Coulter STKS Troubleshooting

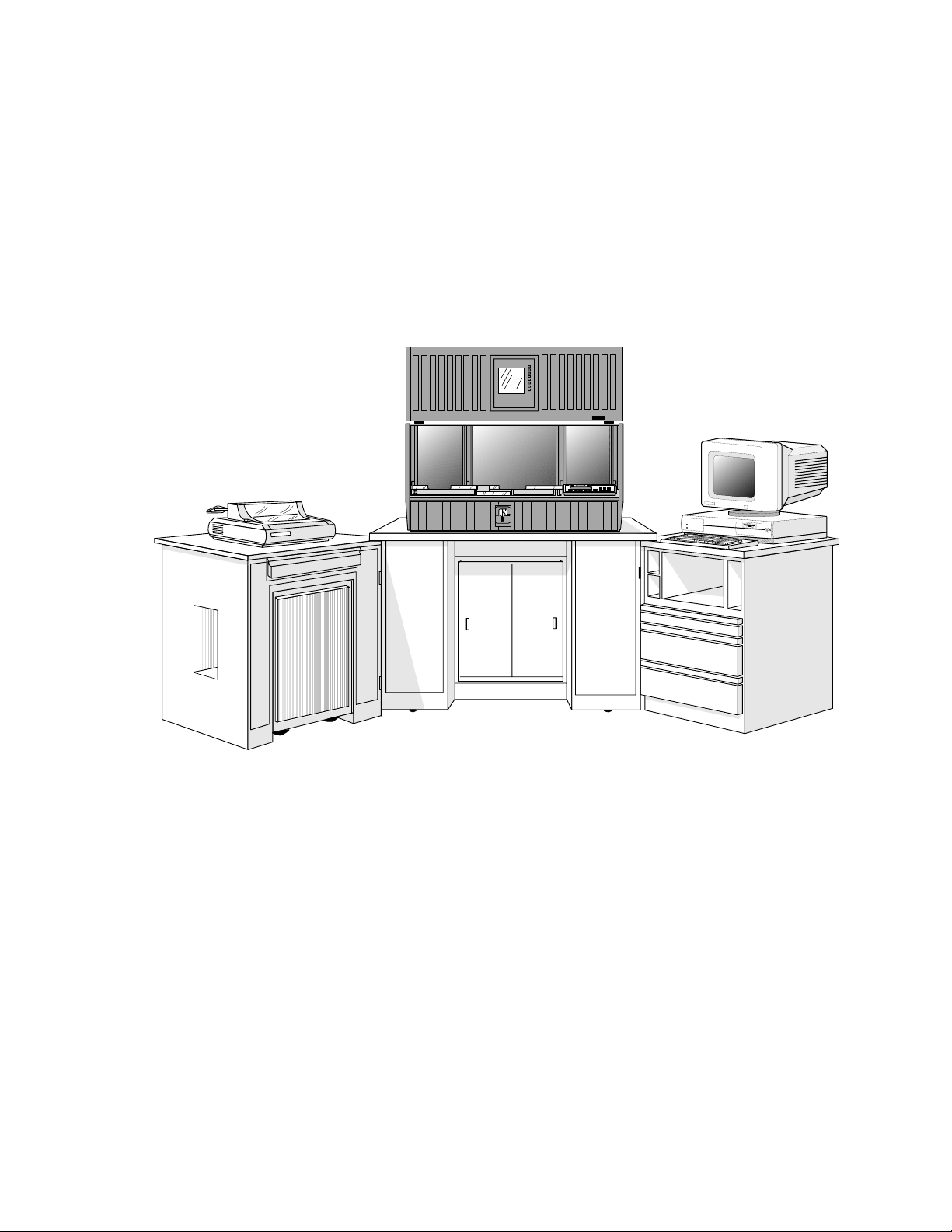

COULTER®STKS Analyzer with Reticulocyte Analysis

Special Procedures

and Troubleshooting

COULTER

STKS

PN 4237187B (March 1995)

COULTER CORPORATION

Miami, Florida 33196

READ ALL PRODUCT MANUALS AND CONSULT WITH COULTER-TRAINED PERSONNEL BEFORE

ATTEMPTING TO OPERATE INSTRUMENT

HAZARDS AND OPERATIONAL PRECAUTIONS AND LIMITATIONS

WARNINGS, CAUTIONS, and IMPORTANTS alert you as follows:

WARNING - Might cause injury.

CAUTION - Might cause damage to the instrument.

IMPORTANT - Might cause misleading results.

CAUTION|

|

System integrity might be compromised and operational errors might occur if:|

|

• Thisequipmentisusedinamannerotherthanspecified.Operatetheinstrumentasinstructedinthe|

Product Manuals.|

|

• You introduced software that is not authorized by Coulter into your computer. Only operate your|

system’s computer with software authorized by Coulter.|

Coulter Corporation urges its customers to comply with all national health and safety standards such as

the use of barrier protection. This may include, but it is not limited to, protective eye wear, gloves, and

suitable laboratory attire when operating or maintaining this or any other automated laboratory analyzer.

In the USA, for Service call Coulter Customer Operations 1-800-526-7694.

1 GENERAL SERVICE AND MAINTENANCE, 1

1.1 LASER MAINTENANCE, 1

1.2 GENERAL PROCEDURES, 1

Power Down, 3

Power Up, 3

Optimize the Disk, 3

Daily, 4

Weekly, 4

Monthly, 4

Set Screen Saver, 5

Position Rocker Bed, 6

Diluter F Key Functions, 6

1.3 COMPONENTS, 10

Cylinders (CL), 11

Manifolds (MF), 11

Pumps (PM), 12

Vacuum Chambers (VC), 12

Pinch Valve (VL) Functions, 13

Solenoid (SL) Functions, 17

CONTENTS

2 CALIBRATION, 21

2.1 GENERAL INFORMATION, 21

2.2 PRECALIBRATION STEPS, 22

Reproducibility Check, CBC/Diff, 23

Sample Requirements, 23

Procedure, Primary Mode, 24

Carryover Check, 26

Sample Requirements, 26

Procedure, 26

2.3 CBC CALIBRATION WITH S-CAL CALIBRATOR, 28

Calibration Summary, 28

2.4 CALIBRATE CBC PARAMETERS WITH WHOLE BLOOD, 37

3 CLEANING PROCEDURES, 39

3.1 CLEAN BLOOD SAMPLING VALVE (BSV), 39

Procedure A, Rinse the BSV Outside Sections, 39

PN 4237187A (November 1993) i

CONTENTS

Procedure B, Remove and Clean the BSV Sections, 40

3.2 CLEAN APERTURES, 44

Procedure A, Zap the Apertures, 44

Procedure B, Bleach the Apertures, 44

Procedure C, Clean the Aperture Baths, 49

Procedure D, Clogged Apertures, 52

Procedure E, Clear Flow Cell, 53

3.3 TRANSPORT SYSTEM, 54

Clean Rinse Trough, 54

Clean Cassettes, 56

Clean Stripper Plate, 56

Clean Rocker Bed Belt, 56

3.4 OTHER COMPONENTS, 56

Clean Air Filters, 57

Clean Vacuum Isolator Chamber (VIC), 58

Clean Waste Chamber, 60

Clean Vacuum Trap Bottle, 61

Bleach RBC Internal Electrode, 62

Drain Overflow Chamber, 64

Clean Drip Plate, 64

4 REPLACE/ADJUST PROCEDURES, 67

4.1 REPLACE REAGENTS, 67

4.2 REPLACE WASTE CONTAINER, 68

4.3 REPLACE FUSES, 69

4.4 REPLACE APERTURE BATHS, 70

4.5 REPLACE O-RINGS, 71

4.6 REPLACE CHECK VALVES, 72

4.7 REPLACE AIR FILTERS, 73

4.8 REPLACE CHOKES, 73

4.9 ATTACH TUBING TO A FITTING, 73

4.10 REPLACE PIERCING NEEDLE, 73

Decontaminate Needle, 73

ii PN 4237187A (November 1993)

