CPS SCA23KTL-DO/US-480, SCA28KTL-DO/US-480 Installation And Operation Manual

1

CPS SCA Series Grid-tied PV Inverter

CPS SCA23/28KTL-DO/US-480

Installation and Operation Manual

Version 1.4

SHANGHAI CHINT POWER SYSTEMS CO., LTD.

2

Table of Contents

Before You Start… ...................................................................................... 4

Chapter 1 IMPORTANT SAFETY INSTRUCTIONS .................................... 5

Chapter 2 Overview .................................................................................... 8

2.1 Inverter for grid-tied PV systems ................................................... 8

2.2 Product features ............................................................................ 8

2.3 Product protection functions ......................................................... 9

2.4 Circuit structure design ................................................................. 9

2.5 Appearance Description ................................................................ 11

Chapter 3 Installation ................................................................................. 12

3.1 Recommendations before installation ........................................... 14

3.2 Mechanical installation .................................................................. 15

3.3 Electrical installation ..................................................................... 28

3.3.1 DC connection ....................................................................... 29

3.3.2 AC and ground connection .................................................... 41

3.3.3 Communication connection ................................................... 47

Chapter 4 Commissioning ......................................................................... 56

4.1 Commissioning Checklist .............................................................. 56

4.1.1 Mechanical installation .......................................................... 56

4.1.2 Cable connections ................................................................. 56

4.1.3 Electrical check ..................................................................... 56

4.2 Commissioning steps .................................................................... 56

Chapter 5 User Interface ............................................................................ 59

5.1 Description of LCD panel .............................................................. 59

5.2 Operation state ............................................................................. 61

5.3 Interface types .............................................................................. 61

5.4 Menu functions.............................................................................. 63

5.4.1 Operation information ............................................................ 64

5.4.2 Alarm ..................................................................................... 65

3

5.4.3 History ................................................................................... 65

5.4.4 System configuration ............................................................. 67

5.4.5 Power dispatch ...................................................................... 70

5.4.6 System protection parameters setup ..................................... 70

5.4.7 System control parameters ................................ .................... 72

5.4.8 Arcing fault current interruption .............................................. 79

Chapter 6 Operation ................................................................................... 82

6.1 Start-up ......................................................................................... 82

6.2 Shut-down ..................................................................................... 82

6.3 Operation mode............................................................................. 82

6.4 Grid-tied power generation ............................................................ 84

Chapter 7 Maintenance and De-installation .............................................. 86

7.1 Fault shut down and troubleshooting ............................................. 86

7.1.1 LED fault and troubleshooting ............................................... 86

7.1.2 LCD fault and troubleshooting ............................................... 86

7.2 Product maintenance .................................................................... 94

7.2.1 Check the electrical connection ............................................. 94

7.2.2 Clean the air vent filter ........................................................... 94

7.2.3 Replace cooling fans ............................................................. 94

7.2.4 Replace the inverter .............................................................. 97

7.3 De-installing the inverter ................................................................ 99

Chapter 8 Technical Data

100

Chapter 9 Limited Warranty ............................................................................................ 104

Appendix: Instruction of inverter selection ................................................................... 105

4

Before You Start…

This manual contains important information regarding installation and safe

operation of this unit. Be sure to read this manual carefully before using.

Thank you for choosing this CPS Grid-tied PV Inverter. This PV Inverter is a

high performance and highly reliable product specifically designed for the North

American Solar market.

If you encounter any problems during installation or operation of this unit, first

check the user manual before contacting your local dealer or supplier. This

user manual is applicable for the following 2 models: CPS

SCA23KTL-DO/US-480 and CPS SCA28KTL-DO/US-480.

Instructions inside this user manual will help you solve most installation and

operation difficulties. Contact your local supplier if the problem still exists.

Please keep this user manual on hand for quick reference.

5

Chapter 1 IMPORTANT SAFETY INSTRUCTIONS

(SAVE THESE INSTRUCTIONS)

Please read this user manual carefully before product installation. CPS

reserves the right to refuse warranty claims for equipment damage if the user

fails to install the equipment according to the instructions in this manual.

Warnings and symbols in this document

DANGER:

DANGER indicates a hazardous situation which, if not avoided, will

result in death or serious injury.

WARNING:

WARNING indicates a hazardous situation which, if not avoided,

could result in death or serious injury.

CAUTION:

CAUTION indicates a hazardous situation which, if not avoided,

could result in minor or moderate injury.

NOTICE:

NOTICE indicates a hazardous situation which, if not avoided,

could result in equipment working abnormally or property loss.

INSTRUCTION:

INSTRUCTION indicates important supplementary information or

provides skills or tips that can be used to help you solve a problem

or save you time.

6

Markings on the product

HIGH VOLTAGE:

The product works with high voltages. All work on the product

must only be performed as described in this document.

HOT SURFACE:

The equipment is designed to meet international safety

standards, but surfaces can become hot during operation. Do

not touch the heat sink or peripheral surfaces during or shortly

after operation.

EARTH GROUND:

This symbol marks the location of grounding terminal, which

must be securely connected to the earth through the PE

(protective earthing) cable to ensure operational safety.

WARNING:

All the installation and wiring connections should be performed only

by qualified technical personnel. Disconnect the inverter from PV

modules and the Power Grid before maintaining and operating the

equipment.

DANGER:

Please disconnect the inverter from AC grid and PV modules before

opening the equipment. Make sure hazardous high voltage and

energy inside the equipment has been discharged.

Do not operate or maintain the inverter until at least 5 minutes after

disconnecting all sources from DC and AC sides.

7

NOTICE:

This inverter is designed to connect AC power only to the public grid.

Do not connect the AC output of this equipment directly to any private

AC power equipment.

CAUTION:

CPS SCA23/28KTL-DO series inverter is approx 55kg (≈122

pounds).

Please ensure the mounting is properly installed before hanging the

inverter on the bracket.

CAUTION:

CPS SCA23/28KTL-DO series inverter have the Arc Fault Detection

feature in the disabled mode by default. Please ensure that this

setting meets local code requirements. If you need to enable this

feature for your install then please call our HOTLINE: 855-584-7168,

or contact your local sales or service manager for assistance.

INSTRUCTION:

Please check with your local electricity supply company before

selecting the grid standard. If the inverter is operated with a wrong

grid standard, the electricity supply company may cancel the

operation license.

Putting the inverter into operation before the overall system complies

with the national rules and safety regulation of the application is not

permitted.

8

Chapter 2 Overview

2.1 Inverter for grid-tied PV systems

CPS SCA23/28KTL-DO/US-480 series inverter is suitable for use with

commercial and large scale PV grid-tied systems. The system is generally

made up of PV modules, DC power distribution equipment, PV inverter and AC

power distribution equipment (Figure 2-1). The inverter converts the DC from

PV modules to AC with the same frequency and phase as the AC grid. All or

part of the AC power is supplied to local loads, and the surplus power is

supplied to the electricity grid.

DC power

distribution

equipments

AC Grid

Bidirectional

electric meter

AC power

distribution

equipments

Figure 2-1 Grid-tied PV system

2.2 Product features

High conversion efficiency:Advanced 3-level conversion technology;

Max. efficiency: 98.6%;CEC efficiency: 98%

Strong grid adaptability: 7 grid standards applicable; Reactive power

adjustable; PF value:±0.8, Remote Curtailment

Flexible communication: Supports standard modbus communications to

ensure compatibility with 3rd party monitoring and control systems

Wide DC input voltage range: Operating DC Input Voltage Range:

300-900Vdc; Max DC input voltage: 1000V

Long service life: Uses thin-film capacitors to extend inverter’s service life

9

2 MPPTs: Dual and independent MPPT (Maximum Power Point Tracking)

enable maximum design flexibility and optimize energy harvest over the life

of the system

Integrated AFCI: Integrated AFCI (Arc Fault Circuit Interruption) feature

enables the need to meet advanced local electrical and grid codes. This

feature is disabled by default but can be enabled if needed in the field.

Please contact CPS at HOTLINE: 855-584-7168 number to get

instructions.

High protection degree: NEMA 4 protection degree meets the needs of

both indoor and outdoor use;

Intelligent Integration: Embedded DC/AC switches and up to 8 fused

string inputs eliminates the need for external combiner boxes and

simplifies installation.

2.3 Product protection functions

Polarity reverse protection of DC input

Short circuit protection

DC input insulation against ground monitoring

AC output voltage and frequency monitoring

Integrated Arc Fault Detection and Interruption *

Leakage current against ground monitoring

Monitoring of DC injection from AC output

Anti-islanding protection

Input and output over-voltage protection

Input over-current protection

Environmental temperature monitoring

Module temperature monitoring

* The AFCI function ships from factory in disabled mode, to enable this feature please contact CPS at

HOTLINE: 855-584-7168 number to get instructions.

10

2.4 Circuit structure design

The basic schematic diagram of CPS SCA23/28KTL-DO/US-480 series

inverter is shown in Figure 2-2.

The input of PV modules passes through surge protection circuitry, DC

EMI wave filter, and the front-end boost circuitry to achieve maximum power

tracking and boost up voltages. The output of the inverter converts the DC

voltage to 3-phase AC voltage. The high frequency AC components are

removed with a wave filter. Then the 3-phase AC voltage is passed through

two-stage relays and EMI wave filter to produce high quality AC power.

