Page 1

®

BETTER BY DESIGN

P.O. Box 1037

650 S. Royal Lane, Suite 100

Coppell, TX 75019

(800) 486-4892

8:00 to 5:00 CST (Central Standard Time)

Toll Free Fax: (877) 304-1728

email: customerservice@craftmade.com

www.craftmade.com

®

MEJOR DISEÑO

Tripod Ceiling Fans

P. O. Box 1037

650 S. Royal Lane, Suite 100

Coppell, TX 75019 EE.UU.

(800) 486- 4892

8:00 a 5:00 CST (Hora local central)

Número de fax sin cargo: (877) 304-1728

Correo electrónico: customerservice@craftmade.com

www. craftmade.com

®

UNE CONCEPTION EXCEPTIONNELLE

P. O. Box 1037

650 S. Royal Lane, Suite 100

Coppell, TX 75019 EE.UU.

de 8 heures à 17 heures (Heure standard du centre)

Numéro de télécopieur gratuit : (877) 304-1728

Email: customerservice@craftmade.com

www. craftmade.com

ME52

Installation Instructions

Models: CT52, D52, FR52,

ME52 & OL52

FR52 OL52D52CT52

®

BETTER BY DESIGN

Page 2

Read and Save These Safety Precautions

What You Have

1. Turn off electricity at main switch before wiring or servicing fan in order to avoid

possible electrical shock.

2. All wiring must be in accordance with the National Electric Code (ANSI/NFPA

70-1999) and local electrical codes. Electrical installation should be performed by a

qualified licensed electrician.

3. After making the wire connections, the wires should be spread apart with the

grounded conductor and the equipment-grounding conductor on the one side of the

outlet box and the ungrounded conductor on the other side of the outlet box.

4. The splices after being made should be turned upward and pushed carefully up into

the outlet box.

5. Conductor of a fan identified as grounded conductor to be connected to grounded

conductor of power supply, conductor of a fan identified as ungrounded conductor

to be connected to an ungrounded conductor of power supply, conductor of fan

identified for equipment grounding to be connected to an equipment-grounding

conductor.

6. Fan should not be mounted in an area where it might get wet.

7. To reduce the risk of fire, electric shock or personal injury, mount to outlet box

marked "Acceptable for Fan Support" and use mounting screws provide with the

outlet box.

8. For safety and best operating results, we recommend that you have a qualified

electrician assemble and install your fan.

9. WARNING: To reduce the risk of fire or electric shock, do not use this fan with

any solid state speed control device.

