Crafter Guitar User Manual

Dear Crafter Owner,

Thank you for choosing a Crafter guitar. My father, HyunKwon Park,

founded our company in April 1972 in the basement of his home where he had

just 20 square meters of space and a staff of 4. He chose Sungeum as the brand

name for his guitars. In Korean it means ‘accomplishing the sound’ and is a

name which, in the Korean language, captured the spirit, passion and ethos of

the company and its products. The fledgling company enjoyed early success

with its fine classical guitars which soon acquired a reputation for excellence

from the local musicians. As a result of the ever increasing demand

HyunKwon Park expanded rapidly moving three times to ever larger

buildings until 1978 when he purchased his own factory in the Yangju City

area, north of Seoul. Finally we had a permanent home for Sungeum guitars.

I joined my father in 1986 and the decision was made to take our guitars to

the international market with the new ‘Crafter’ brand on our headstocks. We

chose the word Crafter with great care. Huge quantities of guitars can be

produced using modern technology and mass production methods. But no

machine can replace a skilled craftsman and the skills which they have

acquired over many years. Our new factory is state of the art but hand

crafting is absolutely central to our manufacturing process.

Sales grew worldwide and, once again, we needed more space so that in 2000

we moved to our own 7,000 square meter purpose built factory. However this

was not to be our final relocation. Domestic sales have grown dramatically in

recent years and Crafter is now the dominant acoustic brand in our Korean

home market. The official opening of our new 10,000 square meter state of the

art production facility took place in May 2009 when guests from around the

world attended the Grand Opening Ceremony.

Today our Crafter brand is registered in more than 40 countries and

distributed by independent distributors. In 2004 we opened our own

distribution company, Crafter USA, to distribute and promote our instruments

in the US, a market which has such a major influence on guitar players

around the world. Since incorporation Crafter USA have won a number of

service awards including the FURMM Retail Group`s best service award in

2007 and a best supplier award from iMSO, the Independent Music Store

Owners’ Group in 2010.

Since the very start in 1972 we have pursued a program of continuous

review and development and we are proud that our innovations, quality and

value have resulted in the instrument that you have chosen ahead of so many

others. Thank you again for choosing Crafter and we hope that your guitar

will give you many years of good service and playing pleasure.