PE

Three level

inverter

N

L1

L2

L3

PV1+

PV1+

PV1+

PV1+

PV1PV1PV1PV1-

DC

Switch

MPPT1

MPPT2

PV1+

PV1-

PV2+

PV2-

AC

Output

PV

Input

PV2+

PV2+

PV2+

PV2+

PV2PV2PV2PV2-

AFD

AC

Switch

Fuses

Figure 2-2 Schematic diagram of CPS SCA23/28KTL-DO series inverter

11

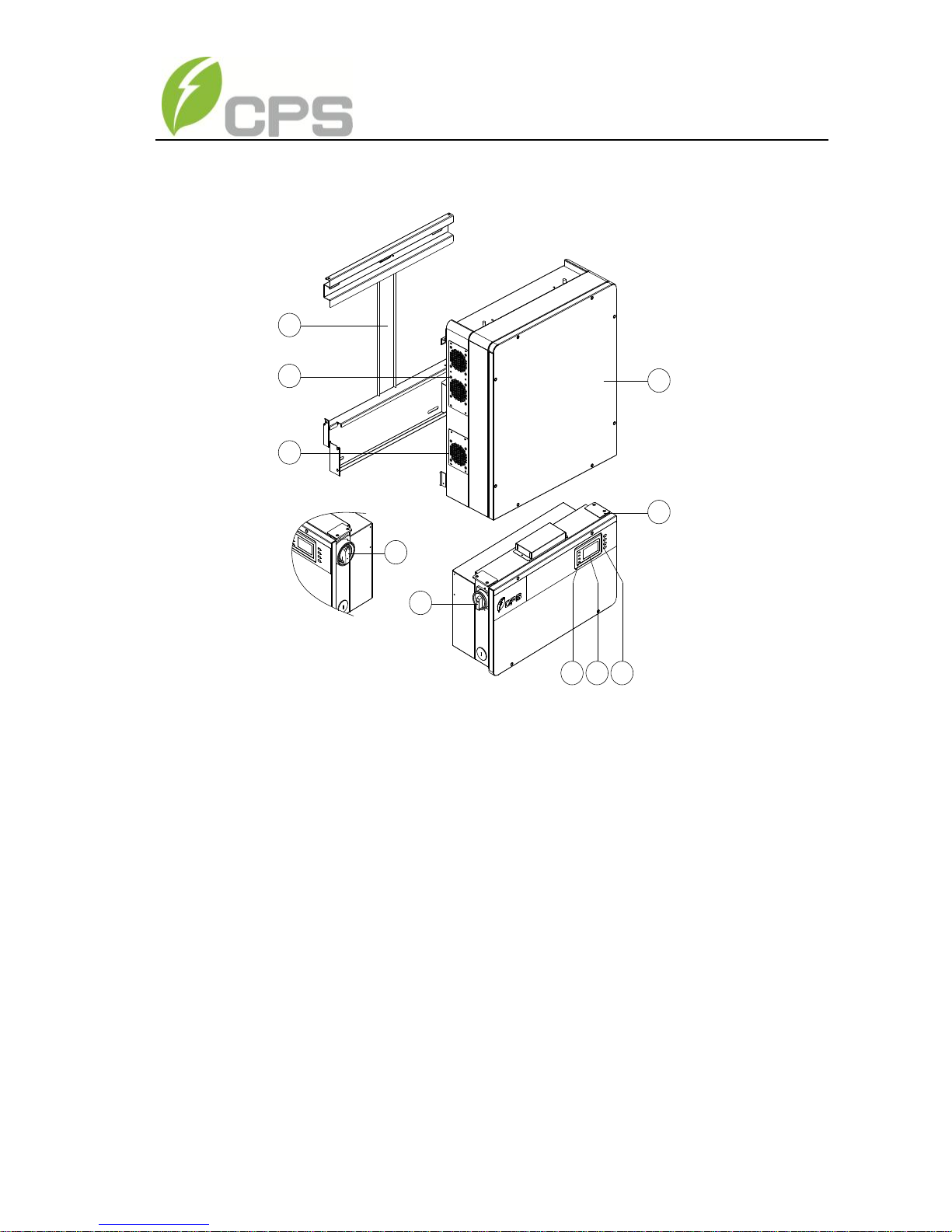

2.5 Appearance Description

1

3

4

4

9

2

5 6 7

8

Figure 2-3 Appearance sketch of CPS SCA23/28KTL-DO series inverter

Main items of the inverter:

1) Main housing of the inverter

2) Wiring box of the inverter

3) Mounting bracket

4) External cooling fans

5) LED indication lights

6) LCD display

7) Key buttons

8) DC switch: DC power on/off

9) AC switch: AC power on/off

12

Chapter 3 Installation

Below is the installation procedure for the inverter. Please read carefully and

install the product step-by-step.

Before installation, please check that the following items are included in

the package:

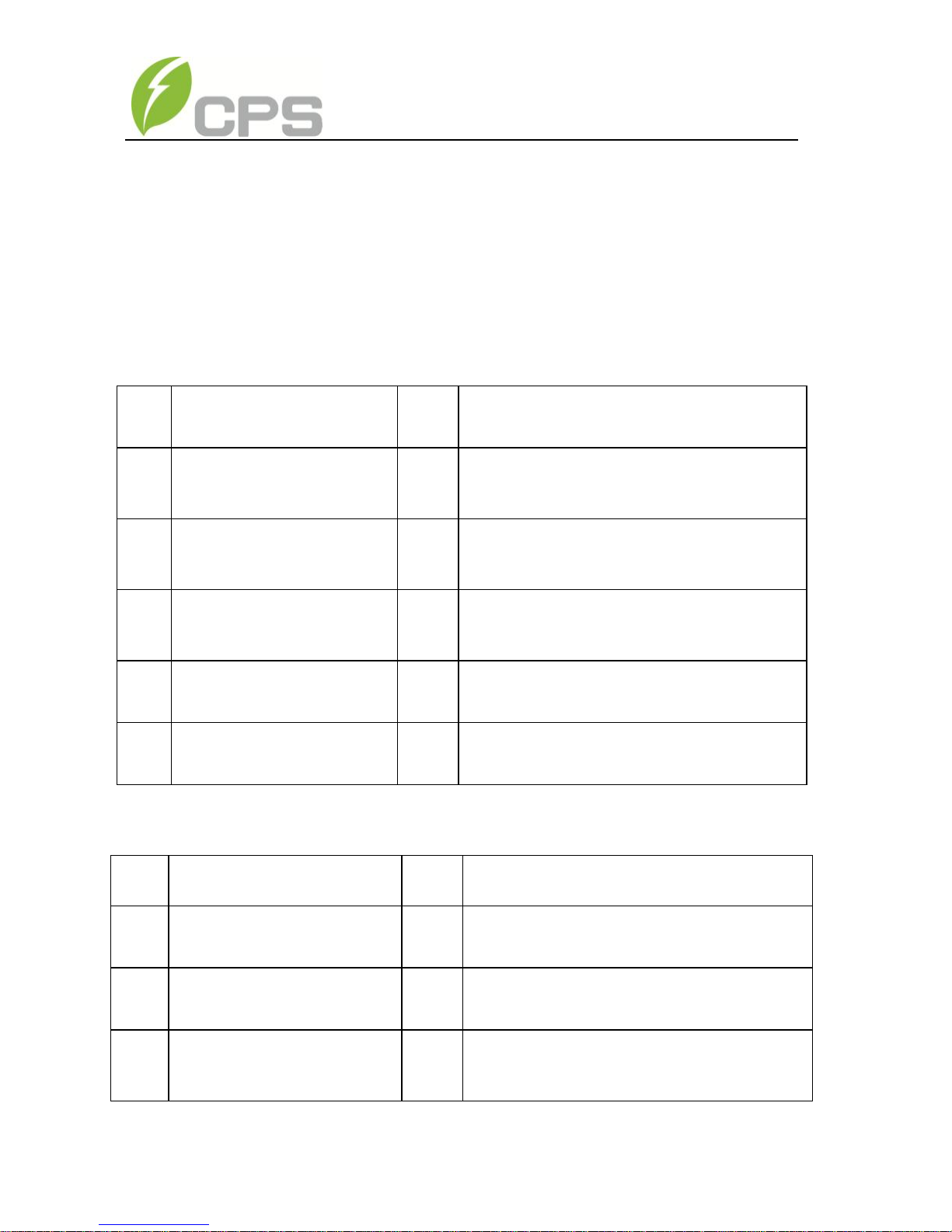

Table 3-1 Main items

No.

Item

Q’ty

Note

(1)

Main housing of the PV

inverter

1 (2)

Wiring box of the PV

inverter

1

(3)

Mounting bracket

1

Upon which inverter is hung and

mounted onto a wall

(4)

User manual

1

Installation and operation manual

(5)

Accessory kit

1

Contains all necessary accessories

The (5) Accessory kit contains items listed below:

Table 3-2 Accessories

No.

Item

Q’ty

Note

(1)

M8 Expansion tubes

8

For mounting bracket

(2)

M8×25 assembling bolts

8

For mounting bracket

(3)

M6X16 screw

6

For wiring box and main housing; 2

spare parts

13

(4)

M5X10 screw

8

For mounting bracket and inverter,

external ground connection

(5)

M3X8 screw

2

For Partition plate; 1 spare part

(6)

M5 flange nut

2

For internal ground stud connection; 1

spare part

(7)

Lifting eye nut M10

2

For lifting the main housing

(8)

OT type terminal

2

For ground connection

(9)

Pre-insulated end

ferrule for AC side

5

For AC output cables, 1 spare part

(10)

Pre-insulated end

ferrule

8

For ground cables

(11)

Pre-insulated end

ferrule for DC side

20

For DC input cables, 4 spare parts

(12)

RJ45 connecter

4

For RS485 or Ethernet

communication, 2 spare parts

(13)

5 pin connector

1

For RS485 communication

(14)

3 pin connector

1

For dry contact communication

(15)

Partition plate

1

For partition signal cable and the

power cable

INSTRUCTION:

The items in the accessory kit table above are for the standard

configuration. The accessories may vary if optional parts are

purchased.

14

3.1 Recommendations before installation

Check that the product environmental specifications (protection degree,

operating temperature range, humidity and altitude, etc) meet the

requirements of the specific project location;

Make sure that the power grid voltage is within normal range;

Ensure that the local electricity supply authority has granted permission

to connect to the grid;

Ensure that local code requirement is met by enabling the AFCI function

from the LCD screen. This feature is disabled by default but can be

enabled in the field.

