Country Hearth 2200iA Owner's Operation And Instruction Manual

Owner’s Operation and Instruction Manual

C

S

S

U

C

O

M

P

A

N

Y

U

N

I

T

E

D

S

T

A

T

E

S

S

T

O

V

E

MODEL: 2200iA

Fireplace Insert

Masonry Fireplace Insert or Zero-Clearance (metal) Fireplace Insert

SAFETY TESTED TO UL 1482-2010 and ULC-S628-1993

Also tested to Australian Standards: AS/NZS 4012:1999, AS/NZS 4013:1999 and AS/NZS 2918:2001

US ENVIRONMENTAL PROTECTION AGENCY PHASE II CERTIFIED WOODSTOVE

See Appendix A for Special Australian Installation, Operation and Safety Requirements.

DO NOT use this appliance in a mobile home, manu-

CAUTION!

Please read this entire manual before you install and use your new

heater. Failure to follow instructions

may result in property damage,

bodily injury, or even death.

THIS MANUAL WILL HELP YOU TO OBTAIN EFFICIENT, DEPENDABLE SERVICE FROM THE HEATER, AND ENABLE YOU TO

ORDER REPAIR PARTS CORRECTLY. KEEP IN A SAFE PLACE FOR FUTURE REFERENCE.

French version is available for download from the U. S. Stove website: http://www.usstove.com/

United States Stove Company

South Pittsburg, TN 37380, USA

factured home, trailer, or tent.

SAFETY NOTICE:

If this heater is not properly installed, a house fi re may

result. For your safety, follow the installation instructions.

Contact local building or fi re offi cials about restrictions

and installation in your area.

SAVE THESE INSTRUCTIONS

227 Industrial Park Road

P.O. Box 151

1-800-750-2723

852161

CONGRATULATIONS!

You’ve purchased a heater from North America’s oldest manufacturer of wood burning products. By heating with wood

you’re helping to CONSERVE ENERGY! Wood is our only Renewable Energy Resource. Please do your part to pre-

serve our wood supply. Plant at least one tree each year. Future generations will thank you.

The instructions pertaining to the installation of your wood stove comply with UL-1482 and ULC-S628 standards.

SAFETY INSTRUCTIONS

1. The installation of this appliance must comply with your local

building code rulings.

2. DO NOT INSTALL THIS APPLIANCE IN A MOBILE HOME,

MANUFACTURED HOME, TRAILER OR TENT (NO EXCEPTIONS PER HUD FEDERAL STANDARD: 24 CFR CH.XX).

3. Verify that the appliance is properly installed before fi ring for

the fi rst time. This appliance should be installed by a qualifi ed

installer to insure a correct and safe installation. NEVER use

temporary or makeshift compromises during the installation.

4. If there are any missing or damaged components of the appliance, contact your dealer immediately. DO NOT OPERATE

THIS APPLIANCE WITH MISSING OR DAMAGED PARTS.

5. WARNING: RISK OF FIRE. Observe the minimum clearances to combustibles stated in this manual and on the labels

attached to the appliance. DO NOT store wood, any type

of fl ammable vapors or liquids, place furniture, rugs,

carpet, clothing or other combustible objects within the

clearance area.

6. DO NOT connect this appliance to any air distribution duct

or system.

7. DO NOT tamper with the combustion air control of this unit

beyond normal adjustment range.

8. Provide adequate combustion air to the room where the appliance is installed. Restricting combustion air will result in a

lazy fi re which causes soot or creosote buildup and greatly

reduces effi ciency.

9. Always connect this appliance to a chimney that vents to the

outside. Never vent into another room, crawl space, attic,

or inside a building. DO NOT CONNECT THIS UNIT TO A

CHIMNEY FLUE SERVING ANOTHER APPLIANCE.

10. DO NOT connect a wood burning appliance to an aluminum

Type B gas vent. This is not safe. Use approved masonry

or a UL 103 HT (U.S.) Listed Residential Type and Building

Heating Appliance Chimney. Use a 6” diameter chimney, that

is high enough to create suffi cient draft.

11. Be sure your chimney is safely constructed and in good

repair. Have the chimney inspected by the fi re department

or a qualifi ed inspector. Your insurance company should be

able to recommend a qualifi ed inspector.

12. Creosote or soot may build up in the chimney liner or chimney

and cause a house/building fi re. Inspect the chimney and

chimney liner twice monthly during the heating season and

clean if necessary.

13. In the event of a chimney fi re, turn the air controls to the

closed position, leave the building and CALL THE FIRE

DEPARTMENT IMMEDIATELY!

14. To prevent injury, do not allow anyone to use this appliance

that is not familiar with its correct operation. Do not operate

this appliance while under the infl uence of alcohol or drugs.

15. CAUTION: HOT SURFACES. KEEP CHILDREN AWAY.

DO NOT TOUCH WHILE IN OPERATION. CONTACT MAY

CAUSE SKIN BURNS.

2 Ussc

16. Children should be alerted to the hazards from high surface

temperatures. Never leave small children unsupervised

when they are in the same room as the appliance during

operation. To prevent burns, always wear protective clothing,

leather hearth gloves, and eye protection when refueling or

fi re maintenance. Always be aware of heated surfaces. Heat

radiating from the appliance can potentially discolor, melt,

or even ignite combustible materials. KEEP ALL COMBUS-

TIBLE MATERIALS WELL AWAY FROM THE HEATER!

17. WARNING: RISK OF FIRE. Keep the feed door tightly closed

at all times except when tending the fi re.

18. DO NOT overfi re this appliance. Overfi

feed door is left open during operation. If any part of the

appliance glows, you are overfi ring. Adjust air controls to a

lower setting to slow down the fi re.

