CPC MultiFlex RTU Installation And Operation Manual

026-1706 Rev 1 10-29-02

MultiFlex RTU Rooftop

Controller Installation and

Operation Manual

1640 Airport Road, Suite 104

Kennesaw, GA 31044

Phone: (770) 425-2724

Fax: (770) 425-9319

ALL RIGHTS RESERVED.

The information contained in this manual has been carefully checked and is believed to be accurate. However, Computer Process Controls, Inc. assumes no responsibility for any inaccuracies that may be contained herein. In no event will

Computer Process Controls, Inc. be liable for any direct, indirect, special, incidental, or consequential damages resulting

from any defect or omission in this manual, even if advised of the possibility of such damages. In the interest of continued

product development, Computer Process Controls, Inc. reserves the right to make improvements to this manual, and the

products described herein, at any time without notice or obligation.

READ ALL INSTRUCTIONS CAREFULLY

If the equipment is not used in the manner specified by the manufacturer, the protection provided

by the equipment may be impaired.

SAVE THIS INSTRUCTION MANUAL

This instruction manual contains important operating instructions for the MultiFlex RTU rooftop

control board.

Table of Contents

1 OVERVIEW OF THE MULTIFLEX RTU ................................................................................................................ 1

1.1. D

IFFERENCES BETWEEN THE MULTIFLEX RTU AND ARTC ....................................................................................... 1

1.2. T

HE RTU’S I/O POINTS................................................................................................................................................ 1

1.3. I

NDEPENDENT SYSTEM CONTROL ................................................................................................................................ 1

2 MOUNTING AND POWERING ................................................................................................................................. 2

2.1. S

NAP-TRACK INSTALLATION........................................................................................................................................ 2

2.2. T

HE PLUG-IN OUTPUT BOARD ..................................................................................................................................... 3

2.3. P

OWERING THE MULTIFLEX RTU BOARD ................................................................................................................... 3

2.3.1. Choosing Transformer Sizes ................................................................................................................................. 4

2.3.2. MultiFlex RTU Power Wiring............................................................................................................................... 4

2.3.2.1. New-Style MultiFlex RTU Boards (with Isolated Power Supply) ..................................................................................... 4

2.3.2.2. Old-Style MultiFlex RTU Boards No Isolated Power Supply) .......................................................................................... 5

2.3.3. Wire Types and Maximum Distances.................................................................................................................... 6

2.4. T

HE MULTIFLEX RTU BATTERY AND BATTERY ENABLE JUMPER ............................................................................. 7

3 THE I/O NETWORK .................................................................................................................................................... 8

3.1. W

IRING TYPES.............................................................................................................................................................. 8

3.1.1. Daisy Chains ......................................................................................................................................................... 8

3.1.2. Network ID Numbers ............................................................................................................................................ 8

3.1.2.1. Numbering the MultiFlex RTU .......................................................................................................................................... 9

3.1.3. Setting the Baud Rate............................................................................................................................................ 9

3.1.4. Setting the Terminating Resistance Jumpers ........................................................................................................ 9

4 RTU INPUT AND OUTPUT SETUP......................................................................................................................... 10

4.1. T

HE INPUTS................................................................................................................................................................. 10

4.1.1. MultiFlex RTU Fixed Input Locations................................................................................................................ 10

4.1.2. Auxiliary Input Types.......................................................................................................................................... 10

4.1.3. Wiring Sensors to the MultiFlex RTU................................................................................................................. 11

4.1.3.1. Wiring ............................................................................................................................................................................... 11

4.1.3.2. Sensor Wiring Types ........................................................................................................................................................ 11

4.1.3.3. Input Type Dip Switches .................................................................................................................................................. 12

4.1.4. Input Connection When Replacing ARTC with RTU .......................................................................................... 12

4.1.5. On-Board Power Connection.............................................................................................................................. 12

4.1.5.1. Current Ratings for On-Board Power Sources ................................................................................................................. 13

4.1.5.2. Powering Sensors Requiring 24VAC Off the Power Transformer................................................................................... 13

