CPI VZC-6967AG, VZC-6967AT, VZC-6967AB, VZC-6967AH, VZC-6967AJ Installation, Operation And Preventive Maintenance Manual

...

INSTALLATION, OPERATION, AND

PREVENTATIVE MAINTENANCE

MANUAL

CHPA (COMPACT HIGH POWER AMPLIFIER)

For Use With Model Numbers...

Service Center Headquarters and Design Center

West Coast Operations

811 Hansen Way

Palo Alto, CA 94303

Manufacturing

East Coast Operations

45 River Drive

Georgetown, ON

Canada L7G 2J4

VZC – 6967AT

VZC – 6967AN

VZC – 6967AM

VZC – 6967AD

VZC – 6967AB

VZC – 6967AG

VZC – 6967AJ

VZC – 6967AH

VZU – 6997AC

VZU – 6997AB

VZU – 6996AB

VZU – 6996AC

VZU – 6997AE

VZU – 6997AG

VZU – 6995AY

VZU – 6997AA

VZU – 6997AD

VZU – 6997AJ

VZU – 6996AY

VZU – 6997CY

VZU – 6997AX

VZU – 6997AY

DOC.01023245 REV.K

THIS DOCUMENT IS THE PROPERTY OF COMMUNICATIONS & POWER INDUSTRIES.

REPRODUCTION OR RELEASE WITHOUT EXPRESS PERMISSION IS STRICTLY PROHIBITED

CHPA SERIES

PROPRIETARY INFORMATION

The design and other information contained in this document are provided solely for the

installation, operation, and maintenance of CPI equipment. Except for rights expressly granted

by contract, all such information is the exclusive property of CPI, Satcom Division. This

document may not be duplicated, in whole or in part, or be used for manufacture without

written permission of CPI, Satcom Division.

Copyright © 2009 by Communications & Power Industries, Inc. All rights reserved.

ii

THIS DOCUMENT IS THE PROPERTY OF COMMUNICATIONS & POWER INDUSTRIES.

REPRODUCTION OR RELEASE WITHOUT EXPRESS PERMISSION IS STRICTLY PROHIBITED

DOC.01023245 REV.K

CHPA SERIES

Table of Contents

SAFETY................................................................................................................................................... S-1

INTRODUCTION................................................................................................................................... S-1

HIGH VOLTAGE EQUIPMENT......................................................................................................... S-1

PERSONNEL OPERATING GUIDELINES ....................................................................................... S-1

WHEN IS VOLTAGE "HIGH"?.......................................................................................................... S-1

GENERAL GUIDELINES................................................................................................................... S-2

MICROWAVE RADIATION................................................................................................................ S-4

PERSONNEL OPERATING GUIDELINES ....................................................................................... S-4

MICROWAVE DISCUSSION............................................................................................................. S-5

GENERAL MICROWAVE GUIDELINES......................................................................................... S-5

PHYSICAL SAFETY........................................................................................................................... S-6

LIFTING HEAVY OBJECTS..............................................................................................................S-6

EXTENDING RACK SLIDES.............................................................................................................S-6

CHAPTER 1 INTRODUCTION............................................................................................................1-1

1.1 OVERVIEW................................................................................................................................. 1-1

1.2 ABOUT THIS MANUAL............................................................................................................1-3

1.3 MAJOR SUBSYSTEMS AND THEIR FUNCTIONS..............................................................1-4

1.4 TECHNICAL DESCRIPTION...................................................................................................1-4

1.4.1 RF SUBSYSTEM..................................................................................................................1-4

1.4.2 POWER SUPPLY SUBSYSTEM .........................................................................................1-6

1.4.3 POWER FACTOR CORRECTION MODULE ....................................................................1-7

1.4.4 POWER PROCESSOR MODULE........................................................................................1-7

1.4.5 HIGH-VOLTAGE MODULE ...............................................................................................1-7

1.4.6 RF POWER MONITOR MODULE......................................................................................1-7

1.4.7 CONTROL AND DISPLAY MODULES.............................................................................1-8

1.5 LRU PHILOSOPHY ...................................................................................................................1-8

1.6 OPTIONAL FEATURES............................................................................................................1-9

CHAPTER 2 UNPACKING AND INSTALLATION..........................................................................2-1

OC.01023245 REV.K

D

THIS DOCUMENT IS THE PROPERTY OF COMMUNICATIONS & POWER INDUSTRIES.

REPRODUCTION OR RELEASE WITHOUT EXPRESS PERMISSION IS STRICTLY PROHIBITED

iii

CHPA SERIES

2.1 OVERVIEW................................................................................................................................. 2-1

2.2 PRE-INSPECTION .....................................................................................................................2-1

2.3 UNPACKING...............................................................................................................................2-1

2.4 PREPARING FOR INSTALLATION....................................................................................... 2-2

2.5 INSTALLATION.........................................................................................................................2-2

2.5.1 MECHANICAL INSTALLATION.......................................................................................2-2

2.5.2 ELECTRICAL CONNECTIONS..........................................................................................2-3

2.5.3 PRIME POWER ....................................................................................................................2-3

2.5.4 GROUNDING .......................................................................................................................2-4

2.5.5 I/O INTERFACES.................................................................................................................2-4

2.5.6 RF CONNECTIONS .............................................................................................................2-4

2.5.7 RF OUTPUT (WAVEGUIDE CONNECTION)(J3).............................................................2-5

2.5.8 COOLING CONSIDERATIONS..........................................................................................2-5

CHAPTER 3 INTERFACES ..................................................................................................................3-1

3.1 OVERVIEW................................................................................................................................. 3-1

3.2 CHPA CONTROL MODE HIERARCHY................................................................................3-1

3.3 SERIAL REMOTE INTERFACE ............................................................................................. 3-2

3.4 RF SWITCH SYSTEM INTERFACE.......................................................................................3-4

3.4.1 RELAY DEFINITIONS ........................................................................................................3-4

3.5 EXTERNAL INTERLOCKS INTERFACE .............................................................................3-6

3.6 COMPUTER INTERFACE........................................................................................................3-8

3.6.1 CIF HARDWARE CONFIGURATION ...............................................................................3-8

3.7 COMPUTER INTERFACE (CIF) PROTOCOL .....................................................................3-9

3.8 PROTOCOL MESSAGE STRUCTURE...................................................................................3-9

3.9 COMMAND AND RESPONSE FORMAT.............................................................................3-10

3.9.1 HEADER AND ENDING BYTES...................................................................................... 3-10

3.9.2 ADDRESS BYTE................................................................................................................3-11

3.9.3 COMMAND BYTE.............................................................................................................3-11

3.9.4 RESPONSE BYTE(S) .........................................................................................................3-11

iv

THIS DOCUMENT IS THE PROPERTY OF COMMUNICATIONS & POWER INDUSTRIES.

REPRODUCTION OR RELEASE WITHOUT EXPRESS PERMISSION IS STRICTLY PROHIBITED

DOC.01023245 REV.K

CHPA SERIES

3.9.5 REJECT BYTE(S)...............................................................................................................3-11

3.9.6 CHECK BYTE.....................................................................................................................3-12

3.9.7 CARRIAGE RETURNS AND LINE FEEDS.....................................................................3-13

3.10 COMMANDS .............................................................................................................................3-13

3.10.1 SLOW COMMANDS..........................................................................................................3-16

3.11 STATUS BYTE DEFINITIONS...............................................................................................3-17

3.12 ID/VERSION MESSAGE .........................................................................................................3-21

CHAPTER 4 INITIAL POWER ON AND CHECKOUT ...................................................................4-1

4.1 OVERVIEW................................................................................................................................. 4-1

4.2 PRE-POWER PROCEDURES...................................................................................................4-1

4.3 USING THE FRONT PANEL....................................................................................................4-2

4.4 INITIAL POWER-ON PROCEDURES....................................................................................4-3

4.4.1 POWER-ON SELF-TEST AND HEATER TIME DELAY..................................................4-3

4.5 VERIFYING OPERATIONAL SETTINGS.............................................................................4-4

4.6 SETTING THE FAULT AND ALARM TRIP POINTS..........................................................4-4

4.7 SETTING SERIAL REMOTE AND CIF PORT PARAMETERS.........................................4-6

4.8 VERIFYING RF OUTPUT LEVEL ..........................................................................................4-7

4.9 VERIFYING RF ALARM AND RF FAULT TRIP POINTS..................................................4-8

4.10 TESTING THE CHPA VIA COMPUTER CONTROL ..........................................................4-9

4.11 TESTING OPTIONAL EQUIPMENT......................................................................................4-9

4.11.1 REMOTE CONTROL INTERFACE ....................................................................................4-9

CHAPTER 5 OPERATION....................................................................................................................5-1

5.1 OVERVIEW................................................................................................................................. 5-1

5.2 ESSENTIAL CHPA OPERATING PROCEDURES...............................................................5-2

5.2.1 TRANSMIT...........................................................................................................................5-2

5.3 NORMAL SHUTOFF .................................................................................................................5-3

5.4 BASIC CHPA OPERATION......................................................................................................5-3

OC.01023245 REV.K

D

THIS DOCUMENT IS THE PROPERTY OF COMMUNICATIONS & POWER INDUSTRIES.