19. DO NOT ELEVATE THE FIRE! Build the fi re directly on the

fi rebrick. This appliance has not been tested with the use of

any means to elevate the fi re and it should not be attempted.

20. Ashes should not be allowed to accumulate more than two

to three inches in the fi rebox.

21. The paint on your appliance is durable but will not stand rough

handling or abuse. The paint used may give off smoke and/or

an odor during the fi rst few fi res. This will occur until the paint

has cured. Animals / people with lung problems should not

be present during the curing process. Build small fi res at fi rst

to help this process and open windows and doors as needed

to clear the smoke and odor. If the appliance is overfi red,

the paint will discolor. When installing your unit, take care

in handling. Clean with soap and water when the appliance

is not in use. Do not use any acids, abrasive cleaners or

scouring soap as these solvents wear and dull the fi nish.

22. DO NOT ROUTE THE BLOWER POWER SUPPLY CORD

NEAR OR ACROSS HOT SURFACES!

23. Canada Installations requires that this fi replace must be

installed with a continuous chimney liner of 6 inch diameter

extending from the fi replace insert to the top of the chimney.

The chimney liner must conform to the Class 3 requirements

of CAN/ULC-S635, Standard for Lining Systems for Existing Masonry or Factory-Built Chimneys and Vents, or CAN/

ULC-S640, Standard for Lining Systems for New Masonry

Chimneys.

24. Permanently seal any opening between the masonry of the

fi replace and the facing masonry.

25. Fireplace insert surround panels may be removed to inspect

fi replace insert and fi replace.

26. U.S. Stove Company requires installing smoke detectors in

the same room as the heater if not already installed. Smoke

expelled from the unit by either paint curing, opening the fuel

loading door, or a negative pressure inside the home could

trigger the smoke detectors.

27. For further information on using your heater

a copy of the National Fire

publication “Using Coal and Wood Stoves Safely” NFPA No.

HS-10-1978. The address of the NFPA is 1 Battery March

Park, Quincy, MA. 02269.

Protection Association (NFPA)

ring will occur if the

safely, obtain

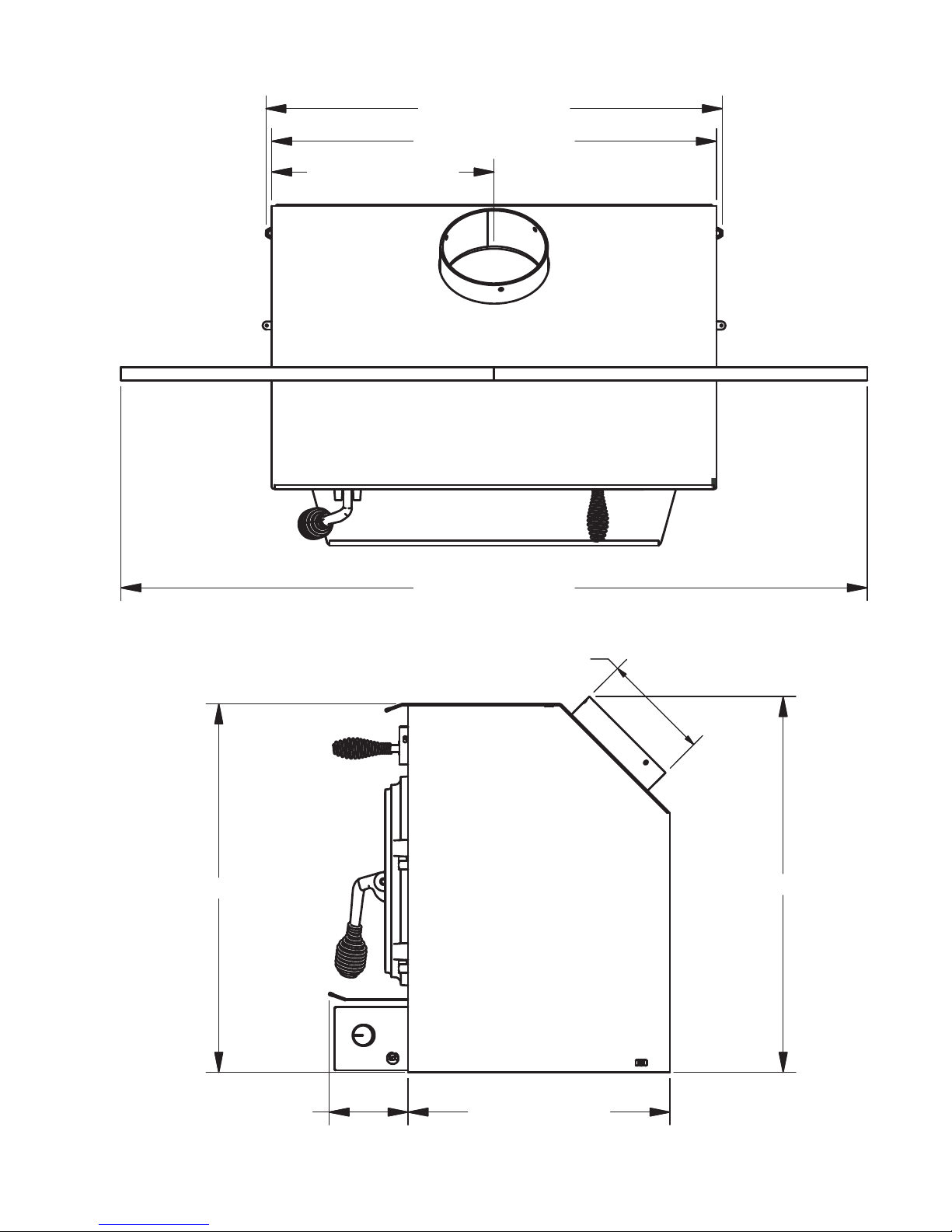

2200I DIMENSIONS

27 1/32 [686.6 mm]

26 11/32 [669.0 mm]

13 5/32 [334.5 mm]

21 13/16 [554.0 mm]

44 7/32 [1123.0 mm]

P6.00 INSIDE

22 1/4 [565.0 mm]

Ussc 3

15 1/2 [394.0 mm]4 11/16 [118.8 mm]

PRE-INSTALLATION REQUIREMENTS

FIREPLACE CONDITION AND

ZERO CLEARANCE REQUIREMENTS

A masonry fi replace must meet minimum code require-

ments, National Fire Protection Association, (NFPA) 211,

or the equivalent for a safe installation. Contact a professional, licensed installer, your local building inspector or

the local fi re authority for the requirements in your area.

