Country Home Products DR CHIPPER C123E-CHP Operating And Assembly Instruction Manual

DR CHIPPER

Operating & Assembly Instruction Manual

Model: 12.0 HP C123E-CHP

This manual contains information concerning proper and improper operating procedures,

warnings, maintenance, troubleshooting, assembly, and tips. Everyone who operates this

machine should read these instructions and be thoroughly familiar with them.

P/N 913-0046

12/30/03

SECTION I – SAFETY

This symbol points out important safety instructions which, if not followed,

could endanger the personal safety and/or property of yourself and others. Read and

follow all instructions in this manual before attempting to operate your chipper. Failure

to comply with these instructions may result in personal injury. When you see this

symbol - heed its warning.

THIS MACHINE IS CAPABLE OF INFLICTING SERIOUS INJURY

IF

OPERATED IMPROPERLY -- READ WARNINGS & CAUTION LABELS.

INTENDED USE

Never use your chipper for any other purpose than chipping limbs. It is designed for this use and any

other use many cause serious injury.

DANGER: Rotating cutting blade.

Keep hands and feet out of inlet and discharge opening while machine is running.

DANGER: This machine can CRUSH, GRIND, CUT, and SEVER parts of your body if

DANGER: Your chipper was built to be operated according to the rules for safe operation

in this manual. As with any type of power equipment, carelessness or error on the part

of the operator can result in serious injury. If you violate any of these rules, you may

cause serious injury to yourself or others.

they enter the inlet or discharge area of your chipper.

2

WARNING: The Engine Exhaust from this product contains chemicals known to the state of

