Cozy CDV336C, CDV335C, CDV256C, CDV155C, CDV156C User Manual

...

DIRECT VENT

WALL FURNACE

INSTALLATION AND

OPERATING INSTRUCTIONS

P/N 70905

REV. 06/2015

MODEL NUMBERS

NA TURAL GAS CDV155C CDV255C CDV335C

L.P . GAS CDV156C CDV256C CDV336C

W ARNING: If the information in these instructions ar e

not followed exactly, a fir e or explosion may result

causing property damage, personal injury or death.

- Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

- WHA T TO DO IF YOU SMELL GAS:

Do not try to light any appliance.

Do not touch any electrical switch; do not use any

phone in your building.

Immediately call your gas supplier from a neighbor’ s

phone. Follow the gas supplier’s instructions.

If you cannot reach your gas supplier, call the fire

department.

- INST ALLATION AND SERVICE MUST BE

PERFORMED BY A QUALIFIED INST ALLER,

SERVICE AGENCY OR THE GAS SUPPLIER.

The appliance may be installed in an aftermarket permanently located, manufactured home (USA only)

or mobile home, where not prohibited by local codes. This appliance is only for use with the type of

gas indicated on the rating plate. This appliance is not convertible for use with other gases, unless a

certified kit is used.

WARNING: Operation of this furnace without the properly installed, furnished vent system and vent

cap could result in Carbon Monoxide (CO) poisoning and possible death. For your safety, this furnace

and the vent system should be inspected at least annually by a qualified service technician.

CDV25/

CDV33-C

INST ALLER: Leave this manual with the

appliance.

CONSUMER: Retain this manual for

future reference.

The coating selected to provide longer life to

the heat exchanger may smoke slightly upon

initial firing. Please provide adequate

ventilation if this occurs.

CDV15-C

This unit is for residential use only and is not approved for installation in greenhouses, or environments

involving dusty, wet, corrosive, or explosive conditions. Such conditions will invalidate the warranty and

may create unsafe conditions.

Installation, maintenance, service, trouble shooting and repairs must be performed by a qualified service agency .

Mr./Mrs. Homeowner , DO NOT attempt any of these procedures yourself as this could expose you to property

damage, personal injury , or loss of life and will invalidate all warranties.

The State of Massachusetts r equires that installation and service of a gas appliance be

performed by a plumber or gas fitter licensed in the Commonwealth of Massachusetts.

CONTENTS

Introduction……………………………. 2

Specifications and Dimensions…………. 2

Safety Rules……………………………. 2/3

Clearances……………………………… 3/4

Location……………………………….. 5

Installation………………………………. 5 - 8

Vent Kits.................................................. 5 - 7

Gas Connection....................................... 8

BBSK Instructions................................... 12/13

Lighting Instructions…………………… 9

Pilot Adjustment……………………….. 10

Burner Orifice…………………………… 10

Wiring Diagram………………………… 10

Removing Main Burner………………… 10

Proper Burner Flame…………………… 11

Thermostat Installation………………… 11

Installing Optional Blower Kit………… 1 1

Maintenance Instructions......................... 19

Trouble Shooting………………………. 18

Parts Drawing………………………….. 14//16

Parts List……………………………….. 15 /17

Warranty……………………………….. 21

INTRODUCTION

THIS IS A GAS-FIRED, DIRECT VENT WALL FURNACE THAT WILL OPERATE SAFELY AND

PROVIDE AN EFFICIENT SOURCE OF HEAT WHEN INSTALLED, OPERATED AND

MAINTAINED AS RECOMMENDED IN THESE INSTALLATION AND OPERATING

INSTRUCTIONS. READ THESE INSTRUCTIONS THOROUGHLY BEFORE INSTALLING,

SERVICING, OR USING THE APPLIANCE. IF YOU DO NOT UNDERSTAND ANY PART OF

THESE INSTRUCTIONS CONSULT LOCAL AUTHORITIES, OTHER QUALIFIED INSTALLERS,

SER VICE TECHNICIAN, THE GAS SUPPLIER OR THE MANUF ACTURER.

