covington Rociprolap Instructions Manual

715 West Colton Avenue

Redlands, CA 92374

Toll Free: (877) 793-6636 US Only

Phone: (909) 793-6636

FAX: (909) 793-7641

Email: sales@covington-engineering.com

Covington Engineering Corp. © 2013

1

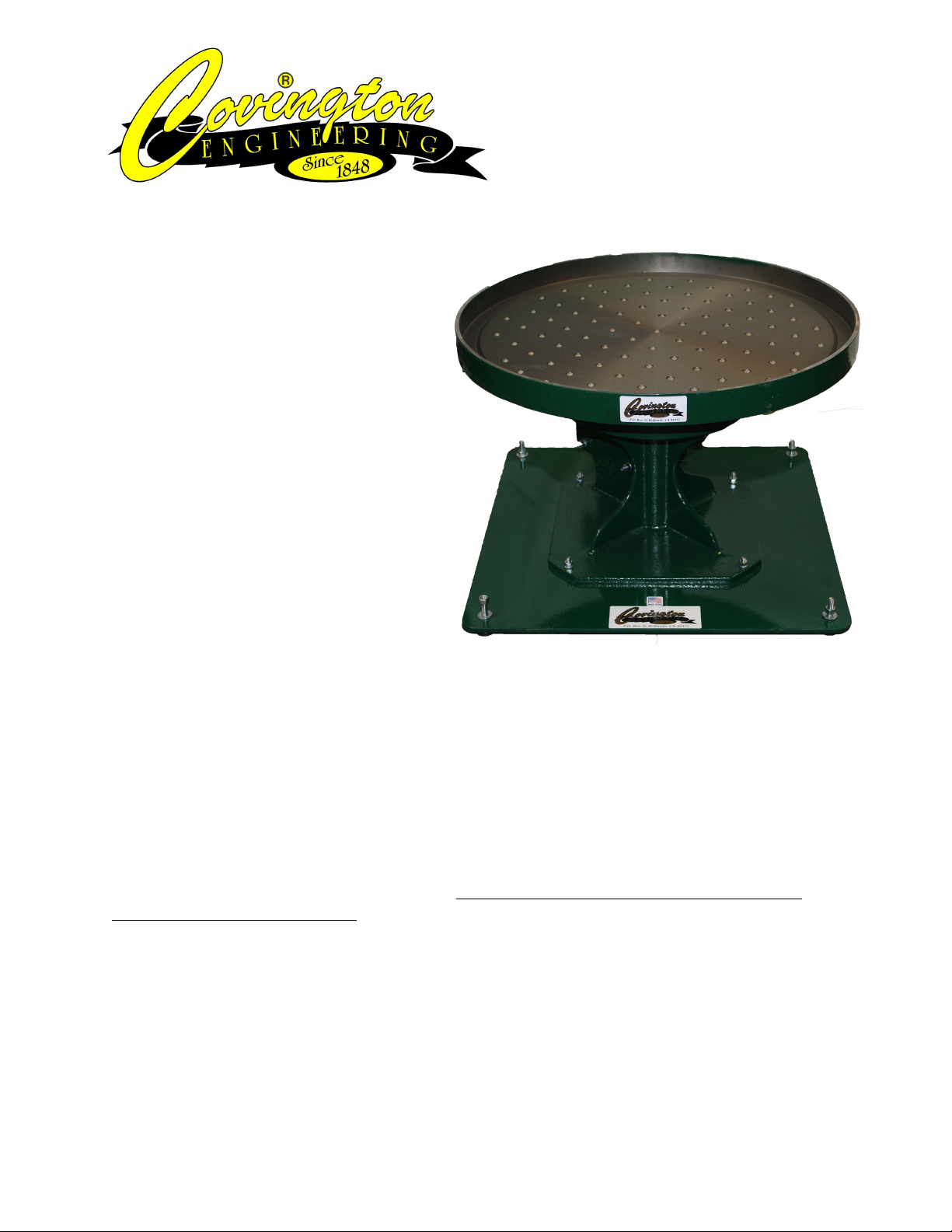

ROCIPROLAP® INSTRUCTIONS

1. Install the four leveling feet with a

washer, lock-washer, and nut on top.

