CPC MultiFlex PAK User Manual

026-1712 Rev 3 03-JAN-2008

MultiFlex PAK Compressor/

Condenser Control Board

User’s Guide

1640 Airport Road, Suite 104

Kennesaw, GA 31044

Phone: (770) 425-2724

Fax: (770) 425-9319

ALL RIGHTS RESERVED.

The information contained in this manual has been carefully checked and is believed to be accurate. However, Computer Process Controls, Inc. assumes no responsibility for any inaccuracies that may be contained herein. In no event will

Computer Process Controls, Inc. be liable for any direct, indirect, special, incidental, or consequential damages resulting

from any defect or omission in this manual, even if advised of the possibility of such damages. In the interest of continued

product development, Computer Process Controls, Inc. reserves the right to make improvements to this manual, and the

products described herein, at any time without notice or obligation.

This product is covered under one or more of the following Computer Process Controls U.S. patents: 6360553,

6449968, 6378315, 6502409, 6578374, and Alsenz U.S. patents 4612776, 4628700, and 4535602.

READ ALL INSTRUCTIONS CAREFULLY

If the equipment is not used in the manner specified by the manufacturer, the protection provided

by the equipment may be impaired.

SAVE THIS INSTRUCTION MANUAL

This instruction manual contains important operating instructions for the MultiFlex PAK boards.

Table of Contents

1 OVERVIEW OF THE MULTIFLEX PRODUCT LINE .......................................................................................... 1

1.1. M

ULTIFLEX PAK ......................................................................................................................................................... 1

1.1.1. Hardware .............................................................................................................................................................. 1

2 MOUNTING AND POWERING ................................................................................................................................. 2

2.1. S

NAP-TRACK INSTALLATION........................................................................................................................................ 2

2.2. T

HE PLUG-IN OUTPUT BOARD ..................................................................................................................................... 3

2.3. P

OWERING THE MULTIFLEX ......................................................................................................................................... 3

2.3.1. Choosing Transformer Sizes ................................................................................................................................. 4

2.3.2. MultiFlex Combination Input/Output Board Power Wiring................................................................................. 4

2.3.2.1. New-Style MultiFlex Combination I/O Boards (with Isolated Power Supply).................................................................. 4

2.3.2.2. Old-Style MultiFlex Combination I/O Boards (No Isolated Power Supply)...................................................................... 5

2.3.3. Wire Types and Maximum Distances.................................................................................................................... 6

3 THE I/O NETWORK .................................................................................................................................................... 7

3.1. W

3.2. D

IRING TYPES.............................................................................................................................................................. 7

AISY CHAINS ............................................................................................................................................................. 7

3.2.1. Network ID Numbers ............................................................................................................................................ 7

3.2.1.1. Numbering the MultiFlex PAK .......................................................................................................................................... 7

3.2.2. Setting the Baud Rate............................................................................................................................................ 8

3.2.3. Setting the Terminating Resistance Jumpers ........................................................................................................ 8

4 I/O BOARD INPUT AND OUTPUT SETUP.............................................................................................................. 9

4.1. T

HE INPUTS................................................................................................................................................................... 9

4.1.1. Input Types Supported by the MultiFlex PAK ...................................................................................................... 9

4.1.2. The PAK Default Input Assignments................................................................................................................... 10

4.1.3. Connecting Sensors to Input Boards................................................................................................................... 10

4.1.3.1. Wiring ............................................................................................................................................................................... 10

4.1.3.2. Sensor Wiring Types ........................................................................................................................................................ 10

4.1.3.3. Input Type Dip Switches .................................................................................................................................................. 10

4.1.4. Power Connection............................................................................................................................................... 11

4.1.4.1. Current Ratings for On-Board Power Sources ................................................................................................................. 11

4.1.4.2. Powering Sensors Requiring 24VAC Off the Power Transformer................................................................................... 11

4.1.5. Sensor Types for MultiFlex Input Points ............................................................................................................ 11

4.2. T

HE RELAY OUTPUTS................................................................................................................................................. 12

4.2.1. Output Types Supported by the MultiFlex PAK.................................................................................................. 12

4.2.2. The PAK Default Output Assignments................................................................................................................ 12

4.2.3. Wiring.................................................................................................................................................................. 12

4.2.4. Output Fail-Safe Dip Switches............................................................................................................................ 12

4.2.5. Relay Output Ratings and Fuse Protection......................................................................................................... 13

4.3. T

HE ANALOG AND DIGITAL OUTPUTS ....................................................................................................................... 14

4.3.1. Digital/Analog Output Types Supported by the MultiFlex PAK......................................................................... 14

4.3.2. The PAK Default Analog/Digital Output Assignments ....................................................................................... 14

5 BOARD STATUS LEDS ............................................................................................................................................. 15

5.1. S

TATUS LED .............................................................................................................................................................. 15

5.2. T

X AND RX LEDS ...................................................................................................................................................... 15

5.3. C

ODE A AND CODE B LEDS ...................................................................................................................................... 15

5.4. R

ELAY OUTPUT LEDS................................................................................................................................................ 16

Table of Contents • v

6 PAK SOFTWARE OVERVIEW................................................................................................................................ 17

6.1. C

OMPRESSOR GROUPS ................................................................................................................................................ 17

6.1.1. Maximum # of Groups......................................................................................................................................... 17

6.1.2. Required Setpoints............................................................................................................................................... 17

6.1.3. Compressor Group Stage Activation and Deactivation...................................................................................... 17

6.1.4. Compressor Control Strategies........................................................................................................................... 18

6.1.4.1. Cyclic ................................................................................................................................................................................ 18

6.1.4.2. Fixed Steps........................................................................................................................................................................ 18

6.1.5. Suction Float ....................................................................................................................................................... 19

6.1.5.1. Suction Float Input Sources.............................................................................................................................................. 20

6.1.5.2. Defrost Inhibit................................................................................................................................................................... 20

