CPC 203-5751 Installation Instructions Manual

TECHNICAL BULLETIN

Part #: 026-4806 Revision 0 Date: 02/26/2003

Wall-Mounted Humidity Sensor (P/N 203-5751)

Installation Instructions

CPC specs a wall-mounted relative humidity (RH) sensor with a 0-5VDC output for use in building control and anti-sweat control applications using CPC input boards.

Specifications

Sensing Element

Accuracy

Stability

Operating

Humidity Range

Temperature

Coefficient

Digitally profiled thin-film capacitive

±2% RH over the range 20%-90% RH

±1%@ 20°C (68°F) annually for 2 years

0-100% RH

±0.03% RH /°C over 0-60°C (32-140°F)

Analog Output

Scaling

Input Power

Enclosure

EMC

Conformance

0-5VDC; 3-wire, observe polarity

0-100% RH

12VDC

High-impact ABS plastic, plenum rated

UL94-5VA, White

EN 50081-1, EN 50082-1, EN 61000-4-4,

EN 61000-4-5, EN 61000-4-3,

ENV 50204, EN 61000-4-6

Choosing a Mounting Location

Mount the sensor indoors in a central location within the zone to be measured, away from doors,

windows, vents, heaters, and outside walls that could affect temperature readings. The sensor

should be at least four feet from the floor, and no higher than necessary to prevent tampering.

Mounting

1. Insert a screwdriver into the gap in the plastic on the bottom

side of the sensor enclosure, and pry the front part of the

enclosure away from the rear mounting plate. Pull the front

away from the mounting plate until the top separates from the

mounting plate.

2. Remove the punch out above the wiring connector so that the

sensor cable can be run into the sensor enclosure (see Figure

1).

3. Use the pre-made holes to mount the plate on a junction box

using the screws provided, or mount it against a wall or riser.

Do not mount the plate upside down or sideways. The plate

should be mounted with the terminal block toward the bottom.

4. If necessary, drill or cut a hole in the wall to allow the sensor

cable to be run through the wall into the sensor’s terminal

block.

COMPUTER PROCESS CONTROLS - http://www.cpcus.com/ Page 1

Figure 1 - Humidity Sensor - Exploded View

Technical Bulletin - Wall-Mounted Humidity Sensor (P/N 203-5751) Installation Instructions