SPECIFICATIONS AND DIMENSIONS

Your Direct Vent Wall Furnace is shipped complete in one carton. This carton contains the furnace, vent

cap, vent tube, air inlet tube, template with rough-in dimensions, installation and operating instructions, and

the thermostat with thermostat wire. NOTE: There will be two cartons if optional vent kit or blower is purchased.

MODEL INPUT GAS TYPE MAX. WALL MIN. WALL

NO. BTU/HR. WIDTH DEPTH HEIGHT CONN. GAS THICKNESS THICKNESS

CDV155C 15,000 18” 9-3/4” 29-3/4” ½” NAT. 24” 5”

CDV156C 15,000 18” 9-3/4” 29-3/4” ½” L.P. 24” 5”

CDV255C 25,000 34-1/2” 9-3/4” 31-3/4” ½” NAT. 24” 5”

CDV256C 25,000 34-1/2” 9-3/4” 31-3/4” ½” L.P. 24” 5”

CDV335C 33,000 34-1/2” 9-3/4” 31-3/4” ½” NAT. 15” 5”

CDV336C 33,000 34-1/2” 9-3/4” 31-3/4” ½” L.P. 15” 5”

SAFETY RULES

1. Improper installation, adjustment, alteration, service, or maintenance can cause property damage, bodily injury, or death.

2. Use in other than a residential application may result in unsatisfactory performance and may void the warranty.

3 . This appliance must be installed in accordance with local codes, if any; if not, follow the National Fuel Gas Code ANSI

Z223.1/NFP A 54 or the National Gas and Propane Installation Code CSA-B149.1.

4 . Do not install this wall furnace in a recreational vehicle or trailer.

5. Do not operate wall furnace unless it is connected to the factory supplied vent system with vent cap in place.

6. Check the rating label attached to the wall furnace to be sure it is equipped for the type gas you intend to use.

7 . Never use a match, candle, flame or other source of ignition to check for gas leaks. Use only soapy water or liquid detergent.

8. Have your wall furnace and vent system inspected at least annually by a qualified service technician.

Page 2

SAFETY RULES - CONT’D.

9 . Before cleaning or servicing, turn off the gas and allow furnace to cool.

10.

Do not operate wall furnace without outer casing in place.

Due to high temperatures, the wall furnace should be located out of traffic and away from furniture and drapes.

11.

12.

Children and adults should be alerted to the hazard of high surface temperature and should be kept away to avoid burns or

clothing ignition.

13.

Young children should be carefully supervised when they are in the same room with the wall furnace.

Do not place clothing or other flammable material on or near the furnace.

14.

15.

Installation and repair should be done by a qualified service technician. The wall furnace should be inspected before use

and at least annually by a professional service technician. More frequent cleaning may be required due to excessive lint

from carpeting, bedding material, etc. It is imperative that control compartments, burner, and circulating air passageways of

the furnace be kept clean.

16. Do not install in a closet, alcove, or small hallway where the furnace could be isolated from the space to be heated by

closing a door.

17. Do not put anything around the furnace or vent cap that will obstruct the flow of combustion and ventilation air.

18. The appliance, when installed, must be electrically grounded in accordance with local codes or, in the absence of local

codes, with the latest edition of National Electrical Code, ANSI/NFPA 70. In Canada, use CSA C22.1 Canadian

Electrical Code.

19. Never operate this furnace without the sight glass in place or with the glass broken or missing.

20. If it is suspected that rising water may enter the furnace, turn off the gas immediately. Do not use this appliance if any part

has been under water. Immediately call a qualified service technician to inspect the appliance and to replace any part of the

control system and any gas control which has been under water.

21. It is necessary to replace damaged gaskets or sealing material within the vent or air intake system. Failure to do so may

result in property damage, personal injury or loss of life.

22.

Any safety screen or guard removed for servicing must be replaced prior to operating heater.