10. To reduce the risk of personal injury, do not bend the blade brackets when installing

Before Assembly

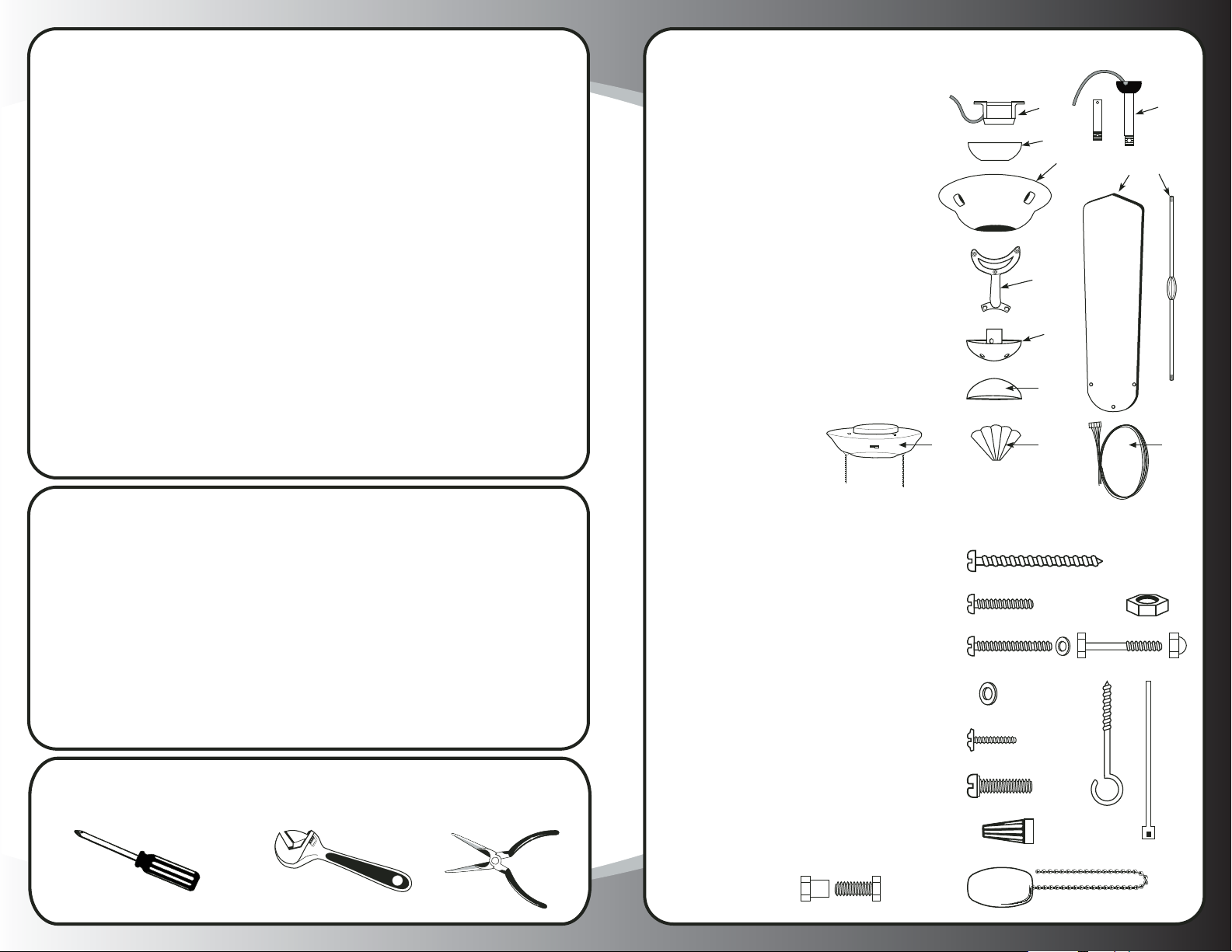

Parts Quantity

1

1. Mounting Bracket 1

2. Down Rod Assembly 2

2" & 6" Rod Supplied

Use desired length)

3. Canopy 1

4. Fan Housing & Motor 1

5. Wood Blades 5

6. Blade Holders 5

7. Decorative Support Rods 3

8. Support Rod Distributor 1

8a. Distributor Cover 1

9. Switch Housing Assembly 1

10. Blade Ornaments 5

11. Wiring Harness 1

12. Balance Kit 1

9

3

6

8

8a

10 11

2

4

7

5

1. Make sure that the fan voltage (120) is compatible with your own electrical system.

2. Check to make sure that your carton contains all the parts mentioned in the parts

list.

NOTE: When the motor is taken out of carton, please put it in a soft cloth to prevent

any damage on the ornamental surface.

CAUTION: Before installing, choose a location for mounting the fan where the blades

have at least 7 feet of clearance from all objects and floor. Mount an outlet box to the

ceiling or use an existing box.

CAUTION: Do not mount fan to sheet rock or drywall type materials. To insure proper

support, use the two #1 wood screws to secure mounting bracket to joist or beam. If the

location you choose does not have a suitable support beam, install a 2”X4” brace between

ceiling joists to support.

