OPERATORS MANUAL

SPECIFICATION SUMMARY

Engine Lubricant

1.7 litres

Recommended SAE30 or 10W - 30 high quality

detergent oil classified for service; SG, SF, SE.

Read and follow the instructions in the engine

manufacturer’s handbook.

Fuel Tank Capacity

7 litres (1.5 gallons)

Transmission

Tuff Torq Heavy Duty Hydrostatic K62,

infinitely variable speed control with

Diff lock. Sealed for life lubrication.

Dimensions (approx.)

Length 1.96m (78”)

Inc Sweeper 3.07m (121”)

Height 1.17m (46”)

Width 1.3m (51”) (excluding Deck)

Weight

A20/50 325Kg

Sweeper 62Kgs

Net 36Kgs

PGC Capacity

390 litres

Forward Speeds

0-7mph

Countax Limited, Countax House, Great Haseley, Oxford OX44 7PF

Tel: (01844) 278800 Fax: (01844) 278792

Email: email@countax.com Website:www.countax.com

®

All figures are approximate. We reserve the right to change specification and price without notice E&OE

© copyright 2002 Countax Limited

Turning Radius

125cm

Recommended Tyre Pressure

FRONT

0.8-1.1KgF/cm (12-16lb PSI)

REAR

0.43-0.7KgF/cm (6*-10lb*PSI)

* Pressure recommended for maximum grip.

NEVER INFLATE ABOVE THE

MAXIMUM PRESSURE SHOWN

A20-50

Page 2 Page 27

Notes:Safety Instructions

CERTIFICATE OF CONFORMITY

EC Declaration of Conformity

I, the undersigned A. Bennett of Countax Limited Great Haseley Oxford

OX44 7PF declare that the Lawnmowers described below :

Model A20/ 50

Power (kW) 14.9

Maximum blade rotation (rpm) 3100

Engine Manufacturer Briggs & Stratton

Engine Type 4 stroke Petrol

Guaranteed Maximum Sound Power level 105dB(A)

Max. Vibration m/s_ (Hands) 2.05

Max. Vibration m/s_ (Seat) 0.53

Cutting Device Cutter

Cutting Device Width 127cm

Complies to the provision of the directive 89/392/EEC amended by

98/37/EC and the regulations transposing it into national law.

Complies with the provisions of "noise emission in the environment by

equipment for use outdoors" directive 2000/14/CE and the regulations

transposing it into national law Complies with the provisions of "electromagnetic compatibility" 89/336/EEC directives and the regulations transposing it into national law.

Tested at : Oxford, England

Signed:

A.Bennett 1/2/02

MANDATORY SAFETY INSTRUCTIONS FOR

THE OPERATION OF GARDEN TRACTORS

1. Read the instructions carefully. Be familiar with the controls and

the use of equipment.

2. Never allow children or people unfamiliar with these instructions

to use the mower.

3. Never mow while people, especially children, or pets are nearby.

4. The operator or user is responsible for accidents or hazards

occurring to other people or their property.

5. Do not carry passengers.

6. All drivers should seek to obtain professional and practical

instruction. Such instruction should emphasise:

• The need for care and concentration when working with this

machine.

• Control of a Tractor sliding on a slope will not be regained by the

application of the brake.

The main reasons for loss of control are:

• Insufficient wheel grip.

• Driving too fast.

• Inadequate braking.

• Incorrect load distribution.

1. Check that the machine complies with all applicable

regulations, including those in force when used on the

public highway.

2. When mowing always wear substantial footwear and long

trousers. Do not operate when barefoot or with open toe

sandals.

3. Warning – petrol is highly flammable:

• Store fuel in containers specifically designed for this

purpose.

• Refuel outdoors only and do not smoke when refuelling.

• Add fuel before starting the engine. Never remove the cap

from the fuel tank or add petrol while engine is running or

when engine is hot.

• If petrol is spilled, do not attempt to start engine but move

the machine away from area of spillage and avoid creating a

source of ignition until petrol vapours have dissipated.

• Replace the fuel tank cap securely.

TRAINING

PREPARATION

Contents Summary:

Safety Instructions -Page 2 and 3

Controls and Indicators - Dashboard -Page 4

Controls -Page 5 and 6

Mulch Deck -Page 7

Rear Discharge Deck -Page 8

Cutter Deck Removal -Page 9

Cutter Deck - Check List -Page 10

Deck Levels - Front to Back -Page 11

Cutter Levelling Side to Side -Page 12

Cutter - Drive Belt -Page 13

Powered Collector -Page 14

CollectorAdjustments -Page 15

Collector Drive Belts -Page 16

Collector Brush -Page 17

Tyres - Check List -Page 18

Tyres - Removal of Wheels -Page 19

Engine - Oil -Page 20

Engine - General Maintenance -Page 21

Electrical -Page 22

A20/50 Wiring Diagram -Page 23

READ THE INSTRUCTION MANUAL BEFORE USING

THE GARDEN TRACTOR AND ENSURE THE

OPERATORS STUDY IT FOR THEIR OWN SAFETY.

THE FOLLOWING PRECAUTIONS ARE OUTLINED

TO HELP PREVENT ACCIDENTS. A CAREFUL

OPERATOR WHO USES COMMON SENSE IS THE

SAFEST OPERATOR.

THESE SAFETY PRECAUTIONS ARE IN ADDITION

TO THOSE IN THE INSTRUCTION MANUAL.

THIS SYMBOL MEANS BE ALERT

CAUTION

Page 26 Page 3

Safety InstructionsNotes:

4. Replace faulty silencers.

5. Before using always inspect to see that the blades, bolts and

cutter assembly are not worn or damaged.

6. Check the condition of the tyres and ensure that they are

inflated to the correct pressure (refer to the specifications).

This is particularly important if the machine is to be taken

on the public highway.

7. Check the mower is in good working order, paying

particular attention to brakes and steering.

8. Check that all linkages, connections, and pivot nuts are

secure and that the wheel nuts are torqued correctly.

1. Do not operate the engine in a confined space where

dangerous fumes can collect.