Installation personnel must be qualified electricians or people who have

received professional training;

Sufficient space is provided to allow the inverter cooling system to

operate normally;

Install the inverter away from flammable and explosive substances;

Avoid installing the inverter in locations that exceed the temperature

limits specified in the inverter data sheet to limit undesirable power loss;

Do not install the inverter near the electromagnetic source which can

compromise the normal operation of electronic equipment;

15

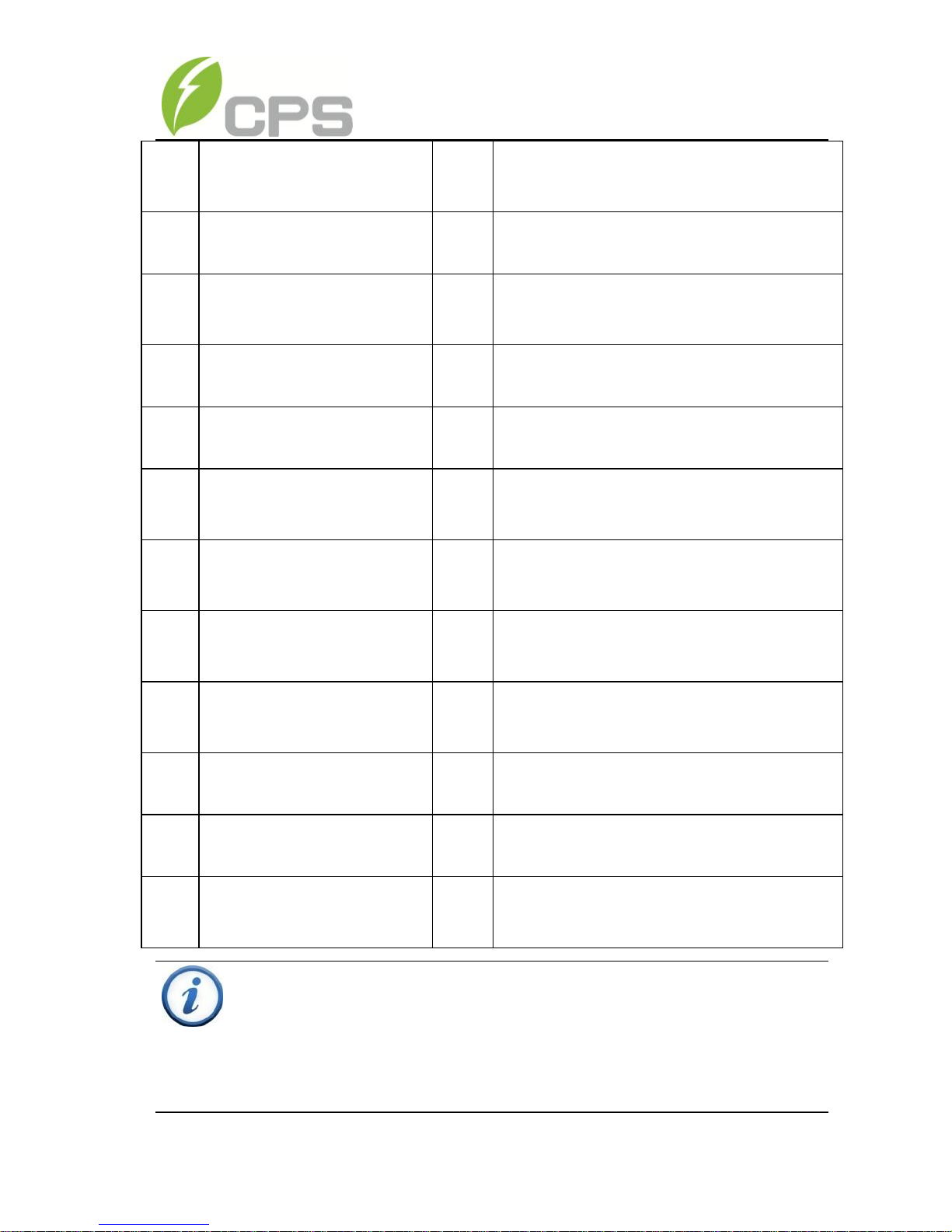

3.2 Mechanical installation

1) Dimensions

DC DISCONNECT

Figure 3-1 Dimensions of CPS SCA23/28KTL-DO series inverter

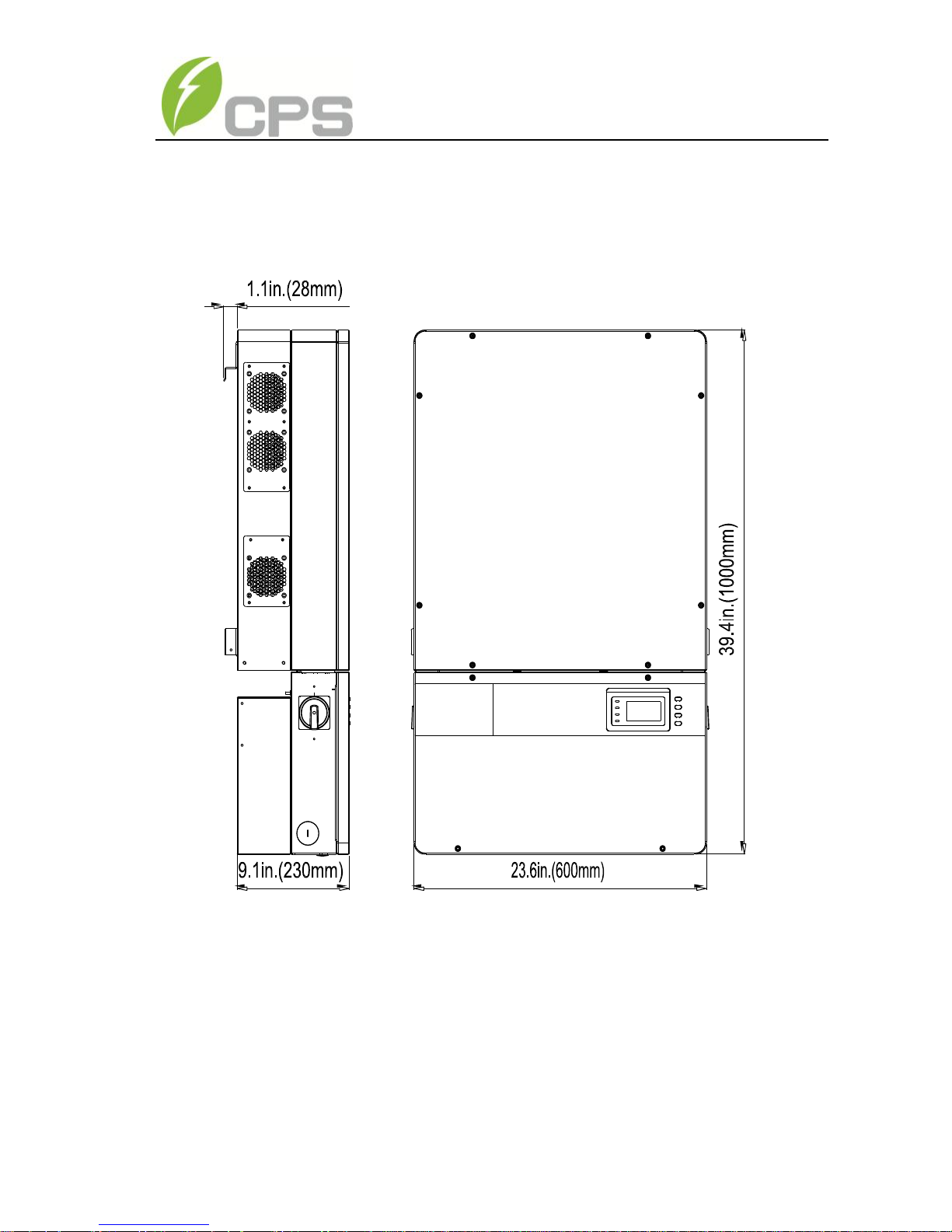

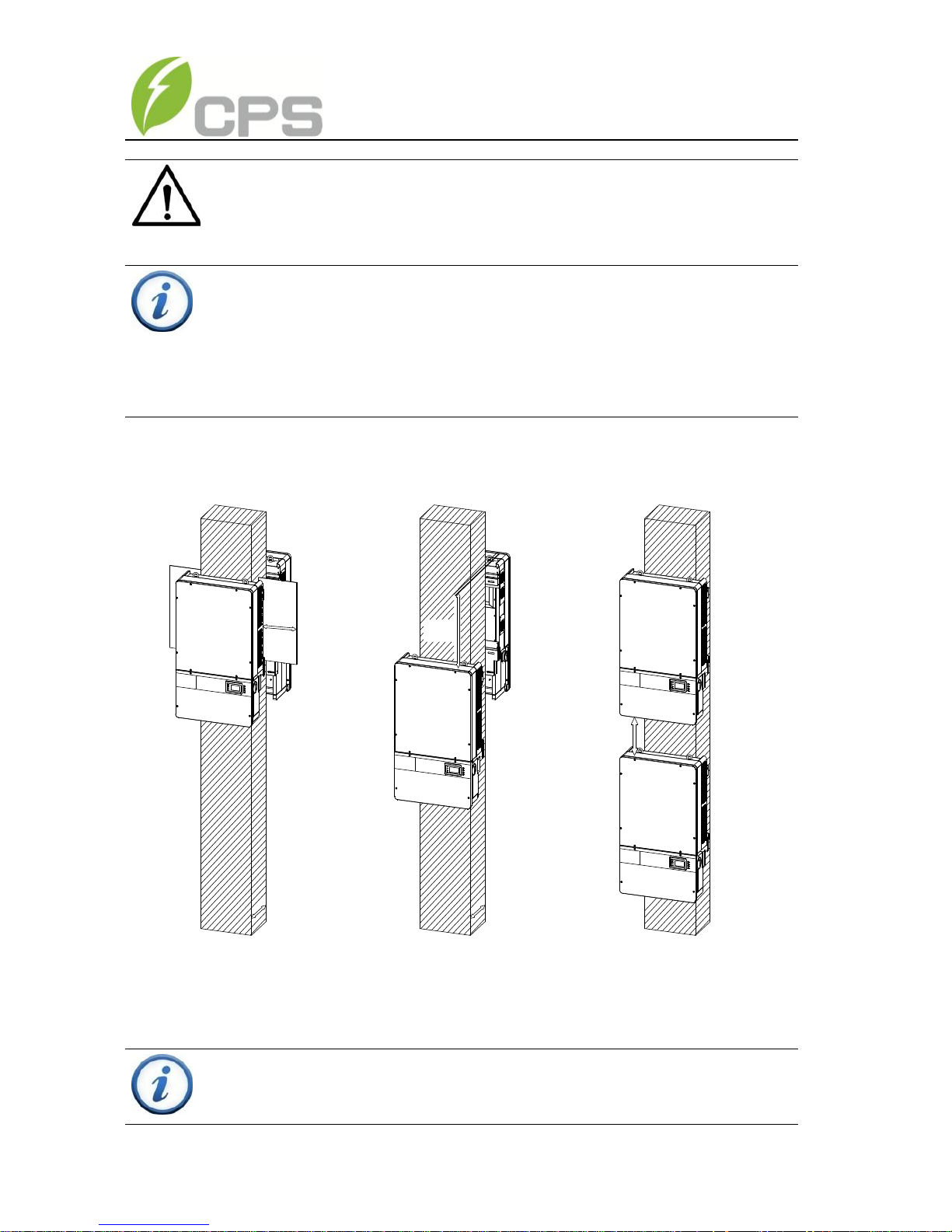

2) Installation method (see Figure 3-2):

Make sure that the mounting structure (wall, rack, etc) is suitable to support

the inverter weight. Follow the mounting guidelines below:

(a) If the location permits, install the inverter vertically.

16

(b) If the inverter cannot be mounted vertically, it may be tilted backward

by no lower than 15 degrees from horizontal.

(c) Do NOT mount the inverter leaning forward.

(d) Do NOT mount the inverter in a horizontal position (<15 degrees).

(e) Do NOT mount the inverter upside down.

