Counterline vision aire Operation And Maintenance Manual

vision aire

Operation and Maintenance Manual

freestanding

01-2018

drop-ins

Chilled Displays

part of the idesign range

Counterline Limited

Randles Road

Knowsley Business Park

Merseyside

L34 9HZ

United Kingdom

tel: + 44 (0)151 548 2211

fax: + 44 (0)151 549 2179

service enquiries: servicelog@counterline.co.uk

spare parts enquiries: spareparts@counterline.co.uk

general enquiries: enquiries@counterline.co.uk

web: www. counterline.co.uk

Contents

Page 1 Operation & Maintenance Manual - Vision Chilled Displays

1. OPERATION

1.0 Switching Your Vision Chilled Display Unit On

1.1 Fault When Switching On

1.2 Temperature Control

1.3 Defrost Cycles

1.4 Display Lighting

1.5 Loading With Food

1.6 Chilled Vision Sliding Rear Doors

1.7 Shelf Adjustment

1.8 Installation Of Wall-Sited Chilled Vision Displays

2. CLEANING

2.0 Cleaning Safety Note

2.1 Stainless Steel

2.2 Sliding Rear Doors

2.3 Vision Glass

2.4 Rear Air Guides

2.5 Cleaning Chilled Display Main Tank

2.6 Condensing Unit Finned Coil

2.7 Automatic Evaporating Drip Tray

3. TROUBLE-SHOOTING

3.0 Ice Build-Up On The Coil

3.1 Self Help Guide

Page 3

Page 3

Page 4

Page 4

Page 5

Page 5

Page 5

Page 5-6

Page 7

Page 7

Page 7

Page 7

Page 7-8

Page 9

Page 10

Page 11

Page 12

Page 13

Page 14

Important Information

Page 2 Operation & Maintenance Manual - Vision Chilled Displays

IMPORTANT

Counterline Ltd cannot be held responsible for any accidents or injuries sustained through misuse or improper operation /

maintenance of its products. Please follow our guidelines set out within this handbook for safe working practice. At the design stage, please ensure that the counter understructure can take the weight of the display(s), and that adequate provision

has been made for lifting and positioning the display, to avoid risk of damage or injury.

SAFETY INFORMATION

It is essential that this Vision unit is provided with an electrical supply by a qualied electrician and

installed by a competent person.

The presence of liquids on the display and risk of spillage must be taken into account in designing the electrical

installation around the unit. For additional safety we strongly recommend the tting of a 30ma trip RCD

protection device to the electrical supply. Under no circumstances should electrical cables or points be installed below

the evaporator tray area, as water may overow and cause a hazard.

Vision display units are heavy. We strongly recommend the use of mechanical lifting equipment when handling the units and

positioning them in counters. If no such lifting equipment is available then sufcient personnel must be available to handle

each unit without contravening Company or site Health and Safety Policies.

Before commencing any cleaning or maintenance operation the Vision unit must be isolated from the mains supply by either

removing the supply plug from its socket or switching off at the local isolator.

NB: Switching off using the power switch on the control panel does not fully isolate the unit. These instructions

must be implemented in conjunction with your own Company’s Health and Safety instructions.

WARRANTY

All Counterline products are guaranteed against faulty materials and workmanship for 12 months from the date of invoice

provided that they have been installed, operated, cleaned and maintained in accordance with these instructions.

This guarantee specically excludes damage caused by misuse, scratched or broken glass, quartz heat lights, uorescent

lights and electronic starters.

WARNING

Operation

Page 3 Operation & Maintenance Manual - Vision Chilled Displays

OPERATION

It is essential that you read the instructions carefully and follow all of the cleaning and maintenance

instructions. Failure to do so can result in premature failure that will not be covered by warranty.

Vision chilled display units are designed to merchandise chilled food maintaining food temperatures by using re-circulated

cold air.

Each shelf level is illuminated by a uorescent strip light for optimum product presentation. Assisted service units have full

height curved glass sneeze screen.

All units have solid glass ends and either xed rear panels or double-glazed doors. The principles of operation and cleaning

are the same for all models whether self help or assisted service, oor mounted or tabletop.

If you have any difculties or need advice please do not hesitate to call our Service department on 0151 548 2211. Make

sure that you have the unit serial number to hand before calling.

Vision units are available as stand-alone units with an integral base or as a drop-in unit with under-slung compressor. The

basic operation and maintenance of these units is the same.