Tools You Need

1. Phillips Screwdriver 3. Needle Nose Pliers 2. Adjustable Wrench

Screw Package Quantity

S1. Wood Screws 2

S2. Screws (for Canopy) 3

S3. Bracket Screws & Washer 2

S4. Washers (for bracket) 2

S5. Blade Screws 16

S6. Motor Screws (4 screws on motor) 11

S7. Wire Connectors 4

S8. Pull Chains 2

S9. Hex Nuts for Support rods 3

S10. Safety Bolt & Nut 1

S11. "J" Hook 1

S12. Zip Tie 1

S13. Cable Clasp 1

S13

S1

S2

S3

S4

S5

S6

S7

S8

S9

S10

S11 S12

Page 3

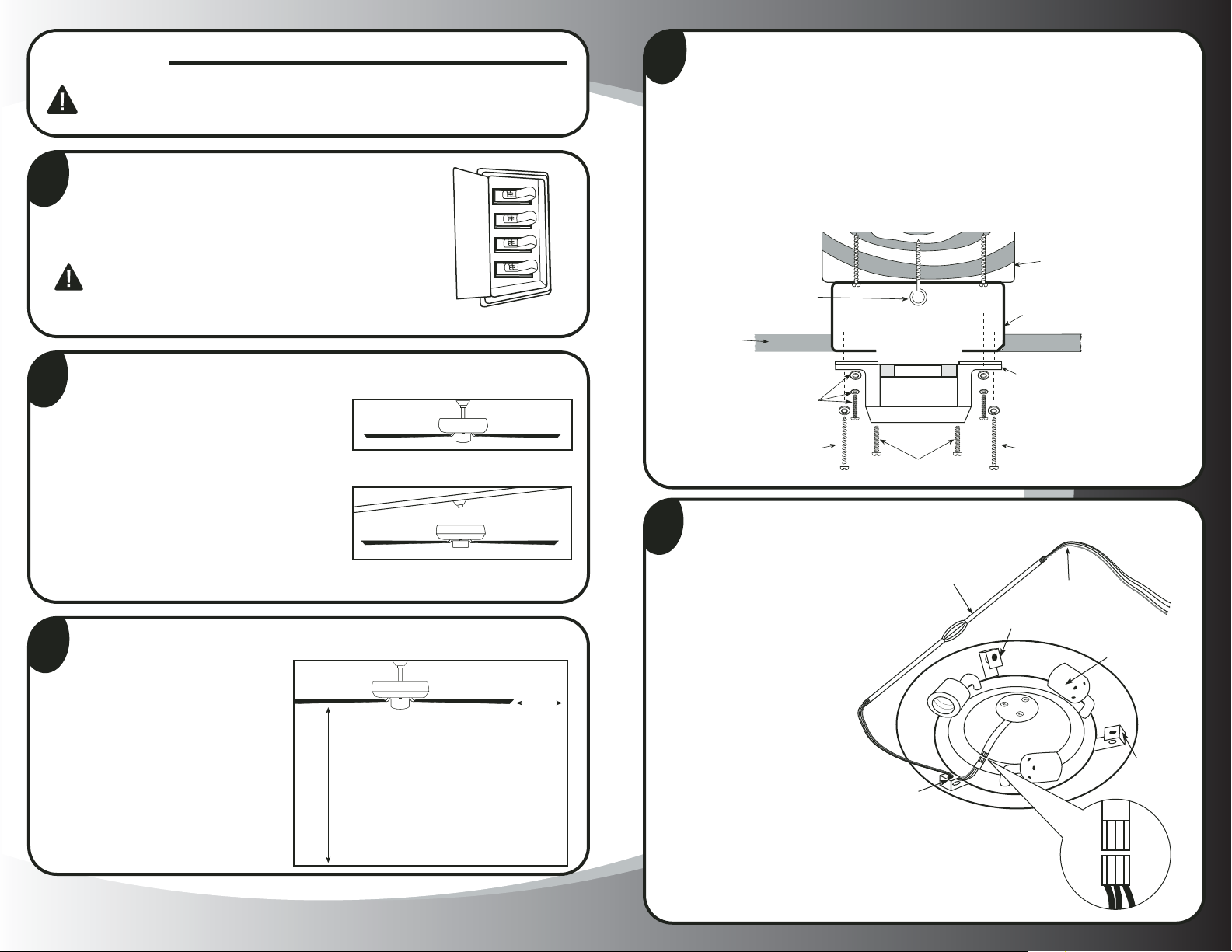

Preparation

Important: When using an existing outlet box, be sure the box is securely

attached to the building structure and can support the full weight of the fan.

