CP CPL40 Use And Maintenance Instructions

Instruction m

anua

l CPL-40 1 of

19

C.P. srl – Via Perotti, 5 – 25125 BRESCIA - ITALY

USE AND MAINTENANCE INSTRUCTION MANUAL

PLANETARY MIXER

CPL40

MECHANICAL SPEED

VARIATION

Instruction m

anua

l CPL-40 2 of

19

USE AND MAINTENANCE INSTRUCTION

MANUAL

MECHANICAL SPEED VARIATION PLANETARY

MIXER

CPL40

This instruction, use and maintenance manual provides the instructions necessary

for

transportation, starting-up, use and maintenance of the mixer. It must be consulted before

any

one of these

acts.

The manual must be read not only by maintenance technicians, but also by operators in

charge

of the mixer who must correctly carry out what is within their line of

competence.

The manual is an integral part of the mixer. It must be kept in a suitable place where it can remain intact

and

where it can be consulted during the whole life of the

machine.

INDEX

SAFETY

INSTRUCTIONS ........................................................................................................................................................................... 3

RESIDUAL RISKS

....................................................................................................................................................................................... 3

RESIDUAL RISKS,

PROHIBITIONS, OBLIGATIONS:

Summarized table

.................................................................................................. 4

SYMBOLS USED AND

QUALIFICATIONS

OF THE

PERSONNEL ............................................................................................................ 5

USE AND DESCRIPTION OF THE

MIXER ................................................................................................................................................. 5

INSTRUCTIONS

FOR USE

........................................................................................................................................................................ 6

IDENTIFICATION,

POSITION OF THE OPERATOR AND DANGEROUS

AREAS .................................................................................... 8

TECHNICAL DATA, PACKAGING, DIMENSIONS AND WEIGHT

............................................................................................................ 9

TRANSPORTATION

AND

HANDLING ........................................................................................................................................................ 9

STORAGE .................................................................................................................................................................................................. 10

INSTALLATION .......................................................................................................................................................................................... 10

PRESERVATION OF THE

MIXER............................................................................................................................................................. 10

WARRANTY TERMS

................................................................................................................................................................................ 10

CLEANING AND MAINTENANCE

OPERATIONS..................................................................................................................................... 11

ROUTINE MAINTENANCE

..................................................................................................................................................................... 12

EXTRAORDINARY MAINTENANCE ......................................................................................................................................................... 12

PERIODICAL MAINTENANCE

................................................................................................................................................................. 13

SPARE PARTS

......................................................................................................................................................................................... 13

MAIN

COMPONENTS................................................................................................................................................................................ 13

DISMANTLING AND WASTE DISPOSAL

................................................................................................................................................. 13

SPARE PARTS

LIST.................................................................................................................................................................................. 14

BLOCKAGE OF MACHINERY AND NECESSARY REMEDIES

............................................................................................................... 16

ELECTRICAL LAYOUT

............................................................................................................................................................................. 16

Instruction m

anua

l CPL-40 3 of

19

SAFETY

INSTRUCTIONS.

The safe and systematic use of the mixer is subordinated to compliance with behavior and standards

listed

hereafter.

Safety standards

§ Personnel must be in good physical and mental conditions and be adequately instructed on the

use

of the mixer having read this

publication.

§ The safety manager of the company, of the operating area and of the department, when

choosing

the person who must use this equipment (a person suitable for the job according to Standards

in

force), must consider his/her cultural preparation, physical suitability and the psychological

aspect

(mental stability, sense of responsibility, etc.). Moreover, based on the attitudes and capacity

that

were verified, the manager must provide this person with proper training, having him/her read

the

present publication, in order to have full knowledge of the mixer and of the rules of

behaviour

applying to

it.

§ The area around the mixer must be well lit, free from other objects and

clean.

§ The personnel in charge of running, cleaning and carrying out maintenance on the mixer must

wear

the required PPE (personal protective

equipment).

§ Do not wear dangling clothing or fluttering hems (ties, napkins, torn suits, open jackets etc.) to

avoid

getting

entangled.

§ During maintenance and cleaning, the operator must disarm the master switch and place the

system

in safe conditions (for example, removing the

plug).

§ Never leave the mixer unattended while it is running. Be careful of abnormal noises or

behavior.

Keep away from rotating parts. Never open the grid before the equipment has come to a

complete

stop.

§ At the end of work, empty the machine completely, disconnect the master switch cutting the

power,

place it in safe conditions and clean it with a neutral degreasing agent (i.e. with Marseille

soap).

Safety devices.

§ The mixer is equipped with some devices which protect its operation as well as the safety of

the

operator. They must not be removed or modified. Their functioning must be checked

periodically.