23. A gas appliance must not be connected to a chimney flue serving a separate solid-fuel burning appliance.

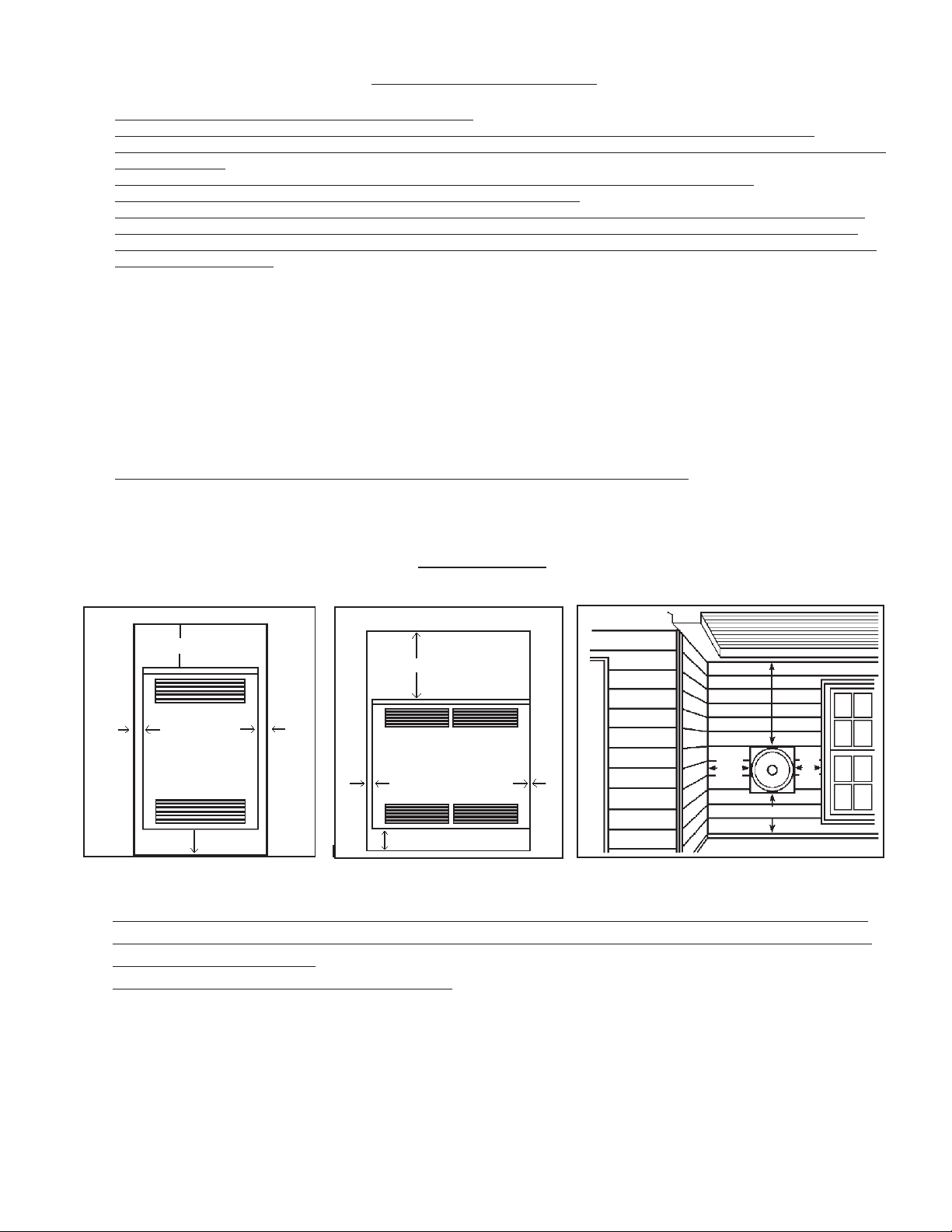

CLEARANCES

CDV15-C CDV25 / CDV33-C ALL VENT CAPS

CEILING

24”

1”

LEFT SIDE WALL

1/2”

FLOOR

FIGURE 1

1.

If the wall furnace is installed directly on carpeting, tile or any combustible material other than wood flooring,

1”

LEFT SIDE WALL

RIGHT SIDE WALL

FIGURE 2

CEILING

30”

1” 0”

4”

FLOOR

RIGHT SIDE WALL

FIGURE 3

12”

Min.

18” Min.

9”

Min.

12” Min.

the wall furnace shall be installed on a metal plate or wood panel secured to the floor, extending the full width

and depth of the wall furnace.