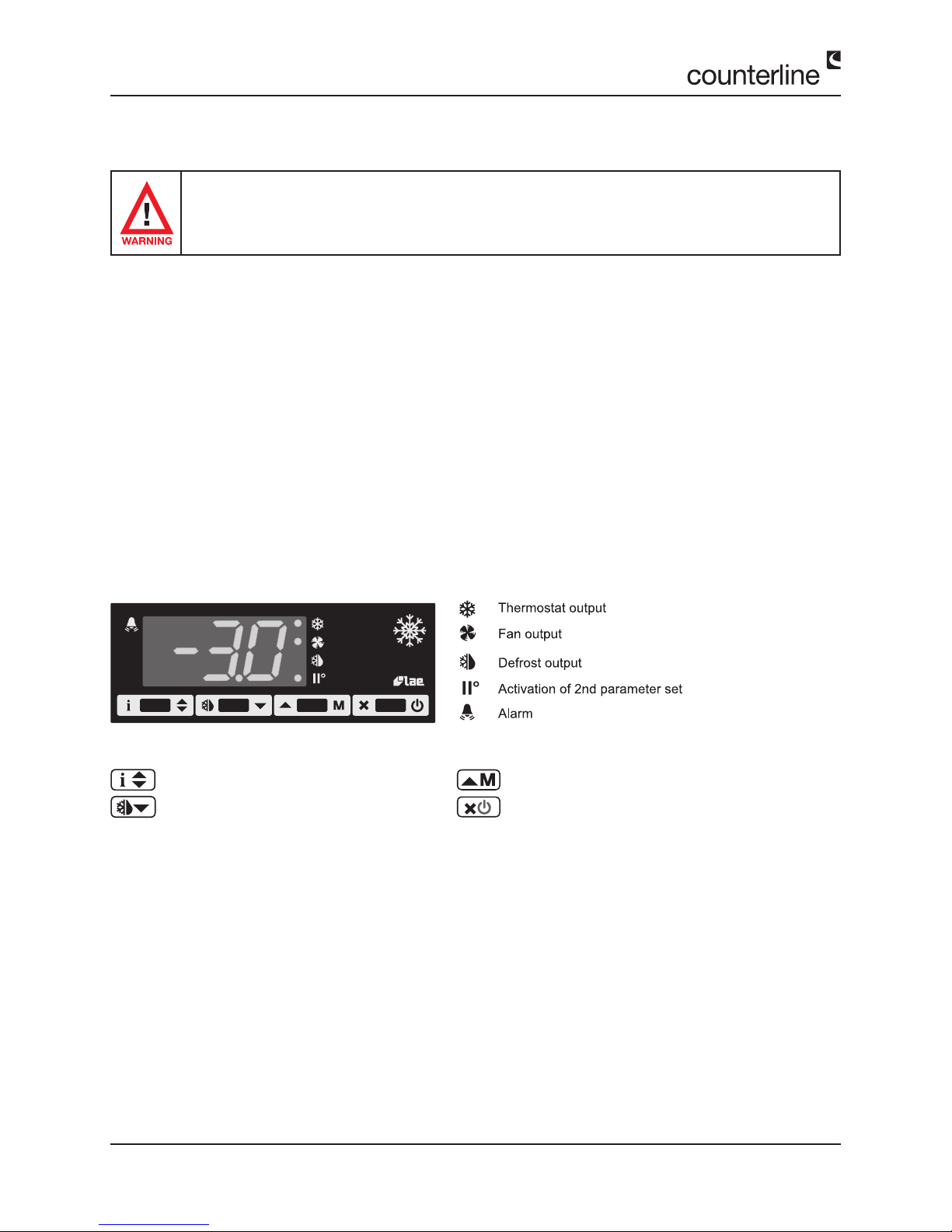

1.0 - SWITCHING YOUR VISION CHILLED DISPLAY UNIT ON

Info / Set point button

Manual defrost / decrease button

Manual activation/ increase button

Stand-by button

INDICATIONSCONTROLLER SET UP

BUTTONS

The digital controller controls both the circulating air temperature and the defrost cycles. It is pre-set to an average air temperature of 0°C, which should maintain food below 5 °C in an ambient temperature below 25 °C.

At this stage there is no need to alter this or any other setting of the digital controller.

1.1 - FAULT ON SWITCHING ON

If after the operation of the main power switch on the control panel it does not illuminate:

1. Check that your Idesign unit has been connected to a mains supply by your installer, and that this supply is live.

2. Isolate the unit and check the supply fuse.

3. Take care to ensure that you replace a fuse with one of the same rating. If you can nd no fault call your installer for

help.

Page 4 Operation & Maintenance Manual - Vision Chilled Displays

Operation

1.2 - TEMPERATURE CONTROL

In the Vision system of chilled food display, the food temperature is maintained at or below 5 °C by a stream of re-circulated

cold air.

The air blows across the display deck, coming from grilles or holes on the operators side and returning to the fans via a

grille at the customer’s side.

It is essential that neither of these grilles be obstructed in any way, as the airow and efciency of the refrigeration

system will be restricted.

The top of the displayed food must also be 50mm lower than the edge of the well or the glass surround if tted. This system

is very effective in a draught free environment with an ambient temperature of no more than 25°C.