ects or other reproductive harm. California to cause cancer, birth def

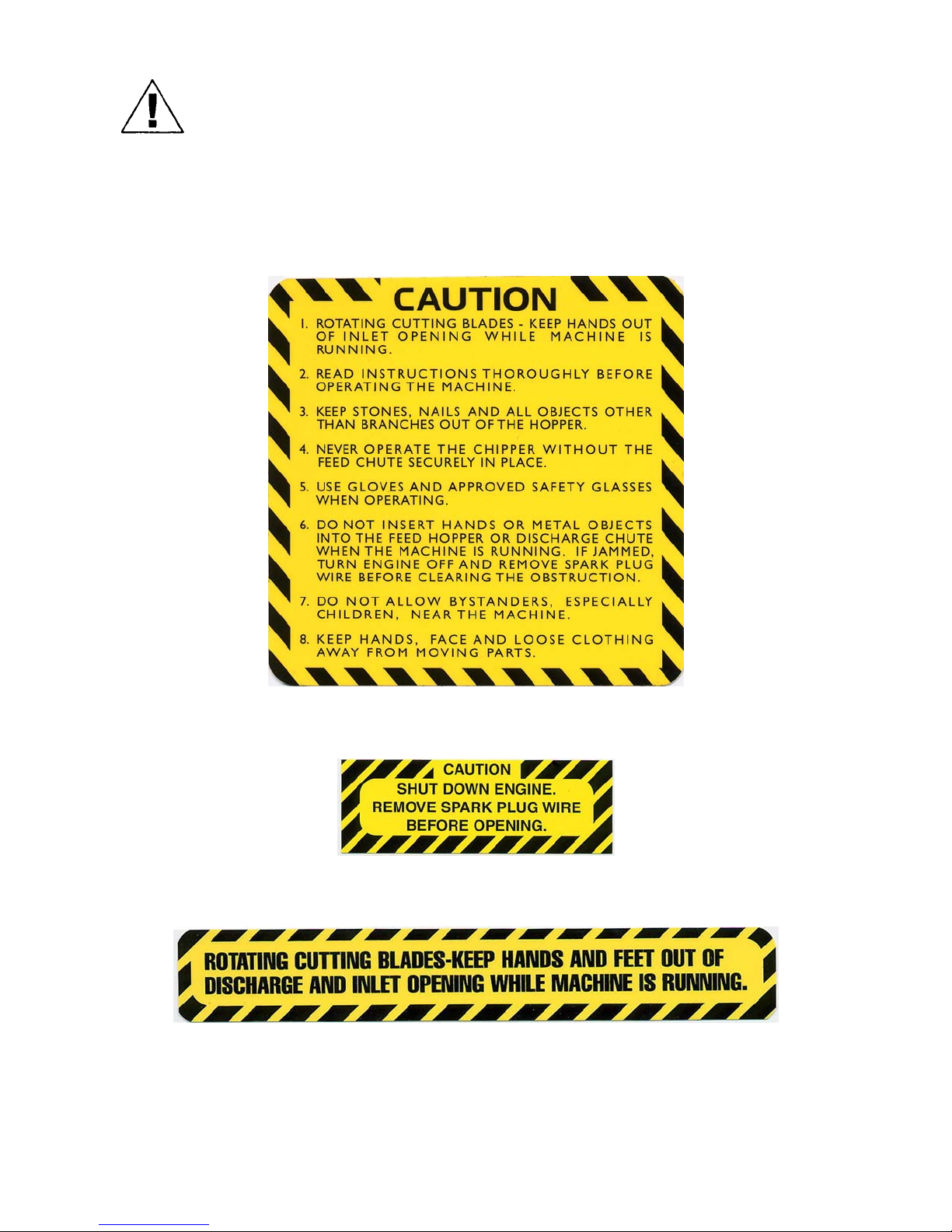

MAKE CERTAIN THAT ALL SAFETY LABELS ON THIS EQUIPMENT ARE

KEPT CLEAN AND IN GOOD CONDITION. IF YOU NEED REPLACEMENT

LABELS, ORDER BY PART NUMBER.