4.2. THE OUTPUTS ............................................................................................................................................................. 13

4.2.1. MultiFlex RTU Fixed Outputs............................................................................................................................. 13

4.2.2. MultiFlex RTU Auxiliary Output Types .............................................................................................................. 14

4.2.3. Wiring Outputs to Points..................................................................................................................................... 14

4.2.4. Output Fail-Safe Dip Switches............................................................................................................................ 15

4.2.5. Relay Output Ratings and Fuse Protection......................................................................................................... 15

4.3. A

NALOG OUTPUTS...................................................................................................................................................... 16

4.3.1. Wiring the RTU Analog Output Points ............................................................................................................... 16

5 BOARD STATUS LEDS ............................................................................................................................................. 17

5.1. S

TATUS LED .............................................................................................................................................................. 17

5.2. T

X AND RX LEDS ...................................................................................................................................................... 17

5.3. T

HE CODE A LED ...................................................................................................................................................... 17

Table of Contents MultiFlex RTU Operator’s Guide • v

5.4. THE CODE B LED ...................................................................................................................................................... 18

5.5. R

ELAY OUTPUT LEDS ................................................................................................................................................ 18

6 SOFTWARE OVERVIEW ......................................................................................................................................... 19

6.1. I

NTRODUCTION TO ZONE CONTROL............................................................................................................................ 19

6.2. T

EMPERATURE CONTROL ........................................................................................................................................... 19

6.2.1. Set Points............................................................................................................................................................. 19

6.2.1.1. Set Point Dead Bands ....................................................................................................................................................... 19

6.2.1.2. Stage ON and OFF Delays................................................................................................................................................ 19

6.2.1.3. Summer/Winter and Occupied/Unoccupied Set Points .................................................................................................... 19

6.3. FAN CONTROL ............................................................................................................................................................ 20

6.4. D

EHUMIDIFICATION AND HUMIDIFICATION CONTROL ............................................................................................... 20

6.4.1. Dehumidification Control ................................................................................................................................... 20

6.4.2. Humidification Control ....................................................................................................................................... 20

6.5. E

CONOMIZATION......................................................................................................................................................... 20

6.5.1. Analog Economizers............................................................................................................................................ 21

6.6. C

URTAILMENT ............................................................................................................................................................ 21

6.7. R

EVERSING VALVE CONTROL .................................................................................................................................... 21

6.8. S

TAND-ALONE OPERATION ........................................................................................................................................ 21

6.9. S

ENSOR FAILURES ...................................................................................................................................................... 22

7 THE MULTIFLEX RTU HAND-HELD INTERFACE........................................................................................... 23

7.1. RTU H

7.2. RTU M

7.3. S

7.4. C

AND-HELD TERMINAL STATUS SCREENS........................................................................................................ 23

AIN MENU....................................................................................................................................................... 24

TATUS MENU ............................................................................................................................................................ 24

ONTROL MENU ......................................................................................................................................................... 25

