CPCLA CM15S1020, CM15S1015, CM15S2025, CM15S1525, CM15S1520 Datasheet

...

Molded DYAD

CM15

®

Features Description

• Small size

• SMT-compatible

• Easily formed leads

• Sputtered ruthenium contacts

• Hermetically sealed contacts

• Fast switching speed — up to 500Hz

• Wide range of available magnetic sensitivities

• Superior mechanical strength

• Enhanced for better auto placement

Clare’s Molded DYAD

for small switching signal applications. This switch has

sputtered ruthenium contacts and an extraordinary seal

strength, achieved by a patented laser sealing of the glass.

In low level or dry switching environments, both switches

typically provide >1 billion operations. The switches have

hermetically sealed contacts and offer a wide range of

available magnetic sensitivities. In addition, the molding

process provides a solid plastic outer shell. This plastic

shell provides superior mechanical strength, eliminates

Applications

• Security

concerns over handling glass switches, and provides an

ideal solution for high speed, automated assembly

environments."

− Proximity sensing

− Smoke alarms

• Automotive

− Level sensor

− Lamp current sensor

• Relays

Ordering Information

A complete part number is represented by the digits to the

right. For example, CM15S1030 is a MOLDED DYAD® with

a minimum operate value of 10NI and a maximum of 30NI.

Refer to the switch operating specification charts for available ranges. Special ranges are available upon request.

"S" for straight switch

blank for SMT

®

dry reed switches are ideally suited

CM15 S XX XX

Maximum Operate Value (NI)

Minimum Operate Value (NI)

Standard Test Coil

The magnetic force (expressed in NI, AT or Ampere Turns) required to cause the reed switch contacts to

close is called the pull-in or operate value.

CM15

Part # Coil - 1

Coil definition NARM1 CTC01

Coil resistance 1200Ω

Number of turns 5,000

Wire size (nom. diameter) 0.0399mm (AWG 46)

Bobbin diameter (inside coil) 3.96mm

Winding length 10.4mm

(1)

Consult factory for test procedure.

The reed switch shall be placed in the test coil with the gap centered in the core of the coil winding.

Test leads and their clips must be non-magnetic.

The longitudinal axis of the test coil and the test switch shall be vertical.

Surface Mount Molded DYAD

Refer to operating characteristics table for complete part number.

MOLDED DYAD

Part # Operate Range (NI)

CM15S1015 10 to 15

CM15S1020 10 to 20

CM15S1030 10 to 30

CM15S1520 15 to 20

CM15S1525 15 to 25

CM15S2025 20 to 25

MOLDED DYAD® Surface Mount

Part # Operate Range (NI)

CM15-2024 10 to 15

CM15-2259 10 to 20

CM15-2282 10 to 30

CM15-2025 15 to 20

CM15-2249 15 to 25

CM15-2026 20 to 25

1

Tolerance = ± 1.5NI

2

Full Blade Sensitivity

3

Surface Mount Switches are packaged 3,000 parts per reel

®

1

1,2,3

DS-CM15-R1

www.clare.com

1

Molded DYAD

CM15

®

Absolute Maximum Ratings (@ 25˚ C)

Parameter Min Typ Max Units

Switching Voltage

CM15 - MOLDED DYAD

Switching Current

CM15 - MOLDED DYAD

Carry Current

CM15 - MOLDED DYAD

®

®

®

200 Volts

0.5 Amps

1.5 Amps

Absolute Maximum Ratings are stress ratings. Stresses

in excess of these ratings can cause permanent damage

to the device. Functional operation of the device at these

or any other conditions beyond those indicated in the

operational sections of this data sheet is not implied.

Exposure of the device to the absolute maximum ratings

for extended period may degrade the device and effect

its reliability.

Switching Frequency

CM15 - MOLDED DYAD

®

500 Hz

Contact Resistance

CM15 - MOLDED DYAD

(See detailed specifications for more information.)

