Count EZCREASER User Manual

EZCREASER

4-2009

Version 1.6

Serial Number ___________________________

Date ___________________________________

INTRO LETTER

Congratulations,

You have purchased the most versatile automatic creasing machine on the market today. Designed to

accommodate the demands of finishing digitally produced media, the EZ Creaser efficiently applies a

rotary actuated compression crease, leaving a crisp, sharp score with no cracking of the image after

the fold, on both the outside and inside creased edge.

Counts trademarked RAC System assures a consistent, controlled compression that is easily adjustable

to the demands of any sensitive media.

The EZ Creaser with it’s microprocessor driven transport promises many years of profitable operation.

Your EZ Creaser was manufactured at Count’s headquarters in Escondido, California. We are proud to

build quality equipment and stand behind our machines knowing that the quality of our product is

exceeded only by the staff which supports it.

Thank you for choosing Count.

Sincerely,

David M. Gilbert

TABLE OF CONTENTS

(JANUARY 2007)

SPECIFICATIONS…………………………………………………………………………………………….1a

SAFETY PROCEDURES/CARE & MAINTENANCE.………………………………………………….1b

COMPONENT IDENTIFICATION…………………………………………………………………………2

SETTING UP YOUR EZ CREASER……………………………………………………………………….3

W/ Optional Stand………………………………………………………………………3

MICROPROCESSOR CONTROLLER EZ CREASER………………………………………………….4

Transport Operation Controls……………………………………………….………5

Programming Controls (mode Selection)…………………………….……..…5

Programming for Creasing………………………………………….…….…………6

Setting up Creasing…………………………….……………………….……….……6

Batch Counter………………………………………………………………….……….7

Total Counter……………………………………………………………………………8

Double Sheet Detector………………………………………………………………8

Programming Notes…………………………………………………………………..8

DELIVERY TRAY ASSEMBLY…………………………………………………………………………….9

FEED TABLE ASSEMBLY………………………………………………………………………………….9

Component Identification…….…………………………………………………….9

Adjusting Feed Rails………..……………………………………………….………10

Setting the Automatic Feeder…………………………………………………….11

Fanning the Paper…………………………………………………………………….11

Loading the Feeder…………………………………………………………………..12

Replacing the Feed Wheels………………………………………………….……12

Feeding Notes…………………………………………………………………………12

Replacing the Friction Plate………………………………………………..……..13

Checking the Sensor…………………………………….…………………………..13

Perf Shaft & Strike Plate……………………………………………………………14

Removing the Perf Shaft to Change Configurations………………………14

ROTARY PERF & SCORE ASSEMBLY………………………………………………………………..15

Component Identification………………………………………………………….15

Perforation & Scoring Assemblies……………………………………………….15

Gripper Wheel Perf Score Mounting……………………………………………16

Folding Direction of Paper…………………………………………………………16

RAC

System

Component Identification……………………………………………….………..17

TROUBLESHOOTING………………………………………………………………………………………..…20

SERVICE DIAGRAMS……………………………………………………………………………………….21-24

(Rotary Actuated Creasing) Assembly……………………………………….17

Adjusting RAC rollers (depth of crease)……………………………………..18

Changing Lower Crease Die……………………………………………………...19

ELECTRICAL SPECIFICATIONS

Power Requirement: 110v, 60 HZ, AC, or International 230v, 50/60HZ, AC

Circuit Protection: Motor/Transformer………………………..3 AMP Circuit Breaker

Microprocessor……………………………..1/4 AMP Slo-Blow

Pulse Board………………………………….3 AMP Slo-Blow

NOTE: Older buildings, overloaded lines, and bad grounds can affect the operation of

your EZ Creaser. A dedicated line is best.

OPERATING SPEEDS

MODE TRANSPORT SPEED 11X17 Sheet(est) 5 ½” Sheet(est)

(Feet per Sec.)

Perf Mode 2.5 8500 12500

Crease Mode 2.0 2500 4400

SPECIFICATIONS

Net Weight: EZ CREASER……………………………………………..250 lbs

Overall Dimensions: …………………………………………………………………32”Lx27”Wx26”D

Boxed Dimensions: …………………………………………………………………36”Lx36”Wx30”D

Min. Sheet Size: ………………………………………………………………..3”x5”

Max. Sheet Size: …………………………………………………………………18”x20”

NOTE: The EZ CREASER is capable of handling many types of applications above and

beyond the standard specifications. It is possible to feed quite a variety of jobs, from

30” sheets to die cut stocks. However, the performance of the EZ CREASER on these

special applications is directly related to the experience of the operator.