Your insurance company should be able to recommend a

qualifi ed inspector.

Inspections should include the following:

1. Condition of the fi replace and chimney. A masonry

fi replace and chimney MUST be inspected prior to installation of this appliance. They must be free from

cracks, loose mortar, creosote deposits, blockage or

other evidence of deterioration. If found, these items

MUST be repaired prior to installation. DO NOT REMOVE BRICKS or MORTAR from existing fi replace

when installing this unit.

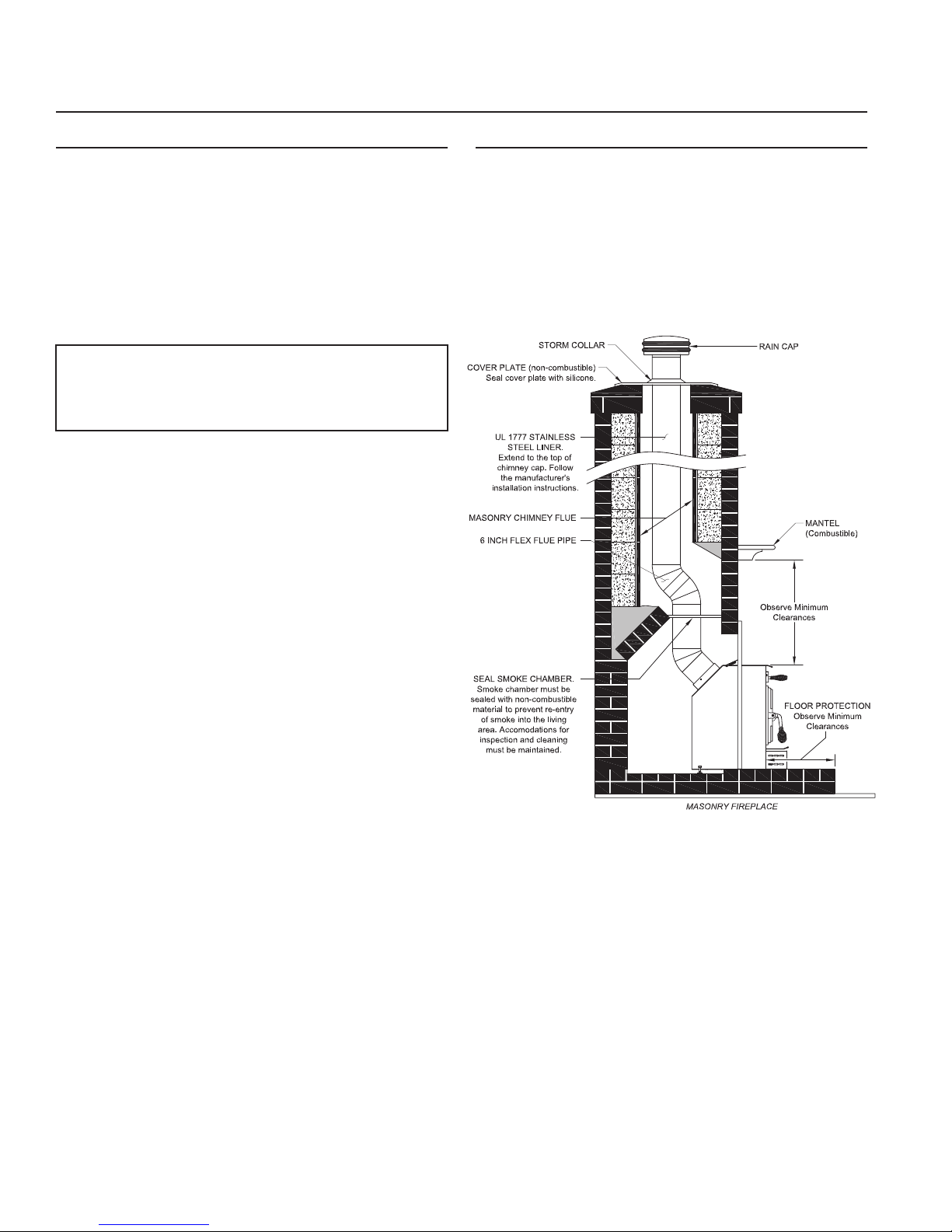

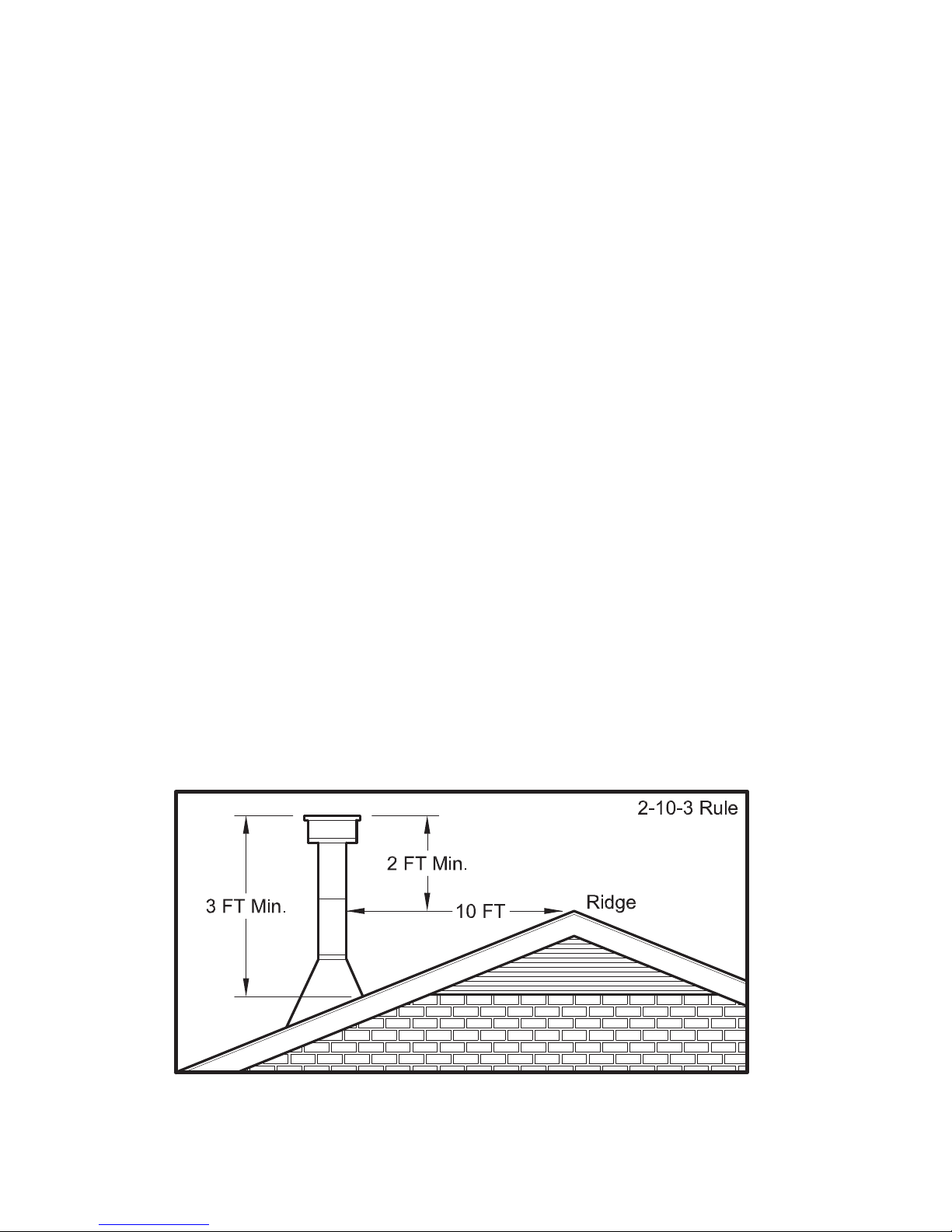

2. Chimney Size. Minimum chimney size is 6˝ (152mm)

diameter. Maintain a 15 ft. minimum overall chimney

height measured from the top of appliance to the top

of the chimney. Chimneys must extend at least 3 ft.

above the roof and at least 2 ft. above the highest

point within 10 ft. of the chimney top. See the Chimney Connections section of this manual.

3. Zero Clearance or Metal Heatform Fireplaces.

These fi replaces and chimneys must meet the mini-

mum code specifi cations as noted above. Factory

built zero clearance fi replaces must be listed and

suitable for solid fuel use. Chimneys must be at least

7 inch diameter to accommodate a required, continuous, stainless steel liner from the appliance’s fl ue col-

lar to the top termination of the chimney.

Only detachable parts that can be easily replaced (i.e.

damper parts, screens, doors and side, and back refractory panels) are to be removed. These parts must

be stored and readily available for replacement if the

appliance is ever removed. The removal of any parts

that render the fi replace unusable for burning solid

fuel requires a permanent label to be affi xed by the in-

staller that states the fi replace is unsuitable for burn-

ing solid fuel unless the missing parts are replaced

and the fi replace is restored to its original, certifi ed

condition.

4. Chimney Caps. Mesh type chimney caps and spark

arrestors must be able to be removed for regular inspection and cleaning. Otherwise the mesh should be

removed to prevent possible plugging. Check your local fi re and building codes.

5. Chimney Liner. The chimney must be suitable for

burning solid fuel. Install a continuous stainless steel

liner from the fl ue collar of the appliance to the top of

the chimney. Liner must be UL Listed to UL1777.