080-0967

080-0970

091-0055

3

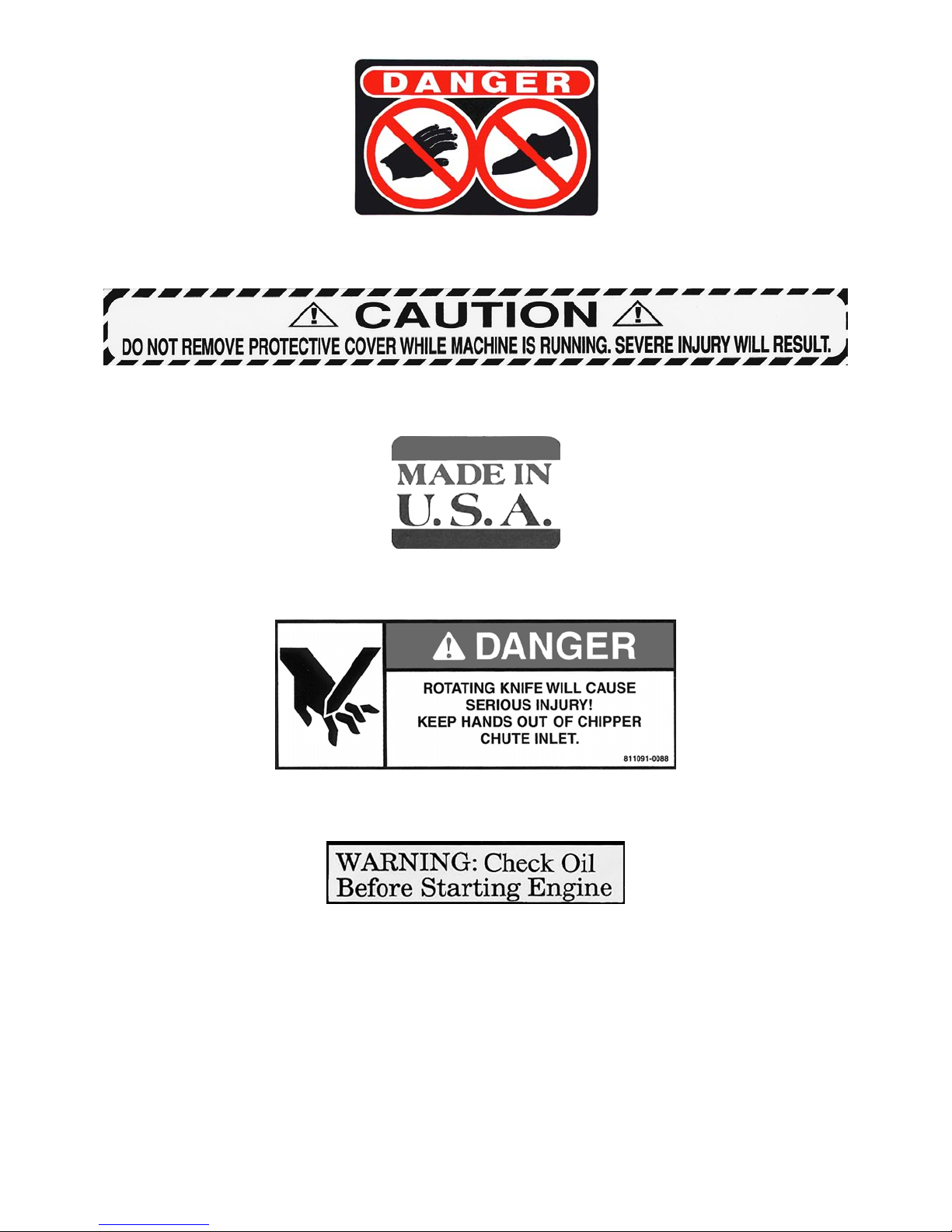

091-0057

091-0059

091-0062

091-0088

091-0256

4

091-0380

091-0381

913-0265

5

SAFE OPERATION PRACTICES

TRAINING

• Read this owner’s manual carefully in its entirety before attempting to assemble this machine. Read,

understand, and follow all instructions on the machine before operation. Be completely familiar with the

controls and the proper use of the machine before operating it. Keep this manual in a safe place for future and

regular reference and for ordering replacement parts.

• Never allow children to operate the unit. Never allow adults to operate the equipment without proper

instruction. Only responsible individuals who are familiar with these rules of safe operation should be allowed

to use your unit.

• Keep the area of operation clear of all persons, particularly small children and pets. Stop the engine when they

are in the vicinity of the unit. Keep work area clean and clear of branches or obstacles, which could cause you

to stumble or fall.

• Keep in mind that the operator or user is responsible for accidents or hazards occurring to other people, their

property, and themselves.

• Your chipper is a powerful tool, not a plaything. Exercise extreme caution at all times. Your unit has been

designed to chip. Do not use it for any other purpose.

• If situations occur which are not covered in this manual, use care and good judgment. Contact your place of

purchase for additional assistance.

PREPARATION

• Thoroughly inspect the area where the equipment is to be used and remove all foreign objects.

• Do not operate the machine without wearing adequate outer garments and safety goggles. Always wear safety

glasses or goggles during operation and while performing any adjustment or repair, to protect eyes from foreign

objects that may be thrown from the machine. Be sure your glasses or goggles fit properly.

• Avoid loose-fitting clothes and use protective footwear that will improve footing on slippery surfaces. Shirt and

slacks that cover the arms and legs and steel-toed shoes are recommended. Secure hair above shoulders.

Do not wear loose clothes or jewelry that can be caught in moving parts. Never operate a unit in bare feet,

sandals or sneakers. Wear gloves when feeding material into the chipper chute. Be sure your gloves fit

properly and do not have loose cuffs or drawstring.

• Warning: Fuel is highly flammable and the vapors are explosive. Take the following precautions.

• Store fuel and oil in approved containers.

• Keep away from heat and open flame, and out of the reach of children.

• Refuel outdoors only and do not smoke while refueling.

• Check and add fuel before starting the engine. Never remove gas cap or add fuel while the engine is

running or when the engine is hot. Allow engine to cool before refueling.

• If fuel is spilled, do not attempt to start the engine but move the machine away from the area of spillage and

avoid creating any source of ignition until fuel vapors have disappeared.

• Replace all fuel tank and container caps securely.

• Never store the machine or fuel container inside where there is an open flame or spark, such as a gas hot

water heater, space heater, clothes dryer or furnace.

• To reduce fire hazard, keep engine and muffler free of debris build-up. Clean up fuel and oil spillage.

Allow unit to cool at least five minutes before storing.

• Never attempt to make any adjustments while the engine is running.

6

OPERATION

• Never place your hands, feet, or any part of your body in the chipper chute, discharge opening, or near or

under any moving part while the engine is running. Keep clear of the discharge opening at all times. If it

becomes necessary to push material into the chipper chute, use a small diameter stick, NOT YOUR HANDS.

• Keep your face and body back from chipper chute to avoid accidental bounce back of any material.

• The machine should only be operated on a level surface. Never operate your unit on a slippery, wet, muddy, or

icy surface.

