a minimum

85 octane/85 AKI (89 RON) gasoBine is acceptable. To

remain emissions compliant, high altitude adjustment is

required. Operation without this adjustment will cause de-

creased performance, increased fuel consumption, and

increased emissions. See a Craftsman Service Dealer for

high altitude adjustment information.

Operation of the engine at altitudes below 2,500 feet (762

meters) with the high altitude kit is not recommended.

11

How to Add FueU

WARNmNGGasoline and its vapors are extremely

flammable and explosive.

_Fire or explosion can cause severe burns or death.

When Adding Fuel

•Turn engine off and let engine cool at least 2 minutes

before removing the fuel cap.

Fill fuel tank outdoors or in well-ventilated area.

• Do not overfill fuel tank. To allow for expansion of

gasoline, do not fill above the bottom of the fuel tank

neck.

• Keep gasoline away from sparks, open flames, pilot

lights, heat, and other ignition sources.

• Check fuel lines, tank, cap, and fittings frequently for

cracks or leaks. Replace if necessary.

If fuel spills, wait until itevaporates before starting

engine.

Before Starting

1. Check the tire pressure; add or release air as needed

to bring pressure to values listed on Specifications

page.

2. Check guards, deflectors and covers to make sure all

are in place and securely tightened.

3. Check engine oil and add oil as needed to bring level

up to the FULL mark (A, Figure 2).

FIGURE 2

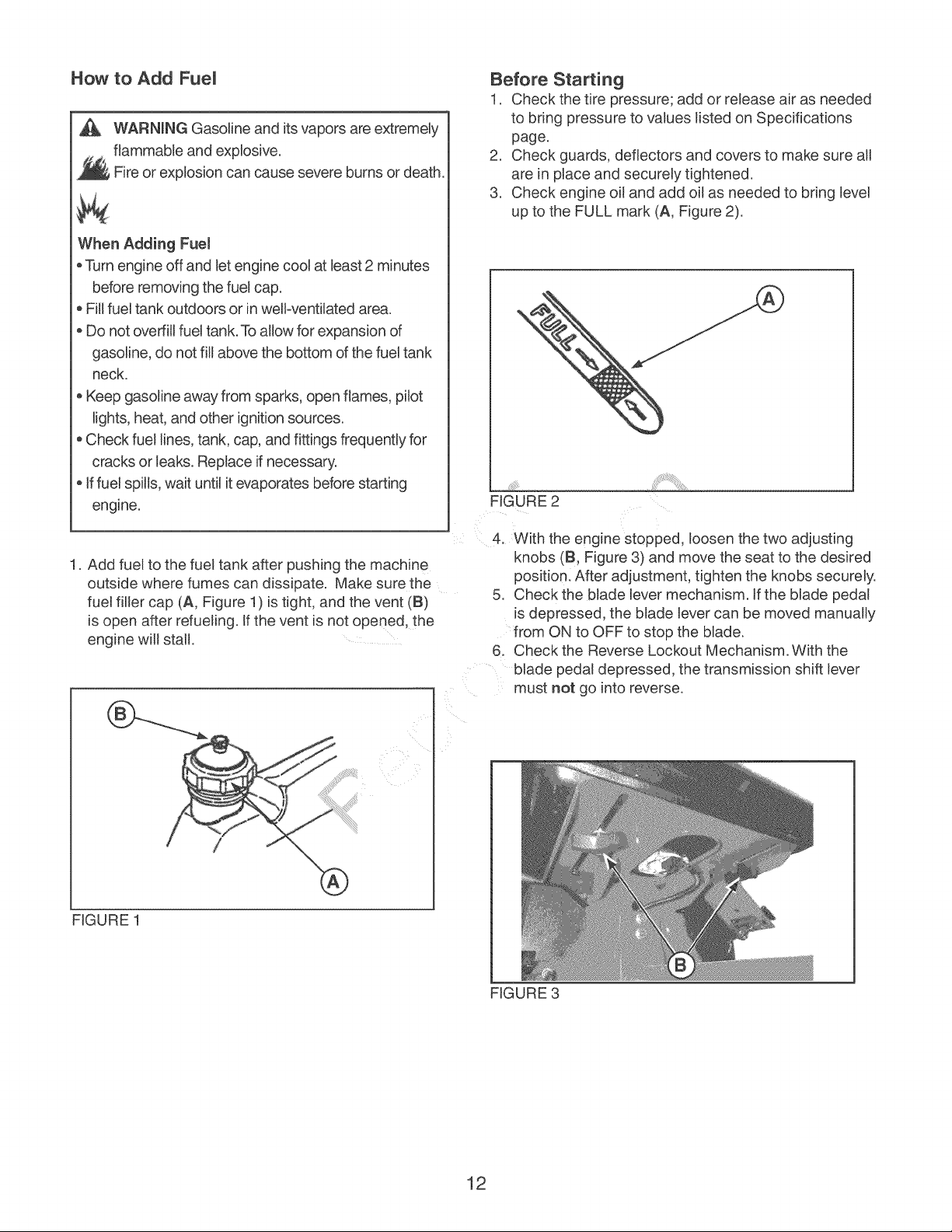

1. Add fuel to the fuel tank after pushing the machine

outside where fumes can dissipate. Make sure the

fuel filler cap (A, Figure 1) is tight, and the vent (B)

is open after refueling. If the vent is not opened, the

engine will stall.

®

FIGURE 1

4. With the engine stopped, loosen the two adjusting

knobs (B, Figure 3) and move the seat to the desired

position. After adjustment, tighten the knobs securely.

5. Check the blade lever mechanism. If the blade peda_

is depressed, the blade lever can be moved manually

from ON to OFF to stop the blade.

6. Check the Reverse Lockout Mechanism. With the

blade pedal depressed, the transmission shift lever

must not go into reverse.

FIGURE 3

12

How to Start the Engine

WARNmNG Gasoline and its vapors are extremely

flammable and explosive.

_Fire or explosion can cause severe burns or death.

When Starting Engine

• Ensure that spark plug, muffler, fuel cap and air

cleaner (if equipped) are in place and secured.

• Do not crank the engine with the spark plug removed.

• Ifengine floods, set choke (if equipped) to OPEN/RUN

position, move throttle (if equipped) to FAST postion

and crank until engine starts.

WARNING Running engine gives off carbon

monoxide, an odorless, colorless, poison gas.

Breathing carbon monoxide can cause headache,

fatigue, dizziness, vomiting, confusion, seizures,

nausea, fainting or death.

• Operate equipment ONLY outdoors.

• Keep exhaust gas from entering a confined area

through windows, doors, ventilation intakes, or other

openings.

WARNING DO NOT start the engine with the

transmission shift lever ina drive position. Follow starting

instructions carefully.

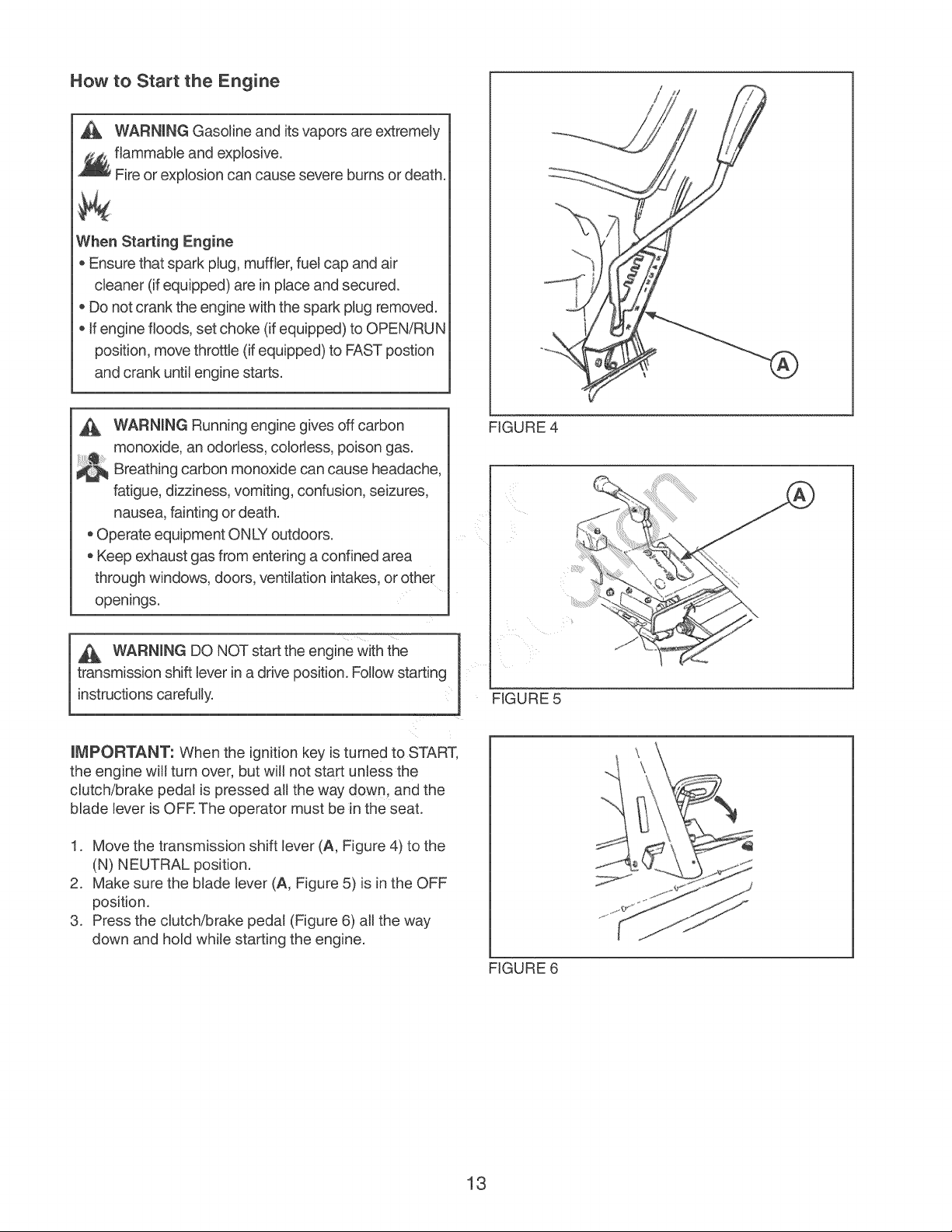

iMPORTANT: When the ignition key is turned to START,

the engine will turn over, but will not start unless the

clutch/brake pedal is pressed all the way down, and the

blade lever is OFE The operator must be in the seat.

1. Move the transmission shift lever (A, Figure 4) to the

(N) NEUTRAL position.

2. Make sure the blade lever (A, Figure 5) is in the OFF

position.

3. Press the clutch/brake pedal (Figure 6) all the way

down and hold while starting the engine.

FIGURE 4

FIGURE 5

FIGURE 6

13

4. Move the engine speed control (Figure 7) to the

CHOKE position to start a cold engine.

5. Turn the ignition key (Figure 8) to the START position

until the engine starts.