4 Ussc

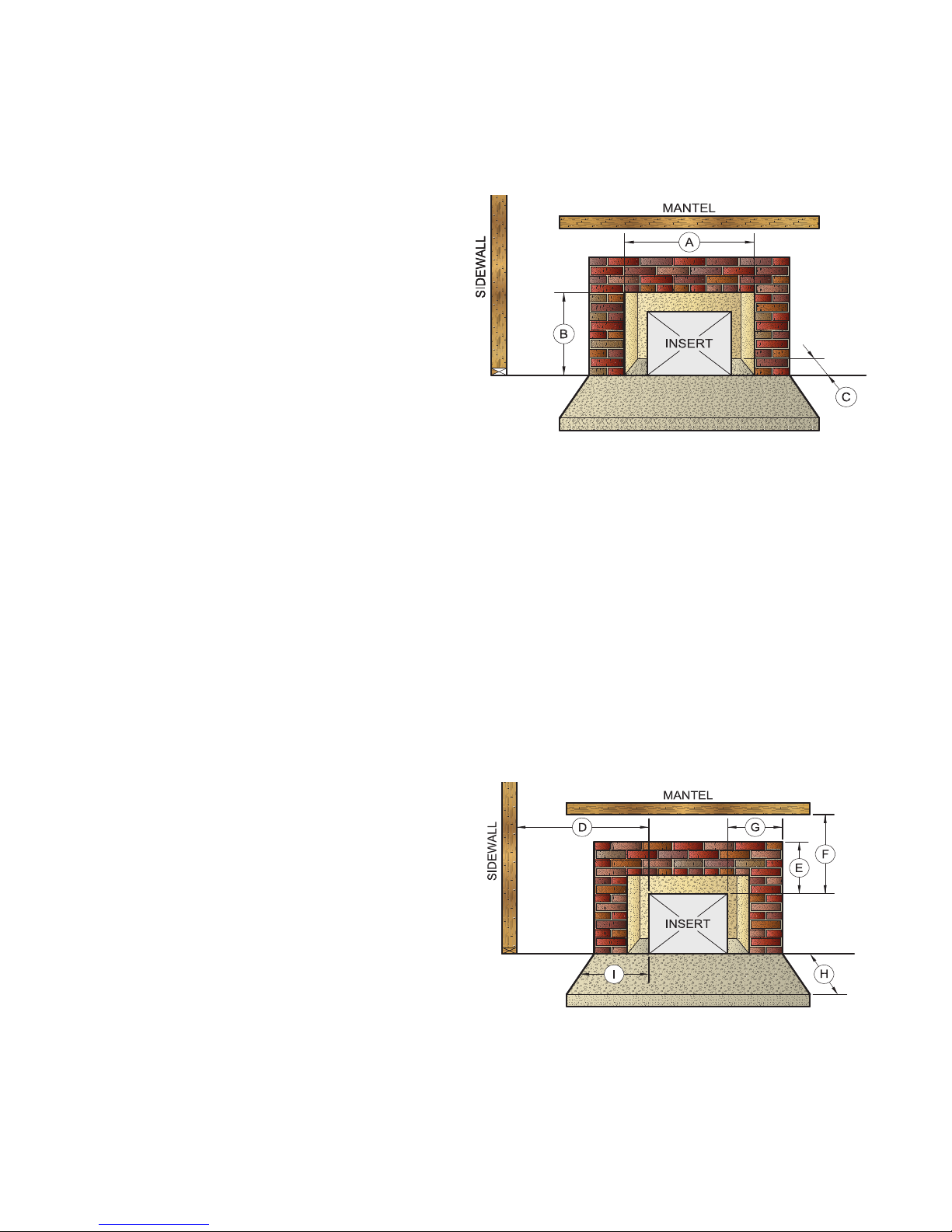

6. Fireplace Opening Dimensions.

A. Minimum Width ...............................29˝ [737mm]

B. Minimum Height ..............................23˝ [584mm]

C. Minimum Depth ..............................14˝ [356mm]

7. Combustible Material Clearances. The fi replace

and chimney must be inspected to make sure there

is adequate clearance to combustible materials. This

includes the top, side, front, and back as well as

concealed combustibles in the chimney and mantle

areas. Your local building inspector or fi re authority

should have information on whether older fi replace

meet current codes and are suitable for use. See also

fi gure 1 and fi gure 2.

D. Min. Distance to Sidewall ..................9˝ [228mm]

E. Min. Distance to Top Trim ................14

F. Min. Distance to Mantle ...................19˝ [482mm]

G. Min. Distance to Side Trim .................9˝ [228mm]

H. Min. Floor Protector Front ................12˝ [304mm]

I. Min. Floor Protector Side ...................6˝ [152mm]

Min. Floor Protector Side Canada ....8” [203]

8. Makeup Air Requirements. This appliance requires

an adequate supply of makeup air to operate safely

and effi ciently. In some areas, this is a building code

requirement. Inadequate air supply will cause poor

combustion, ineffi cient operation, creosote buildup,

back drafting and smoke puffi ng into the living areas.

If any of the following conditions are evident, a makeup air supply MUST be installed.

˝ [355mm]

PRE-INSTALLATION REQUIREMENTS continued...

a. Existing fuel-fi red equipment shows evidence of

back puffi ng, smoke roll-out, ineffi cient operation,

or excessive smell in the living area.

b. Opening a window or door alleviates any of the

above problems or symptoms.

c. The building is constructed with a well-sealed va-

por barrier, tight fi tting windows, or has powered

exhaust fans.

d. Excessive condensation on windows in the winter.

e. The building has a ventilation system installed.

f. If, once installed, the solid-fuel appliance does not

draw steadily, burns poorly or ineffi ciently, back-

drafts or experiences back-puffi ng when adding

fuel.

VENTING (DRAFT) REQUIREMENTS

The chimney fl ue is a critical component to the proper and

effi cient operation of any heating appliance. Heating appli-

ances do not create draft, draft is provided by the chimney.

This appliance requires a draft of 0.05 in. water column

(0.1 Pa) at the fl ue collar.

WARNING: RISK OF FIRE - EXCESSIVE DRAFT CAN

CAUSE OVERFIRING AND A POSSIBLE STRUCTURE

FIRE. DO NOT OPERATE THIS APPLIANCE WITH

THE FLUE DRAFT EXCEEDING 0.06 in. w.c. (0.1 Pa).

To achieve proper draft, your chimney must meet three

minimum height requirements; minimum height from top of

appliance (15 ft. total height from top of appliance), minimum

height above roof penetration (3 ft.), and minimum height

(2 ft.) above highest point of roof within a 10 ft. diameter

from the chimney.

The chimney must also meet minimum and maximum

cross sectional requirements. For that reason a continuous 6˝ stainless steel liner from the fl ue collar to the top

of the chimney is required. A stainless steel adapter is

recommended for fastening the stainless steel liner to the

fl ue collar. The male (or crimped) end of the adapter must

be installed inside the fl ue collar to allow condensation or

creosote in the liner to drain back into the fi rebox. Chimney

liners and/or adapters must be permanently fastened using

a minimum of three (3) screws at each connection.