vi • MultiFlex RTU Operator’s Guide 026-1706 Rev 1 10-29-02

1 Overview of the Multi-

Flex RTU

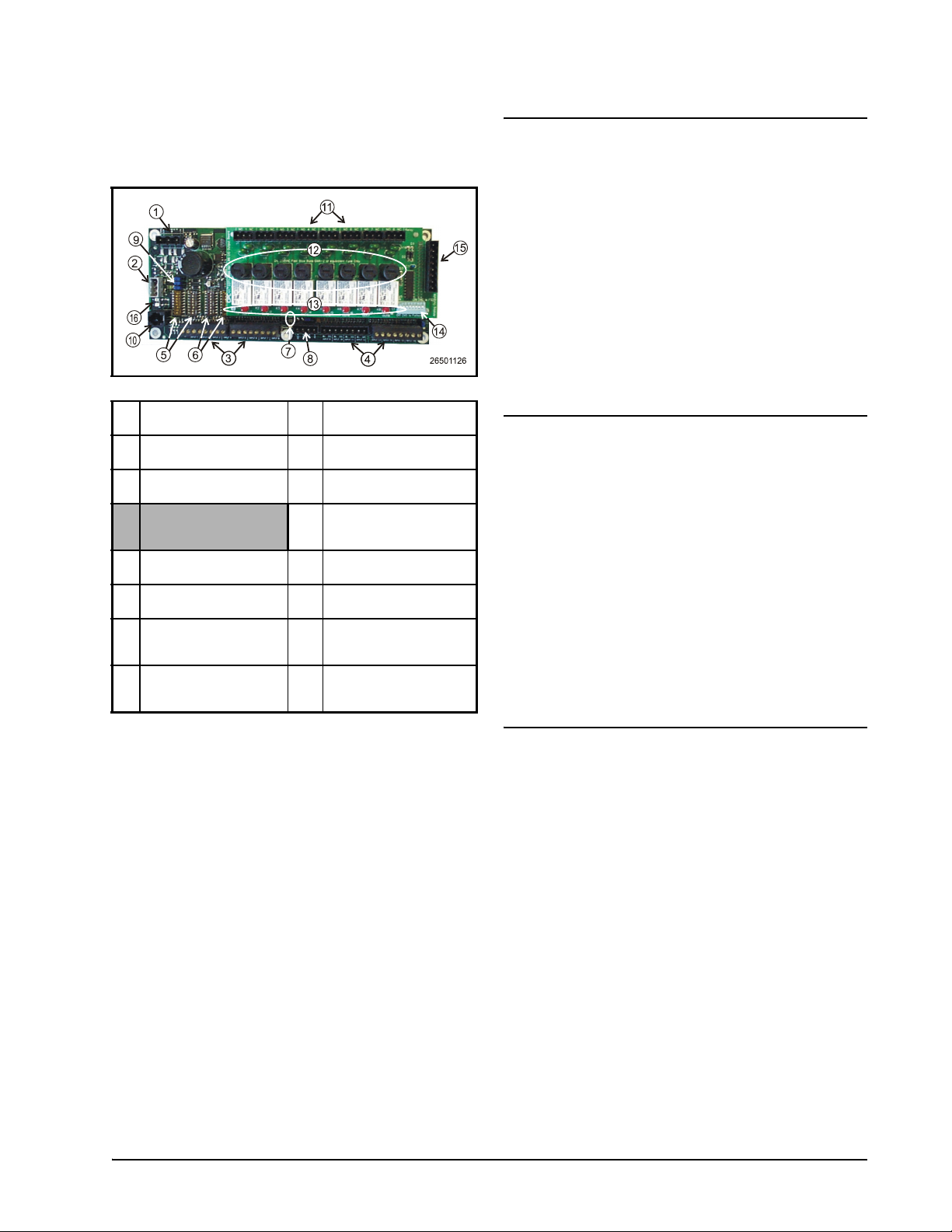

LEGEND

1 INPUT POWER

(24VAC)

2 RS485 I/O NETWORK 10 HAND-HELD TERMI-

3 RTU INPUTS 1-8 11 RELAY OUTPUT CON-

4 RTU INPUTS 9-16 (NOT

ACTIVE FOR RTU)

5NETWORK ID DIP

SWITCHES (S3, S4)

6 INPUT TYPE DIP

SWITCHES (S1, S2)

7 BOARD STATUS LEDs

(Code A, Code B, General

Status)

8 DC POWER OUTPUTS

(3 at +5VDC, 1 at

+12VDC)

Table 1-1 - MultiFlex RTU

9 RS485 I/O TERMINA-

TION JUMPERS

NAL JACK

NECTORS

12 RELAY OUTPUT FUSES

(2A rated, 250V slowblow)

13 RELAY STATUS LEDs

14 OUTPUT FAIL-SAFE

SWITCHES

15 ANALOG OUTPUTS (#1

and #2 active for RTU, #3

and #4 inactive)

16 NETWORK STATUS

LEDs

1.1. Differences Between the MultiFlex RTU and ARTC

The MultiFlex RTU is a hardware replacement for CPC’s ARTC rooftop unit control

boards, which are now discontinued. The RTU

firmware is in every way identical to the ARTC,

and is compatible with both Einstein BX and the

REFLECS BCU controllers. The only difference

between the RTU and ARTC is the RTU uses

the MultiFlex hardware platform, which is

smaller and more robust.