2. RESIDENTIAL GARAGE INSTALLATION: Gas utilization equipment in residential garages shall

be installed so that all burners and burner ignition devices are located not less than 18 inches (46cm)

above the floor . Such equipment shall be located, or protected so it is not subject to damage by a

moving vehicle. Use care in selecting a good location within the garage. DO NOT locate the appliance

where heated air will be directed onto a nearby parked vehicle. Paint may discolor or rubber may

harden and crack. DO NOT allow heated discharge air to blow directly onto open or closed containers

of paint, gasoline or other liquids having flammable vapors.

Page 3

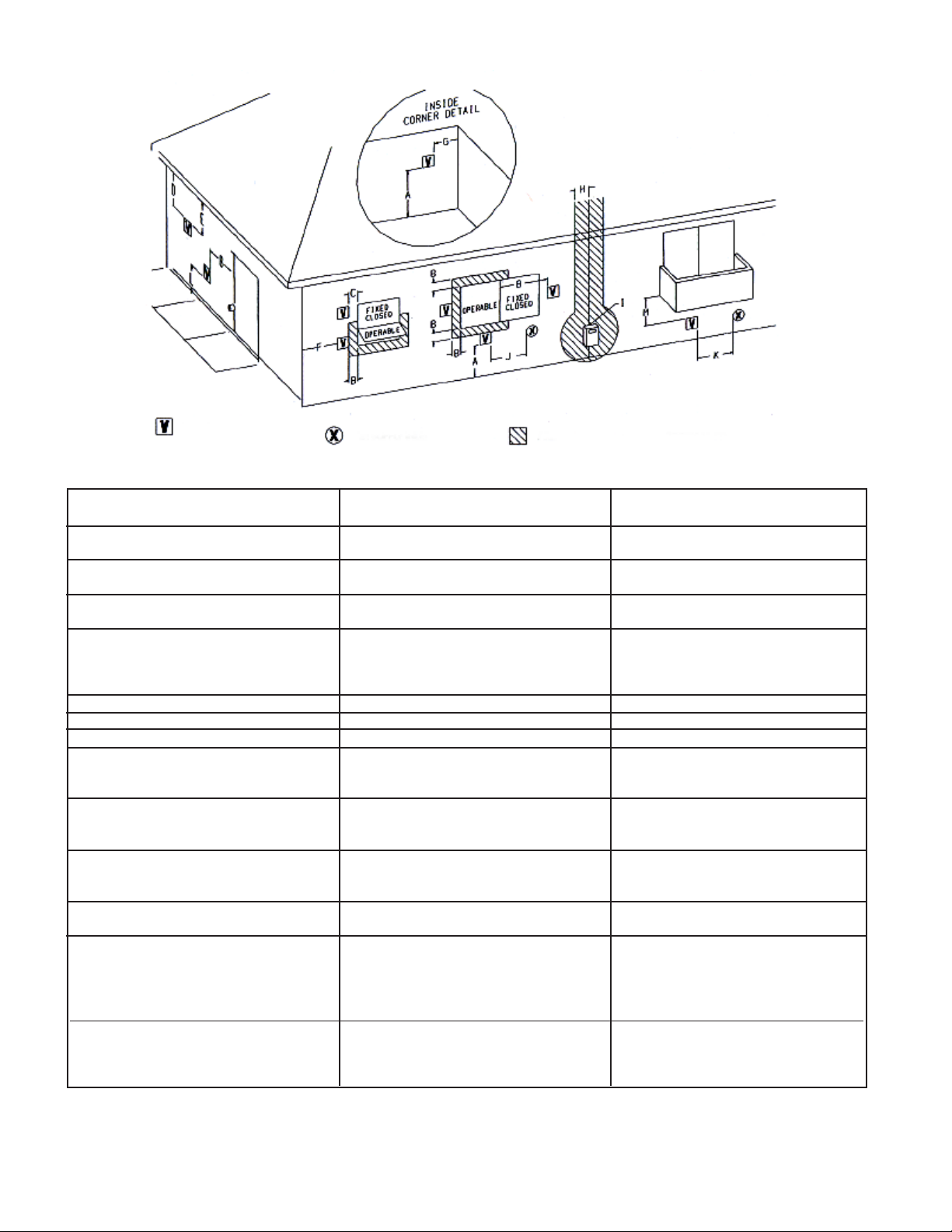

V ent T erminal

Air Supply Inlet

Area where terminal is not permitted

VENT TERMINAL CLEARANCES

REFERENCE LETTER TO DRA WING CANADIAN INST ALLATIONS U.S. INSTALLA TIONS

1

2

A = Clearance above grade, veranda, 12 Inches (30 cm) 12 Inches (30 cm)