Replace Needle, 74

4.11 REPLACE CASSETTE SPRING CLIP, 76

4.12 REPLACE CASSETTE LABELS, 77

4.13 CHANGE RINSE TROUGH PAD, 77

4.14 ADJUST HEMOGLOBIN LAMP VOLTAGE, 78

4.15 ADJUST TUBE DETECTOR, 79

5 TROUBLESHOOTING, 81

5.1 ANALYZER RESET PROCEDURE, 81

5.2 DMS RESET PROCEDURE, 83

DMS Not Working, 83

Printer Not Ready, 84

Lost Clusters, 84

CONTENTS

5.3 RAMP AND PRECISION TESTS, 85

5.4 RETIC REPRODUCIBILITY CHECK, 85

5.5 PROLONGED SHUTDOWN PROCEDURE, 87

5.6 ANALYZER CLOCK STOPPED, 87

5.7 ANALYZER ALERT MESSAGES, 89

5.8 DILUTER DIAGNOSTIC MESSAGES, 100

5.9 DMS ERROR MESSAGES, 107

5.10 GRAPHIC/LASER PRINTER PRECAUTIONS, 113

INDEX, 119

ILLUSTRATIONS

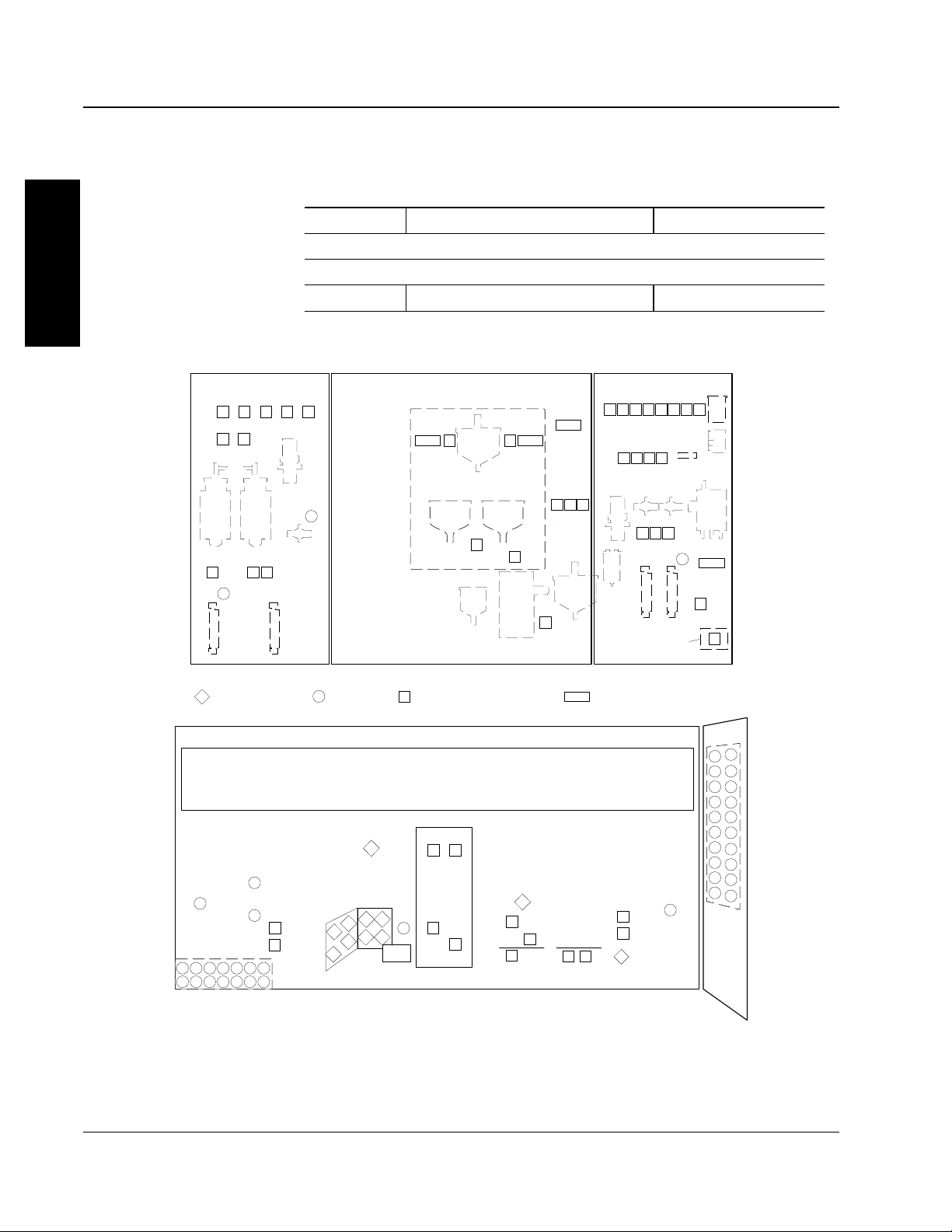

1 Diluter Front Panel, 2

2 Screen Saver Setup, 6

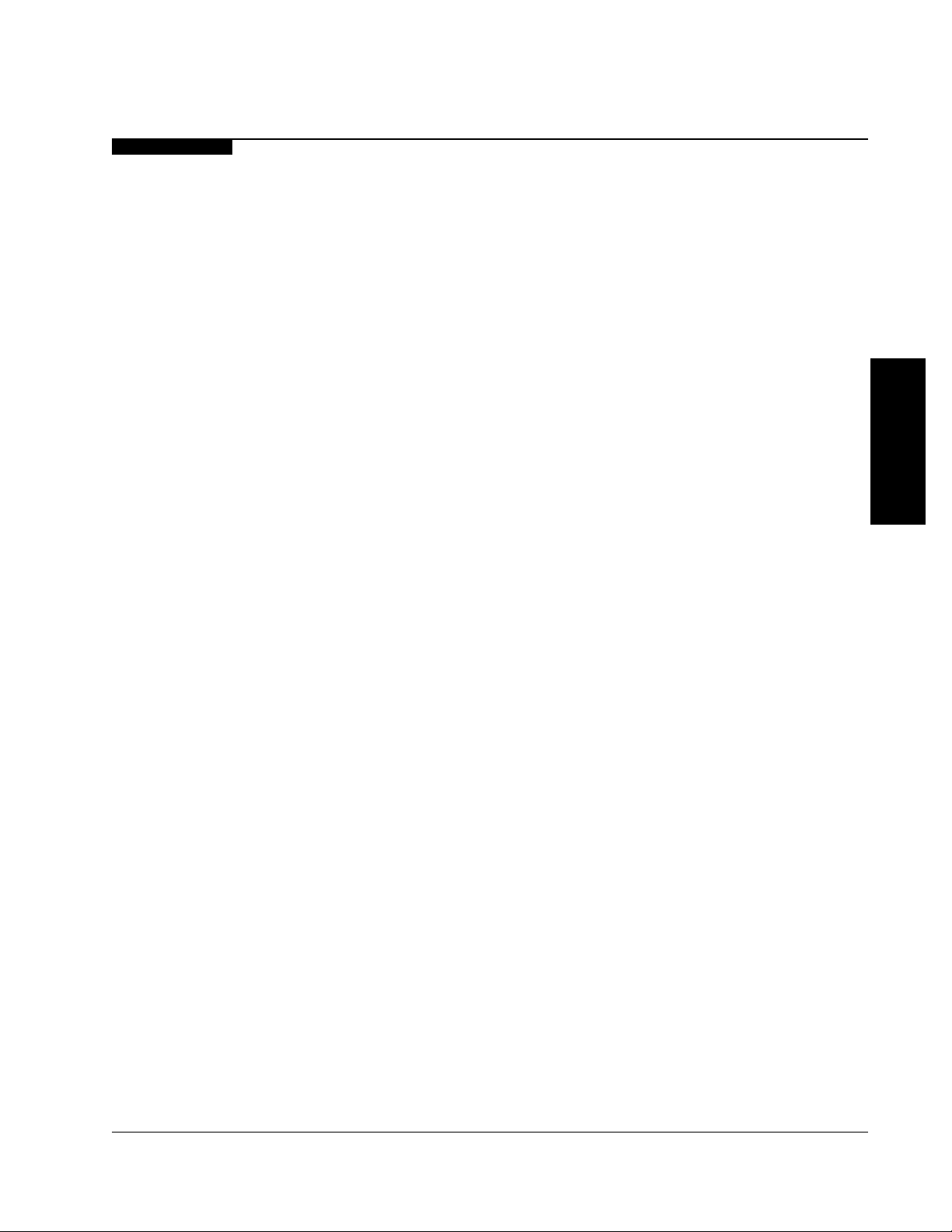

3 Pinch Valve and Solenoid Locations, 20

4 Reproducibility, 25

PN 4237187B (March 1995) iii

CONTENTS

5 Carryover Acceptable Screen, 28

6 CBC Calibration Screen, 30

7 Calibration Criteria Flowchart, 33

8 Blood Sampling Valve (BSV), 41

9 RBC and WBC Aperture Baths, 45

10 Aperture Bath, Blocks and Housings, 51

11 Rinse Trough, 55

12 Location of Air Filters, 57

13 Clean VIC, 59

14 Drip Plate, 64

15 Replace Piercing Needle, 75

16 Tube Detector Adjustment, 80

17 Reset Button Location, 82

18 Retic Reproducibility, 86

TABLES

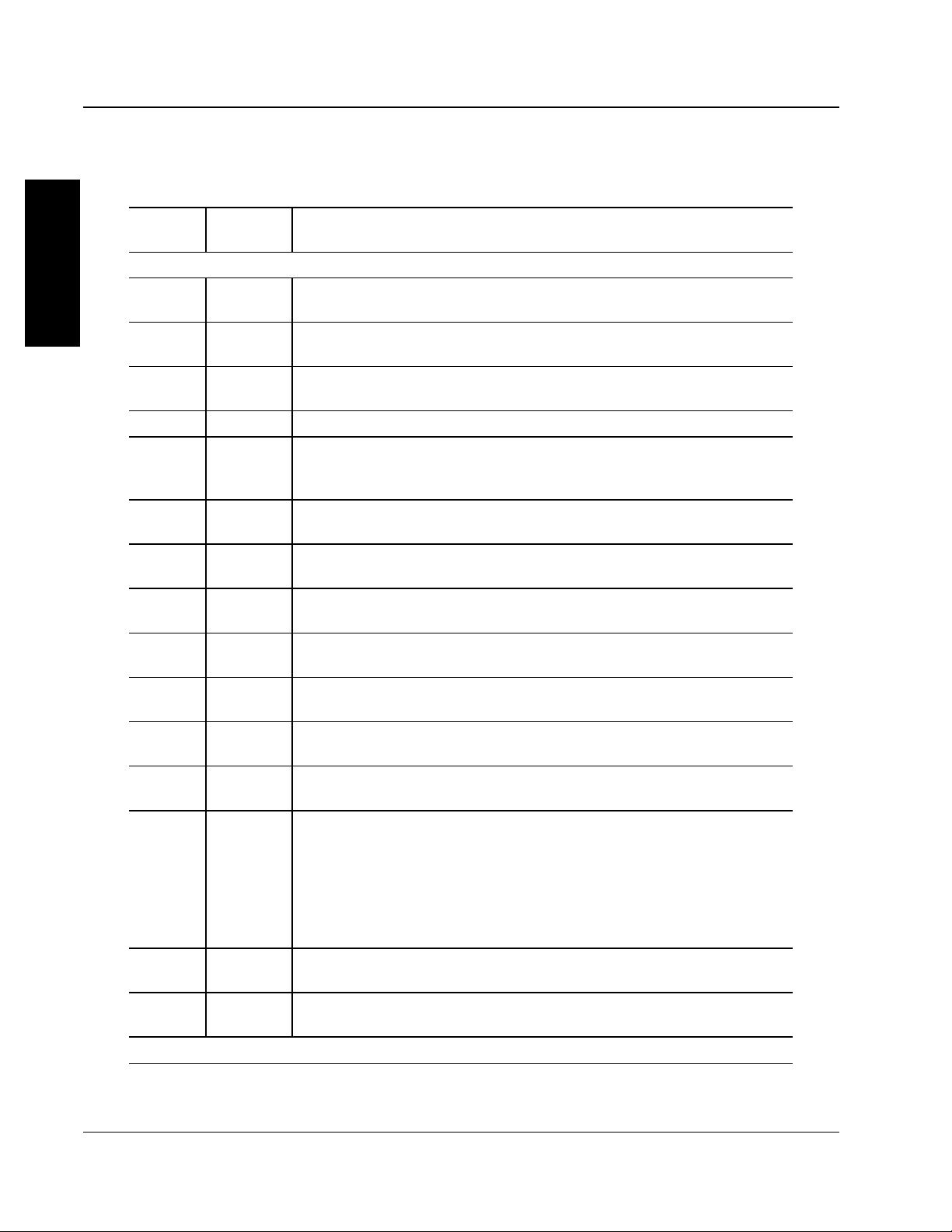

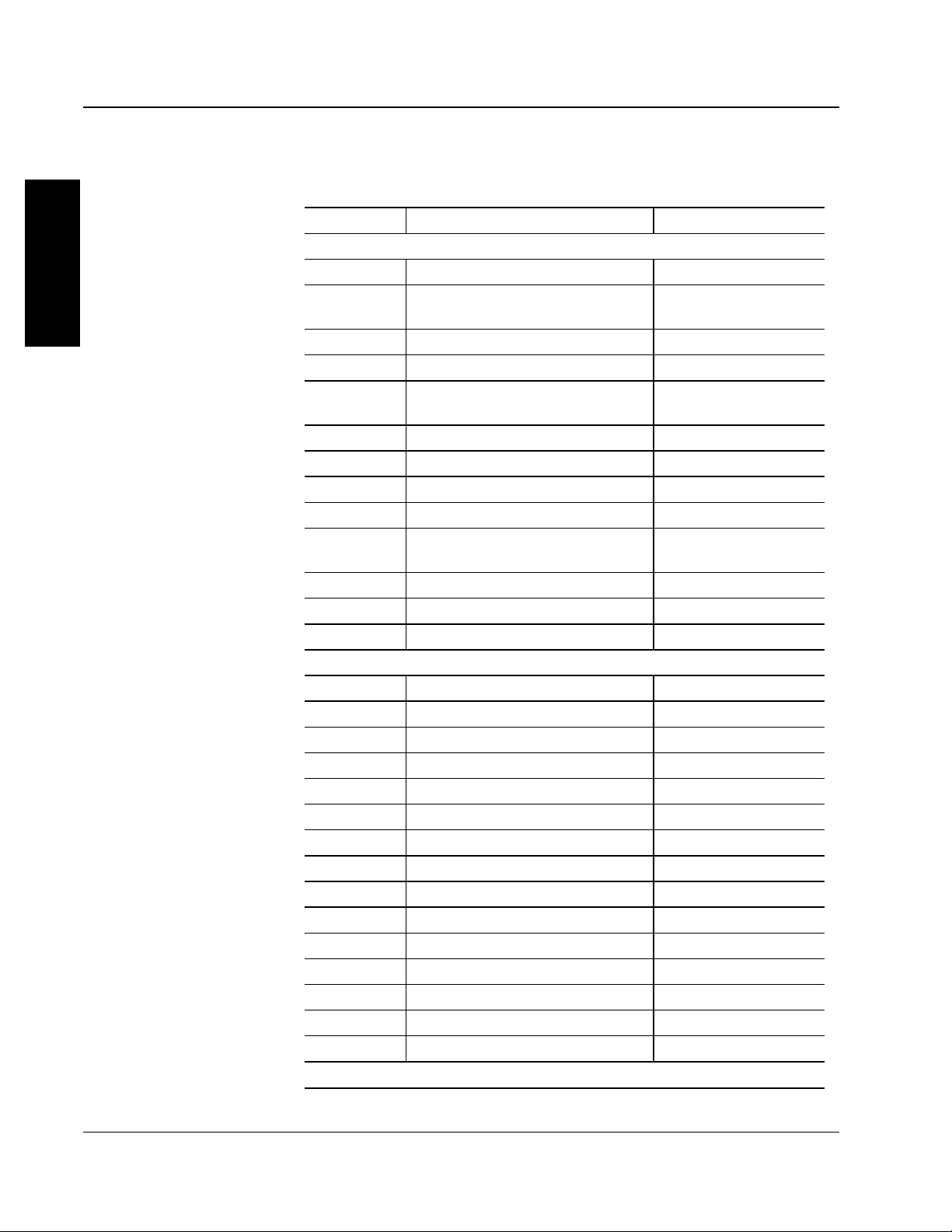

1 Diluter F Key Functions, 7

2 Cylinders, 11

3 Manifolds, 11

4 Pumps, 12

5 Vacuum Chambers, 12

6 Pinch Valves, 13

7 Solenoids, 17

8 Open-Fuse Indications, 69

9 Analyzer ALERT Messages, 89

10 Diluter Diagnostic Messages, 101

11 DMS Error Messages, 107

iv PN 4237187B (March 1995)

1.1 LASER MAINTENANCE

All service and maintenance of the laser module must be done by trained

Coulter personnel. Removal of the module must be performed only by a

Coulter Representative.

1.2 GENERAL PROCEDURES

GENERAL SERVICE AND MAINTENANCE 1

1

GENERAL

WARNING

Do not try to remove the laser module from the Diluter.

IMPORTANT

If a power failure or reset occurs during a cycle, after power up, press

PRIME APERT before cycling samples.

This section details the cleaning, replacement, and adjustment