1.2. The RTU’s I/O Points

The compact size of the RTU allows technicians to easily field-mount the RTU in a rooftop

unit or enclosure close to it, allowing for easy

local connection of sensors and transducers. The

board has eight analog inputs, pre-configured for

quick connection to space temperature sensors,

supply and return air temperature sensors, and

fan and compressor proofs. Its eight relay outputs, rated 2.0 amps max, are used for activating

and deactivating fans, heat and cool stages,

economizers, and other systems or devices.

The MultiFlex Rooftop Unit Board (RTU)

(P/N 810-3062) is a “smart” combination input/

1.3. Independent System

Control

output board designed to control package rooftop HVAC units. The MultiFlex RTU is capable

of controlling heat and cool stages, fans, humidification and dehumidification devices, economizers using on-board I/O and control

algorithms, as well as monitor and interact with

other building control systems and peripherals

(such as smoke alarms and CO2 sensors).

The RTU can control a rooftop unit independently without the need of a central controller

(such as CPC’s Einstein BX Refrigeration Controller). However, the RTU is designed to interface with an Einstein BX or BCU to allow it to

work with other RTUs together to control large

zones. Networking RTU to a central controller

also allows you to view status on Einstein &

UltraSite32 status screens, report alarms, and

control dehumidification.

The RTU’s configuration can be programmed either with a CPC Hand-Held Terminal (HHT) or through the Einstein front panel.

Differences Between the MultiFlex RTU and ARTC Overview of the MultiFlex RTU • 1

2 Mounting and Power-

ing

The MultiFlex boards are usually mounted

by the refrigeration equipment manufacturer.

Therefore, the installer need only make the necessary connections between the boards and the

site controller(s).

In some instances, an installer may be

required to mount an I/O board. There are no

restrictions on the location of these boards; however, for ease of network configuration, it is recommended that the boards be located adjacent to

the Einstein. I/O boards may be mounted without an enclosure, but they should be mounted in

a location that is not easily accessible to avoid

tampering or damage.