Failure to do so can result in serious injury or death.

Step 1

1

Turn off circuit breakers and wall switch to the fan

supply line leads.

4

Step 4

Prior to securing mounting bracket, screw "J" hook (S10) into ceiling outlet

box as a secondary support means. Secure mounting bracket (#1) to the

outlet box (A) by tightening bracket screws & washers (S3) as shown. If not

mounting to an outlet box, use wood screws (S1) and washers (S3) and

mount securely to ceiling beam. Be sure at this point to insert canopy

screws (S2) in bracket. NOTE: Do not mount directly to sheet rock or ceiling tile.

NOTE: J Hook installation is a Canadian requirement only.

Warning: Failure to disconnect power supply prior to

installation may result in serious injury or death. To

reduce the risk of shock, this fan must be installed with

an isolating wall control/switch.

Step 2

2

Determine mounting method to use.

A. Downrod Mount

B. Angle Mount

Craftmade Part #45AD (see dealer)

IMPORTANT: If using the angle mount

method, check to make sure the ceiling

angle is not steeper than 35°. Angles greater

than 35° will require a 45° angle adapter.

3

Check to make sure blades are

at least 30” from any

obstruction. Check downrod

length to ensure blades are at

least 7' above the floor.

Step 3

84”

(2.1m)

Min.

Downrod Installation

(Normal Ceilings)

Downrod Installation

(Vaulted Ceilings)

30”

0.75m

Min.

“J” Hook (S10)

Ceiling

Bracket Screws

& Washers (S3)

Wood Screws (S1)

OUTLET BOX

Canopy Screws (S2)

Step 5

5

Viewing fan housing and

motor from top, securely

plug the connector from the

wire harness into the wiring

harness connector (see diagram).

Locate the decorative rod

support bracket (A).

Using a decorative

rod (#7), insert wiring

harness (#11), including

steel cable, through

hole in support bracket (A)

and rod. Firmly hand

tighten rod into bracket

(rod must be fully seated

into bracket). Install remaining

two rods (#7) in support brackets

(B and C)and firmly hand tighten.

Support

Bracket (A)

Decorative Rod (#7)

Support Bracket (C)

Support Beam

Outlet Box (A)

Mounting Bracket (1)

Wood Screws (S1)

Fan Housing & Motor

Wire Harness (#11)

Light

Socket

Support

Bracket

(B)

Page 4

6

Step 6

Insert wires, including steel cable, from top of support rod (#7) through

hole "A" in bottom of "support arm distributor" (#8). Insert ends of

remaining two rods into holes "B" and "C" in bottom of distributor.

Place wires through hex nut and tighten nut securely onto support rod.

Use hex nuts to secure remaining two rods into place. Insert wires

through hole "D" and pull through top of downrod section of distributor.

Side View of Support Arm

Distributor Assembly (#8)

D

Downrod Section

7

Step 7

Locate downrod assembly (#2).

Loosen ball screw on black hanging

ball to free lock pin. Black hanging

ball will slide down. Remove ground

screw and green ground wire.

Remove hanging ball from downrod

and save all parts. Insert wires and

steel cable from distributor assembly

through downrod. Screw downrod

into top of Support Arm Distributor

Assembly (#8), being careful that

wires are pulled through.

Lock Pin

Downrod

Assembly

(#2)

Green Ground

Wire

Ball Screw

Hanging Ball

Downrod

Support Arm

Distributor

Assembly (#8)

A B

Support Rod (#7)

Wiring Harness

(including steel wire)

A

Hex Nut

C

CAUTION:

Do not mount fan to sheet rock or

drywall type materials. To insure

proper support use the two #1 wood

screws to secure mounting bracket to

joist or beam, if the location you

have chosen does not have a suitable

support beam, install a 2" x 4" brace

between ceiling joists to support fan,

or one of the many NEC and UL

approved ceiling fan braces.