NOTE: If after 5 seconds of cranking the engine does not

start, release the key, make sure the clutch/brake pedal is

fully depressed, and attempt starting again after waiting

for approximately 20 seconds.

6. After the engine starts, move the engine speed control

to the FAST position and allow a brief warm-up until

engine runs smooth.

How to Operate the Mower BUade

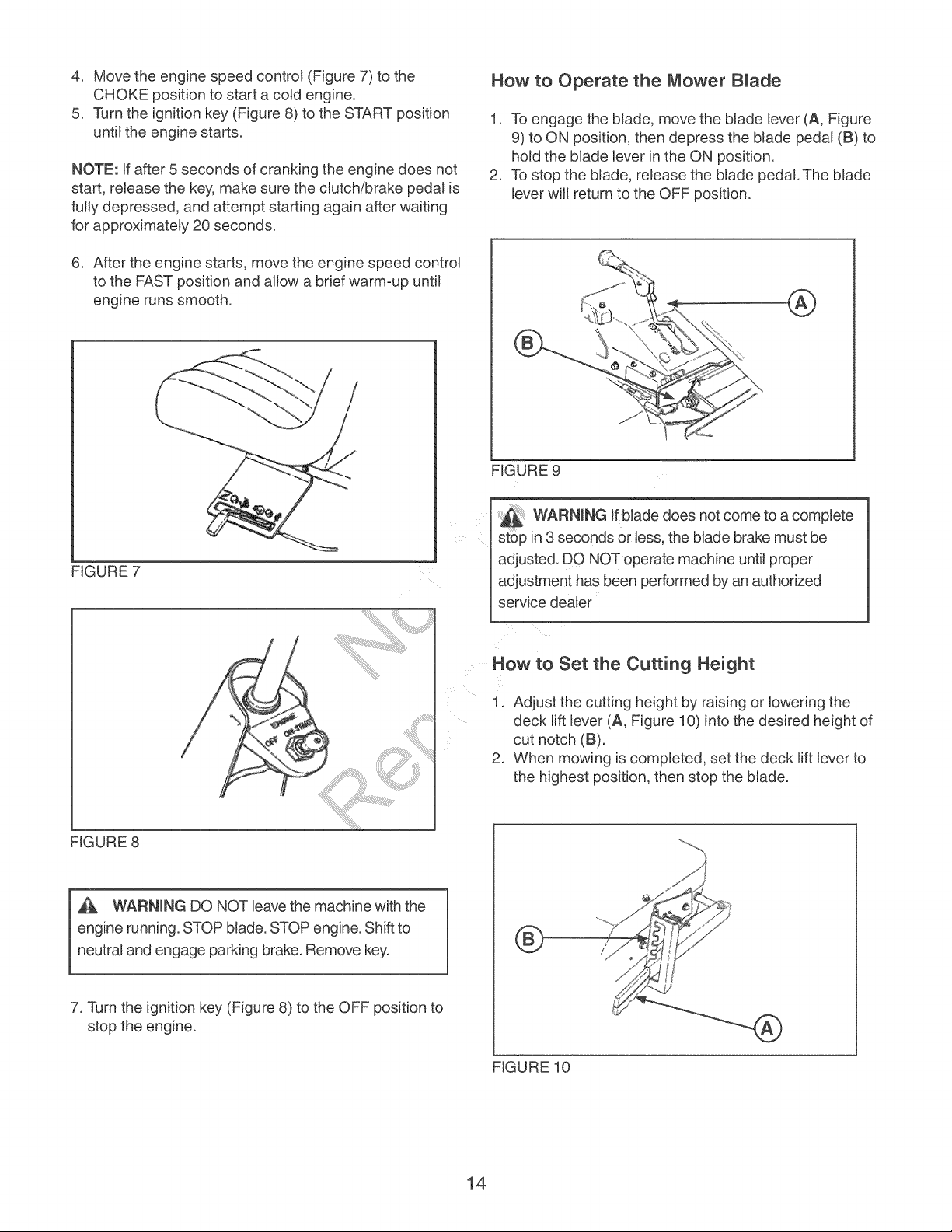

1. To engage the blade, move the blade lever (A, Figure

9) to ON position, then depress the blade pedal (B) to

hold the blade lever in the ON position.

2. To stop the blade, release the blade pedal. The blade

lever will return to the OFF position.

FIGURE 9

FIGURE 7

FIGURE 8

WARNmNGDO NOT leave the machine with the

engine running. STOP blade. STOP engine. Shift to

neutral and engage parking brake. Remove key.

WARNmNG If blade does not come to a

s_opin 3 seconds or less, the blade brake must be

adjusted. DO NOT operate machine until proper

adjustment has been performed by an authorized

service dealer

complete

How to Set the Cutting Height

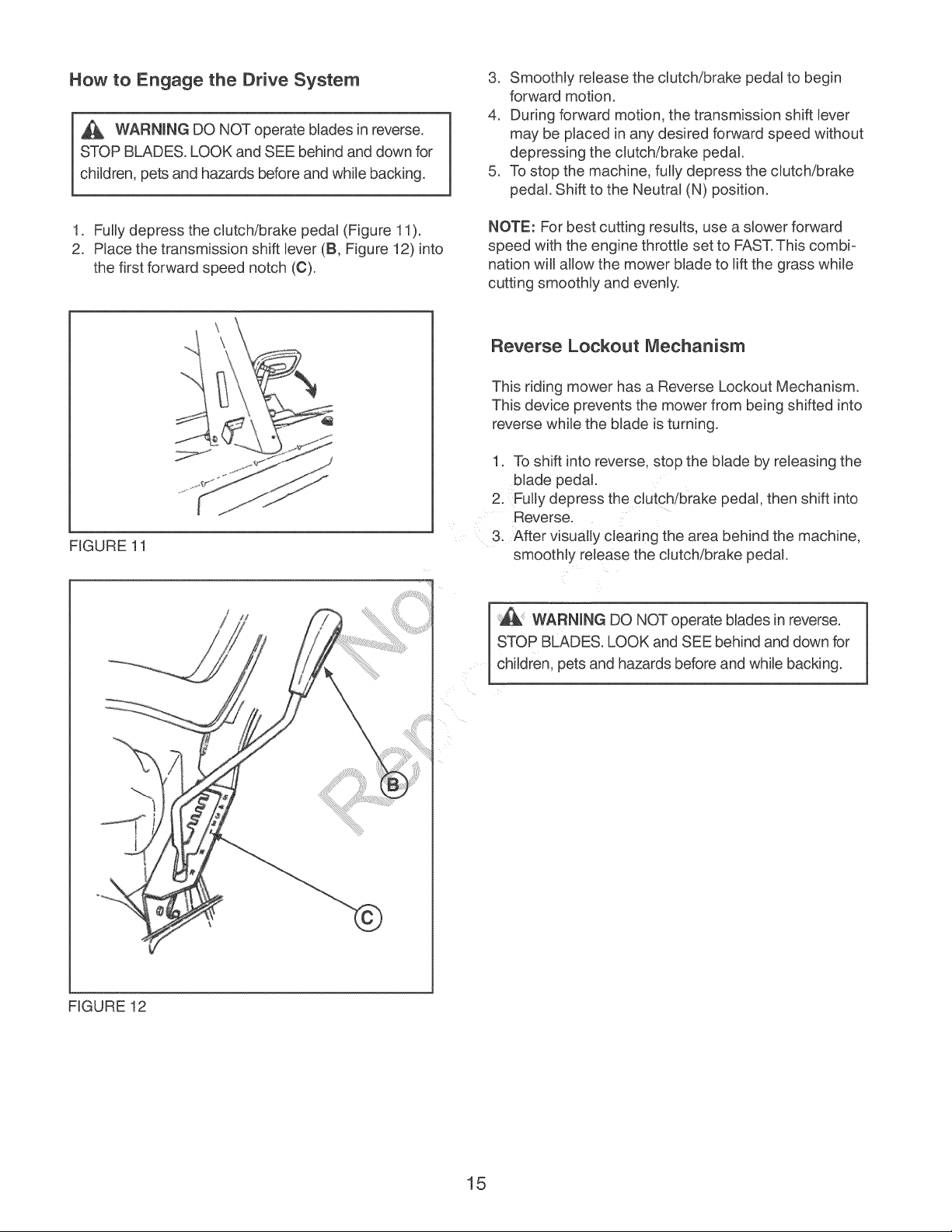

1. Adjust the cutting height by raising or lowering the

deck lift lever (A, Figure 10) into the desired height of

cut notch (B).

2. When mowing is completed, set the deck lift lever to

the highest position, then stop the blade.

®

7. Turn the ignition key (Figure 8) to the OFF position to

stop the engine.

F_GURE 10

14

How to Engage the Drive System

WARNmNGDO NOT operate blades in reverse.

STOP BLADES. LOOK and SEE behind and down for

children, pets and hazards before and while backing.

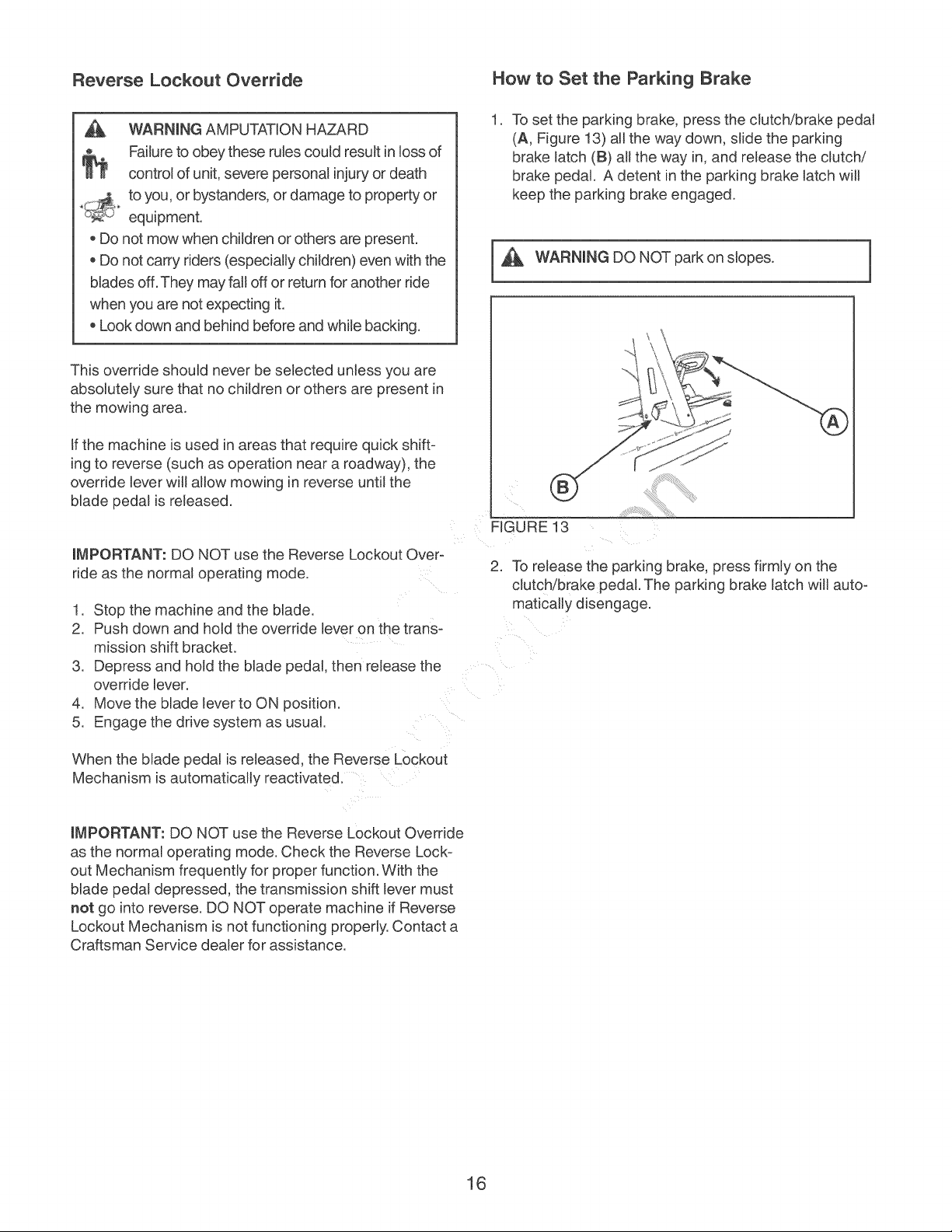

3. Smoothly release the clutch/brake pedal to begin

forward motion.