§ Master switch: cuts power from the mixer, for maintenance in safe

conditions.

§ Circuit breaker switch: cuts power if the electric motor

overheats.

§ Fixed guards: All casings and guards fixed with screws or mechanical locks can be removed only

for

maintenance, by specialized personnel and in the prescribed modalities. When the work is over,

they

must be mounted

immediately.

§ Mobile guards: Movement of the grid activates a micro switch which prevents the mixer from

running

if the grid is open. If the grid is lifted while the mixer is running, it stops the cycle unconditionally,

just

like an emergency stop. The start button must be pressed for the mixer to

restart.

Safety Standards applied to the mixer.

§ EN 292 Safety of

machinery.

§ EN 294 Minimum distances to prevent accidental

contact.

§ CEI 17-13. Low-voltage switchgear and control gear

assemblies.

§ Community Directives: 89/392/EEC, 89/336/EEC, 91/368/EEC, 93/44 EEC, 93/68

EEC.

RESIDUAL

RISKS

Danger for limbs: Going beyond the protective grid or removing the casing during maintenance, it

is

possible to access the moving organs of the

mixer.

They are dangerous areas where serious physical injuries can occur. Do not introduce limbs or

other

objects without having placed the mixer in safe

conditions.

Danger of electrocution: the mixer must not operate without an adequate earthing system. It must

be

connected to a system built in compliance with construction standards in force in the country where

it

is

installed.

Automatic cycle: after starting up the mixer, it follows an automatic operating cycle. Never go

past

the safety barriers with your limbs or other objects while it is

running.

RESIDUAL RISKS, PROHIBITIONS, OBLIGATIONS: Summarized

table.

Instruction m

anua

l CPL-40 4 of

19

Obligation to

disconnect

mixer before working

on

it.

Stability for machinery: if there is

the

possibility of slipping on wet or

greasy

surfaces or positioning the equipment

in

unstable places (ships, planes or

other),

use the appropriate attachments

for

stable fixing (4 anchoring devices

with

200 kg resistance, M8

screws)

Obligation to carry

out

earthling.

ATTENTION!

§ Where the required PPE during

operations.

§ Clean the mixer thoroughly after

use.

§ Do not remove the safety devices or protective

casings.

§ Do not introduce any object through the protective grid with organs in movement: danger of objects

being thrown.

§ Before carrying out any maneuver beyond the protective grid, wait for the mixer to come to a complete

stop.