1a

BEFORE USE:

• Read through the owner’s manual. Follow instructions CAREFULLY.

• NEVER use a wet area. Electric shock could occur.

• Use a GROUNDED outlet and a GROUNDED circuit. Do no use ungrounded

equipment on the same circuit.

• Always use a dedicated line. DO NOT use with line splitting surge protector.

DURING USE:

• Keep fingers and hands away from creasing bar, perf blades, and rubber

rollers.

• Keep cords clear of moving parts.

AFTER USE:

• Turn off machine at the rear panel, then unplug the main power cord. This

will prevent damage to your machine by power/voltage spikes.

• To unplug cords, always grasp the plug body, never pull on cords to

disconnect. Wire fatigue and possible shock could result from improper

disconnect procedures.

BE ALERT! BE CAREFUL!

SAFETY PROCEDURES

CARE AND MAINTENANCE

The EZ CREASER is a precision machine. It is very important to keep it free of excessive

dust, dirt and foreign matter. We recommend that you keep the machine

when not in use.

BEARINGS: The bearings are sealed roller bearings and are designed to be self

lubricating, however dirt and dust can get into them causing clogging and dirt build up.

It is recommended to occasionally oil them under heavy use.

STRIKE DIE: The groove in the lower die should be cleaned periodically using a

toothbrush to remove any dirt or build up.

SENSOR EYE: Clean the upper and lower sensor with a Q-tip (avoid moving the sensor

to clean). Clean when necessary.

REMOVEABLE SCREWS: When these show signs of wear or stripping, replace as soon

as possible. If these strip or hollow out they can be costly to remove. If you do keep

your EZ CREASER clean and in top condition, it will give you years of service.

1b

covered

Machine Stand

Pg. 3

COMPONENT IDENTIFICATION

Feed Rail Assembly

Perf and Score Assemblies

Crease Bar

Feed Table Assembly

Paper Stop

Delivery Tray

Microprocessor Pg. 4

Feed Table Assembly Pg. 9

Delivery Tray Pg. 9

Perf and Score Assemblies Pg. 15

Crease Bar Pg. 17

REFERENCES

2

Microprocessor

Machine Stand

SETTING UP YOUR EZ CREASER

STAND (

1. Open top half of box and remove components.

2. Assemble stand.

3. Place machine on stand as shown below.

4. Unscrew feed rail guide shaft, slide shaft out.

Place feed rails on feed table and slide shaft

back in going through feed rail guide brackets.

5. Place delivery tray in front so tray hooks under steel dowels directly below the exit

shaft shaft. Locate the magnetic paper stops and position them on the tray.

6. Inspect the remaining parts and place them near the machine where they are easily

accessible.

7. Plug in your machine. NOTE: the EZ CREASER required only 115v so any standard

outlet will accommodate it. However, it is important that the line has a good ground.

Also make sure the circuit is not overloaded with other equipment.

(NOTE: 230v will be used for European models)

optional

)