4. During forward motion, the transmission shift lever

may be placed inany desired forward speed without

depressing the clutch/brake pedal.

5. To stop the machine, fully depress the clutch/brake

pedal. Shift to the Neutral (N) position.

1. Fully depress the clutch/brake pedal (Figure 11).

2. Place the transmission shift lever (B, Figure 12) into

the first forward speed notch (C).

FIGURE 11

NOTE: For best cutting results, use a slower forward

speed with the engine throttle set to FAST.This combi-

nation will allow the mower blade to lift the grass while

cutting smoothly and evenly.

Reverse Lockout Mechanism

This riding mower has a Reverse Lockout Mechanism.

This device prevents the mower from being shifted into

reverse while the blade is turning.

1. To shift into reverse, stop the blade by releasing the

blade pedal

2. Fully depress the clutch/brake pedal, then shift into

Reverse.

3. After visually clearing the area behind the machine,

smoothly release the clutch/brake pedal.

WARNmNGDO NOT operate blades in reverse.

STOP BLADES. LOOK and SEE behind and down for

children, pets and hazards before and while backing.

FIGURE 12

15

Reverse Lockout Override How to Set the Parking Brake

WARNmNGAMPUTATION HAZARD

Failure to obey these rules could result in loss of

control of unit, severe personal injury or death

to you, or bystanders, or damage to property or

equipment.

• Do not mow when children or others are present.

• Do not carry riders (especially children) even with the

blades off.They may fall off or return for another ride

when you are not expecting it.

• Look down and behind before and while backing.

This override should never be selected unless you are

absolutely sure that no children or others are present in

the mowing area.

If the machine is used in areas that require quick shift-

ing to reverse (such as operation near a roadway), the

override lever will allow mowing in reverse until the

blade pedal is released.

iMPORTANT: DO NOT use the Reverse Lockout Over°

ride as the normal operating mode.

1. Stop the machine and the blade.

2. Push down and hold the override lever on the trans-

mission shift bracket.

3. Depress and hold the blade pedal, then release the

override lever.

4. Move the blade lever to ON position.

5. Engage the drive system as usual.

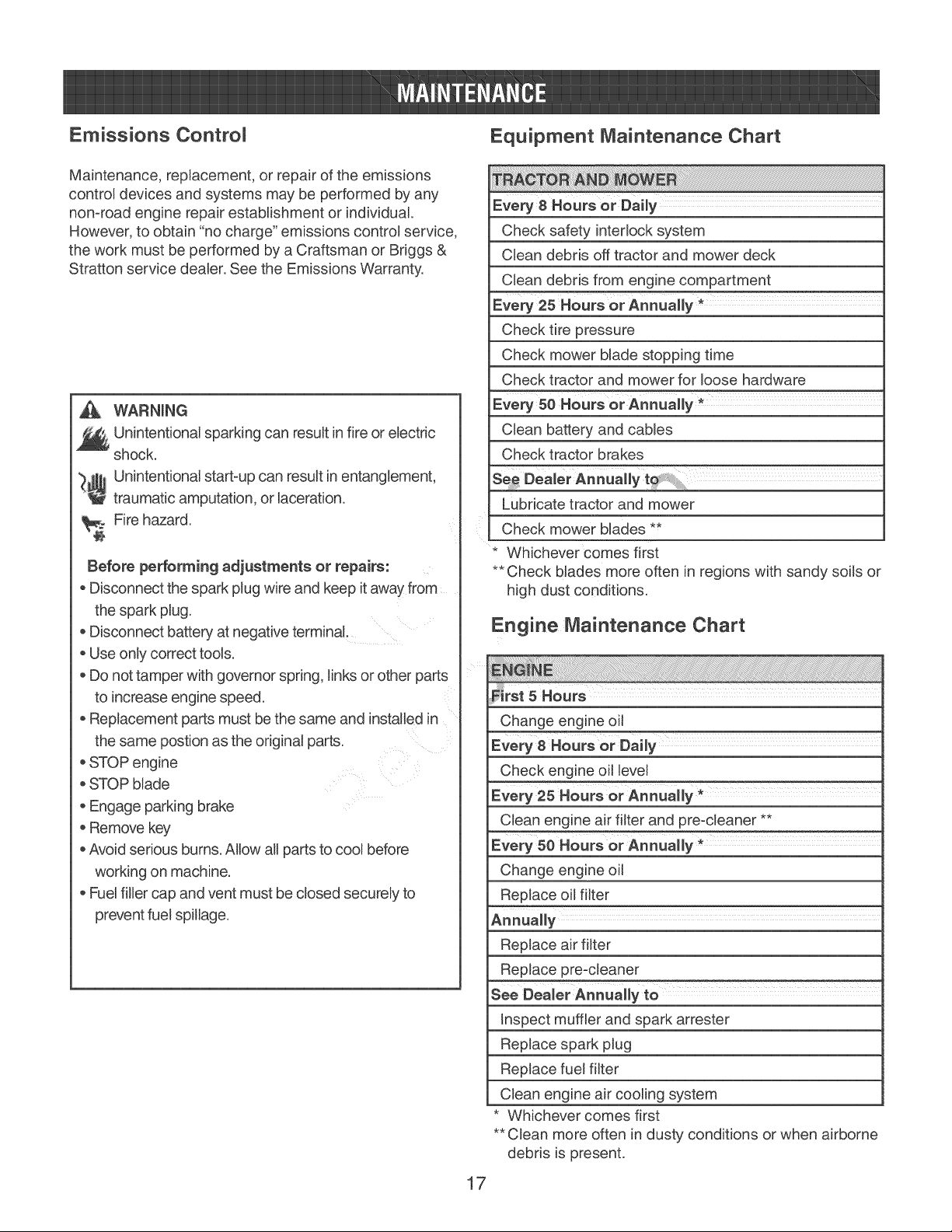

To set the parking brake, press the clutch/brake pedal

(A, Figure 13) all the way down, slide the parking

brake latch (B) all the way in, and release the clutch/

brake pedal. A detent in the parking brake latch will

keep the parking brake engaged.

-_ WARNmNGDO NOT park on slopes.

FIGURE 13

2. To release the parking brake, press firmly on the

clutch/brake pedal. The parking brake latch will auto-

matically disengage.

When the blade pedal is released, the Reverse Lockout

Mechanism is automatically reactivated.

IMPORTANT: DO NOT use the Reverse Lockout Override

as the normal operating mode. Check the Reverse Lock-

out Mechanism frequently for proper function. With the

blade pedal depressed, the transmission shift lever must

not go intoreverse. DO NOT operate machine if Reverse

Lockout Mechanism is not functioning properly. Contact a

Craftsman Service dealer for assistance.

16

Emissions Contro_

Maintenance, replacement, or repair of the emissions

control devices and systems may be performed by any

non-road engine repair establishment or individual.

However, to obtain "no charge" emissions control service,

the work must be performed by a Craftsman or Briggs &

Stratton service dealer. See the Emissions Warranty.

Equipment Maintenance Chart

Every8 Hours or Uaily

Check safety interlock system

Clean debris off tractor and mower deck

Clean debris from engine compartment

Every 25 Hours or Annually *

Check tire pressure

Check mower Made stopping time

Check tractor and mower for loose hardware

WARNING

_ Unintentional sparking can result infire or electric

_ shock.

Unintentional start-up can result in entanglement,

traumatic amputation, or laceration.

Fire hazard.

Before performing adjustments or repairs:

• Disconnect the spark plug wire and keep it away from

the spark plug.

Disconnect battery at negative terminal.

• Use only correct tools.

Do not tamper with governor spring, links or other parts

to increase engine speed.

Replacement parts must be the same and installed in

the same postion as the original parts.

• STOP engine

• STOP blade

• Engage parking brake

• Remove key

• Avoid serious burns. Allow all parts to cool before

working on machine.

Fuel filler cap and vent must be closed securely to

prevent fuel spillage.

Every 50 Hours or Annually *

Clean battery and cables

Check tractor brakes

Lubricate tractor and mower

Check mower blades **

• Whichever comes first

•* Check blades more often in regions with sandy soils or

high dust conditions.

Engine Mair tenance Chart

Change engl ne oil

Every 8 Hours or Daily

Check engine oi_level

Every 25 Hours or Annually *

Clean engine air filter and pre-cleaner ""

Every 50 Hours or Annually *

Change engine oil

Replace oil filter

Replace air fiker

Replace pre-c[eaner

See Dealer Annually to

Inspect muffler and spark attester

Replace spark plug

Replace fuel fiker

Clean engine air cooling system

Whichever comes first

** Clean more often in dusty conditions or when airborne

debris is present.

17

Check Safety _nteHockSystem Check Reverse Lockout Mechanism

This unit is equipped with safety interlock switches. Do

not attempt to bypass safety switches, and never tamper

with safety devices.

OperationaU SAFETY Checks

Test 1 -- Engine should NOT crank when:

o Mower blade lever isON, or

o Transmission is in Forward or Reverse positions, or

o Clutch/brake pedal is released.

Test 2 -- Engine SHOULD crank when:

o Mower blade isOFF, and

o Transmission is in Neutral (N) position, and

o Clutchipeda_ is fully depressed.

Test 3 _ Engine shoumd SHUT OFF when:

o Operator rises off seat with the mower blade ON

o Operator rises off seat wkh the transmission engaged

o Operator rises off seat with the parking brake OFF.

Test 4 _ Check Mower BmadeStopping Time

The mower blade should come to a complete stop within

three seconds after the mower blade is turned OFF.

WARNmNGIf Reverse Lockout Mechanism is

not functioning properly, DO NOT operate machine

until proper adjustment has been performed by an

authorized service dealer.