2. Mow only in daylight or in good artificial light.

3. Before starting the engine, disengage blade and attachment

drives and shift into neutral.

4. Take care on slopes of more than 10º incline or decline

(Maximum safe operation is at 15º).

5. Remember that there is no such thing as a ‘safe’slope.

Travel on grass slopes requires particular care to guard

against overturning:

• Do not stop or start suddenly when going up or downhill.

• Engage clutch slowly. Always keep machine in gear,

especially when travelling downhill.

• Machine speed should be kept low on slopes and in tight

turns.

• Stay alert for humps and hollows and other hidden hazards.

• Avoid mowing across the face of the slope.

6. Watch out for traffic when crossing or near roadways.

7. Stop the blades rotating before crossing surfaces other than

grass.

8. When using the machine, never direct discharge of material

toward bystanders or allow anyone near the machine while

in operation.

9. Never operate the mower with defective guards, shields or

without safety protective devices in place and in good

working order.

10.Do not change governor settings to increase the revs of the

engine. Operating an engine at excessive speed increases

the risk of injury.

11.Before leaving the operators position:

• Disengage the drive to the cutter blades and attachments

and lower the attachments.

• Change to neutral and set the parking brake.

• Stop the engine and remove the ignition key.

12 .Disengage drive to attachments, stop the engine and

disconnect the spark plug lead or remove ignition key

before:

• Clearing blockages.

• Checking, cleaning or working on the mower.

• Refuelling.

• Removing the grass catcher.

• After striking a foreign object. (Inspect the mower for

damage and make repairs before restarting the Tractor).

• If the machine starts to vibrate abnormally check immediately

and call dealer if necessary.

13.Disengage drive to attachments when transporting or not in use.

14.Reduce the throttle setting during engine run-out.

15.Never work on the mower when the engine is running.

1. Check that all nuts, bolts, and screws are tight to be sure the

equipment is in safe working condition.

2. Never store the equipment with petrol in the tank inside a

building where fumes may reach open flame or spark.

3. Allow the engine to cool before storing in any enclosure.

4. To reduce the risk of fire keep the engine, silencer and battery

compartment free of grass, leaves, petrol or excessive grease.

5. Check the grass catcher frequently for wear and tear or

deterioration.

6. Replace worn or damaged parts for safety.

7. If the tank has to be drained, this should be done outdoors.

8. Be careful during adjustments of the machine to prevent

entrapment of the fingers between moving blades and fixed parts

of the machine.

9. Do not use steam cleaners or high pressure washers directly

towards bearings or electrical components (Countax do not

recommend the use of these power cleaners).

SUPPLEMENTARY INSTRUCTIONS FOR USE

OF COUNTAX A20/50 TRACTOR

1. Use good sense at all times and, to ensure this Tractor is safe and

serviceable, fit only original manufacturers’ supplied spares.

2. When inspecting the area to be cut, note also the position of any

stumps, manhole covers, bumps and depressions and avoid them

to prevent damaging the blade.

3. We recommend the use of standard UNLEADED fuel and that

you ensure the fuel tank is full before you start the machine.

4. Always disconnect both battery terminals before attempting any

work in the engine compartment.

5. Do not leave the Tractor unattended and running.

6. Do not put hands near moving belts or the Power Take-Off pulley

while it is rotating.