(a)

(c) (d) (e)

(b)

Figure 3-2 Mount the inverter correctly

NOTICE:

When the inverter is mounted backward by ≥15° outdoor, shield

17

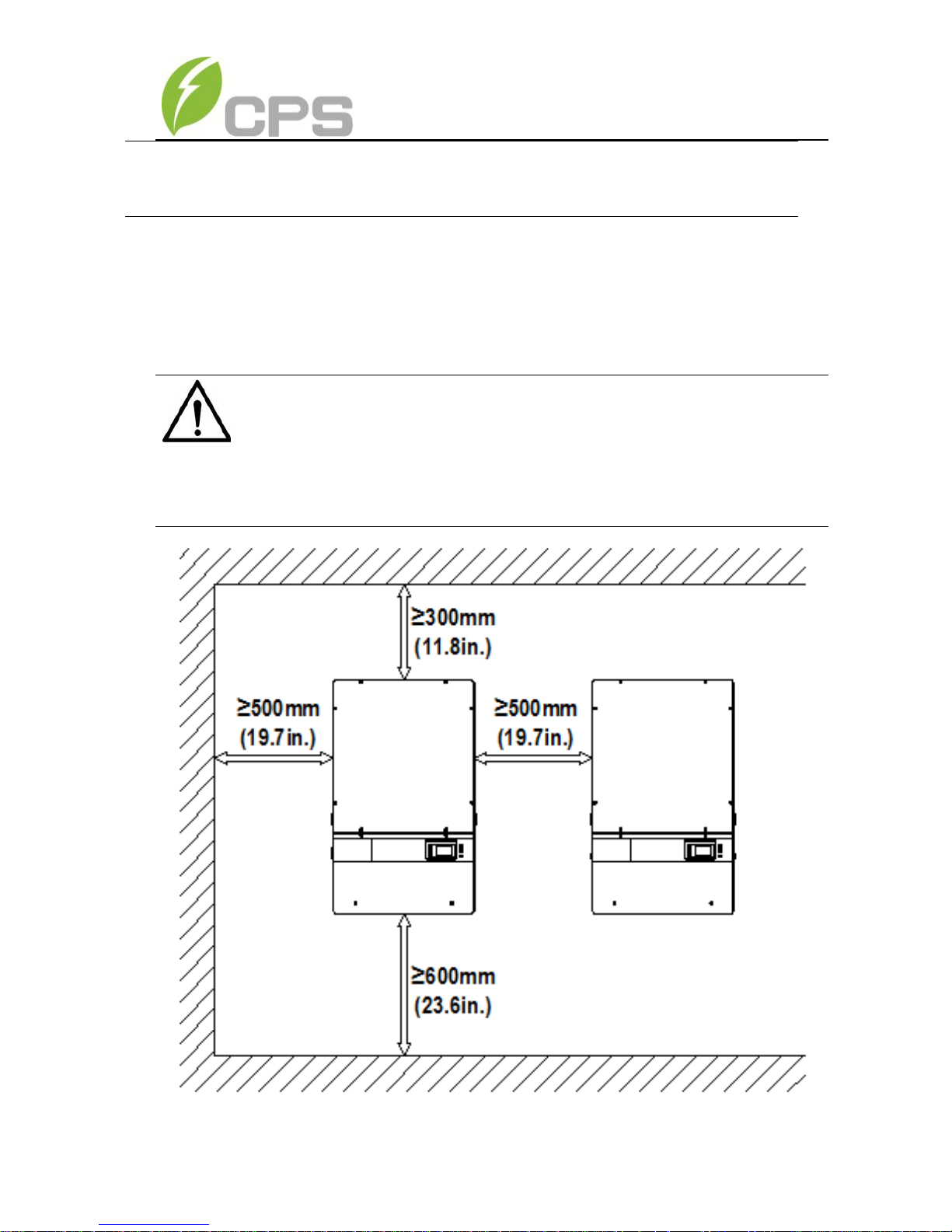

3) Installation space requirement (see Figure 3-3):

The distances between the inverters or the surrounding objects should meet

the following conditions:

Figure 3-3 Inverter wall mounting dimensions

cover is recommended to be installed above the inverter to avoid

direct sunlight.

NOTICE:

The spacing between two adjacently mounted inverters should be

≥500mm (19.7 inches). Ensure that the air space around the inverter

is well ventilated.

18

¡ Ý200mm

(7.9in.)

¡ Ý300mm

(11.8in.)

¡ Ý600mm

(23.6in.)

¡ Ý300mm

(11.8in.)

¡ Ý300mm

(11.8in.)

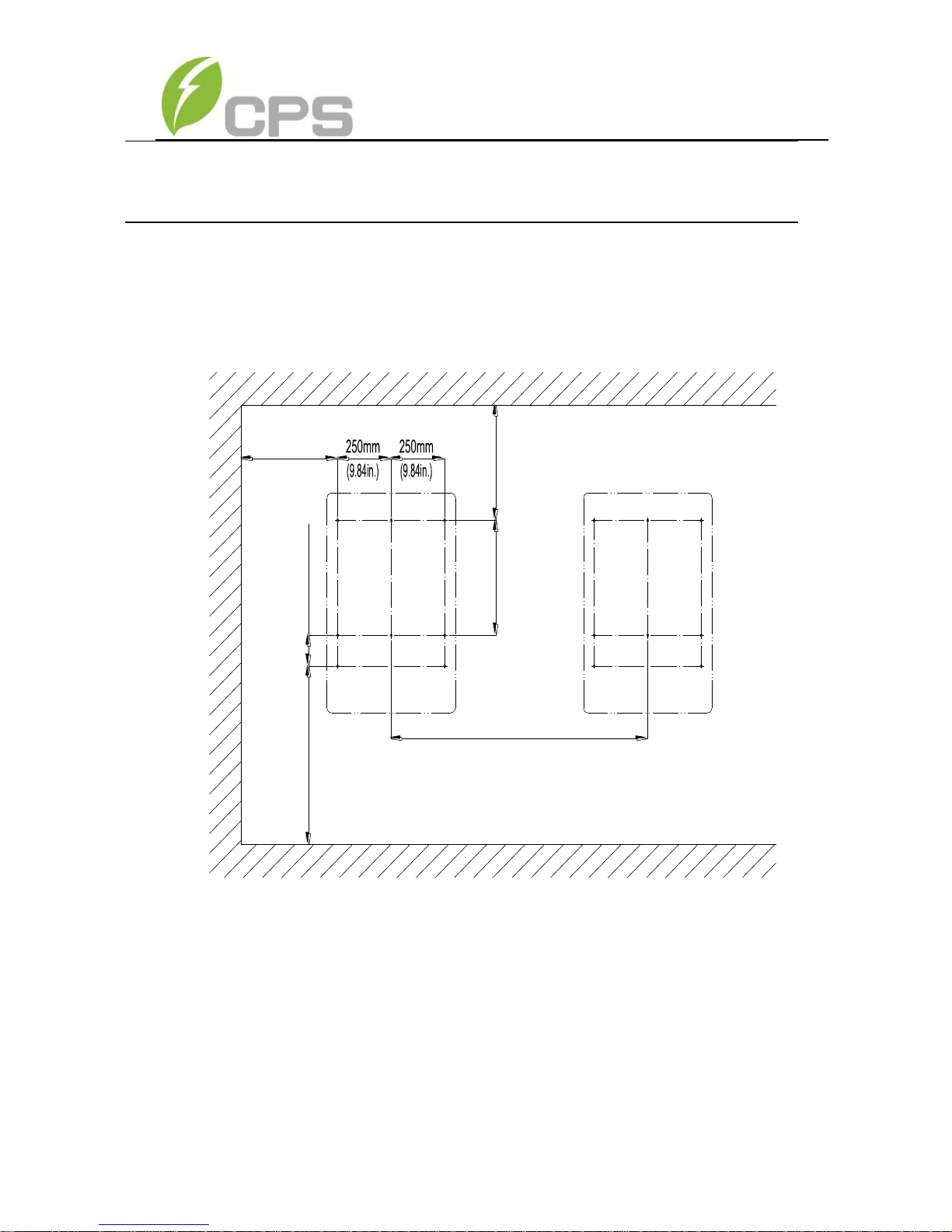

Figure 3-4 Inverter pillar mounting dimensions

NOTICE:

The installation clearance between two inverters needs to be

increased when the ambient temperature is higher than 45℃.

INSTRUCTION:

If the inverter is tilted backward by no lower than 15° from horizontal,

the bottom clearance distance can be reduced according to specific

conditions.

INSTRUCTION:

If the inverter is installed in open air on metallic brackets (instead of

19

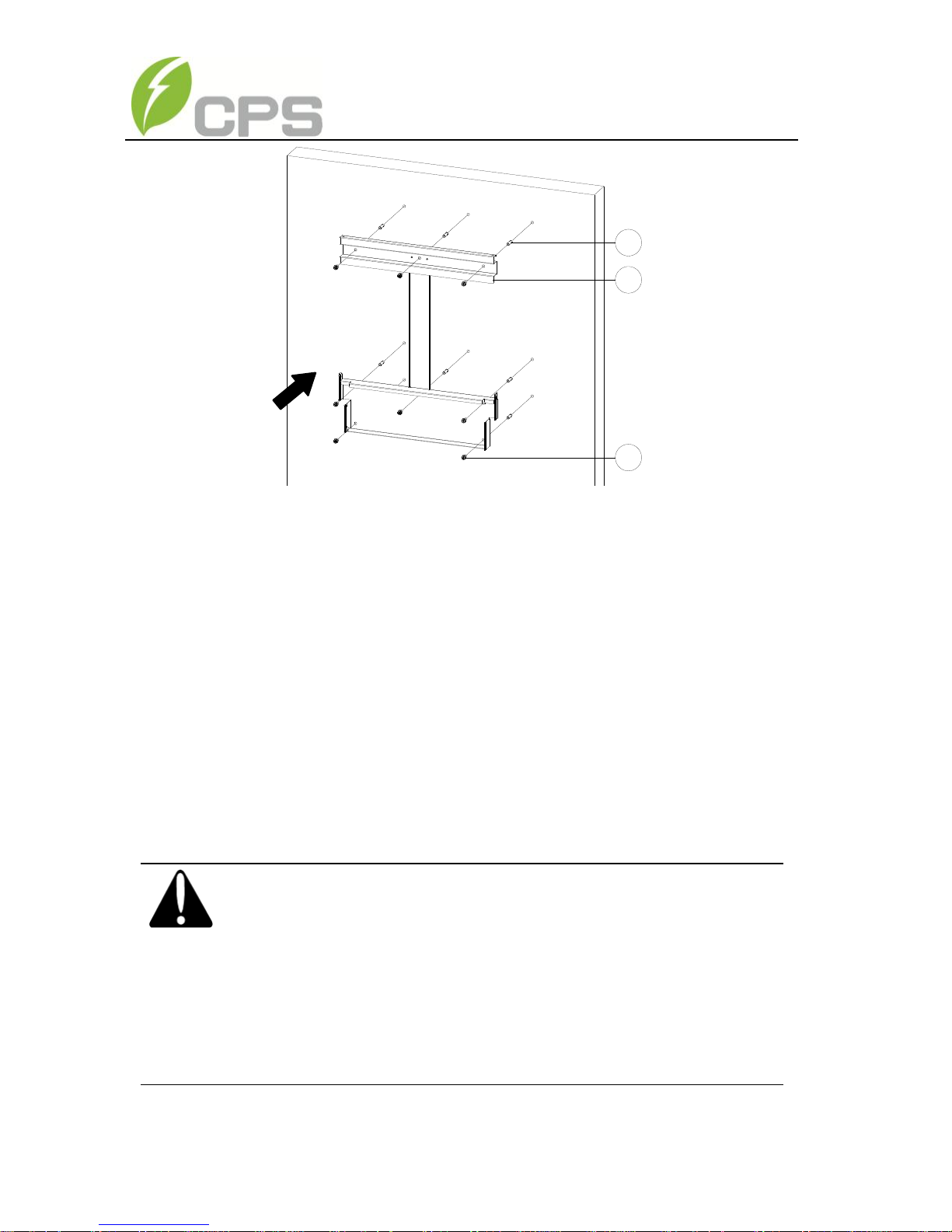

4) Mount the inverter onto the bracket

(1) Mark the 8 holes on the bearing surface for mounting the bracket as

shown in Figure 3-5;

813mm(min.)

425mm(min)

550mm(min.)

522mm

140mm(5.51in.)

1100mm(min.)

(21.7in.)

(16.7in.)

(32in.)

(43.3in)

(20.55in.)

Figure 3-5 Dimensions of holes on the bearing surface

(2) Drill holes at the marked positions with a 10mm (0.4in.) drill and put the

M8 expansion tubes① into the holes; Fasten the mounting bracket② with

the M8x25 assembling bolts③ in the accessory kit.

Tool: Electric drill (Ф10mm/0.4in. head), No. 13 wrench

solid wall), the top clearance distance can be reduced to as minimum

as 100mm (3.94in.).

20

1

2

3

Figure 3-6 Secure the mounting bracket

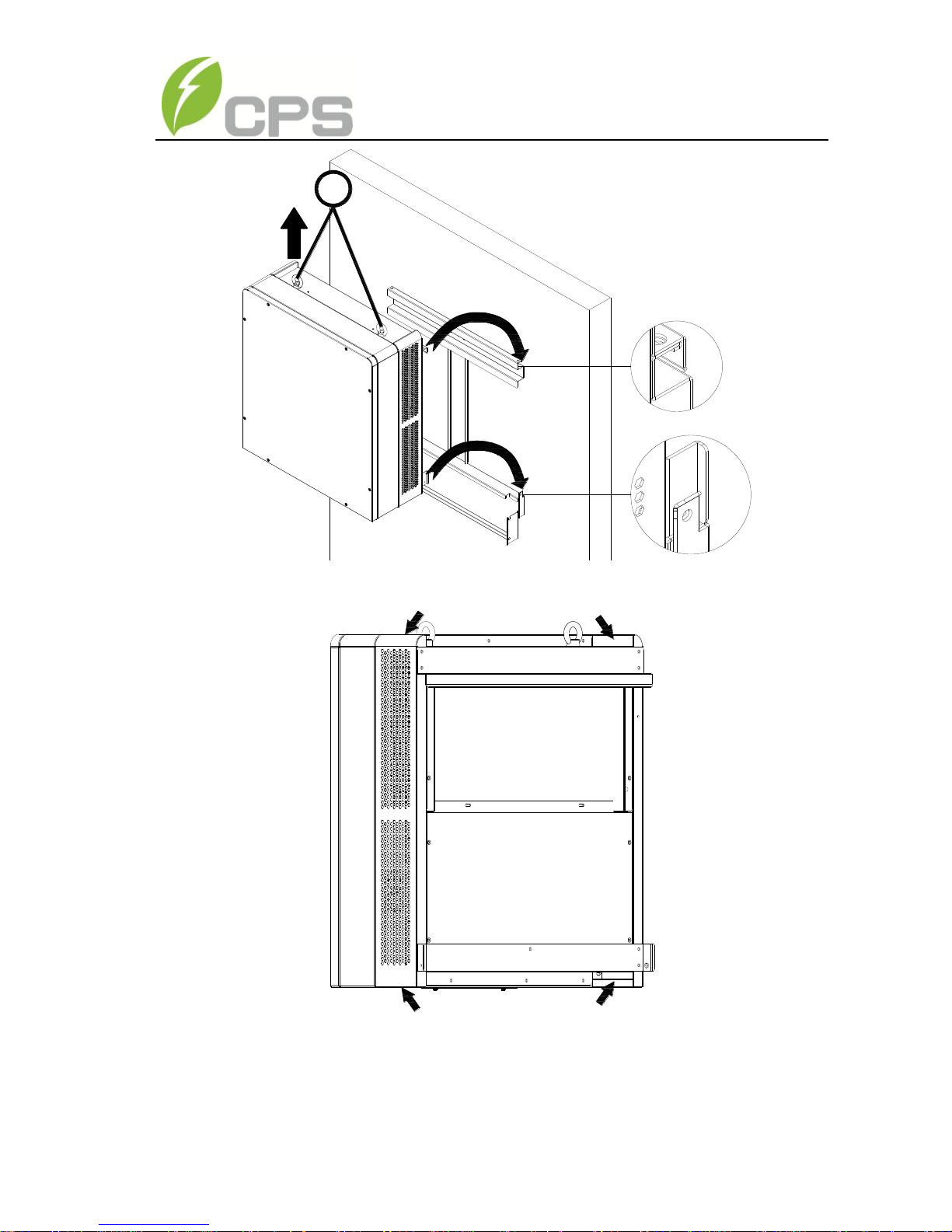

(3) Hang the inverter onto the mounting bracket as shown in Figure 3-7 and

Figure 3-8;

Lift mounting: Take out the lifting eye nut M10 (2pcs) from the

accessory kit, and screw them on the bolts at the top of the inverter. Use

sling rope or bar (inserted through both lifting eye nuts) to lift the inverter

onto the bracket. The minimum angle between the two sling ropes should

be less than 90 degrees.

Manual mounting: Two people grab the handle positions marked in

Figure 3-8, and mount the inverter onto the bracket.

CAUTION:

The main housing of the CPS SCA23/28KTL-DO series inverter is

about 46.5kg (≈102.5 pounds).

Please ensure the mounting is properly installed before hanging

the the inverter on the bracket. It is recommended to have at least

2 people to mount the inverter due to the weight of the equipment.