Check the function of the Reverse Lockout Mechanism

with the engine OFR

1. Depress and hold the b_ade pedal.

2. Depress and ho{d the clutch/brake pedal

3. The transmission shift lever must not go into re-

verse.

CUean Debris Off Tractor, Mower Deck, and

Engine Compartment

WARNmNGCombustible debris, such as leaves,

grass, brush, etc can catch fire.

o Remove accumulated debris from muffler area, mower

deck, and engine compartment.

WARNmNGIf blade does not come to a compJete

stop in 3 seconds or less, the blade brake must be

adjusted. DO NOT operate machine until proper

adjustment has been performed by an authorized

service dealer.

Remove any grass clippings, dirt, leaves, or other debris

from the unit and engine compartment.

1 Stop engine and allow engine to cool.

2 Remove ignition key, then disconnect sparkpJug wire

from spark p{ug.

3 Wear safety goggles. Using a brush and/or com-

pressed air, clean debris from aHsurfaces of tractor

and top of mower deck.

4 Clean engine compartment thoroughly, including any

debris from the intake screen on the top of the engine,

exposed engine cooling fins, and around the air filter

assembly.

18

Check Tire Pressure CUean Battery and CabUes

Tire pressure should be checked (Figure 14) periodically,

and maintained at the pressures listed on the Specifica-

tions page. The pressures shown provide proper traction,

improve cut quality, and extend tire life.

NOTE:These pressures may differ from the "Max Infla-

tion" stamped on the side-wall of the tires.

FIGURE 14

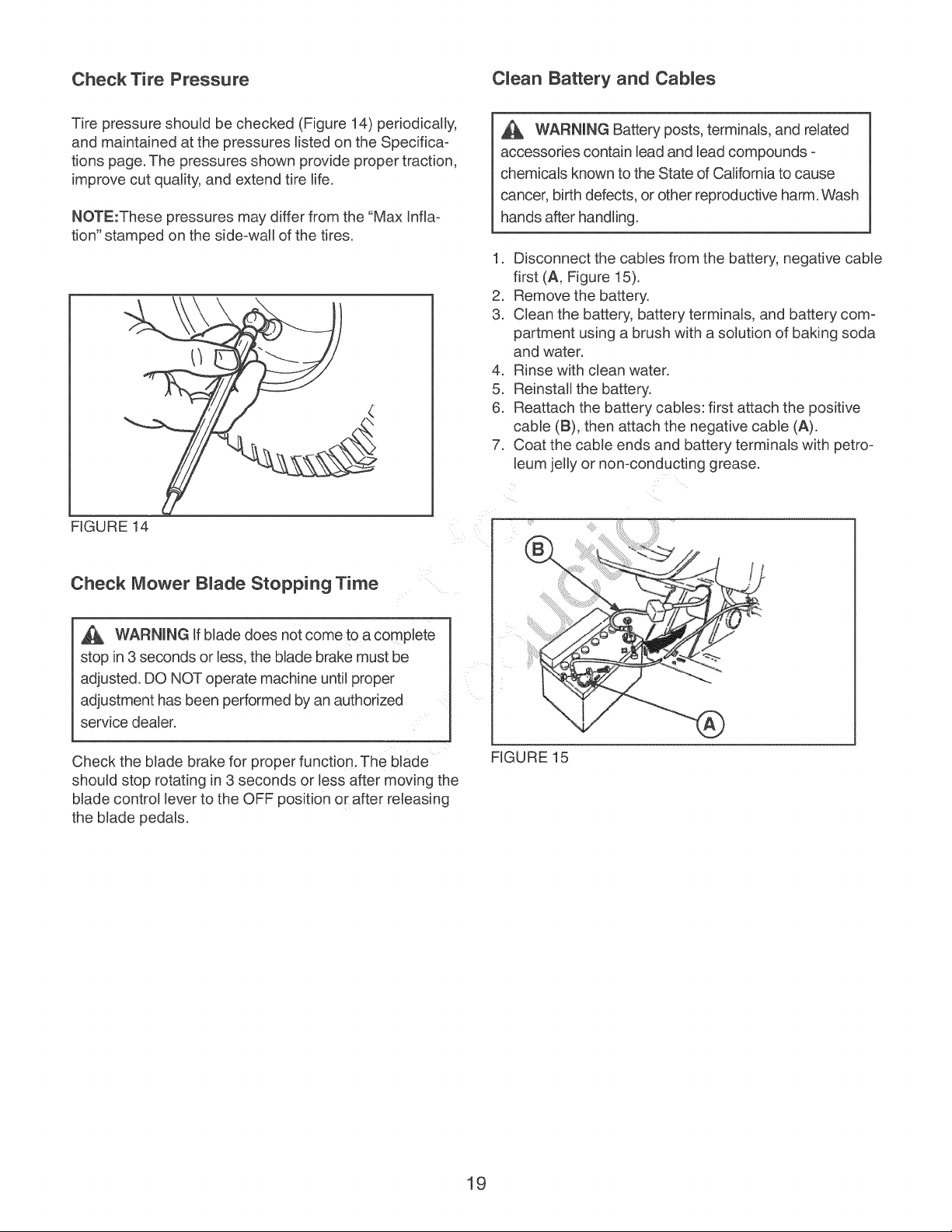

WARNmNGBattery posts, terminals, and related

accessories contain Leadand lead compounds -

chemicals known to the State of California to cause

cancer, birth defects, or other reproductive harm. Wash

hands after handling.

1. Disconnect the cables from the battery, negative cable

first (A, Figure 15).

2. Remove the battery.

3. Clean the battery, battery terminals, and battery com-

partment using a brush with a solution of baking soda

and water.

4. Rinse with clean water.

5. Reinstall the battery.

6. Reattach the battery cables: first attach the positive

cable (B), then attach the negative cable (A).

7. Coat the cable ends and battery terminals with petro-

leum jelly or non-conducting grease.

Check Mower BUade Stopping Time

WARNING If blade does not come to a complete

stop in 3 seconds or less, the blade brake must be

adjusted. DO NOT operate machine until proper

adjustment has been performed by an authorized

service dealer.

Check the blade brake for proper function. The blade

should stop rotating in 3 seconds or less after moving the

blade control lever to the OFF position or after releasing

the blade pedals.

FIGURE 15

19

Check Tractor Brakes

Check the brakes for proper function. Engage the park-

ing brake, and push the machine. The rear tires should

skid. Drive the machine forward and apply the brake. The

machine should come to a complete stop in less than 5 ft.

How to Change the Engine Oil

How to Service the Air Filter

WARNING Gasoline and its vapors are extremely

flammable and explosive.

_Fire or explosion can cause severe burns or death.

Never start or run the engine with the air cleaner

assembly or the air filter removed.

Used oil is a hazardous waste product and must be

disposed of properly. Do not discard with household

waste. Check with your local authorities, service center,

or dealer for safe disposal/recycling facilities.

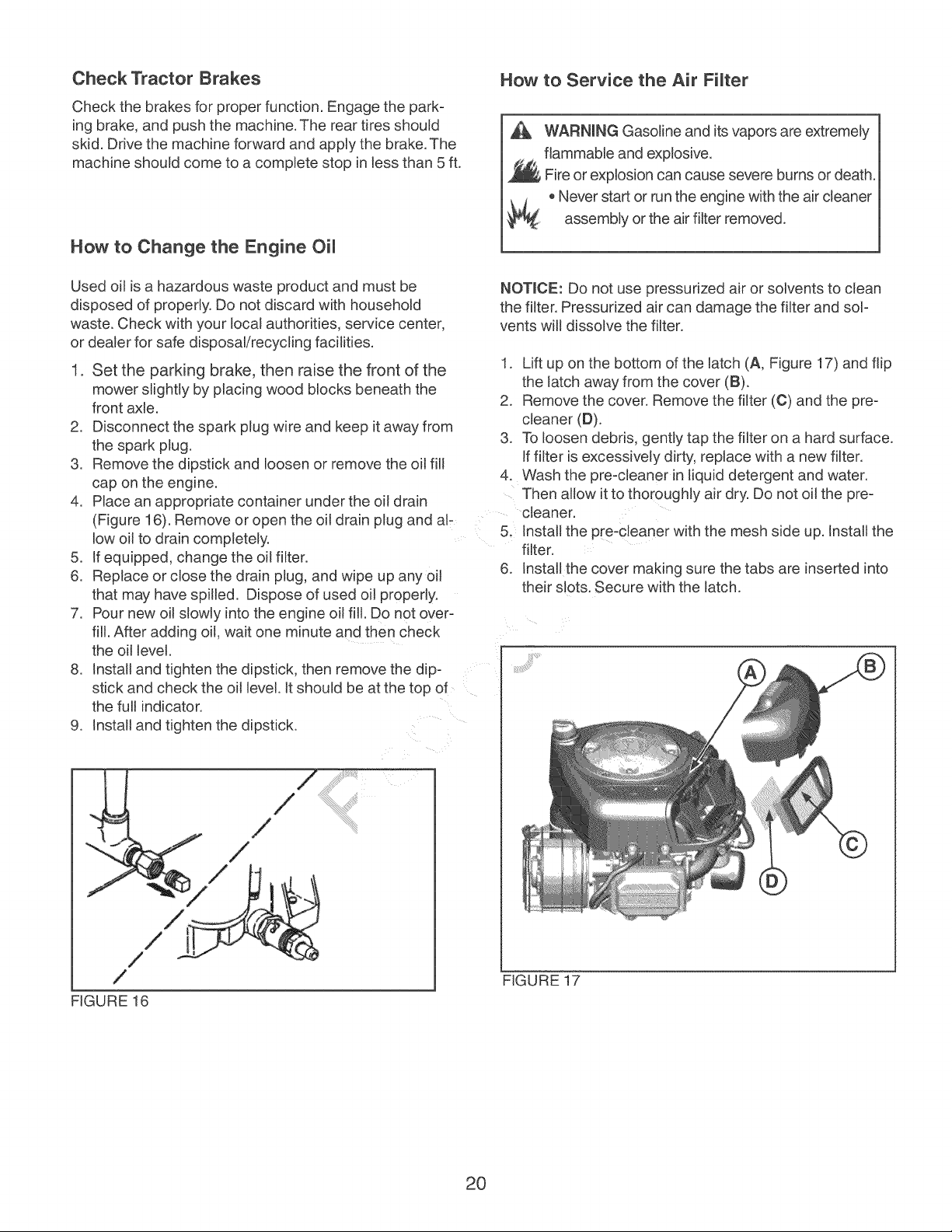

1. Set the parking brake, then raise the front of the

mower slightly by placing wood blocks beneath the

front axle.

2. Disconnect the spark plug wire and keep itaway from

the spark plug.

3. Remove the dipstick and loosen or remove the oil fill

cap on the engine.

4. Place an appropriate container under the oil drain

(Figure 16). Remove or open the oil drain plug and al-

low oil to drain completely.

5. If equipped, change the oil filter.

6. Replace or close the drain plug, and wipe up any oil

that may have spilled. Dispose of used oil properly.

7. Pour new oil slowly into the engine oil fill. Do not over-

fill. After adding oil, wait one minute and then check

the oil level.