6.1.5.3. Bad Case Temp Inhibit ..................................................................................................................................................... 20

6.1.5.4. Suction Float During Loss of Communication ................................................................................................................. 21

6.2. CONDENSER CONTROL................................................................................................................................................ 21

6.2.1. Condenser Control Strategies ............................................................................................................................. 21

6.2.1.1. Staged Fans ....................................................................................................................................................................... 21

6.2.1.2. VSD Fan ........................................................................................................................................................................... 21

6.2.1.3. Fan Sequencer................................................................................................................................................................... 21

6.2.2. Minimum Pressure Set Point............................................................................................................................... 22

6.2.3. Discharge Pressure Max..................................................................................................................................... 22

6.2.4. Condenser Spray ................................................................................................................................................. 22

6.2.5. Interlock .............................................................................................................................................................. 22

6.2.6. Quiet Mode.......................................................................................................................................................... 23

6.2.6.1. Exiting or Cancelling Quiet Mode .................................................................................................................................... 23

6.2.7. Safety Features.................................................................................................................................................... 23

6.2.7.1. Discharge Trip .................................................................................................................................................................. 23

6.2.8. Alarms ................................................................................................................................................................. 23

7 MULTIFLEX PAK E2 INTERFACE........................................................................................................................ 24

7.1. A

DDING/DELETING A PAK ......................................................................................................................................... 24

7.1.1. Adding a PAK...................................................................................................................................................... 24

7.1.2. Deleting a PAK.................................................................................................................................................... 25

7.2. S

ETTING THE "CONNECTED" AND "READ SETPOINTS" ATTRIBUTES.......................................................................... 25

7.2.1. Verifying Online Status ....................................................................................................................................... 25

7.3. V

IEWING THE PAK STATUS SCREEN.......................................................................................................................... 26

7.3.1. Inputs and Set Points........................................................................................................................................... 26

7.3.2. Compressor Groups ............................................................................................................................................ 27

7.3.3. Compressor Status............................................................................................................................................... 27

7.3.4. Condenser Fans................................................................................................................................................... 27

7.3.5. Connected and PAK State ................................................................................................................................... 28

7.4. P

ROGRAMMING THE PAK USING E2........................................................................................................................... 28

7.4.1. Screen 1: General................................................................................................................................................ 28

7.4.2. Screen 2: Comp Setpts......................................................................................................................................... 28

7.4.3. Screen 3: Cond Setpts ......................................................................................................................................... 29

7.4.4. Screen 4: Float Setup .......................................................................................................................................... 29

7.4.5. Screen 5: PAK Inputs .......................................................................................................................................... 29

7.4.6. Screen 6: Outputs................................................................................................................................................ 30

7.4.7. Screen 7: PAK Outputs ....................................................................................................................................... 30

7.4.8. Screen 8: Fixed Steps .......................................................................................................................................... 30

7.4.9. Screen 9: Safety................................................................................................................................................... 31

7.4.10. Screen B: Alarms............................................................................................................................................... 31

8 MULTIFLEX PAK HAND-HELD TERMINAL INTERFACE ............................................................................. 32

8.1. T

HE HHT INTERFACE ................................................................................................................................................. 32

vi • MultiFlex I/O Board I&O Manual 026-1712 Rev 3 03-JAN-2008

8.1.1. Navigation........................................................................................................................................................... 32

8.2. PAK S

8.3. PAK S

TART SCREENS................................................................................................................................................. 33

TATUS SCREENS............................................................................................................................................... 33

8.3.1. Status Screen 1 .................................................................................................................................................... 33

8.3.2. Status Screen 2 .................................................................................................................................................... 33

8.3.3. Status Screen 3 .................................................................................................................................................... 33

8.3.4. Status Screen 4 .................................................................................................................................................... 34

8.3.5. Status Screen 5 .................................................................................................................................................... 34

8.3.6. Status Screen 6 .................................................................................................................................................... 34

8.3.7. Status Screen 7 .................................................................................................................................................... 35

8.3.8. Status Screen 8 .................................................................................................................................................... 35

8.3.9. Status Screen 9 .................................................................................................................................................... 35

8.3.10. Status Screen 10 ................................................................................................................................................ 35

8.3.11. Status Screen 11 ................................................................................................................................................ 35

8.4. PAK C

ONFIGURATION SCREENS ................................................................................................................................ 36

8.4.1. The PAK Configuration Menu ............................................................................................................................ 37

8.4.1.1. 1 - General ........................................................................................................................................................................ 37

8.4.1.2. 2 - Comp SP...................................................................................................................................................................... 38

8.4.1.3. 3 - Outs.............................................................................................................................................................................. 40

8.4.1.4. 4 - CondSP........................................................................................................................................................................ 41

8.4.1.5. 5 - Input............................................................................................................................................................................. 43

8.4.1.6. 6 - Safety ........................................................................................................................................................................... 44

Table of Contents • vii

1 Overview of the Multi-

Flex Product Line

The MultiFlex line of control system boards

provides a wide variety of input, output, and

smart control solutions, all of which are based on

a single universal hardware platform. The board

design uses flash-uploadable firmware and plugin expansion boards to configure the base platform board and apply it for use as an input

board, relay output board, analog output board,

or a combination I/O board.

1.1. MultiFlex PAK

The PAK is a distributed pack controller that

controls compressors and condenser fans. The

PAK can control up to 16 compressors, controlled in up to 8 compressor groups.

The PAK can control up to 4 condenser fan

groups containing up to 8 total condenser fans.

The PAK condenser control strategy is sequential TD control with setpoint/deadband using ON

and OFF delays. The PAK supports use of both

single-speed fan stages and VS fans.

1.1.1. Hardware

The MultiFlex PAK boards consist of two

circuit boards: a bottom layer with 16 combination digital/analog inputs, and a plug-in top layer

which contains a combination of 8 relay outputs

and 4 analog DC voltage outputs, which can be

used as digital or analog outputs.