OPERATION

MAINTENANCE AND STORAGE

Page 4 Page 25

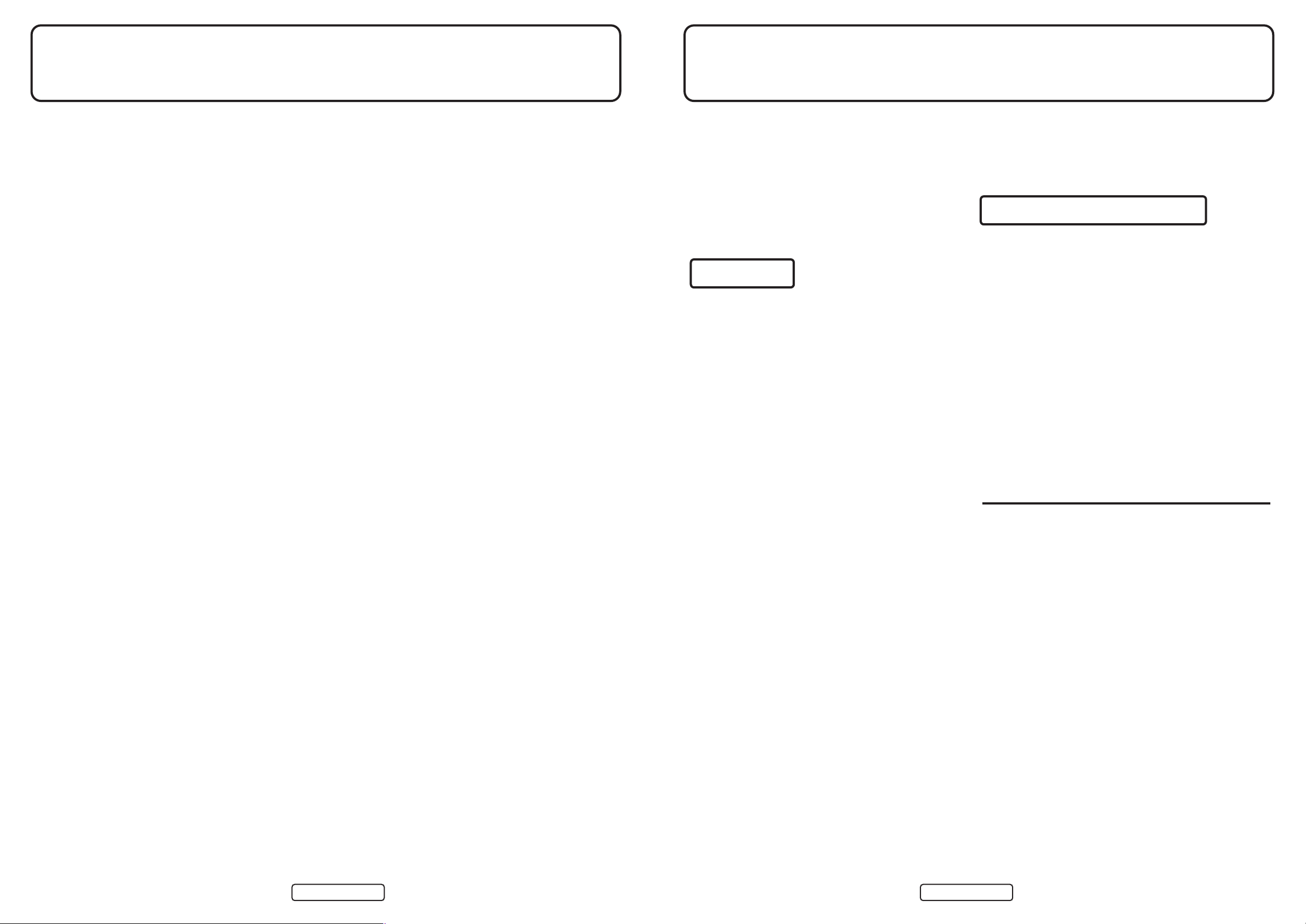

Notes:Controls and Indicators - Dashboard

IGNITION

The ‘Key Start’controls both the ignition

and the starter. Insert the key and turn to

the 1st position, the dashlights will come

on (check that all is ready to start), then

turn further to activate the starter. Release

when engine starts. To stop, turn the key

to the left (having first switched off both

cutter and PTO).

IT IS ALWAYS GOOD PRACTICE

TO REMOVE THE KEYAND KEEP

IT SAFE.

As with a car, it is important to prevent

unauthorised use by children who could

injure themselves.

CHOKE

An independent choke is fitted to the

A20/50. This choke should be used in

combination with a fast throttle setting to

start a cold engine. Cancel as soon as

possible. Do not use choke on a warm

engine.

CUTER ON/OFF SWITCH

The cutter switch controls the

Electromagnetic Blade Clutch. It works

like a light switch (but in reverse) – UP

for ON and DOWN for OFF. Although it

always returns to the central position and

the cutter deck will automatically be

turned off when the engine is switched

off, it is not good practice to rely on this.

The cutter deck should always be

switched

OFF as soon as you have

finished cutting and certainly BEFORE

stopping the engine or getting off the

Tractor.

THROTTLE

The lever is pushed forward and up for

FAST, back and down for SLOW. A

cold engine is started on the

FAST

setting with choke, a warm one on the

FAST setting. The Choke setting should

be cancelled as soon as possible and the

engine operated on

FAST setting at all

times.

HEADLIGHT SWITCH

The headlights are turned ON by switching

the rocker switch on. The headlights will

not operate when the ignition is

OFF. Turn

the headlights OFF before starting or

stopping.

O

Page 24 Page 5

Controls - Forward/ReverseHE Wiring Diagram

Page 6 Page 23

Wiring DiagramControls - Levers

POWER-TAKEOFF (PTO)

Push the lever down and to the left to engage the pto, to disengage

push the lever down and lift to the right.

ELECTRIC LIFTS

The cutting height is adjusted by rotating the ‘dial-a-height’switch

anti-clockwise to lower the deck and clockwise to raise the deck.

The indicated heights (1-lowest to 10-highest) are shown for

guidance purposes only. To get the best from this refinement use it

to continuously adjust cutting height to suit ground and grass

conditions. Do not make downward adjustments on the move until

you are familiar with this height control, to avoid scalping.

Raising the Auxiliary Lift is achieved by pressing the switch (

B) to

the left of the dashboard – UP to raise, DOWN to lower (fig 3).

PGC NET EMPTY SWITCH

A third switch is fitted to those Tractors with a Powered Grass

Collector. This switch empties the collector net via an electric

actuator mechanism that lifts the grass box and pushes out the

bottom pan, fully emptying the collector contents. Press the switch

UP to open and DOWN to close the net (fig 5).

SEAT ADJUSTMENT

The seat on the A20/50 is adjustable forwards and rearwards to suit

the operator. Simply lift the seat latch at the front of the seat (fig 4)

and slide the seat forwards or backwards to suit. Always ensure the

seat is latched back into position before driving off.

(A) Dial-

a-height

Switch

(B)Auxiliary

Lift Switch

fig 1

fig 2

fig 3

fig 4

fig 5

PGC Net Empty

Switch

Press UP to empty

and DOWN to Close

Electric ClutcElectric Clutch

Switc Switch

Light SwitcLight Switch

LoomLoom

ConnectorConnector

RedRed

LoomLoom

ConnectorConnector

Light LoomLight Loom

ConnectorConnector

Brake SwitcBrake Switch

Fuel SolenoidFuel Solenoid

Soc Socketket

RegulatorRegulator

StarStarterter

MotorMotor

Seat SwitcSeat Switch

P.T.O.

SocSocketket

(Red / Blue)(Red / Blue)

Ignition Cut OutIgnition Cut Out

(Bolt on Connector)(Bolt on Connector)

Ignition Cut OutIgnition Cut Out

(Female Spade Connector)(Female Spade Connector)

Connector For H.E.Connector For H.E.

EarEarth Connectorth Connector

For H.E. For H.E.

IgnitionIgnition

SwitcSwitch

15A15A20A20A

20A20A

SolenoidSolenoid

Electric ClutcElectric Clutch

BatterBattery

EngineEngine

1

2

4

5

TRATRACTCTOR OR WIRING DIAWIRING DIAGRAMGRAM

Ignition SocIgnition Socketket

10A10A

10A10A

12 Red / 12 Red / Yellow w

1 WhiteWhite

2 Red / Blue 2 Red / Blue

3 Br 3 Brownwn

4 Gre4 Grey

5 Red / Blue

6 White / RedWhite / Red

7 Black

8 Purple

9 Yellow

10 Green10 Green

11 Orang11 Orange

13 Blue13 Blue

Orange

Purple

Black

Red

Red /

Blue

+

-

3

6

PTO

IMPORTANT - READ SAFETY INSTRUCTIONS BEFORE OPERATING THIS MACHINE

MULCHING

For Best results;