8. Install and tighten the dipstick, then remove the dip-

stick and check the oil level. It should be at the top of

the full indicator.

9. Install and tighten the dipstick.

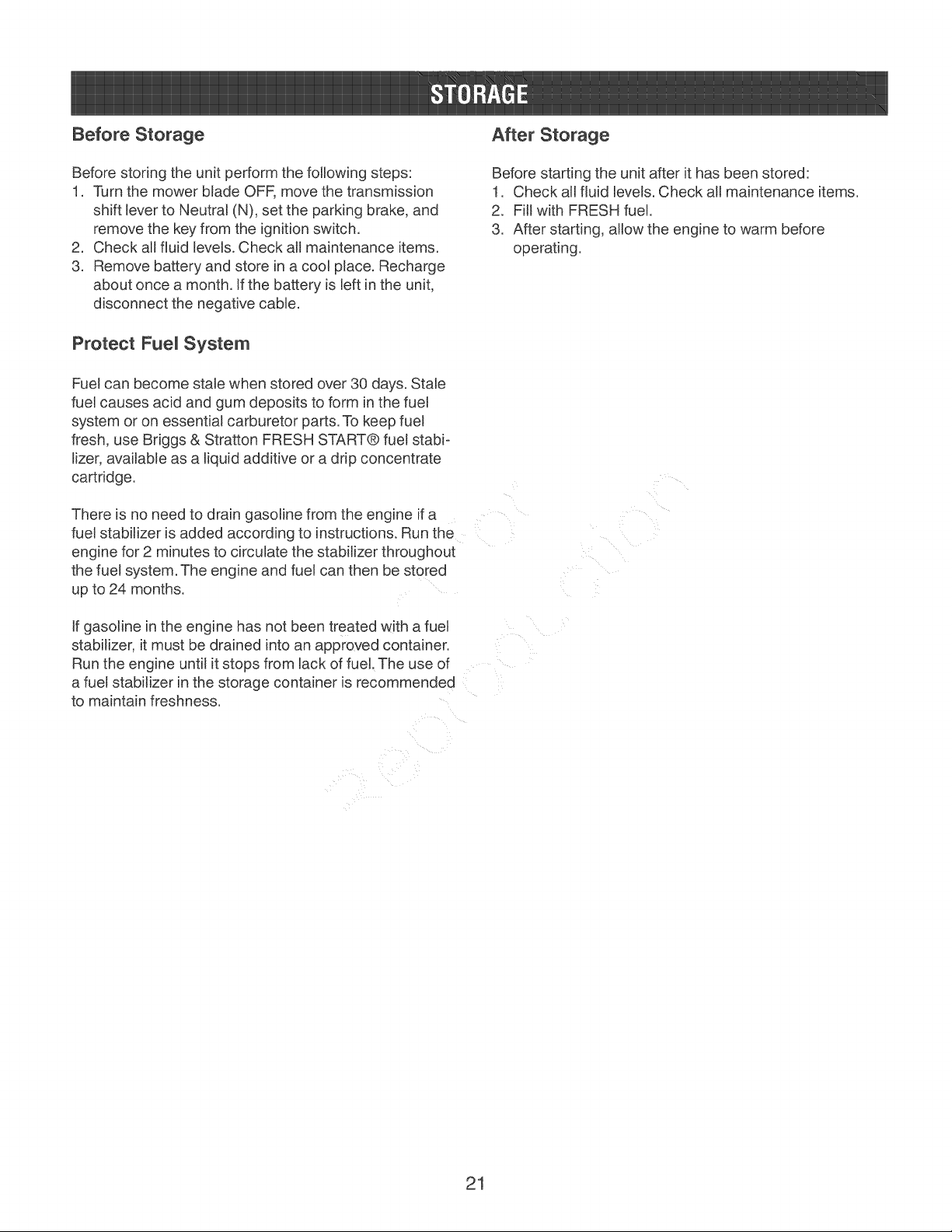

NOTICE: Do not use pressurized air or solvents to clean

the filter. Pressurized air can damage the filter and sol-

vents will dissolve the filter.

1. Lift up on the bottom of the latch (A, Figure 17) and flip

the latch away from the cover (B).

2. Remove the cover. Remove the filter (O) and the pre-

cleaner (D).

3. To loosen debris, gently tap the filter on a hard surface.

if filter is excessively dirty, replace with a new filter.

4. Wash the pre-cleaner in liquid detergent and water.

Then allow itto thoroughly air dry. Do not oil the pre-

cleaner.

5. Install the pre-cleaner with the mesh side up. Install the

filter

6 Install the cover making sure the tabs are inserted into

their slots. Secure with the latch.

/

/

FIGURE 16

/

/

/

FIGURE 17

2O

©

Before Storage After Storage

Before storing the unit perform the following steps:

1. -Palmthe mower blade OFF, move the transmission

shift lever to Neutral (N), set the parking brake, and

remove the key from the ignition switch.

2. Check all fluid levels. Check all maintenance items.

3. Remove battery and store in a cool place. Recharge

about once a month. If the battery is left in the unit,

disconnect the negative cable.

Protect FueU System

Fuel can become stale when stored over 30 days. Stale

fuel causes acid and gum deposits to form in the fuel

system or on essential carburetor parts. To keep fuel

fresh, use Bdggs & Stratton FRESH START® fuel stabi-

lizer, available as a liquid additive or a drip concentrate

cartridge.

There is no need to drain gasoline from the engine if a

fuel stabilizer is added according to instructions. Run the

engine for 2 minutes to circulate the stabilizer throug bout

the fuel system. The engine and fuel can then be stored

up to 24 months.

Before starting the unit after it has been stored:

1. Check all fluid levels. Check aHmaintenance items.

2. Fill with FRESH fuel.

3. After starting, allow the engine to warm before

operating.

If gasoline in the engine has not been treated with a fuel

stabilizer, it must be drained into an approved container.

Run the engine until it stops from lack of fuel. The use of

a fuel stabilizer in the storage container is recommended

to maintain freshness.

21

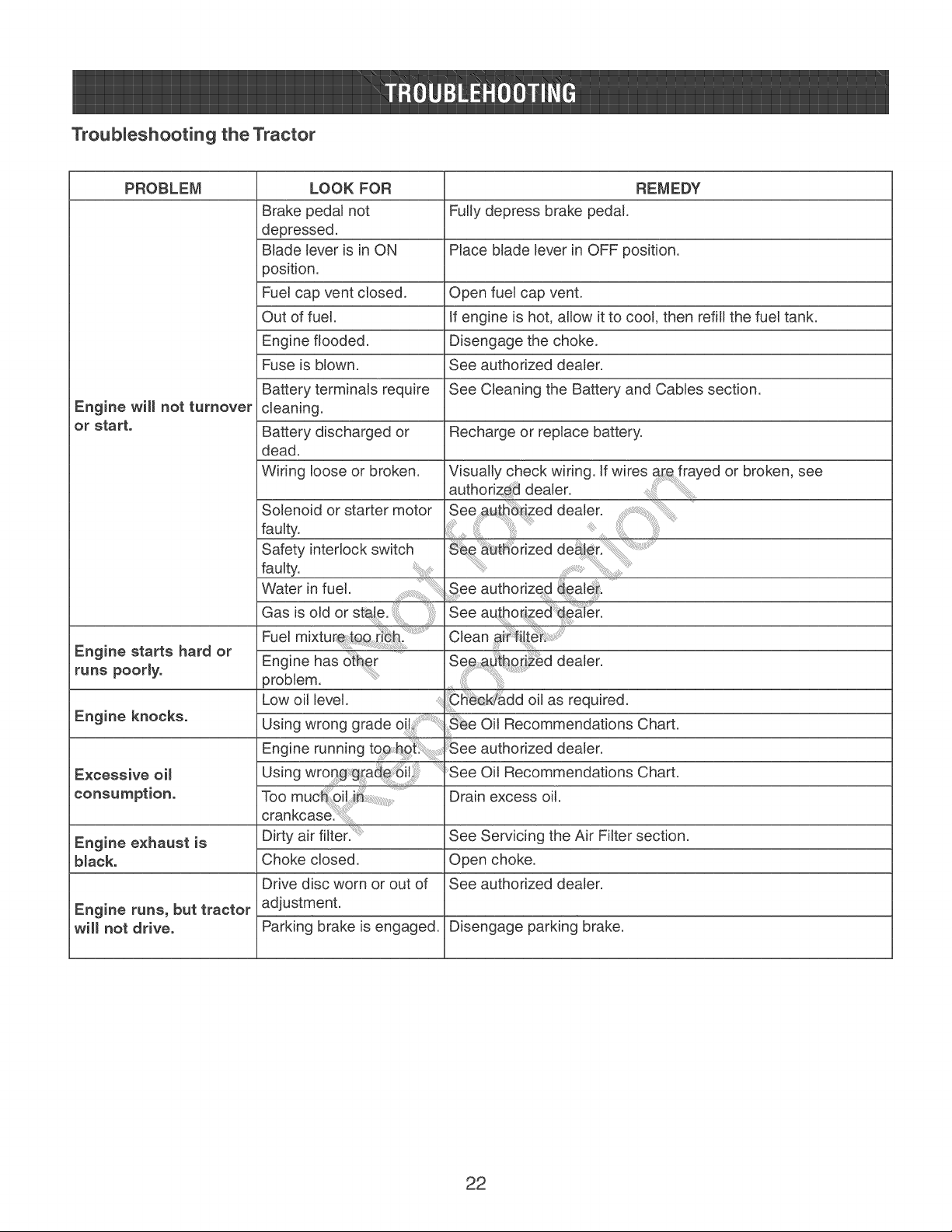

TroubUeshooting the Tractor

PROBLEM

Engine will not turnover

or start.

Engine starts hard or

runs pooHy.

Engine knocks.

LOOK FOR

Brake pedal not

depressed.

Blade lever is in ON

position.

Fuel cap vent closed.

Out of fuel.

Engine flooded.

Fuse is blown.

Battery terminals require

cleaning.

Battery discharged or

dead.

Wiring loose or broken.

Solenoid or starter motor

faulty.

Safety interlock switch

faulty.

Water in fuel. .....

Gas is old or stae. .........

Fuel mixture _ee ........

Engine has S_her

problem.

Low oil level.

Using wrong grade o

Engine running

using

REMEDY

Fully depress brake pedal.

Place blade lever in OFF position.

Open fuel cap vent.

If engine is hot, allow it to cool, then refill the fuel tank.

Disengage the choke.

See authorized dealer.

See Cleaning the Battery and Cables section.

Recharge or replace battery.

Visually check wiring. If wires a_efrayed or broken, see

authorize8 dealer.

See au_6_:_izeddealer ....... .....

_e _a¢_Srized

See authorized 8eal_.

See auSho_ize8_e_i_r.

See a_ho[i_d dealer.

C_Be:Wadd oil as required.

_ee OHRecommendations Chart.

:See authorized dealer.

See OHRecommendations Chart.

Drain excess oil.

Engine exhaust is Dirty air filter .... See Servicing the Air Filter section.

Mack. Choke closed. Open choke.