REPRODUCTION OR RELEASE WITHOUT EXPRESS PERMISSION IS STRICTLY PROHIBITED

v

CHPA SERIES

5.5 CHPA STATES AND DESCRIPTION......................................................................................5-4

5.6 INITIALIZATION AND POWER-ON SELF-TEST (POST) STATE...................................5-4

5.7 HEATER TIME DELAY (HTD) STATE..................................................................................5-5

5.8 STANDBY STATE ......................................................................................................................5-6

5.9 TRANSMIT STATE....................................................................................................................5-7

5.10 FAULT STATE............................................................................................................................5-7

5.11 CHPA CONTROL MODES AND HIERARCHY....................................................................5-8

5.12 RF CONTROL MODES .............................................................................................................5-9

5.13 SPECIAL CHPA FUNCTIONS ...............................................................................................5-10

5.13.1 FACTORY AUTHORIZED ACCESS MODE ...................................................................5-10

5.14 TERMINOLOGY ...................................................................................................................... 5-10

5.15 EXITING A MENU...................................................................................................................5-11

5.16 DATA ENTRY RULES.............................................................................................................5-11

5.17 QUICK ACCESS CODES.........................................................................................................5-13

CHAPTER 6 MAINTENANCE .............................................................................................................6-1

6.1 OVERVIEW................................................................................................................................. 6-1

6.2 SCHEDULED PREVENTIVE MAINTENANCE....................................................................6-1

6.3 MECHANICAL PREVENTIVE MAINTENANCE.................................................................6-2

6.4 VISUAL INSPECTION...............................................................................................................6-4

6.4.1 INSPECTING AND CLEANING AIR FILTERS.................................................................6-5

6.4.2 CHECKING A3 LEDS AND DISPLAY...............................................................................6-5

6.4.3 COLLECTOR AIR SYSTEM MAINTENANCE .................................................................6-5

6.4.4 CHECKING B1 COLLECTOR BLOWER...........................................................................6-6

6.4.5 MISCELLANEOUS CLEANING.........................................................................................6-6

6.5 ELECTRICAL PREVENTIVE MAINTENANCE ..................................................................6-6

6.6 SPARE TWT MAINTENANCE AND PERIODIC OPERATION OF THE AMPLIFIER. 6-6

6.7 PERFORMANCE TESTING .....................................................................................................6-8

vi

THIS DOCUMENT IS THE PROPERTY OF COMMUNICATIONS & POWER INDUSTRIES.

REPRODUCTION OR RELEASE WITHOUT EXPRESS PERMISSION IS STRICTLY PROHIBITED

DOC.01023245 REV.K

CHPA SERIES

6.8 POWER AND GAIN ...................................................................................................................6-8

CHAPTER 7 DRAWINGS AND SCHEMATICS................................................................................7-1

CHAPTER 8 SUPPLEMENTARY DATA............................................................................................8-1

APPENDIX A SPECIFICATIONS.......................................................................................................A-1

APPENDIX B CONTROL APPEARANCE AND CONTENT ..........................................................B-1

B.1 OVERVIEW................................................................................................................................B-1

B.2 BUTTONS ...................................................................................................................................B-1

B.3 LEDS............................................................................................................................................B-2

B.4 BEEPER.......................................................................................................................................B-3

B.5 ALPHANUMERIC DISPLAY DEFINITION .........................................................................B-3

B.6 METERS......................................................................................................................................B-5

B.6.1 HVPS METER DISPLAY LIST: .........................................................................................B-5

B.6.2 RF METERS.........................................................................................................................B-5

B.6.3 METER ORDER ..................................................................................................................B-5

B.6.4 METER LIST........................................................................................................................B-6

B.7 FAULT MESSAGES THAT CORRESPOND TO DIGITAL STATUS LINES...................B-6

B.8 FAULT MESSAGES GENERATED BY LIMIT COMPARISONS .....................................B-7

B.9 ALARMS.....................................................................................................................................B-8

B.10 CONTROL MENU.................................................................................................................B-9

B.11 DATA ENTRY RULES..........................................................................................................B-9

B.11.1 CATEGORIES....................................................................................................................B-13

B.11.2 RF CONTROL....................................................................................................................B-13

B.11.3 LINEARIZER CONTROL (OPTIONAL)..........................................................................B-14

B.12 LINEARIZER ADJUSTMENT...........................................................................................B-15

B.13 RF TRIP LIMITS/SWITCH PORT RELAY SETTINGS................................................B-16

B.13.1 FAULT LOG ......................................................................................................................B-17

B.13.2 FACTORY AUTHORIZED ACCESS CODE (FAAC).....................................................B-18

B.13.3 FAULT TRIP SETTING ....................................................................................................B-19

OC.01023245 REV.K

D

THIS DOCUMENT IS THE PROPERTY OF COMMUNICATIONS & POWER INDUSTRIES.

REPRODUCTION OR RELEASE WITHOUT EXPRESS PERMISSION IS STRICTLY PROHIBITED

vii

CHPA SERIES

B.13.4 FACTORY TESTS.............................................................................................................B-19

B.13.5 RESET ELAPSED TIME METERS ..................................................................................B-19

B.13.6 RESET TO FACTORY DEFAULTS.................................................................................B-20

B.13.7 CHPA HVPS TEST MODE ...............................................................................................B-20

B.13.8 USER TESTS......................................................................................................................B-21

B.13.9 TIME/DATE SET...............................................................................................................B-22

B.13.10 REMOTE/COMPUTER INTERFACE PARAMETERS...............................................B-23

B.13.11 SOFTWARE VERSIONS...............................................................................................B-26

B.13.12 ELAPSED HOURS INFORMATION............................................................................B-26

B.14 QUICK ACCESS CODES....................................................................................................B-27

B.15 POST FAULTS .....................................................................................................................B-29

B.16 SOFTWARE ERROR CODES............................................................................................B-29

B.16.1 FLASH RAM - OPERATION AND PROGRAMMING................................................... B-30

B.16.2 TO FORCE THE CHPA TO USE EPROM CONTENTS..................................................B-30

B.16.3 REPROGRAMMING THE FLASH RAM.........................................................................B-30

B.16.4 TROUBLESHOOTING AND ERROR MESSAGES ASSOCIATED WITH THE FLASH

RAM B-32

APPENDIX C REPLACEABLE PARTS.............................................................................................C-1

APPENDIX D WARRANTY AND SUPPORT INFORMATION.....................................................D-1

APPENDIX E OPTIONS AND FEATURES .......................................................................................E-1

APPENDIX F OPTIONAL L-BAND BUC .......................................................................................... F-1

F.1 OVERVIEW................................................................................................................................F-1

F.2 PRECAUTIONS .........................................................................................................................F-2

viii

THIS DOCUMENT IS THE PROPERTY OF COMMUNICATIONS & POWER INDUSTRIES.

REPRODUCTION OR RELEASE WITHOUT EXPRESS PERMISSION IS STRICTLY PROHIBITED

DOC.01023245 REV.K

CHPA SERIES

List of Figures

Figure 1-1. The CHPA ...........................................................................................................................1-2

Figure 1-2. CHPA RF Diagram.............................................................................................................1-4

Figure 1-3. Power Supply Block Diagram ..........................................................................................1-6

Figure 2-1. Rear Panel of CHPA...........................................................................................................2-3

Figure 3-1. Setting Termination Resistors...........................................................................................3-3

Figure 3-2. Setting Serial Format..........................................................................................................3-7

Figure 4-1. The CHPA Series Front Panel...........................................................................................4-2

Figure 5-1. Control Panel ......................................................................................................................5-1

Figure 5-2. Example: Accessing CHPA Features...............................................................................5-9

Figure 6-1. TWT Amplifier Test Setup ..............................................................................................6-10

Figure B-1. Front Panel Picture ........................................................................................................... B-1

List of Tables

Table 1-1. CHPA Model Number and Frequency Ranges ...............................................................1-1

Table 1-1. CHPA Model Number and Frequency Ranges (continued)..........................................1-2

Table 3-1. Serial Remote Interface Pin Assignment (J6)....................................................................3-3

Table 3-1. Serial Remote Interface Pin Assignment (J6) (continued) ..............................................3-4

Table 3-2. Low RF Relay Function.......................................................................................................3-5

Table 3-3. RF Switch Pin Assignment (J5) ..........................................................................................3-6

Table 3-4. Interlocks Interface Pin Assignments (J8).........................................................................3-7

Table 3-5. CIF (Computer Interface) Pin Assignment (J7)................................................................3-9

Table 3-6. Reject Bytes .........................................................................................................................3-11

Table 3-6. Reject Bytes (continued)....................................................................................................3-12

Table 3-7. Query Commands..............................................................................................................3-14

Table 3-8. CHPA Commands .............................................................................................................3-15

Table 3-8. CHPA Commands (continued)........................................................................................3-16

Table 3-9. Slow Commands ................................................................................................................3-16

Table 3-10. Interface Commands........................................................................................................3-16

Table 3-11. Summary Status Bytes.....................................................................................................3-17

OC.01023245 REV.K

D

THIS DOCUMENT IS THE PROPERTY OF COMMUNICATIONS & POWER INDUSTRIES.

