CPS SCA50KTL-DO/US-480, SCA60KTL-DO/US-480 Installation And Operation Manual

CPS SCA Series Grid-tied PV Inverter

CPS SCA50KTL-DO/US-480

and SCA60KTL-DO/US-480

Installation and Operation Manual - Rev 3.0

CHINT POWER SYSTEMS AMERICA CO.

Revision 3.0 - Feb 2018

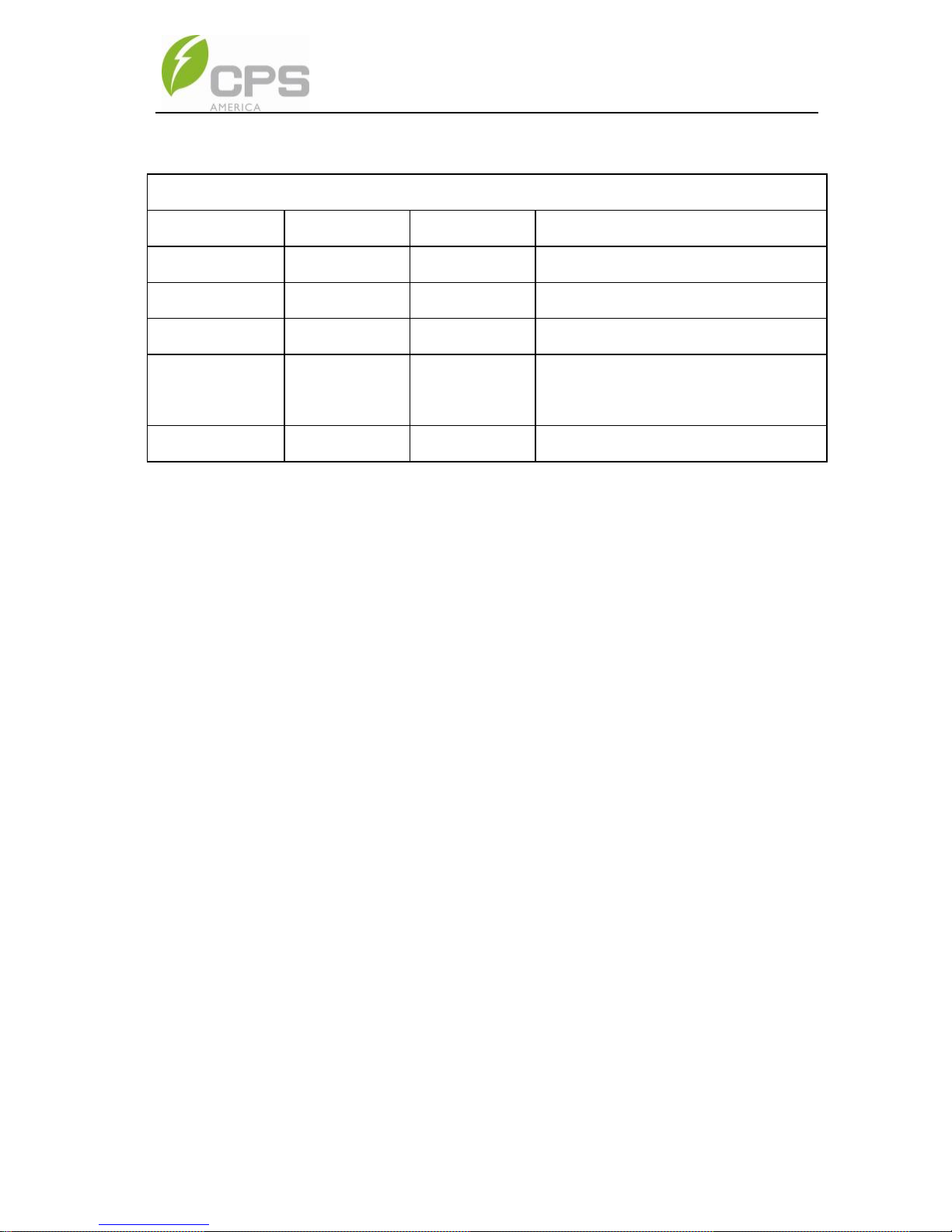

Revision History

Rev Number

Chap/Sec

Rev Date

Description

1.0

N/A

Aug 2016

Initial Release

2.0

3

Sep 2016

H4 Wirebox, Operating Mode

2.1

3

Feb 2017

H4 Termination, AC Terminal

2.2

3, 5, 7, 8

Sept 2017

AC Terminal, Parameters,

Trouble-Shooting, Accessories

3.0

3, 5, 6, 10

Feb 2018

Increased kVA Ratings

Table of Contents

Before You Start… .................................................................................. 1

1. IMPORTANT SAFETY INSTRUCTIONS ............................................ 3

2. Overview ............................................................................................ 6

2.1. Inverter for grid-tied PV systems 6

2.2. Product Features 7

2.3. Product Protection Functions 8

2.4. Appearance and Main Item Description 9

2.5. Schematic Diagram and Circuit Design 10

2.6. Anti-islanding Detection 11

2.7. DC Ground Fault Protection 11

2.8. Surge Suppression 11

2.9. DC Arc-fault Protection 11

3. Installation ....................................................................................... 12

3.1. Recommendations before Installation 15

3.2. Mechanical Installation 17

3.3. Electrical Installation 31

4. User Interface .................................................................................. 67

4.1 Description of LCD Panel 67

4.2 Operation State 69

4.3 Interface Types 70

4.4 Main Menu 72

4.4.1 Measurement Data ........................................ 73

4.4.2 Setting ........................................................... 74

4.4.3 Power ON/OFF .............................................. 99

4.4.4 History Record ............................................... 100

4.4.5 Device Information ........................................ 101

5. Commissioning ............................................................................... 102

5.1 Mechanical Installation 102

5.2 Conductor Connections 102

5.3 Electrical Check 102

5.4 Commissioning Steps 103

6 Operation .......................................................................................... 109

6.1 Start-Up 109

6.2 Shut-Down 109

6.3 Operation Mode 110

6.4 Grid-tied Power Generation 110

6.5 Firmware Upgrade 111

7 Maintenance and De-installation .................................................... 113

7.1 Product Maintenance 113

7.1.1 Check Electrical Connections ........................ 113

7.1.2 Clean the Air Vent Grate ................................ 113

7.1.3 Replace the Cooling Fans ............................. 114

7.1.4 Replace the Inverter ...................................... 115

7.2 De-installing the Inverter 117

8 Fault Shutdown and Troubleshooting ........................................... 118

8.1 LED Fault and Troubleshooting 118

8.2 LCD Fault and Troubleshooting 119

9 Accessories ..................................................................................... 126

9.1 Fuse Bypass Terminals 126

9.1.1 Bypass Input Terminal Instructions: ............... 126

9.2 Shade Cover (SSC-60ST) 128

9.2.1 Protection from Harsh Conditions .................. 128

9.2.2 Increased Energy Production ......................... 128

10 Technical Data.................................................................................. 129

10.1 Datasheet 129

10.2 Measurement Tolerances 131

10.3 Production Graphs 132

10.3.1 Input Voltage Derating Graph ........................ 132

10.3.2 High Temperature Derating Graph ................. 136

10.3.3 Altitude Derating Graph ................................. 136

10.3.4 Grid Voltage Derating Graph .......................... 137

11 Limited Warranty ............................................................................. 138

1

Before You Start…

Scope

This Installation and Operation manual contains important information, safety

guidelines, detailed planning and setup information for installation, as well as

information about configuring, operating and troubleshooting the

CPS SCA50KTL-DO/US-480 and CPS SCA60KTL-DO/US-480

3-Phase String Inverters. Here after in this manual this equipment may be

referred to simply as the inverters. Be sure to read this manual carefully before

operating or servicing the inverters.

Audience

The information in Chapters 2 “Overview”, 5 “User Interface", 6 "Operation”,

and 8 "Accessories" is intended for the owner and operator of the inverter, and

does not require any special training or qualifications. The information in

Chapters 3 “Installation”, 4 "Commissioning", 7 “Maintenance and

De-Installation” is intended for qualified personnel only. Qualified personnel

have training, knowledge, and experience in:

Installing electrical equipment and PV power systems (up to 1000VDC).

Applying all local installation codes.

Analyzing and eliminating the hazards involved in performing electrical

work.

Selecting and using Personal Protective Equipment (PPE).

Installation, commissioning, troubleshooting, and maintenance of the inverter

must be done only by qualified personnel.

2

Thank you for choosing a CPS 3-Phase String Inverter. These PV Inverters

are high performance and highly reliable products specifically designed for the

North American Solar market.

Instructions inside this user manual will help you solve most installation and

operation difficulties. Installation, commissioning, troubleshooting, and

maintenance of the inverter must be performed by qualified personnel. If you

encounter any problems during installation or operation of this unit, first check

the user manual before contacting CPS Customer Service. This user manual is

applicable for the following models:

CPS SCA50KTL-DO/US-480 and CPS SCA60KTL-DO/US-480

Please keep this user manual on hand for quick reference.

The manual will be periodically updated or revised due to the product

development or improvement. The latest version of this manual can be

acquired via the website at www.chintpowersystems.com.