procedures that are your responsibility. General operations that may

apply to numerous procedures are described below. They include:

Power Down

Power Up

Optimize the Disk

Set Screen Saver

Position Rocker Bed

Diluter

Coulter recommends a Preventive Maintenance Inspection (PMI) once a

year by a Coulter Service Representative.

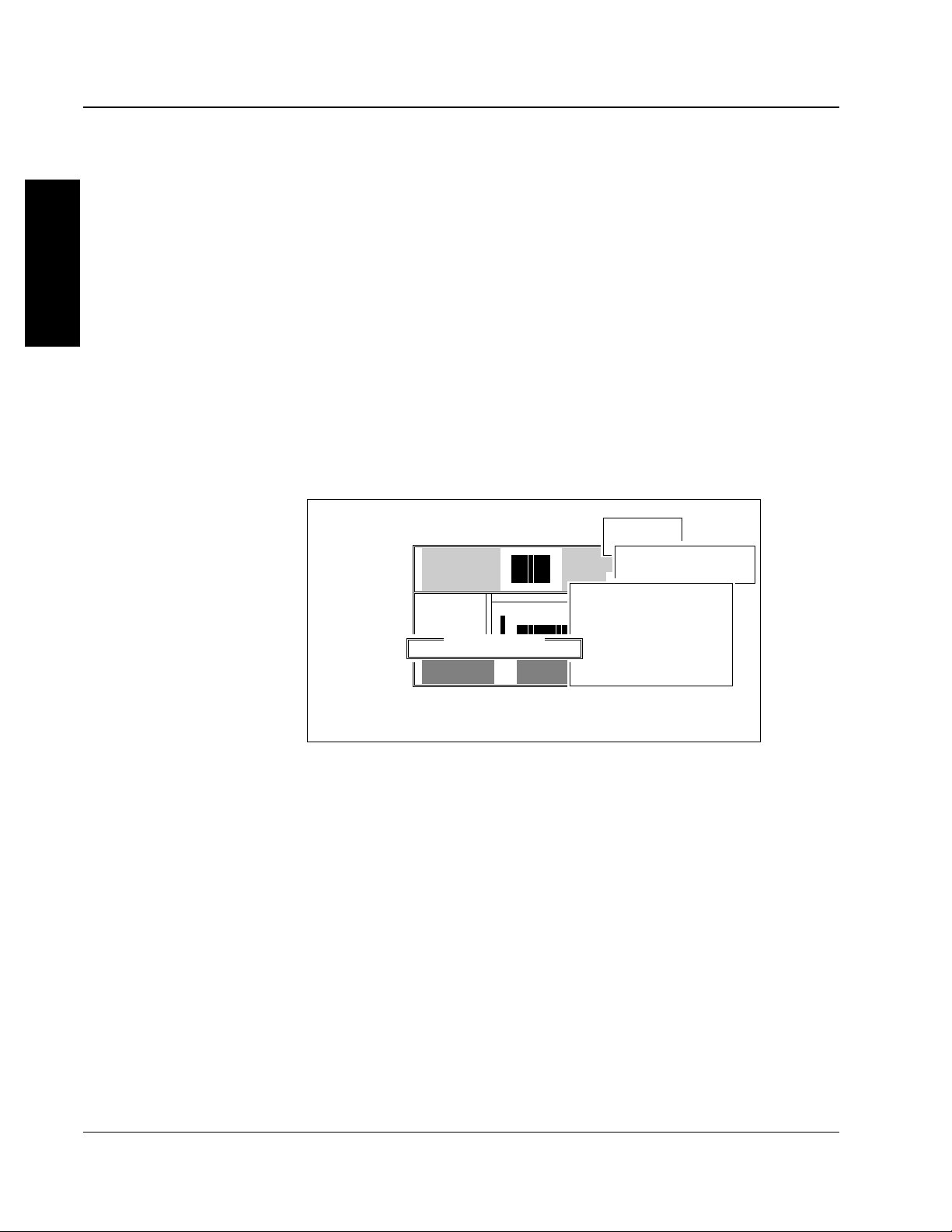

Figure 1 illustrates component location on the Diluter front panel.

F Key Functions

PN 4237187A (November 1993) 1

GENERAL SERVICE AND MAINTENANCE

A

GENERAL

67

1

8

9

VL30 VL31 VL32 VL33 VL34 VL35 VL36 VL37

VL19

10

11

12

GA1

VC15

RG2

PM8

VL43

VL38

VL40

VL44

PM7

VL20 VL18 VL22

VL47

VL46

VL48

VL50

SOL47

VC14

VL49

13

7187002

PM10

PM9

14

17. HGB CUVETTE HOLDER

18. BATH OVERFLOW CHAMBER (VC10)

19. NEEDLE-RINSE PUMP (PM1)

20. WBC DILUENT DISPENSER (PM3)

21. RINSE MIX CHAMBER PUMP (PM11)

22. 1mL BACKWASH PUMP (PM6)

23. RBC DILUENT DISPENSER (PM2)

17 16 15

VL14 VL15 VL16

VL13

VL4 VL7

12345

VL3

VL2

VL1

PM4

VL6

VL5

9. ELECTRONIC MANOMETER WINDOW

10. MANOMETER RANGE SCALE

11. CBC LYTIC REAGENT PUMP (PM8)

12. SHEATH TANK (VC15)

13. 5mL CLEANING AGENT PUMP (PM10)

14. 5mL HGB PUMP (PM9)

15. FOAM TRAP (VC14)

16. WASTE CHAMBER (VC11)

SOL1

SOL5

PM11

1. ERYTHROLYSE II PUMP (PM4)

2. RBC BATH (VC2)

3. VACUUM ISOLATOR (VC1)

4. WBC BATH (VC3)

5. STABILYSE PUMP (PM12)

6. CBC LYTIC REAGENT PUMP (PM7)

7. MANOMETER REGULATOR

8. SHEATH FLOW RESTRICTOR

PM6

22 21 20 19 18

PM = PUMP

PM1

VL11VL10

PM3

VL12

PM2

Figure 1 Diluter Front Panel

VC = VACUUM CHAMBER

23

2 PN 4237187A (November 1993)

GENERAL PROCEDURES

Power Down

1. Turn off the Graphic Printer.

2. Turn off the Ticket Printer.

3. Turn off the DMS.

4. Press

5. Turn off the MAIN POWER circuit breaker on the Power Supply.

6. Unplug the primary power cord from the wall outlet.

7. Verify that the power is disconnected:

8. Turn off the MAIN POWER circuit breaker.

POWER OFF on the Diluter keypad.

a. Turn on the MAIN POWER circuit breaker.

b. Check the front panel of the Power Supply and be sure there

are no lamps lighted. If any lamp lights, the power is still

connected; you must repeat steps 5, 6 and 7.