REPRODUCTION OR RELEASE WITHOUT EXPRESS PERMISSION IS STRICTLY PROHIBITED

ix

CHPA SERIES

Table 3-12. Secondary Status Bytes....................................................................................................3-18

Table 3-13. Fault and Miscellaneous Status......................................................................................3-19

Table 3-13. Fault and Miscellaneous Status (continued) ................................................................3-20

Table 3-14. Information/Error Messages..........................................................................................3-20

Table 3-14. Information/Error Messages (continued) ....................................................................3-21

Table 4-1. Helix and RF Settings Ranges ............................................................................................4-5

Table 4-1. Helix and RF Settings Ranges (continued).......................................................................4-6

Table 5-1. Front Panel Categories ......................................................................................................5-11

Table 5-1. Front Panel Categories (continued).................................................................................5-12

Table 5-1. Front Panel Categories (continued).................................................................................5-13

Table 6-1. Preventive Maintenance Schedule CHPA........................................................................6-2

Table 6-1. Preventive Maintenance Schedule CHPA (continued)...................................................6-3

Table 6-2. Recommended Test and Service Equipment Description..............................................6-3

Table 6-2. Recommended Test and Service Equipment Description (continued) ........................6-4

Table 7-1. Compact HPA Drawings ....................................................................................................7-1

Table B-1. Front Panel Button Description ........................................................................................ B-2

Table B-2. Front Panel LEDs................................................................................................................ B-3

Table B-3. Front Panel Categories..................................................................................................... B-10

Table B-3. Front Panel Categories (continued) ............................................................................... B-11

Table B-4. Default Values For User Features................................................................................... B-12

Table B-5. RF Display Preferences .................................................................................................... B-13

Table B-6. RF Alarms and Faults....................................................................................................... B-16

Table B-7. User Tests and Results ..................................................................................................... B-21

Table B-8. Time/Date Settings .......................................................................................................... B-22

Table B-9. Computer Interface Parameters...................................................................................... B-23

Table B-9. Computer Interface Parameters (continued) ................................................................ B-24

Table B-10. Computer Interface Parameters.................................................................................... B-24

Table B-10. Computer Interface Parameters (continued) .............................................................. B-25

Table B-11. Software Versions........................................................................................................... B-26

Table B-12. Elapsed Hours Feature................................................................................................... B-26

Table B-13. POST Faults ..................................................................................................................... B-29

Table B-14. Software Error Codes..................................................................................................... B-29

x

THIS DOCUMENT IS THE PROPERTY OF COMMUNICATIONS & POWER INDUSTRIES.

REPRODUCTION OR RELEASE WITHOUT EXPRESS PERMISSION IS STRICTLY PROHIBITED

DOC.01023245 REV.K

CHPA SERIES

Table C-1. Replaceable Parts Listing ..................................................................................................C-1

Table C-1. Replaceable Parts Listing (continued).............................................................................C-2

OC.01023245 REV.K

D

THIS DOCUMENT IS THE PROPERTY OF COMMUNICATIONS & POWER INDUSTRIES.

REPRODUCTION OR RELEASE WITHOUT EXPRESS PERMISSION IS STRICTLY PROHIBITED

xi

CHPA SERIES

This page is intentionally left blank.

xii

THIS DOCUMENT IS THE PROPERTY OF COMMUNICATIONS & POWER INDUSTRIES.

REPRODUCTION OR RELEASE WITHOUT EXPRESS PERMISSION IS STRICTLY PROHIBITED

DOC.01023245 REV.K

S-1

CHPA SERIES

Safety

Introduction

In addition to the High Voltage Equipment Personnel Operating Guidelines given in this chapter,

included by reference are the following pertinent sections of the International Standard EN60215,

Safety Requirements for Radio Transmitting Equipment:

• Appendix D, Guidance on Assessing the Competence of Personnel for Designation as

Skilled, and also Sub-clause 3.1 of the Standard.

• Appendix E, Guidance on Safety Precautions to be Observed by Personnel Working on

Radio Transmitting Equipment, and also Sub-clauses 3.2, 3.7, and 22.1 of the Standard.

High Voltage Equipment

Personnel Operating Guidelines

This guideline document presents operating practices for operators and technicians who work

with high voltage equipment. In the context of this discussion any voltage that is lethal is viewed

as "high voltage." Therefore, even prime power (115 to 440VAC) is dangerous because prime

power potentials have been known to cause death or injury.

Electrical circuits operate quickly and do not allow a careless individual a second chance. When

dealing with high voltage, the results are very consistent and predictable and hazards associated

with high voltage are always present. The fact that the control switch says OFF does not mean

you are safe.

Note: The guidelines presented in this chapter are not academic. They are

based on the experience of engineers and technicians who have years of

experience with high voltage circuits.

When is Voltage "High"?

As stated earlier, any voltage that can kill you should be treated as high voltage. Voltages

associated with prime power generally do not jump the air gap between people and the

equipment. Usually exposed circuit elements such as a terminal, bare piece of wire, or some noninsulated surface must be touched.

D

OC.01023245 REV.K

THIS DOCUMENT IS THE PROPERTY OF COMMUNICATIONS & POWER INDUSTRIES.

REPRODUCTION

OR RELEASE WITHOUT EXPRESS PERMISSION IS STRICTLY PROHIBITED

S-1

CHPA SERIES

One of the problems associated with prime power is some equipment can be "floating" above

ground. In this case, if you place one hand on the equipment chassis and the other on earth

ground, you can be jolted, injured, or killed. 440VAC can stimulate an involuntary muscle

response that will either literally throw you across a room or seize and hold you across the voltage

terminals. 600 or more volts can hold you indefinitely. If the potential is sufficient to drive 200

milliamps through your body you will be held indefinitely. Some people consider the 200 to 600

volt range to be worse than potentials of thousands of volts.

General Guidelines

In addition to the above, the following practices have proven effective for personnel who deal

with high voltage equipment.

a. Hands off. Avoid contact with any potential source of high voltage. Keep hands out

of the equipment when it is operating.

b. Avoid accidental contact. Make sure that some other part of your body does not come

in contact with the high voltage circuits. It is easy to forget the hazards when you are

concentrating on a frustrating or interesting task. Pens and badges in shirt pockets

could contact the equipment.

c. Never work on high voltage circuits when you are alone. If anything should happen

to you, your only chance may be prompt action by some other person. Be sure

someone else is present and knows what to do in any emergency (e.g., how to shut

equipment off, first aid, who to call, etc.)

d. Use one hand when working with high voltage circuits. Many people recommend

that you put one hand in your pocket when you use a probe or other piece of

equipment inside a high voltage section.

e. Do not float measuring equipment above ground. Make all measurements with

respect to ground. If you float an instrument, do not reach inside the equipment.

Although it is more difficult to get the right setup, it is well worth the effort.

f. Do not assume that the level of risk is a function of size. Some large high power

voltage equipment looks docile. One reason the equipment is so big is to get the

proper separation between high voltage points. On the other hand, just because the

equipment is small is no assurance of safety. Dense packaging results in more difficult

access and increases the chance that you will accidentally hit the wrong point.

g. Always discharge high voltage capacitors. High voltage capacitors store a lot of

energy for long periods of time. High voltage capacitors also exhibit a "memory" in

that they can recover after discharge and reach lethal levels. In addition to the

"memory" problem, there have been instances where the built-in safety features have

failed or have been miswired. Each and every time you go to work on a piece of high

voltage equipment, use a discharge device with a long handle to discharge every

high voltage capacitor.

h. Do not depend on the automatic features of the equipment to save you. You never

know when someone has left a circuit disabled, if there has been a wiring error, or if a

component has failed.

S-2

THIS DOCUMENT IS THE PROPERTY OF COMMUNICATIONS & POWER INDUSTRIES.

REPRODUCTION

OR RELEASE WITHOUT EXPRESS PERMISSION IS STRICTLY PROHIBITED

DOC.01023245 REV.K

CHPA SERIES

i. Take personal responsibility to assure that no one can turn on the high voltage

circuits when you are working on the equipment. Precautions would include taping

down (or installing a keeper) on controls/circuit breakers and/or disconnecting the

power source to the high voltage circuits, activating interlocks that prevent high

voltage turn on, etc. Know where the power disconnects are and use them. Do NOT

rely on anyone not to turn on the high voltage.

j. Set up your test equipment with the power off. Conduct the power-on operations

when you have your hands out of the equipment.

k. Do not use short probes for high voltage measurements. A short probe does not

allow any margin for error. If your hand slips you could accidentally come into contact

with a danger point. A long probe avoids the whole problem.

l. Read the instruction manual. The best insurance is foreknowledge of hazards.

m. Create a favorable environment for safe operations. This means that if people are

crowding you, stop the operation if it involves high voltage. Pressure can lead to

carelessness. In the same way, fatigue is also an enemy. STAY ALERT AT ALL TIMES

WHEN WORKING WITH HIGH VOLTAGE.

n. Do not become over-confident. Maintain a healthy respect for high voltage.

o. A good operating practice is to check the potential between the equipment chassis

and earth ground before you complete the circuit with your body. As voltage levels

increase, the protection you get from insulation and air gap diminishes. For example,

in a piece of equipment that involves beam voltages of about 16kV, the beam

transformers look very safe with massive insulation on the outside of the coils.