- Do not reduce the height of the grass by more than 1/3 in a single pass

- Mow often - short clippings of 25mm (1") or less decompose more quickly

- If possible, avoid cutting in the wet

- Always cut with the engine at full running speed

- If an unsightly residue is present - increase cutting height

- Vary mowing pattern from cut to cut

- Always keep the underside of the deck clean to permit good grass flow

- Always ensure that blades are sharp and in good condition

VIBRATION TESTED TO THE FOLLOWING STANDARDS

BS 6842:1987, DD ENV 25349:1993, SI 1992:3073, BS6841:1987

O

O

15 MAX

15 MAX

EXERCISE CAUTION WHEN CUTTING

ON SLOPES

O

Page 22 Page 7

Mulch DeckElectrical

MULCH MOWING

Mulching can save time, avoids gathering

piles of rotting cuttings and feeds your

lawn. It is however necessary to observe

certain rules to mulch mow successfully:

• Reduce the height of the grass by no

more than 1/3rd its height in each pass.

If the grass has grown long make

several passes to achieve the cut height

you require.

• Always cut with the throttle set to

FAST – mulching needs the full

running speed of the engine.

• Mow often, particularly in Spring and

early Summer. Short clippings of

25mm (1") or less decompose more

quickly.

• If possible avoid cutting in the wet.

• If an unsightly residue of cuttings is

being left – increase the cutting height.

• Vary the mowing pattern from cut to

cut.

• Always keep the underside of the

cutting deck clean to ensure good grass

flow.

• Always check that the blades are sharp

and in good condition – but do not

attempt to sharpen or replace them

yourself. New Countax blades are not

expensive and it is good practice to ask

your dealer to change them regularly.

There are five 20 Amp fuses on the

A20/50 Tractor.

1. 20Amp (

yellow) for charging circuit.

2. 20Amp (

yellow), ignition, safety

switches.

3. 20Amp (yellow) electric lift for Cutter

Deck and Auxiliary lift.

4.20Amp (

yellow) located left-hand side

of the console is for net emptying circuit.

To check - remove fuse and check small

window, there should be an unbroken

metal strip bridging the gap (fig 4).

Note - If No.2 20Amp fuse blows when

the ignition key is turned this means there

is a short between the red and blue

coloured wire and the body of the Tractor.

The usual places to investigate are:

• The electrical PTO and socket.

• Seat switch wires (fig 3).

If fuses blow after these have been

checked, call your dealer.

PRINTED CIRCUIT BOARD

FUSES

There are 2 10Amp Blade fuses on the

circuit board (fig 5) which can be reached

by removing the cover (fig 1). These two

fuses control the lights and the

Electromagnetic Blade Clutch. If the

problem is not a fuse and you cannot see

any loose connections - call your dealer.

ELECTROMAGNETIC BLADE

CLUTCH

If the blade clutch disengages without

being switched off these are the possible

causes:

• You have got off the seat - the safety

switch will disengage the cutter.

• The battery has lost charge and will no

longer hold the clutch in operation.

• Fuse blown on Printed Circuit Board -

see above.

• Faulty Safety Switch or break in wire -

see your dealer.

fig 1

fig 2

fig 4

fig 5

fig 3

Fuse Box

PCB located

under the

Dashboard

Possible

source of short

- Seat Switch

Printed Circuit Board

Mulch Deck

Blades

Mulch Deck

Pulley Arrangement

The Mulch Deck

Process

Hour Meter

(Located on the

other side of the

PCB)

10 Amp Blade

Fuse for

Electric Clutch

10 Amp Blade

Fuse for Lights

1

2

3

20

20

20Amp

( yellow )

20

20

20Amp

( yellow )

20

20

20Amp

( yellow )

Page 8 Page 21

Engine - General MaintenanceRear Discharge Deck

fig 1

Specified Belts and Blades

Engine/Deck Belt - B56 Dayco Super II - Pt No. 22940100 (IBS)

Engine/Deck Belt - B57 Dayco Super II - Pt No. 22871200 (MULCH)

Deck Internal Drive Belt (Mulcher) - BB112 Pt No. 228000900

(Rear Discharge) - Dayco Super II BB155 Pt No. 22950200

Mulcher Blades x3 Pt No. - 216938100

IBS RH Blade Pt No. 169381300

IBS LH Blade Pt No. 169381400

IBS Front Blade Pt No. 1692000

PGC Drive Belt Super II A49 - Pt No. 228001200

PTO Drive Belt - Dayco Super II A92 - Pt No. 22950100

Transmission Drive Belts - A92 Dayco Super II - Pt No. 22950100

N.B. Only use specified Belts and Blades - Never accept a substitute!

Routing for IBS internal deck drive belt

VANGUARD

Page 20 Page 9

Cutter Deck Removal

(Mulch/Rear Discharge Deck)

Engine - Oil

The Rear Discharge Deck is used in conjunction with the

PGC. It ejects the grass rearwards after cutting for the

Powered Grass Collector to collect. Either the Mulch Deck or

the Rear Discharge Deck can be fitted to the A20/50 using the

following instructions:

REMOVAL OF CUTTER DECK

The cutter deck can be quickly removed for servicing or

cleaning or to give greater clearance when driving or towing

over uneven ground.

Follow this sequence:

1. Put cutter to lowest position.

2. De-tension the Cutter Drive Belt with the lever under the

left (nearside) running board.

3. Remove the 3 securing pins from the front of the deck

(fig 3 – A, B and C) by pulling out the spring clips.

4. Remove pin G and remove deck tension bar.

5. Remove fifth anti-scalp wheel (fig 6)

6. Remove the 2 securing pins from the back of the deck

(fig 2 – D and E).

7. Slip the Cutter Drive Belt off the Engine Pulley.

8. Slide the deck out.

9. If you are going to use the Tractor without the deck, remove

the Securing Bar (F).

WHEN REPLACING THE CUTTER DECK, RE-TENSION

THE BELT WITH THE LEVER UNDER THE RUNNING

BOARD. Then check the belt tension (see page 13).