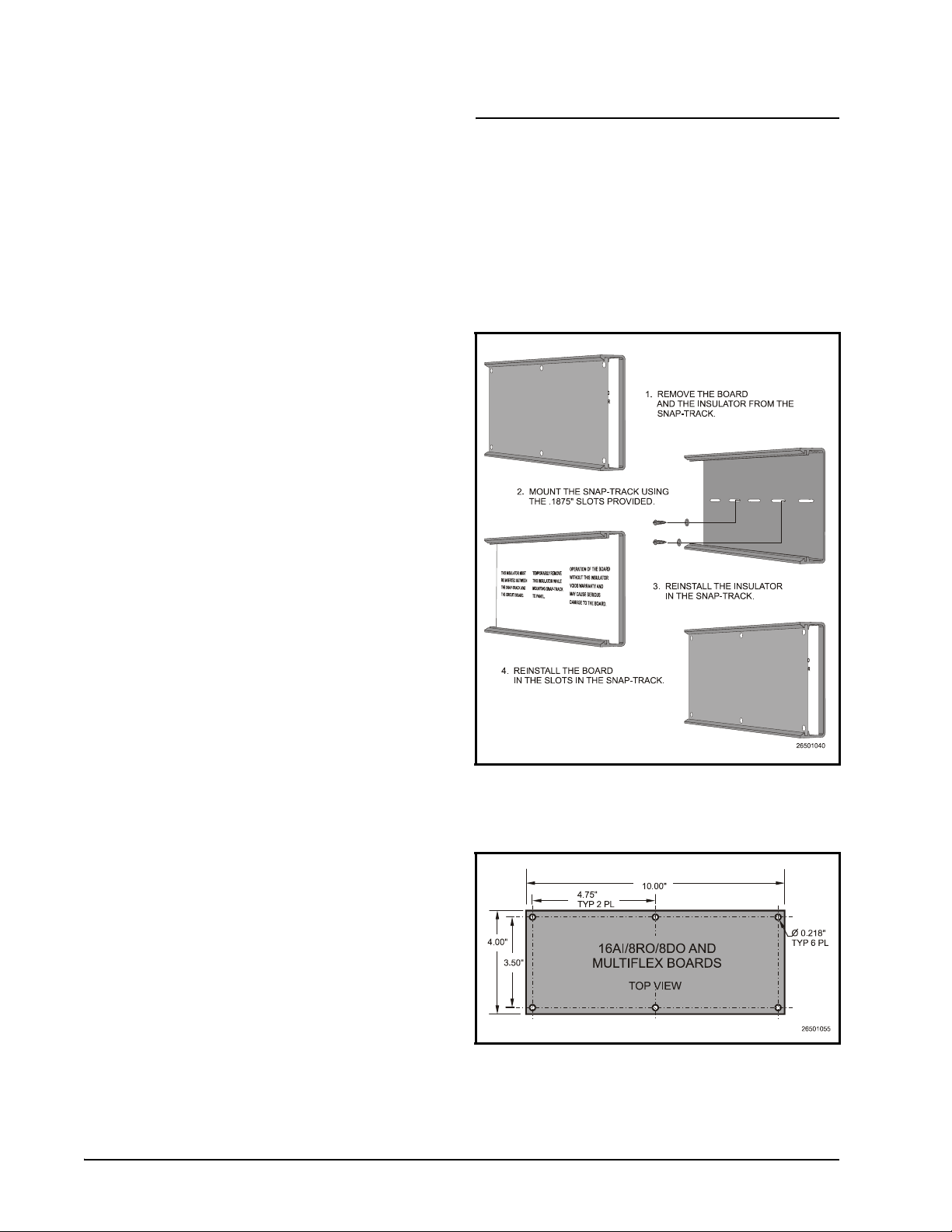

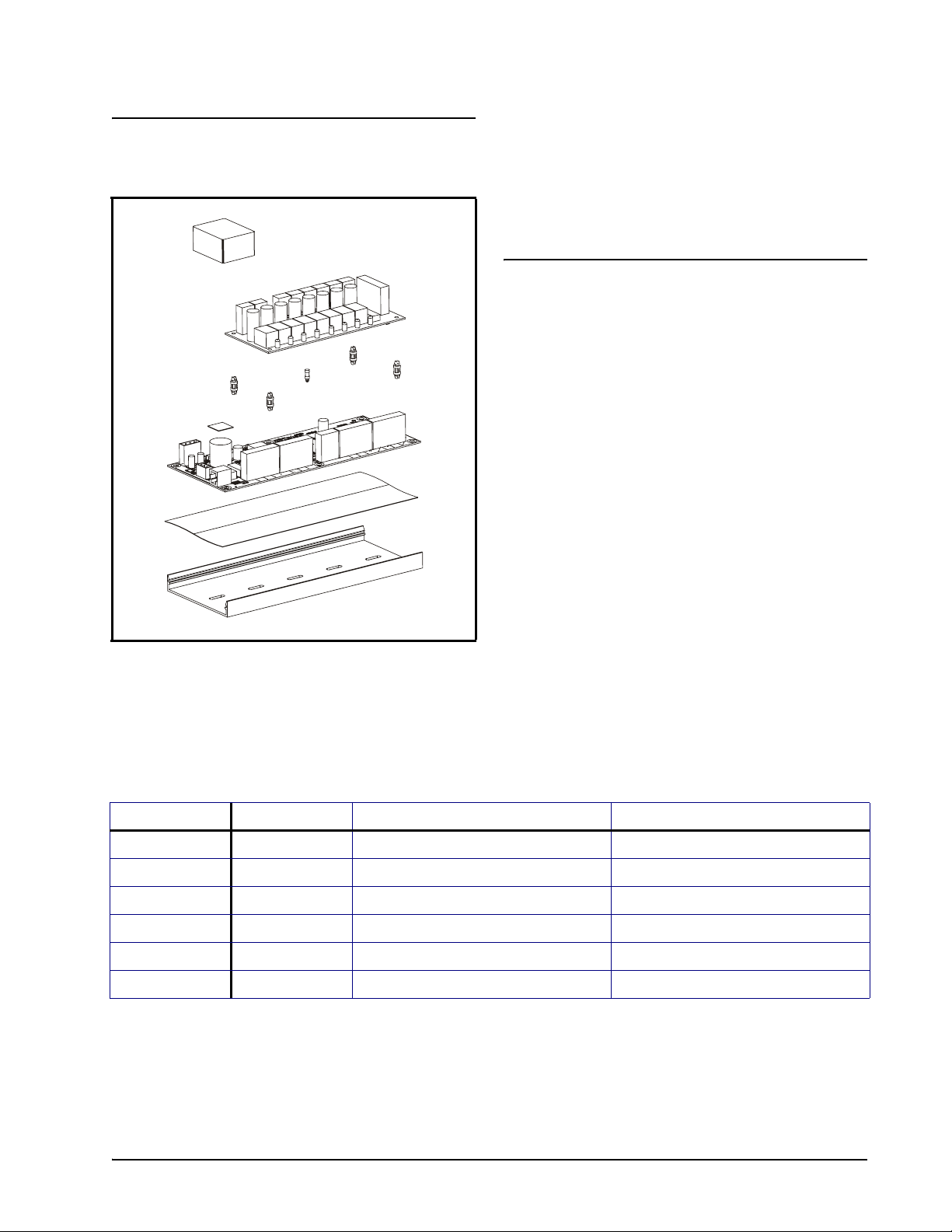

2.1. Snap-Track Installation

MultiFlex boards not supplied in a custom

panel or other enclosure are supplied with a

snap-track for easy installation. The insulation

sheet and I/O board must be removed from the

track before the track is mounted. The snap-track

is mounted using the 0.1875” mounting slots.

Figure 2-1 shows this installation procedure.

Figure 2-1 - MultiFlex Snap-Track Mounting

Figure 2-2 provides mounting dimensions

for the MultiFlex board.

Figure 2-2 - MultiFlex Board Dimensions

2 • MultiFlex RTU Operator’s Guide 026-1706 Rev 1 10-29-02

2.2. The Plug-In Output Board

The additional board makes the MultiFlex

RTU boards considerably taller than the MultiFlex 16 and other CPC I/O boards. If you will be

mounting these boards in an enclosure, the board

will need at least 2.5" of clearance between the

base board and the panel door.

2.3. Powering the MultiFlex

RTU Board

All models of MultiFlex require a 24VAC

Class 2 input power source. The MultiFlex RTU

requires the power source to be non-center-

tapped.

CPC supplies a wide variety of 24VAC

transformers with varying sizes and either with

or without center taps. Table 2-1 shows the

transformer sizes and whether they are centertapped or non-center-tapped.

Figure 2-3 - Exploded View — MultiFlex RTU

The MultiFlex RTU has an output sub-board

that plugs to the top of the base board. Typically,

these boards are shipped with the output board

pre-installed on the board using stand-offs, so no

additional hardware setup should be necessary.

Xformer P/N VA Rating Primary Voltage Center Tap?

640-0041 50 VA 110 VAC No

640-0042 50 VA 220 VAC No

640-0056 56 VA Multi-tap (120/208/240 VAC) Yes

640-0050 75 VA 110 VAC No

640-0045 75 VA 220 VAC No

640-0080 80 VA Multi-tap (120/208/240 VAC) Yes

Table 2-1 - Transformers Compatible with MultiFlex

The Plug-In Output Board Mounting and Powering • 3

2.3.1. Choosing Transformer Sizes

In most site installations, a single trans-

former will power multiple devices. Choose a

transformer with a VA rating large enough to

power all devices that will be attached to it.