InJae Park

President

2

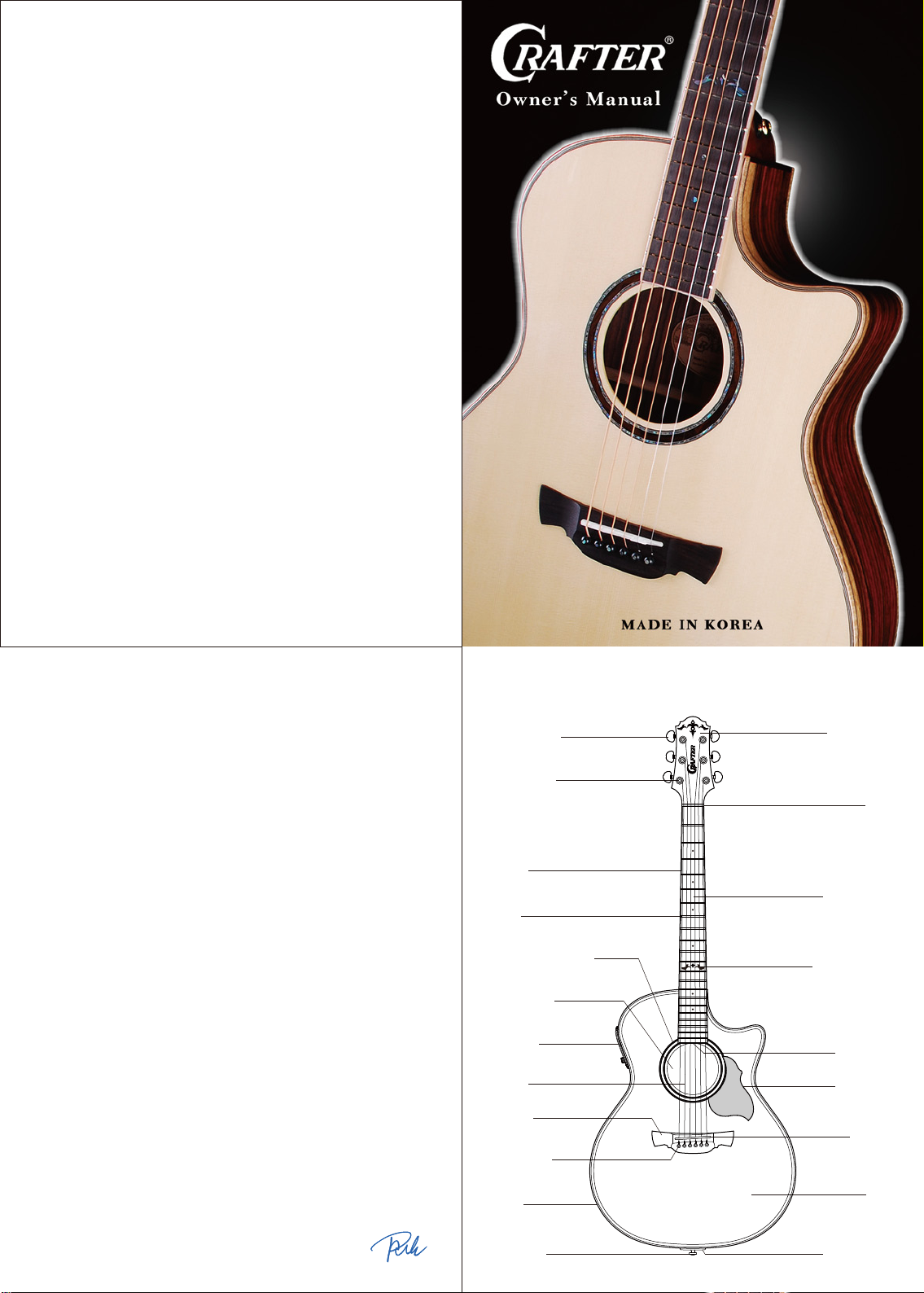

Tuning Key

String Post

Neck

Fret

Soundhole Rosette

Soundhole

Preamp

String

Bridge

Bridge Pin

Body

Strap Pin

Crafter Guitar Parts

Headstock

Nut

Fingerboard

Position Mark

Truss Rod

Pickguard

Saddle

Top

Battery Case

Output Jack

3

On recei ving your gui tar

Remove protect ive films off a ny plastic parts suhch as the pic kguard.

Also remove the hang tags from the tu ning keys and an y packing

material which is attached to t he instr ument.

Care of your Guitar

Cleaning

The fingerboa rd and st rin gs will tend to collect sweat a nd dirt. Keep

both hclean by wipi ng dow n the finger board and strings with a clean

dr y soft clot h afte r each time you use your instrume nt. You ma y also

clean the fi ngerboard more thorou ghl y with lemon oil and a soft clean

clot h. Do this wit h the st rings off. A convenien t time would be whe n

cha ngi ng str ings.

Dir t and residue which collect on the neck, bod y and headstock should

be cleaned off regularly using a clean dr y soft cloth, or bet ter still a

micro fiber clean ing clo th such as the Craf ter Guitar Micro Fiber Clot h.

Use a little guitar polish to remove stu bborn dirt but do not us e any

abras ive or so lvent b ased cleaners.

Tuning

This will ha ve much to do wit h your level of ability and experience as a

guita rist. W ith the exception of those few gif ted individ uals who have

perf ect pitch a nd knowledge of gu ita r tu nin g, we recommend you use

an electronic tuner. This is a sim ple, inexpensive and quick way to tu ne

you r guitar w ith an accuracy that only exper ienced pla yers could

previously ac hieve.

Most of our recent electro/acoustic models

incorporate a t uner i nto the gui tar's pream p.

But for those models t hat don't, as well as all

purely acoust ic models, we recommend our

Crafter headstock tuner (TG-200 or TS-10)

which clips on to t he headstock of your

guita r. For more informat ion visit ou r

Crafter website or ask you r dea ler.

-50 +50

Auto Tuner TS-10

CHROMA

TS-10 Tuner

WARNING

When plugged into an amplifier or electronic device, do not handle

your guitar or any connections with wet hands, or on a wet surface,

or in a hot humid sweaty environment.