2. Insert one steel disc in each bearing cup

making sure the steel disc sets down

flat. Place two nylon thrust bearings in

each container. Add three or four drops

of machine oil onto bearings.

3. Install the lap plate ensuring the plate

rests on the nylon thrust bearings by

twisting the plate back and forth. The

plate should turn freely. A visual

inspection will make certain.

4. Place a level on the machined surface

of the lap plate. Adjust leveling feet

until level. Turn level 90 degrees or one

quarter turn and adjust feet until level.

5. Start the machine and let run for

approximately five minutes. Check the

leveling feet by placing a finger against

the plastic pads and the floor. If one vibrates or bounces, loosen the nut and screw the foot

down by hand. Tighten the nut securely. Observe the lap plate in operation. With no load on

it, the lap plate should revolve about two to three times per minute. When lapping or

polishing it is normal for the lap plate to either slow down or revolve in the opposite

direction of the no load condition.

Caution: Take extreme care with the wearing ring surface. This is the portion of the plate that

rides on the nylon thrust bearings. It must be kept scrupulously clean and well oiled with 30 or

40 wt. oil. Never use grease.

HAZARDOUS CONDITION WARNING: NEVER START THE ROCIPROLAP WITH

THE LAP PLATE REMOVED.

MISCELLANEOUS ADVICE

• Inspect the nylon thrust bearings each time the plate is removed. If they are dirty or

discolored then the thrust plate is not being kept clean.

• When the plate begins to revolve faster than normal it is an indication that the thrust balls are

failing or that you have too much oil on the bearings. If too much oil is not the problem (the

problem usually is overly worn bearings), you must change the complete set. The nylon

715 West Colton Avenue

Redlands, CA 92374

Toll Free: (877) 793-6636 US Only

Phone: (909) 793-6636

FAX: (909) 793-7641

Email: sales@covington-engineering.com

Covington Engineering Corp. © 2013

2

thrust bearings are measured and packaged in sets – individual bearings may vary by as much

as .005 of an inch. Mixing them could damage the machine.

• Clean your material and machine thoroughly after each lapping operation. One grain of 80-

grit can scratch your material if allowed to mix with the next lapping operation.

• Never leave your flats on the lap plate when the machine is stopped for an indefinite period

of time. The can and will stick to the lap plate. Should you ever have this problem, add water

to the plate and start the machine. If the flat won’t come loose, jar it slightly with a block of

wood. Place the edge of the flat on the bumper ring when through with a lapping procedure

to avoid it sticking to the lap plate.

• After using the machine, when the machine won’t be in use for a day or so, put a thin coat of

oil on the inside of the plate. This will keep it from rusting.

• Never do fine (400g or 600g) lapping on a rusty plate. The scale from the rust will scratch the

surface of your material.

• Never overcrowd the plate. A 16” piece is the normal operating maximum for the 20” model,

Use the proportion should be followed in the other plate sizes.

LAPPING PROCEDURE

For a 24” Plate: With the machine running, pour about two (2) cups of 80-grit on the lap plate.

Add two (2) cups of water. Stop the machine and place material to be lapped on the lap plate and

start the machine. As the material begins the grind, the grit and water mixture will become a

creamy slurry. Maintain this creamy state throughout grinding process for maximum abrasion.

Note: Use equal amounts of grit and water to begin on all other plate sizes and lap into a

creamy slurry.

Always wash plate thoroughly between cycles to eliminate cross contamination of grits.

Testing for Flatness: Wash the piece off. Using an aluminum marking pencil, mark a 2” square

grid on the bottom of the piece. Replace the piece and lap for about 10 minutes. Remove piece

and examine the bottom. If the lines have been removed, the piece is flat and ready for the next

operation.

Second Lapping Operation: Once the material has been lapped flat on 80-grit, repeat the first

process using 220g and equal amounts of water.

Third Lapping Operation: Repeat the first operation using equal amounts of 400-grit and water.

Fourth Lapping Operation: Repeat the first operation using equal amounts of 600-grit and

water.

Polishing: Install the polishing pad, splash guard, and bumper ring. Start the machine and place

½ cup of Cerium Oxide on the pad and add enough water to create a creamy slurry. Most objects

Loading...

Loading...