TO CLEAN CUTTER DECK

Remove the deck as instructed, stand it on its side and hose off

accumulated cuttings. This may be necessary routinely to

prevent build-up of cuttings, particularly at the beginning of

the season when the grass is lush and wet. Thoroughly wash

the underside of the cutter deck as regularly as possible.

ENGINE TO CUTTER DRIVE BELT

REPLACEMENT

Follow this sequence:

1. Pull the Belt Tension Lever (page 13 fig 1) forward.

2. Lower the Cutter Deck to the lowest position.

3. Remove the belt from the forward Electric Clutch Pulley –

it will slip off.

4. Remove the Cover of the Cutter Deck Pulley Housing –

loosen and remove the 1/4" UNF nut and bolt using two

7/16" spanner/sockets – then slide (tap) the cover off.

5. Remove the belt from the Cutter Deck Pulley – you may

have to ease it off by rotating the pulley.

6. Now replace with the CORRECT BELT (see previous page)

by reversing this procedure, taking care to fit the belt

into the ‘V’grooves.

7. Pull back the Belt Tension Lever so the belt is tensioned.

Now check and adjust belt tension as detailed on page 13.

fig 1

fig 2

fig 4

fig 3

fig 5

SECUREDUNSECURED

C

B

A

F

G

D

E

D

E

F

C

B

A

fig 6

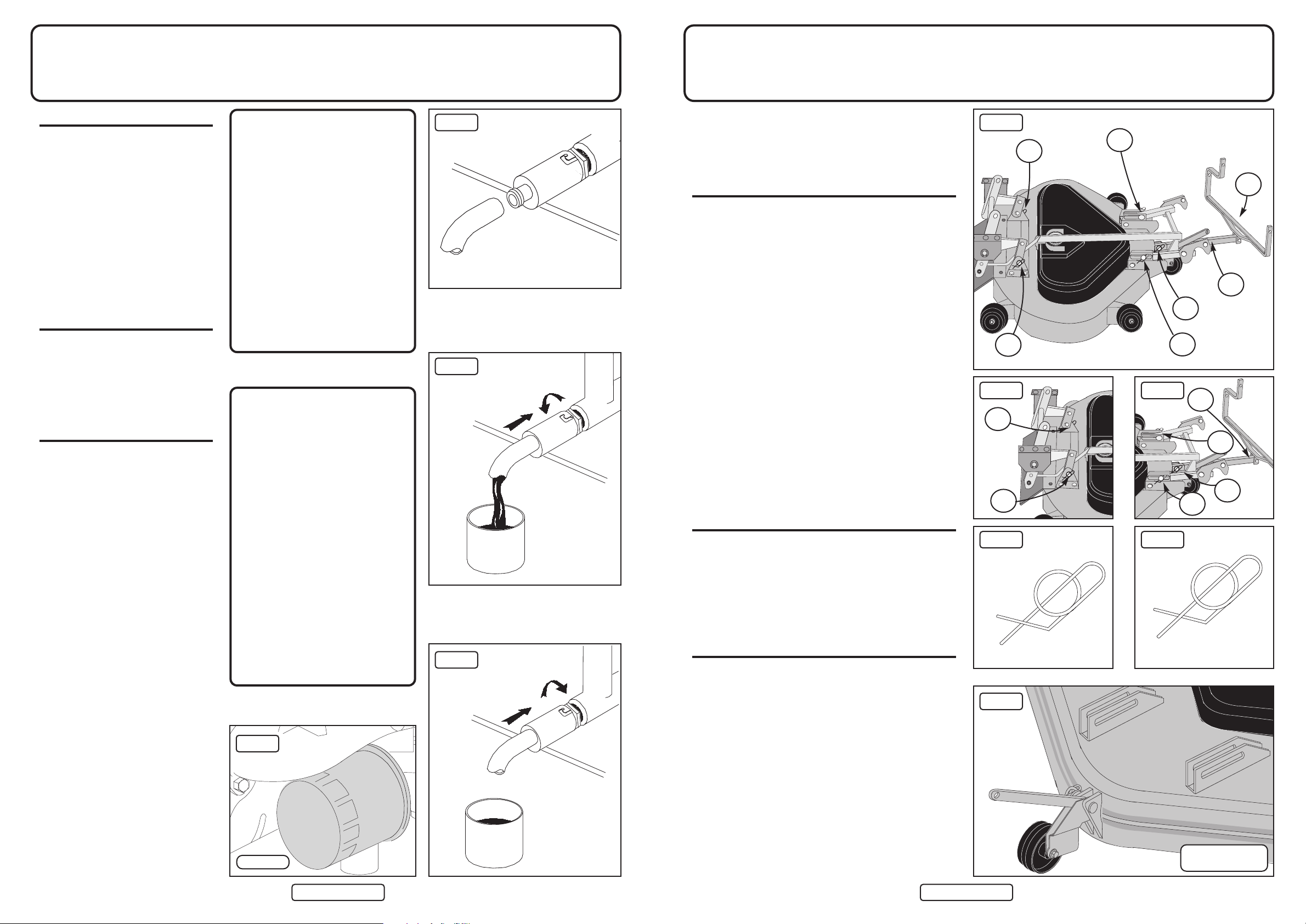

OIL DRAINING

NOTE: OIL SHOULD BE CHANGED

WITHOUT FAILAFTER THE FIRST

FIVE HOURS OF RUNNING.

The A20/50 Tractor has an oil drain

adaptor (fig 1) located on the right hand

(off side) of the engine. This is like a

bayonet light fitting, which you push in

and turn anti-clockwise to release. A

short length of clear hose is supplied in

the toolkit that fits on this adaptor so that

waste oil can be poured into a can or

bottle.

BEFORE DRAINING

* Start up the engine and allow to idle

until it is warm (about five minutes).

* Switch off the engine, lift open the

bonnet, and unscrew the oil

cap/dipstick.

TO DRAIN

* Locate the Oil Drain (fig 1).

* Remove the Yellow Dust Cap.

* Fit the short length of hose supplied

over the nozzle of the adaptor (see fig

2) and direct the other end into a

container large enough to take 2 litres

of waste oil.