Drive disc worn or out of See authorized dealer.

Engine runs, but tractor adjustment.

will not drive. Parking brake is engaged. Disengage parking brake.

22

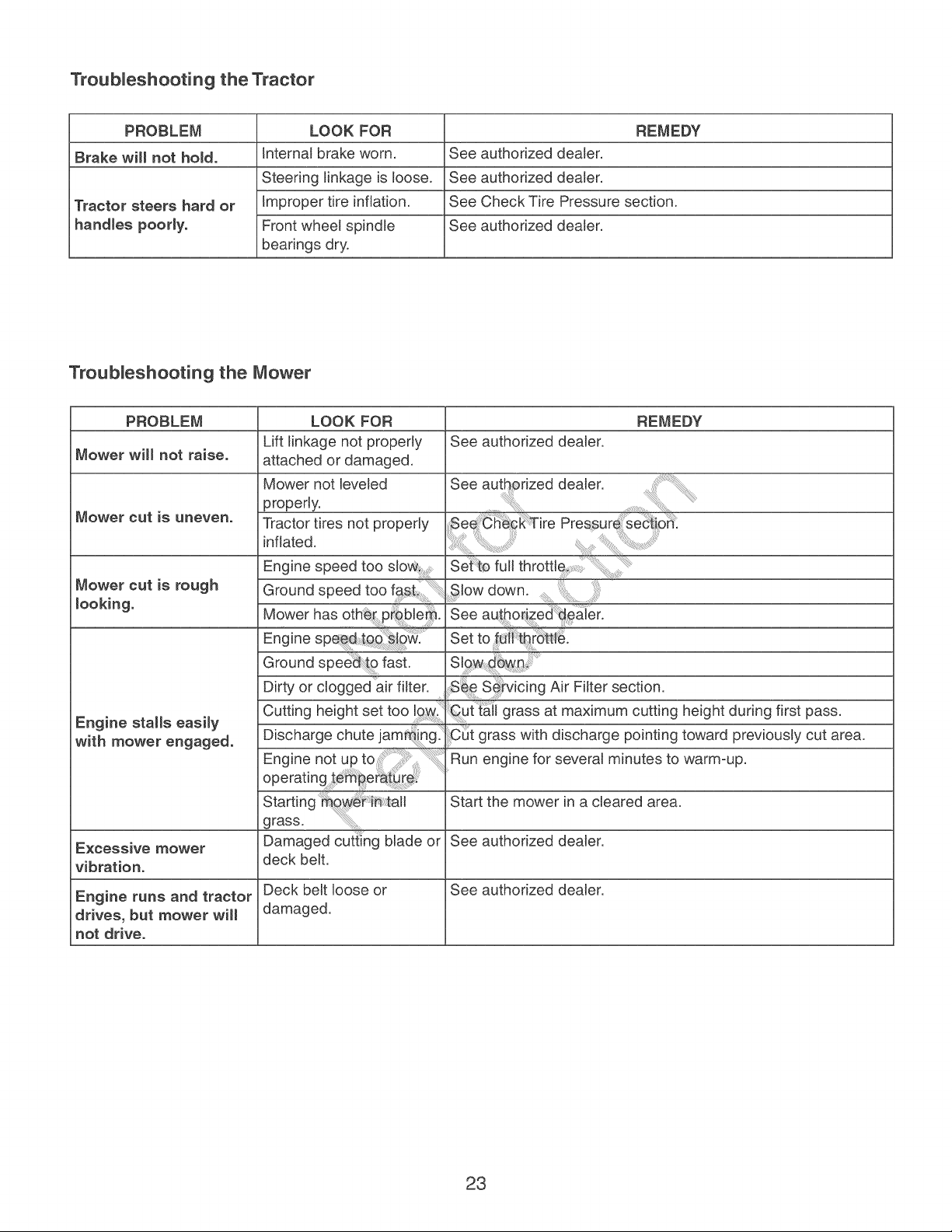

TroubUeshooting the Tractor

PROBLEM LOOK FOR REMEDY

Brake will not ho_d. internal brake worn. See authorized dealer.

Steering linkage is loose. See authorized dealer.

Tractor steers hard or improper tire inflation. See Check Tire Pressure section.

handles poorly. Front whee_ spindle See authorized dealer.

bearings dry.

TroubUeshooting the Mower

PROBLEM

Mower will not raise.

Mower cut is uneven.

Mower cut is rough

_ooking°

Engine stal_s easily

with mower engaged.

Excessive mower

vibration.

Engine runs and tractor

drives, but mower will

not drive.

LOOK FOR

Lift linkage not properly

attached or damaged.

Mower not leveled

properly.

Tractor tires not properly

inflated.

Engine speed too slow;

Ground speed too fas_

Mower has other p _ble_.

Engine speed _o_::_l:o_:.....

Ground specs _ofast.

Dirty or clogged air filter.

Cutting height set too low:

Discharge chute jam_::ing

grass.

Damaged cuttlng blade or

deck belt.

Deck belt loose or

damaged.

REMEDY

See authorized dealer.

See autherized dealer.

Se_te full throttle:::":

,,;_i_i_i_.... _';'_,_,_';i_:_,_;

Slow down.

See authorized deaier.

8_e S_wicing Air Filter section.

Gut _il grass at maximum cutting height during first pass.

CGt grass with discharge pointing toward previously cut area.

Run engine for several minutes to warm-up.

Start the mower in a cleared area.

See authorized dealer.

See authorized dealer.

23

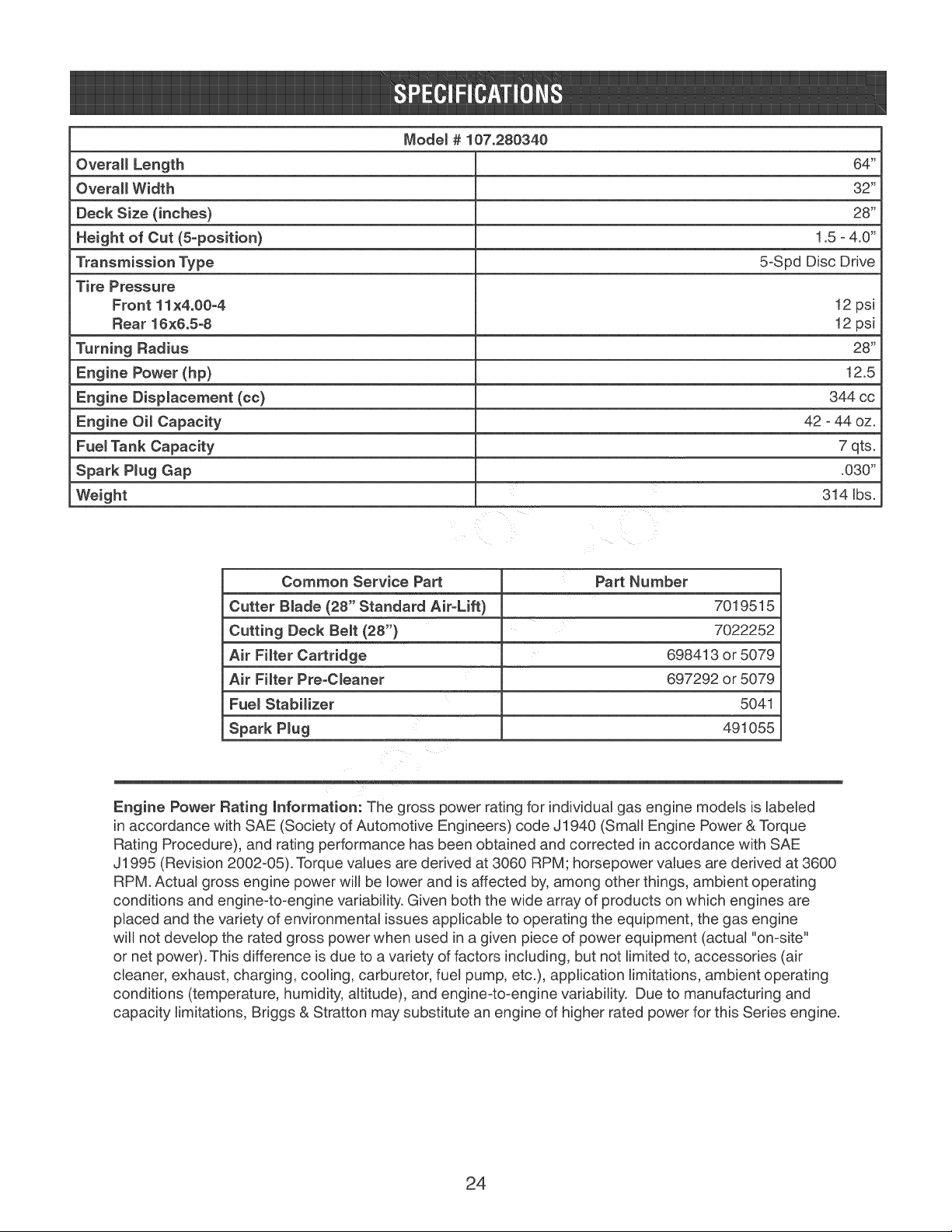

ModeE # 107o280340

Overall Length 64"

Overall Width 32"

Deck Size (inches} 28"

Height of Cut (5-position} 1.5 - 4.0"

Transmission Type 5-Spd Disc Drive

Tire Pressure

Front 11×4°00-4 12 psi

Rear 16x6.5-8 12 psi

Turning Radius 28"

Engine Power (hp} 12.5

Engine Displacement (cc} 344 cc

Engine OH Capacity 42 - 44 oz.

Fue_Tank Capacity 7 qts.

Spark PEug Gap .030"

Weight 314 Ibs.

Common Service Part

Cutter B_ade (28" Standard Air-Lift)

Cutting Deck Belt (28"}

Air FHter Cartridge

Air FHter Pre-CEeaner

Fue_ Stabilizer

Spark P_ug

Engine Power Rating Information: The gross power rating for individual gas engine models is labeled

in accordance with SAE (Society of Automotive Engineers) code J 1940 (Small Engine Power & Torque

Rating Procedure), and rating performance has been obtained and corrected in accordance with SAE

J1995 (Revision 2002-05). Torque values are derived at 3060 RPM; horsepower values are derived at 3600

RPM. Actual gross engine power wifl be lower and is affected by, among other things, ambient operating

conditions and engine-to-engine variabilky. Given both the wide array of products on which engines are

placed and the variety of environmental issues applicable to operating the equipment, the gas engine

will not develop the rated gross power when used ina given piece of power equipment (actual "on-site"

or net power). This difference is due to a variety of factors including, but not limited to, accessories (air

cleaner, exhaust, charging, cooling, carburetor, fuel pump, etc.), application limitations, ambient operating

conditions (temperature, humidity, altitude), and engine-to-engine variability. Due to manufacturing and

capacity limitations, Bdggs & Stratton may substitute an engine of higher rated power for this Series engine.

Part Number

7019515

7022252

698413 or 5079

697292 or 5079

5041

491055

24

nual d

or

®

Tractor ¢ortac6sped con motor trasero con arranque

eJ6ctrico

ModeJo N-°

107.280340 (Motor Briggs & Stratton de 12,5 HP con pJataforma deJ

cortac6sped de 71 cm [28 puJg.])