• Exercise caution to avoid slipping or falling.

• Stay alert for hidden hazards or traffic. Do not carry passengers.

• If the cutting mechanism strikes a foreign object or if your machine should start making an unusual noise or

vibration, immediately stop the engine, remove the spark plug wire(s) and wait for all moving parts to come to a

complete stop. After the machine has come to a complete stop proceed as follows:

• Inspect for any damage.

• Repair or replace any damaged parts before restarting and operating the machine.

• If the machine should start to vibrate abnormally, immediately stop the engine, remove the spark plug wire(s)

and wait for all moving parts to come to a complete stop and inspect for the cause. Vibration is generally a

warning sign of trouble.

• Stop the engine when leaving the operating position, and when making any repairs, adjustments and

inspections.

• Take all possible precautions as recommended by the manufacturer when leaving the machine unattended.

Stop the engine and remove the key if so equipped.

• Before cleaning, repairing, or inspecting, shut off the engine and make certain the flywheel and all moving parts

have come to a complete stop. Disconnect the spark plug wire and keep the wire away from spark plug to

prevent accidental starting. Do not use flammable solutions to clean air filter.

• Never run this machine in an enclosed area as the exhaust from the engine contains carbon monoxide, which

is an odorless, tasteless, and deadly poisonous gas.

• Keep all guards and safety devices in place and operating properly. Do not operate the machine if all safety

guards are not in place.

• Do not use the unit with the chipper hopper removed.

• The muffler and engine become hot and can cause a severe burn. Do not touch.

• Keep children and pets away.

• Tragic accidents can occur if the operator is not alert to the presence of small children.

• Keep children out of the work area and under the watchful eye of a responsible adult

other than the operator.

• Be alert and turn the unit off if a child enters the area.

• Never allow children to operate the chipper.

• Do not overload or attempt to chip material beyond manufacturers recommendation. Personal injury or

damage to the machine could result.

• Never operate the machine at high transport speeds or on hard or slippery surfaces.

• Never allow bystanders near the unit while running.

• Only use accessories approved for this machine by the manufacturer. Read, understand, and follow all the

instructions provided with the approved accessory.

• Only operate unit in good daylight. Do not operate unit at night or in dark areas where your vision may be

impaired.

• Use extreme caution when reversing or pulling the machine towards you.

• Do not tamper with the engine’s governor setting. The governor controls the maximum safe operation speed

and protects the engine. Over-speeding the engine is dangerous and will cause damage to the engine and to

the other moving parts of the machine. See your authorized dealer for engine governor adjustments.

• Start the engine according to the manufacturers instructions. Keep hands and feet away from inlet and

discharge areas.

• Never pick up or carry the machine while the engine is running.

• Do not operate while under the use of alcohol, drugs, or medication. A clear mind is essential for safety.

• Do not allow anyone who is not alert to operate this machine.

• When feeding material into this equipment, be extremely careful that pieces of metal, rocks, or other foreign

objects are not included. Personal injury or damage to the machine could result.

• Keep area of discharge clear of people, animals, buildings, glass or anything else that will obstruct clear

discharge, cause injury or damage. Wind can also change discharge direction, so be aware.

7

• Do not allow an accumulation of processed material to build up in the discharge area as this will prevent proper

discharge and can result in kick-back from the chipper chute.

• Do not allow any part of the engine, especially around the cooling fans and muffler, to become clogged with

processed material, leaves, oil, grease or any other combustible material.

• Do not operate engine if air cleaner or cover over carburetor air-intake is removed, except for adjustment.

Removal of such parts could create a fire hazard.

MAINTENANCE AND STORAGE

• Keep machine, attachments and accessories in safe working condition.

• Check engine mounting bolts and other hardware at frequent intervals for proper tightness. Never operate your

chipper in poor mechanical condition or when in need of repair. Be sure all safety guards and shields are in

proper position. These safety devices are for your protection.

• Never store machine with fuel in the fuel tank inside a building where ignition sources are present, such as hot

water and space heaters, clothes dryers and the like. Allow the engine to cool before storing in any enclosure.

• Always refer to the operator’s manual for important details if the machine is to be stored for an extended

period.

• If the fuel tank is to be drained, do this outdoors.