Physical contact with the beam coil when the system is operating can be fatal.

Although the equipment is placard to warn people of the presence of high voltage, it is

virtually impossible to placard every point of danger in a system.

p. If you do not know how the equipment works and what the hazards associated with

the equipment are in specific terms, do NOT handle the equipment. The greatest

protection you can have when dealing with high voltage equipment is specific detailed

knowledge on that particular piece of equipment.

q. Avoid "haywire" test setups. It is easy to get in trouble if the setup you are using has a

jumble of wires.

r. Make sure your connections are secure. Do NOT allow leads to slip off and move

about in an uncontrolled fashion. Even if it is not one of the high voltage leads, a free

lead could (and generally does) move exactly to where you do not want it. The only

safe connection is a mechanically secure one.

s. Watch out for unterminated high voltage leads. Some connectors depend on circuit

loading to avoid arcing between closely spaced terminals. Unloaded high voltage lines

or plugs can lead to arcing situations.

D

OC.01023245 REV.K

THIS DOCUMENT IS THE PROPERTY OF COMMUNICATIONS & POWER INDUSTRIES.

REPRODUCTION

OR RELEASE WITHOUT EXPRESS PERMISSION IS STRICTLY PROHIBITED

S-3

CHPA SERIES

t. Shut off the high voltage when you are making low voltage measurements. It does

not make sense to increase danger needlessly. While there may be times when you

cannot shut off the high voltage during a low voltage measurement, this is generally

not the case.

u. Remove the test equipment when you have finished a measurement program. There

have been many instruments destroyed or damaged because a test program was

conducted in a haphazard manner, rather than in an orderly progression from start to

finish. Experience has shown in many instances when a little order would have

prevented a tragedy or avoided an expensive mistake.

v. Be extremely wary when making filament voltage measurements. The cathode of

tubes is elevated above (or below) ground and the filament voltages usually cannot be

measured with reference to ground. Do everything you can to assure that the high

voltage cannot be turned on when you are making your measurements. This includes

disconnecting the high voltage drive source, shorting out appropriate leads, taping

down switches, and anything else you can think of to protect yourself.

w. When troubleshooting a unit, assume that the switches and components are

defective. You may shut off the high-voltage switch in some systems, but if the switch

were defective, the high voltage would still be on. Returned units are potential booby

traps.

x. Make sure that your workstation is stable. Flimsy work surfaces or supports for the

equipment or the test instruments represent a real threat. Do NOT use a setup that you

know is unstable and/or dangerous.

y. Use a 1-minute rule. Wait 1 minute or more after you have shut off the equipment

before you work on a unit. Part of the reason for a 1-minute rule is that some of the

dielectrics (insulators) used for high voltage circuits can store a charge. While the

amount of charge stored is a function of the size of the object, a 1-minute rule provides

an additional margin of safety.

z. Maintain a healthy respect for any kind of live circuit. Complacency can hurt or kill

you. Your continued wariness is your best insurance against injury or death.

Microwave Radiation

Personnel Operating Guidelines

This guideline presents operating practices appropriate for operators and technicians who work

with equipment involving microwave radiation. Keep in mind that levels of microwave radiation

that do not induce immediate physical discomfort in most individuals can be sufficiently high to

induce longer-term effects.

S-4

THIS DOCUMENT IS THE PROPERTY OF COMMUNICATIONS & POWER INDUSTRIES.

REPRODUCTION

OR RELEASE WITHOUT EXPRESS PERMISSION IS STRICTLY PROHIBITED

DOC.01023245 REV.K

CHPA SERIES

CPI Satcom Division equipment usually is related to amplification of a RF signal from an external

source. Even if a source is not connected to the amplifier you are working with, there are

situations where the amplifier can go into a self-induced mode and generate high levels of RF

energy. This condition can exist if the unit is operated with high voltage ON and without proper

termination on the input and output of the amplifier.

CAUTION! PROTECT YOURSELF AND THOSE AROUND YOU FROM UNWANTED RF

EXPOSURE. ALWAYS TERMINATE THE AMPLIFIER INPUT AND OUTPUT WITH A

RF DUMMY LOAD BEFORE YOU TURN THE HIGH VOLTAGE ON. THIS WILL

REDUCE THE CHANCES OF OSCILLATION DUE TO INTERNAL AMPLIFIER NOISE.

Microwave Discussion

Limit exposure to microwave radiation to prevent unwanted biological effects. There are other

effects that can lead to problems if you are careless in operating or servicing microwave

equipment. The permissible levels are quite low in comparison to the power levels of the

amplifiers built by CPI (e.g., less than 10 milliwatts vs. 20 to 10,000 Watts delivered by different

units)

Local radiation levels can be detected with the proper equipment. The permissible levels are

currently being studied by a number of organizations. In the past the U.S. Safety Codes

established a dosage rate of 10mw/cm. Sq. Recently the permissible level has been reduced to

1mw/cm. sq. in the United States, as has been the case in several European countries.

General Microwave Guidelines

The purpose of these guidelines is to provide practical approaches to control unwanted

microwave energy associated with the operation and servicing of CPI Satcom Division equipment.

The following approaches are effective in both laboratory or field environments:

a. Always terminate the output waveguide or coaxial connector with a dummy RF load

(capable of dissipating full CW RF power). Similarly, terminate the input to avoid the

possibility of the amplifier being driven by stray leakage signals. Incorporate the

terminations prior to applying prime power to the amplifier. This procedure prevents selfoscillation and irradiation of the local equipment.

b. Do not look into the output port of the powered RF amplifier. Treat the powered amplifier

as though it is a loaded gun. Your eyes are particularly vulnerable parts of your body.

c. Shut off the unit if you are trying to locate a RF leak. As noted earlier, the levels of concern

are very low. Examine the physical unit with the high voltage OFF. If you have to survey the

RF runs with the power ON to find the leaky joint or component, start by testing the system

with low RF input and a radiation meter.

If the microwave radiation exceeds 0.5mw/cm. sq., shut OFF the high power voltage and consult

your supervisor. Work quickly (not at a panic pace) to minimize the dose level. The dose you get

is directly proportional to the power level and the time you are exposed. Exposure to microwave

radiation can induce both thermal and non-thermal biological effects, especially with the eyes.

D

OC.01023245 REV.K

THIS DOCUMENT IS THE PROPERTY OF COMMUNICATIONS & POWER INDUSTRIES.

REPRODUCTION

OR RELEASE WITHOUT EXPRESS PERMISSION IS STRICTLY PROHIBITED

S-5

CHPA SERIES

If you damage the lens of your eyes by exposure to microwave radiation, cataracts can result.

Consider that small microwave ovens are very effective in cooking foods. If you follow these

guidelines you can minimize exposure of yourself and other people in the operations that you

control.

Physical Safety

Lifting Heavy Objects

Back and other injuries can result from one person trying to lift too much weight.

Use extreme caution when lifting klystrons. Klystrons weigh up to 100 pounds (45 kg) and

require two persons to lift them.

Due to the weight of the drawers, at least two persons are required for installation of the drawers

to the final rack assembly. At least two people are also required for removal of the drawers from

the rack assembly.

Extending Rack Slides

a. Serious injuries can result from heavily loaded racks or drawers falling forward.

b. Due to the weight of the drawers, the rack must be securely bolted to the floor in all four

corners to prevent tipping when the drawer slides are extended.

c. Verify that all slides are securely mounted and that all latches and stops are functioning

properly.

d. Serious injuries can also result from hands, fingers, or clothing getting caught in slides and

drawers when extended drawers are being pushed back into a rack.

e. Exercise extreme caution when sliding extended drawers back into a rack.

S-6

THIS DOCUMENT IS THE PROPERTY OF COMMUNICATIONS & POWER INDUSTRIES.