1

GENERAL

Power Up

Optimize the Disk

1. Plug the primary power cord into the wall outlet.

2. Turn on the MAIN POWER circuit breaker on the Power Supply.

3. Press

4. Turn on the DMS.

5. Turn on the Ticket Printer.

6. Turn on the Graphic Printer.

This system is equipped with the OPTune™ utility, a software utility

that optimizes the hard drive on your DMS. Optimizing organizes files

on your hard drive so that the DMS is faster and more efficient. The

OPTune utility runs when you turn on the DMS and when you reset the

DMS.

POWER ON on the Diluter keypad.

PN 4237187A (November 1993) 3

GENERAL SERVICE AND MAINTENANCE

GENERAL

1

The OPTune utility performs three types of optimization: daily, weekly

and monthly. The type it uses depends on how long it has been since the

last optimization.

Daily

The fastest method, this type leaves each file

• 100% defragmented

• sorted in ascending order by name

• in contiguous order

Weekly

Takes about 50% longer than the daily method. Does everything the

daily method does, plus it optimizes in the packed mode. It arranges the

files on your hard drive so that they are end-to-end, with no space

between them. Thus, new files are likely to be written to disk without

being fragmented.

Monthly

The most thorough method. Does everything the weekly method does,

plus it physically arranges files on the disk in the same order as the

sorted directory entries. This method takes longer, but increases

efficiency when accessing many files in sequential order.

The OPTune utility initially takes about 45 minutes to an hour to

optimize a 240MB hard drive. After that, daily optimization takes about

30 to 40 seconds. The OPTune utility reorganizes only those files that

need it; it does not reoptimize unnecessarily.

You can bypass the OPTune utility process by pressing while the

OPTune utility screen is in view. When the message Do you want to stop?

[Y/N] appears, press . This message appears: User terminated Verify.

The optimizing process stops and the system goes into the DMS

program.

If there is a hard disk failure during the optimization process, for

example lost clusters or cross-linked files, the OPTune utility prompts

you to continue. Answer Yes to go on with the process. However, if this

happens more than once a week, record the incident in your DMS

maintenance log or your logbook and call Coulter Customer Operations.

4 PN 4237187A (November 1993)

GENERAL PROCEDURES

If you always leave your system turned on, we recommend that you run

the OPTune utility at least once a week, using one of these two options:

1

Option A

1. Turn off the Graphic Printer.

2. Turn off the DMS.

3. Wait at least 15 seconds.

4. Turn on the DMS.

5. Turn on the Graphic Printer.

Option B

Select

Special Functions

Sample Analysis Set up

Reset DMS

When you reset the DMS or turn it off then back on, these functions

default to these conditions:

GENERAL

Set Screen Saver

• Data Base storage: ON (DB↑)

• XB: ON (XB↑)

• AutoPrint: NONE (PR↓)

• AutoTransmit: OFF (HC↓)

Reset these options as needed according to your laboratory’s protocol.

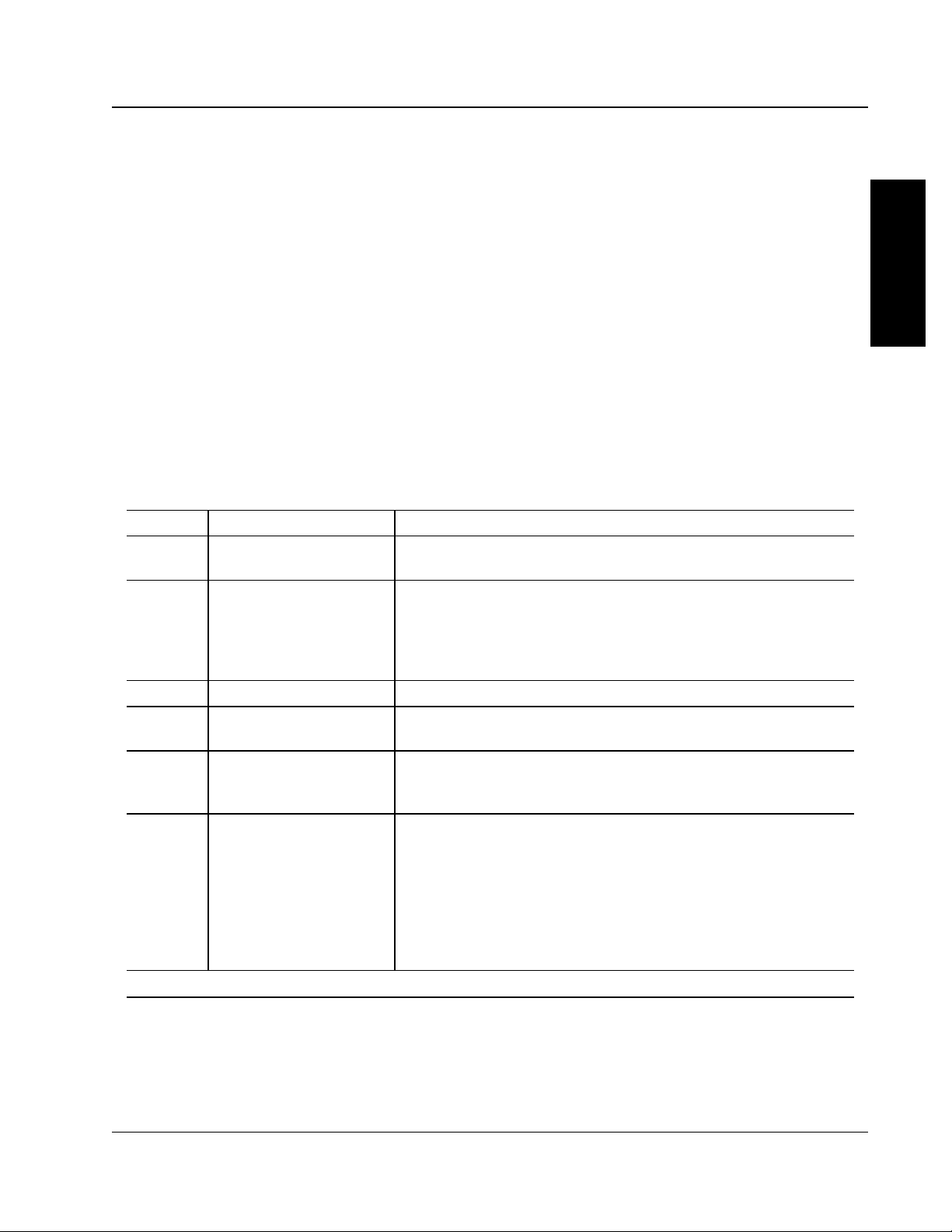

The screen saver function makes the screen go blank when it is not being

used. Figure 2 illustrates the Setup window. Select

Special Functions

Set Up

System Set Up

Screen Saver Time Out

PN 4237187A (November 1993) 5

GENERAL SERVICE AND MAINTENANCE

GENERAL

1

Set the time, in minutes, for the length of time to elapse before the screen

goes blank. You can enter from 0 to 99 minutes.

• A number from 1 to 99 means that, if there is no keystroke in that

many minutes, the screen goes blank. The screen also goes blank

when the compressor times out.

The screen turns back on under these conditions:

- The DMS receives a sample run.

- You press a key on the DMS keyboard. The DMS executes the

keystroke as it applied to the screen before it went blank.

• Zero means the screen saver will not be activated.

Sample Analysis Controls Start Up Special Functions

DMS 2A Diagnostics

Control set up

Sample analysis set up

C System set up|

Screen Saver Setup anguage

Screen Saver Delay: 0 Minutes QAP ID #|

Change Supervisor Password

Screen Saver Time Out|

(931951) COPYRIGHT 1989-1993 COULTER CORPORATION, ALL RIGHTS RESERVED

F1-Help F3-Error Log F5-Other F9-Main menu F10-Previous menu

07/14/93 17:17 OPR DMS↑ PR↓ TK↓ HC↓ DB↑ XB↓ WL↑ HWL↓ QC↑ 59

CBC/Diff/Retic

Set Up|

Shift

Reagents

Institution

Communication def

Electronic reference

atabase

Figure 2 Screen Saver Setup

Position Rocker Bed

When the compressor is off, the rocker bed is not locked in position and

can be tilted easily.

Diluter F Key Functions

The Diluter F key functions are listed in Table 1. To select these

functions, press

6 PN 4237187A (November 1993)

F X X ENTER where XX is the function number.

GENERAL PROCEDURES

During these functions, a related message appears on the Diluter keypad;

when the routine is finished, the message returns to the function

number.

For example, when you select F01, the burn circuit activates and the

message appears;

CLEAN APERTURES

after which the message returns to:

FUNCTION = 01

1

GENERAL

To repeat the function, press

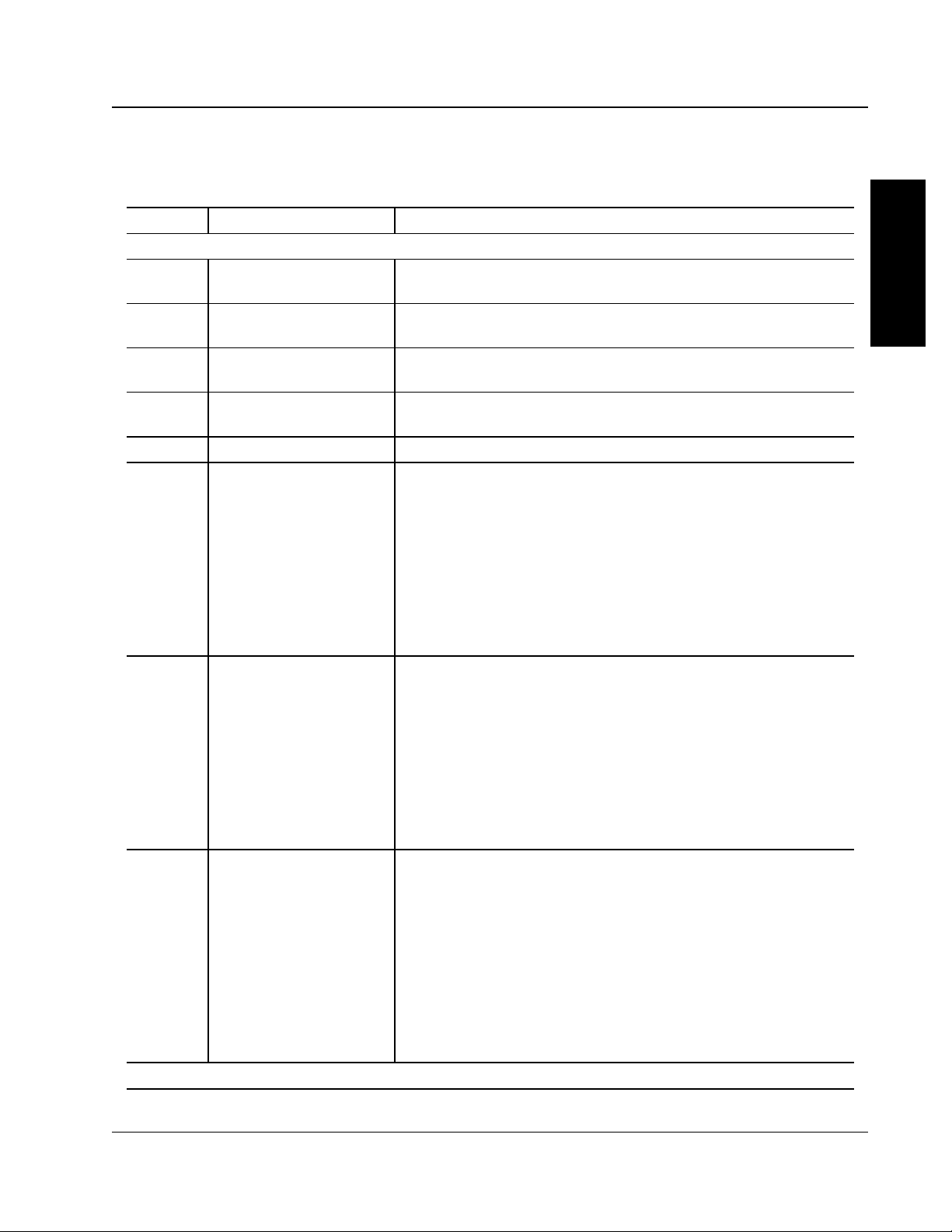

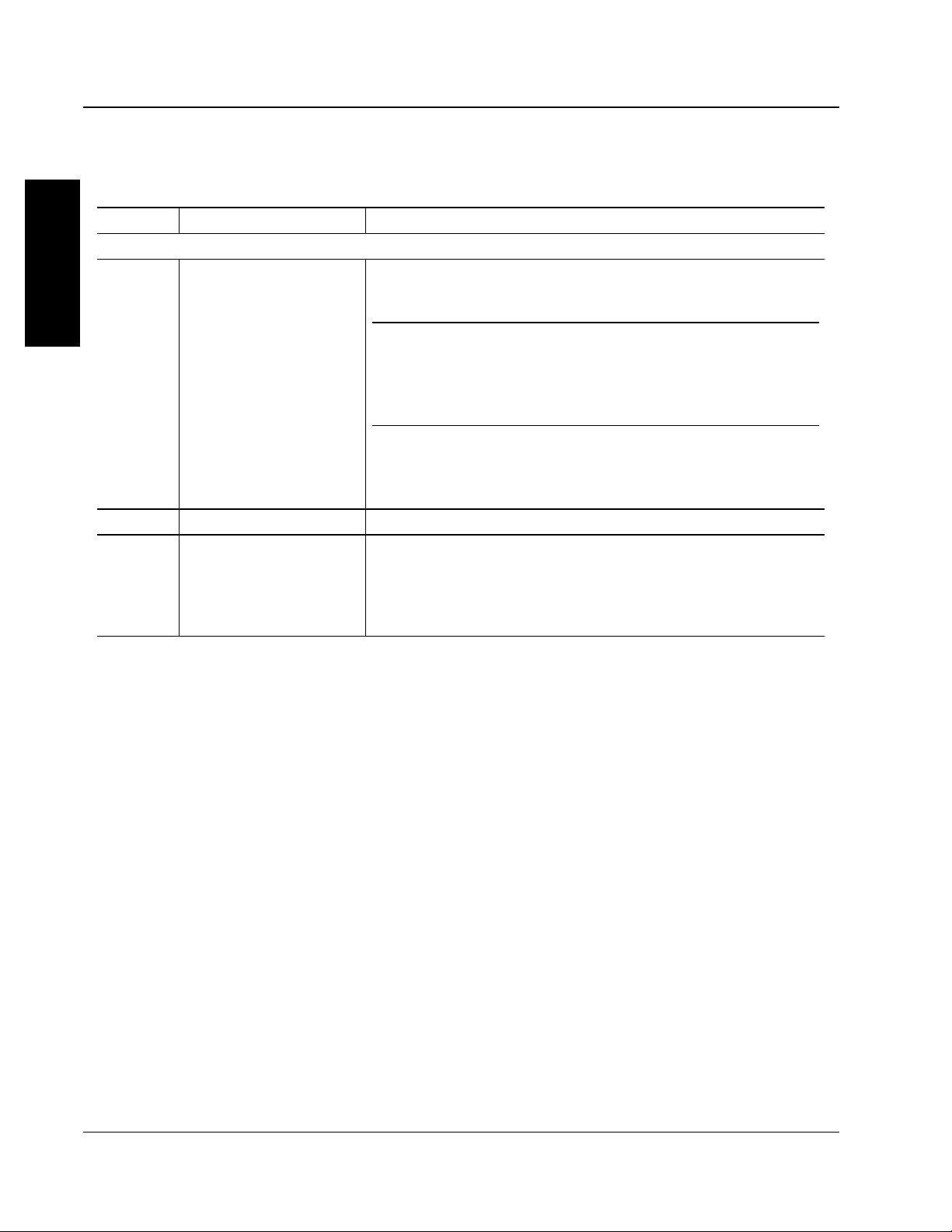

Table 1 Diluter F Key Functions

Function Message Description

F01

F02

F03

F04

F05

F06

CLEAN APERTURES

PRIME CBC LYSE

RBC AND WBC MIX

DILUENT DISPENSE

SOLENOID XX

RELEASE B.S.V.

The burn circuit activates. This function applies current across

the apertures to "burn" protein or debris off the apertures.

The following sequence occurs twice:

• Drains both baths then dispenses CBC lytic reagent into the

WBC bath three times to prime the lyse line.

• The WBC bath drains and the cycle repeats.

• It then fills both baths with diluent and primes the apertures.

Causes mixing bubbles to enter both the RBC and WBC baths.

Dispenses 1 mL of diluent through the Secondary mode

aspirator tip.

Use to manually activate individual solenoids (see Table 7).

Enter the desired solenoid number (for numbers less than 10,

enter a leading zero), and press ENTER.

• Drains the baths

• Bleeds off pressure

• Rotates the BSV back and forth five times

ENTER. To exit the function, press STOP.

Use to check BSV function, free a stuck valve, or when cleaning

the BSV to ease removal. Press STOP twice to exit the function.

This function does not refill the baths; use RINSE to refill them

with diluent.

continued

PN 4237187A (November 1993) 7

GENERAL SERVICE AND MAINTENANCE

Table 1 Diluter F Key Functions

Function Message Description

continued

F07

GENERAL

BARCODE READ RATE

TEST

Checks the bar-code read rate on the cassette bar-code label,

and on the four types of tube bar-code labels.

1

F08

F09

PRIME SWEEP FLOW

ZAP APERTURES

1. Enable the bar-code reader.

2. Remove the cap-piercing needle so that extensive piercings

do not cause a plugged needle.

3. Place a cassette of bar-code labeled tubes on the rocker

bed.

4. Select the function, then the following appears on the

Diluter display:

A00B00C00D00E00

A represents Interleaved 2-of-5

B represents Code 39®Bar code

C represents Codabar

D represents the cassette label

E represents code 128

The cassette automatically moves to the piercing station

and the bar-code reader scans both the cassette and tube

labels. On the display, the appropriate category increments

by one each time a label from that category is read. Press

STOP twice to exit the function.

Primes the sweep-flow lines.

• Applies pressure behind the baths

• Drains and rinses the baths four times with cleaning agent

• Draws the cleaning agent behind the apertures

• Zaps the apertures 10 times

After this function is complete, you must execute the startup

cycle to purge the system of the cleaning agent.

F10

F11

F12

F13

RAISE NEEDLE

EXTENDED PRIME

EXTENDED CLEAR

PURGE MODE

Causes the piercing needle to rise and the rocker bed to lock in

the backward position. Press STOP twice to exit.

Pulls fluid through the apertures to the vacuum isolator chamber

for 60 seconds. Aperture current turns on and aperture lamp

intensity increases for viewing the aperture screen.

Clears the apertures for 60 seconds. Use to clear bleach.

Use to clear air bubbles or debris from the flow cell.