The communication interface is RS485 I/O

using the Standard Extended Address Form for

CPC Distributed Controllers. Currently, the PAK

is designed to interface with the CPC E2 RX

controller, and the previous generation refrigeration controller, the Einstein RX.

MultiFlex PAK Overview of the MultiFlex Product Line • 1

2 Mounting and Power-

ing

The MultiFlex boards are usually installed

by the refrigeration or building equipment manufacturer. Therefore, the installer need only

make the necessary connections between the

boards and the site controller(s).

In some instances, an installer may be

required to mount an I/O board. There are no

restrictions on the location of these boards; however, for ease of network configuration, it is recommended that the boards be located adjacent to

the E2. I/O boards may be mounted without an

enclosure, but they should be mounted in a location that is not easily accessible to avoid tampering or damage.

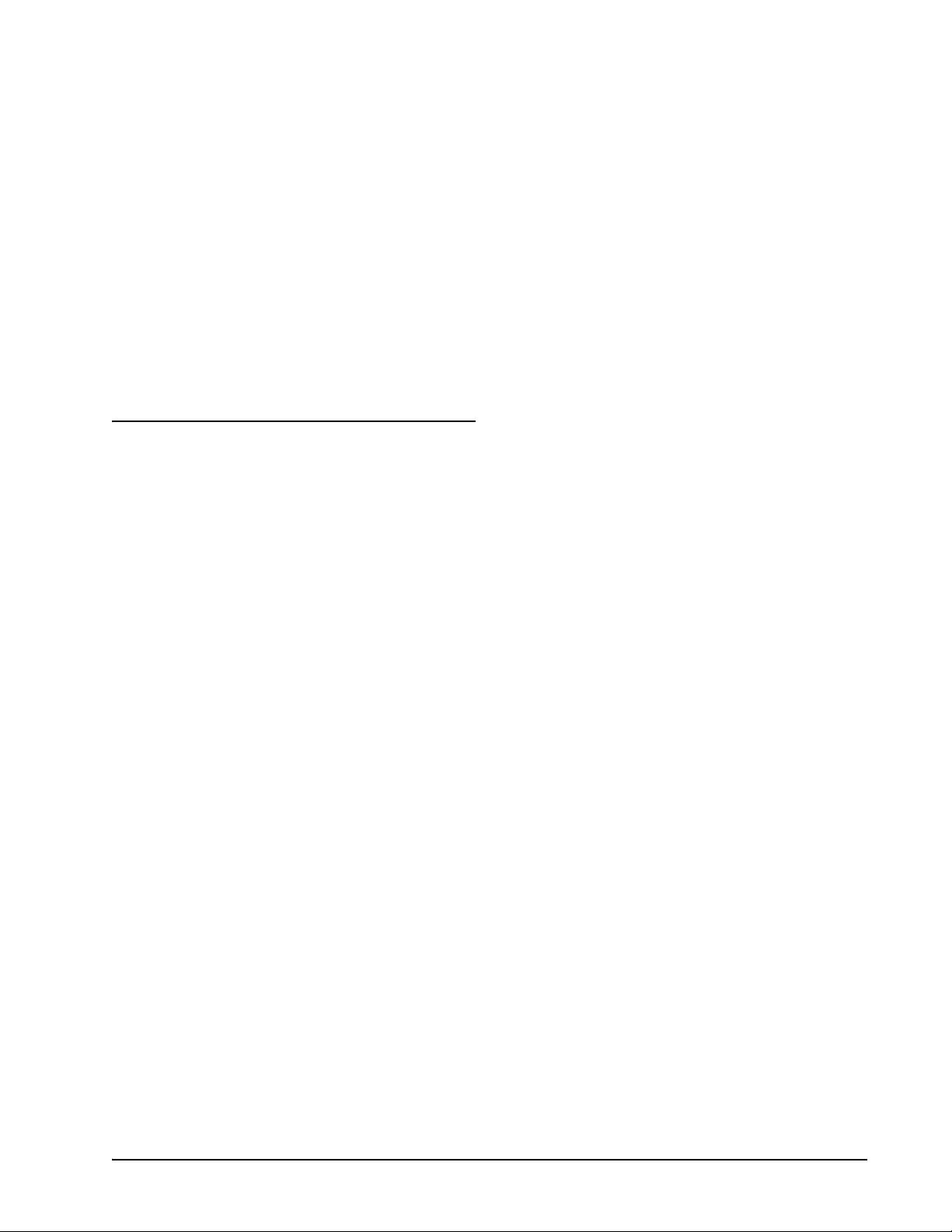

2.1. Snap-Track Installation

MultiFlex boards not supplied in a custom

panel or other enclosure are supplied with a

snap-track for easy installation. The insulation

sheet and I/O board must be removed from the

track before the track is mounted. The snap-track

is mounted using the 0.1875” mounting slots.