Para obtener respuestas a sus preguntas

sobre este producto, Ilame al:

Linea de ayuda de Sears Craftsman

Lunes a sabado de 5 a.m. a 5 p.m.

Sears, Roebuck and Co., Hoffman Estates, JL60179 EE.UU.

Visite nuestro sitio Web de Craftsman: www.sears.com/craftsman

7103268

Modificaci6n B

Gracias por comprar este producto fabricado con la catidad Craftsman. Nos complace que

haya depositado su confianza en nuestra marca. Cuando se opera y se mantiene segQn 1as

instrucciones de este manual, su producto Craftsman le puede brindar muchos a_os de servicio

confiabte.

Este manuaU contiene informaci6n de seguddad para que tome conciencia de los peligros y

riesgos asociados a esta maquina y c6mo evitarlos. Esta maquina se dise_6 y pens6 soXamente

para obtener un corte de acabado de cesped establecido y no fue prevista para otros prop6sitos.

Es importante que lea y comprenda a cabalidad estas instrucciones antes de que intente arrancar

u operar este equipo. Guarde estas instrucciones para consuUtas futuras.

SerialNo. O000t

ForParts

Sears,RoebuckandCo, HoffmanE_

Cuando se comunique con el centro de

manter_imiento para pedir piezas de repuesto,

mantenimiento o informaci6n_ el usuario DEBE

tenet estos n5meros a su disposici6n.

Registre su nombreinOmero de modelo, los n0meros de

identificaci6n del fabricante y los nOmeros de serie del

motor en el espacio proporcionado para tenet un acceso

facil.

La etiqueta de identificaci6n esta situada en el lado de

abajo del asiento, incline el asiento hacia delante para

acceder a la etiqueta de identificaci6n.

Nembre/n_mere de descripcl6n del medele

N_rnere de Inventnrie N_mere de seHe de In unldad

I:echa de cemprn

FnbHcnnte de_meter ffiede_e de_meter

Tipe/espedficncienes de_ meter Cddlge!n_mere de seHe de_meter

Para obtener respuestas a sus preguntas sobre este

producto, Ilame a la linea de ayuda de Sears Craftsman en

el 1-800-659-5917, de lunes a sabado de 5 a.m. a 5 p.m.

2

N[3meros de identificaci6n

Declaraci6n de garantia

Declaraci6n de emisiones

Seguridad del operario

Caracteristicas y mandos

Funcionamiento

GARANTmA COMPLETA DE FABRICACiON

Cuando se opera y mantiene de acuerdo con todas las instrucciones que se proporcionan, sJalguna pieza no

ampliable de este equipo faHa deUdo a un defecto en los materiales o en la fabncaci6n dentro de dos a_os desde la

fecha de compra, Ilame a 1-800-659-5917 para solicitar una reparaci6n gratuita en su hogar.

La cubierta y el eje delantero se repararan de manera gratuita durante cinco a_os desde la fecha de compra si se trata

de un defecto de material o de fabricacion.

La cobertura de la garantia anterior se aplica solo durante 90 dias desde la fecha de compra si este equipo se usa

alguna vez con prop6sitos comerciales o de arriendo.

2 Mantenimiento 17

3 AImacenaje 21

4 Localizaci6n de fallas 22

5 Especificaciones tecnicas 24

10 Repuestos PTS-1

11

En todos los casos, si la reparaci6n no es posible, el equJpo se reemp_azara de manera gratuita con el mismo modelo o

un modelo equivalente.

La bateda se reemplazara de manera gratuita durante 90 dias desde la fecha de compra si tiene defectos en los

materiales o en lafabricaci6n (o se comprueba que no almacena carga).

Esta garantia SOLAMENTE cubre defectos de materia_ y fabricaci6n. Sears NO pagara:

o Articulos desechables que se gasten durante el uso normal, entre los que se incluyen, entre otros cuchiHas, bujias,

depuradores de aire, correas y filtros de aceite.

o Servicio de mantenim]ento normal, cambios de aceite o afinamientos.

o Reemplazo o reparaci6n de neumaticos debido a pinchazos por objetos exteriores, como clavos, espinas, tocones o

vidrios.

Reemplazo o reparaci6n de neumaticos o ruedas producto de desgaste normal, accidentes o funcionamiento o

mantenimiento inadecuados.

o Reparaciones necesarias debido a abuso del operador, incluidos, entre otros, da_os provocados por remolcar

objetos que sobrepasen la capacidad del equipo con asiento, impactos a objetos que doblen el bastidor o cigOerhal,

o sobrepasar la velocidad del motor.

o Reparaciones necesarias debido a neg_igencia del operador, incluidos, entre otros, da_os electncos y mecanicos

provocados por almacenamiento inadecuado, no utilizar el grado ni la cantidad correcta de aceite de motor, no

mantener la cubierta libre de desperdicios inflamables o no mantener al equipo con asiento segOn las instrucciones

que se incluyen en el manual del operador.

o Limpiezas o reparaciones al motor (sistema de combustible) provocadas por combustible que se determine como

contaminado u oxidado (deteriorado). En general, se debe utilizar el combustible dentro de 30 dias a partir de la

fecha de compra.

o Desgaste y deterioro normal de los acabados exteriores o reemplazo de la etiqueta del producto.

Esta garantia s61ose aplica mientras este producto este dentro de los Estados Unidos.

Esta Garantia le otorga derechos legales especificos, y Ud. puede ostentar otros derechos, que pueden variar de

estado en estado.

Sears, Roebuck and Co., Hoffman Estates, _L60179

3

Emissions Control SystemWarranty Statement

California, United States and Canada Emissions Centre] Defects Warranty

Statement

TheCaliforniaAirResourceBoard(CARB),U.S.EPAadeB&Sarephasedtoexplainthe

EmissionsControlSystemWarrantyonyour smalloff-roadengine(SORE).InCalifor-

nai,newsmalloff-roadenginesmodelyear2006andlatermustbedesigned,builtand

equippedtomeettheState'sstdgentanti-smogstandards.Elsewherein theUnitedStates,

newnon-road,sparkoignitionenginescertifiedfor modelyear1997andlatermust meet

similarstandardssetforth bythe U.S.EPA.B&Smustwarranttheemissionscontrolsys-

ternonyourengineforthe periodsoftimelistedbelow,providedtherehasbeennoabuse,

neglectorimpropermaintenanceofyour smalloff-roadengine.

Youremissionscontrolsystemincludespartssuchasthecarburetor,aircleaner,ignition

system,fuelline,mufflerandcatalyticconverter.Alsoincludedmaybeconnectorsand

otheremissionsrelatedassemblies.

Whereawarrantableconditionexists,B&Swillrepairyoursmalloff-roadengineat no

costto youincludingdiagnosis,partsandlabor.

Briggs & Straiten Emissions Control Defects Warranty Coverage

Smalloff-roadenginesarewarrantedrelativetoemissionscontrol partsdefectsfor a

periodof two years,subjectto provisionssetforth below.If anycoveredparton your

engineis defective,the partwill berepairedor replacedby B&S.

Thefollowing arespecificprovisions relativeto your EmissionsControlDefectsWarrantyCoverage.It is in additiontothe B&Senginewarrantyfor non-regulatedenginesfound

in the Operatingand MaintenanceInstructions.

1.WarrantedParts 3.

Coverageunderthis warrantyextendsonlyto the paris sted below _neemissions

control systemsparts)to the extent these partswere oresemon_r_eergme

purchased.

a. FuelMeteringSystem

CoWstartenrichmentsystem(soft choke)

Carburetorandinternalparts

Fuelpump 4.

Fuelline, fuel linefittings, clamps

Fueltank,capandtether

Carboncanister

b. Air InductionSystem

Aircleaner

Intakemanifold

Purgeandvent line

c. IgnitionSystem 5.

Sparkplug(s)

Magnetoignition system

d. CatalystSystem

Catalyticconverter

Exhaustmanifold

Airinjection systemor pulsevalve

e. MiscellaneousItems Usedin AboveSystems

Vacuum,temperature,position,time sensitivevalvesandswitches

* Connectorsandassemblies

2.Lengthof Coverage

B&Swarrantstothe initial ownerand eachsubsequentpurchaserthat theWarranted 6.

Partsshall befreefrom defectsin materialsandworkmanshipwhich causedthe

failureof theWarrantedpartsfor a periodof twoyearsfrom the datetheengineis

deliveredto a retailpurchaser.

Owner's Warranty Responsibility

Asthesmalloff-roadengineowner,youarerespoesibbfor theperformanceof therequired

maintenancelistedinyour OperatingandMaintenanceInstructions.B&Srecommends

thatyouretainallyour receiptscoveringmaintenanceon yoursmalloff-roadengine,but

B&Scannotdenywarrantysoldyfor the lackof receiptsor foryourfailureto ensurethe

performanceof allscheduledmaintenance.

Asthesmalloff-roadengineowner,youshouldhoweverbeawarethatB&Smaydenyyou

warrantycoverageifyour smalloff-roadengineor aparthasfaileddueto abuse,neglect,

impropermaintenanceor unapprovedmodifications.

Youareresponsibbfor presentingyoursmalloff-roadengineto anAuthorizedB&SService

Dealerassoonasaproblemexists.Theundisputedwarrantyrepairsshouldbecompleted

ina reasonableamountoftime,notto exceed30 days.

Ifyou haveanyquestionsregardingyour warrantyfightsandresponsibilities,you should

contactaB&SServiceRepresentativeat(414)259-526£

Theemissionswarrantyis a defectswarranty.Defectsarejudgedon normalengineperfoP

mance.Thewarrantyis not relatedto anin-useemissionstest.

No Charge

Repair or replacement of any Warranted Part will be performed at no charge to the

owner, nc_uo_rg diagnostic labor which leads to the determination that a War-

rained Part is defecttive, if the diagnostic work is performed at an Authorized B&S

Service Dealer as listed in the "Yellow Pages" under "Engines, Gasoline," "Gasoline

En_lnes." "Lawn Mowers," or similar category.

ClaimsandCoverageExclusions

Warrantyclaims shaftbefliedmaccordancewith the provisionsofthe B&SEngine

WarrantyPolicy.Warrantycoverageshallbeexcludedfor failures ofWarrantedParts

whicharenot original B&Spartsor becauseof abuse,neglector impropermain_

-[enanceas setforth in the B&SEngineWarrantyPolicy.B&Sis notliableto cover

failuresof WarrantedPartscausedbythe useof add-on, non-original,or modified

parts.

Maintenance

AnyWarrantedPartwhich is notscheduledfor replacementasrequiredmaintenance

or whichis scheduledonlyfor regularinspectionto the effect of "repairor replaceas

necessary"shallbewarrantedasto defectsfor thewarranty period. AnyWarranted

Partwhichis scheduledfor replacementasrequired maintenanceshaftbewarranted

asto detectsonlyfor the periodof time up tothefirst scheduledreplacementfor

[na_part.Any replacementpartthat is equivalentinperformanceanddurabilitymay

se useom[ne performanceof any maintenanceor repairs.The owner is responsible

for theperformanceof all requiredmaintenance,asdefinedin theB&S Operating

andMaintenanceInstructions.