continued

8 PN 4237187A (November 1993)

GENERAL PROCEDURES

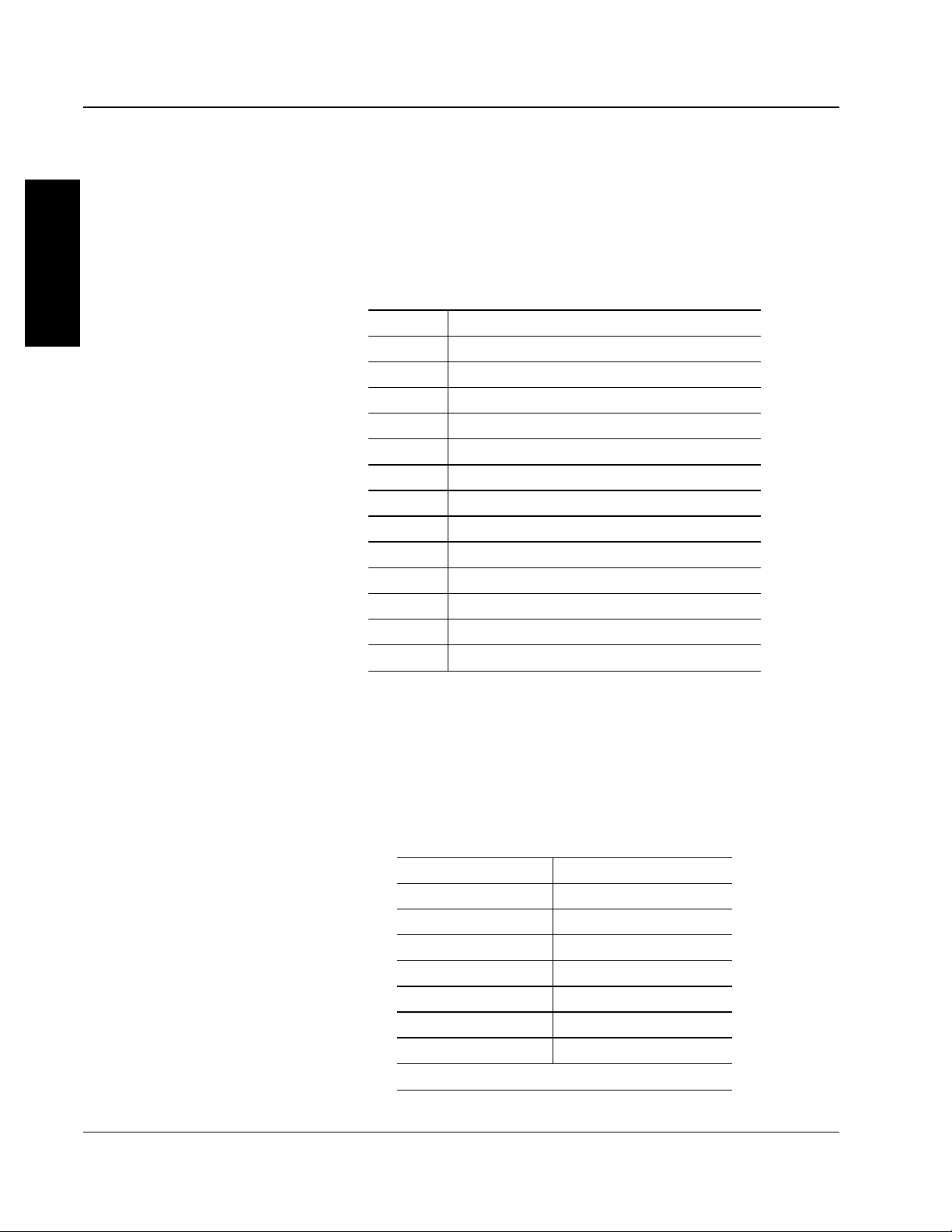

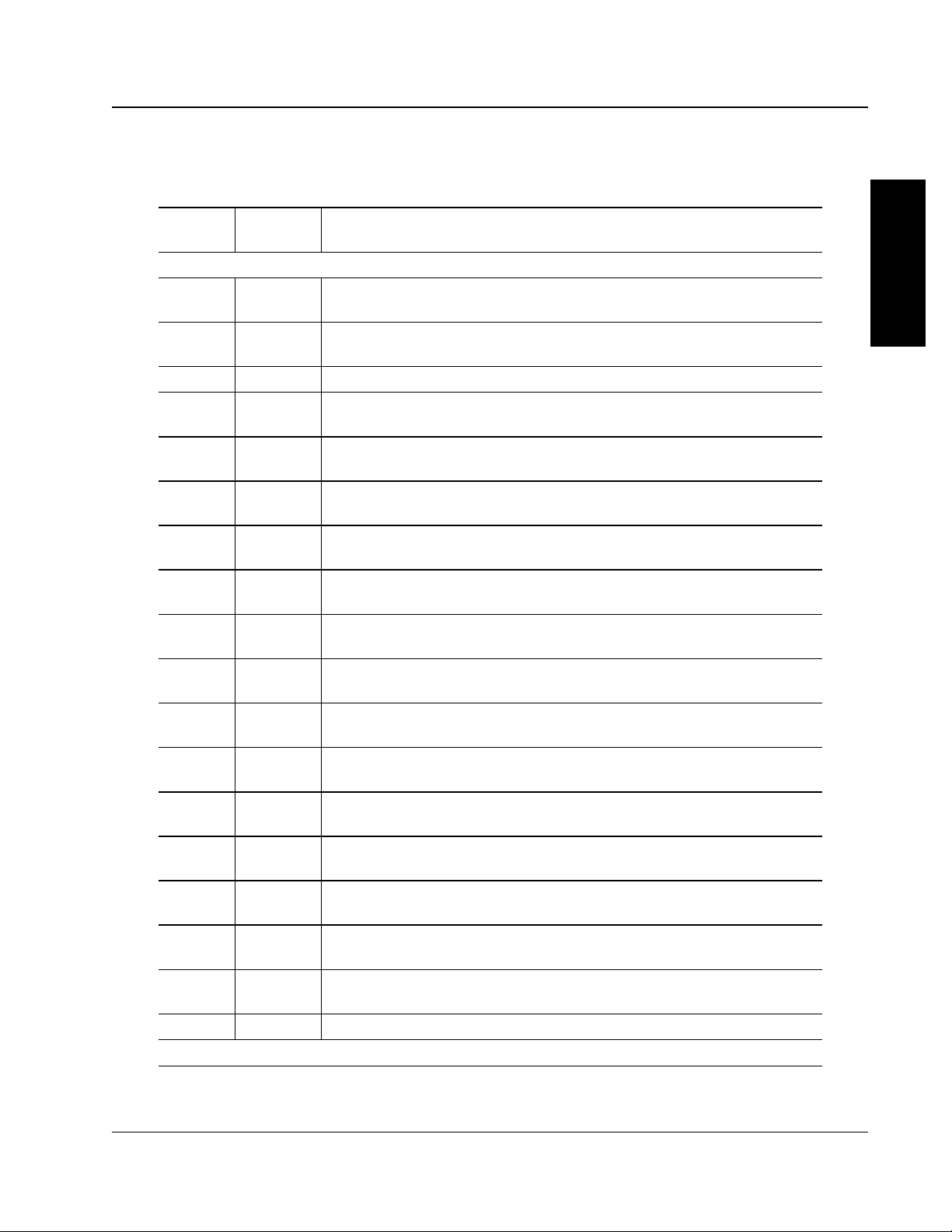

Table 1 Diluter F Key Functions

Function Message Description

continued

F14

F15

F16

F17

F20

F44

F45

PRIME PAK LYSE

PRIME PAK PRESRV

PRIME DILUENT

PRIME SCATTER PAK

FILL SHEATH TANK

CLEAR FLOW CELL 1

CLEAR FLOW CELL 2

Used to prime the diff lyse lines for troubleshooting. For Service

use only.

Used to prime the diff preservative reagent lines for

troubleshooting. For Service use only.

Use to prime diluent lines when you replace the diluent

container.

Use to prime the diff reagents when you replace the SCATTER

PAK.

Used to fill the sheath tank as needed. For Service use only.

What it does to flow cell

• purges it with cleaning agent

• turns on its aperture current

• applies low pressure to it

• alternately applies vacuum to the bottom

• checks it for a clog

• leaves it in diluent

See the Clear Flow Cell procedure for instructions on the use of

this function.

What it does to flow cell

• purges it with cleaning agent

• turns on its aperture current

• applies 30 psi to top of it

• alternately applies vacuum to the bottom

• checks it for a clog

• leaves it in diluent

1

GENERAL

See the Clear Flow Cell procedure for instructions on the use of

this function.

F46

CLEAR FLOW CELL 3

Use only if F44 and F45 fail to clear flow cell.

What it does to flow cell

• purges it with cleaning agent

• turns on its aperture current

• applies low pressure to it

• alternately applies vacuum to the bottom

• leaves it in cleaning agent

See the Clear Flow Cell procedure for instructions on the use of

this function.

continued

PN 4237187A (November 1993) 9

GENERAL SERVICE AND MAINTENANCE

Table 1 Diluter F Key Functions

Function Message Description

continued

F55

F56

GENERAL

F57

1

F95

F96

LATRON CONTROL

F55 = DIFF

F56 = RETIC

F57 = DIFF + RETIC

SOLENOIDS FREE

TUBE ADVANCE

Access this function before you aspirate LATRON primer and

control.

Do not use this function to aspirate anything except

LATRON control or LATRON primer. Other material can

cause damage to the system.

This function causes approximately 1.5 mL of primer or control to

be aspirated through the Secondary mode aspirate tip directly

into the flow cell.

Frees the pressure from all solenoids. Press STOP twice to exit.

Use when you adjust the tube detector; causes a cassette to

move through the piercing station one tube position at a time.

Press STOP to halt the advance and make adjustments, ENTER

to continue the advance and check alignment. Press STOP twice

to exit the function.

CAUTION

1.3 COMPONENTS

This section includes

List of Cylinders

List of Manifolds

List of Pumps

List of Vacuum Chambers

Pinch Valve Functions

Solenoid Functions

Summary of Pinch Valve/Solenoid/Component Relationships

10 PN 4237187A (November 1993)

COMPONENTS

Cylinders (CL)

Manifolds (MF)

Table 2 lists the cylinders and the components they operate.