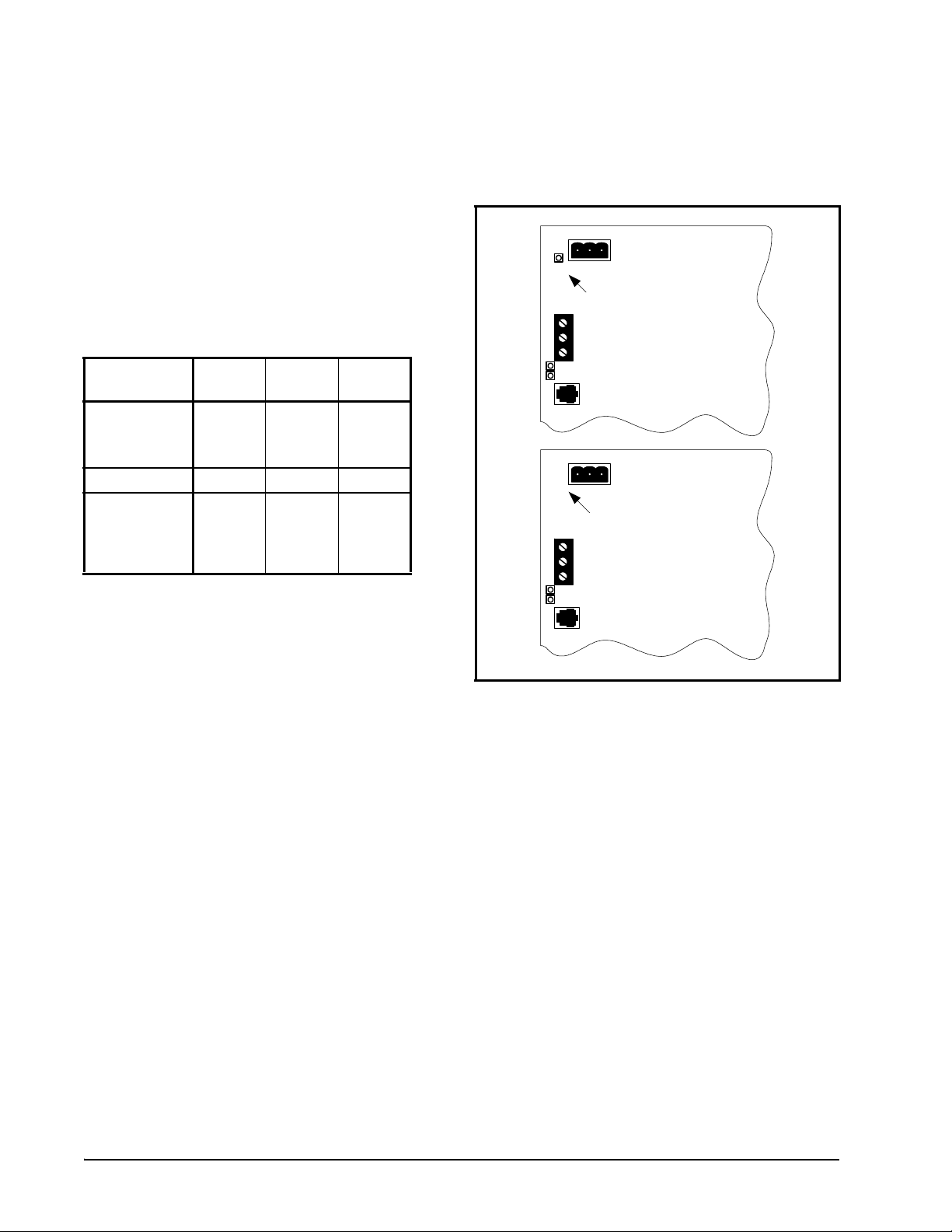

Figure 2-1 shows this installation procedure.

Figure 2-1 - MultiFlex Snap-Track Mounting

Figure 2-2 provides mounting dimensions

for the MultiFlex board.

