CPI GTR 50 Service Manual

Collaboration

Professional

Inn

o

v

a

ti

o

n

§CONTENTS§

PREFACE.....................................................................................41-1

TROUBLE SHOOTING……………….….................................42-1∼ 2-6

ENGINE REMOVALE INSPECTION......................................43-1∼ 3-2

LUBRICATION SYSTEM………………..…............................44-1∼ 4-2

FUEL SYSTEM………………………………............................45-1∼ 5-4

CYLINDEER HEAD-CYLINDER PISTON.........……............46-1∼ 6-5

TRANSMISSION SYSTEM………...........................................47-1∼ 7-6

CRANKSHAFT-CRANKCASE...................…..........................

48-1∼ 8-4

A.C.GENERATOR......................………...........……......……..

49-1∼9-2

ELECTRIC SYSTEM………………………………………….410-1∼10-4

CPI MOTOR

PREFACE GTR50

《1-1》

THE CONTENTS OF THIS MANUAL PROVIDE THE SERVICE

INFORMATION FOR CPI \GTR50.

MOST CHAPTERS START WITH A SYSTEM OR ASSEMBLY

ILLUSTRATION AND SPECIFICATIONS THE FOLLOWING

PAGES GIVE DETAIL PROCEDURES.

IF YOU DO NOT KNOW WHAT THE SOURCE OF THE

TROUBLE IS, PLEASE GO TO THE TROUBLESHOOTERS FOR

ADDITIONAL HELP.

ALL THE CONTENTS OF THIS MANUAL ARE BASED ON

THE LATEST MODEL INFORMATION CPI RESERVES THE

RIGHT TO MAKE CHANGE AT ANY TIME WITHOUT NOTICE

AND WITHOUT ANY RESPONSIBILITY OR ENGAGEMENT ON

OUR PART.