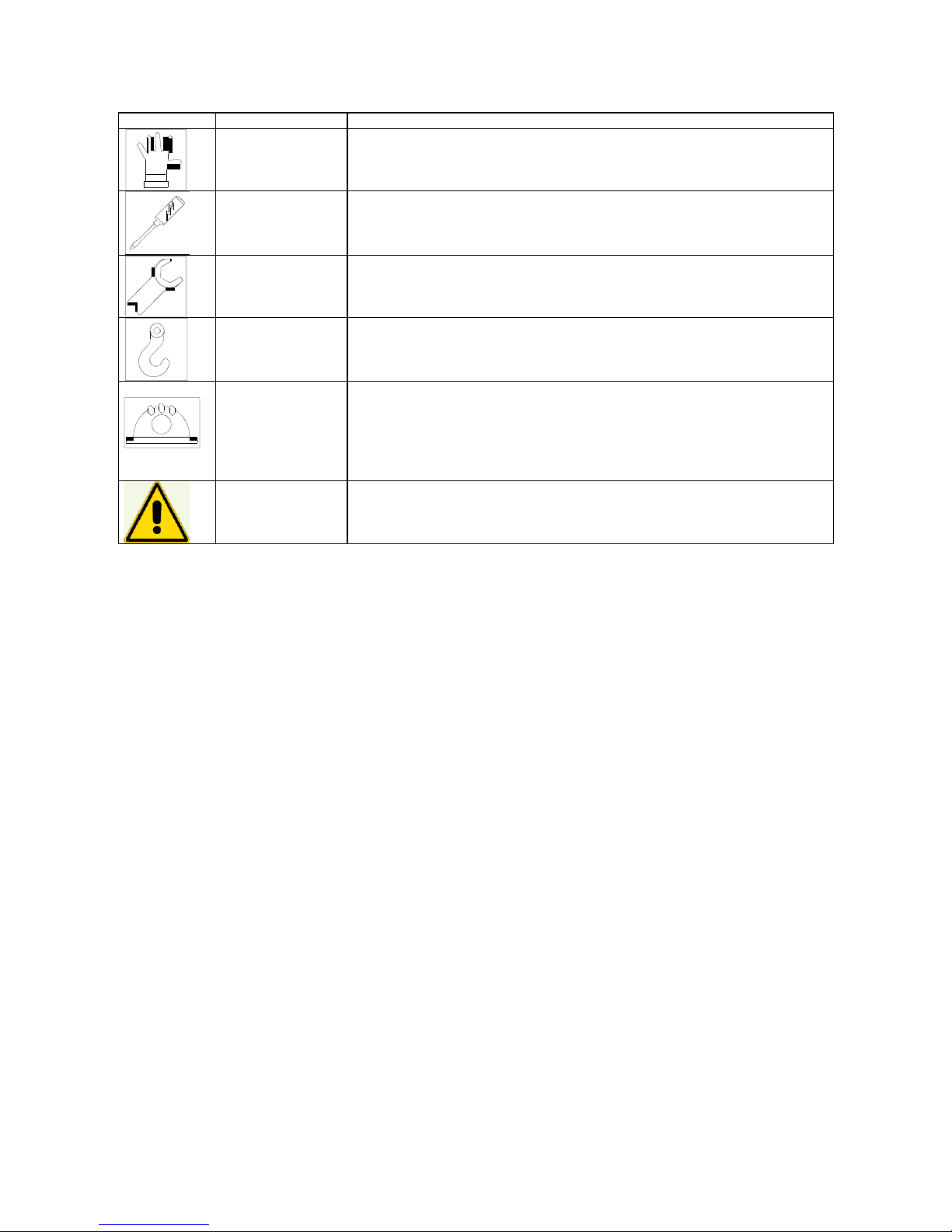

SYMBOLS USED AND QUALIFICATIONS OF THE

PERSONNEL.

The following indicates the qualifications of personnel required to operate the

mixer.

Instruction m

anua

l CPL-40 5 of

19

The symbols placed on a chapter mean to recall the specific skill needed for the intervention

described

therein. Wherever no symbols are present, the chapter applies to

everyone.

Symbol Description

Features

OPERATOR Person acquainted with operating, adjusting and programming the mixer and

its

protection and safety systems, who knows possible work cycles and

ingredients

to be used with relative maximum admitted amounts and who has read

and

understood the use and maintenance

manual.

ELECTRICAL

MAINTENANCE

TECHNICIAN

Person in good health who due to qualification, job or experience is qualified

to

carry out the profession of electrical maintenance technician and who has

read

and understood the use and maintenance

manual.

MECHANICAL

MAINTENANCE

TECHNICIAN

Person in good health who due to qualification, job or experience is qualified

to

carry out the profession of mechanical maintenance technician and who has

read

and understood the use and maintenance

manual.

PERSON

IN

CHARGE

OF

HANDLING

ZIONE

ASSISTANCE

Tel.

+39

030.3581864

Fax

+39

030.3581859

Person in good health who due to qualification, job or experience is qualified

to

carry out handling of loads and who has read and understood the use

and

maintenance

manual.

§ Requesting manual

updates.

§ Phone customer assistance concerning functioning, starting or faults

of

machinery.

§ Requesting spare parts, repairs, system overhauls, interventions on

site.

§ Training

courses

ATTENTION. This sign requests you to pay particular attention to the operations

indicated.

Lack of compliance can cause harm to personnel or damage to the

mixer.

USE AND DESCRIPTION OF THE

MIXER:

CPL40 planetary mixers are highly professional machines, capable of excellent performance. Driven by

a

high-power motor they use a belt speed variator with a high transmission ratio that is capable of a

great

excursion between low and high speed and a proportional speed of the

instrument.

The change of speed allows you to perfectly whip, beat, mix, amalgamate and air out ingredients

ensuring

excellent results of the finished

product.

The cemented, hardened and rectified gears and the wide size of the belt allow use of the high

power

installed. Together with the steel structure, they make the mixer sturdy and

reliable.

The bowl-lowering device, easy disassembly and the tools supply the mixer with great

professionalism.

The accessories provided with the machine have been built with the utmost care: whisk, blade and

spiral,

together with the shape of the bowl ensure the best mixing

results.

The safety devices and electrical control equipment complying with European Standards complete

the

machinery.