3

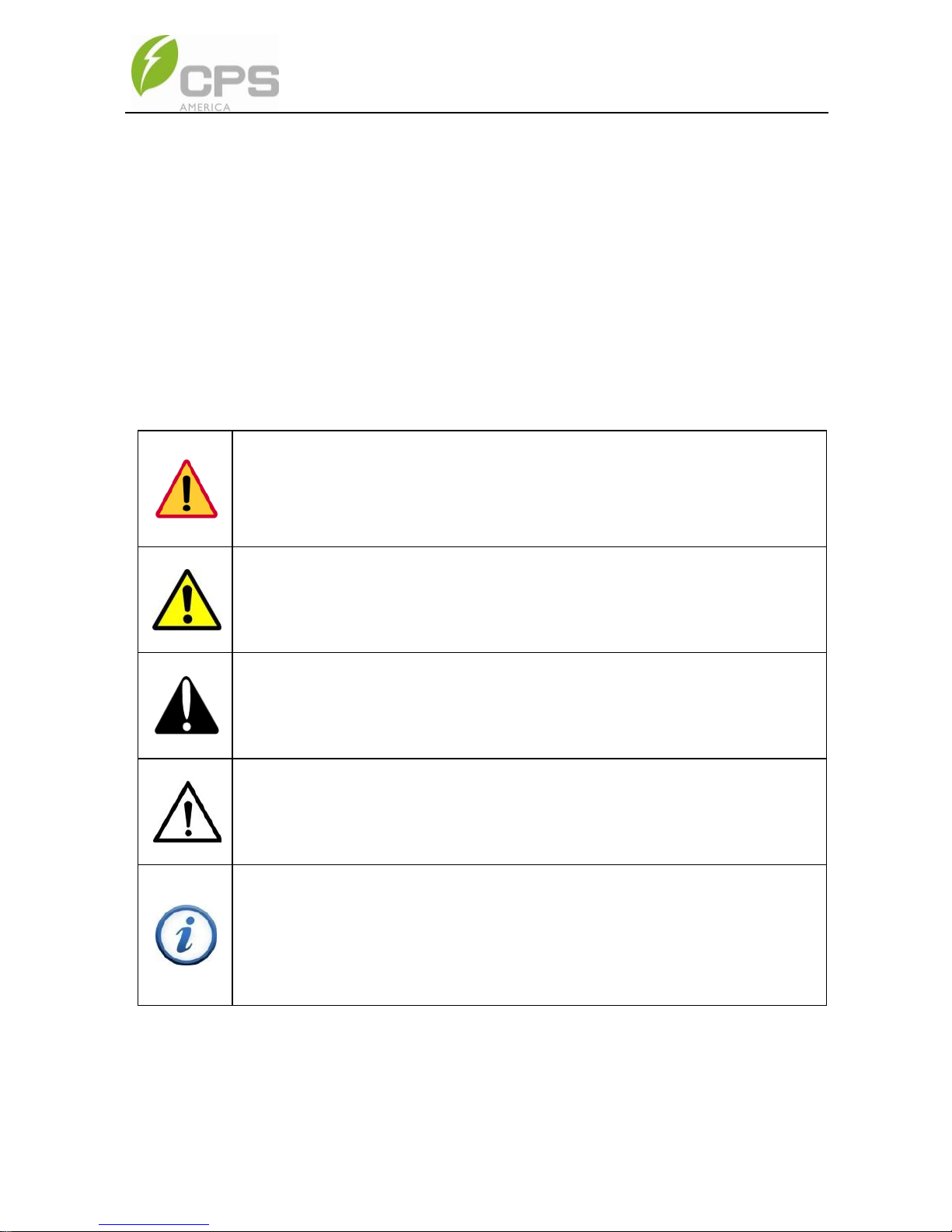

1. IMPORTANT SAFETY INSTRUCTIONS

(SAVE THESE INSTRUCTIONS)

Please read this user manual carefully before installation of the inverter. CPS

reserves the right to refuse warranty claims for equipment damage if the user

fails to install the product according to the instructions in this manual.

Warnings and symbols in this document

DANGER:

DANGER indicates a hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING:

WARNING indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION:

CAUTION indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

NOTICE:

NOTICE indicates a hazardous situation which, if not avoided, could

result in the inverter working abnormally or property loss.

INSTRUCTION:

INSTRUCTION indicates important supplementary information or

provides skills or tips that can be used to help you solve a problem or

save you time.

4

Markings on the product

HIGH VOLTAGE:

This inverter operates with high voltages. All work on the inverter

must only be performed as described in this document.

HOT SURFACE:

The inverter is designed to meet international safety standards, but

surfaces can become hot during operation. Do not touch the heat

sink or peripheral surfaces during or shortly after operation.

EARTH GROUND:

This symbol marks the location of the grounding terminal, which

must be securely connected to Ground through the AC EGC

(Equipment Grounding Conductor) to ensure operational safety.

WARNING:

All the installation and wiring connections must be performed by

qualified technical personnel. Disconnect the inverter from the PV

modules and the AC grid before maintaining or servicing the

equipment.

Risk of electric shock and fire. Use only with PV modules that have

a maximum system voltage of rating of 1000VDC or higher.

Electric shock Hazard. The DC conductors of this photovoltaic

system are normally ungrounded but will become intermittently

grounded without indication when the inverter performs the PV array

isolation measurement.

Shock Hazard. The inverter is energized from both AC and DC

sources. Disconnect all energy sources before servicing.

For continued protection against risk of fire, replace only with same

type and ratings of fuse.

5

DANGER:

Disconnect the inverter from the AC grid and PV modules before

removing covers or opening the equipment. Wait at least 5 minutes

after disconnecting from the DC and AC sources before servicing or

maintaining the inverter. Ensure hazardous high voltage and energy

inside the inverter has been discharged prior to servicing.

NOTICE:

The inverters are designed to only interconnect with an AC power

source as part of the public electric utility grid. Do not connect the AC

output of the inverters directly to any private electric utility power

equipment. The inverters are to be installed with floating or

ungrounded PV arrays only.

CAUTION:

CPS SCA50KTL-DO/US-480 and SCA60KTL-DO/US-480 inverters

weigh approximately 56kg (123.5 pounds). The wirebox portion

weighs approximately 15kg (33 pounds).

Ensure the mounting bracket is properly installed before hanging the

inverter and wirebox on the bracket. A team of two is recommended to

lift and place the inverter and wirebox into position.

INSTRUCTION:

Please check with your local electric utility supply company before

selecting a grid standard. If the inverter is operated with an incorrect

grid standard, the electric utility supply company may cancel the

interconnection agreement.

Placing the inverter into operation before the overall system complies

with the national codes, rules and safety regulations of the application

is also not permitted.

6

2. Overview

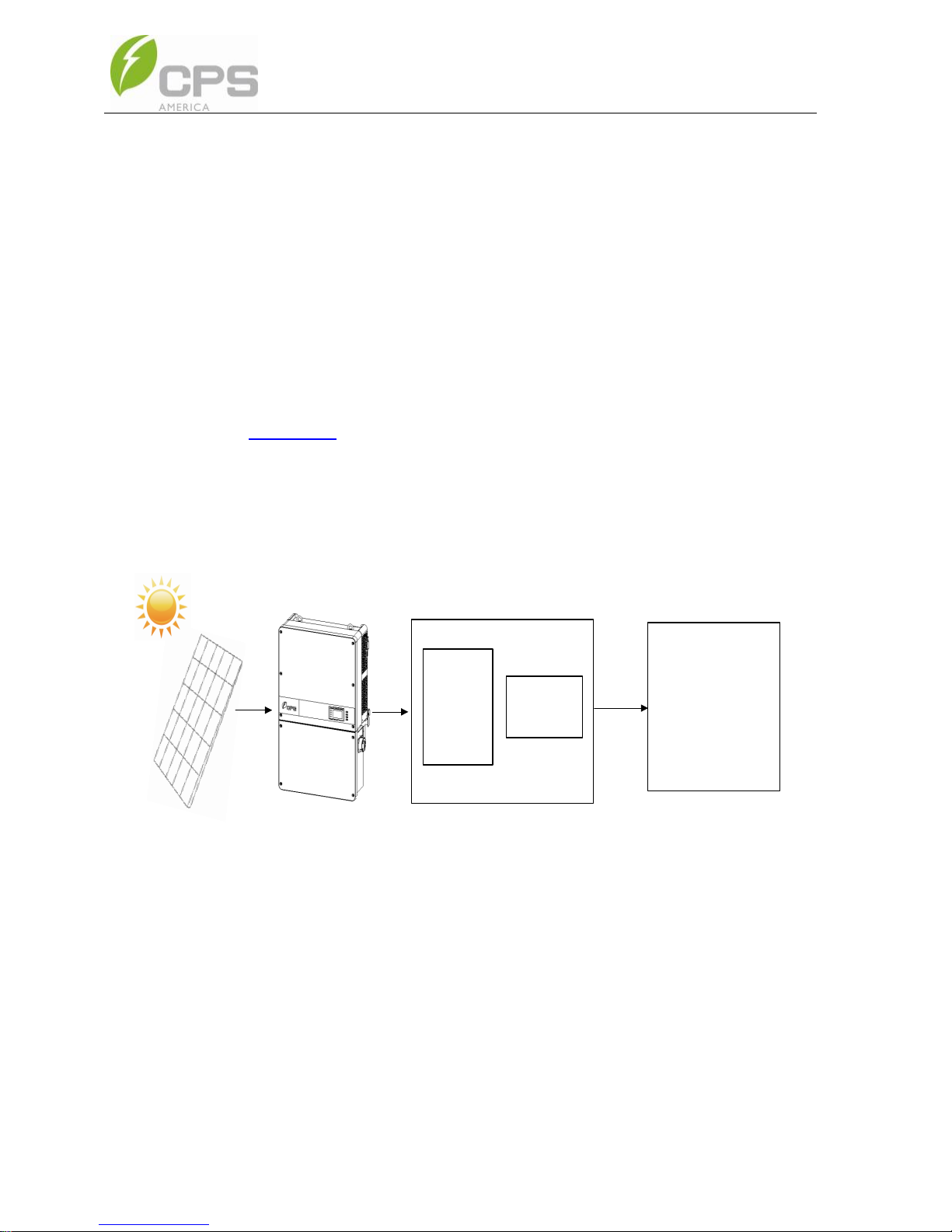

2.1. Inverter for grid-tied PV systems

CPS SCA50KTL-DO/US-480 and SCA60KTL-DO/US-480 3-Phase

Transformerless String Inverters are designed for use with an ungrounded

array in carport, commercial rooftop, and large utility scale PV grid-tied

systems. The system is generally made up of PV modules, a 3-Phase String

Inverter with a fused combiner/disconnect, and AC power distribution

equipment (Figure 2-1). The inverter converts the available DC energy from

the PV modules to AC power by synchronizing the output current to the same

frequency and phase as the AC grid. All or part of the AC power is supplied to

local loads, and the surplus power is exported to the electric utility grid.