21

Figure 3-7 Mount the main housing on the bracket by lifting

Figure 3-8 Position of grab handle

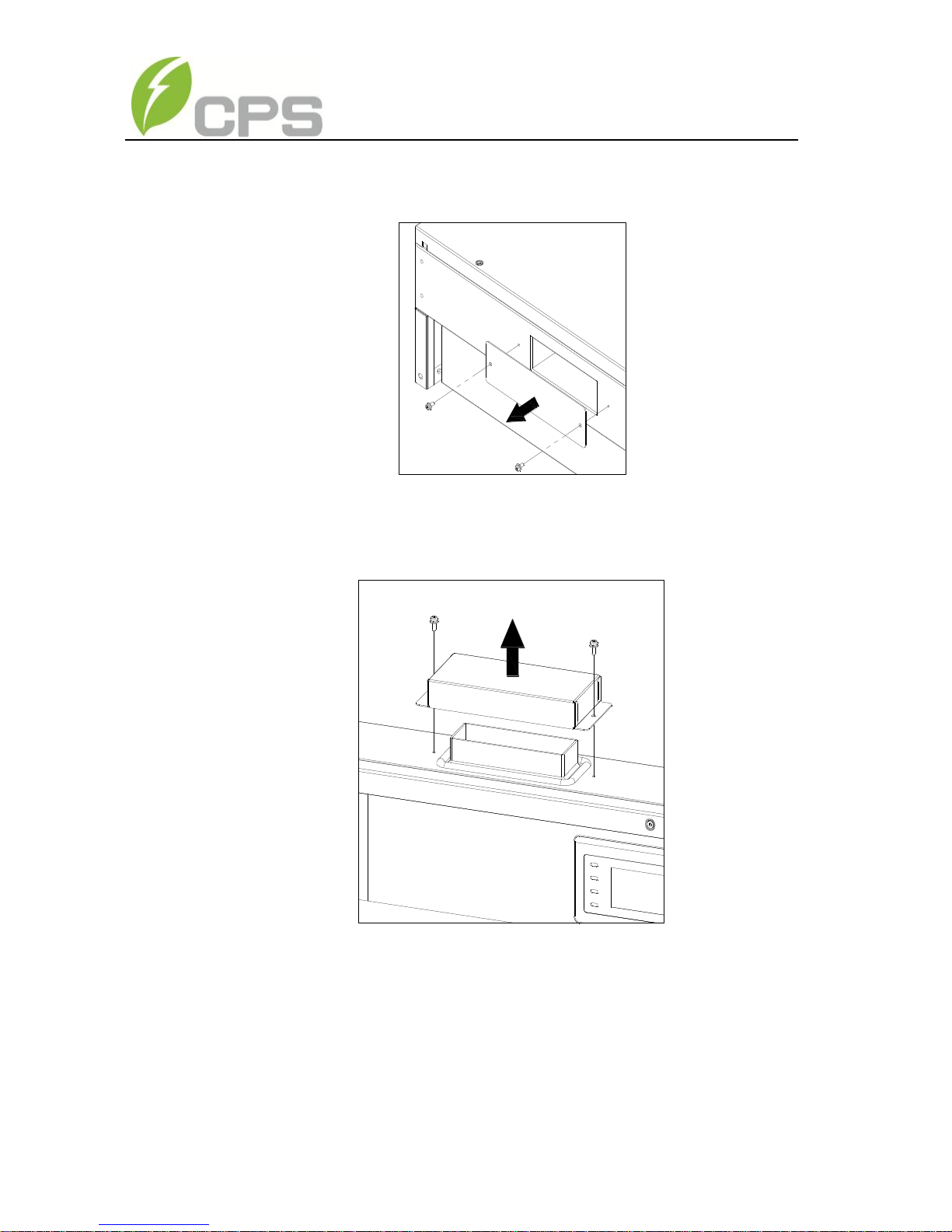

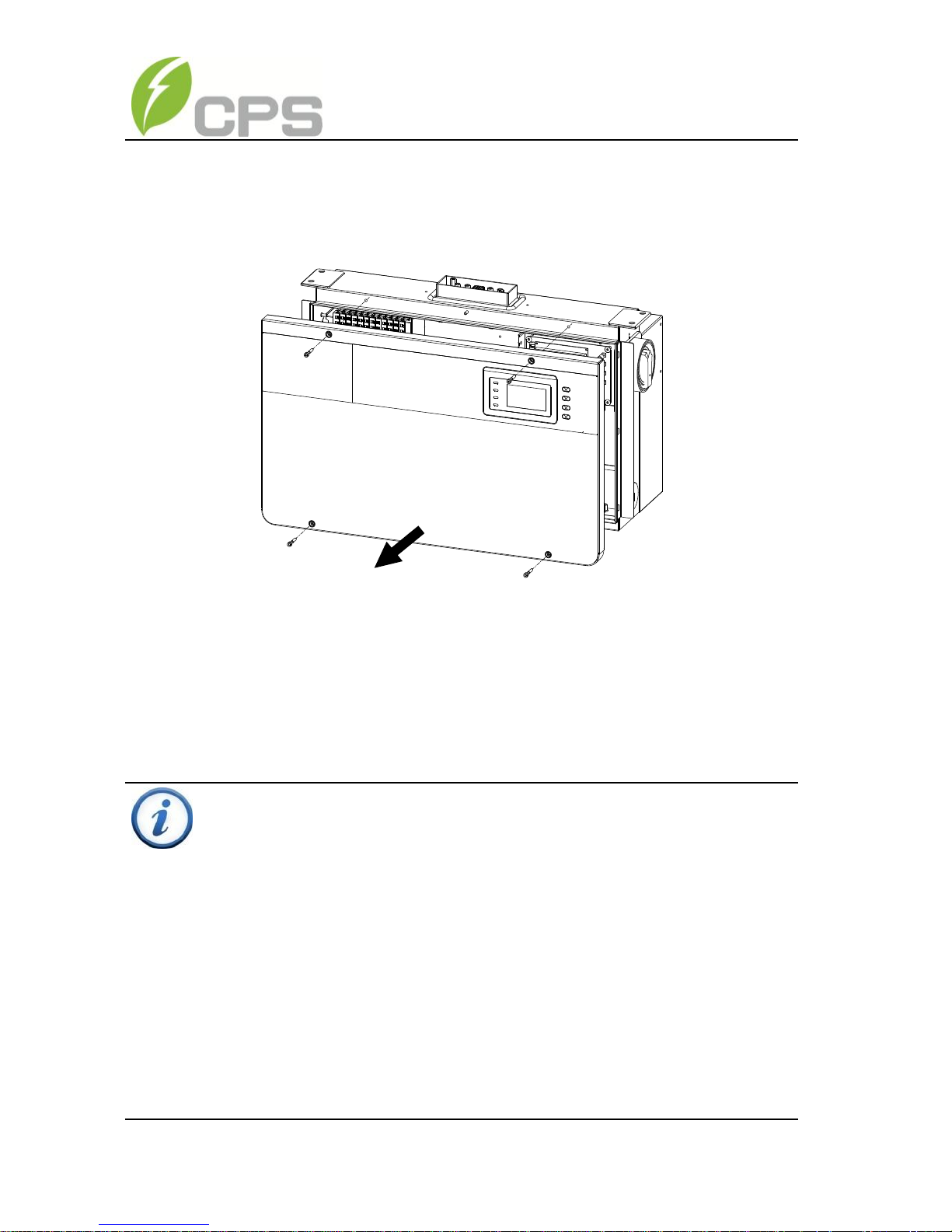

(4) Install the wiring box

① Remove the cover plate at the bottom of the main housing. (see Figure

22

3-9)

Tool: No.2 Phillips head screwdriver

Figure 3-9 Cover plate of the main housing

② Remove the cover board at the top of the wiring box (see Figure 3-10)

Figure 3-10 Cover board of the wiring box

Save the cover board and screws, and fix the board on the left side of the

wiring box after the wiring box is attached to the inverter housing (see

step 6, Figure 3-13)

Tool: No.2 Phillips head screwdriver

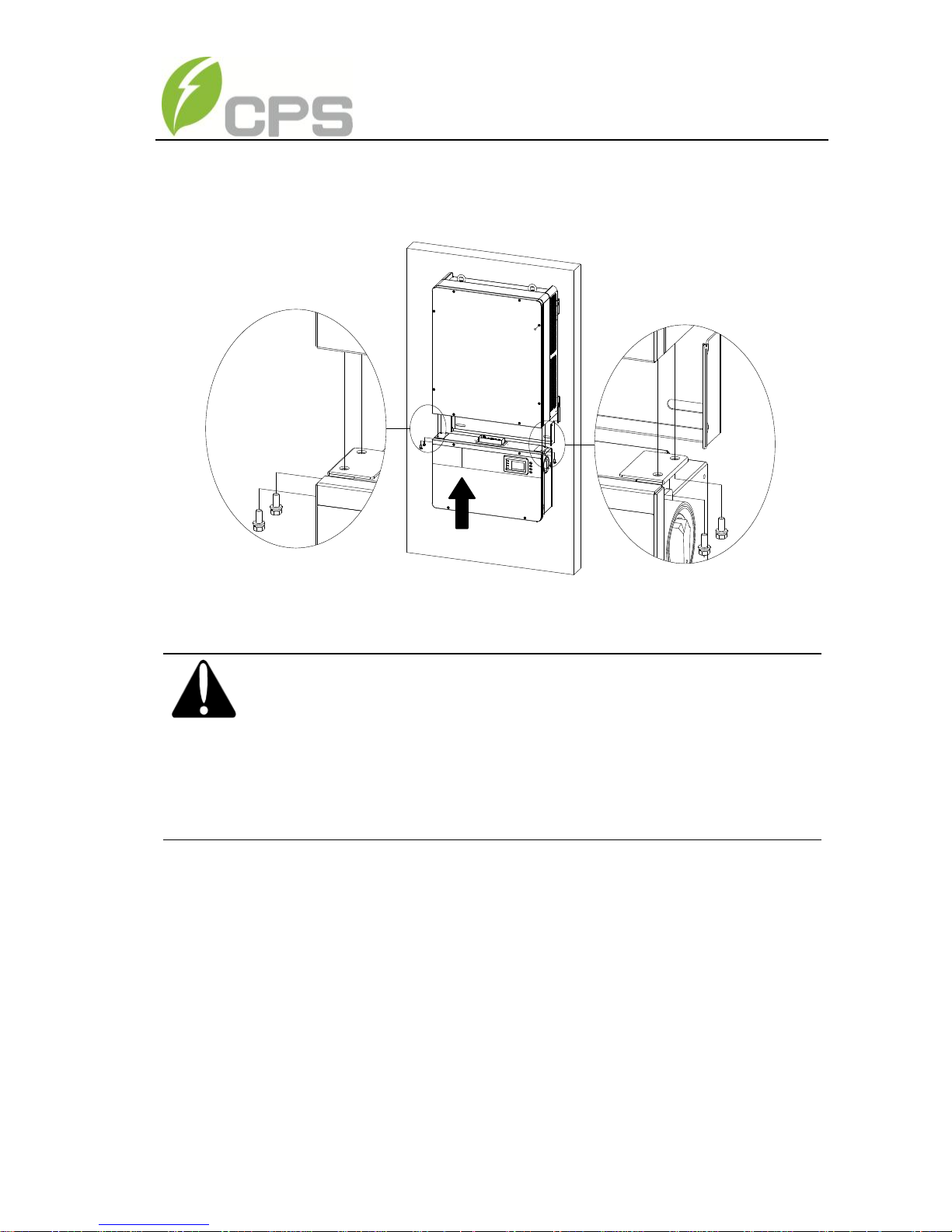

③Insert the wiring box to the main housing, and use M6x12 screws (4pcs)

23

to attach the wiring box to the inverter housing. (see Figure 3-11)

Tool: No. 10 Wrench, torque value of 2.8N.m

Figure 3-11 Installation of the wiring box

(5) Attach the main housing and the wiring box to the mounting bracket with

the M5x10 bolts (6 pcs). (see Figure 3-12)

Tool: No.2 Phillips head screwdriver, torque value of 1.6N.m

CAUTION:

The total weight of the CPS SCA23/28KTL-DO series inverter is

about 55kg (≈122 pounds).

Please ensure the mounting is properly installed before hanging the

the inverter on the bracket.