Instruction m

anua

l CPL-40 6 of

19

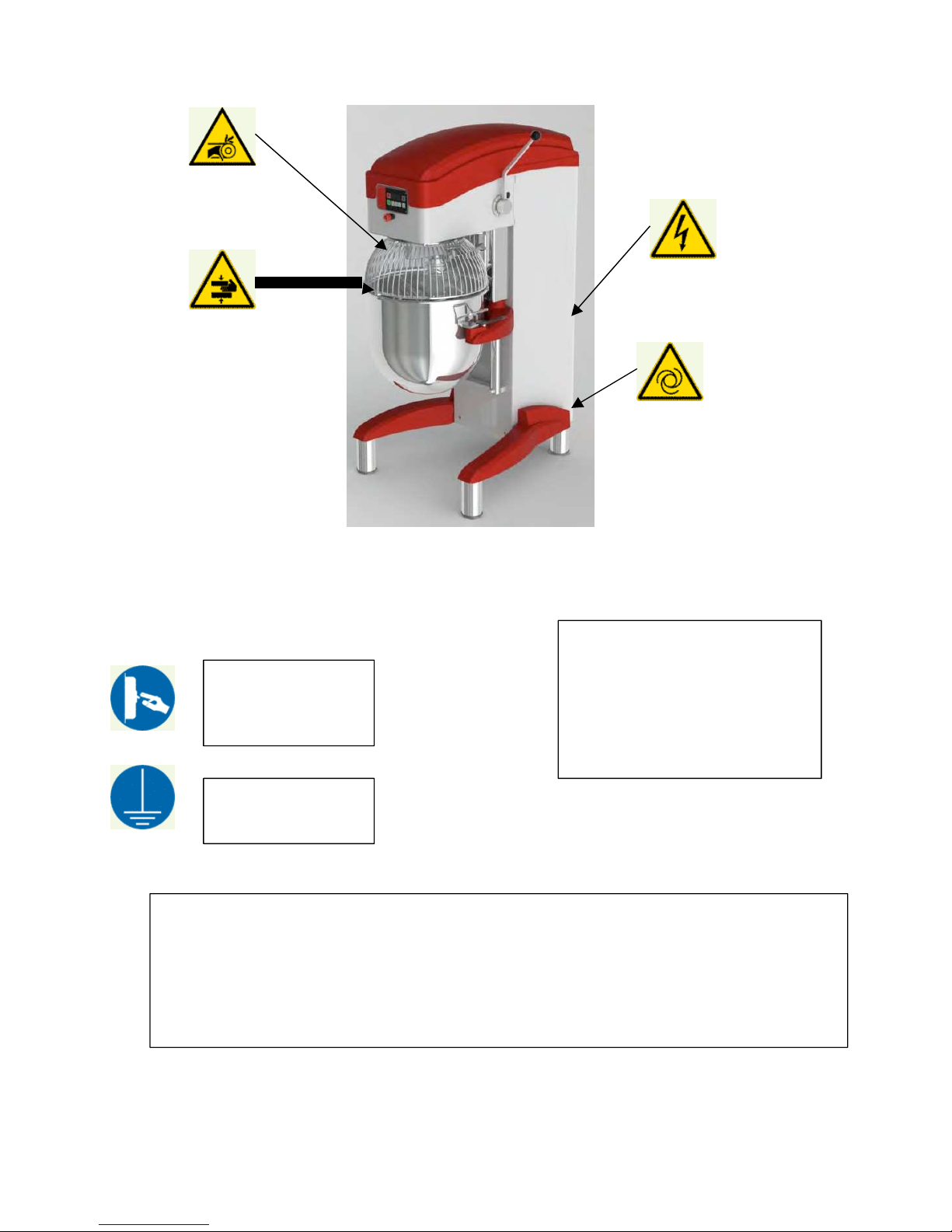

ELECTRICAL

PANEL

SPEED

CHANGE

GRID

PROTECTION

BOWL

LOCKING

HANDLES

INSTRUCTIONS FOR

USE

To be able to work; the bowl must be mounted and the bowl protective grid closed. Otherwise it will

be

blocked by the safety

systems.

DO NOT REMOVE OR TAMPER WITH THE ELECTRICAL OR MECHANICAL GUARDS OR

SAFETY

DEVICES ON THE

MACHINE.

The bowl must be in position BEFORE the tools. It must be inserted with the

bowl

lever down, putting the bowl plate, placed at the back of the bowl, on the bowl

lifting

arc.

Complete positioning by having the holes on the bowl support plates match

with

the centering pins. Block the bowl with the

handles.

If it was not previously done, rotate the protective grid of the

bowl

to the open position and, after having chosen the tool, insert it

into the tool holder shaft. Once it is inserted, turn the

tool

clockwise, having the transmission pin enter the work position

as

indicated in the figure. Lower it and insert the tool lock

ring.

Using the arrows é and ê , on the control panel to lift the bowl to the working position and

close the

protective grid of the bowl. At this point, after inserting the ingredients, start the work

cycle.

Loading...

Loading...