AC Grid

Bidirectional

electric meter

AC power

distribution

equipment

Figure 2-1 Grid-tied PV system

7

2.2. Product Features

High conversion efficiency: Advanced 3-level conversion topology with

Space-Vector PWM; Max. efficiency: 98.8%, CEC efficiency: 98.5%.

Grid adaptability: IEEE 1547 Interconnect Standard and CPUC Rule 21

applicable; Reactive Power; >0.99 PF (±0.8 adjustable), Full Active Power

rating to +/-0.91 PF, and optional local or remote Active Power Curtailment.

Flexible communication: Supports standard CPS Modbus RS485, SunSpec

Modbus, and HTTPS/XML communications to ensure compatibility with 3rd

party monitoring and control systems. Flex Gateway enables further

command/control as well as remote firmware upgrades.

Wide DC input voltage range: Operating DC Input Voltage Range:

200-950VDC; Max DC input voltage: 1000VDC.

Long Service Life: Designed with thin-film capacitors to extend inverter's

service life.

3 MPPTs: Multi-channel MPPT (Maximum Power Point Tracker) enable

maximum design flexibility and energy harvest optimization over the life of the

system.

Separable Wirebox: The wirebox enables fused input of either discrete wiring

using the Standard wirebox, or an optional H4 wirebox with quick-fit connectors

for connection of industry standard conductor assemblies.

High protection degree: Powder coated aluminum NEMA 4X enclosure

meets the demanding needs of both indoor and outdoor use.

Intelligent Integration: Integrated load break rated DC/AC disconnect

switches, and up to 15 fused string inputs eliminate the need for external DC

combiner boxes, simplifying installation and the need for DC BOS equipment.

8

2.3. Product Protection Functions

Reverse polarity protection of DC input

AC and DC Short circuit protection

Arc-fault detection and circuit interruption

Anti-islanding detection with bi-directional frequency perturbation

DC Input and AC output over-voltage protection

DC Input over-current protection

DC input insulation against ground monitoring

DC injection of AC output

AC output voltage and frequency monitoring

Leakage current against ground monitoring

Internal enclosure temperature monitoring

IGBT power module temperature monitoring

9

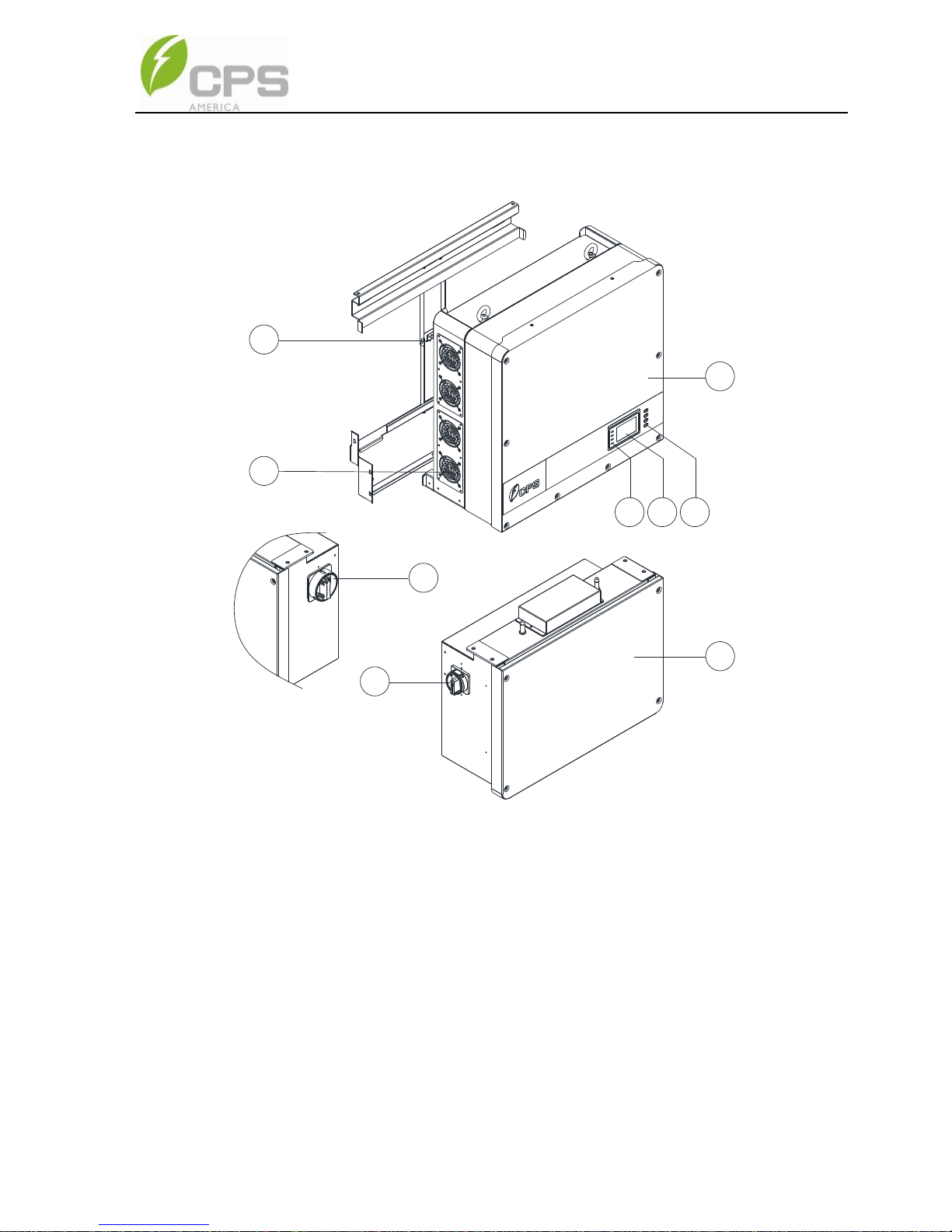

2.4. Appearance and Main Item Description

2

8

9

5 6 7

1

3

4

Figure 2-3 Diagram of the Inverter assembly

Main items of the Inverter:

① Main inverter enclosure

② Inverter wirebox

③ Inverter mounting bracket

④ Cooling fans

⑤ LED indicator lights

⑥ User LCD display

⑦ User Key buttons

⑧ DC switch: DC power on/off

⑨ AC switch: AC power on/off

10

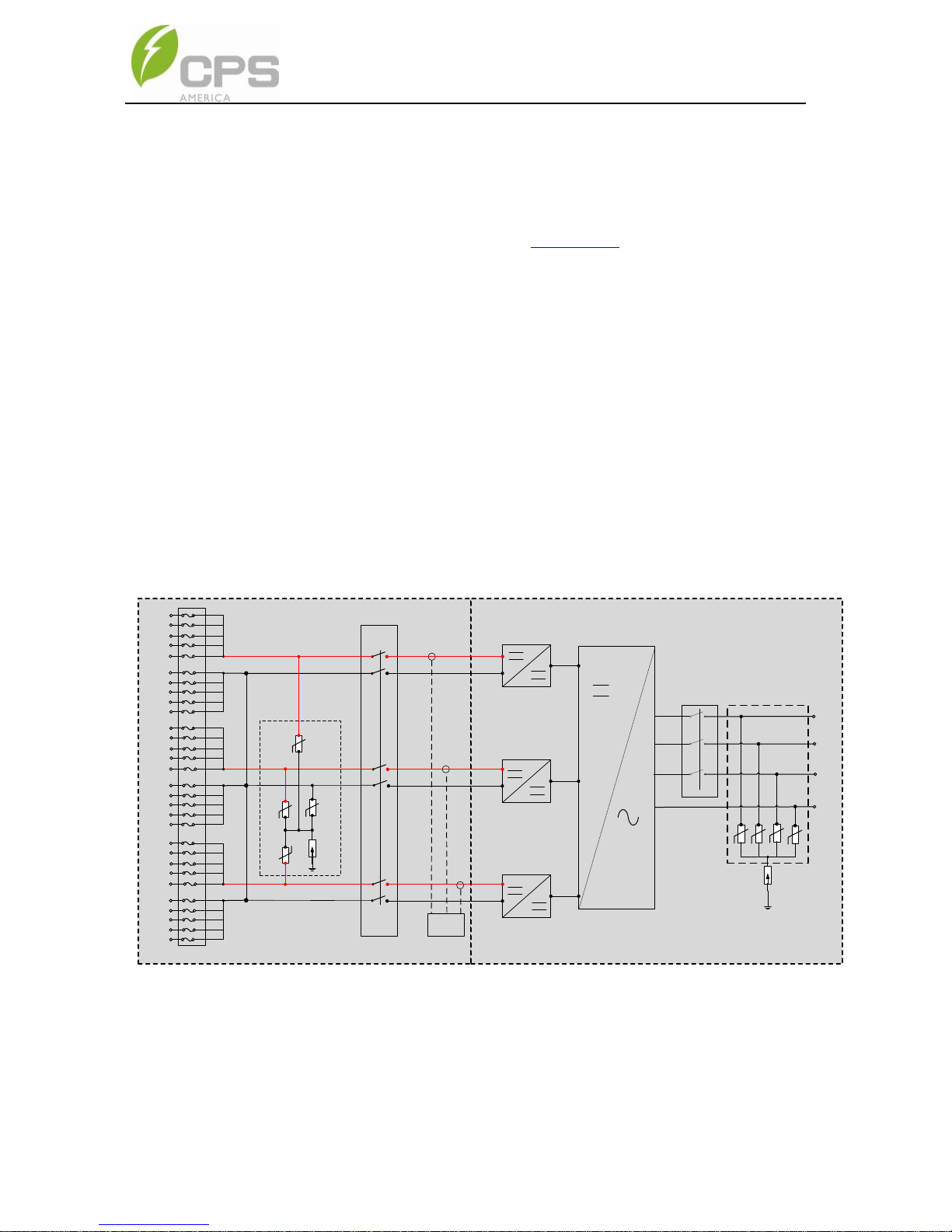

2.5. Schematic Diagram and Circuit Design

The basic electrical schematic diagram of CPS SCA50KTL-DO/US-480 and

SCA60KTL-DO/US-480 inverters are shown in Figure 2-2. The input from PV

source circuits passes through surge protection circuitry, DC EMI wave filters,

and independent DC-DC boost circuitry to achieve maximum power point

tracking and boost the voltages to a common DC bus. The inverter uses line

voltage and frequency measurements to synchronize to the grid and converts

the available PV energy to AC power by injecting balanced 3-phase AC current

into the electric utility grid. Any high frequency AC component is removed by

passing through a two-stage relay and EMI wave filter to produce high quality

AC power.