Chimneys outside of the home or on an exterior wall are

diffi cult to keep at operating temperatures and may result

in increased creosote buildup, less draft, back drafting

problems and poor appliance performance and should be

avoided.

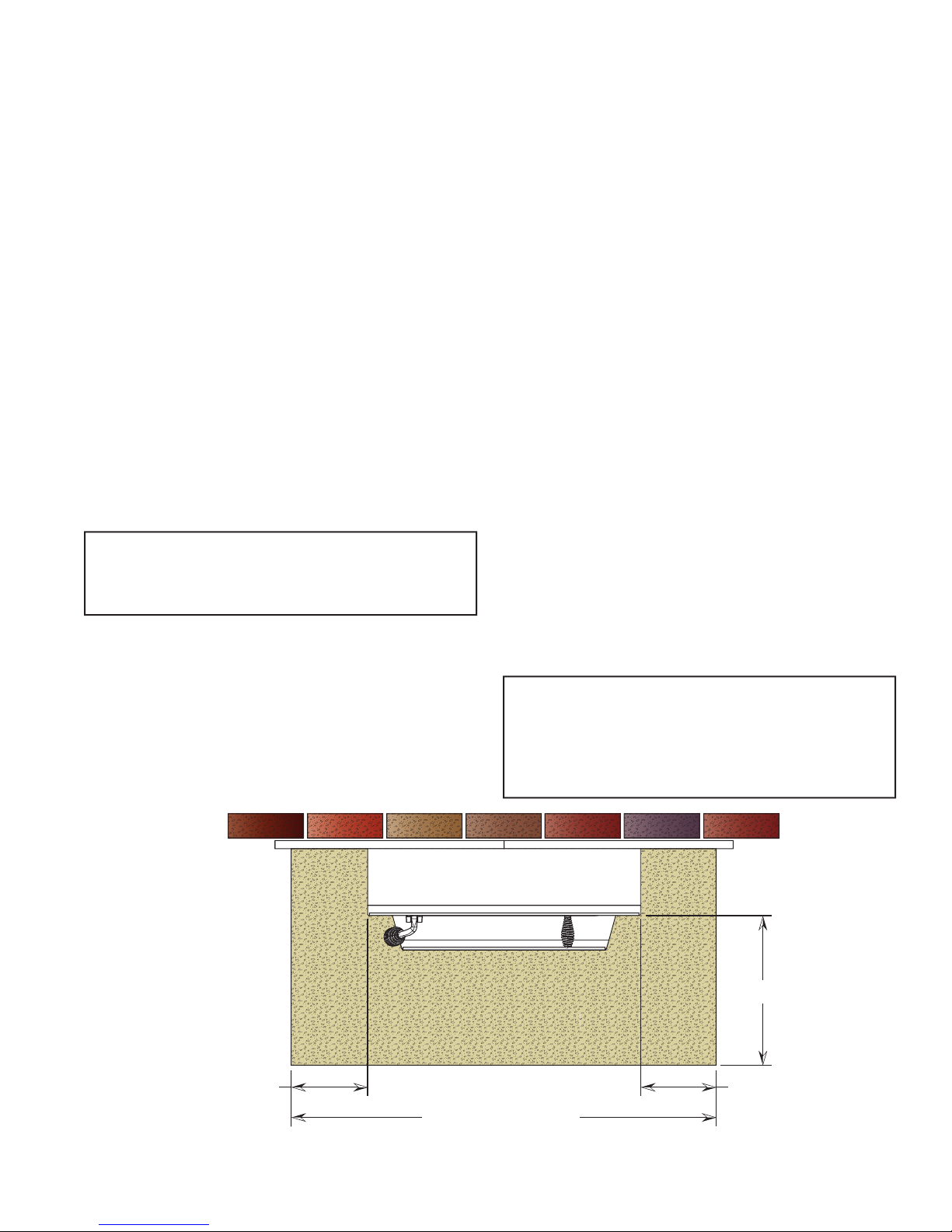

FLOOR PROTECTOR

A solid non-combustible fl oor, concrete or solid masonry,

must extend 6˝ to either side of the body of the appliance

and 12˝ in front of the face of the appliance.

When combustible fl ooring falls within these minimum

dimensions, it must be covered with a listed fl oor protec-

tor meeting the requirements of UL 1618, such as Hy-C

or Imperial Model UL 2840BK or equivalent with 0.84 Rfactor, 1” thick. (Note: to calculate R-value of alternative

materials see Floor Protector Material Calculations at

the back of this manual.) A grouted ceramic fl oor tile that

meets local building codes and the minimum 0.84 R-factor

requirements is considered a durable equivalent.

WARNING: RISK OF FIRE - DO NOT ALLOW COMBUSTIBLE MATERIALS (CARPET, FURNITURE,

FUELS) TO BE PLACED ON OR COVER THE FLOOR

PROTECTOR. ALL COMBUSTIBLE MATERIALS MUST

REMAIN OUTSIDE OF THE MINIMUM CLEARANCE

DIMENSIONS.