CPI MOTOR

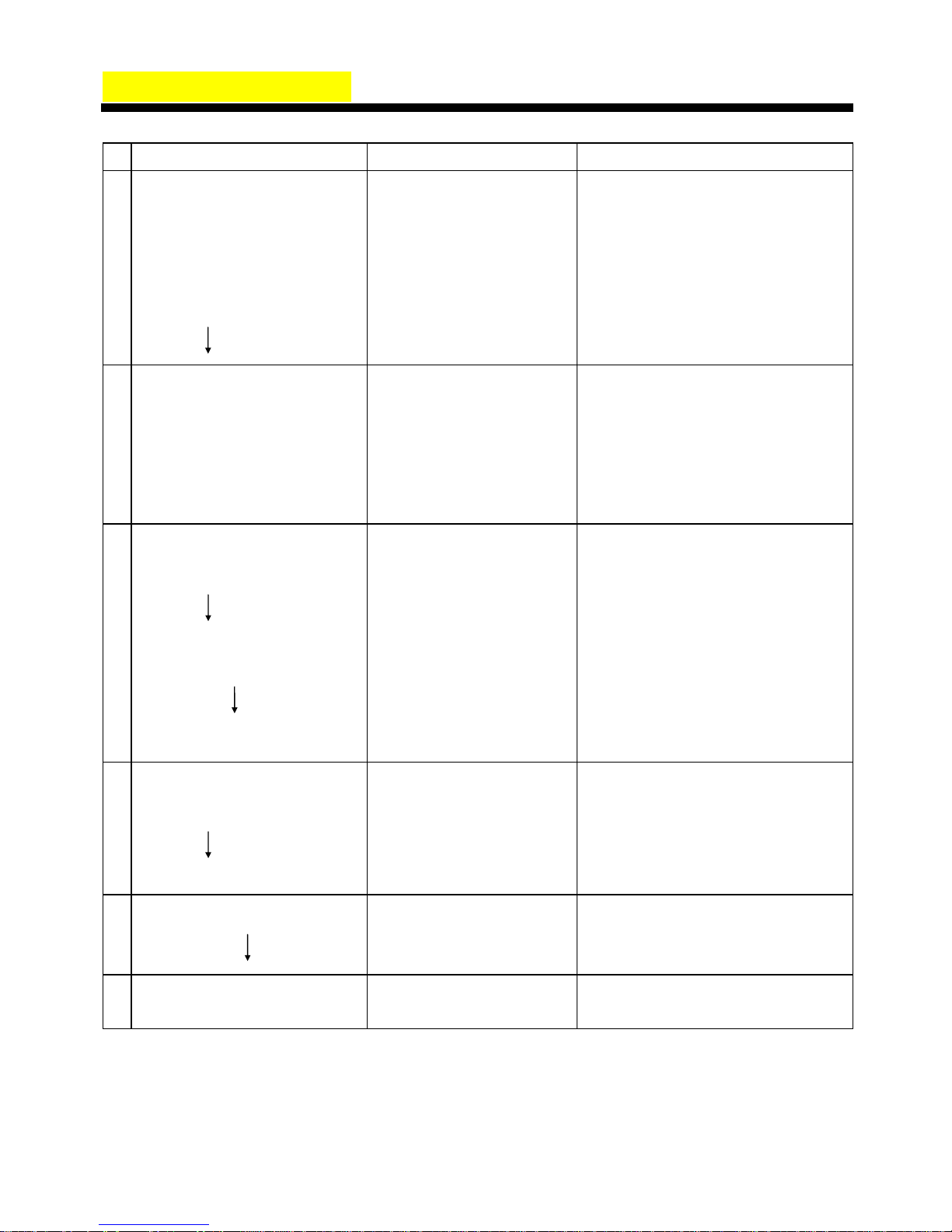

TROUBLE SHOOTING GTR50

《2-1》

ENGINE WILL NOT START OR IS HARD TO START

PROBABLE CAUSE

1

CHECK IF FUEL REACHES

CARBURETOR

FUEL REACHES

CARBURETOR

FUEL DOES NOT REACH

CARBURETOR

(1) NO FUEL IN TANK

(2) CLOGGED FUEL LINE BETWEEN

FUEL TANK AND CARBURETOR

(3) CLOGGED FUEL VALVE

(4) CLOGGED FUEL TANK CAP

BREATHER HOLE

2

REMOVE SPARK PLUG AND

TEST SPARK

GOOD SPARK

WEAK OR NO SPARK

(1) FAULTY OR FOULED PLUG

(2) FAULTY C.D.I.