REPRODUCTION

OR RELEASE WITHOUT EXPRESS PERMISSION IS STRICTLY PROHIBITED

DOC.01023245 REV.K

1-1

CHPA SERIES

Chapter 1

Introduction

1.1 Overview

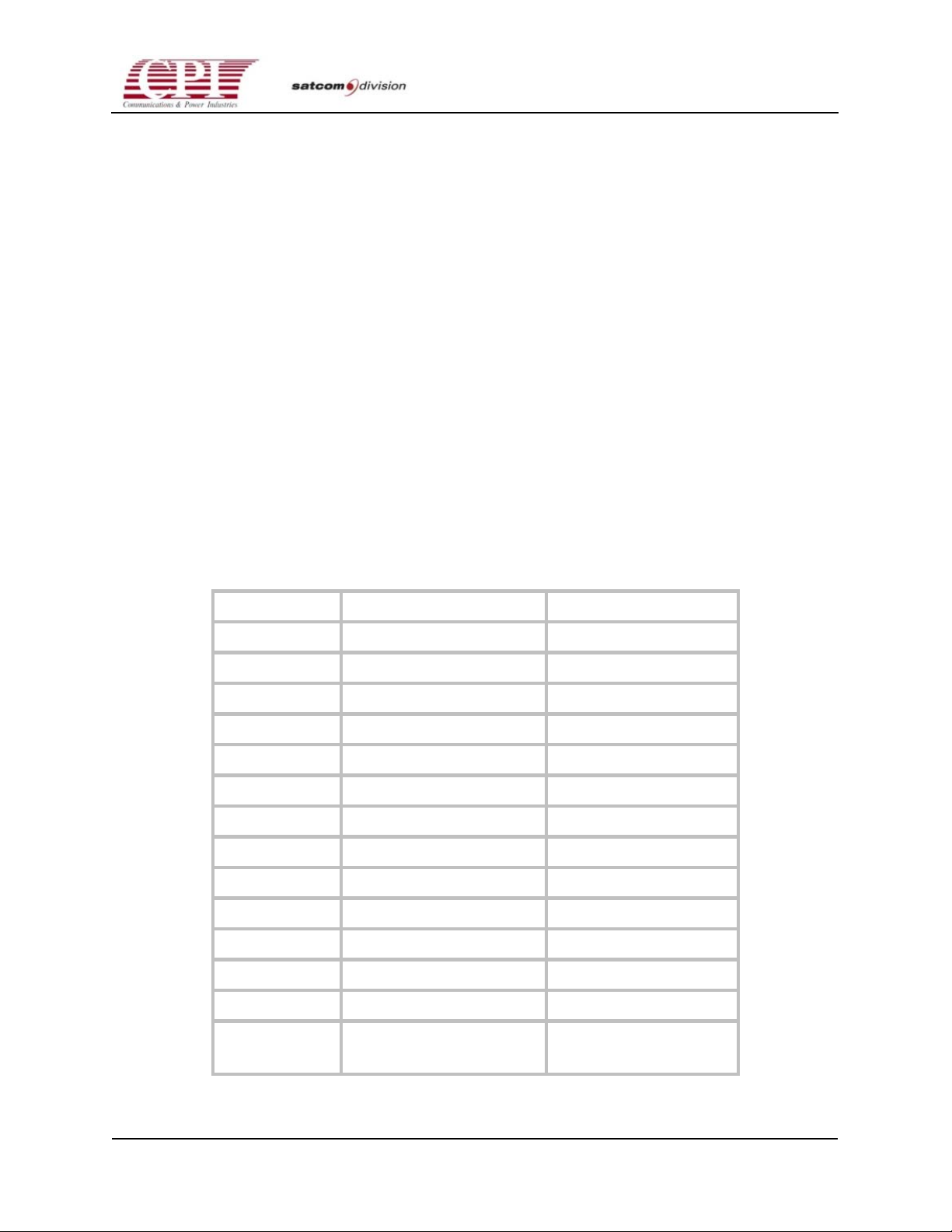

The new Compact High Power Amplifier (CHPA) series is designed for satellite communication

earth stations, satellite news- gathering vehicles, and fly-away applications operating in the C

and Ku and DBS frequency bands. Radio frequency (RF) power of up to 700 watts (for C- and

Ku- and DBS band amplifiers) is available in this series.

The model numbers, frequency ranges, and rated output power at the waveguide flange of the

high power CHPA series are as follows:

Table 1-1. CHPA Model Number and Frequency Ranges

Model No. Frequency Range (GHz) Rated Power (Watts)

VZC-6967AM 5.850 - 6.725 650

VZC-6967AN 5.850 - 7.075 650

VZC-6967AT 5.850 - 6.650 650

VZC-6967AD 5.715 - 6.425 602

VZC-6967AB 5.850 - 6.650 602

VZC-6967AG 5.850 - 7.075 602

VZC-6967AJ 5.725 - 6.725 602

VZC-6967AH 6.425 - 7.100 650

VZU-6996AB 12.75 - 14.50 501

VZU-6997AB 12.75 - 14.50 650

VZU-6997AC 13.75 - 14.50 602

VZU-6996AC 13.75 - 14.50 501

VZU-6997AE 14.00 - 14.80 602

OC.01023245 REV.K

D

VZU-6997AG 14.70 - 15.32 602

(549 above 15GHz)

THIS DOCUMENT IS THE PROPERTY OF COMMUNICATIONS & POWER INDUSTRIES.

REPRODUCTION OR RELEASE WITHOUT EXPRESS PERMISSION IS STRICTLY PROHIBITED

1-1

CHPA SERIES

Table 1-1. CHPA Model Number and Frequency Ranges (continued)

Model No. Frequency Range (GHz) Rated Power (Watts)

VZU-6997AA 13.00 - 13.25 602

VZU-6997AD 13.75 - 14.50 650

VZU-6997AJ 12.75 - 13.25 650

VZU-6995AY 17.30 - 18.40 407

VZU-6996AY 17.30 - 17.80 501

VZU-6997CY 17.30 - 18.40 650

VZU-6997AX 17.30 - 18.40 624

VZU-6997AY 17.30 - 18.10 624

The CHPA series has been specifically designed for enhanced performance and ease of

operation. In addition, the CHPA incorporates the use of a microprocessor control system,

thereby simplifying interfacing with remote control and monitor facilities. Flash RAM allows

firmware updates to be made without opening the unit. Implementation of a compact,

lightweight, wideband TWT (traveling wave tube) permits continuous, efficient use across the

entire frequency band. The CHPA also supports the unique internal linearizer, which can be

controlled from the front panel, optional remote panel, and serial computer interface.

Design of the CHPA is also based on the extensive use of LRUs (line replaceable units).

Comprehensive diagnostic procedures allow field personnel to quickly isolate a faulty LRU;

extensive use of captive hardware on the LRU helps to speed the replacement of the LRU so

that the CHPA can be returned to service with a minimum of downtime.

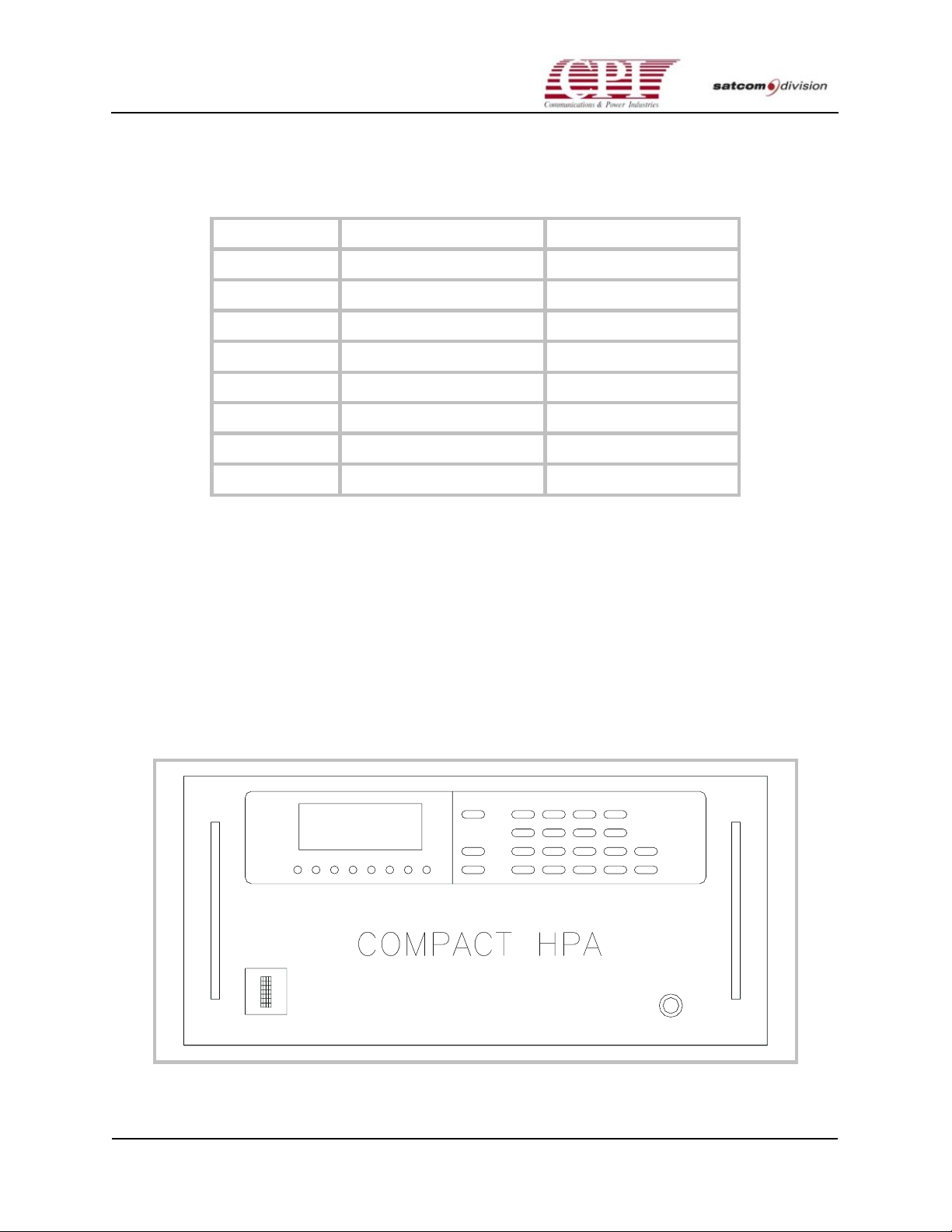

Figure 1-1. The CHPA

1-2

THIS DOCUMENT IS THE PROPERTY OF COMMUNICATIONS & POWER INDUSTRIES.