• Follow the manufacturer’s recommendations for safe loading, unloading and storage of machine.

• If it is necessary for any reason to unclog the feed intake or discharge openings or to inspect or repair the

machine where a moving part can come in contact with your body or clothing, shut the machine off, allow all

moving parts to come to a complete stop disconnect the spark plug wire(s) and allow the engine to cool before

attempting to unclog, inspect or repair.

• Check the knife mounting screws at frequent intervals for proper tightness. Also visually inspect the knife for

wear or damage. Replace the knife with parts that meet original equipment specifications.

• Knives should be checked for sharpness and the bolts attaching them to the flywheel for tightness every 8-10

hours of operation.

• Replace the nylock nuts securing the knife every time you replace the knife.

• Check the gap between the knife and wear plate every time you sharpen or replace the knife, or every 8-10

hours of operation.

• Never tamper with safety devices. Check their proper operation regularly.

• Inspect the belt each time you use the unit. Look for damage, worn areas or tears. Do not use the unit if this

condition exists.

• Do not tamper with the engine’s governor setting. The governor controls the maximum safe operation speed

and protects the engine. Over-speeding the engine is dangerous and will cause damage to the engine and to

the other moving parts of the machine. See your authorized dealer for engine governor adjustments.

BEFORE STARTING ENGINE

ALWAYS CHECK OIL LEVEL

8

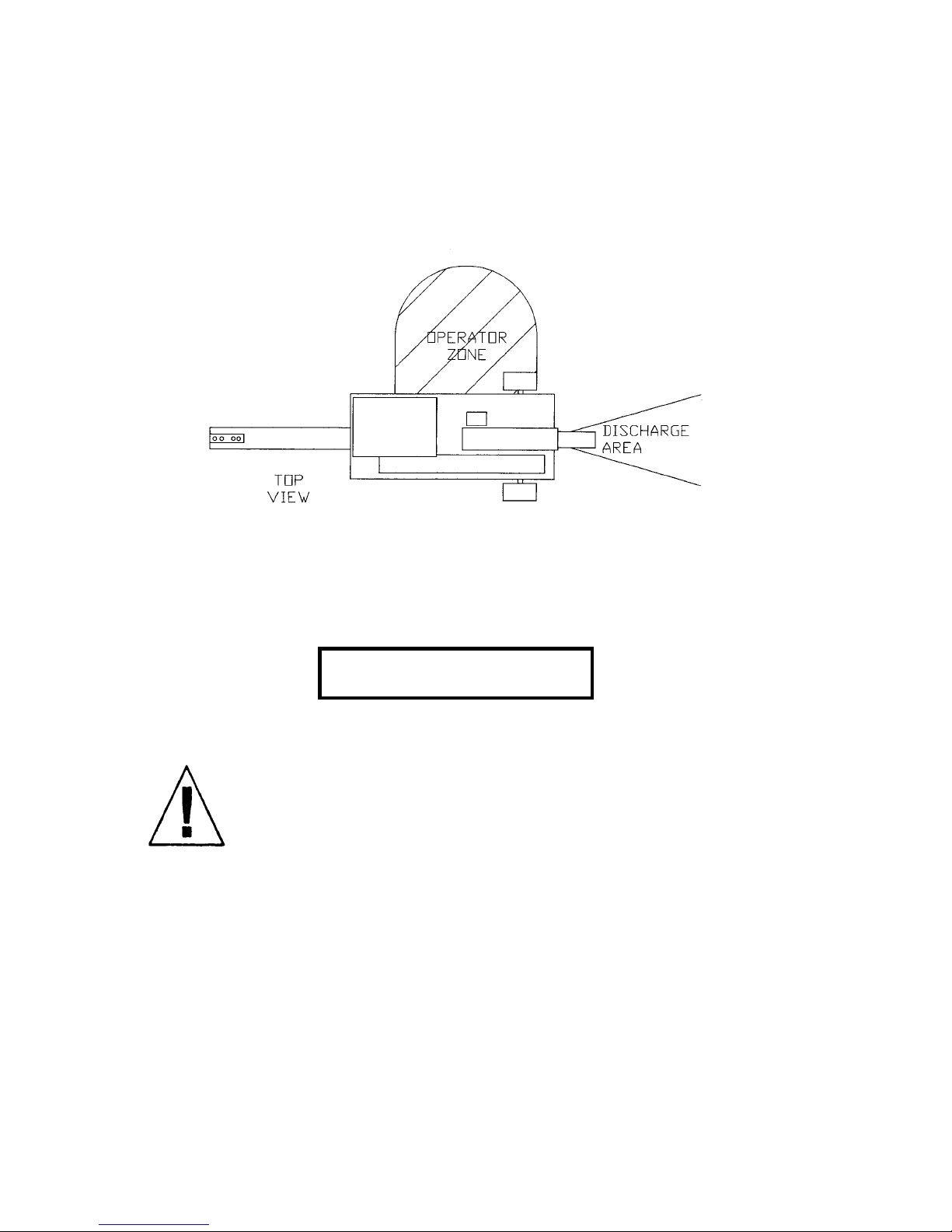

• Only operate your chipper from the operator zone.

• Know how to turn your unit off.

• Never move your chipper or leave it unattended with the engine running.

• Follow engine owner’s manual for engine maintenance and repair.

YOUR RESPONSIBILITY

• Restrict the use of this power machine to persons who read, understand and

follow the warnings and instructions in this manual and on the machine.

SAVE THESE INSTRUCTION

FOR FUTURE REFERENCE

HAZARD: This unit is equipped with an internal combustion

engine and should not be used on or near any unimproved

forest-covered, brush-covered or grass-covered land unless the

engine’s exhaust system is equipped with a spark arrester

meeting

arrester

working order.