porch, deck, or balcony

B = Clearance to window or door that 12 Inches (30 cm) 9 Inches (23 cm)

may be opened

C = Clearance to permanently closed 12 Inches (30 cm) 9 Inches (23 cm)

window

D = V ertical clearance to ventilated sof fit 1 8 Inches (46 cm) 18 Inches (46 cm)

located above the terminal within a

horizontal distance of 2 Feet (61 cm)

from the center line of the terminal

E = Clearance to unventilated soffit 18 Inches (46 cm) 18 Inches (46 cm)

F = Clearance to outside corner 12 Inches (30 cm) 12 Inches (30 cm)

G = Clearance to inside corner 12 Inches (30 cm) 12 Inches (30 cm)

H = Clearance to each side of center line 3 Feet (91 cm) within a height Clearance in accordance with

extended above meter/regulator 15 Feet (4.5m) above the meter/ local installation codes and the

assembly regulator assembly requirements of the gas supplier

I = Clearance to service regulator 3 Feet (91 cm) Clearance in accordance with

vent outlet local installation codes and the

requirements of the gas supplier

J = Clearance to nonmechanical air supply 12 Inches (30 cm) 12 Inches (30 cm)

inlet to building or the combustion

air inlet to any other appliance

K = Clearance to a mechanical air supply 6 Feet (1.83 m) 3 Feet (91 cm) above if within

inlet 10 Feet (3 m) horizontally

L = Clearance above paved sidewalk or 7 Feet (2.13m) A vent shall not Clearance in accordance with

paved driveway located on public terminate directly above a sidewalk or local installation codes and the

property paved driveway that is located between requirements of the gas supplier

two single family dwellings and

serves both dwellings

M = Clearance under veranda, porch, 12 Inches (30 cm) permitted only if Clearance in accordance with

deck, or balcony veranda, porch, deck, or balcony is local installation codes and the

fully open on a minimum of two sides requirements of the gas supplier

1

In accordance with the current CSA-B149.1 Natural Gas and Propane Installation Code

2

In aaccordance with the current ANSI Z223.1 / NFPA 54 National Fuel Gas Code

Page 4

LOCATION

1) The wall furnace must be installed on an outside wall.

2) For optimal heat distribution, locate furnace as centrally as possible in the area to be heated and where occupants may move

about freely without coming into contact with the grille.

3) If the furnace is installed in a basement, a 12” clearance must be maintained between ground level and the bottom of the

vent cap. Do not install furnace where vent cap will terminate in a window well or any other opening below ground level.

INSTALLATION

Failure to follow these instructions carefully could result in poor performance, property damage, personal

injury or death.

STEP 1. LOCATE VENT OPENING. Locate wall studs and center 9” vent opening a minimum of 22”

for CDV15 or 24-1/8” for CDV25/33 above the floor. To locate furnace at minimum clearance from floor, remove template from

carton and set on floor at location desired. On model CDV15, position template no closer than 1” from either side wall. For

model CDV25/33, position template 1” minimum from a left side wall or 0” from a right side wall. Check outside wall to be sure

there is proper clearances around the vent cap. See Figure 3. Next, mark and cut out the vent openings on both the inside and

outside walls (be sure to keep the holes level). See Figure 5. If a higher location on the wall is desired, raise bottom of template

to desired height, make sure template is level and centered between studs, mark and cut out vent openings.