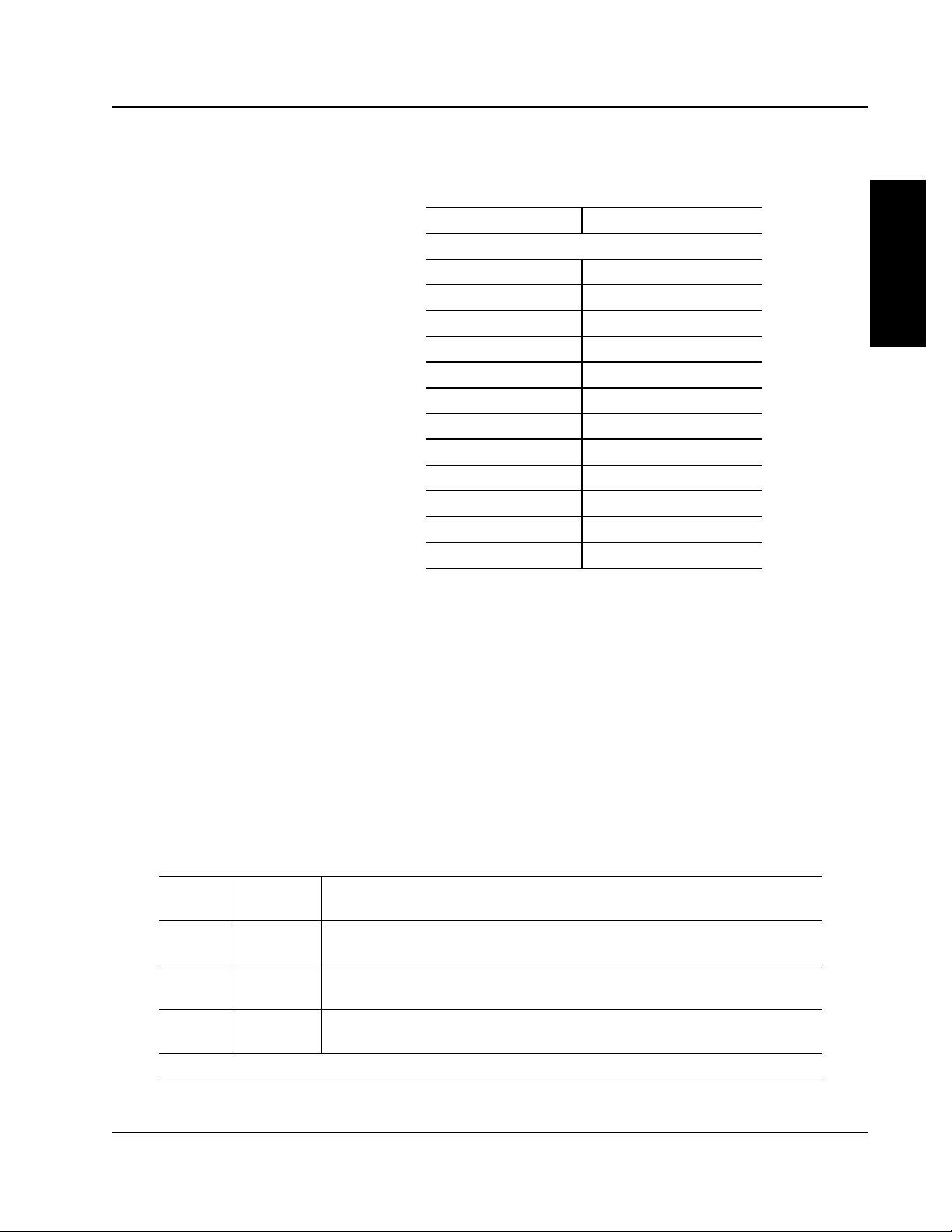

Table 2 Cylinders

Cylinder Operates

CL1 BSV front

CL2 BSV back

CL3 needle

CL4 left lift

CL5 right lift

CL6 tube ram

CL7 bar-code reader

CL8 bed rocker

CL9 belt advance

CL10 stripper plate

1

GENERAL

Table 3 lists the Manifolds and their output.

Table 3 Manifolds

Manifold Output

MF1 5 psi, level sense switches

MF2 pneumatic/hydraulic source input to Diluter, waste

MF3 30 psi

MF4 vacuum

MF6 30 psi, solenoid (SL) manifold

MF7 5 psi

MF8 5 psi, mixing bubbles

MF9 30 psi

MF10 vacuum

MF11 30 psi, SL manifold

MF12 vacuum

MF13 30 psi, SL manifold

MF15 30 psi

PN 4237187A (November 1993) 11

GENERAL SERVICE AND MAINTENANCE

Pumps (PM)

Table 4 lists the pumps and what they operate.

GENERAL

1

Table 4 Pumps

Pump Operates

PM1 needle rinse, 0.77 mL

PM2 RBC diluent dispense, 10 mL

PM3 WBC diluent dispense, 6 mL

PM4 5 diff lyse, 0.536 mL

PM6 backwash, 1 mL

PM7 3 diff lyse, 0.52 mL

PM8 3 diff lyse, 0.52 mL

PM9 Hgb blank, 5 mL

PM10 cleaning agent, 5 mL

PM11 rinse, 1 mL

PM12 leukocyte preservative, 0.193 mL

PM13 Primary mode aspiration, 0.250 mL

PM14 Secondary mode aspiration, 0.150 mL

Vacuum Chambers (VC)

Table 5 lists the vacuum chambers and the components they control.

Table 5 Vacuum Chambers

Vacuum Chamber Controls

VC1 vacuum isolator (VIC)

VC2 RBC bath

VC3 WBC bath

VC4 RBC bath aperture 1

VC5 RBC bath aperture 2

VC6 RBC bath aperture 3

VC7 WBC bath aperture 1

continued

12 PN 4237187A (November 1993)

COMPONENTS

Table 5 Vacuum Chambers

Vacuum Chamber Controls

continued

VC8 WBC bath aperture 2

VC9 WBC bath aperture 3

VC10 bath overflow

VC11 waste chamber (Diluter)

VC13 waste chamber (Diff)

VC14 foam trap

VC15 sheath tank

VC16 sheath flow

VC17 vacuum tank

VC18 flow cell

VC19 mixing chamber

VC20 foam trap

1

GENERAL

Pinch Valve (VL) Functions

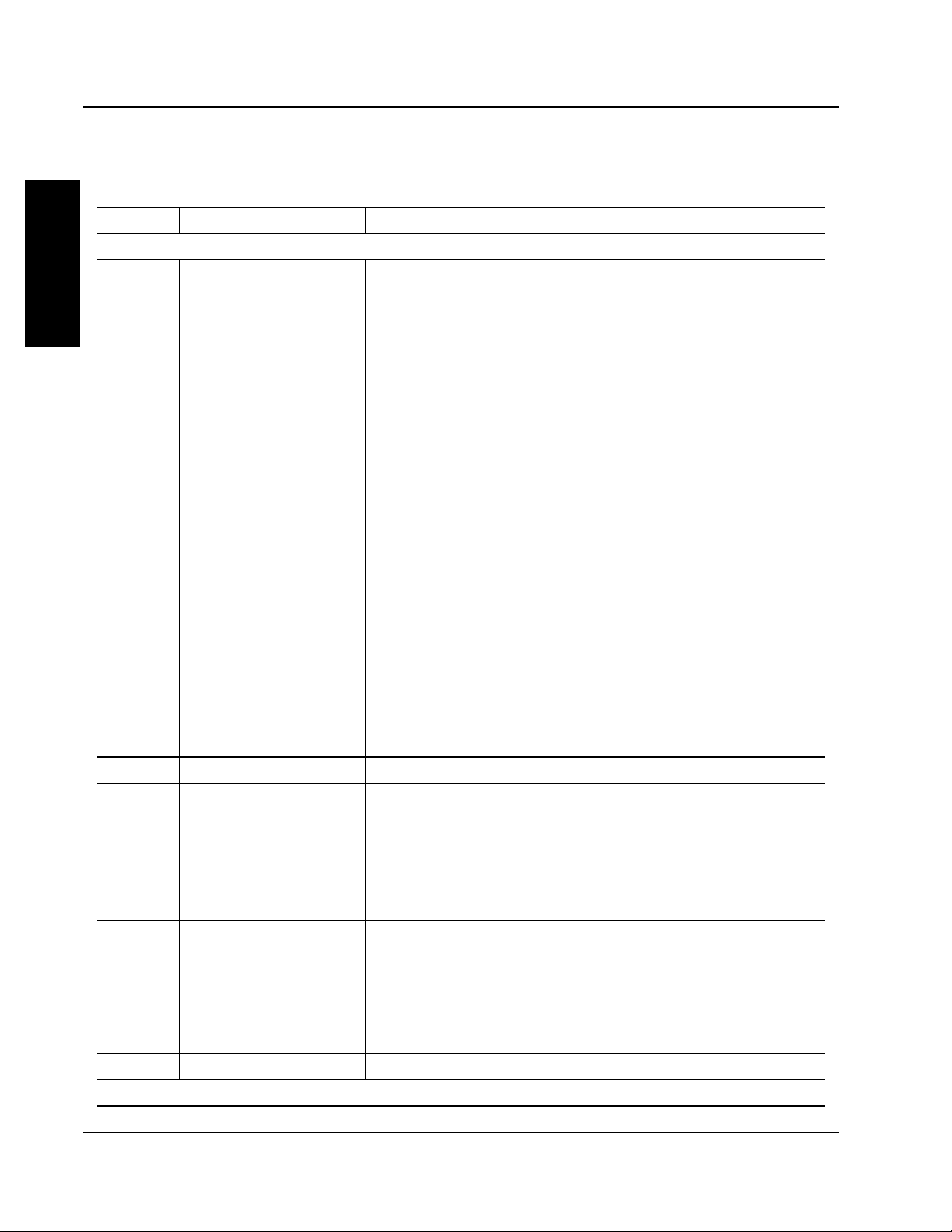

Table 6 lists the pinch valves sequentially, shows which solenoid (SL)

controls the pinch valve, and gives each valve’s function. See Figure 3 for

most locations.