Where ambient temperatures above 25 °C or draughty conditions exist, the display will not maintain food temperatures at

required levels.

Your digital controller will be pre set at the factory to give a food display temperature of 2/5°C in typical operating conditions. Under normal conditions the controller displays the actual temperature of the cold air around the food.

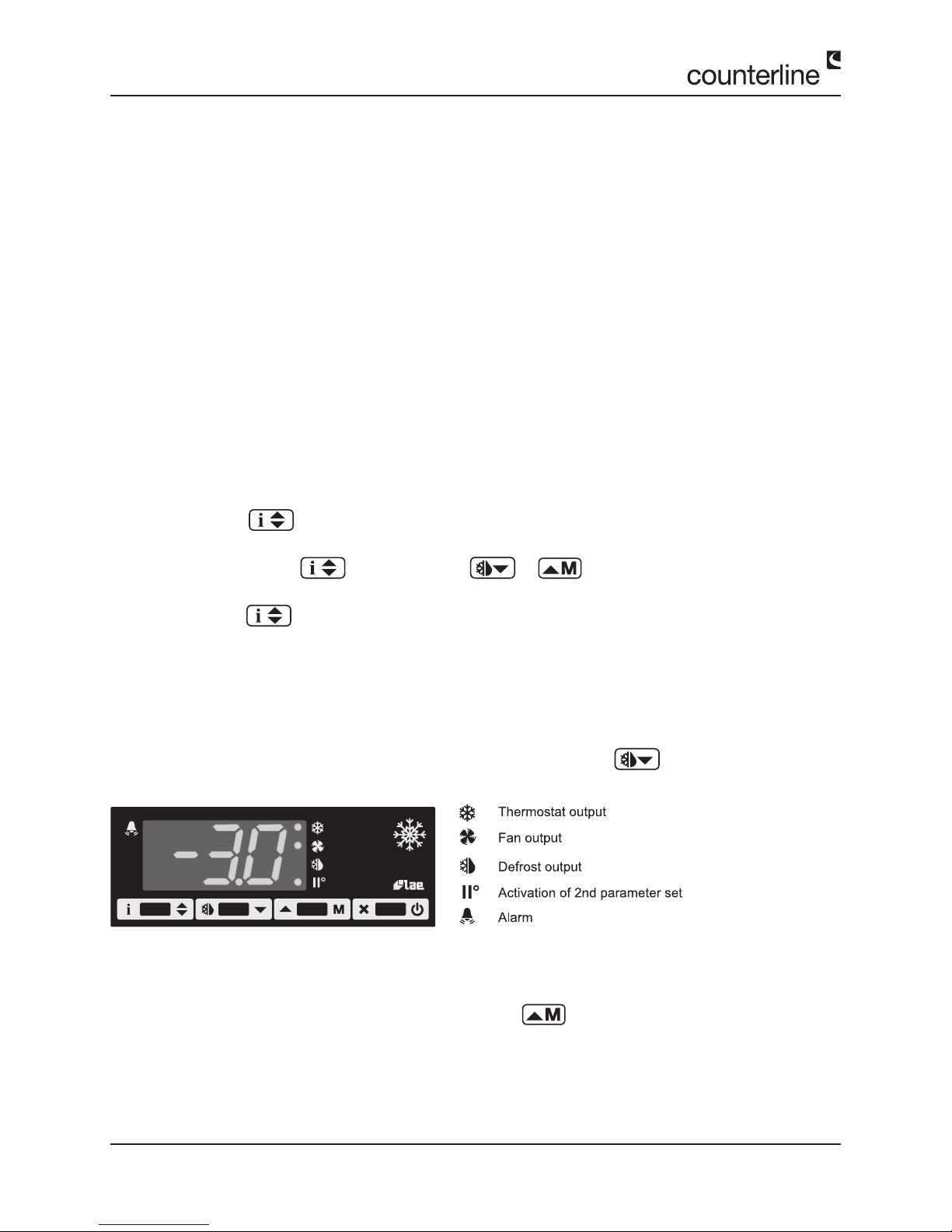

If you need to alter the pre set temperature proceed as follows:

Gantry digital controller (See diagram below)

1. Press Button for a least half a second, to display the set point value.

2. By keeping the button pressed, use button or to set the desired value.

3. When button is released, the new value is stored.

It is important that only small adjustments of say 1 or 2°C are made to the controller at any one time. The unit should then

be allowed to operate for at least one normal working day and food core temperatures monitored before any further adjustments are made.

1.3 - DEFROST CYCLES

On a gantry controller, if required, a manual defrost can be started by pressing button for ve seconds.

1.4 - DISPLAY LIGHTING

On a gantry control display lights are switched on by pressing button with the light symbol on it. If the lights do not

come on, consult the self help page on section 3 of this manual.

Loading...

Loading...