®

150 mΩ

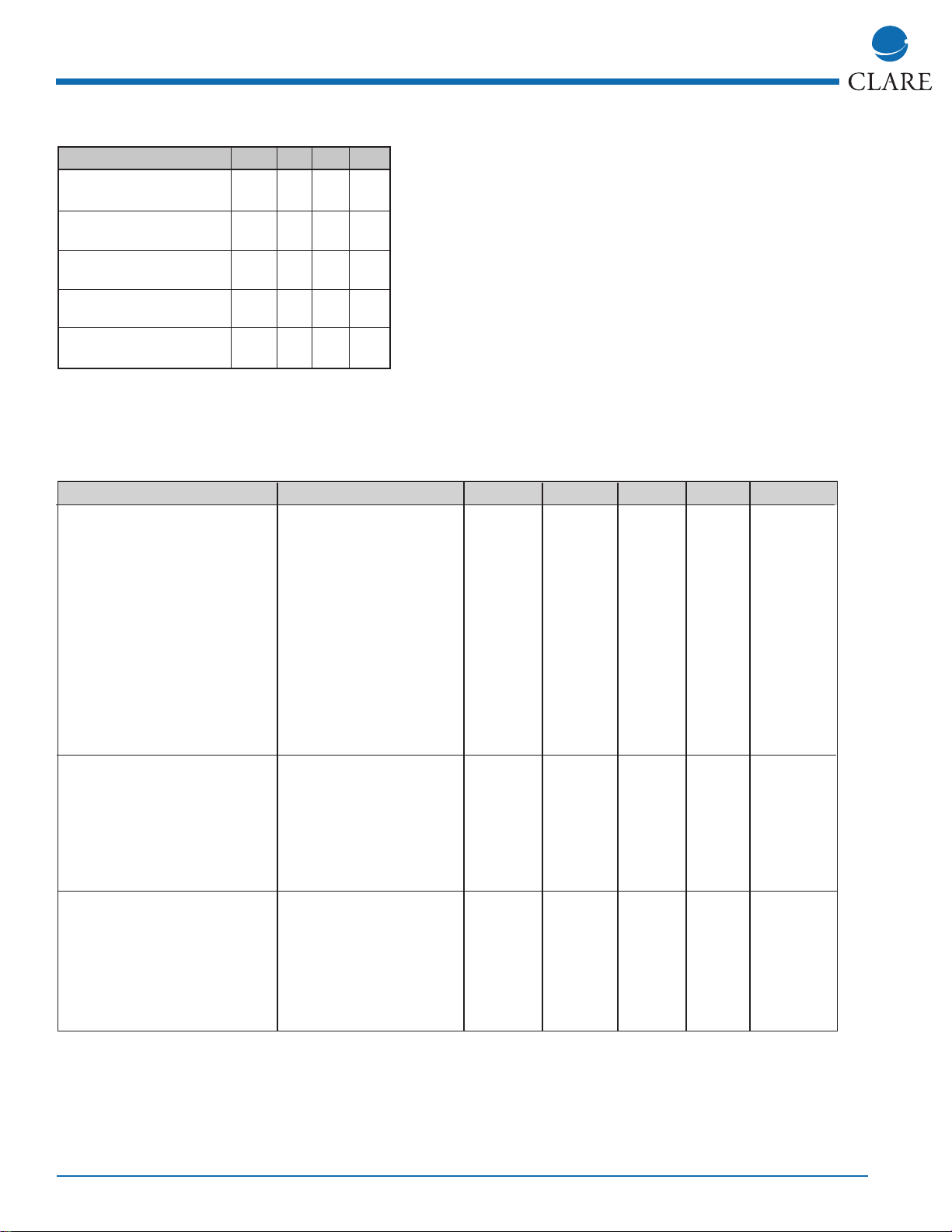

Specifications

All parameters are at 25°C unless otherwise stated.

PARAMETER CONDITIONS SYMBOL MIN TYP MAX UNITS

Contact Ratings

Operate ampere turns range Full Blade Tolerance = ± 1.5NI AT 10 - 30 NI

Release ampere turns range Full Blade Tolerance = ± 1.5NI AT 5 - 30 NI

Switching Voltage Max DC/PeakAC Resistive V

Switching Current Max DC/PeakAC Resistive I

Carry Current Max DC/PeakAC Resistive I

L

L

C

Contact Rating Max DC/PeakAC Resistive - - - 10 VA

Life Expectancy 1V, 10mA Signal Level - - 1000 - x10

10V, 10mA Low Level - - 500 - x10

50V, 100mA Telecom Load - - 2 - x10

100V, 100mA Rated Loads - - 2 - x10

Static Contact Resistance 50mV, 10mA

(1)

CR - 80 150 mΩ

Contact Material - - Ru - -

Switch Specifications

Insulation Resistance

(2)

100V, 25°C, 40% RH IR 10

Capacitance Across Open Contacts - - 0.3 - pF

Dielectric Strength

Operate Time, At nominal coil voltage, T

(5)

Between Contacts - 250 300 - VDC/Peak AC

OP

including bounce 10Hz Square Wave

Release Time Zener-Diode Suppression

(3)

T

REL

Environmental Ratings

Storage Temperature T

Operating Temperature T

A

O

Soldering Temperature - - - +240 °C

Vibration 5Hz - 200Hz G - - 20 -Gs

1

Shock 11±1ms,

Shock - survivability 11±1ms,

/2 Sine Wave S - - 30 Gs

1

/2 Sine Wave S - - 500 Gs

- - 200 VDC

- - 500 mAmps

- - 1.5 Amps

9

10

11

- Ω

- - 0.5 ms

- - 0.2 ms

-40 - +125 °C

-40 - +125 °C

6

Ops

6

Ops

6

Ops

6

Ops

(1)

Contact resistance measured with 4 terminal method, 1.1" between test leads

(2)

>1012 Ω is available upon request

(3)

A 24V zener in series with a diode across the coil

(4)

Use caution not to exceed vibration resistance limits while ultrasonically cleaning. Contact Clare Engineering for more details/recommendations

(5)

15 ampere turn minimum

2

www.clare.com

Rev. 1

Loading...

Loading...