* Press the adaptor in; turn anti-

clockwise to lock (fig 3). Remove hose

and store for next use. Replace Yellow

Dust Cap.

* Refill with recommended oil (SAE30

detergent oil classified for service SG, SF, SE) to engine manufacturer’s

instruction.

DO NOT OVERFILL

The use of lubricants that are not

recommended may lead to excessive

wear or damage - and this will NOT be

covered by warranty.

ALWAYS READ AND FOLLOW THE

ENGINE MANUFACTURER’S

INSTRUCTIONS ON ALL MATTERS

RELATING TO USE AND

MAINTENANCE. OBSERVING THE

OIL CHANGE INTERVALS WILL

GREATLY ENHANCE THE SERVICE

LIFE OF YOUR ENGINE!

N.B.

The information contained in

the following pages is given

on the understanding that

Countax accepts no

responsibility for work

carried out by a customer or

for any damage thus caused

whether or not the service

instructions have been

misunderstood. To be

absolutely sure that your

warranty terms are not

breached, service work

should only be carried out by

a Countax dealer.

Before carrying out any

repair or servicing

Ensure that the Tractor is on

a firm level surface.

Apply the handbrake.

Disconnect the battery.

Extinguish all naked flames.

Oil Filter

fig 4

fig 1

fig 2

fig 3

Removal of Fifth

Anti-scalp wheel

Page 10 Page 19

Tyres - Removal of WheelsCutter Deck - Check List

CUTTER FAILS TO START OR CUTS OUT

WHEN SWITCHED ON

Check:

* Are you on the Tractor? – Unless you sit on the seat the safety

switch cuts out the Cutter Deck.

* Is the battery low? – The Clutch Engage Switch will only

operate if the battery is well charged.

* Does the 10Amp-blade fuse on the printed circuit board need

replacing? (see page 22)

* That either the cutter switch or the safety switch on the seat is not

faulty – if so, call your dealer.

UNEVEN CUT (CUTS SHORTER ONE SIDE

THAN THE OTHER)

Check:

* That the tyres are all inflated to the correct pressure (see back

page).

* That the front axle is pivoting freely.

* That the deck suspension brackets are moving freely and not

hitching up.

* That the side to side deck level adjustment is correct

(see page 12).

CUT IS UNEVEN OR UNTIDY IN ONE OR MORE

SECTORS

Check:

* That Cutter Deck is levelled correctly front to back (see page 11).

* That one or more of the blades are not worn or damaged – if so,

call your dealer.

THE CUTTER SEEMS TO LOSE POWER AND

THE BELT SLIPS AND OVERHEATS

Check:

* That the Tensioner Rod is correctly applied.

* That the Cutter Belt Tension is correct (page 13).

* That the Cutter Deck is not clogged with wet cuttings.

* That the Cutter Drive Belt is not worn.

We do not recommend that customers attempt to

change cutting blades themselves - Remember

that it is never worthwhile to have blades

reground - It is cheaper and better to replace.

Re-grinding is likely to affect the hardening of the

blade and its balance.

Page 18 Page 11

Deck Levels - Front to BackTyres - Check List

The Cutter Deck should be set so that it is parallel to the

surface it is cutting with a maximum variation from side to

side, or front to back of 3mm. Check this by placing the

Tractor on a hard level surface and measuring the clearance

heights front to back and side to side with a steel ruler or tape

with the Cutter set one adjustment up from its lowest position.

If the Cutter Deck seems to require levelling first check these

other possible causes:

1. Are the tyres inflated correctly all round – if not, inflate to

the correct pressures.

2. Are the Cutter Deck Hanger Brackets (fig 2) moving

freely or are they hitching up. To check this lift the cutter

deck to its highest position and lift and rock it, watching to

ensure that the brackets move freely – if not clean and

grease.

3. Is the Front Axle pivoting freely? – If not, clean and oil.

4. Is there any impact damage that has bent or distorted the

Deck or Suspension Brackets (a matter for your dealer).

If the Deck is still uneven: -

LEVELLING FRONT TO BACK

(You need two people for this operation – one to lift the Deck

while the other removes or relocates the Trunnion)

1. Ensure that the Anti-Scalp Wheels are all adjusted in the

same hole – if not, rectify (fig 3).

2. Lower the Cutter Deck to a position one above the lowest

setting – check levels with the ruler or tape.

3. Now locate the front to back Adjustment Rod to the right

(offside) of the cutter. At the rear end of this Rod, near the

rear offside wheel, you will find the Trunnion (fig 2) that

links the rod to the Deck Hanger Bracket. Both the

Trunnion and the Rod are threaded and adjustment is

achieved by rotating the Trunnion to ‘in effect’shorten or

lengthen the Rod.

4. To free the Trunnion use a 9/16" spanner or socket to

remove the 3/8" Nyloc nut and washer and push it free.

5. Rotate the Trunnion to advance it up the Rod to lift the back

of the Deck. Rotate it the other way to lift the front.

Adjustment is rapid so try one or two turns and relocate the

Trunnion Bracket and secure – then check the effect. Repeat

and re-check if necessary.

TOOLS REQUIRED:

Steel Ruler or Tape

9/16” AF Socket

1/2” Spanner

1/2” Socket

13mm Spanner

13mm Socket

Reversible Ratchet

12” Extension Bar

fig 1

fig 2

fig 3

Front to Back

Adjustment Rod

Countax Tractors are fitted with grassland tyres that are designed to present a

large area to the ground for grip; and are soft profile to prevent marking your

turf. They are of thicker section and tougher than most 4 ply tyres.

Persistent punctures and tyre deflation are nevertheless a problem experienced

by about 5% of Countax customers. This is not a problem just for Countax

owners – it is shared by the users of all types of off-road machinery fitted with

pneumatic tyres. In practically every case there is a common cause – THORNS!

Blackthorn, Hawthorn, and Rose are usually at the bottom of it and will

puncture any tyres not fitted with very expensive guards.

There are less expensive ways to overcome this problem – so check and avoid

these possible causes:

1. The rim of the wheel has become damaged –breaking the seal on the

tubeless tyre. There are two possible solutions:

* If the damage is not severe, treat with Countax tyre sealant (Pt No 52903501).