WIRE BOX INVERTER POWER HEAD

L1

L2

L3

N

PV1+

PV1+

PV1+

PV1+

PV1+

PV1-

PV1PV1-

PV1-

PV1-

MPPT1

MPPT2

AC

Output

PV Input

PV2+

PV2+

PV2+

PV2+

PV2+

PV2-

PV2-

PV2-

PV2PV2-

AC

Switch

Fuses

MPPT3

PV3+

PV3+

PV3+

PV3+

PV3+

PV3PV3-

PV3-

PV3-

PV3-

DC SPD

PV1+

DC Switch

Three

level

inverter

AFD

PV2+

PV3+

PV-

PE

AC SPD

Figure 2-2 Schematic Diagram of the CPS SCA50/60KTL-DO/US-480 Inverter

11

2.6. Anti-islanding Detection

The SCA50KTL-DO/US-480 and SCA60KTL-DO/US-480 inverters include

Unintentional Islanding detection as required by UL 1741/IEEE 1547. The

inverter will continuously make bi-directional perturbations to the frequency of

the output current by injecting a small amount of reactive power to detect a

possible islanding condition. If the grid is stable, these small perturbations will

have negligible effects on the system voltage frequency. However, in an

islanded condition the changes in reactive power will force the frequency of the

system voltage to deviate significantly, which will trigger the inverter to cease

operation and disconnect from the grid.

2.7. DC Ground Fault Protection

The inverters include residual current detection GFCI as part of the DC ground

fault detection method required by UL 1741. If there is a ground fault in the PV

array, the ground fault detection circuitry will detect leakage current, trigger an

alarm, and the inverter will cease operation. See Chapter 5 for further

information regarding GFCI Static and Dynamic trip thresholds and operation.

2.8. Surge Suppression

Standard Waveform Peak Values

Surge Category

Ring Wave

Combination Wave

B

6kV/0.5kA

6kV/3kA

"Standard 1.2/50 μs - 8/20 us Combination Wave"

"Standard 0.5 μs - 100 kHz Ring Wave"

2.9. DC Arc-fault Protection

The inverters include DC Arc-fault detection compliant with UL 1699B. The

inverter will detect electrical noise that is indicative of a DC series arc. Upon

detection of an arc-fault, the inverter will cease operation.

12

3. Installation

This chapter describes the planning and installation procedures for the

SCA50KTL-DO/US-480 and SCA 60KTL-DO/US-480 inverters. Please read

carefully and install the products following the step-by-step instructions.

The inverter and other main items are shipped in two separate packages,

consisting of A.) the main inverter enclosure and B.) the wirebox, mounting

bracket, user manual, and accessory kit. Before installation, please check that

the following items are included in the packages:

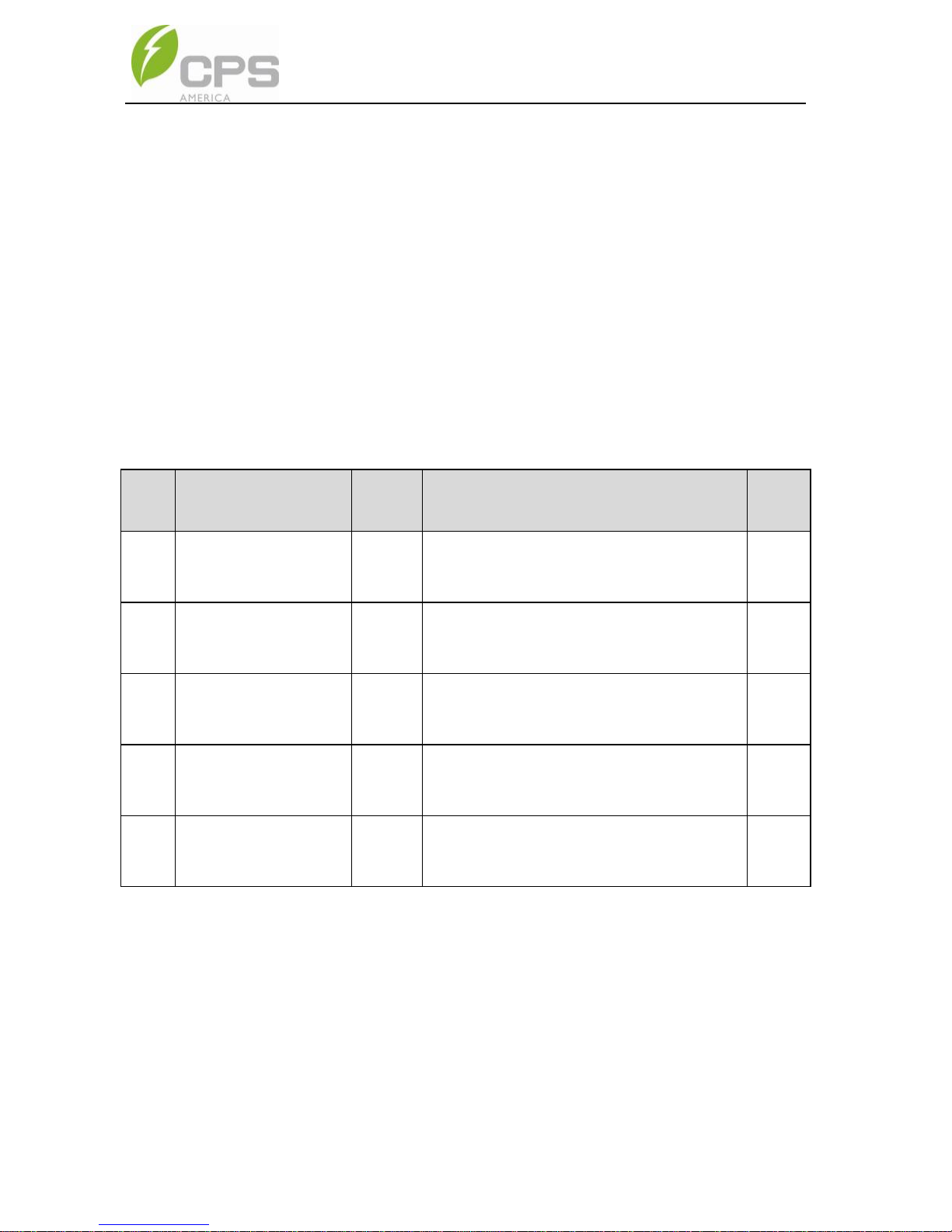

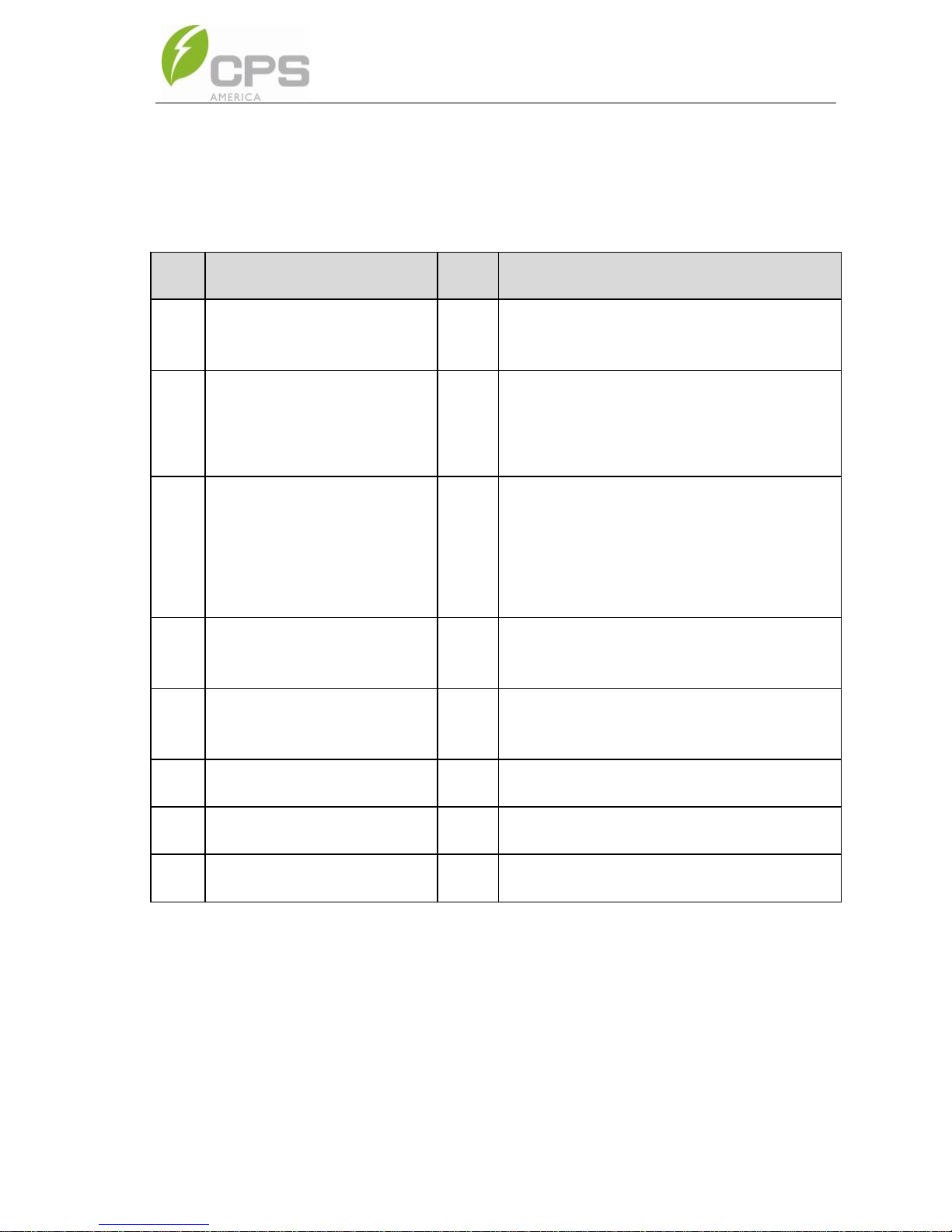

Table 3-1 Main Items

No.