Part #: 026-4806 Revision 0 Date: 02/26/2003

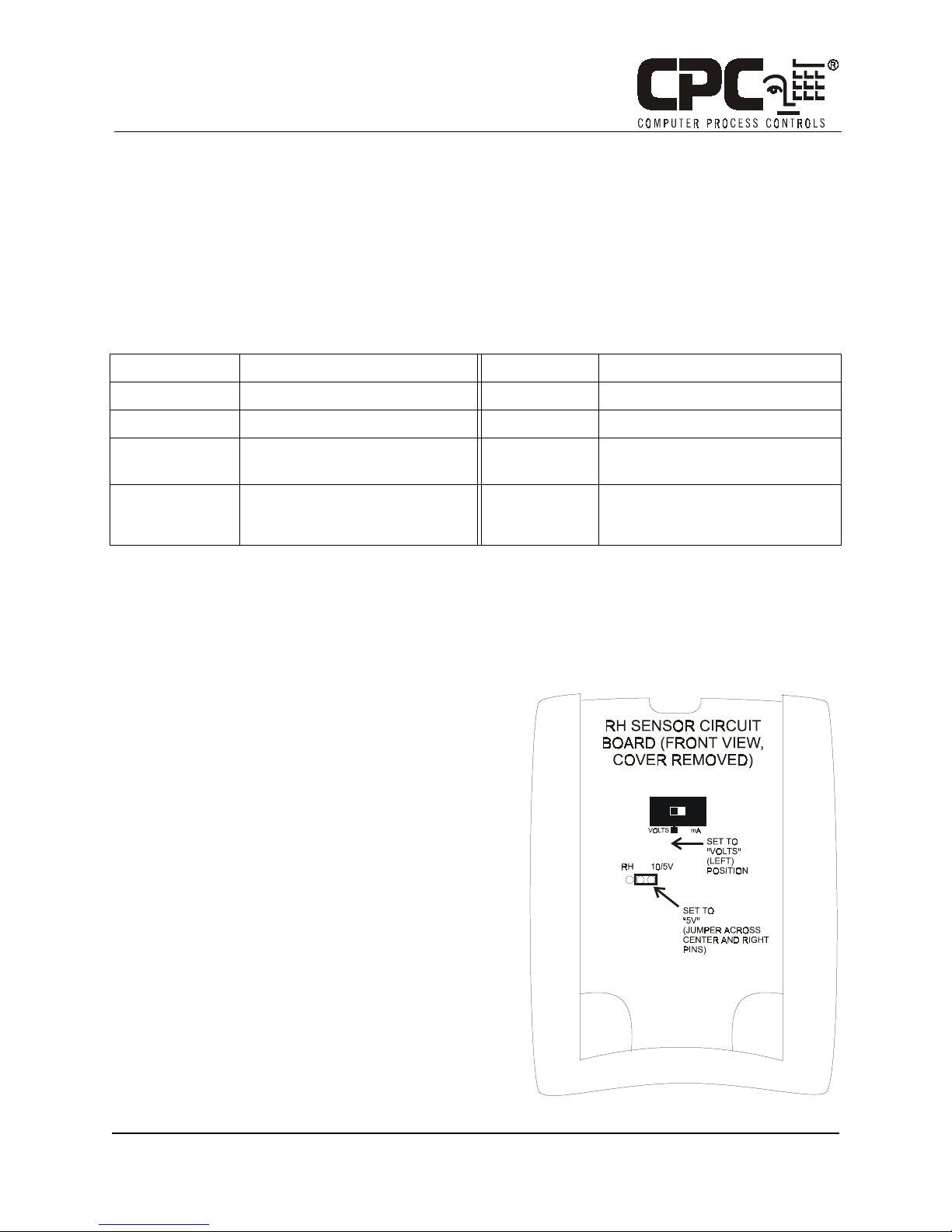

Wiring

1. Use Belden #8771 shielded three-conductor cable

or equivalent.

2. Connect the RED, BLACK, and WHITE wires to

the screw terminals the sensor’s connector as

shown in Figure 2. Clip the SHIELD wire.

3. Connect the SHIELD and BLACK wires to the

0V terminal of the input board. Connect the

WHITE wire to the SIG terminal of the input

board.

4. Connect the RED wire to the +12V power terminal on the input board.

5. Locate the input dip switch for the sensor point, and set to the OFF position (LEFT for MultiFlex, DOWN for 16AI). Refer to

the input board’s user manual for locations of the input dip switches.

Figure 2 - Sensor and Input Board Wiring

Finishing the Installation

Once the back plate of the sensor is mounted and the sensor and

board wiring is complete:

1. Attach the sensor circuit board enclosure to the mounting plate. Push the top of the

front part onto the mounting plate so the hooked mounting tabs fit underneath the

circuit board enclosure, and push the bottom part down so that the three prongs on

the back of the circuit board fit into the wiring connector. Continue pushing until

the front part is flush with the mounting plate.