Figure 2-2 - MultiFlex Board Dimensions

2 • MultiFlex I/O Board Operator’s Guide 026-1712 Rev 3 03-JAN-2008

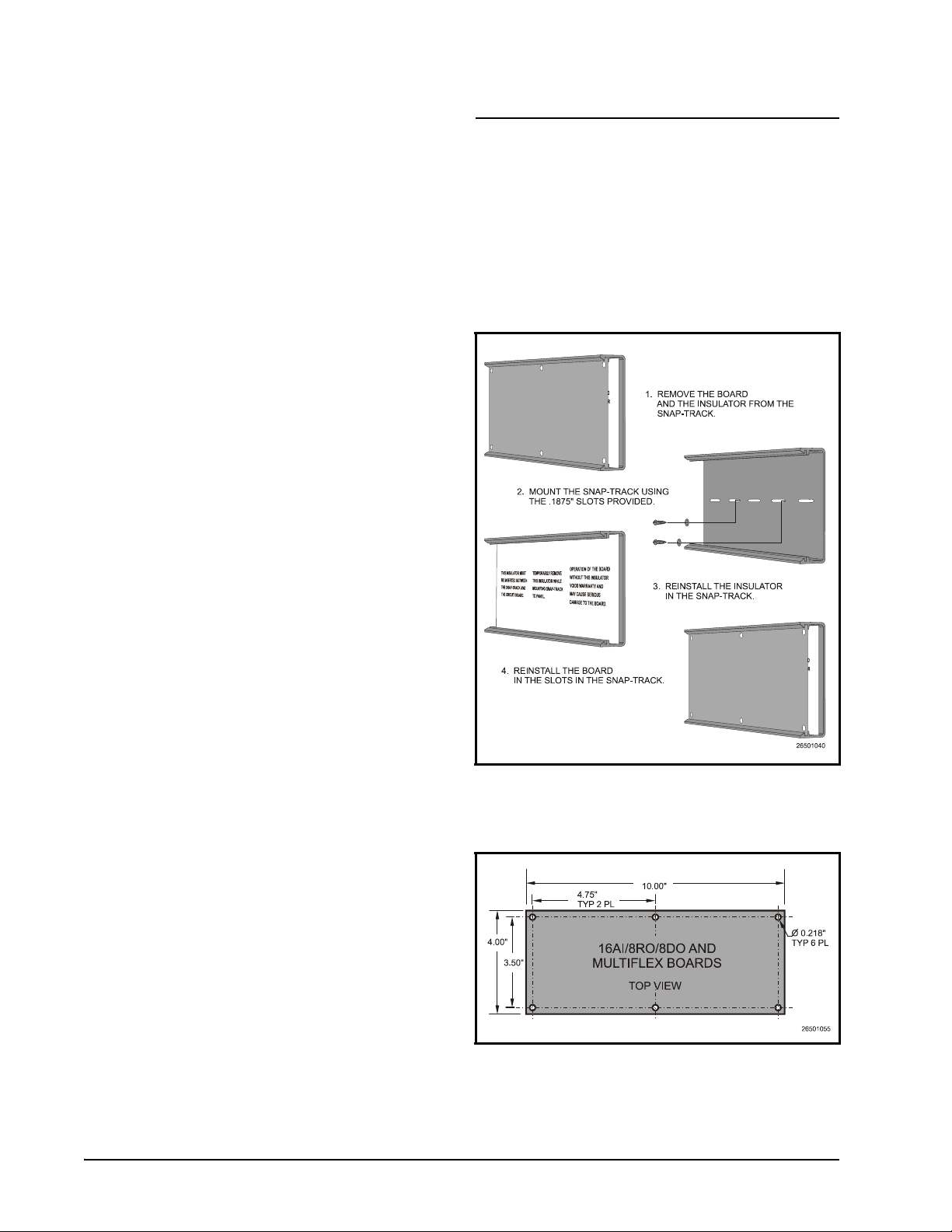

2.2. The Plug-In Output Board

The additional board makes the MultiFlex

combination boards considerably taller than the

MultiFlex 16 and all previous-generation CPC I/

O boards. If you will be mounting these boards

in an enclosure, the board will need at least 2.5"

of clearance between the base board and the

panel door.

2.3. Powering the MultiFlex

All models of MultiFlex require a 24VAC

Class 2 input power source. The MultiFlex PAK

requires the power source to be center-tapped.

CPC supplies a wide variety of 24VAC transformers with varying sizes and either with or

without center taps. Table 2-1 shows the trans-

former sizes and whether they are center-tapped

or non-center-tapped.

Figure 2-3 - Exploded View -- MultiFlex Combination I/O Board

All MultiFlex boards except the MultiFlex

16 have output sub-boards that plug in to the top

of the base board. These boards are shipped with

the output board pre-installed on the board using

stand-offs, so no additional hardware setup

should be necessary.

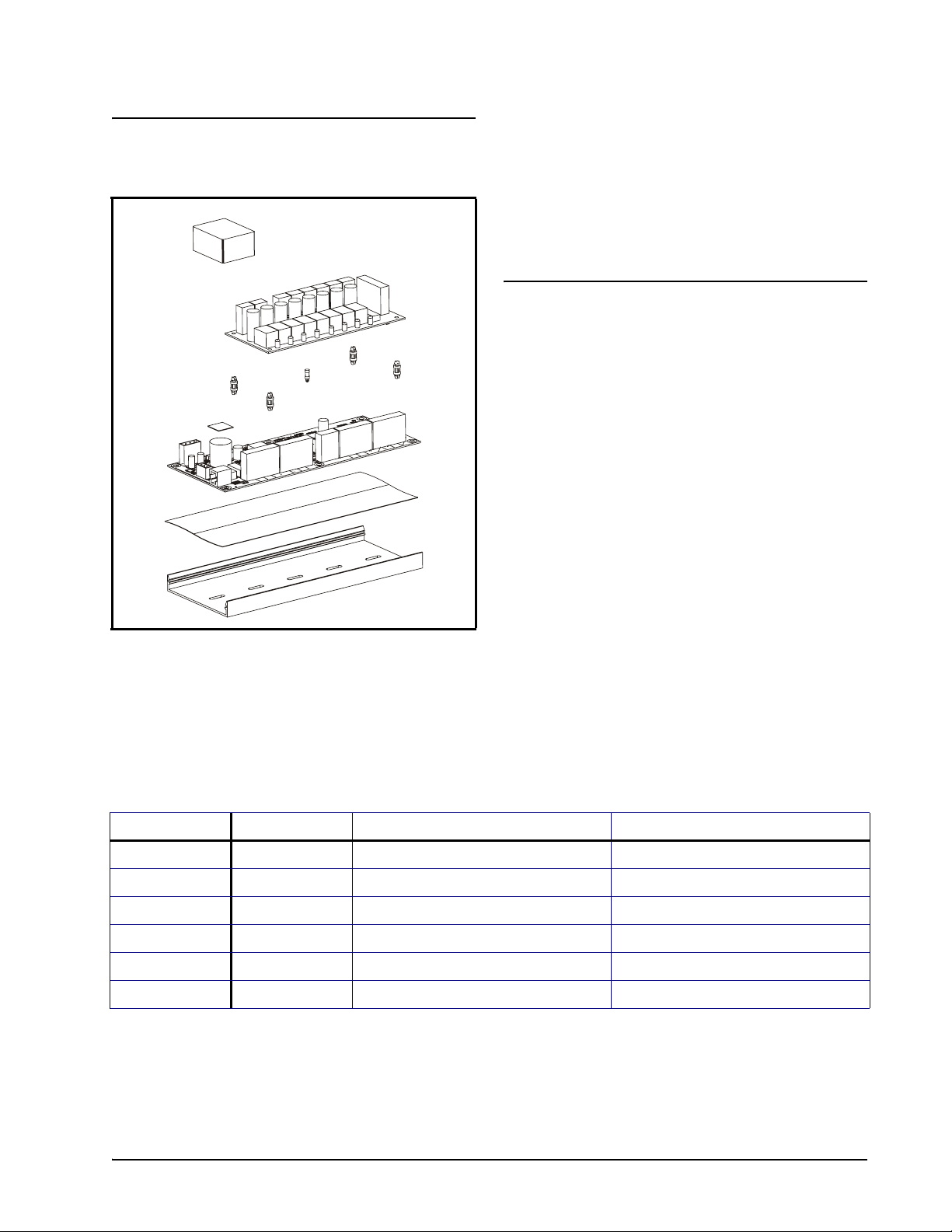

Xformer P/N VA Rating Primary Voltage Center Tap?