Item

Q’ty

Note

Box

(1)

Main enclosure of

the PV inverter

1 A

(2)

Wiring box of the

PV inverter

1 B

(3)

Mounting bracket

1

Bracket upon which the PV inverter

is hung and mounted

B

(4)

User manual

1

PV inverter installation and

operation manual

B

(5)

Accessory kit

1

Kit contains all necessary hardware

and accessories for installation

B

13

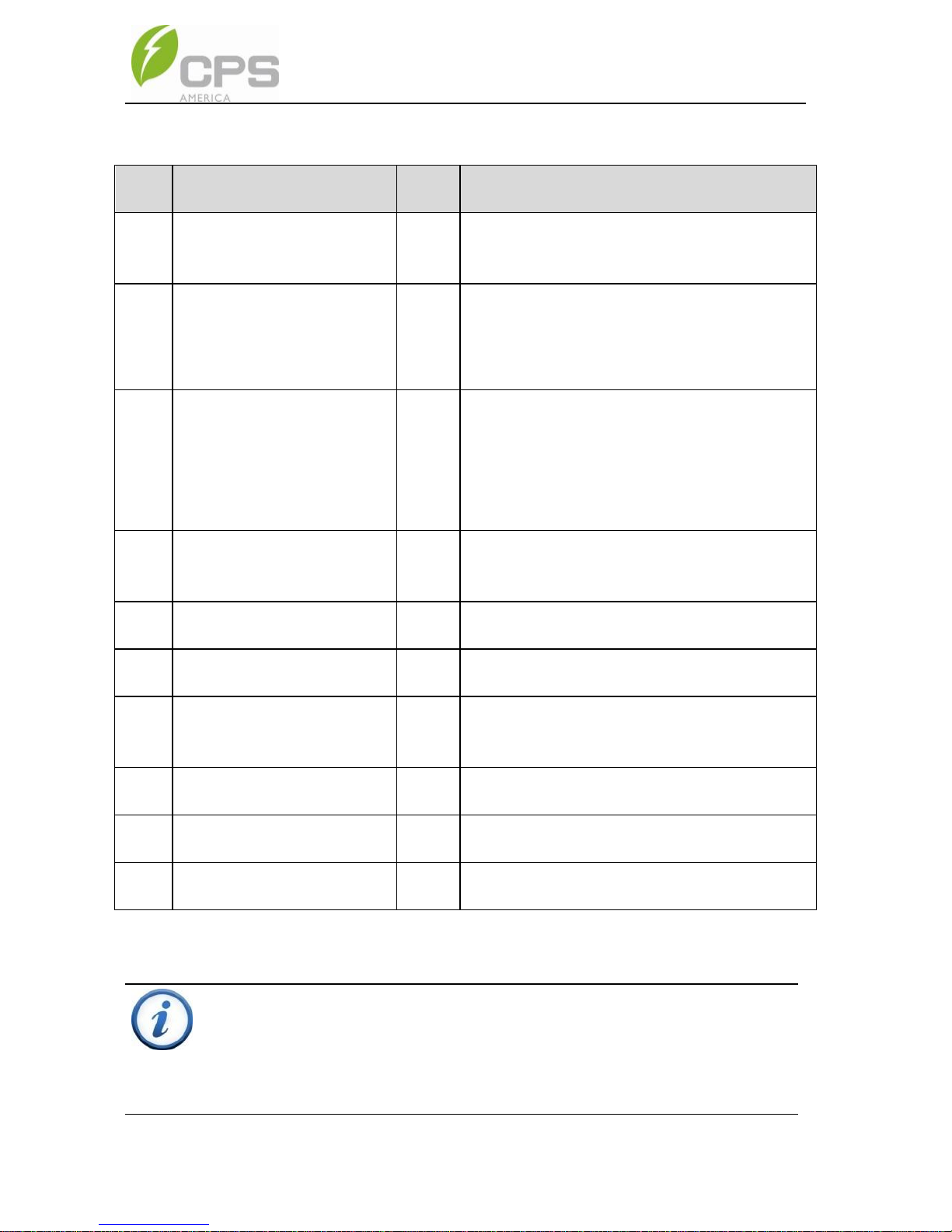

Note that the items in the Accessory Kits vary between the Standard wirebox

and H4 wirebox, the items listed below:

Table 3-2 Accessory Kit (Standard wirebox)

No.

Item

Q’ty

Note

(1)

M8 Expansion Anchors

8

For attaching the mounting bracket to

a concrete wall or surface

(2)

M8×25mm machine

bolts with integrated

lock washer

8

Used with M8 expansion anchors

(3)

M6 X18mm Phillips

screw

11

4 for securing the wiring box to the

main enclosure; 6 for securing the

inverter to the mounting bracket; 1 for

the External Ground connection

(4)

5 pin PCB connector

plug

1

For the RS485 communication

(5)

#10 AWG Wire ferrules*

33

30 for PV conductors, includes 3

spares

(6)

M8 Nut

4

For the AC terminal block

(7)

M8 Flat washer

4

For the AC terminal block

(8)

M8 Spring washer

4

For the AC terminal block

*Wire ferrules included in the accessories are not mandatory for installation.

14

Table 3-3 Accessory Kit (H4 wirebox)

No.

Item

Q’ty

Note

(1)

M8 Expansion Anchors

8

For attaching the mounting bracket to

concrete wall or surface

(2)

M8×25mm machine

bolts with integrated

lock washer

8

Used with M8 expansion anchors

(3)

M6 X18mm Phillips

screw

11

4 for securing the wiring box to the

main enclosure; 6 for securing the

inverter to the mounting bracket; 1 for

the External Ground connection

(4)

5 pin PCB connector

plug

1

For the RS485 communication

(5)

PV Connector (Male)

15

For the PV input. #14 AWG contact

(6)

PV Connector (Female)

15

For the PV input. #14 AWG contact

(7)

Tool for PV Connector

1

For assembling/disconnecting PV

Connector

(8)

M8 Nut

4

For the AC terminal block

(9)

M8 Flat washer

4

For the AC terminal block

(10)

M8 Spring washer

4

For the AC terminal block

INSTRUCTION:

The items in the Accessory Kit Table 3-2 and Table 3-3 above are for

the standard configuration. The accessories provided may vary if

optional parts are purchased.

15

3.1. Recommendations before Installation

See Chapter 10, Technical Data for specification ranges and limits.

Check that the inverter environmental specifications (protection degree,

operating temperature range, humidity and altitude, etc) meet the

requirements of the specific project location.

Make sure that the electric utility grid voltage is within range for the grid

standard chosen.

Ensure that the local electric utility grid authority has granted permission

to connect to the grid.

Installation personnel must be qualified electricians or those who have

received professional training.

Wear and use proper PPE (personal protective equipment) during

installation.

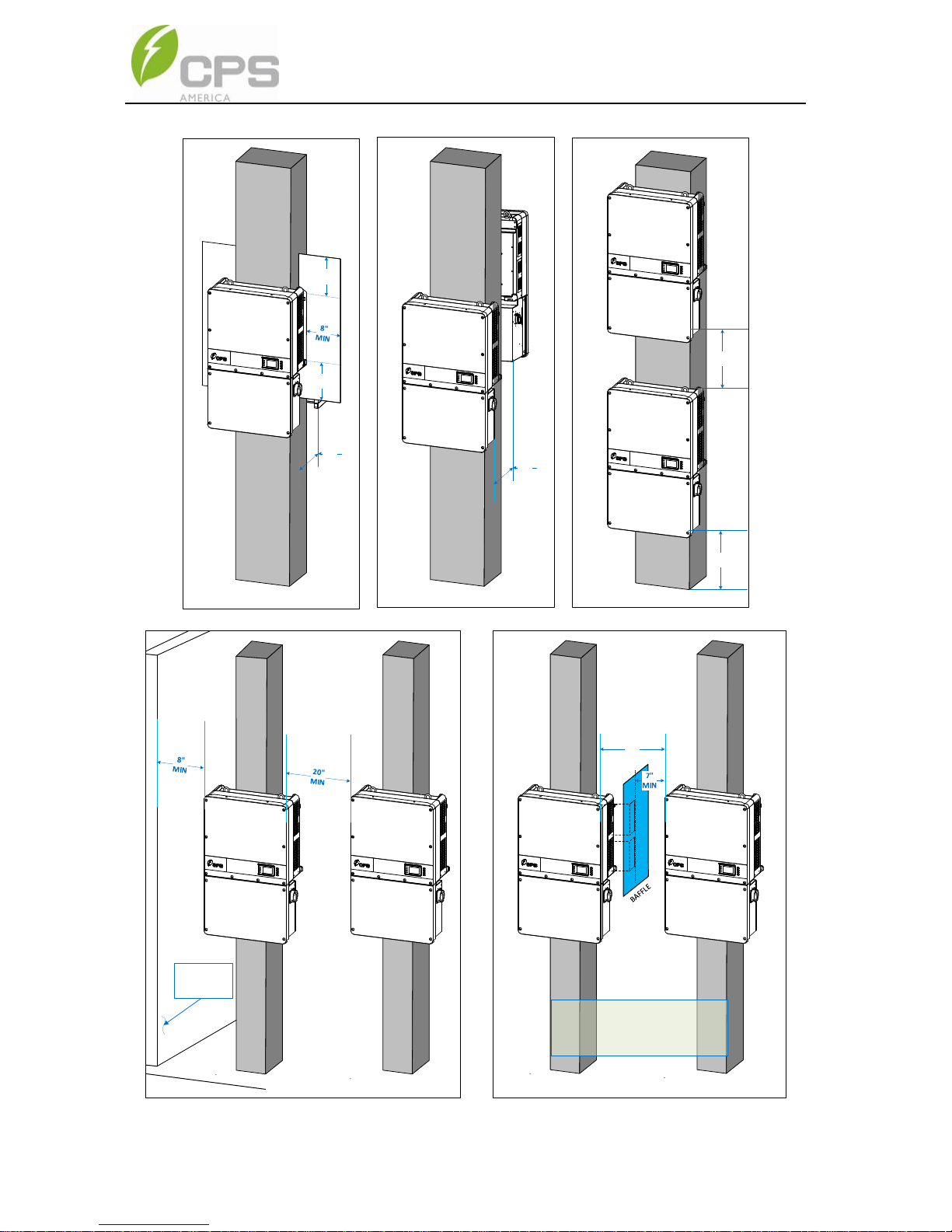

Sufficient space according to Figure 3-3 and Figure 3-4 must be

provided to allow the inverter cooling system to operate effectively.