(3) BROKEN OR SHORTED HIGH

TENSION CORD

(4) FAULTY IGNITION SWITCH

(5) INCORRECT IGNITION TIMING

3

TEST CYLINDER

COMPRESSION

NORMAL COMPRESSION

LOW COMPRESSION

(1) ENGINE NOT CRANKED

(2) NO VALVE CLEARANCE

(3) VALVE STUCK OPEN

(4) WORN CYLINDER AND PISTON

RINGS

(5) BLOWN CYLINDER HEAD GASKET

(6) FLAW IN CYLINDER HEAD

(7) INCORRECT VALVE TIMING

(8) BURNED VALVE

4

START ENGINE

ENGINE FIRES

ENGINE FIRES, BUT

DOES NOT START

(1) CHOKE VALVE OPEN

(2) CARBURETOR PILOT SCREW OPEN

(3) AIR LEAKING THROUGH IN TAKE

PIPE

(4) INCORRECT IGNITION TIMING

5

REMOVE SPARK PLUG

DRY PLUG

WET PLUG

(1) FLOODED CARBURETOR

(2) CHOKE VALVE CLOSED

6

START ENGINE WITH

CHOKE CLOSED

CPI MOTOR

TROUBLE SHOOTING GTR50

《2-2》

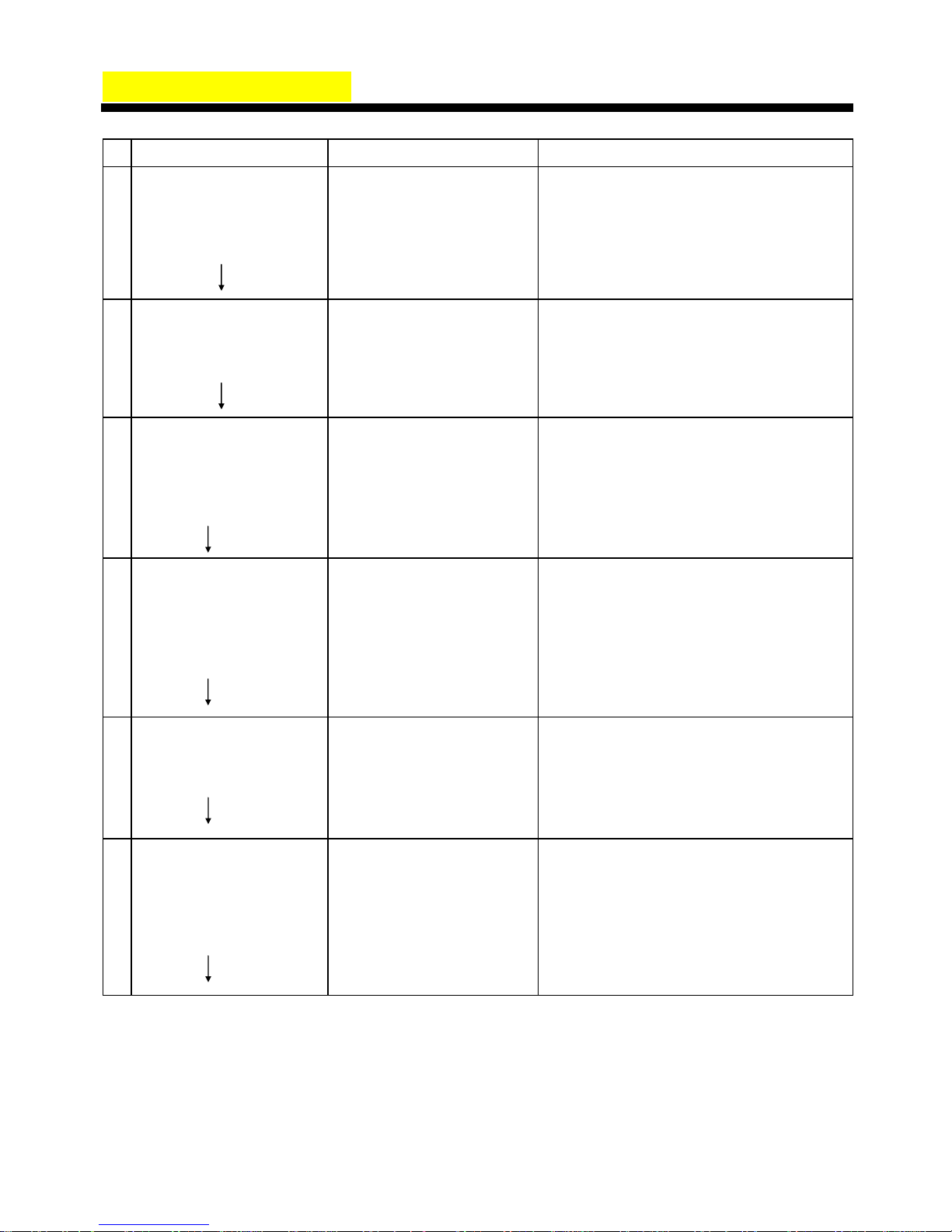

ENGINE LACKS POWER

FLOW PATH BAD SITUATION PROBABLE CAUSE

1

RAISE WHEELS OFF

GROUND AND SPIN

WHEELS SPIN FREELY

WHEELS DO NOT SPIN

FREELY

(1) DRAGGING BRAKE

(2) FAULTY WHEEL BEARING

(3) OVERTIGHTENED DRIVE CHAIN

(4) WHEEL BEARING NOT

LUBRICATED PROPERLY

2

CHECK TIRE

PRESSURE

NORMAL PRESSURE

INCORRECT TIRE

PRESSURE

(1) PUNCTURED TIRE

(2) FAULTY TIRE VALVE

3

RAPIDLY

ACCELERATE FROM

LOW TO SECOND

ACCELERATES

DOES NOT ACCELERATE

WITH ENGINE SPEED

RAISED

(1) SLIPPING CLUTCH

(2) WORN OR UNEVEN CLUTCH

FACINGS

(3) CLUTCH PLATE WARPED

4

REV UP GRADUALLY

ENGINE SPEED

INCREASES

ENGINE SPEED DOES

NOT INCREASE

(1) CARBURETOR CHOKE CLOSED

(2) CLOGGED AIR CLEANER

(3) CLOGGED FUEL LINE