Table 2-2 gives the VA ratings of the MultiFlex

RTU in conjunction with other MultiFlex

boards. Refer to your site controller’s manual for

VA ratings of the other I/O boards that may be

powered by one of these transformers.

Unit VA VAC Center

tapped?

MultiFlex 16 624Yes

MultiFlex 88,

88AO, 168,

and 168AO

MultiFlex RTU 15 24 NO

Table 2-2 - Device Power Requirements

15 24 NO

2.3.2. MultiFlex RTU Power Wiring

The MultiFlex RTU boards do not use a cen-

ter tap. Instead, the 0V terminal on the board

should be connected to a separate Earth ground.

Important! The rules that must be fol-

lowed when connecting a MultiFlex RTU

board to a transformer are different depending on whether you have a "new style" MultiFlex board with an isolated power supply (all

MultiFlex boards shipped after November 1,

2002) or an "old style" MultiFlex board (all

MultiFlex boards shipped before November

1, 2002).

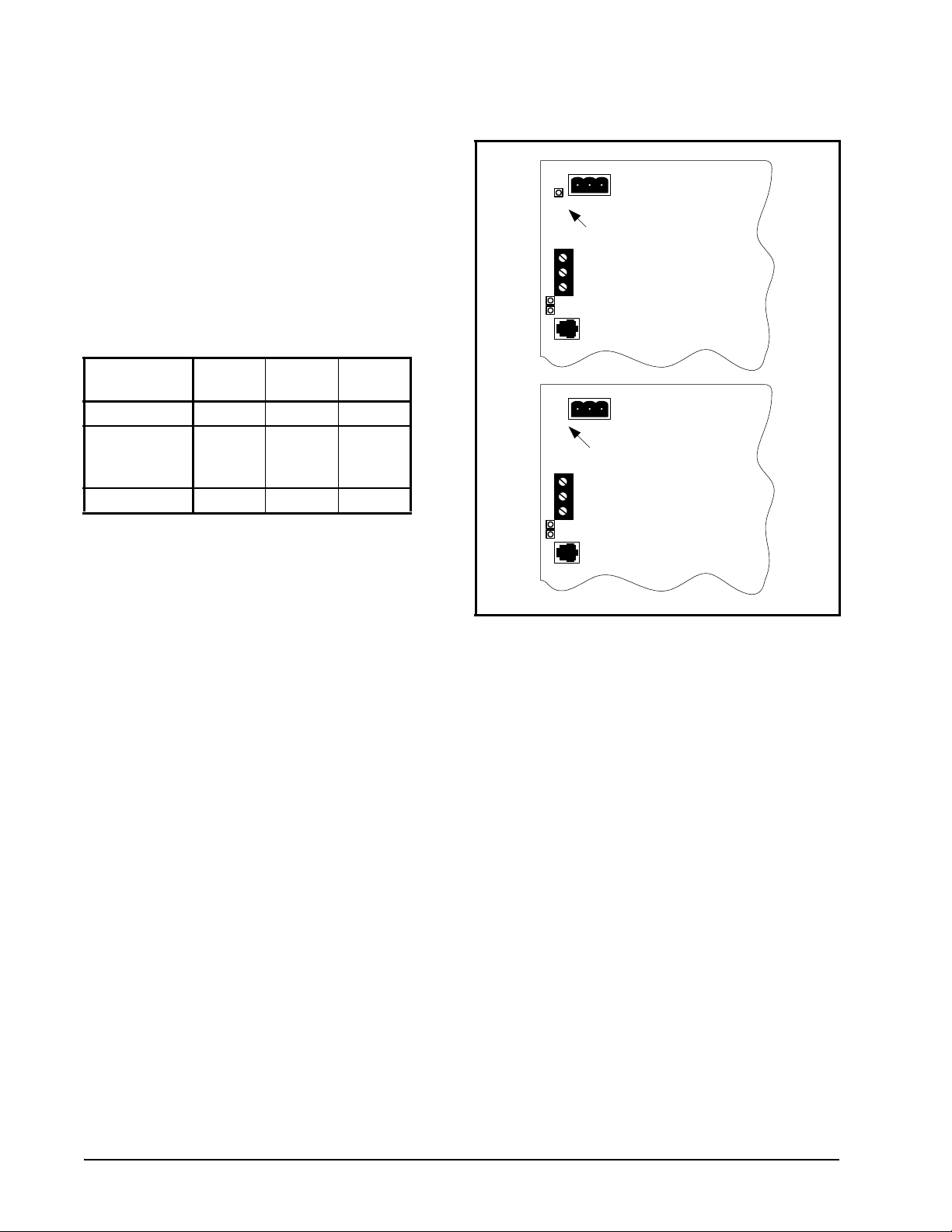

A new-style MultiFlex board has a green

power LED located next to the 24VAC connection terminal in the upper right corner of the circuit board (see Figure 2-4 for reference).

24 VAC

POWER LED

New Style

MultiFlex Board

(Top Left Corner)

24 VAC

NO POWER LED

Old Style

MultiFlex Board

(Top Left Corner)

Figure 2-4 - New-Style vs. Old-Style MultiFlex Board

If there is a green power LED next to the

connector, your MultiFlex is a new-style Multi-

Flex -- refer to Section 2.3.2.1., New-Style MultiFlex RTU Boards (with Isolated Power Supply)

for power wiring instructions.

If there is no green power LED next to the

connector, your MultiFlex is an old-style Multi-

Flex -- refer to Section 2.3.2.2., Old-Style MultiFlex RTU Boards No Isolated Power Supply) for

power wiring instructions.

2.3.2.1. New-Style MultiFlex RTU Boards (with Isolated Power Supply)

The new-style MultiFlex board can be connected to any of the center-tapped transformers

mentioned in Table 2-2, provided the 0V terminal of the board is connected to an Earth ground.