REPRODUCTION OR RELEASE WITHOUT EXPRESS PERMISSION IS STRICTLY PROHIBITED

DOC.01023245 REV.K

CHPA SERIES

1.2 About This Manual

This manual contains information that describes installation, operation, and maintenance

procedures for the Compact High Power Amplifier (CHPA) series. Because specialized training

is required for some phases of installation and repair, certain parts of this manual are directed

only to trained personnel. Warnings appear at the appropriate points to caution all users of

potential RF or high-voltage hazards.

Each chapter begins with a clearly marked tab; this allows the reader to have rapid access to a

particular section. A “Contents,” “List of Figures,” and “List of Tables” are included at the

beginning of the manual for reference to each section.

Chapter 1, “Introduction,” contains a brief overall description and a detailed technical

description of the CHPA. The design philosophy and a brief description of the optional features

are also included in this chapter.

Chapter 2, “Unpacking and Installation,” contains procedures for preparing the site for

installation and unpacking the CHPA. It also describes the steps required to make the

necessary power connections.

Chapter 3, “Interfaces,” describes the CHPA’s built-in interfaces to external devices; also listed

are detailed descriptions for each connection. The communication protocol and command set

used for computer control of the CHPA are also included in this chapter.

Chapter 4, “Initial Power-On and Checkout,” describes the TWT (traveling wave tube)

preconditioning procedures, use of the Front Panel to start up and check out the CHPA, and

instructions for configuring the CHPA for the particular site installation; this includes setting

serial port parameters.

Chapter 5, “Operation,” contains procedures for normal start-up, shutdown, and detailed

operational modes of the CHPA.

Chapter 6, “Maintenance,” contains procedures for scheduled maintenance; also explained are

fault and alarm conditions.

Chapter 7, “Drawings and Schematics,” contains drawings of the various frequency band

CHPAs. It also includes detailed RF schematics and an overall system interconnect drawing.

Chapter 8, “Supplementary Data,” consists of five appendixes; contained are detailed

specifications for the CHPA, a listing of control and display functions, and a summary of

optional features that are available from CPI. Also contained are service and warranty

information and a list of replaceable parts.

OC.01023245 REV.K

D

THIS DOCUMENT IS THE PROPERTY OF COMMUNICATIONS & POWER INDUSTRIES.

REPRODUCTION OR RELEASE WITHOUT EXPRESS PERMISSION IS STRICTLY PROHIBITED

1-3

CHPA SERIES

1.3 Major Subsystems and Their Functions

The CHPA (Figure 1-1) is packaged in an 8.75-inch-tall slide-mounted drawer suitable for

standard 19-inch rack mounting. This enclosed assembly houses both the RF and power supply

sections. The overall amplifier enclosure measures approximately 19" (w) x 8.75" (h) x 24" (d),

plus fan and external air duct adapters, and weighs approximately 90 lb.

The RF section includes the TWT (traveling wave tube), SSIPA (solid-state intermediate power

amplifier) with integrated PIN diode attenuator, input/output isolation circuits, RF detectors,

and output filter.

The power supply section includes the power factor correction, power processor, and highvoltage regulation circuitry as well as monitor and control circuitry.

Microprocessor circuits provide automatic sequencing to control both CHPA operation and

continuous monitoring of critical parameters.

The front panel of the unit serves as the primary user interface housing all monitor and control

functions including a type “N” RF connector to sample and measure output RF power.

Protection circuits are included to permit safe, efficient, and reliable operation of the CHPA.

Detailed specifications for the CHPA are provided in Appendix A of Chapter 8,

“Supplementary Data.”

1.4 Technical Description

1.4.1 RF Subsystem

A conservative, field-proven approach is used in the CHPA RF subsystem. The RF block

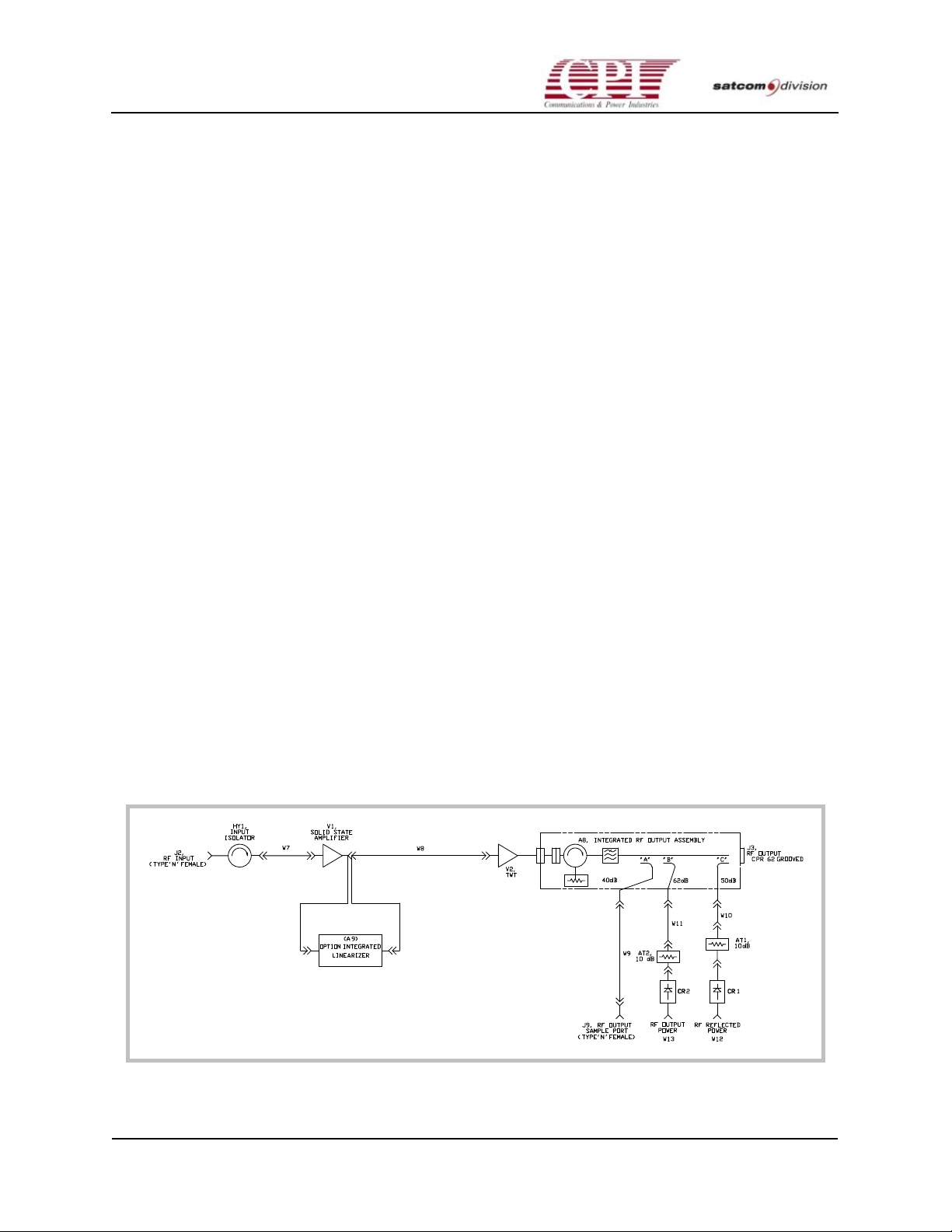

diagram (Figure 1-2) identifies all major circuit elements for this technical description.

1-4

Figure 1-2. CHPA RF Diagram

THIS DOCUMENT IS THE PROPERTY OF COMMUNICATIONS & POWER INDUSTRIES.

REPRODUCTION OR RELEASE WITHOUT EXPRESS PERMISSION IS STRICTLY PROHIBITED

DOC.01023245 REV.K

CHPA SERIES

A low-level RF input signal is applied to the CHPA via a type “N” connector (isolator) located

at the rear of the enclosure. The isolator limits the input voltage standing wave ratio (VSWR) to

a level of 1.3:1 or less back to the source. The RF input is then routed to the SSIPA, which

includes an integrated PIN diode attenuator. The attenuator, controlled via the front panel, has

a control range of a nominal 20 dB with quick response and excellent linearity. Built-in memory

circuits are provided to return the attenuator to a previously set level in the event of prime

power outages.