(4) CLOGGED FUEL TANK CAP

BREATHER HOLE

(5) CLOGGED MUFFLER

5

CHECK IGNITION

TIMING

CORRECT TIMING

INCORRECT TIMING

INCORRECT TIMING ADJUSTMENT

6

CHECK VALVE

CLEARANCE

CORRECT VALVE

CLEARANCE

INCORRECT VALVE

(1) INCORRECT VALVE CLEARANCE

(2) WORN VALVE SEAT

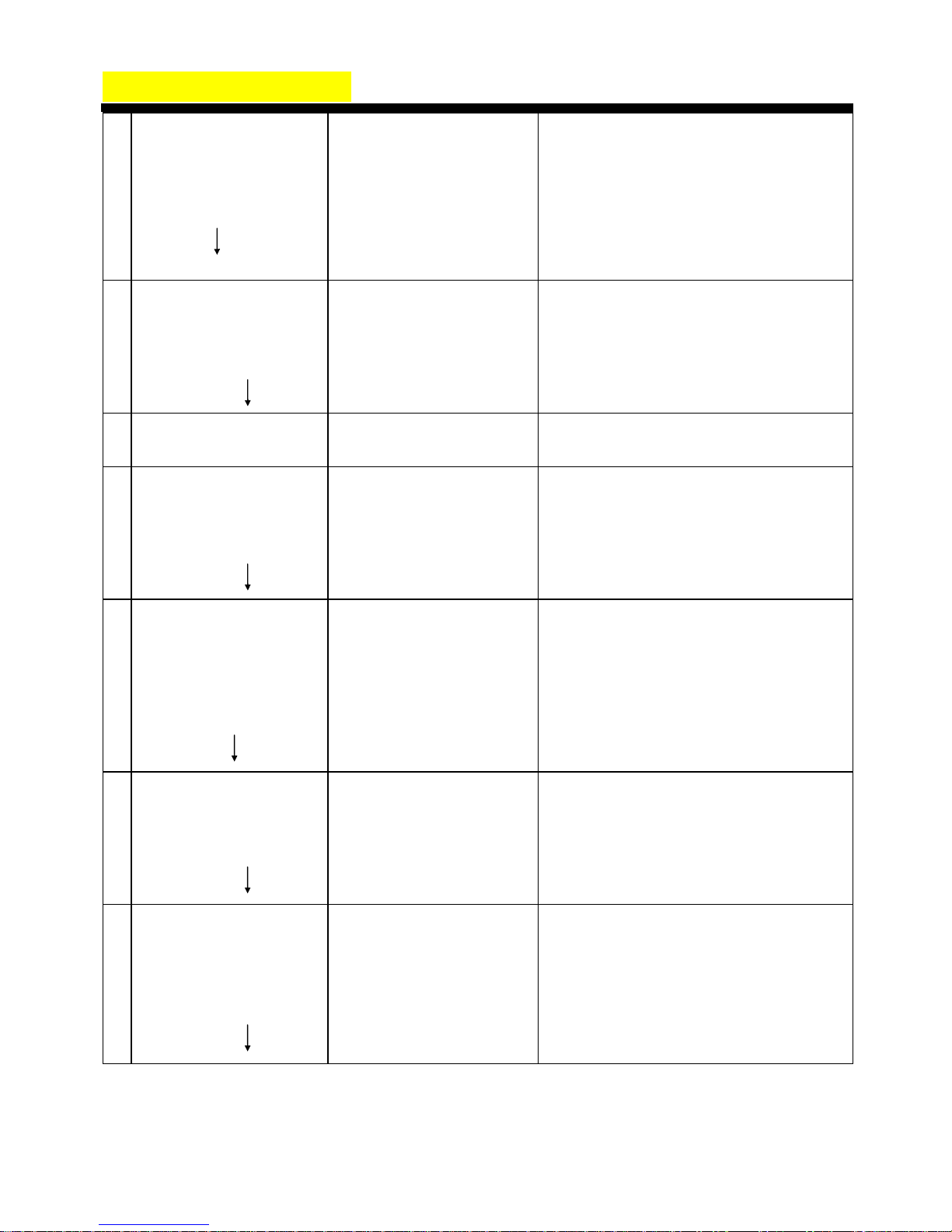

CPI MOTOR

TROUBLE SHOOTING GTR50

《2-3》

7

TEST CYLINDER

COMPRESSION

NORMAL

COMPRESSION

LOSS OF COMPRESSION

(1)VALVE STUCK OPEN

(2) WORN CYLINDER AND PISTON RINGS

(3) BLOWN CYLINDER HEAD GASKET

(4) INCORRECT VALVE TIMING

(5) FLAWS IN CYLINDER HEAD OR

CYLINDER

8

CHECK CARBURETOR

FOR CLOGGING

CARBURETOR NOT

CLOGGED

CARBURETOR CLOGGED (1) CARBURETOR JETS CLOGGED

9

REMOVE SPARK PLUG PLUG FOULED OR

DISCOLORED COLORED

(1) FOULED PLUG

(2) INCORRECT HEAT RANGE PLUG

10

CHECK OIL LEVEL

AND CONDITION

CORRECT ENGINE OIL

LEVEL

OIL DIRTY OR LEVEL

INCORRECT

(1) LEVEL TOO LOW OR HIGH

(2) CONTAMINATED OIL

11

REMOVE CYLINDER

HEAD COVER AND

CHECK

SUFFICIENTLY

LUBRICATION

INSUFFICIENTLY

LUBRICATED

(1) CLOGGED OIL PASSAGE

(2) POOR OIL PUMP DELIVERY

12

CHECK IF ENGINE

OVERHEATS

ENGINE DOES NOT

OVERHEAT

ENGINE OVERHEATS

(1) EXCESSIVE CARBON IN

COMBUSTION CHAMBER

(2) INCORRECT FUEL

(3) SLIPPING CLUTCH

13

RAPIDLY

ACCELERATE OR URN

AT HIGH SPEEDS

ENGINE DOES NOT

KNOCK

ENGINE KNOCKS

(1) WORN PISTON OR CYLINDER

(2) MIXTURE TOO LEAN

(3) INCORRECT FUEL

(4) EXCESSIVE CARBON IN

COMBUSTION CHAMBER

(5) LGNITION TIMING TOO EARLY

CPI MOTOR

TROUBLE SHOOTING GTR50