640-0041 50 VA 110 VAC No

640-0042 50 VA 220 VAC No

640-0056 56 VA Multi-tap (120/208/240 VAC) Yes

640-0050 75 VA 110 VAC No

640-0045 75 VA 220 VAC No

640-0080 80 VA Multi-tap (120/208/240 VAC) Yes

Table 2-1 - Transformers Compatible with MultiFlex Board

The Plug-In Output Board Mounting and Powering • 3

2.3.1. Choosing Transformer Sizes

In most site installations, a single trans-

former will power multiple devices. Choose a

transformer with a VA rating large enough to

power all devices that will be attached to it.

Table 2-2 gives the VA ratings of the MultiFlex

board products. Refer to your site controller’s

manual for VA ratings of the other I/O boards

that may be powered by one of these transformers.

Unit VA VAC Center

tapped?

MultiFlex PAK,

CUB, RTU,

and RCB

MultiFlex 16 624Yes

MultiFlex 88,

88AO, 168,

168AO and

168DO

Table 2-2 - Device Power Requirements

15 24 NO

15 24 NO

2.3.2. MultiFlex Combination Input/ Output Board Power Wiring

A new-style MultiFlex PAK board has a

green power LED located next to the 24VAC

connection terminal in the upper right corner of

the circuit board (see Figure 2-4 for reference).

24 VAC

POWER LED

New Style

MultiFlex Board

(Top Left Corner)

24 VAC

NO POWER LED

Old Style

MultiFlex Board

(Top Left Corner)

The MultiFlex PAK boards do not use a center tap. Instead, the 0V terminal on the board

should be connected to a separate Earth ground.

Important! The rules that must be followed when connecting a MultiFlex PAK

board to a transformer are different depending on whether you have a "new style" MultiFlex board with an isolated power supply (all

MultiFlex boards shipped after November 1,

2002) or an "old style" MultiFlex board (all

MultiFlex boards shipped before November

1, 2002).

Figure 2-4 - New-Style vs. Old-Style MultiFlex Board

If there is a power LED next to the connector, your MultiFlex is a new-style MultiFlex --

refer to Section 2.3.2.1., New-Style MultiFlex

Combination I/O Boards (with Isolated Power

Supply) for power wiring instructions.

If there is no power LED next to the connector, your MultiFlex is an old-style MultiFlex -refer to Section 2.3.2.2., Old-Style MultiFlex

Combination I/O Boards (No Isolated Power

Supply) for power wiring instructions.

2.3.2.1. New-Style MultiFlex Combina-

tion I/O Boards (with Isolated

Power Supply)

The new-style MultiFlex board can be connected to any of the center-tapped transformers

mentioned in Table 2-2, provided the 0V termi-

nal of the board is connected to an Earth ground.

4 • MultiFlex I/O Board Operator’s Guide 026-1712 Rev 3 03-JAN-2008

A center-tapped transformer may power

both center-tapped and non-center-tapped boards

at the same time, as long as none of the non-

center-tapped MultiFlex boards are old-style

MultiFlex boards. If an old-style MultiFlex

shares the same center-tapped transformer as a

device that uses the center tap, boards on the network will be damaged. Figure 2-5 shows how to

wire a non-center tapped device to a centertapped transformer.

You may also tie one side of the secondary

(but not BOTH sides) or the center tap to an

earth ground, provided none of the boards powered by the same transformer are old-style MultiFlex boards (see Section 2.3.2.2.).

Figure 2-6 - Non-Center-Tapped Transformer Wiring

Figure 2-5 - Wiring Non-Center Tapped MultiFlex Boards to

Transformers With a Center Tap

In addition, the MultiFlex combination

boards can be powered by one of the 50VA or

75VA non-center-tapped transformers listed in

Table 2-1 on page 3. Figure 2-6 shows how to

wire the transformers to the MultiFlex boards.

All wire connections to earth ground should

be less than six (6) inches long and use a wire

gauge of at least 14AWG.

2.3.2.2. Old-Style MultiFlex Combination I/O Boards (No Isolated

Power Supply)

Like the new-style MultiFlex board, the oldstyle MultiFlex board can be connected to any of

the center-tapped transformers mentioned in

Table 2-2, provided you follow the following

three rules:

Rule 1: Ground the 0V terminal on the oldstyle MultiFlex board to an Earth ground.

Do not connect the center tap of the transformer to the 0V terminal.

Rule 2: Do not power an old-style MultiFlex

non-center-tapped board with a transformer

that is also powering a center-tapped device.

Powering the MultiFlex Mounting and Powering • 5

This means you cannot connect an old-style

MultiFlex non-center tapped board to a transformer that is powering a MultiFlex 16, 16AI,

8RO, 4AO, 8DO, a Gateway board, or any previous generation CPC board that uses centertapped power. Doing so will destroy the MultiFlex board.

the transformer that supplies power to them is

not enough to be concerned with. But it is very

important not exceed this maximum wire length

or the boards will malfunction.

Use these formulas to determine if the wire

gauge you are using fits within specification:

Rule 3: The secondary of the transformer

must not be grounded on any side.

Verify that neither side of the transformer

secondary is connected to earth ground before

powering the old-style MultiFlex board. A

grounded secondary will damage the MultiFlex

board.

In addition, the old-style MultiFlex combination boards can be powered by one of the 50VA

or 75VA non-center-tapped transformers listed

in Table 2-1 on page 3. Figure 2-6 shows how to

wire the transformers to the MultiFlex boards.

2.3.3. Wire Types and Maximum

Distances

For powering I/O boards, use only the listed

wire types from Table 2-3. Three-conductor non-

shielded cables are the recommended wire for

connecting between the center tapped transformer and the I/O boards. Shielded cable should

not be used for power wiring. The center tap

should be wired with the third conductor to earth

ground at the transformer.

14 AWG:

Feet = 0.40/(VA/24) x 0.005

18 AWG:

Feet = 0.40/(VA/24) x 0.013

(VA is the total VA rating of the I/O boards)

For example, if you had an 80 VA load:

14 AWG: 24 ft. (rounded down)

18 AWG: 9 ft.

Figure 2-7 - Power Wire Lengths

Each MultiFlex board should have its 0V terminal taken to a short, solid earth ground.