24

Figure 3-12 Fix the main housing and wiring box on the bracket

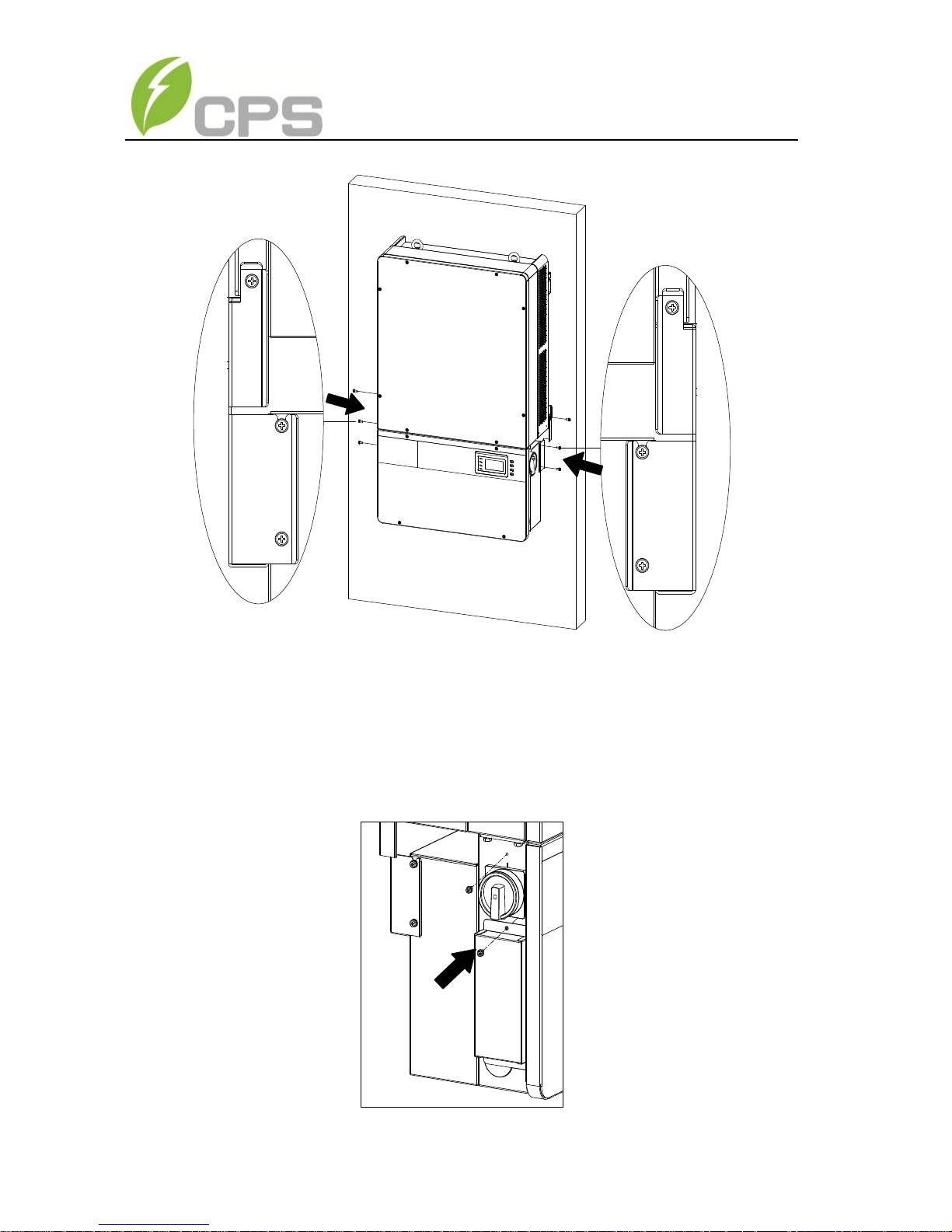

(6) Attach the cover board shown in Figure 3-10 to the left side of the wiring

box. (see Figure 3-13)

Tool: No.2 Phillips head screwdriver, torque value of 1.2N.m

Figure 3-13 Attach the cover board to the left side of the wiring box

25

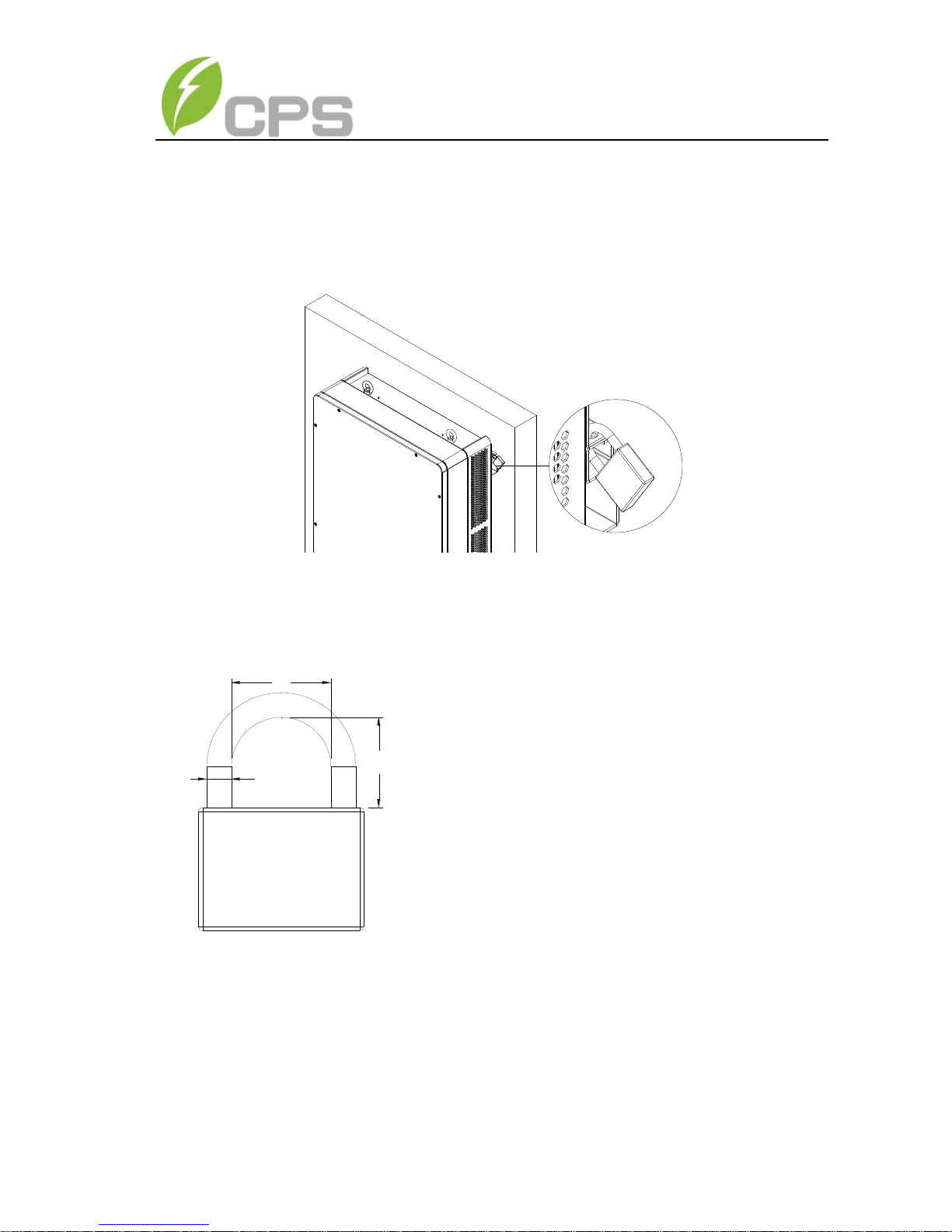

(7) Optional - Install an anti-theft padlock when the installation is complete.

The anti-theft padlock is used to prevent the inverter from being stolen

when the equipment is installed outdoors. You can lock the inverter on the

bracket, as shown in Figure 3-14:

Figure 3-14 Location of the anti-theft padlock

The anti-theft padlock should meet the requirement of the dimensions

shown in Figure 3-15:

B

C

A

Figure 3-15 The dimensions of anti-theft padlock

Recommended lock size:

A: Ф3~6mm

B: 20~50mm

C: 20~50mm

26

5) Removing/Replacing the wire box cover:

(1) Use a 3mm (0.12in.) Hex screwdriver to remove the 4 screws on the

wiring box and take off the cover. (see Figure 3-16(a))

Figure 3-16(a)- Take off the cover of the wiring box

(2)To replace the cover use a 3mm (0.12in.) Hex screwdriver to replace the 4

screws on the cover.

INSTRUCTION:

It is important to use a hand tool (e.g. Hex key, Allen key/socket or

T-handle, 3mm) and not power drivers or other types of screw drivers.

Also, it is important to hold the cover in alignment with balanced force

across the cover, not weighted toward any edge, for screw to

Pem®-nut alignment. Partially engage all four screws to Pem®-nuts a

few rotations before tightening any one screw. This is important to

maintain alignment and avoid thread damage.

27

INSTRUCTION:

We posted on our website, www.chintpowersystems.com, under the

Service menu a ‘how to’ video showing the best technique for

installing the wire-box cover.