《2-4》

POOR PERFORMANCE AT IDLE AND LOW SPEEDS

FLOW PATH BAD SITUATION PROBABLE CAUSE

1

CHECK IGNITION

TMING AND VALVE

CLEARANCE

CORRECT TIMING AND

CLEARANCE

INCORRECT TIMING

AND CLEARANCE

(1) INCORRECT TIMING

ADJUSTMENT

(2) INCORRECT VALVE CLEARANCE

2

CHECK CARBURETOR

PILOT SCREW

ADJUSTMENT

CORRECTLY ADJUSTED

INCORRECTLY

ADJUSTED

(1) MIXTURE TOO LEAN

(2) MIXTURE TOO RICH

3

CHECK FOR AIR

LEAKS

NO AIR LEAKS

AIR LEAKS

(1) FAULTY CARBURETOR PACKING

(2) CARBURETOR NOT SECURELY

TIGHTENED

(3) FAULTY INTAKE PIPE GASKET

4

REMOVE SPARK PLUG

AND TEST SPARK

WEAK OR

INTERMITTENT SPARK

(1) FAULTY OR FOULED PLUG

(2) FAULTY C.D.I.

(3) MAGNET AT FAULT

CPI MOTOR

TROUBLE SHOOTING GTR50

《2-5》

POOR PERFORMANCE AT HIGH SPEED

FLOW PATH BAD SITUATION PROBABLE CAUSE

1

CHECK IGNITION

TIMING AND VALVE

CLEARANCE

CORRECT TIMING AND

CLEARANCE

INCORRECT TIMING

AND CLEARANCE

(1) INCORRECT TIMING ADJUSTMENT

(2) INCORRECT VALVE CLEARANCE

2

DISCONNECT FUEL

LINE AT CARBURETOR

AND CHECK FOR

CLOGGING

UNRESTRICTED FUEL

FLOW

RESTRICTED FUEL

FLOW

(1) EMPTY FUEL TANK

(2) CLOGGED FUEL LINE

(3) CLOGGED FUEL TANK CAP

BREATHER HOLE

(4) CLOGGED FUEL PETCOCK

3

CHECK FUEL FILTER,

FUEL VALVE AND

CARBURETOR JET FOR

CLOGGING

NOT CLOGGED

CLOGGED

(1) CLOGGED JET

(2) CLOGGED FUEL FILTER

(3) CLOGGED FUEL VALVE

4

REPLACE

CARBURETOR MAIN

JET

CONDITION IMPROVED

CONDITION

AGGRAVATED

(1) JET SIZE TOO SMALL

(2) IF CONDITION IS IMPROVED WITH

SMALL JET:

A) CLOGGED AIR CLEANER

B) CHOKE NOT OPENED FULLY

5

CHECK VALVE TIMING

CORRECT

INCORRECT

INCORRECT VALVE TIMING

ADJUSTMENT

6

CHECK VALVE SPRING

TENSION

SPRING TENSION

CORRECT

WORN OR BROKEN

SPRING

FAULTY VALVE SPRING

CPI MOTOR

TROUBLE SHOOTING GTR50

《2-6》

SMOKY EXHAUST

FLOW PATH BAD SITUATION PROBABLE CAUSE

1

RUN MOTORCYCLE A

LONG DISTANCE AT

HIGH SPEED

THIN EXHAUST

EMITTED

BLACK SMOKE EMITTED

(1) WORN CYLINDER AND PISTON

RINGS

(2) OIL LEVEL TOO HIGH

(3) PISTON RINGS INCORRECTLY

INSTALLED

(4) FAULTY PISTON OR CYLINDER

(5) FLAWS IN CYLINDER HEAD

2

RETURN THROTTLE

GRIP QUICKLY

WHITE SMOKE EMITTED

(1) WORN INTAKE VALVE GUIDE OR

STEM

(2) EXCESSIVE VALVE-TO-GUIDE

CLEARANCE

POOR HANDLING

FLOW PATH BAD SITUATION PROBABLE CAUSE

1

IF STEELING IS HEAVY

CHECK TIRE PRESSURE

(1) STEERING HEAD ADJUSTER TOO

TIGHT

(2) DAMAGED STEERING CONES OR

STEEL BALLS

2

IF EITHER WHEEL IS

WOBBLING

(1) EXCESSIVE WHEEL BEARING

PLAY

(2) DISTORTED RIM

(3) IMPROPERLY INSTALLED WHEEL

HUB

(4) SWING ARM PIVOT BUSHING

EXCESSIVELY WORN

(5) DISTORTED FRAME