Power Wiring Types

14 AWG Belden 9495 or equivalent

18 AWG Belden 9493 or equivalent

Table 2-3 - Power Wiring Types

The wire length from the transformer and the

number of boards connected to the same wire

determines the type wire gauge used. In most

cases, the distance between the I/O boards and

6 • MultiFlex I/O Board Operator’s Guide 026-1712 Rev 3 03-JAN-2008

3 The I/O Network

All MultiFlex PAK boards and controllers

use an RS485 network connection to communicate with E2 site controllers. Technicians who

are familiar with CPC’s previous generation

16AI, 8IO, and ARTC boards will find the network setup procedure for the MultiFlex boards

to be very much the same.

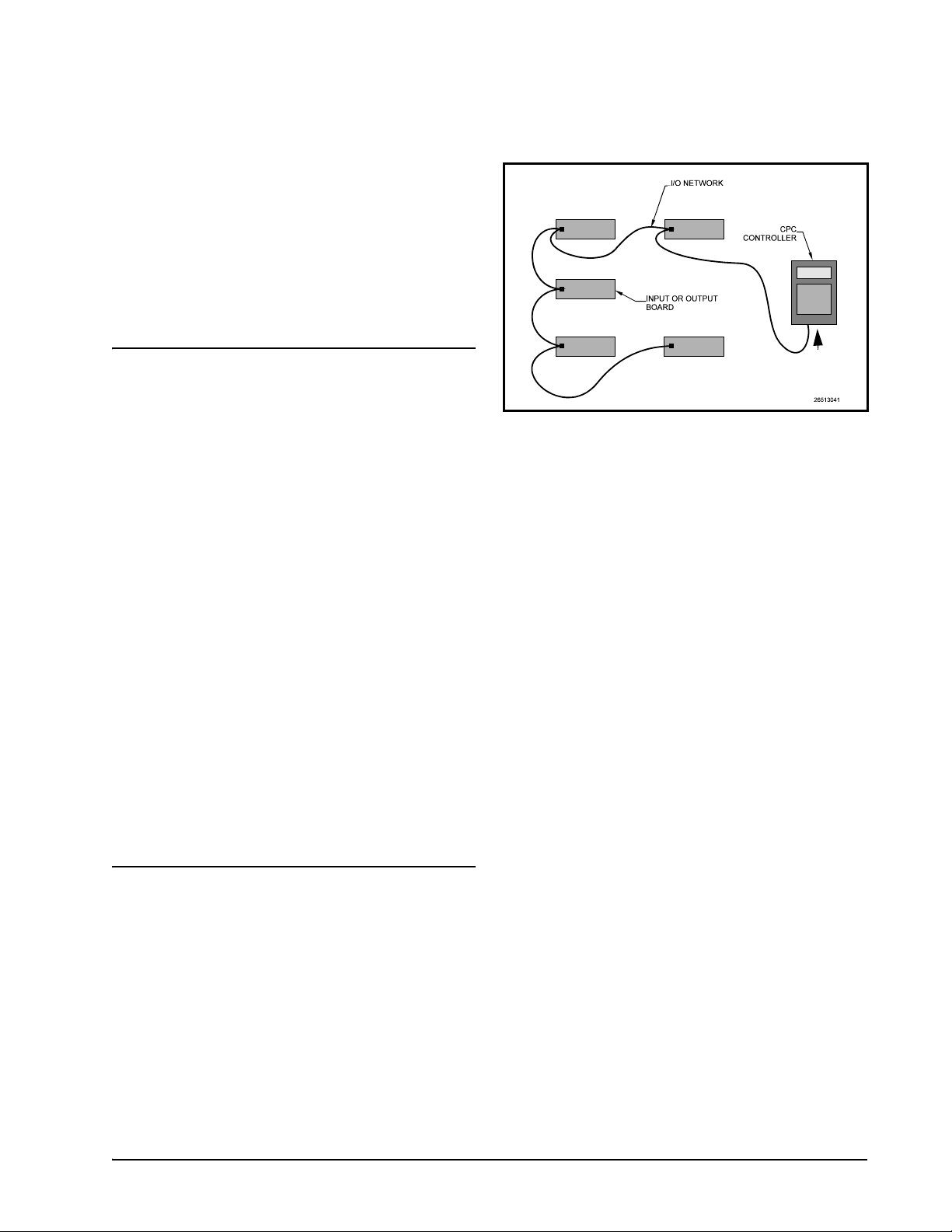

3.1. Wiring Types

A diagram of this network arrangement is

shown in Figure 3-1.

TERMINATION

TERMINATION

CPC specifies all RS485 I/O and MODBUS

wiring used by the E2 must be Belden 8641

(24AWG, 300V, CPC P/N 135-8641); Belden

8761 (22 AWG, 300V not stocked by CPC); or a

600V-shielded 22AWG equivalent stocked by

CPC (P/N 135-0600). These are two-connector

shielded twisted pair cable that support a maximum daisy chain cable distance of 4000 feet

(1219 m) between the E2 and the end device on

the network.

Provided the cable can be routed away from

noise generators and avoid running in parallel

with high-voltage wire, any of the three specified cables will provide adequate shielding from

external noise. For more instructions on best

practices for minimizing noise, refer to publication 026-1903, E2 Controller Wiring Practices,

available in the Product Manuals section of the

Emerson Retail Solutions website (http://

www.emersonretailsolutions.com/library).

Figure 3-1 - I/O Network Configurations

3.2.1. Network ID Numbers

Each device on an RS485 segment has a network dip switch that must be used to assign the

board a unique network ID number.

The network ID number makes a board

unique from other boards on the network of the

same type. This allows the site controller to find

it and communicate with it.

Boards of the same type should be numbered

in sequence, starting with one and continuing

with two, three, etc.