Install the inverter away from flammable and/or combustible substances.

Avoid installing the inverter in locations that exceed the temperature

limits specified for the inverter to prevent undesirable power loss.

Do not install the inverter near an electromagnetic source which can

compromise the normal operation of electronic equipment.

NOTICE:

The allowable ambient temperature range for the

SCA50KTL-DO/US-480 and SCA 60KTL-DO/US-480 inverters is

defined based on the following conditions;

Condition 1: -40°C to 70°C, Inverter not installed, and in storage (in

packaging or unpackaged).

Condition 2: -30°C to 60°C, Inverter installed, connected to electric

utility grid and operating during daylight hours.

Condition 3: No low temp limit to 70°C, Inverter installed, connected to

electric utility grid but non-operating (daylight or nighttime hours).

16

NOTICE:

Outdoor Installations for Extended Periods without Power

CPS advises against leaving inverters mounted outdoors for an

extended period of time (more than 90 days) and/or allowing inverters

exposed to cycles of freezing temperature without both DC and AC

power connected to the inverters under normal operation.

The CPS inverter enclosures are designed to conform to NEMA4 (or

IP65), however there exists the possibility of water condensation inside

the inverter enclosure when it is left exposed to an outdoor environment

without power to operate for an extended period of time. Moisture in the

air could enter the power head of the inverter through the small opening

between wiring box and power head during the time that the wiring box

cover is opened for wiring purposes. When the inverter is exposed to

temperature swings, especially in cold weather, moisture inside the

inverter power head could condense over the aluminum heatsink area

where inverter semiconductors are mounted. Water droplets on the

heatsink may cause a short-circuit to live semiconductor devices. When

the PV source is applied to the inverter, this PV power source could

cause the inverter to fail and result in a short-circuit across the PV

array.

If such a situation in which the inverter is mounted outdoors without

operating power occurs, CPS recommends that the inverter power

head be inspected for water condensation before any DC or AC power

can be applied to inverter. Without inspection, customers will run the

risk of having inverter electronic circuit damage when power is applied

to inverter during startup. It is advised that customers contact CPS for

further advice and to arrange schedule for CPS service personnel to

perform inspection of inverter on site.

- CPS hotline: 855-584-7168

17

3.2. Mechanical Installation

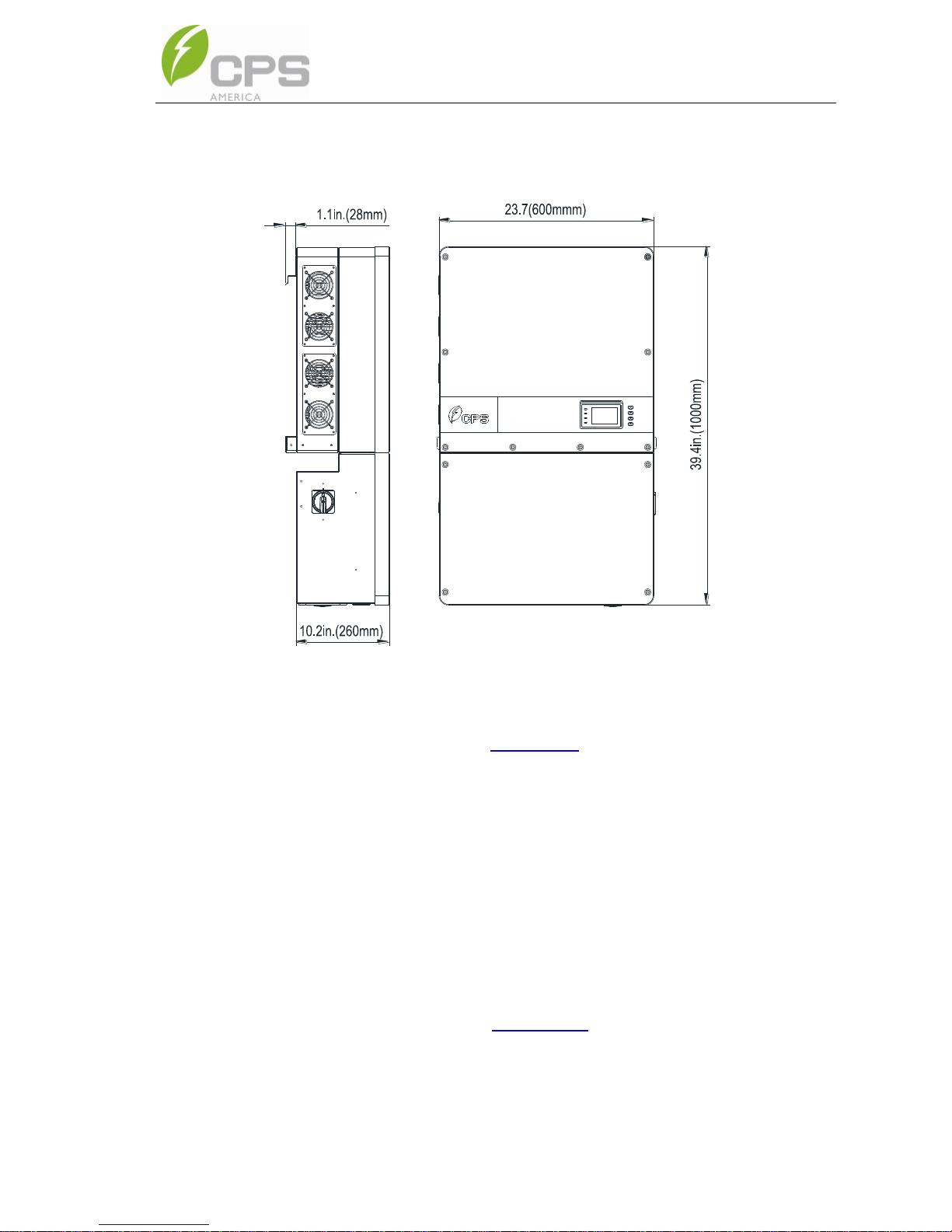

3.2.1. Dimensions

Figure 3-1 Dimensions of the Inverter

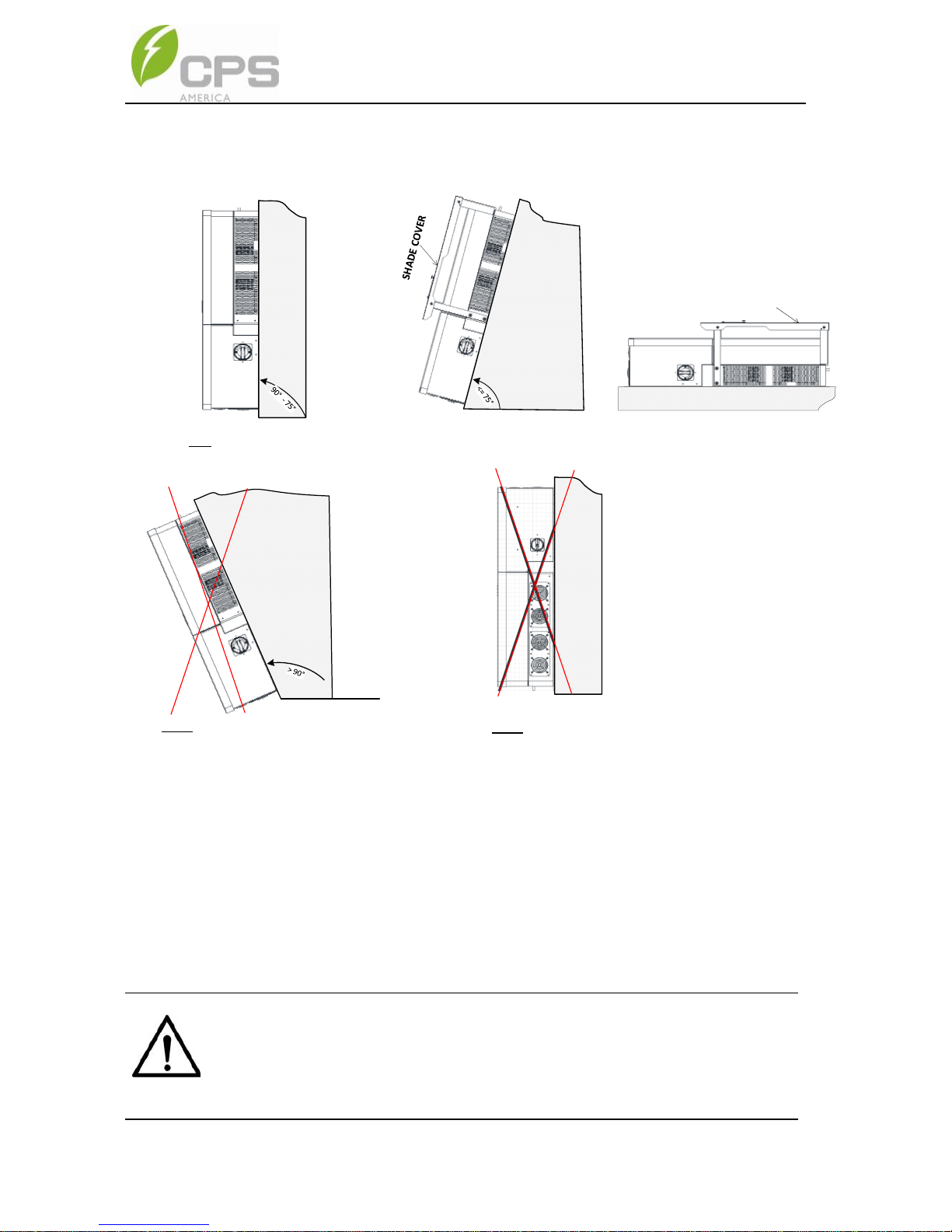

3.2.2. Installation Method (see Figure 3-2):

Ensure that the mounting structure (wall, rack, roof, etc) is suitable to

support the weight of the inverter. Follow the mounting guidelines below:

(a) If the location permits, install the inverter vertically.