The SSIPA is designed to be transparent to final amplifier RF parameters and is temperature

compensated to minimize drift. As a result, the overall TWT CHPA gain is specified to be

stable within ± 0.25 dB/24 hours with 10 percent line voltage variations. The output of the

SSIPA is connected to an isolator that protects the SSIPA from TWT failure. The SSIPA and

TWT provide a combined subsystem gain of at least 75 dB at maximum rated power for the Cband and 75 dB for the Ku-band.

The TWTs employed in this power amplifier feature air-cooled, dual depressed collectors for

efficient operation, and periodic permanent magnet (PPM) focused helix design. They are

designed especially for compact, lightweight applications involving satellite uplink service. The

output waveguide assembly interfaces to the TWT and protects the tube from abnormal or

transient conditions that could permanently damage the TWT. This assembly consists of a fourport circulator, harmonic filter, receive reject filter, and three-port directional coupler. The

high-power isolator provides a low VSWR to the external waveguide run and antenna feed.

The isolator assists in protecting the TWT from excessive reflected power due to

damaged/broken waveguides or antenna components. The isolator is rated such that it will

safely dissipate all reflected power equal to the full rated output of the CHPA for the duration

of time until the protection circuits shut off the high-voltage power supplies. In addition, the

isolator is designed such that it can safely dissipate a VSWR mismatch of 2.0:1 (12 percent of

forward RF power) indefinitely.

The harmonic filter contained in the output waveguide assembly provides a minimum of 60 dB

attenuation at the second harmonic and 45 dB attenuation at the third harmonic. The receive

reject filter serves as a high-pass filter cutting off below-band signals. Finally, the three-port

directional coupler provides one reflected power port coupled via a detector to the RF power

monitor assembly for reverse power protection, and two for forward power: one for the user to

monitor forward RF power via a type “N” connector on the front panel, and one for use by the

optional forward power metering circuit, which uses a similar detector to process the RF signal.

The RF sample port, calibrated in coupling ratio versus frequency, permits independent

monitoring of CHPA output power levels through the use of an external spectrum analyzer or

portable power meter. High reflected RF protection circuitry is standard, and reflected power

information is sent to the front panel for display. User-settable low and high RF power alarms

are also available.

The output and reflected power level readouts are also available for remote monitoring via the

optional CPI remote control panel or via the Computer Interface (CIF) port located at the rear of

the enclosure. The RF drive is adjustable via the Serial Remote and CIF port. Also, the RF

sample port, calibrated in coupling ratio versus frequency, permits independent monitoring of

CHPA output power levels through the use of an external spectrum analyzer or portable power

meter.

OC.01023245 REV.K

D

THIS DOCUMENT IS THE PROPERTY OF COMMUNICATIONS & POWER INDUSTRIES.

REPRODUCTION OR RELEASE WITHOUT EXPRESS PERMISSION IS STRICTLY PROHIBITED

1-5

CHPA SERIES

The standard RF output interface, provided by the user, to connect the CHPA to the external

waveguide run is a CPR-137F (flange) termination for the C-band, and WR-75F for the Ku-band.

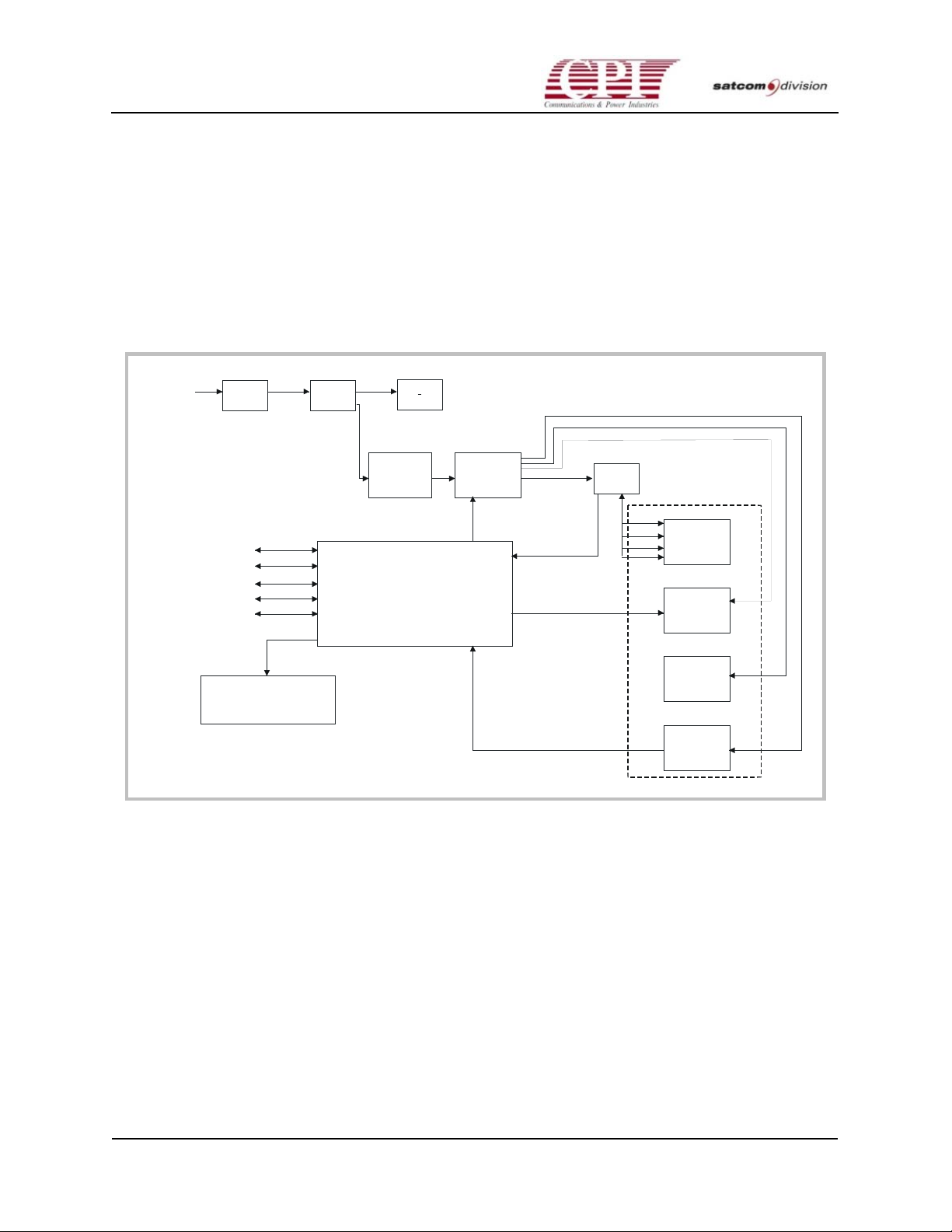

1.4.2 Power Supply Subsystem

The power supply portion of the CHPA provides all of the internal voltages necessary to

operate the TWT, RF driver (SSIPA), the forced-air cooling system, and auxiliary circuits for

control, monitoring, and protection of the CHPA. Other than the AC input power, no other

external power supplies or voltages are required for operation. A simplified block diagram of

the power supply is shown in Figure 1-3.

AC

Input

Flash RAM Programming

Serial Remote Control

(For use with CPI Remote Panel)

Switching I/F

Computer I/F

User Interlocks

EMI

Filter

Control

&

Display

Circuit

Breaker

220-240

VAC

Power Factor

Correction

Module

Micro-controller

Fans

375 VDC

Power

Processor

DC Power

RF Metering

& Faults

Control

&

Monitor

Control

HV

Module

Figure 1-3. Power Supply Block Diagram

Helix

Cathode

Coll. 1

Coll. 2

RF Subsystem

TWT

Linearizer

(optional)

SSIPA

RF Monitor

DC

Power

DC

Power

DC

Power

The traveling wave tube derives its operation from four DC power supplies: a low-voltage

filament (heater) supply, a high-voltage helix supply, and two high-voltage collector supplies.

The power supply design utilized in the CHPA is of the SMPC (switch mode power

conditioner) type, which has an excellent reputation for reliability and stability. An added

advantage of the SMPC approach over outdated linear power supplies is its intrinsic high

efficiency and safe operation. By limiting the amount of the instantaneous stored energy in the

power supply, the risk of permanent damage to the CHPA due to abnormal or transient

conditions is avoided. The momentary level of stored energy (measured in joules) is well below

the maximum limit of energy that the tube can safely dissipate during normal operation. The

principal circuit modules are discussed in the following paragraphs.

1-6

THIS DOCUMENT IS THE PROPERTY OF COMMUNICATIONS & POWER INDUSTRIES.

REPRODUCTION OR RELEASE WITHOUT EXPRESS PERMISSION IS STRICTLY PROHIBITED

DOC.01023245 REV.K

CHPA SERIES

1.4.3 Power Factor Correction Module

Input primary power––single-phase, 208-240 VAC, 47-63 Hz––flows via an EMI filter and the

main circuit breaker to both the cooling system power supply and the Power Factor Correction

Module. This module provides a regulated 375 VDC to the power processor and allows the

CHPA to meet the requirements of IEC-555 regarding total harmonic distortion.

