CPC ESC3 Installation Manual

Computer Process Controls, Inc. — ESC3 Installation Guide

P/N 026-4700

Rev 1 3/11/05

ESC3 Overview

The ESC3 is a cost-effective electronic refrigeration controller that provides

control of compressor, fan and defrost management. The ESC3 provides control

of a compressor (or solenoid) valve in response to temperature variations.

The ESC3 comes in two models: a controller with a pluggable 10A relay for

defrost control (P/N 850-3500) and a controller with no defrost relay (P/N 850-

3510).

The ESC3 provides outputs for controlling for defrost and fans. This allows the

ESC3 to be used in applications requiring a defrost signal (as required in electric

defrost systems).

Operation

Temperature Control

Temperature control in the ESC3 is accomplished by comparing the temperature

reading of the case temperature probe against the temperature setpoint. The compressor output is used to control the temperature. If the temperature is above the

temperature setpoint (L1) + the hysteresis setpoint (rd), the compressor output is

turned on (subject to the conditions described in the compressor operation section). If the temperature is below the temperature setpoint – the hysteresis setpoint, the compressor output is turned off.

Note that the compressor output can also be used to control a refrigeration solenoid to regulate the temperature in a case.

Compressor Control

Several setpoints are available that allow the operation of the compressor output

to be tailored to match individual needs.

Min On/Off Times and Minimum Cycle Time Minimum ON/

OFF compressor times can be specified, as well as a minimum time delay

between compressor cycles. These parameters help prevent short-cycling.

Compressor Power ON delay The compressor power on delay set-

point (c0) allows the user to specify a delay after the power up of the controller.

The compressor output will not come on regardless of the temperature reading,

until this amount of time has expired.

Compressor Safety Cycle If the temp sensor fails, the ESC3 can be

programmed to cycle the compressor ON for a fixed amount of time, followed

by a 15-minute OFF time, until the probe failure is fixed. You may also specify

the compressor be fully ON or OFF during probe failure.

Fan Control

The fan output is controlled by the ESC3 based on the current operating mode

(defrost, cooling, etc.) and the setpoints which affect fan operation. It may be set

to run only when required based on case temperature, or it may be set to be

always ON regardless of temperature. In addition to these two basic modes, you

may also turn the fans OFF during defrost, specify the fan will be ON only when

the compressor is running, and delay fan activation after defrost drip time.

Defrost Control

The ESC3 can control the defrost function of a case. The ESC3 executes defrost

cycles at a user-defined time interval. Electric, Off Cycle and Hot Gas defrost

types are supported.

The ESC3 features a number of options to customize operation and termination

of a defrost cycle. A defrost cycle can be terminated based on time or temperature. When termination by temperature is used, a minimum and maximum

defrost time can be specified.

You may also program the ESC3 to begin a defrost cycle after power-up (after a

user-defined delay time) and initiate a defrost manually (see the description for

“Defrost Key” on this page).

Alarm Control

The ESC3 has several alarm functions. In addition to alarms based on high and

low air temperatures, it will alarm if a probe failure is detected. If you are using

defrost, the ESC3 will also generate an alarm when the defrost cycle did not terminate as expected (such as when the ESC3 is programmed to terminate at a

temperature set point and the set point was never reached).

Interface

The ESC3 features a 3 digit LED display that shows the case temperature. Alternately, the display can be configured to display the product temperature if a

product temperature probe is connected. The temperature can be displayed in

either °C or °F.

Three keys on the front panel provide an indication of operating status as well as

allowing setpoints to be changed.

Alarm Key The Alarm key illuminates when the controller has

detected an alarm condition. This key is also used to reset an alarm condition and

to enter the setup mode (allowing setpoints to be changed).

Compressor Key The Compressor key illuminates when the com-

pressor output is on. When the ESC3 is in setup mode, this key is used to select a

setpoint to be modified and to change the value of the setpoint.

Defrost Key The Defrost key illuminates when the ESC3 is in defrost

mode. Press the defrost key for 5 seconds to go into manual defrost mode. The

key is also used in setup mode to select a setpoint to be modified and to change

the value of the setpoint.

Alarm Operation

Indications on the Display If the defrost, or compressor key blinks.