WARNING:

To reduce the risk of fire, electric shock or personal injury, mount to outlet box

marked "acceptable for fan support" and use mounting screws provided with

the outlet box. Most outlet boxes commonly used for the support of lighting

fixtures are not acceptable for fan support and may need to be replaced.

Consult a qualified electrician if in doubt.

B

Top View of Support

Arm Distributor (#8)

8

Step 8

Position downrod so the hole in the downrod aligns with the hole in the

distributor assembly. Insert safety bolt (S10) through distributor assembly

and downrod and attach nut. Tighten firmly. Tighten set screw "A"

against downrod. Place distributor cover (#8a) over support arm

distributor (#8). Next place canopy (#3) over downrod assembly (#2).

Replace hanging ball, insert hanging pin through downrod and tighten set

screw "C" in hanging ball into downrod.

Threaded Set

Screw Hole

Hanging

Pin

Hanging

Ball

WARNING:

Failure to completely tighten downrod as described in steps 7 & 8 above could

result in the fan loosening and possibly falling.

Ground

Wire

Ball

Screw

Safety Bolt

and Nut

Set Screw (C)

Downrod (2)

Canopy (3)

Distributor

Cover (8a)

Set Screw (A)

Distributor

Assembly (2)

Page 5

Step 9

9

Thread steel cable through cable clasp

Thread steel cable through cable clasp

(S13). Loop wire over and thread back

(S13). Loop wire over and thread back

through cable clasp, making sure loop is

through cable clasp, making sure loop is

large enough to attach on to "J hook

large enough to attach on to "J hook

(S10) in outlet box. Tighten screw

(S10) in outlet box. Tighten screw

securely to ensure that loop does not

securely to ensure that loop does not

come loose.

come loose.

Step 9

Cable Clasp (S13)

Step 10

10

For added security, attach safety cable from fan unit to "J" hook (S10) in

outlet box. Secure by looping zip tie (S11) through safety cable and "J"

hook. Tighten zip tie securely. Lift fan onto the mounting bracket (#1).

Turn housing until hanging ball seats itself into ball socket (listen for

click).

Support Beam

“J” Hook (S10)

11

Step 11

1. Connect fan wires to ceiling wires: white fan wire to white outlet wire,

black to black and green to green. Wire connectors (S6) are provided for

your convenience. If an additional blue wire is present then also connect

the blue wire to the black wire. (Optional light kit may be wired to

individual wall switches, if desired.)

2. After connections

are made, turn

splices upward

White (Neutral)

and push carefully

into outlet box.

Separate blue and

Black (Power)

black wires on one

side of the box, and

white and green wires

on the other side.

There are 4 colored

wires coming from the

top of the motor

(including ground wire).

Ground

White

Black

Blue

Wire

Connectors

(S6)

Ground

(Green)

Outlet Box

Ground (Green)

OUTLET BOX

Green Ground Wire

NOTE: Parts furnished will allow

you to install your fan at up to a

35° angle. Angles greater than 35°

will require a 45° angle adapter

(see dealer). NOTE: J Hook

installation is a Canadian

requirement only.

WARNING: To reduce the risk of fire, electric shock or personal injury, mount

so outlet box marked "acceptable for fan support" and use mounting screws

provided with the outlet box. Most outlet boxes commonly used for the support

of lighting fixtures are not acceptable for fan support and may need to be

replaced. Consult a qualified electrician if in doubt.