* If the damage is significant – order a new wheel

Front wheel - (Pt No 198000500)

Rear Wheel - (Pt No 198000700)

2. You have Hawthorn, Blackthorn, or Wild Rose in your hedges – these will

puncture any tyre. It makes sense to check any area you intend to cut or drive

over and to remove any branches.

The long-term solution is to treat all four tyres with Countax tyre sealant –

follow the instructions on the bottle.

IF YOUR TYRES SPIN OR LOSE GRIP CHECK:

1. Are the tyres correctly inflated –

• Front wheels 0.8Kgf/cm (12lb PSI)* to 1.1Kgf/cm (16lb PSI)

• Rear wheels 0.43Kgf/cm (6lb PSI)* to 0.7Kgf/cm (10lb PSI)

*Pressure recommended for maximum grip.

2. Are you in too high a gear for the conditions? If so, select a lower gear or

speed setting.

Deck Hanger

Bracket

Anti-Scalp

Wheels

Trunnion

Rear Deck

Cradle

Adjustment

holes

Page 12 Page 17

Collector BrushCutter Levelling Side to Side

LEVELLING SIDE TO SIDE

Adjustment is best done with the Deck in

a position one up from its lowest cut –

check the level both sides and levelling is

then achieved by adjusting the left

(nearside) of the Deck at two points:

REAR ADJUSTMENT

1. Find the Deck Level Disc (fig 1)

near the back nearside wheel. This has

a concentric slot in which the Deck

Levelling Rod is located.

2. Using a 13mm spanner, loosen the

8mm Nyloc nut

A securing this stud

just enough to permit some movement.

3. Now lift or depress the Deck

depending on the adjustment you wish

to achieve. This will move the disc up

or down around the stud

B – the higher

up and nearer the centre of the disc the

higher the Deck is lifted on the left

hand side.

4. Check with your ruler or tape and

having levelled the Deck at the rear,

re-tighten the Nyloc nut.

FRONT ADJUSTMENT

1. Having levelled the rear of the Deck

check if the front is level. If not, you

will need to find the Deck Adjustment

Plate (fig 2) which is forward of the

Cutter Deck near the front (nearside)

wheel.

2. Before making adjustments loosen the

two sets of nuts and bolts (

A and B)

securing the Deck Levelling Bracket

(

C) using a 13mm spanner and 13mm

socket.

3. Then, using a 13mm spanner, loosen

(upper) locknut (

D).

4. Now adjust the height by using a

ratchet or spanner to turn the Nyloc nut

(

E) clockwise (up) to raise the Deck or

anti-clockwise (down) to lower it.

5. When level is achieved tighten up all

nuts and bolts.

For the closest cut set the anti-scalp

wheels (fig 3) in the middle adjustment

holes. If you are experiencing scalping

this can be minimised by setting the

wheels in the lowest adjustment holes.

Page 16 Page 13

Cutter - Drive BeltCollector - Drive Belts

Before carrying out tests or adjustments

(the problem may be simpler) – first

CHECK the following points:

1. Is the Engine to Cutter Drive Belt

slipping? Check that the Drive Belt

Tension Lever (fig 1) under the left

running board is in the rear (tensioned)

position. If not, rectify – this is the

most likely cause.

2. Has debris collected in the Cutter Deck

Pulley Housing (Page 9)? If so remove

the cover and remove the

obstruction.

ENGINE TO CUTTER DRIVE

BELT TENSION

The correct tension of the Cutter Drive

Belt (Engine to Deck) is critical. If

incorrectly set it can lead to engine

damage.

To check the tension, follow this

procedure:

1. Put the Deck in a middle cutting height

position (5 on the decal).

2. Select the midway position on the Belt

between the front (Electric Clutch)

pulley and rear (Cutter Deck) pulley

and using, a spring balance; apply a

2Kg (4 to 5lbs) pull (fig 2).

3. Using a ruler or tape, measure the

deflection achieved which must be

13mm (1/2"). If more the belt tension

must be increased, if less decreased.

To correct the tension, follow this

procedure:

1. Release the tension on the belt by

pulling the Belt Tension Lever forward

(see fig 1).

2. Taking care not to burn yourself on a

hot exhaust, locate the Trunnion at the

end of the Belt Tension Rod – lift the

bonnet and look to the front (nearside)

close to the exhaust (see fig 3).

3. Remove the spring clip and washer

holding the Trunnion in place on the

Deck Tension Cradle (fig 3a) and

release the Trunnion so it can be

turned.

4. Both the Trunnion and the Belt Tension

Specified Belts and Blades

Engine/Deck Belt - B57 Dayco Super II -

Pt No. 22940100

Deck Internal Drive (Mulcher) - BB112

Pt No. 228000900

(Rear Discharge) - Dayco Super II BB155

Pt No. 22950200

Mulcher Blades x3 Pt No. - 16938100

IBS RH Blade Pt No. 169381300

IBS LH Blade Pt No. 169381400

IBS Front Blade Pt No. 1692000

PGC A49 Drive Belt Pt No. 22923400

PTO Drive Belt - Dayco Super II A92 -

Pt No. 22950100

Transmission Drive Belts - A91 Dayco

Super II - Pt No. 228001500

N.B. Only use specified Belts and Blades

- Never accept a substitute!

Rod are threaded. You increase Belt

tension by winding the Trunnion

towards the end of the Rod and reduce

tension by winding in the reverse

direction.

5. Having made the adjustment re-locate

and secure the Trunnion, re-tension the

Belt with the Belt Tensioner Lever –

then re-check the Belt tension.

ON NO ACCOUNT MUST THE

TRACTOR BE RUN WITH THE

ENGINE TO CUTTER DRIVE BELT

OVER-TENSIONED AS IT WILL

DAMAGE THE ENGINE. As any such

damage will NOT be covered by

warranty you may prefer that your

dealer sets the tension.

fig 1

fig 2

fig 3

View from underside

Trunnion

Deck Tension

Washer

Cradle

Spring Clip

Deck Tension Rod

WARNING

REPLACING AND

TENSIONING PTO DRIVE

BELT CONNECTION

It is important that the belt from PTO to

collector (Part No. 22923400) is crossed

over in the correct direction (fig 1) before

being fitted over the collector pulley. The

easiest way to do this is to place the belt

on the PTO pulley and then stand behind

the Tractor holding the belt with two

hands. Turn the right hand above the left

and fit the belt on to the collector pulley.