(b) If the inverter cannot be mounted vertically, it may be tilted backward

at any angle from vertical to horizontal.

(c) When tilted backward at ≤75° from horizontal in an outdoor

environment, the CPS Shade Cover (SSC-60ST) accessory is

required to be installed. See Section 9.2 for more information.

(d) Do not mount the inverter leaning forward.

(e) Do not mount the inverter upside down.

18

a.) NO SHADE COVER REQUIRED

SHADE COVER

b.) SHADE COVER REQUIRED

c.) NOT > 90° TILTED FORWARD

d.) NOT UPSIDE DOWN

Figure 3-2 Inverter Mounting Options

NOTICE:

When the inverter is mounted tilted backward at ≤75° from horizontal

in an outdoor environment, the CPS Shade Cover (SSC-60ST)

accessory must be installed on the inverter to avoid direct sunlight.

19

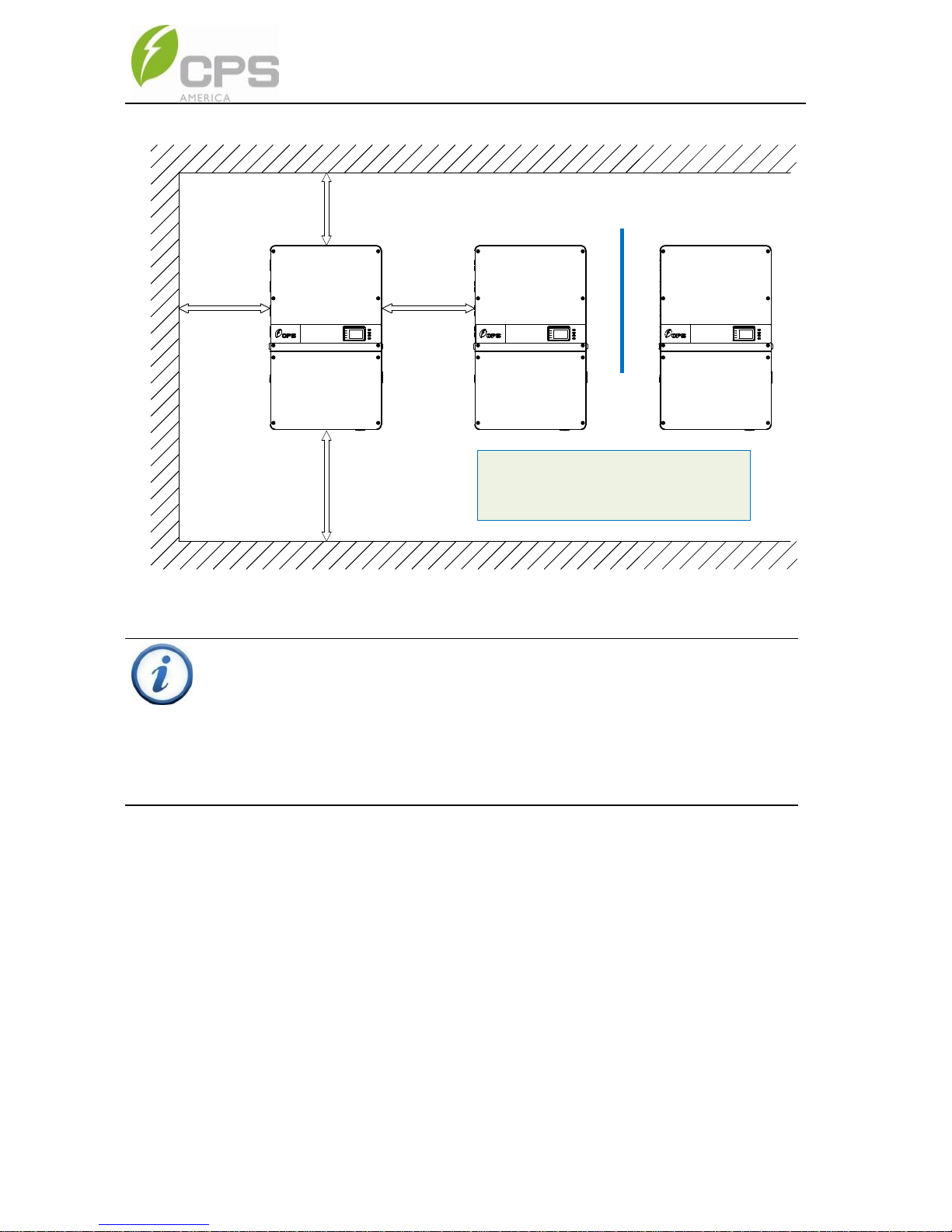

3.2.3. Installation Space Requirement

The distances between the inverters or the surrounding objects should

meet the following conditions:

≥300mm

(11.8in.)

≥300mm

(11.8in.)

≥500mm

(19.7in.)

=600mm

(23.6in.)

Note:This dimension can be modified

according to installation requirements.

NOTICE:

The spacing between two adjacently mounted inverters must be

≥19.7in (500mm). Spacing should be enlarged for installation

locations with ambient temperature higher than 45°C. Ensure that the

air space around the inverter is well ventilated. The spacing below the

inverter is intended to ensure the LCD and Keypad height are well

positioned for the user, and may be decreased, however

consideration must be taken for locations known to flood or have

seasonal snow build up.

20

300mm

(11.8in.)

300mm

(11.8in.)

500mm

(19.7in.)

=600mm

(23.6in.)

BAFFLE

BAFFLE MUST:

1. EXTEND MIN. ABOVE AND BELOW FANS

2. EXTEND 4" MIN. PAST FRONT OF INVERTER

3. LOCATED 8" MIN. FROM BOTH INVERTERS

Figure 3-3 Inverter Wall Mounting Dimensions

INSTRUCTION:

If the inverter is installed on Unistrut or the array racking (instead of

solid wall), the space from the bottom of one inverter to the top of the

inverter below may be as small as 3.9in (100mm). The spacing below

may be as small as 11.8in (300mm).

21

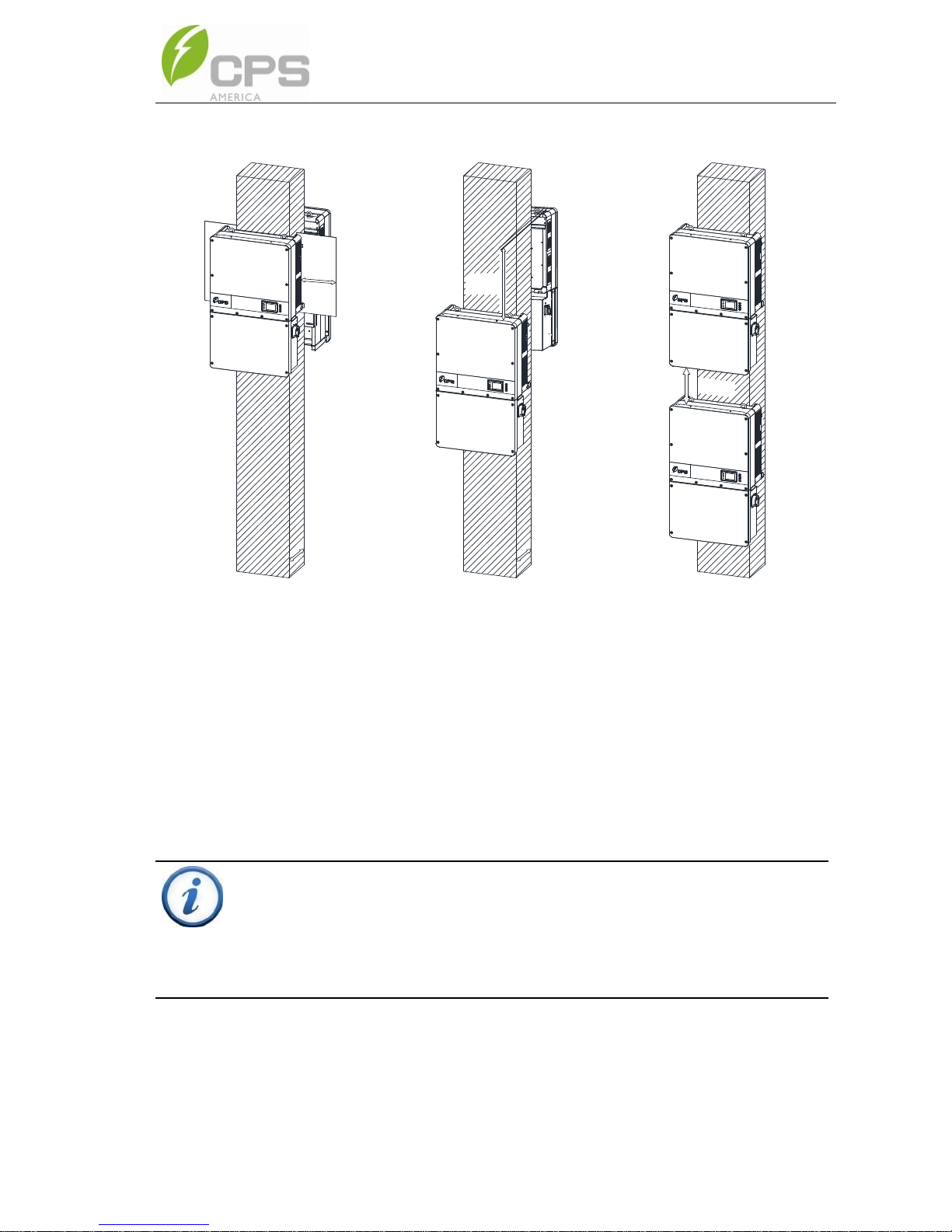

8in.