ConsequentialCoverage

Coveragehereundershallextendtothe failure of any enginecomponentscausedby

thefailureofanyWarranted Partstill underwarranty.

Enginesthatarecertified to meettheCaliforniaAirResourcesBoard(CARD)Emis-

sions Standardmust displayinformationregardingthe EmissionsDurabilityperiod

andthe Air Index.Briggs& Stratton makesthis informationavailabletothe con-

sumer on our emissions labels.Theengineemissionslabelwifl indicatecertification

information.

TheEmissionsDurability Perioddescribesthe numberof hoursof actual running

time forwhich the engineis certifiedto beemissionscompliant,assumingproper

maintenancein accordancewihtthe OperatingandMaintenanceinstructions. The

following categoriesareused:

_'Joderate:

Engineis certifiedto be emissionscompliant for 125 hours ofactual runningtime.

mntermediate:

Engineis certifiedto be emissionscompliant for 250 hours ofactual runningtime.

Extended:

Engineis certifiedto be emissionscompliantfor 500 hoursof actualenginerunningtime.

Forexample,atypicalwalk-behindlawn moweris used20 to 25 hoursperyear.There-

fore,theEmissiensDurability Peried ofanenginewith an intermediate rating would

equateto 10to 12years.

Briggs& Strattonenginesarecertifiedto meetthe UnitedStatesEnvironmentalProtec-

tion Agency(ESEPA)Phase2emissionsstandards.ForPhase2 certifiedengines,the

EmissionsCompliancePeriodreferredto on the EmissionsCompliancelabel indicatesthe

numberof operatinghours forwhichthe enginehasbeenshownto meetFederalemis-

sions requirements.

Forengineslessthan 225cc displacement.

CategoryC=125 hours,CategoryB=250 hours,CategoryA=500 hours

Forenginesof 225ccor moredisplacement.

CategoryC=250 hours,CategoryB=500 hours,CategoryA= 1000hours

4

[nstrucciones importantes de seguridad

GUARDE ESTAS INSTRUCCIONES - Este

manual contiene instrucc[ones importantes

que se deben seguir durante e[ ajuste inic[a[, [a

operad6n y e[ mantenimiento de[ equipo.

ADVERTENC[A El escape del motor de

este producto contiene sustandas quimicas que

el estado de California sabe que causan cancer,

defectos congenkos u otros daffos reproductivos.

S[mbo[os de seguridad y sus significados

DETENCION

[Iol

GASES RETROCES0 EXPLOS[0N

TON[COS RAPID0

USE PRODUCTO SUPERF[C[E ESTRANOULADOR

PROTECC[ON QU[M[CO CAUENTE

PARALOS0J0S PELIGROS0

LEAEL COMBUSTIBLE

MANUAL

E[ simbo[o de a[erta de seguridad indica

un posib[e pe[igro de [esiones persona[es Se

usa una pa[abra (PELIGRO. ADVERTENCIA o

PRECAUC[ON) como seffa[ con el simbo[o de

a[erta para designar un grado o nive[ de gravedad

de[ pe[igro. Se puede usar un simbo[o de seguridad

para representar e[ tipo de pe[igro. Se usa [a

pa[abra AWSO como seha[ para dirigir practicas no

re[acionadas con [esiones persona[es.

RAP[DO LENTO ACE[TE

ENOEND[DO/

APAGADO

ADVERTENC[A Ciertos componentes en

este producto y sus accesorios relacionados

contienen sustancias quimicas que el estado

de California sabe que causan cancer, defectos

congenitos u otros daSos reproductivos. LAvese las

manes despues de la manipulaci6n.

ADVERTENC[A Los bornes, terminales y

accesorios relacionados con [a bateria contienen

p[omo y compuestos de p[omo, productos

quimicos que e[ estado de California sabe que

producen cancer y defectos congenitos u otros

daSos reproductivos. LAvese las manos despues

de usarlos.

ADVERTENC[A El motor encendido [ibera

mon6xido de carbono, un gas venenoso,

nco[oro e nodoro.

Respirar mon6xido de carbono puede causar

dolor de cabeza, fatiga, vertigo, v6mitos,

confusi6n, ataques, nAuseas, desmayos o

nc[uso la muerte.

* Opere el equipo SOLO en e[ exterior.

* Evite que e[ gas del escape entre en Areas

cerradas a trav6s de ventanas, puertas,

entradas de vent[laci6n u otras aberturas.

PEL[GRO indica un pe[igro que, si no se evita,

producira [a muerte o [esiones graves.

ADVERTENC[A indica un pe[igro que, si

no se evita, podria producir [a muerte o [esiones

graves.

PRECAUC[6N [nd[ca un pe[[gro que, s[ no se

evita, podria producir [esiones menores o moderadas.

AV[SO dirige practicas no re[acionadas con

[esiones persona[es.

5

ADVERTENCIA: iEsta maquina cortacesped es capaz de amputar manos y pies y puede lanzar objetos

que pueden causar lesiones y daSos! Si no se cumplen las siguientes instrucciones de SEGURIDAD, el

operador o los transeOntes podrian sufrir lesiones graves o la muerte. El propietario de la maquina deberb.

comprender estas instrucciones y permitira utilizar la maquina 0nicamente a personas que comprendan

estas instrucciones. Todas las personas que hagan funcionar la maquina deberan ser dueSas de si mental y

fisicamente y no deberan hallarse bajo la influencia de ningOn tipo de sustancias que puedan deteriorar sus

capacidades visuales, su destreza o capacidad de juicio.

Protecci6n a la infancia

Pueden ocurrir accidentes graves si el usuario no esta

atento ante la presencia de ni_os. Los ni_os suelen

sentirse atraidos por la unidad y por la actividad del

cortacesped. Nunca de por hecho que los ni_os vayan a

permanecer en el Oltimo lugar en el que los vio.

1.MANTENGA a los ni_os fuera del area de corte y bajo

la vigilancia atenta de alg0n adulto responsable.

2. NO PERMITA que ni_ios ni otros se monten en la

maquina, en sus accesodos ni en el equipo remolcado

(incluso con las cuchillas DESCONECTADAS).

Poddan caerse y resultar gravemente heddos.

3. PERMITA Qnicamente que adultos y adolescentes

responsables con capacidad de juicio madura y bajo la

supervisi6n cercana de un adulto utilicen la maquina

4. NO opere las cuchillas marcha atras. DETENGA LAS

CUCHILLAS. MIRE detras y debajo de Ud. antes de

retroceder y antes de retroceder y mientras Io haga

por si hay ni_os, animales domesticos u otros peligros.

5. PONGA ESPECIAL CUIDADO al acercarse a esquinas

cerradas, arbustos, arboles u otros objetos que

puedan obstaculizar lavisi6n.

O6mo evitar que vuelque

Las pendientes son un factor de gran p(_rdidaen los casos

de perdida de control yen los accidentes en los que

vuelca el cortacesped, que pueden resultar en lesiones

graves o incluso la muerte. Todas las pendientes requ_eren

mayor PRECAUCION. Si no puede ir hacia atras sobre una

pendiente con el cortacesped, o no se siente seguro sobre

la pendiente, NO corte el cesped en la misma. Ponga

el mayor cuidado con los recogedores de hierba y otros

elementos anexos: afectan al manejo y a la estabiJidad de

la maquina. Consulte laGuia de trabajo en pendientes que

encontrara al final de esta secci6n.

1.NO opere la maquina en pendientes que excedan

los 10 grados, Io que equivale a 1,1 m (3,5 pies)

verticalmente por cada 6,1 m (20 pies) hodzontalmente.

2. DESCONECTE las cuchillas cuando se desplace

cuesta arriba. Utilice una velocidad lenta evitando

giros bruscos.

3. NO maneje la maquina hacia delante y hacia atras

en medio de las pendientes. Manejela hacia arriba y

hacia abajo. Practique sobre las pendientes con las

cuchiHas desconectadas.

4. EVITE arrancar, detenerse, o girar en pendientes. Si la

maquina se detiene mientras sube o los neumaticos

pierden tracci6n, DESCONECTE las cuchillas y

retroceda lentamente en linea recta hacia abajo.

5. ESTP ALERTA ante la presencia de hoyos y otros

peligros ocultos. La hierba alta puede ocultar obstaculos.

Mantengase lejos de cunetas, deslaves, alcantarillas,

cercas y objetos que puedan salir proyectados.

6. MANTENGA UNA DISTANCIA DE SEGURIDAD

minima de 0,9 metros (3 pies) de separaci6n desde el

borde de zanjas y otros desniveles. La maquina podria

volcar si se mete una parte en un desnivel.

7. Comience siempre a moverse hacia delante

lentamente y con precauci6n.

8. Manipule pesos o un transportador de carga con peso

segOn las instrucciones proporcionadas junto con

el recolector de hierba. NO MANEJE la maquina en

pendientes que excedan los 10 grados.

9. NO coloque su pie en elsuelo para intentar estabilizar

la maquina.

10. NO utilice el cortac(_sped sobre hierba homed& La

reducci6n de tracci6n puede causar deslizamiento.

11. Escoja una velocidad lo suficientemente baja de

manera tal que no tenga que detenerse ni hacer

cambios en pendientes. Los neumaticos pueden

perder tracci6n en las pendientes incluso cuando los

frenos funcionen debidamente.

12. NO maneje la maquina en circunstancias en que la

tracciono la direcci6n o la estabilidad sean dudosas.

13. Siempre mantenga la maquina con un cambio a_bajar

pendientes. NO utilice el punto muerto (ni libere el

hidroorodamiento) para bajar una pendiente.

Antes de cortar el c_sped

1.Lea. cornprenda y siga las instrucciones y advertencias

en este manual y las indicadas sobre la maquina, el

motor y sus accesorios. Conozca los controles y el uso

apropiado de la maquina antes de comenzar.

2. Unicamente deben hacer funcionar la maquina

personas maduras y responsables y s61odespues de

la adecuada instrucci6n.

3. Los datos indican que operadores de 60 o mas a5os

estan implicados en un amplio porcentaje de lesiones

relacionadas con el uso de tractores cortacesped.

Estos operadores deberan evaluar su capacidad de

utilizar la unidad de manera Iosuficientemente segura

como para protegerse a si mismos y a los demas

frente a graves lesiones.

4. Manipule el combustible con especial precauci6n.

Los combustibles son infiamables y sus vapores,

explosivos. Utilice un recipiente de combustible

homologado. NO retire la tapa del combustible ni

ahada combustible con el motor en marcha. A5ada

combustible Qnicamente en exteriores y con el motor

parado y frio. Limpie el carburante derramado sobre la

maquina. NO fume.

5. Practique el manejo de la maquina con LAS

CUCHILLAS DESCONECTADAS para aprender los

controles y desarrollar destrezas.

6. Revise la zona de cesped que se va a cortar y retire

objetos como juguetes, cables, piedras, ramas y

otros elementos que puedan causar lesiones si

6

Loading...

Loading...