3

EZ CREASER

MICROPROCESSOR CONTROLLER

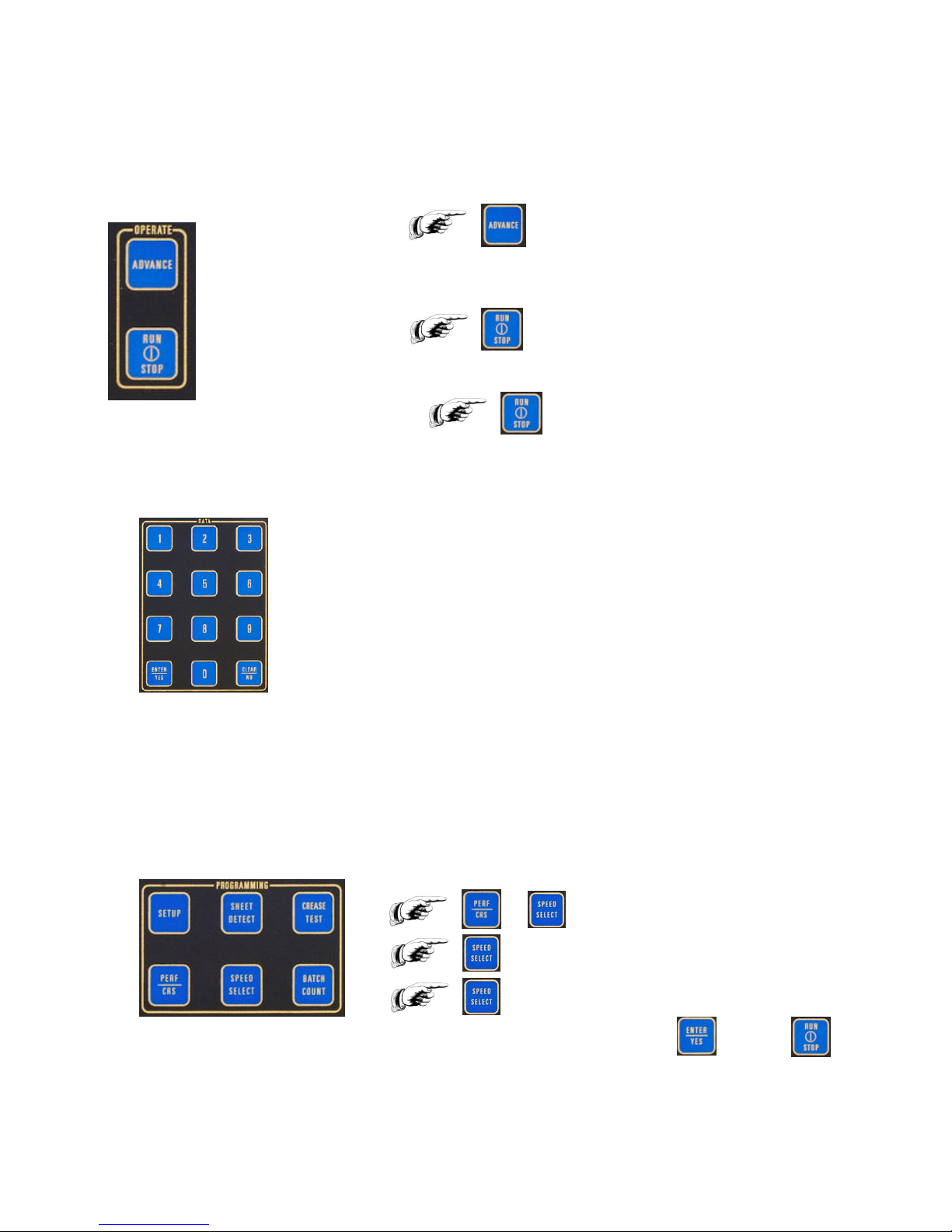

THE MICRO-CONTROLLER CONSISTS OF FOUR SECTIONS:

2. Operate Controls

3. Programming Controls

4. Data Pad

Controller Display

The LCD displays programming information, prompts response, and verifies entered

data or commands. The LCD also conducts a self-diagnosis test whenever power is

turned on. A countdown sequence from 9 to 0 will appear. If a number is missing from

the sequence this indicates a failure in a component. If this occurs, contact the Count

service department for further details. At the display of “EZ Creaser” the microprocessor

is clear and ready to accept the entries. The micro-controller is also equipped with

volatile memory so when power is turned off the EZ Creaser will retain the last

programmed entry.

1. Controller Display

4

TRANSPORT OPERATION

• A document may be slowly advanced through the transport by

pushing and holding this button.

EXAMPLE:

The motor should advance transport at slow speed and stop

whenever finger is lifted.

• Controls on-off function of motor.

EXAMPLE:

Machine will run at mode and speed previously selected. If no

mode has been selected, it will automatically run in perf mode

at low speed.

• Machine will stop.

NOTE: If the EZ CREASER is stopped while a sheet is under the sensor,

the display will flash “sensor blocked”

••••Data Keys 0-9:

required for distances and crease designation.

••••Enter/Yes:

keys and answers display prompted questions.

••••Clear/No:

for clearing total count. Answers “no” to display

prompted questions.

PROGRAMMING CONTROLS

Speed Select:

the speed selected on the display.

Mode Select: PERF/CRS

runs in. By Default and every time your machine is powered off the machine will

start in PERF mode. Press the PERF/CRS mode button twice to enter into Crease

Mode.

EXAMPLE: DISPLAY READS:

These may be pressed until the desired mode is selected, then: Pressing

will now run transport at selected mode.

Pushing this will select speed, low, medium or high and show

Pushing this will Change the mode your machine

5

DATA PAD

Allows entry of numeric data

Stores input information from data

Erases errors entered and prompts

(Mode Selection)

CRS Mode Low Speed

CRS Mode Med Speed

CRS Mode High Speed

Loading...

Loading...