24in.

12in.

12in.

12in.

Figure 3-4 Inverter Pillar or Column Mounting Dimensions

INSTRUCTION:

If the inverter is installed on a pillar or column (instead of solid wall),

the space from the bottom of one inverter to the top of the inverter

below may be as small as 12in (300mm).

22

8"

MIN

8"

MIN

12"

MIN

BAFFLE

BAFFLE

12"

MIN

12"

MIN

12"

MIN

A)

B)

C)

D)

E)

14"

MIN

BAFFLE MUS T:

1. EXTEND MIN. ABOVE AND BE LOW FANS

2. EXTEND 4" MIN. PAST FRONT OF INVE RTER

3. LOCATED 7" MIN. FROM BOTH IN VERTERS

WALL OR

PASSIVE

CABINET

23

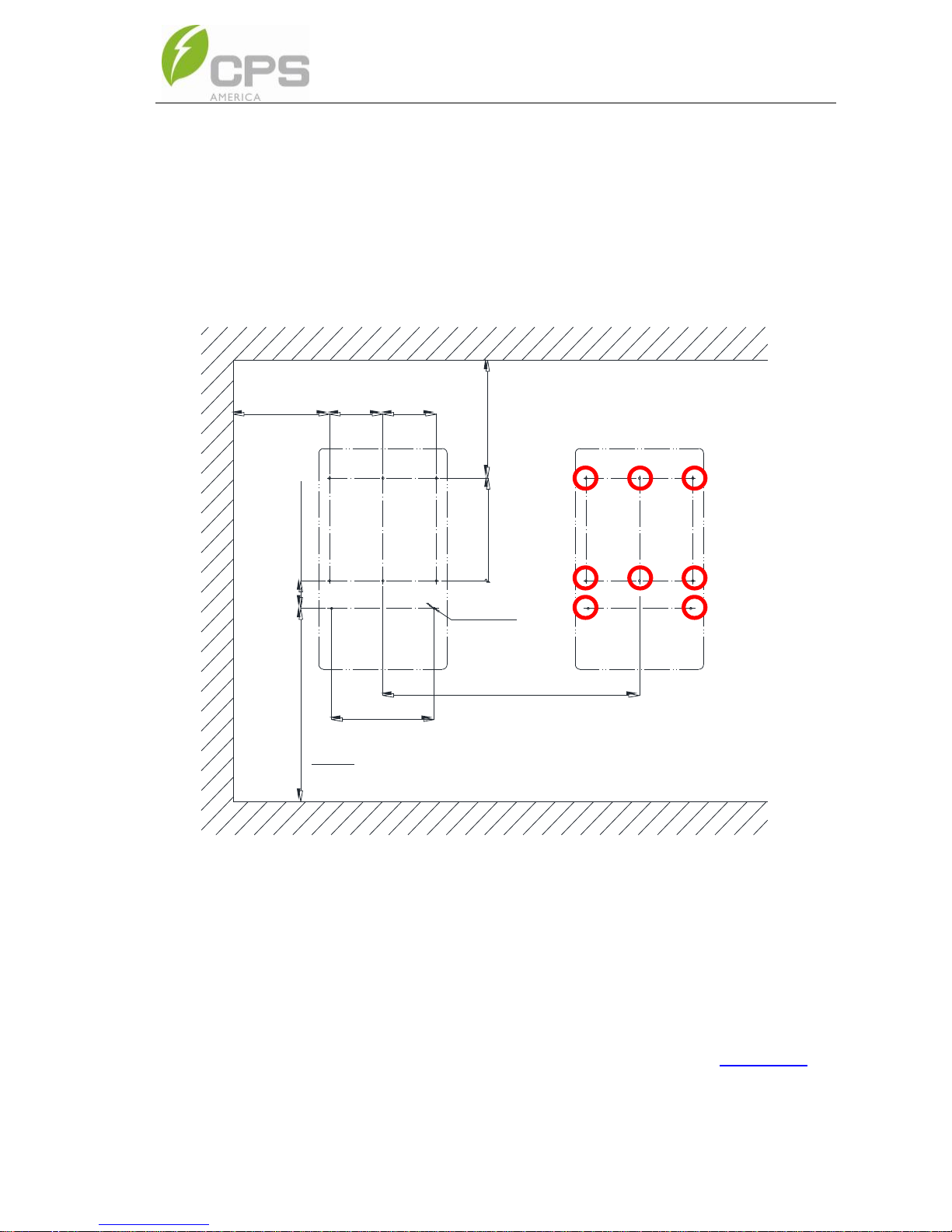

3.2.4. Mounting the Inverter onto the Bracket

1. Locate and mark the 8 holes on the wall, PV racking structure, or

bearing surface for attaching the inverter mounting bracket as shown

in Figure 3-5.

=874mm(34.4in.)

≥435mm

250mm

≥350mm

465mm

125mm(4.9in.)

≥1100mm(min.)

(13.8in.)

(9.84in.)

250mm

(9.84in.)

(17.1in.)

(43.3in)

(18.3in.)

8-? 10.0

480~500mm

(18.9~19.7in)

Note:This dimension can be modified

according to installation requirements.

Figure 3-5 Dimensions of the bracket anchoring holes for mounting

a. PV Racking Mount: Locate holes or anchors at the marked

positions; Fasten the Mounting Bracket ② with the M8x25

Assembling Bolts ③ supplied with the Accessory Kit. M8

nuts are not provided in the Accessory Kit. See Figure 3-7.

Tools Required: No. 13 wrench(es)

24

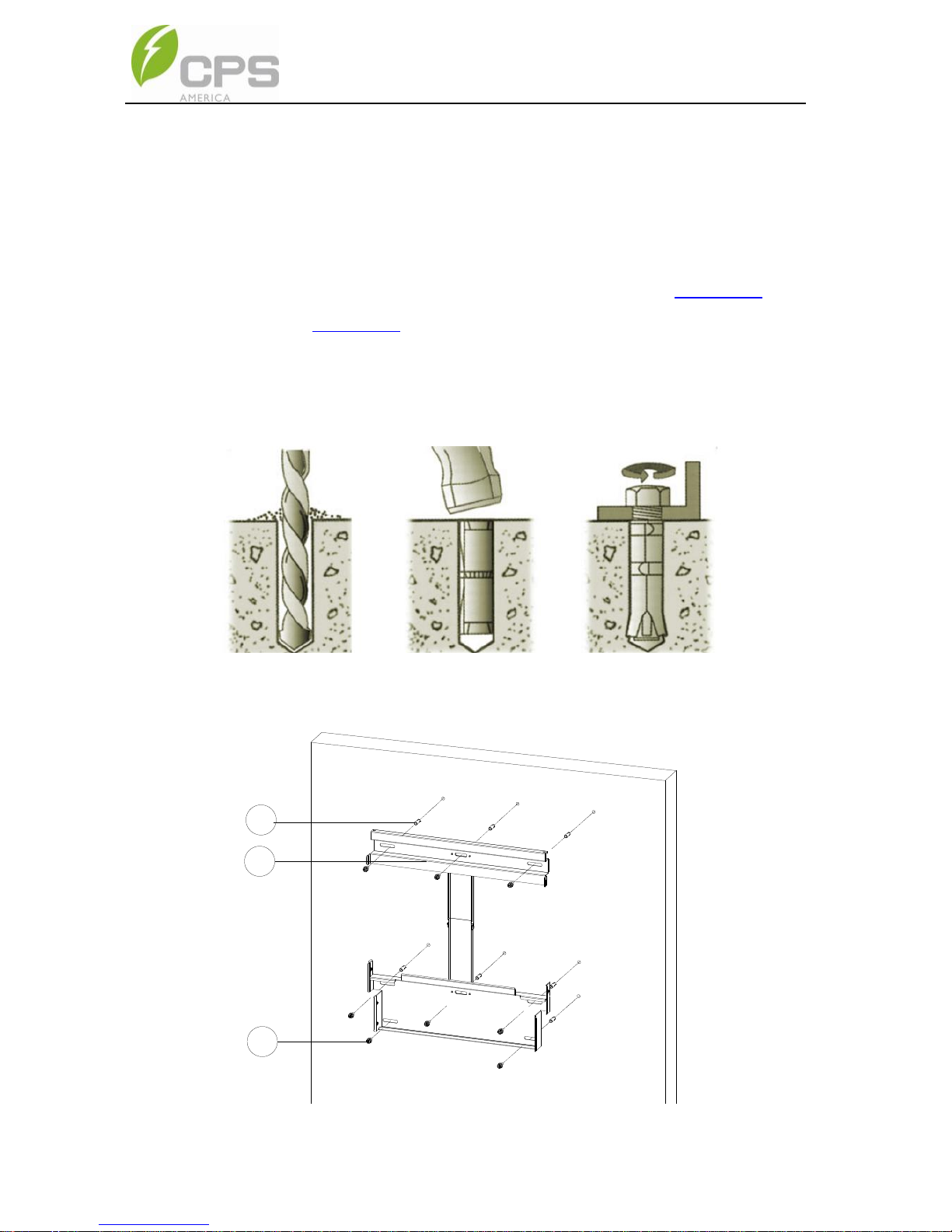

b. Concrete Wall Mount: Drill holes at the marked positions

with a 0.4in. (10mm) masonry bit and insert the M8

Expansion Anchors ① into the holes; Fasten the

Mounting Bracket ② with the M8x25 Assembling

Bolts ③ supplied with the Accessory Kit. Figure 3-6 and

Figure 3-7.

Tools Required: Electric drill (Ф10mm/0.4in. masonry bit),

No. 13 wrench

Figure 3-6 Drill holes, set Anchors, and tighten Assembling Bolts

1

2

3

Figure 3-7 Secure the Mounting Bracket

Loading...

Loading...