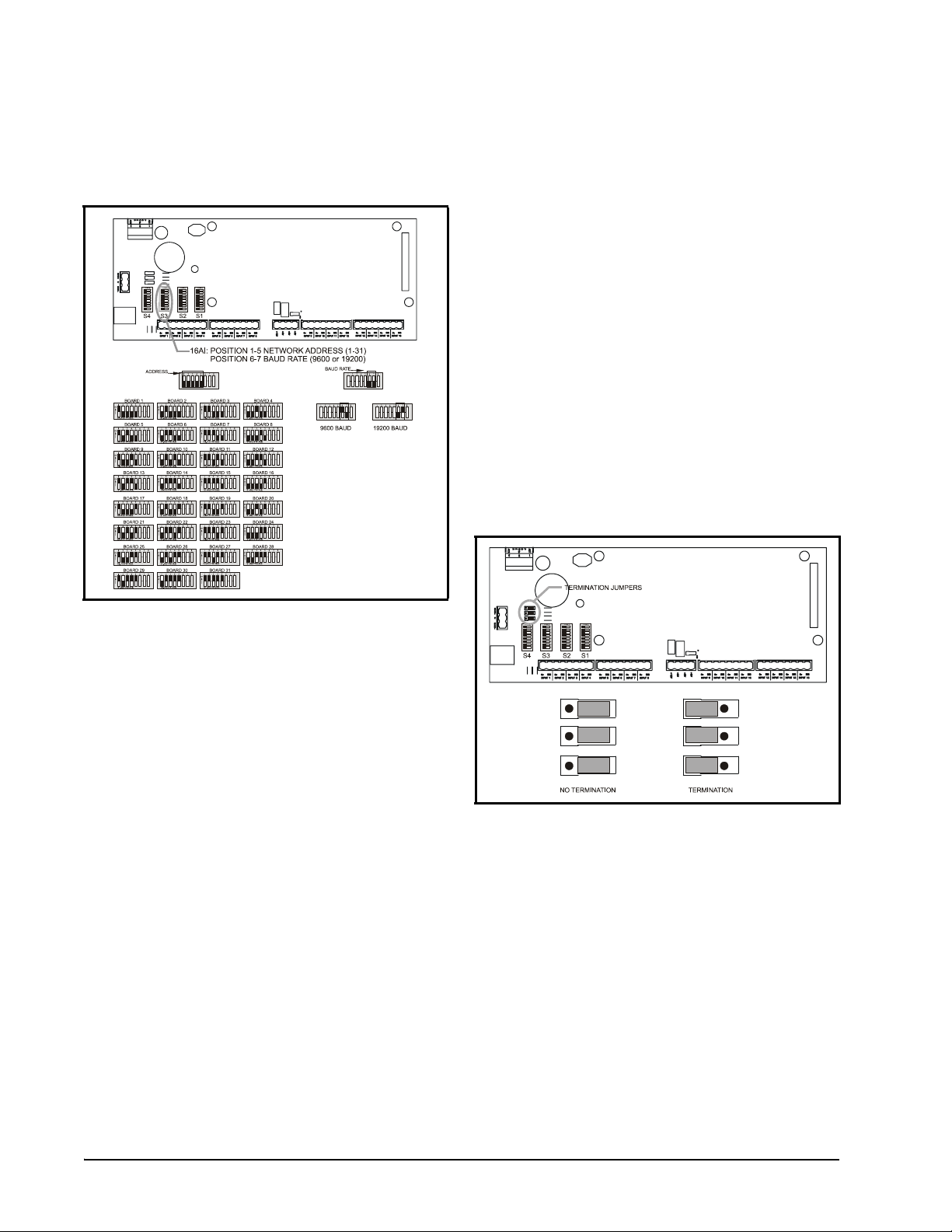

3.2.1.1. Numbering the MultiFlex PAK

The network ID on the MultiFlex PAK is set

using the first five dip switches on dip switch

bank S3. Refer to Figure 3-2 for dip switch setting instructions.

3.2. Daisy Chains

The RS485 Input/Output (I/O) network is

wired in a daisy-chain configuration. In a daisy

chain, boards are wired together in series with no

branches or "star configurations," and the network is terminated at either end of the daisy

chain.

Wiring Types The I/O Network • 7

NOTE: The MultiFlex PAK may only be

numbered up to 16, since E2 will only speak to

a maximum of 16 PAK boards. A PAK numbered above 16 will be ignored.

3.2.3. Setting the Terminating Resistance Jumpers

All MultiFlex boards and other RS485

devices have a set of terminating resistance

jumpers (one jumper for each wire lead). These

jumpers are labeled JP2, JP3, and JP4 on the

MultiFlex board.

The purpose of the jumpers is to indicate the

two ends, or termination points, of the segment.

On a daisy chain, one device at the beginning

and one device on the end must be terminated.

On the MultiFlex, this is done by placing all

three termination jumpers in the OUT (toward

the left edge of the board) position. To unterminate a MultiFlex, these jumpers must be set to

the IN (toward the center of the board) position.

Figure 3-3 shows the termination jumper settings for all MultiFlex boards.

Figure 3-2 - 16 Network ID and Baud Rate Switches

3.2.2. Setting the Baud Rate

All I/O boards have dip switches that determine the baud rate at which they communicate.

Currently, the baud rate dip switch in network

components may be set at either 9600 or 19200

baud. Either may be used -- refer to your site

controller’s user manual for the baud rate recommendation (currently 9600 baud for both

REFLECS and E2 controllers).

On all MultiFlex boards, switches 6 and 7 on

S3 are used to set the baud rate. To communicate

at 9600 baud, set switch #6 UP and #7 DOWN.

For 19200 baud, set switch #6 DOWN and #7

UP. Refer to Figure 3-2 for a visual look at how

the switches must be set.

Figure 3-3 - I/O Network Termination Jumper Settings

8 • MultiFlex I/O Board Operator’s Guide 026-1712 Rev 3 03-JAN-2008

Loading...

Loading...