(6) IMPROPER DRIVE CHAIN TENSION

OR ADJUSTMENT

3

IF THE MOTORCYCLE

PULLS TO ONE SIDE

(1) MISAPPLIED SHOCK ABSORBER

(2) FRONT AND REAR WHEELS NOT

ALIGNED

(3) BENT FRONT FORK

(4) BENT SWING ARM

CPI MOTOR

ENGINE REMOVAL/INSTALLATION GTR50

《3-1》

ENGINE REMOVAL

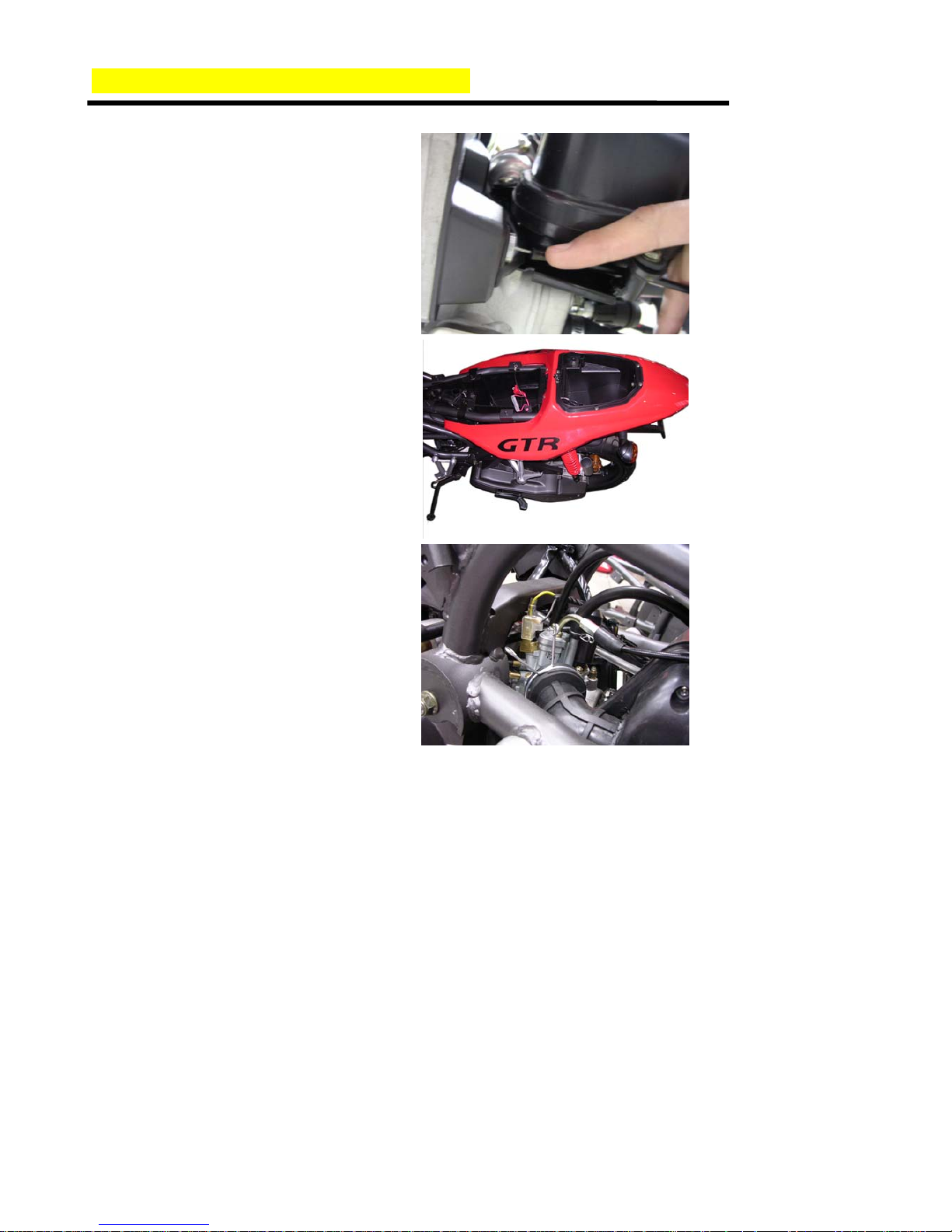

1. Open and remove the seat.

2. Remove the rear luggage case.

Remove the side cover.

Remove the throttle valve from the carburetor.

Disconnect the earth wire of engine.

Disconnect the coil wire.

Disconnect the A.C.G. wire.

Disconnect the start motor wire.

Disconnect the starter plunger wire.

CPI MOTOR

ENGINE REMOVAL/INSTALLATION GTR50

《3-2》

Disconnect the fuel & the vacuum tube.

Disconnect the spark plug cap.

Disconnect the rear brake cable.

Remove the setting bolt of rear cushion.

Remove the setting bolt of engine.

Remove the engine.

ENGINE INSTALLATION

The installation sequence is essentially the reverse

of removal.

NOTE:

Route all the wire and cable properly.

Adjust the throttle cable free play.

clearance.

Adjust the rear brake free play.