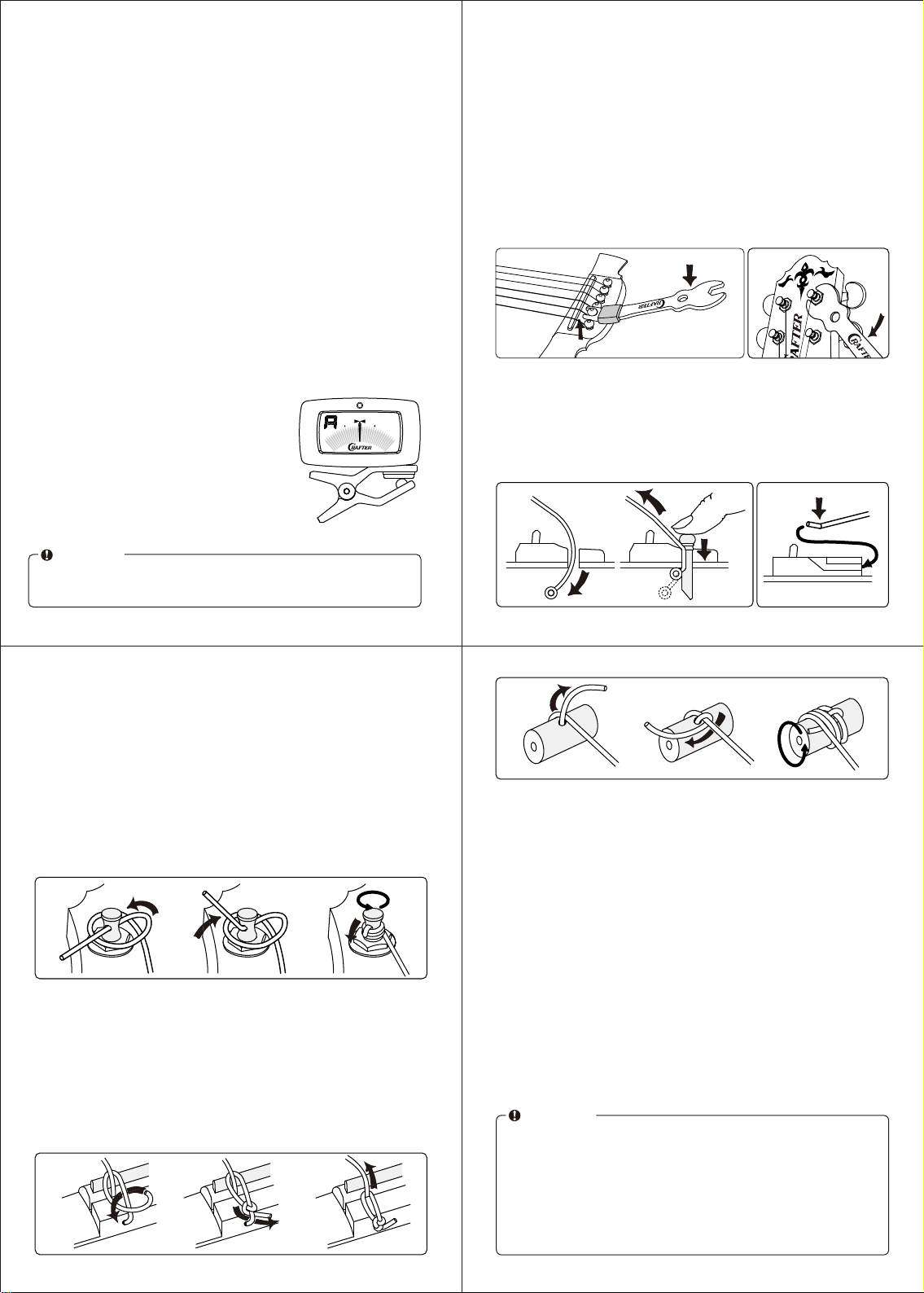

Replacing st rings

You r Crafter gu ita r is str ung with D'A dda rio light gauge acoustic

strings. The gauges are; E 1st - .012, B 2nd - .016, G 3rd - .024, D 4th – .032,

A 5th - .042, E 6th - .053. Provided yo u restri ng with the same, or

ap proxima tely the same gauges, you r guit ar shou ld not req uire any

ad justment. If you do cha nge to a ligh ter or a hea vier ga uge, it ma y be

necessary to reset the tr uss rod to maintain the correct cur vat ure of the

neck /fingerboa rd.

We recommend that you r eplace one st ring at a time as t his will

minimize th e stress on the neck.

Sta rt with the low E (6th st ring). Slack off the t ension with t he tu ning

key so the st ring is q uit e loose. Then carefully pry ou t the bridge pin

which will release the string. A Crafter BR-100 bridge pin rem over will

sim plify t his task. Please make su re that the string is properly slacked

off so t hat it does not spri ng ou t and possi bly ca use injury, pa rticularly

to your eyes or face.