It means that the corresponding function is delayed by a timing routine or inhibited. Other two-character messages may appear on the screen to indicate changes

of state or alarm conditions:

Code Meaning

E0

E1

LO

HI

Ed

dF

Viewing and Changing the Temperature Setpoint The tem-

perature setpoint is the comparison point for the control temperature input. To

change the set point value:

1. Press the Alarm key for more than 5 seconds until the setpoint is displayed

2. Press the Compressor key and Defrost keys to raise/lower the value.

3. Press and hold for five seconds the Alarm key again to accept the new

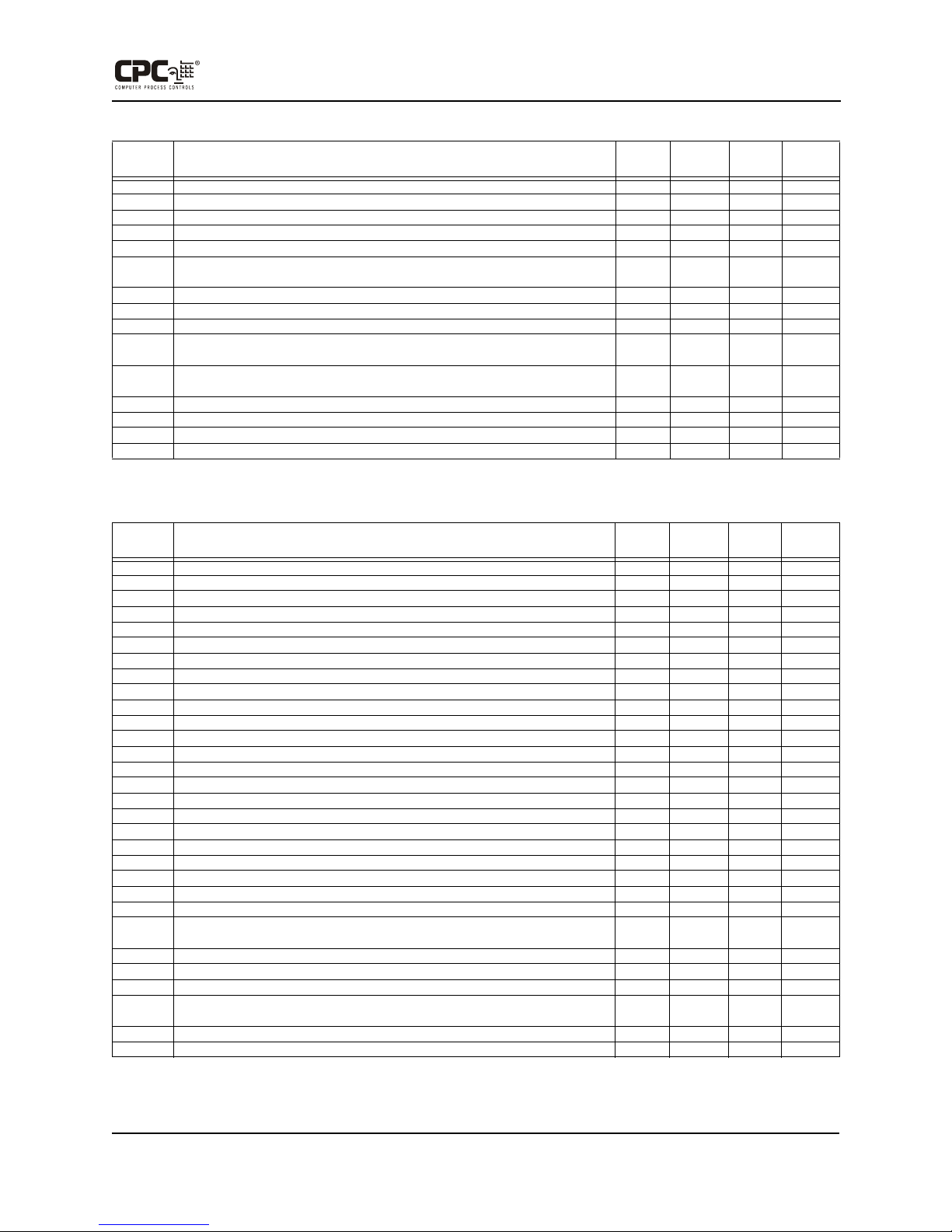

Changing Other Setpoints There are two levels of setpoints in the

ESC3. The first level does not require a password to change (unless the buttons

are locked out). The setpoints that can be changed in this manner are identified

in Table 1 (back side) as a USER setpoint. All other setpoint do require a password to change and are identified in Table 2 (back side) as an OEM setpoint.

To change USER-level setpoints:

1. Press the Alarm key and hold it until the letters PS are displayed.

2. Use the Compressor and Defrost key to scroll through the codes for the

3. When the code is displayed for the setpoint you wish to change, press the

4. Press the Compressor or Defrost key to change the value

5. Press the Alarm key to go back to the code.

6. If you have more set points you wish to change, press the Compressor or

7. When finished changing setpoints, press and hold the alarm key for five

power cycles to this unit, all setpoint changes will be lost.

To change OEM-level setpoints, the password must be entered. To do this press

and hold the alarm key until the letters PS are displayed. When PS is displayed

release the alarm key and 0 will be displayed. Press the compressor or defrost

keys to enter the password (22 is the default) then press the Alarm key. PS will

be displayed again. At this point, pressing the compressor or defrost key will

scroll through the legend for all setpoints. To change the setpoints, use the identical procedure that is used to change a USER setpoint.