STEP 2. ROUGH-IN GAS SUPPLY . Install a ½” diameter gas supply line. This line can enter through the

floor, side, or rear wall. For location of gas connection to valve, see Fig. 4. The gas supply line must have an individual manual

shut off valve located outside the cabinet, accessible from the room where the heater is installed. Install a drip leg immediately

ahead of the gas valve and provide a 1/8” N.P.T. plugged tapping, accessible for test gauge connection, immediately upstream of

the gas supply connection. The furnace and the individual shut off valve must be disconnected from the gas supply piping system

during any pressure testing of that system at test pressures in excess of 1/2” psig (3.5kPa). The furnace must be isolated from the

gas supply piping system by closing the individual manual shut off valve during any pressure testing of the gas piping system at

test pressures equal to or less than 1/2” psig (3.5kPa).

STEP 3. INSTALLING FURNACE – 5” TO 9” WALLS. Use only the exhaust tube, air intake

tube, wall thimble extension, and vent terminal provided with furnace. Do not attempt to lengthen the exhaust or air intake tubes,

this could cause an imbalance in the furnace resulting in poor performance and pilot outage, see Figure 6. Extend the telescoping

wall thimble extension (surrounding the wall thimble assembly) to approximately 9 inches. Center the wall thimble assembly in

the 9 inch opening and attach to inside wall using eight (8) screws. The wall thimble extension should extend through the

opening and be adjusted so end of wall thimble extension is even with outside wall. Install furnace flush to wall by sliding

exhaust tube and air intake tube through the wall thimble assembly. Secure the furnace to the wall with screws through each of

the four holes in the mounting brackets located on the back of the furnace. These holes are spaced so as to allow the screws to

enter into studs that are on 16 inch centers. On certain types of wall, anchors (not provided) may be required. Slide the vent

terminal onto the exhaust tube and the air intake tube. Secure vent terminal and vent terminal spacer plate to wall providing a

slight downward slope to the vent tubes. This will prevent water from entering. Anchors (not provided) may be required. Caulk

around vent terminal spacer plate with putty provided. See Figure 7. NOTE: Some framing may be necessary to provide a flat

surface for the vent terminal spacer plate to butt against, so rain cannot enter through cut out.

Page 5

INSTALLING FURNACE – 9 TO 15” WALLS (CDV15/CDV25-C). For

9” to 15” wall use V ent Kit No. VK1525/9-15-B. Do not attempt to lengthen the exhaust tube, air intake tube, or wall thimble extension

provided with furnace or the VK1525/9-15-B Vent Kit. Disconnect the air intake tube, and the exhaust tube from the back of the

furnace and discard. See Figure 6. Replace with exhaust tube and air intake tube from Kit No. VK1525/9-15-B. Discard the 5”

telescoping wall thimble extension that surrounds the wall thimble assembly. Center the wall thimble assembly in the 9” openin g and

attach to inside wall using eight (8) screws. Install furnace flush to wall by sliding exhaust tube and air intake tube through the wall

thimble assembly. Secure the furnace to the wall with screws through each of the four holes in the mounting brackets located o n the

back of the furnace. These holes are spaced so as to allow the screws to enter into studs that are on 16-inch centers. On certain

types of wall, anchors (not provided) may be required. From outside the building install the thick wall thimble extension, Part No.

43835, supplied in V ent Kit No. VK1525/9-15-B by sliding it through the cut out and over the wall thimble assembly . The wall thimble

extension should be even with the outside wall (some trimming may be necessary). Slide the vent terminal onto the exhaust tube and

the air intake tube. Secure vent terminal and vent terminal spacer plate to wall providing a slight downward slope to the vent tubes.

This will prevent water from entering. Anchors (not provided) may be required. Caulk around the vent terminal spacer plate with

putty provided. See Figure 7. NOTE: Some framing may be necessary to provide a flat surface for the vent terminal spacer plate to

butt against, so rain cannot enter through cut out.

INSTALLING FURNACE – 15” TO 24” WALLS (CDV15/CDV25-C).

For 15” to 24” wall use only V ent Kit No. VK1525/15-24-B. Do not attempt to lengthen the exhaust tube, air intake tube, or wall thimble

extension provided with furnace. The VK1525/15-24-B Vent Kit has a one inch restrictor in the exhaust tube which is necessary for

proper and safe operation of this furnace. Do not use any other vent kit. Disconnect the air intake tube and the exhaust tube from

the back of the furnace and discard, see Figure 6. Install the exhaust tube and air intake tube from Vent Kit No. VK1525/15-24-B.