“J” Hook (S10)

Zip Tie (S11)

Safety Cable

Outlet Box (A)

Ceiling

Mounting Bracket (#1)

Wire Connnections

Outlet Box Fan wires

Black Black

(Hot wire for fan)

Green Green (Ground wire)

White White (Neutral wire)

Black Blue (Light kit wire)

Downrod Ground

(Green)

Mounting Bracket

Ground (Green)

Page 6

Modular Wiring Plug (A)

Modular Wiring Plug (B)

Switch Housing (9)

Screws (F)

Mounting Slots (D)

Mounting Plate (E)

12

Blade Screws (S5)

Blade Holder (6)

Blade (5)

Blade Ornament (10)

Blade Holder

Screws (S6)

Step 12

Attach canopy (#3) to the

mounting bracket by placing

screws (S2) into slot in

canopy. Twist clockwise to

lock into place. Tighten screws

firmly.

Ceiling

Canopy (3)

Screws (S2)

Bottom of Canopy

14

Remove rubber cushions,

saving motor screws for

blade installation. Using

motor screws (S5) provided,

line up holes from the blade

arm with the holes in the

motor housing. Tighten

screws securely.

Step 14

5 Blade Installation

Step 13

13

For blade assembly, position blade holder (#6), blade (#5) and blade

ornaments (#10) so that all screw holes are aligned (as shown in figure

below). Using blade screws (S5), insert through top of blade holder,

through blade, and into blade ornament. Tighten securely.

CAUTION: Install blade holders to motor only after motor installation is

complete. This will prevent damage to the blade holders which have been

carefully balanced. IMPORTANT: Remove rubber cushions, saving motor screws

for installation.

15

Step 15

1. To install the Switch Housing Assembly (#9), locate both modular

wiring plugs (A) and (B). One extends from the mounting plate (E) on

bottom of fan body and one extends from the Switch Housing (#9). Align

the two plugs so the latch on the side of the plugs will engage when

pushed together. Push the two plugs firmly together until latched.

2. Loosen 2 of the 3 screws (F) on mounting plate. Completely remove

one of the screws. Raise switch housing (#9) and align the mounting slots

(D) in the switch housing with the mounting screws (F) on the mounting

plate on bottom of fan body. Rotate the switch housing to the right until

the two screws are completely seated into mounting slots. Replace screw

that was removed. Tighten the three mounting screws securely.

IMPORTANT: Be sure that no wires are caught in mounting slots or pinched between

switch housing and mounting plate.

CAUTION

To reduce the risk of personal injury, DO NOT bend the blade arms when

installing them. When balancing the blades, or cleaning the fan, do not insert

foreign objects in between rotating fan blades.

Page 7

16

Motor Pull Chain

Slide Switch

Uplights Pull Chain

1. The sequence of operation for the motor pull/chain switch is

OFF-HI-MED-LOW.

2. Push the slide switch RIGHT for FORWARD, and LEFT for

REVERSE action of the blades.

3. The pull chain switch for the uplights and side body lighting in the

body of the fan is two positions - ON/OFF.

4. The Fresco (FR52) and Constantina (CT52) has a four-way switch:

OFF-UPLIGHTS-SIDE BODY-BOTH.

Operation Instructions

CAUTION

Even if your fan is mounted with the blades more than 7 feet from the floor, be

careful to avoid placing your raised arms or any object in the path of the blades.

Page 8

17

Electrical Connections

Electrical Connections Continued…

Connect black and blue (if provided) fan wires to black outlet wire.

Connect white fan wire to white outlet wire and green grounding lead

wire from the grounding conductor to the supply circuit (see figure A).

Use wire connectors provided with your fan. No loose strands or loose

connections should be present. After wires have been connected, they

must be spread apart so the green and white are on one side of the outlet

box and the black and blue are on the other side. Turn splices upward

and carefully push all wiring into outlet box. For optional wall control see

figure B or Figure C for alternate wiring. When wall switches are

employed, switches should be UL listed

for use with ceiling fan.

NOTE: Make sure fan on/off switch is always at "high speed" location if your fan is

controlled by additional wall switch.

Ground

White

White

Black

Light Switch

Ground

Blue

Figure B

Black

Green

White

Black

Figure A

Blue

Black

Green

White

Black

Switch

Switch

Ground

White

Fan

Light

Blue

Figure C

Black

Black

Green

White

Loading...

Loading...