1.4.4 Power Processor Module

The power processor circuits provide the necessary line and load regulation of the input 375

VDC bus, which is converted via the switch regulator and bridge circuit to a nominal 230 VAC,

25 kHz to drive the high-voltage module. A sample of the helix high-voltage output is returned

to the switch regulator for error feedback correction and sends a pulse-width modulated signal

through an optical isolator to the switching transistors. This approach allows careful regulation

of the TWT helix and collector voltages and protects both supplies from

overvoltage/undervoltage or short-circuit conditions. Low-voltage outputs produced by the

power processor (+/-15 VDC, +5VDC, and 16 VAC) are used to operate various internal circuit

functions as well as provide power for the RF monitor circuit, front panel display, SSIPA, and

optional internal linearizer. Internal sensors provide the necessary over-current protection

functions.

1.4.5 High-Voltage Module

The High-Voltage Module provides the following key power supply functions: regulated TWT

heater supply, regulated TWT high-voltage helix and collector supplies, helix supply

current/voltage monitoring, and fault protection.

The High-Voltage Module contains the transformers, rectifiers, filters, and voltage/current

sense circuits for all critical TWT voltages and currents. The incoming 230 VAC, 25 kHz signal

is applied to the primary of a multi-section high-voltage transformer, which provides all of the

high-voltage levels necessary to operate the traveling wave tube. Since the helix and collectors

share the same transformer and regulator, the high-voltage circuit design establishes the

collector voltages at 52 percent (collector #1) and 26 percent (collector #2) depression below the

helix voltage. This relationship permits optimum efficiency and substantial energy savings

while extending the useful life of the TWT. A separate step-down transformer with rectifier and

filter network operating off the 16 VAC supply is employed to provide the regulated low

voltage to power the TWT heater.

1.4.6 RF Power Monitor Module

The RF power monitor assembly receives signals from the reflected and forward power RF

detectors for use in fault/alarm sensing and power metering. This monitor assembly feeds

voltages to the microprocessor controller; it is the controller that monitors the RF levels to

determine RF high/low faults or high/low alarms. This assembly also contains hardware for

peak measurements. The reflected RF fault sensor protects the TWT against excessive reflected

power due to abnormal waveguide or antenna conditions.

OC.01023245 REV.K

D

THIS DOCUMENT IS THE PROPERTY OF COMMUNICATIONS & POWER INDUSTRIES.

REPRODUCTION OR RELEASE WITHOUT EXPRESS PERMISSION IS STRICTLY PROHIBITED

1-7

CHPA SERIES

1.4.7 Control and Display Modules

The Control and Display modules are designed to assure correct operation of the power

amplifier with minimal operator training. These microprocessor-based modules provide

automatic sequencing of CHPA operation and monitoring and control of all critical parameters

via both the front and rear panel interfaces. Flash RAM allows firmware updates to be made

without opening the unit.

The Display Module communicates to the user all necessary information required to monitor

and control the amplifier. Measured readings such as reflected RF power, helix voltage, helix

current, attenuator setting, and forward RF power are all available via the alphanumeric

display. Status LEDs are also included on the panel.

Detailed fault information and user-settable interface parameters are available to the user

through a menu system.

The Control Module is central to the CHPA. All control, input/output, and decision making,

with the exception of critical module, level decisions, is done by the Control Module. All rear

panel user interfaces are also communicated to via the Control Module. To survive AC power

loss, all user settings and operating parameters such as RF trips, TWT operating voltages, serial

port baud rate, and PIN diode attenuation setting, etc., are stored in the battery-backed random

access memory (RAM).

1.5 LRU Philosophy

The maintenance concept employed in the CHPA series is to localize a malfunction or circuit

failure down to the level of an LRU (line replaceable unit), extract the LRU, and replace it with

an equivalent part provided in the spares kit. This procedure can be completed in the field

without resorting to the costly practice of returning the entire CHPA to the depot for servicing.

The philosophy is to configure the LRUs as building blocks with a specific function that can be

monitored by sensors and fault indicators on a real-time basis.

The CHPA contains circuitry to protect itself from operational damage caused by abnormal AC,

DC, RF faults, or insufficient cooling.

Personnel safety is of utmost importance and is safeguarded by proper grounding and also by

access interlocks and covers that prevent physical entry into the high-voltage sections.

1-8

THIS DOCUMENT IS THE PROPERTY OF COMMUNICATIONS & POWER INDUSTRIES.

REPRODUCTION OR RELEASE WITHOUT EXPRESS PERMISSION IS STRICTLY PROHIBITED

DOC.01023245 REV.K

CHPA SERIES

1.6 Optional Features

To customize and enhance the functioning of the CHPA, CPI provides a range of options.

These include the following:

• An Internal Linearizer. The internal linearizer extends the linear operating region of the

amplifier. It is easily installed inside the CHPA and is controlled through the front panel,

optional remote panel, and serial computer interface.

• A Separate Remote Control Panel. This Remote panel has identical functions and

configuration as the one supplied with the CHPA.

• Redundant and Power Combined Subsystems. The TWT amplifier can be configured in a

1:1, 1:2, or 1:3 auto switching or power combined configuration as required by the end user.

OC.01023245 REV.K

D

THIS DOCUMENT IS THE PROPERTY OF COMMUNICATIONS & POWER INDUSTRIES.

REPRODUCTION OR RELEASE WITHOUT EXPRESS PERMISSION IS STRICTLY PROHIBITED

1-9

CHPA SERIES

This page is intentionally left blank.

1-10

THIS DOCUMENT IS THE PROPERTY OF COMMUNICATIONS & POWER INDUSTRIES.

REPRODUCTION OR RELEASE WITHOUT EXPRESS PERMISSION IS STRICTLY PROHIBITED

DOC.01023245 REV.K

2-1

CHPA SERIES

Chapter 2

Unpacking and Installation

2.1 Overview

This chapter contains instructions for site preparation, unpacking, and installation of the

Compact High Power Amplifier (CHPA). Instructions for the optional CHPA Remote Control

and Switching/Power Combined subsystems are supplied separately with those items. The

CHPA’s built-in interface connections for optional equipment are described in Chapter 3,

“Interfaces,” of this manual.

2.2 Pre-Inspection

Inspect the exterior of each for evidence of damage in shipment. If damage seems evident,

immediately contact the carrier that delivered the equipment and submit a damage report.

Failure to do so could invalidate future claims.

2.3 Unpacking

Carefully unpack and remove all items (inspect the interior of the container for damage). Save

all packing material until all inspections are complete. It is recommended that all packing

material be saved for potential future use. Verify that all items listed on the packing slips have

been received.

Inspect all items for evidence of damage in shipment. If damage seems evident, immediately

contact the carrier that delivered the equipment and file a claim. Failure to do so could

invalidate future claims. Check the unit thoroughly for damaged or loose parts. To remove the

top cover of the unit, remove the screws around the sides of the cover and lift the cover off.

After visual inspection is complete, reinstall the cover and carefully tighten all screws.

OC.01023245 REV.K

D

THIS DOCUMENT IS THE PROPERTY OF COMMUNICATIONS & POWER INDUSTRIES.

REPRODUCTION OR RELEASE WITHOUT EXPRESS PERMISSION IS STRICTLY PROHIBITED

2-1

CHPA SERIES

2.4 Preparing For Installation

It is recommended that an electrical inspection for verification of customer interface connections

be performed before and after the installation of the equipment in its final operational location;

the following basic steps must be completed:

1. Verify proper CHPA RF input and output terminations. (See Warning.)

2. Verify that all CHPA user interface connectors to be used match pin-out data in Chapter 3,

“Interfaces.”

3. Verify proper prime power connection to the CHPA. See Drawings & Schematics in

Chapter 7, for AC voltage specifications.

Warning: Operating the Compact High Power Amplifier (CHPA) without

proper termination or under excessive load voltage standing wave ratio

(VSWR) could cause destruction of the traveling wave tube (TWT) and will

void the warranty. (See specifications in See Drawings & Schematics in

Chapter 7.)

2.5 Installation

Installation of the CHPA includes four phases:

• Mechanical installation

• Electrical connections

• RF connections

• Cooling considerations

2.5.1 Mechanical Installation

The CHPA is designed for rack slide mounting in a standard 19-inch (48.3 cm) wide rack

cabinet. Use the following procedure for this installation:

1. Determine the required front panel arrangement and exact panel locations for the CHPA on

the rack cabinet.

2. Mount the mating slides (supplied) to the rack cabinet using the supplied hardware.

3. Install the CHPA on the mating slides and securely fasten the front panel to the rack cabinet

rails.

Once the unit is installed on the slides and fastened to the cabinet, the balance of the installation

procedures can be completed.

2-2

THIS DOCUMENT IS THE PROPERTY OF COMMUNICATIONS & POWER INDUSTRIES.

REPRODUCTION OR RELEASE WITHOUT EXPRESS PERMISSION IS STRICTLY PROHIBITED

DOC.01023245 REV.K

Loading...

Loading...