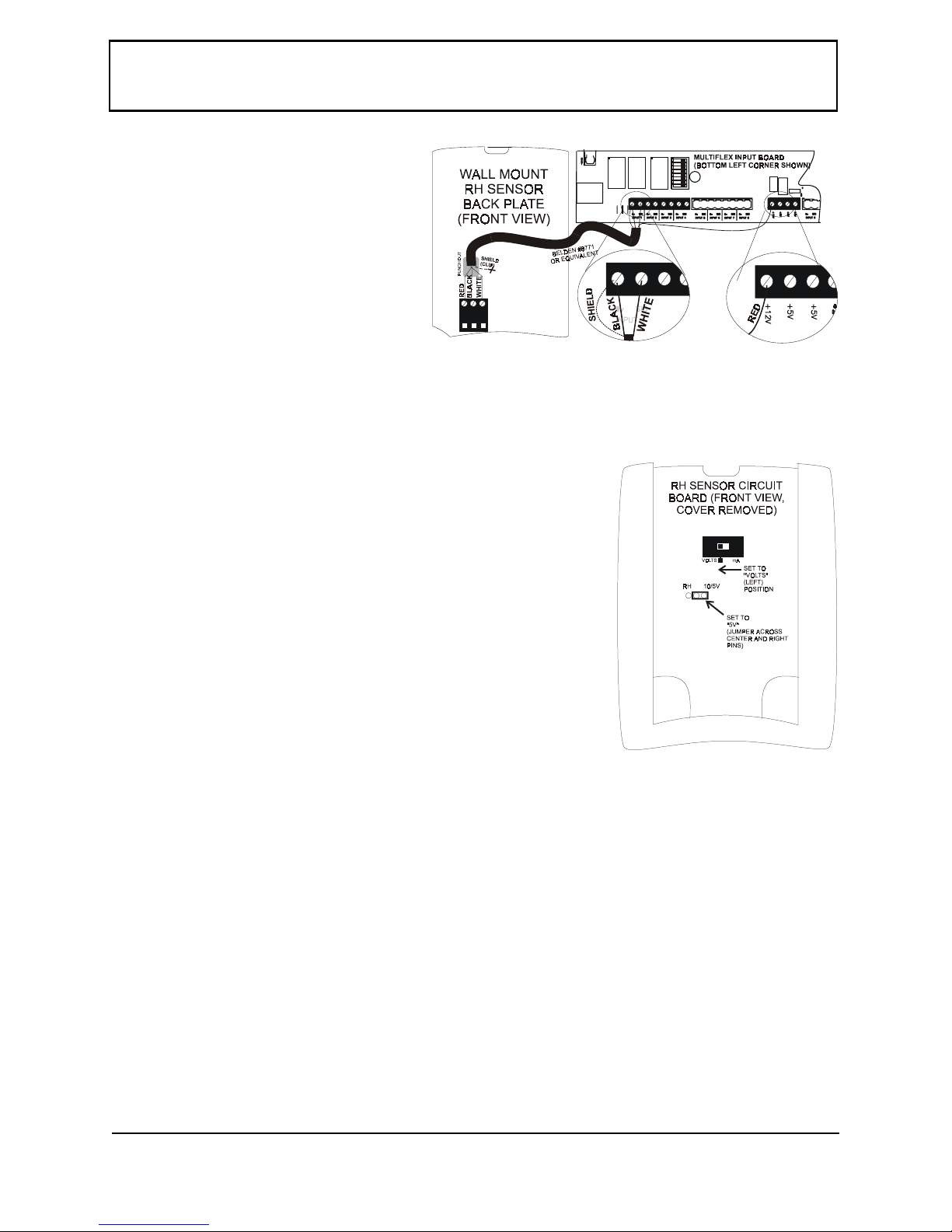

2. Before putting the cover on the sensor circuit board enclosure, check the position of

the switch and the jumper on the front of the circuit board. The switch should be set

to the VOLTS (left) position. The jumper should be set to the 5V position (across

the center and right pins). If either or both of these are in the wrong position, set

them to the correct position. Refer to Figure 3 for positioning.

3. Replace the front cover by inserting the hooked tab at the top of the cover into the

slot on the front of the circuit board enclosure so that it snaps into place. Press the

bottom of the cover until it snaps into the enclosure.

Figure 3 - Switch & Jumper Settings

Calibration and Replacement

The sensing element of the 203-5751 wall-mount RH sensor is pre-calibrated and will require no

physical adjustment. If the sensor drifts over time, the sensor can be ‘recalibrated’ by replacing

the pluggable sensing element. Contact CPC to order replacement elements (P/N 203-5795).

To replace a sensor element, use a screwdriver to pry the sensor circuit board off the mounting

plate. The sensing element is located on the back of the circuit board (see Figure 1). Note the ori-

entation of the sensor element before unplugging it and plug the new sensor element in using

the same orientation. Replace the circuit board when finished. There is no other calibration

method needed, and no adjustments are present in the unit.

Note: Do not expose sensor element to the fumes of curing RTV silicone rubber. Doing so

will damage the calibration of the element.

COMPUTER PROCESS CONTROLS - http://www.cpcus.com/ Page 2

Loading...

Loading...