Discard the 5” telescoping wall thimble extension that surrounds the wall thimble assembly. Center the wall thimble assembly i n the

9” opening and attach to inside wall using eight (8) screws. Install furnace flush to wall by sliding exhaust tube and air intake tube

through the wall thimble assembly. Secure the furnace to the wall with screws through each of the four holes in the mounting

brackets located on the back of the furnace. These holes are spaced so as to allow the screws to enter into studs that are on 16-inch

centers. On certain types of walls, anchors (not provided) may be required. From outside the building install the wall thimble

extension, Part No. 43730, supplied in Vent Kit No. VK1525/15-24-B by sliding it through the cut out and over the wall thimble

extension. For walls 15” to 19” the wall thimble extension, air intake tube, and the exhaust tube must be trimmed even with the outside

wall. Slide the vent terminal onto the exhaust tube and into the air intake tube. Secure vent terminal and vent terminal spacer plate

to wall providing a slight downward slope to the vent tubes. This will prevent water from entering. Anchors (not provided) may be

required. Caulk around the vent terminal spacer plate with putty provided, see Figure 7. NOTE: Some framing may be necessary to

provide a flat surface for the vent terminal spacer plate to butt against, so rain cannot enter through the cut out.

INSTALLING FURNACE – 9 TO 15” WALLS (CDV33-C). For 9” to 15” wall use Vent

Kit No. VK33/9-15-B. Do not attempt to lengthen the exhaust tube, air intake tube, or wall thimble extension provided with furnace

or the VK33/9-15-B Vent Kit. Disconnect the air intake tube, and the exhaust tube from the back of the furnace and discard. See

Figure 6. Replace with exhaust tube and air intake tube from Kit No. VK33/9-15-B. Discard the 5” telescoping wall thimble extension

that surrounds the wall thimble assembly. Center the wall thimble assembly in the 9” opening and attach to inside wall using e ight

(8) screws. Install furnace flush to wall by sliding exhaust tube and air intake tube through the wall thimble assembly. Secure the

furnace to the wall with screws through each of the four holes in the mounting brackets located on the back of the furnace. These

holes are spaced so as to allow the screws to enter into studs that are on 16-inch centers. On certain types of wall, anchors (not

provided) may be required. From outside the building install the thick wall thimble extension, Part No. 43835, supplied in V en t Kit No.

VK33/9-15-B by sliding it through the cut out and over the wall thimble assembly. The wall thimble extension should be even with

the outside wall (some trimming may be necessary). Slide the vent terminal onto the exhaust tube and the air intake tube. Secure vent

terminal and vent terminal spacer plate to wall providing a slight downward slope to the vent tubes. This will prevent water from

entering. Anchors (not provided) may be required. Caulk around the vent terminal spacer plate with putty provided. See Figure 7.

NOTE: Some framing may be necessary to provide a flat surface for the vent terminal spacer plate to butt against, so rain cannot

enter through cut out.

Page 6

18”

CABINET

34-1/2”

CABINET

29-3/4”

22”

1/2”

Center Line Pipe Elbow

SHUT OFF

V ALVE

DRIP LEG

FIG. 4 / CDV15-C

1” MINIMUM SIDE WALL TYP.

WALL STUDS

16” O.C.

TEMPLATE

9” DIA.

OPENING

8”

1/8” N.P.T.

PRESSURE TAP

9”

GAS VALVE

INLET

1/2”

1/2” BLACK IRON PIPE

FLOOR

GAS

SUPPLY

9” DIA.

OPENING

4”

13-3/8”

FLOOR

31-3/4”

24-1/8”

FIG. 4 / CDV25/33-C

1” MINIMUM SIDE WALL TYP.

16-5/8”

SHUT OFF

VALVE

DRIP

LEG

WALL STUDS 16” O.C.

TEMPLATE

MOUNTING

HOLES

GAS V AL VE

INLET

1/8” N.P.T.