US - 6 in. [152mm]

CAN - 8 in. [203mm]

Ussc 5

12 inches [305mm]

FLOOR PROTECTOR

US - 6 in. [152mm]

CAN - 8 in. [203mm]

US - 38 inches [965mm]

CAN - 42 inches [1.06M]

DŝŶŝŵƵŵ&ůŽŽƌWƌŽƚĞĐƚŽƌ^ƉĞĐŝĮĐĂƟŽŶƐ

ASSEMBLY INSTRUCTIONS

TOOLS AND MATERIALS REQUIRED FOR INSTALLATION

TOOLS

• Pencil

• 6 foot Folding Ruler or Measuring Tape

• Tin Snips

• Drill: Hand or Electric

• 1/8” dia. Drill Bit (for sheet metal screws)

• Screwdrivers (Blade and Phillips type)

• 14mm Nut Driver or Ratchet with 14mm Socket

CAUTION: THIS APPLIANCE IS HEAVY. MAKE

SURE THAT YOU HAVE ADEQUATE HELP AND USE

PROPER LIFTING TECHNIQUES WHENEVER MOVING THIS APPLIANCE.

1. Clean the fi replace opening properly disposing of

any ashes in a closed metal container. See Safety

Instructions.

2. Install a 6˝ (152mm) minimum diameter, continuous

stainless steel chimney liner into the existing chimney. The liner must extend to the top of the existing

chimney. Use only listed chimney liners that meet

UL1777 standards. Follow liner manufacturer installation instructions.

MATERIALS

(NOTE: The following items are NOT included with your stove.)

Flooring Protection: as specifi ed herein.

Chimney Liner: Continuous stainless steel chimney liner

(as required)

Stainless Steel Adapter (connects the liner to the fl ue collar)

1/2” Sheet Metal Screws

Furnace Cement (manufacturer recommends Rutland

Code 78 or equivalent)

3. Remove or lock the fi replace damper in the open

position. Note: Masonry or damper plate may be removed to accommodate the chimney liner provided

this does not weaken any structural components of

the existing fi replace or chimney nor reduces protec-

tion of combustible materials required by national

building codes. Consult with your local building or fi re

authority before doing this.

4. Uncrate the appliance, remove all packing materials,

and any items stored in the fi rebox.

5. WARNING: Any fi replace which has had parts re-

moved or modifi ed to accommodate the installation

of this appliance MUST have a warning plate permanently installed in a visible location stating that the

fi replace is unfi t for use with solid fuel. Permanently

attach the warning plate to a visible location in the

fi replace.

6. Position the appliance into the fi replace opening until

the top lip of the air jacket is fl ush with the fi replace

facing.

8. Level the appliance with the adjusting screws at the

rear of the appliance.

9. Connect the chimney liner to the appliance using a

stainless steel adapter and securing with a minimum

of three (3) sheet metal screws. The liner MUST be

attached with the male (or crimped) end of the adapter inside the fl ue collar of the appliance to allow con-

densation and/or creosote to drain back into the fi re-

box.

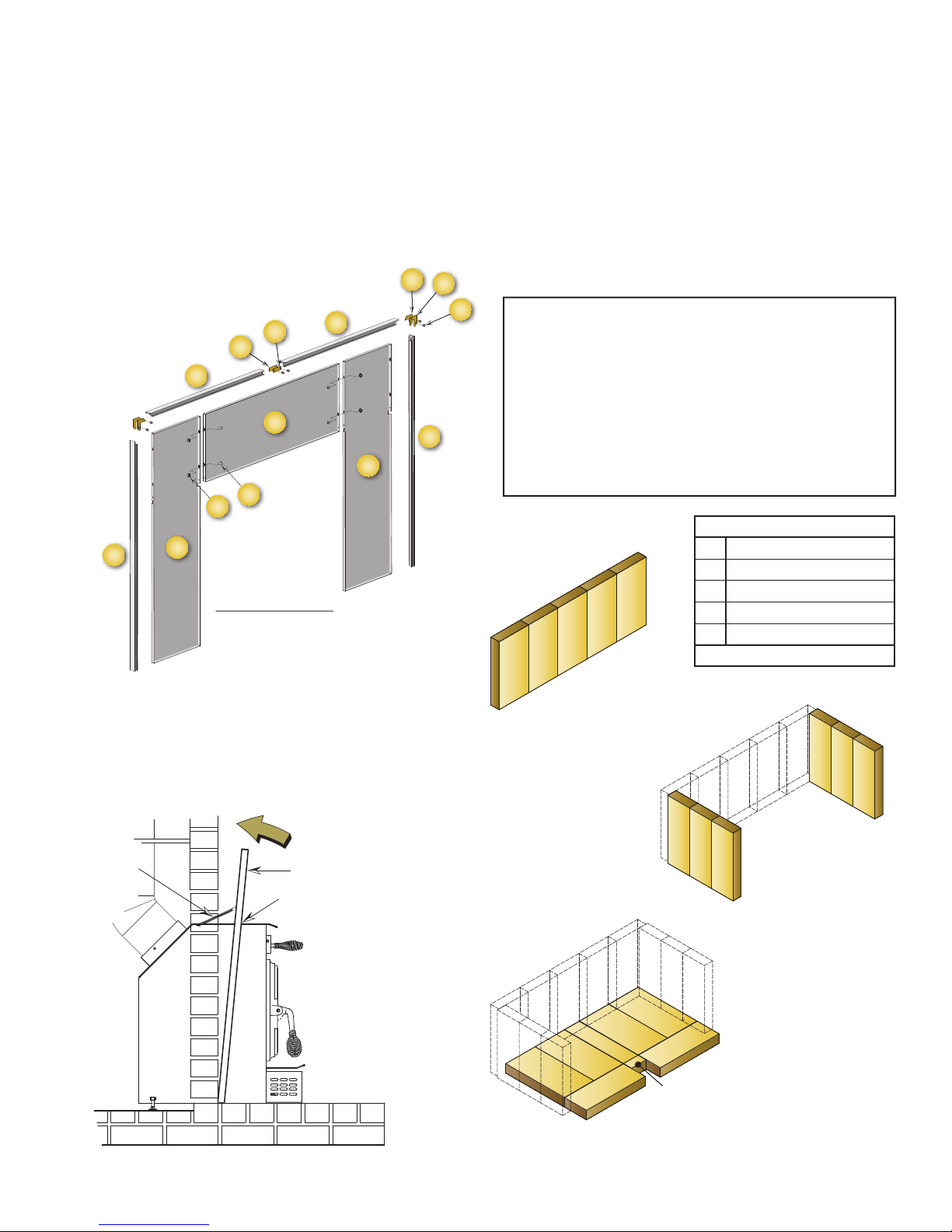

10. Assemble the Surround. Lay pieces face down on

carpet or other soft surface to protect fi nish during

assembly. The Surround consists of two side panels,

a top panel, and a decorative trim frame.