28

3.3 Electrical installation

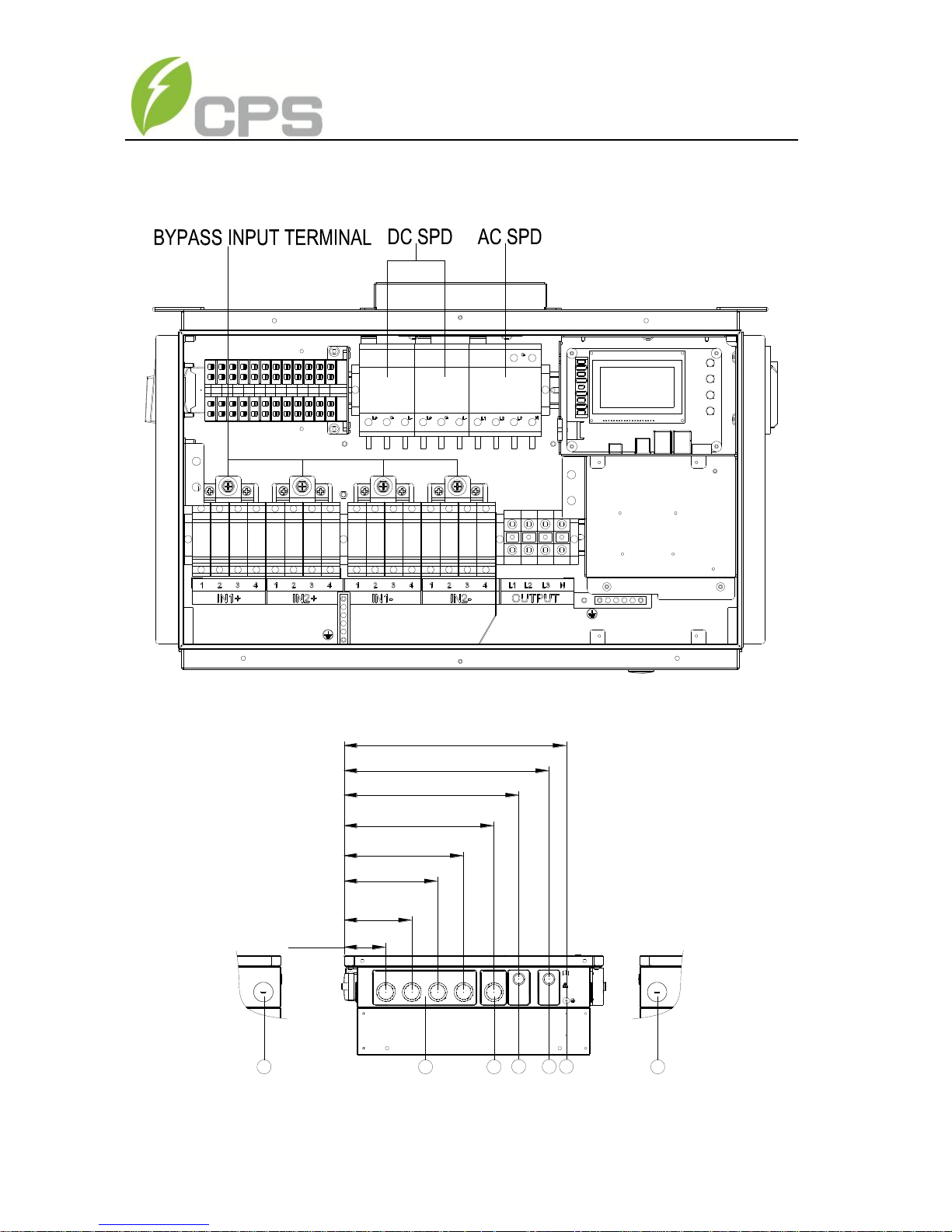

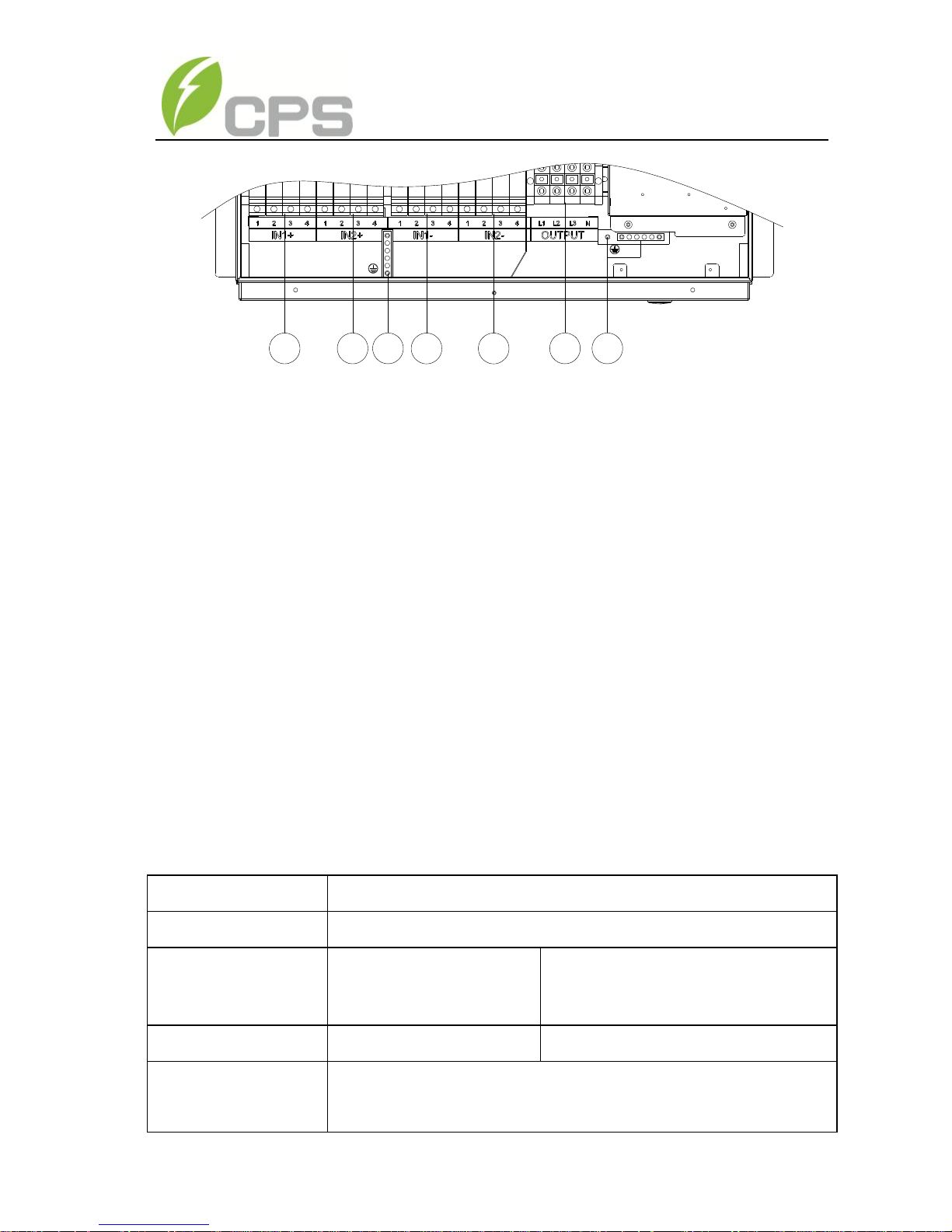

The connection interface of CPS SCA23/28KTL-DO series inverter:

Figure 3-16(b) : Full view of wiring box with options.

Figure 3-17 External connection ports

WARNING:

High touch current .

Earth connection essential

before connecting supply.

For more details please

see the user manual.

DC INPUT AC OUTPUT

COMM. PORT ANTENNA

16 2

3 475

3.8 in.

6.2 in.

8.5 in.

10.9 in. (277mm)

13.7 in. (347mm)

15.9 in. (405mm)

18.7 in. (475mm)

(97mm)

(157mm)

(217mm)

20.3 in. (515mm)

29

Figure 3-18 Internal connection points

① Knockout holes for DC input cable, 1-1/4” or 1”

② Knockout hole for AC output cable, 1-1/4” or 1”

③ Knockout hole 1/2inch & 3/4inch,for comm. cable

④ Knockout hole 1/2inch & 3/4inch,for comm. cable,reserved

⑤ External ground connection point

⑥ Side hole for DC input cable, 1-1/4”

⑦ Side hole for AC output cable, 1-1/4”

⑧ DC input fuse holders

⑨ AC output terminal block

⑩ Internal ground connection point & grounding studs

Choose the cables for inverters according to the following configuration table:

Table 3-3 Cables specifications

Position

Cable

DC input (﹢/﹣)

DC cables specifications refer to Table3-6

AC output

(L1/L2/L3/N)

Cable #10~2AWG

#8AWG cable recommended

PE

Cable #10~6AWG

#8AWG cable recommended

RS485

communication

UTP CAT-5e or 3x#22~18AWG communication cable (eg.

Belden 3106A)

8 8

8 8

9 1010

30

3.3.1 DC connection

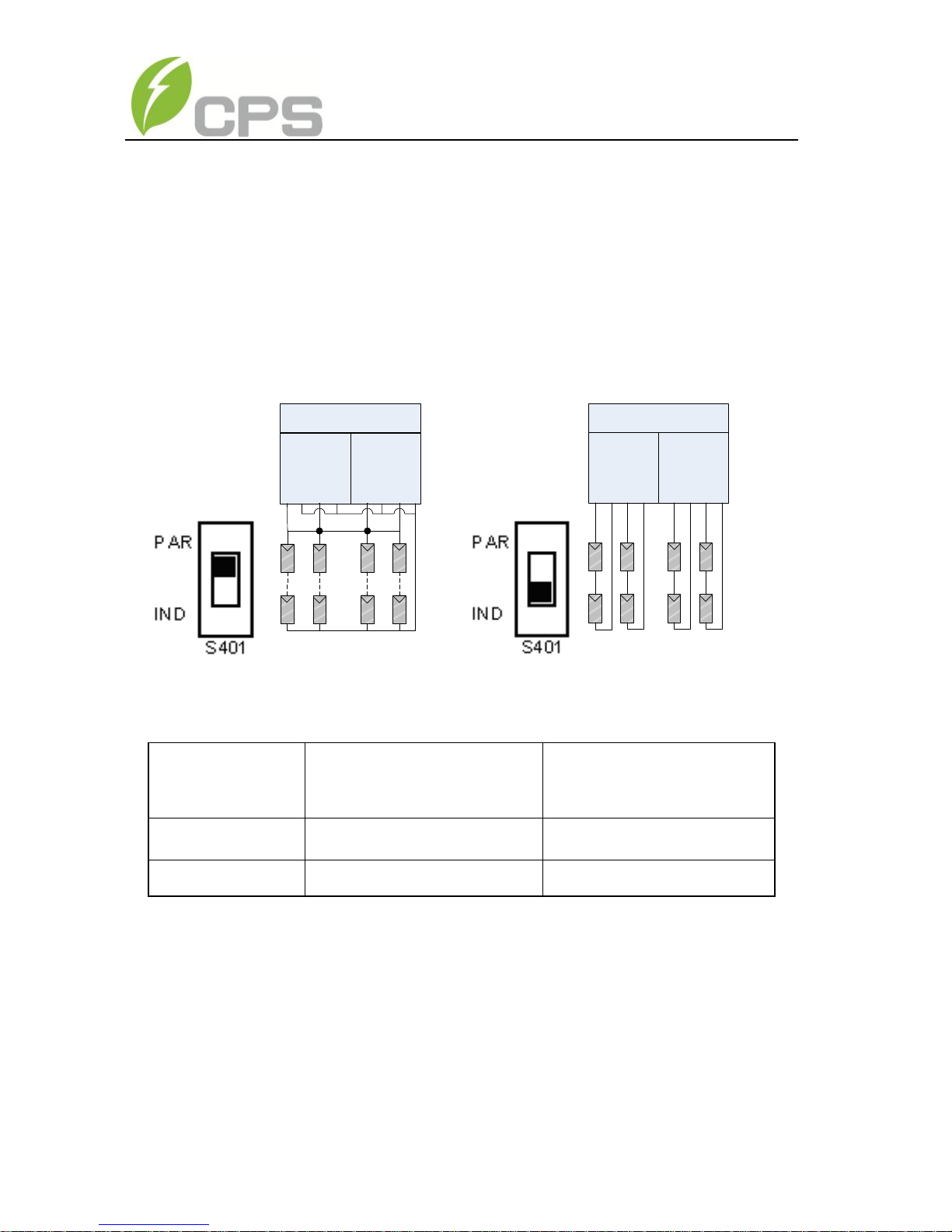

1) Working mode

CPS SCA23/28KTL-DO series inverter has two PV input sections: DC

Input-1 and DC Input-2. These two sections can work under “Parallel mode” or

“Independent mode”. (see Figure 3-19)

Under Parallel mode, the two PV input sections share one MPP Tracker;

Under Independent mode, each PV input section works with one MPP Tracker.

n1=n2 =n3=n4

DC

Input-1DCInput-2

Inverter

n1 n2 n3 n4

DC

Input-1DCInput-2

Inverter

n1 n2 n3 n4

n1=n2 n3=n4

Figure 3-19(a) Parallel mode Figure 3-19(b) Independent mode

Table 3-4 DC input power specification

Inverter model

Max. DC input power

Rated DC input power

of each input section

SCA23KTL-DO

31kW

15.5kW

SCA28KTL-DO

38kW

19kW

Remarks: The standard configuration is “Parallel mode”. If it needs to

switch to the “Independent mode”, please take the follow:

1. Remove the cover of the wiring box. Use 3mm (0.12in.) Hex

screwdriver to remove the 4 screws on the wiring box and take off the

cover. (see Figure 3-16(a))

2. Remove the protection cover. (see Figure 3-20a)

3. Use No.2 Phillips head screwdriver to remove the jumper busbar,

Loading...

Loading...