To check that you have this right - start

your Tractor and engage the PTO lever

and check that the brush is revolving

against the forward direction of the

Tractor (see page 15 fig 1).

CORRECT BELT TENSION

To check tension:

1. Lower the collector to the operating

position and check the tension using a

spring balance and a ruler.

2. Select a place on the belt midway

between the PTO pulley and the

collector pulley.

3. Pull and measure the deflection using a

ruler (fig 2). It should be 19mm at 2kgs

(4-5lbs).

If the tension needs to be adjusted - first:

1. Relocate the Collector from the

Tractor.

2. Locate the adjustment holes on the

Locking Arms. These holes take the

nuts and bolts on which the Locking

Arm hinges.

3. To increase tension on the belt undo

each nut and bolt and relocate them

one or more holes forward (towards

the Tractor). To slacken move the bolts

back. Ideally the bolts should be in the

same hole on each Locking Arm,

however fine adjustment to get the

right tension may only permit you to

move one bolt - this is OK but there

should not be more than one hole

difference from side to side.

4. Replace the Collector on the Tractor

and re-check the belt tension.

CHECKING, TENSIONING

AND REPLACING SIDE

DRIVE BELT (fig 3)

1. First remove Collector from the

Tractor (page 14).

2. To remove the plastic cover, remove

the two nuts and bolts (A) using a 1/2”

spanner and socket.

3. Using a 1/2” spanner and socket,

slacken the nut and bolt (B) holding

the tension pulley and slide the pulley

out of the way.

4. Remove the belt and fit the Countax

replacement (Dayco Super II A38 Part

No. 22950300)

5. Tension the belt by sliding back and

securing the belt tensioner. The tension

is not critical but the belt must not be

too tight. The ideal is 13mm (1/2”)

deflection at 2Kgs (4/5lbs) pull use a spring balance and ruler or tape

to check.

6. Make sure that the rectangular cover

plate fits over the adjustment slot failure to do this will allow cuttings

and grit to accumulate and damage the

pulleys and belt assembly.

7.Replace the plastic cover.

PLEASE NOTE:

The information contained in

the following pages is given

on the understanding that

Countax accepts no

responsibility for work

carried out by a customer or

for any damage thus caused,

whether or not the service

instructions have been

misunderstood. To be

absolutely sure that your

warranty terms are not

breached, service work

should only be carried out by

a Countax dealer.

fig 3a

19mm deflection 2kgs push or pull

To Tighten

To Slacken

fig 1

fig 2

fig 3

Cutter Belt

De-Tensioned

Cutter Belt

Tensioned

A

Kg

B

cm

Kg

cm

Page 14 Page 15

Collector AdjustmentsPowered Collector

CONNECTION

To connect the Powered Collector to the

Tractor, ensure that both are on an even

surface with the Locking Levers (fig 3)

on the collector facing the Lift Arms on

the Tractor. Move the collector manually

to the Tractor. Lower the Lift Arms using

the button (Page 6 fig 3) on the dash

console.

At the end of each Lift Arm you will find

a Locating Lug . Slide the Channels on

either side of the Powered Collector over

the Lugs but do not engage the Locating

Lever yet. Ensure that the Rubber Flap at

the opening of the PGC locates on top of

the Transmission Grass Deflector.

INSTALLING THE DRIVE

BELT

Place the Drive Belt over the PTO pulley

(beneath the Tractor seat). Standing

adjacent to the Tractor, extend the belt

with both hands parallel to the ground.

Now twist the belt to form a figure ‘8’the right-hand up and the left-hand down.

In this position place the other end of the

belt over the Powered Collector Pulley.

Be sure that this is installed the right way

round otherwise the brush will work in

reverse and collection will be poor!

Lock Locating Lever (fig 3) over the Lift

Arm Lugs . Rotate Locking Clips over

Lift Arm Lugs.

PTO DRIVE BELT TENSION

Engaging the Locating Lever tensions the

belt which should not be run too tight - to

check the tension there should be a 19mm

deflection with light finger pressure

(2Kgs) at a midway point between PTO

pulley and Sweeper pulley. It is

important after attaching the Sweeper to

the Tractor, to check the Belt Tension and

adjust this if necessary; this must be done

before the Sweeper is put into operation

and with the Sweeper on the ground.

With light finger pressure, 2kgs (4lbs),

there should be a total deflection of

19mm (3/4”) at midway point between

PTO pulley and the Sweeper pulley. If a

spring balance is available a pressure of

4-5lbs (1.81-2.26Kgs) is required for a

deflection of 3/4” (19mm).If the Belt

Tension is incorrect it can be adjusted by

movement of Sweeper Locking Levers

on the threaded rod. Ensure the lock nuts

are suitably tightened after adjustment.

N.B. Do not overtighten lock nuts as

lever needs to pivot.

TO USE: RAISE SWEEPER TO THE

TRANSPORT POSITION

Using the switch on the dashboard, lift

the PGC to the transport position. We

recommend that you drive to and from

the area to be swept with the Powered

Collector in this transport position and

with the P.T.O disengaged.

When you reach the area to be swept,

lower the collector and then engage the

brushes by pushing the sprung PTO lever

to the right to release and engage.

LOWER THE COLLECTOR

Using the lever (page 15 fig 2), lower the

collector.

REMOVING THE NET

When removing the net, we suggest you

employ the assistance of another person.

1. Partially open the Sweeper net

(100mm (4”)). Disconnect opening rod

by pulling back on sprung locking tube

and uncoupling from pin (fig 2).

2. Repeat either side.

3. Undo net locking clip (both sides),

unhook levers from locating pins

(see fig 2).

4. With either person standing each side

of the collector net, slide the net off the

locating arms.

5. Reverse operation for fitting.

fig 1

fig 2

Loading...

Loading...