PRESSURE TAP

GAS SUPPLY

13”

1/2” BLACK

IRON PIPE

MOUNTING

HOLES

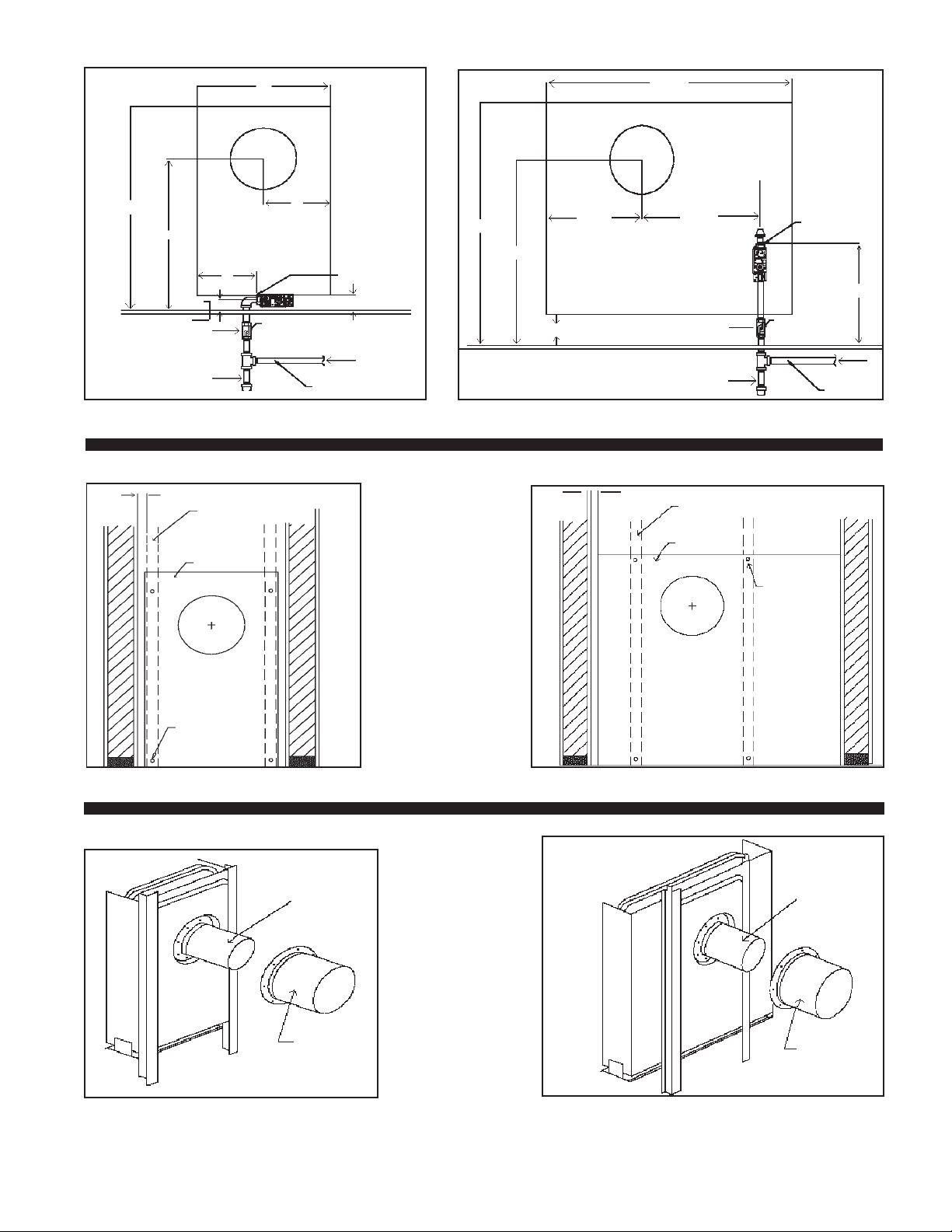

FIG. 5 / CDV15-C

FIG. 6 / CDV15-C

EXHAUST

TUBE

AIR

INTAKE TUBE

FIG. 5 / CDV25/33-C

EXHAUST

TUBE

AIR

INTAKE TUBE

FIG. 6 / CDV25/33-C

Page 7

Loading...

Loading...