CPI MOTOR

ENGINE REMOVAL/INSTALLATION GTR50

《3-3》

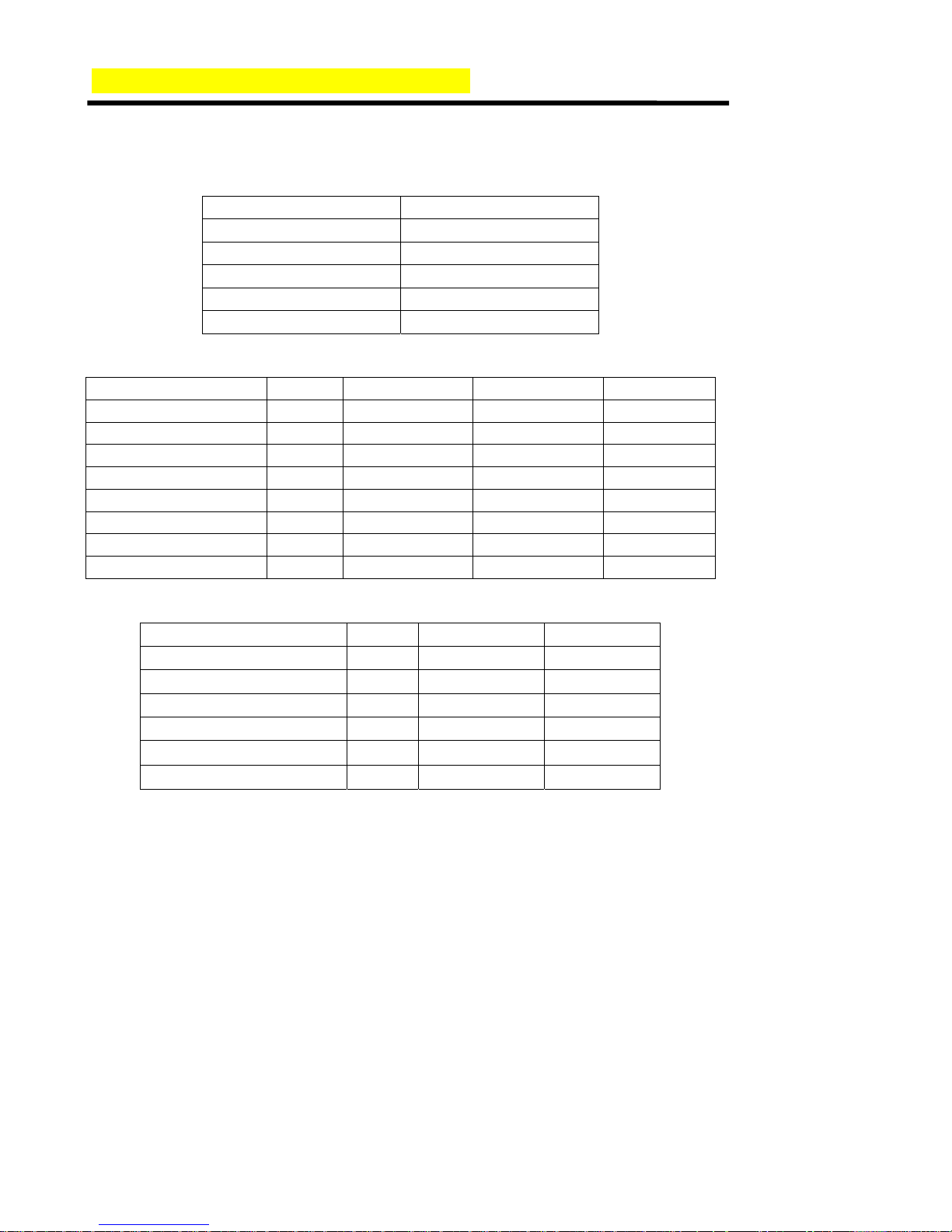

TORQUE

TORQUE STANDARD

SORTS TORQUE(kg-m)

5mm screw, nut 0.5

6mm screw, nut 1.2

8mm screw, nut 2.7

10mm screw, nut 4.0

12mm screw, nut 5.5

INNER OF ENGING

ITEM AMOUNT DIAMETER(mm) TORUQUE(kg-m) REMARKS

Cylinder head bolt, A 2 8 3.0 Stud bolt side

Cylinder head bolt, B 2 8 3.0 Stud bolt side

EXH. pipe joint bolt 2 8 0.9 Spread on thread

Drive face nut 1 17 3.5~4.0

A.C.G. nut 1 17 3.5~4.0

Oil pump bolt 2 6 0.8

Cylinder head cover bolt 2 10 1.5

Spark plug 1 12 1.8

FRAME

ITEM AMOUT DIAMETER(mm) TORQUE(kg-m)

Shaft steering nut 1 10 4.5

FR. Wheel axle nut 1 12 6.0

RR. Wheel axle nut 1 16 9.0

RR. shock absorber bolt (up) 1 10 3.0

RR. shock absorber bolt (down) 1 8 3.0

ENG. Hanger BRKT. Bolt 1 10 5.5

Loading...

Loading...