Air probe has failed

Defrost termination or product probe has failed

Low temperature alarm

High temperature alarm

Defrost timeout has occurred (did not terminate correctly)

Case is in defrost (not an alarm)

and blinking.

value.

different set points (see Table 1 and Table 2).

Alarm key. The value for that setpoint will be displayed.

Defrost key to scroll to the next USER setpoint and follow steps 3-5.

seconds until the display stops flashing.

WARNING! If you do not hold the Alarm key for five

seconds after changing set points, the ESC3 will only

temporarily store your setpoint changes -- when the

1640 Airport Rd. Suite 103 Kennesaw, GA 30144 - http://www.cpcus.com/

Computer Process Controls, Inc. — ESC3 Installation Guide

P/N 026-4700

Rev 1 3/11/05

Code Parameter name Min Max Units

PS Password 0 199 22

/C Offset for air temp sensor (in tenths of a degree: i.e. a value of “1” adds 0.1° to value) -127 127 °C/°F 0

rd Regulator differential (superheat) set point (a “0” in this field = 0.5°C or 0.5°F) 0 19 °C/°F 2

dI Time between defrost cycles (defrost interval) 0 199 hours 8

dt Defrost temperature termination set point -50 127 °C/°F 4

dP Max duration of defrost if using electric or hot gas defrost, or the actual duration of

defrost if doing timed defrost

dd Drip time 0 15 min 2

d8 Alarm delay after defrost 0 15 hours 1

d/ Defrost probe reading (read-only) °C/°F

AL Low temperature alarm differential (subtract this value from the temperature set point

to get low alarm temperature set point) (0 = no low temp alarming)

AH High temperature alarm differential (add this value to the temperature set point to get

high alarm temperature set point) (0 = no high temp alarming)

F1 Fan on at temperature set point (used if F0 = 1) -50 199 °C/°F 5

Fd Fan delay after defrost drip time for each F0 value 0 15 min 1

H5 ID code for programming key -99 +

T External parameter programming -99 199

1199min30

0127°C/°F0

0127°C/°F0

Default

Value

Table 1: User-Level Set Points

Code Parameter name Min Max Units

/2 Reading stability 1 15 4

/4* Display probe: 0=regulation probe, 1=food probe 0 1 NU*

/5 Temperature units (0=°C, 1=°F) 0 1 0

r1 Min allowable set point -60 r2 °C/°F -50

r2 Max allowable set point r1 27 °C/°F 60

r3 Enable “Ed” alarm on display when defrost times out w/o terminating (0=no, 1=yes) 0 1 0

r4* Automatic variation of set point when door switch is active 0 20 °C/°F NU*

c0 Delay compressor start up after switch-on 0 15 min 0

c1 Minimum time between two compressor starts 0 15 min 0

c2 Minimum OFF time 0 15 min 0

c3 Minimum ON time 0 15 min 0

c4 Compressor safety relay (0=always OFF, 100=always ON) 0 100 min 0

cc Continuous cycle duration 0 15 hours 4

c6 Alarm delay after continuous cycle 0 15 hours 2

d0 Type of defrost (0=heater, 1=hot gas, 2=water or resistance, 3=hot gas by time) 0 3 0

d4 Defrost after control switch-on (0=no, 1=yes) 0 1 0

d5 Delay defrost after control switch-on 0 199 min 0

d6 Block of display during defrost (0=no, 1=yes) 0 1 1

d9 Priority of the defrost over anticlogging (0=no, 1=yes) 0 1 0

dC Time selection (0=hours/min, 1=min/s) (used for only dI and dP) 0 1 0

A0 Alarms and fan differential (a “0” in this field = 0.5°C or 0.5°F) 0 19 °C/°F 0

A4* Configuration of the digital input (#1) 0 4 NU*

A7* External alarm delay 0 199 min NU*

F0 Management of fans (0=fans on with specific phases excluded (F2, F3, Fd), 1=on

when temp is above F1 with specific phases excluded (F2, F3, Fd) )

F2 Stop fans when compressor is off (0=no, 1=yes) 0 1 1

F3 Fans OFF during defrost (0=no, 1=yes) 0 1 1

H0* Serial address 0 199 NU*

H1* Selection of the alarm relay operation (0= alarm ON, energized relay, 1=alarm OFF,

de-energized relay)

H2 Buttons enabled/disabled (0=disable, 1=enable) 0 1 1

H4* Buzzer enable/disable (0=enabled, 1=disabled) 0 1 NU*

01 1

01 NU*

Default

Val ue

Table 2: OEM-Level Set Points (Login Required)

* Parameters marked with“NU” are not used in this controller model. Leave these parameters at their default values.

1640 Airport Rd. Suite 103 Kennesaw, GA 30144 - http://www.cpcus.com/

Loading...

Loading...