6 Ussc

ASSEMBLY INSTRUCTIONS continued...

11. Bolt the top panel (1) to the side panels (2 and 14) so

the top surfaces are fl ush to one another using items

3 and 4.

12. Assemble the trim frame. The trim consists of a left (6)

and right (5) side piece and a split top piece (left #8,

right #7). These are joined by corner connectors (11-

13) and two straight center connectors (9-10). These

slide into the channel on the back of the frame and

are secured with two set screws (13) in each piece.

11

12

10

9

7

1

4

3

5

13. The trim slides over the surround assembly and is secured at the base of each side with a machine screw.

14. The Surround Assembly is then slid over the appliance. Slots in the two side panels accommodate the

hood at the top of the appliance (fi gure 6).

14

SURROUND ASSEMBLY

VIEW FROM BACK

Figure 6. Surround Installation

8

2

13

6

15. The surround assembly is held in place with two

springs at the top of either corner of the appliance

(fi gure 6).

16.

Connect power cord of blower to grounded receptacle.

17. Firebrick extends the life of your stove and radiates

heat more evenly. If fi rebricks were removed to posi-

tion appliance, replace them before fi ring appliance.

See fi gure 7 for proper orientation and positioning.

Install the back row fi rst, then sides and fi nally install

bottom fi rebricks.

CAUTION: RISK OF FIRE!

• REPLACE FIREBRICKS BEFORE FIRING WOODSTOVE. POSITION FIREBRICKS SO NO GAPS

REMAIN BETWEEN BRICKS.

• NEVER OPERATE THIS APPLIANCE WITH MISSING OR CRACKED FIREBRICK.

• KEEP FURNISHINGS AND OTHER COMBUSTIBLE MATERIALS AWAY FROM THE STOVE AND

OUTSIDE MINIMUM CLEARANCES.

Figure 7a Back Firebrick Arrangement

Five (5) A-Size

A

A

A

A

Firebrick Dimensions: (inches)

A

B

C

D

E

Note: All Firebrick is 1.25” Thick

4.50” x 9.00”

3.33” x 9.00”

3.38” x 9.00”

2.25” x 9.00”

1.25” x 2.25”

A

Figure 7b Side Firebrick Arrangement

Six (6) B-Size

B

B

B

SPRING

SURROUND

Slots in surround

slide of rebox top

Ussc 7

A

A

D

C

A

A

B

C

E

B

B

Figure 7c Bottom Firebrick Arrangement

Four (4) A-Size

Two (2) C-Size

One (1) D-Size

One (1) E-Size

CHIMNEY SPECIFICATIONS

This appliance must be connected to a listed Stainless

Steel Liner, that meets UL1777, which extends from the

collar to the chimney cap according to the specifi cations

listed on the previous pages.

Chimneys perform two functions:

1. As a means of exhausting smoke and fl ue gases which

are the result of fuel combustion.

2. The chimney provides “draft,” which allows oxygen to

be continuously introduced into the appliance, so that

proper combustion is possible. This stove relies on

natural draft to operate.

NOTICE: Always provide a source of fresh air into the

room where the stove is located. Failure to do so may

result in air starvation of other fuel burning appliances and

the possible development of hazardous conditions, fi re,

or death.

Your appliance itself does not create draft. Draft is provided by the chimney. To achieve proper draft your chimney

must meet the three minimum height requirements detailed in fi gure 8. A minimum draft of 0.05 w.c. (measured

in water column) is required for proper drafting to prevent

back puffi ng, smoke spillage, and to maximize perfor-

mance. (Gauges to measure draft are readily available

at stove stores and are economical to rent or purchase.)

Factors such as wind, barometric pressure, trees, terrain

and chimney temperature can have an adverse effect on

the draft. The manufacturer cannot be held responsible

for external factors leading to less than optimal drafting.

Should you have a problem with inadequate draft, you

should contact a licensed heating and cooling contractor

for assistance in solving the problem.

IMPORTANT INSTALLATION POINTS

1. Size chimney fl ue to appliance collar. This stove re-

quires a minimum 6” diameter fl ue.

2. Never connect this unit to a chimney serving another

appliance.

3. The chimney must meet all minimum height requirements.

4. Never use a chimney to ventilate a cellar or basement.

5. Contact your local building authority for approved methods of installation and any necessary permits and/or

inspections.

MASONRY CHIMNEY

Before using an existing masonry chimney, clean the

chimney, inspect the fl ue liner, and make any repairs

needed to be sure it is safe to use. As mentioned previously, this appliance requires a continuous stainless steel

liner from the appliance collar to the chimney cap. Make

repairs before attaching the stove. The connector stove

pipe and fi ttings you will need to connect directly to a ma-

sonry chimney are detailed in the installation instructions.

If the fi replace chimney must go through a combustible

wall before entering the main chimney, consult a qualifi ed

mason or chimney dealer regarding proper materials that

meet all local building and fi re authority codes. The instal-

lation must conform to local building and fi re codes and

latest edition of NFPA 211.

If there is a cleanout opening in the base of the chimney,

close it tightly.

8 Ussc

Loading...

Loading...