BR-100

Bridge Pin Remover

Tak e the ne w string and pass the ba ll end t hrough the hole on the br idge

(fig ur e 1). Then r eplace the bridge pin securing it with gent le pressure.

Keep your fi nger or thumb on t he bridge pin to retain it and pull the

string up so tha t t he ba ll end grips (figure 2). Then press t he bridge pin

firml y home. If your guita r does not have br idge pins bend the end of

the str ing sligh tly to help it pass t hroug h t he h ole (figure 3). Take care

when p ulling the string through the bridge so t hat t he ball end doesn’t

scra tch or dent t he top of the guita r.

(1) (2) ( 3)

4

Next Step; Take the loose end of the 6th string and feed it through the hole in

the tuning key post (figure 4). Allow about 35 mm / 1½ inches of slack and

bend the string upwards tight against the post to create a sharp bend (figure

5). Turn the tuning button to wind the string onto the post with the post

turning in the direction indicated in figure 6. Note also in figure 6 the way that

the windings should lay. Bring the string up to tension so that it is

approximately in tune to low E and cut the end of the string 5 mm / ¼ inch

from the tuning post.

Repeat the above for each string but increasing the slack a little for each string

as you work through so that there is about 50 mm / 2 inches of slack at the

high E 1st string. This allows the number of turns the string is wound around

the post to increase as the strings get thinner. When all the strings have been

replaced, cut the loose ends off about 5 mm / ¼ inch from the post and bend

downwards and out of the way. These ends are sharp and can easily cause

minor injury. Be careful!

(4) (5) ( 6)

Crafter Classical guitars

Crafter classical g uitars use n ylon stri ngs and fixing the st ring to the

bridge and string post of the tuning keys is d ifferen t to a steel st ring

guita r. The st ring is first passed th rou gh the corresponding hole on t he

bridge, wrapped and tied. The procedu re to tie the string to the bridge is

shown in figu res 7, 8 and 9. Once done, t he other en d of the stri ng is

passed t hroug h the hole in the tuning key post and th e post rotated half

a tu rn using the t uning key but ton as show n i n f igu re 10. Allow some

slack for the windings and pass the string u nderneath as s how n in figu re

11. Wind t he rest of the string onto the post as shown in fig ure 12 a nd

bri ng i t up t o te nsion so that it is ro ughly in tune. Fina lly, trim off t he

loose end of the string.

(7) (8) ( 9)

5

(10) (1 1) (12)

Temperature and Humidity

You r Crafter acoust ic gu ita r uses natu ral tim bers for m uch of its

construction. Wood will remain stable in nor mal clima tic condi tions

but will swell or shr ink in an excessivel y hot and h umid or cold and dr y

environment. In s ummer warm moist air will ca use the wood to swell

and the top to rise. This will resul t in a high strin g action. In extreme

circumstances the neck can war p.

Conversely, in win ter the cold air does not hold much moist ure. Heat ing

the air to a comfortable room te mperat ure dries the air further and will

cause the woods of your guitar to lose m oisture and shr ink. This will

ten d to fla tten the top, again cha nging the stri ng height, this ti me

lowering the a ctio n so tha t the strings may buzz against the fre ts. In

extreme cond itions the top could crack.

We strong ly re comme nd th at yo u kee p you r gui tar away from extrem e

heat and h umidity. For exam ple, not i n th e tr unk of a motor car when

the sun i s shini ng or in a ho t humid atmospher e such as i n a bathr oom.

Our guitars a re built in climate cont rolled conditions where the

tem perature is kept at 22°C/72°F a nd the h um idity at a constant 50%.

We recommend t hat you keep y our inst rument in simila r climatic

cond itions. Tha t is at a tem pera ture of bet ween 20°C and 25°C / 68°F and

77°F with the h umidit y bet ween 45% and 55%. Depend ing on yo ur local

cond itions you ma y need a dehu mid ifier to reduce humidity in the

summer a nd a hu midifier if t he air is too dry in winter. Use a

thermometer/h ygr ometer t o monitor the tem perature and humidity.

WARNI NG

• W hen c hangi ng strings, w e rec ommen d tha t you remove and

repla ce one stri ng at a tim e so as not to disturb the way th e bridge

is seat ed.

• Do not use heavy gaug e strin gs. The very hi gh tensio n they

exert on the ne ck, br idge a nd top could re sult i n dama ge to t he

instr ument .

• N ever try to fit ste el strin gs to a classi cal guitar. The tension

exert ed by steel str ings is muc h great er than tha t of classi cal

strin gs.

6

7

Loading...

Loading...