4 • MultiFlex RTU Operator’s Guide 026-1706 Rev 1 10-29-02

A center-tapped transformer may power

both center-tapped and non-center-tapped

devices at the same time, as long as none of the

non-center-tapped MultiFlex boards are oldstyle MultiFlex boards. If an old-style Multi-

Flex shares the same center-tapped transformer

as a device that uses the center tap, the old-style

MultiFlex will be damaged. Figure 2-5 shows

how to wire a non-center tapped device to a center-tapped transformer.

You may also tie one side of the secondary

(but not BOTH sides) to an earth ground, provided none of the boards powered by the same

transformer are old-style MultiFlex boards (see

Section 2.3.2.2.).

Figure 2-6 - Non-Center-Tapped Transformer Wiring

2.3.2.2. Old-Style MultiFlex RTU

Boards No Isolated Power Supply)

Figure 2-5 - Wiring Non-Center Tapped MultiFlex Boards to

Transformers With a Center Tap

In addition, the MultiFlex RTU boards can

be powered by one of the 50VA or 75VA noncenter-tapped transformers listed in Table 2-1 on

page 3. Figure 2-6 shows how to wire the transformers to the MultiFlex boards.

Like the new-style MultiFlex board, the oldstyle MultiFlex board can be connected to any of

the center-tapped transformers mentioned in

Table 2-2, provided you follow the following

three rules:

Rule 1: Ground the 0V terminal on the oldstyle MultiFlex board to an Earth ground.

Do not connect the center tap of the transformer to the 0V terminal.

Rule 2: Do not power an old-style MultiFlex

non-center-tapped board with a transformer

that is also powering a center-tapped device.

This means you cannot connect an old-style

MultiFlex non-center tapped board to a transformer that is powering a MultiFlex 16, 16AI,

8RO, 4AO, 8DO, or any previous generation

CPC board that uses center-tapped power. Doing

so will destroy the MultiFlex board.

Rule 3: The secondary of the center-tapped

transformer must not be grounded on any

side.

Powering the MultiFlex RTU Board Mounting and Powering • 5

Loading...

Loading...