In the State of California, the above is required by law (Section 4442 of the California Public

Resources Code). Other states may have similar laws. Federal laws apply on federal

lands. A spark arrester for the muffler is available through your Briggs & Stratton servicing

dealer.

applicable local or state laws (if any). If a spark

is used, the operator should maintain it in effective

9

SECTION II - ASSEMBLY INSTRUCTIONS

PACKAGE CONTENTS

SKID

CHIPPER CHIPPER HOPPER 4 EA – 5/16-18 X ¾” CARRIAGE BOLTS

TOW BEAM HITCH PLATE 3 EA – 5/16-18 X 1” HHCS

PARTS BOX GLASSES 7 EA – 5/16-18 NYLOCK NUTS

OWNER’S MANUAL 4 EA – 5/16 USS FLATWASHERS

ENGINE MANUAL 1 EA – ¼-20 X 1 1/4” U-BOLT

BOLT BAG 2 EA – ¼-20 NYLOCK NUTS

KNIFE GAUGE 2 EA – ENGINE KEY

TOOLS REQUIRED FOR ASSEMBLY

• 1/2” Wrench or Socket - 2 required

STEP I - UNPACKING AND CHECKING CONTENTS

1. Remove the carton and place the unit on its wheels.

2. After unpacking the shipping carton, compare the contents with the list above.

3. If any parts are missing or damaged, contact Country Home Products at 800-376-9637.

4. Assembly should be done on a clean, level surface.

STEP II - UNIT ASSEMBLY INSTRUCTIONS

1. Assemble chipper hopper (item #20, pg 30) to machine using four each 5/16”-18 x 3/4” carriage bolts, 5/16”-18

nylock nuts and 5/16” flatwashers from the bolt bag. Put head of bolt inside hopper with threads sticking out.

Tighten all hardware with a ½” wrench.

2. Attach the tow beam (item #2, pg 28) to the axle of the machine by putting the u-bolt (item #26, pg 28) from the

bolt bag around the axle and through the two holes in the tow beam per the picture on page 29. Secure with

two ¼-20 nylock nuts.

3. Attach the center of the tow beam to the front of the frame as shown on page 29 with a 5/16-18 x 1” HHCS and

a 5/16-18 nylock nut.

4. Attach the hitch plate (item # 3, pg 28) to the tow beam as shown on page 29 with two 5/16-18 x 1” HHCS (item

#18, pg 28) and two 5/16-18 nylock nuts (item #19, pg 28).

5. Service the engine as per the engine manual.

6. Lubricate both rotor bearings every 8 hours of operation with multi-purpose grease. Also check the bearing

collar set screws regularly to be sure they are tight. If they are loose, reset them with Loctite 243, obtainable at

any hardware store.

PARTS BOX BOLT BAG

10

Loading...

Loading...