Legend: NC = Normally Closed

NO = Normally Open

NA = Normally Activated

Table 6 Pinch Valves

Pinch

Valve Solenoid Pinch Valve Function

VL1 SL18 NC path from RBC diluent dispenser to BSV rear section, port 9

NO path from RBC diluent dispenser to BSV rear section, port 10

VL2 SL18 NC path from WBC diluent dispenser to BSV rear section, port 10

NO path from WBC diluent dispenser to BSV center section, port 8

VL3 SL9 NC 5 psi path to bath overflow chamber to drain it

NO vent to bath overflow chamber

continued

PN 4237187A (November 1993) 13

GENERAL SERVICE AND MAINTENANCE

Pinch

Valve Solenoid Pinch Valve Function

continued

GENERAL

1

VL4 SL63 NC diff lyse pump dispense

VL5 SL8 NC RBC diluent dispenser dispense

VL6 SL7 NC WBC diluent dispenser dispense

VL7 -- Not used

VL10 SL13 NC backwash pump dispense for Secondary mode

VL11 SL42 NC mix chamber rinse pump dispense

VL12 SL42 NC pressure to rinse pump for mix chamber

VL13 SL11 NC RBC count

VL14 SL18 NC path for rinse trough drain to VIC, primary mode

VL15 SL12 NC pressure for WBC bath drain

VL16 SL10 NC WBC count

VL18 SL6 NC pressure for Hgb cuvette drain

VL19 SL16 NC • VIC drain

VL20 SL57 NC Primary mode drain to diff waste chamber

VL22 SL12 NC vacuum to main waste chamber

Table 6 Pinch Valves

NO diff lyse pump fill

NO RBC diluent dispenser fill

NO WBC diluent dispenser fill

NO • backwash pump dispense for Primary mode

• backwash pump fill for both modes

NO mix chamber rinse pump fill

NC vacuum to rinse pump for mix chamber

NO not used

NO not used

NO vent to bath overflow chamber

NO not used

NO vent for Hgb cuvette

• 5 psi to VIC

• Primary and Secondary mode backwash drain to waste

chamber

NO • not used

• vacuum to VIC

• not used

NO Secondary mode drain to diff waste chamber

NO pressure to main waste chamber

continued

14 PN 4237187A (November 1993)

COMPONENTS

Table 6 Pinch Valves

Pinch

Valve Solenoid Pinch Valve Function

continued

VL23 SL12 NC RBC bath drain

NO output to main waste chamber

VL24 SL12 NC WBC bath drain

NO output to main waste chamber

VL26 SL50 NO rinse from PM1 into mix chamber when deactivated

VL28 SL28 NC Hgb cuvette drain to waste chamber

NO vent

VL29 SL49 NC vent diff waste chamber

NO not used

VL30 SL51 NC sample pressure to mix chamber

NO vent for mix chamber

VL31 SL54 NC sheath flow from tank to bottom half of flow cell

NO not used

VL32 SL54 NC sheath flow from tank to top half of flow cell

NO not used

VL33 SL49 NC sample drain from flow cell

NO not used

VL34 SL55 NC forward flush drain to waste

NO not used

VL35 SL12 NO high vacuum to low vacuum regulator

NC not used

VL36 SL61 NC diff rinse pump - cleaner

NO diff rinse pump - diluent

VL37 SL46 NC path for flush upper section of flow cell

NO not used

VL38 SL17 NC high vacuum to VIC

NO low vacuum to VIC

VL40 SL57 NC vacuum for secondary backwash drain to diff waste chamber

NO not used

VL43 SL2 NC dispense lyse to WBC bath

NO lyse pumps fill

VL44 SL60 NC diff preservative pump dispense

NO diff preservative pump fill

VL45 -- Not used

1

GENERAL

continued

PN 4237187A (November 1993) 15

GENERAL SERVICE AND MAINTENANCE

Pinch

Valve Solenoid Pinch Valve Function

continued

GENERAL

1

VL46 SL3 NC pressure to lyse pumps

VL47 SL61 NC cleaner pump dispense

VL48 SL2 NC Hgb blank pump dispense

VL49 SL48 NC vacuum supply to drain mix chamber to diff waste chamber

VL50 SL56 NC • vacuum

VL52 SL44 NO blood and diff lyse delivery to mix chamber, Secondary mode

VL53 SL45 NO diff preservative delivery path to mix chamber

VL54 SL65 NO blood and diff lyse delivery to mix chamber, Primary mode

VL55 SL52 NO sample flow from mix chamber to flow cell

VL56 SL50 NC vacuum on mix chamber

VL57 SL48 NC drain path not used

VL58 SL46 NC flush flow cell lower section

VL59 SL41 NC reverse flush drain from flow cell to waste chamber

VL68 NA SL24 NC Primary mode aspiration disabled

VL69 SL24 NC from secondary aspiration pump to main waste chamber

VL73 NA SL58 NC Secondary mode aspiration and backwash disabled

VL74 NA SL58 NC Primary mode aspiration and backwash disabled

VL76 NA SL64 NC Primary mode aspiration disabled

Table 6 Pinch Valves

NO vacuum to lyse pumps and Hgb blank pump

NO cleaner pump fill

NO Hgb blank pump fill

NO drain path for diff waste chamber

• sheath fill

• not used

NO • sheath flow

• sheath pressure

• flow cell rinse to bottom of flow cell

NC not used

NC not used

NC not used

NO pressure on mix chamber

NO not used

NO not used

NO not used

NO from primary aspiration pump to main waste chamber

NO Secondary mode aspiration enabled

continued

16 PN 4237187A (November 1993)

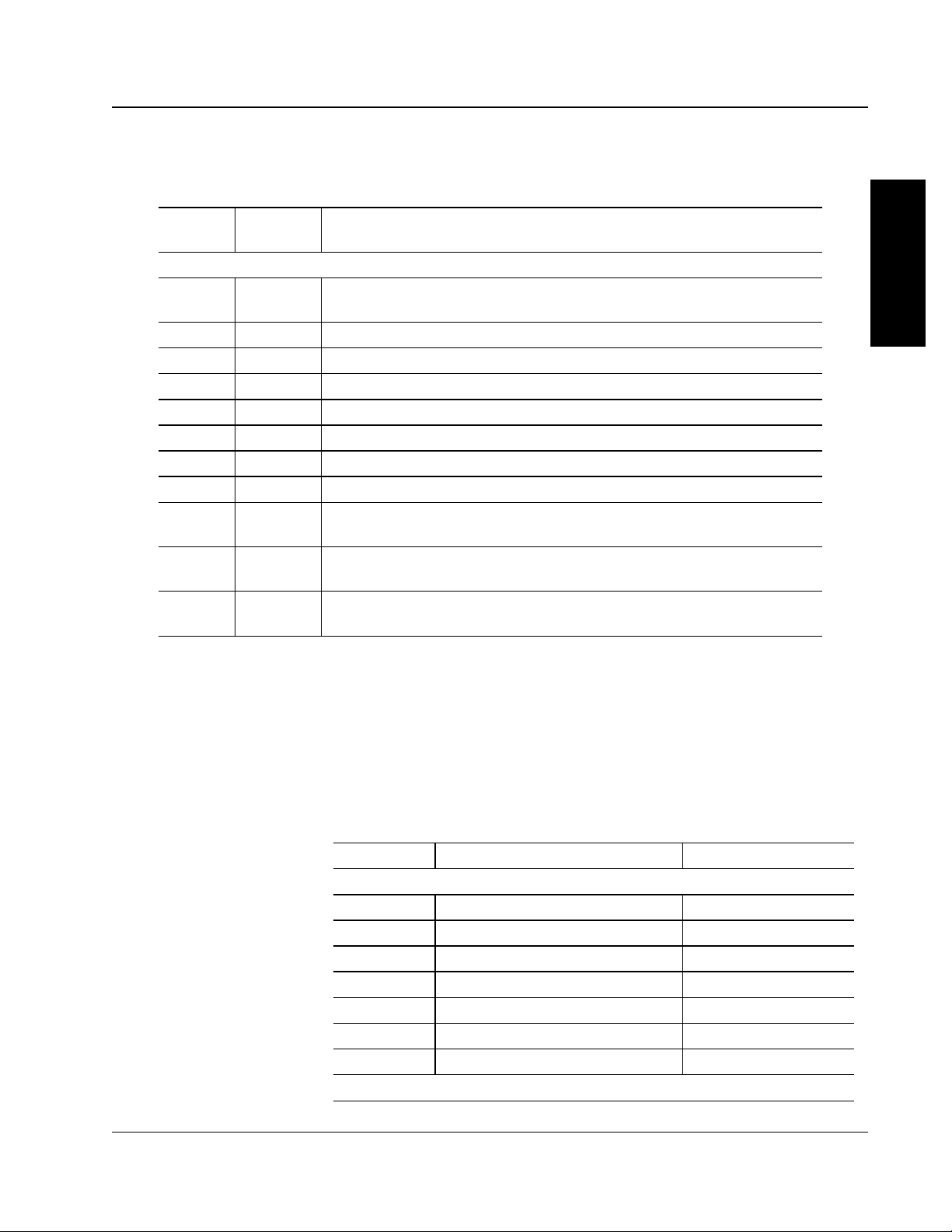

COMPONENTS

Table 6 Pinch Valves

Pinch

Valve Solenoid Pinch Valve Function

continued

VL77 SL62 NC Secondary mode backwash to waste chamber

NO not used

VL78 SL58 NO diff lyse delivery enabled, Primary mode

VL79 NA SL64 NC Secondary mode aspiration disabled

VL81 SL59 NO Primary mode backwash enabled

VL82 SL23 NO needle rinse backwash diluent

VL83 SL58 NO diff lyse delivery enabled, Secondary mode

VL84 -- Not used

VL85 SL59 NO Secondary mode backwash enabled

VL86 SL59 NC vacuum via vacuum tank to aspiration pumps

NO pressure to aspiration pumps

VL87 SL13 NC Secondary mode rinse trough drain

NO Primary mode rinse trough drain

VL88 SL62 NC Primary mode backwash to waste chamber

NO not used

1

GENERAL

Solenoid (SL) Functions

Table 7 lists the solenoid functions and actions. See Figure 3 for most

locations.

Table 7 Solenoids

Solenoid Function Action

Diluter

SL1 Rinse needle PM1

SL2 Lyse/Hgb valve VL43, VL48

SL3 Lyse/Hgb pump VL46

SL4 Hgb drain valve VL28

SL5 Backwash pump PM6

SL6 Hgb/waste drain VL18

SL7 WBC dispense VL6, PM3

continued

PN 4237187A (November 1993) 17

GENERAL SERVICE AND MAINTENANCE

GENERAL

1

Table 7 Solenoids

Solenoid Function Action

continued

SL8 RBC dispense VL5, PM2

SL9 Whole blood aspiration/

Overflow bath drain

SL10 WBC count VL16

SL11 RBC count VL13

SL12 Bath drain (VL 14) VL15, VL22, VL23,

SL13 Manual backwash VL10, VL87

SL14 Cleaner VL27

SL15 Sample valve return CL2

SL16 Vacuum isolator drain VL19

SL17 Segment sample VL38, VL68, VL69,

SL18 WBC dispense to RBC bath VL1, VL2, VL14

SL19 WBC sample mix WBC bath

SL20 RBC sample mix RBC bath

Transport System

SL21 Right lift CL5

SL22 Left lift CL4

SL23 Needle up VL82, CL3

SL24 Manual probe in VL69, VL68, CL1

SL25 Ram tube CL6

SL26 Bar-code reader VL66, CL7

SL27 Backward bed rock CL8

SL28 Bed lock L1

SL29 Stripper plate CL10

SL30 Forward bed rock CL8

SL31 Flipper retract L41, L42

SL32 Spare

SL33 Needle vent pressure QD1-11 to needle

SL34 Manual probe out - NO CL1

SL35 Spare

VL3, VL86

VL24, VL35

CL2

continued

18 PN 4237187A (November 1993)

COMPONENTS

Table 7 Solenoids

Solenoid Function Action

continued

SL36 Belt advance CL9

SL37 Needle down CL3

SL38 Spare

SL39 Spare

SL40 Spare

Diff

SL41 Rev flush VL59

SL42 Rinse - diff VL11, VL12

SL43 Lyse - diff PM1

SL44 Lyse disable - diff, manual VL52

SL45 Quench VL53

SL46 Flush diff VL37, VL58

SL47 Cleaner - diff PM10

SL48 Drain - diff VL57, VL49

SL49 Exit - diff VL29, VL33

SL50 LATRON deliver VL26, VL56

SL51 Sample pressure - diff VL30

SL52 Sample disable - diff VL55

SL53 Waste - diff VC13

SL54 Sheath flow VL31, VL32

SL55 Forward flush VL34

SL56 Sheath refill VL50

SL57 Probe/needle drain VL20, VL40

SL58 Aspirate enable/

Lyse disable

SL59 Backwash disable VL81, VL85

SL60 Quench enable VL44

SL61 Cleaner enable VL36, VL47

SL62 Rinse metering tube VL77, VL88

SL63 Lyse - diff enable VL4

SL64 Segment diff - NO VL76, VL79

SL65 Lyse disable - diff auto VL54

VL78, VL83 (VL74,

L73)

1

GENERAL

continued

PN 4237187A (November 1993) 19

GENERAL SERVICE AND MAINTENANCE

37

1

5

50

47

ON REAR

THREE WAY PINCH VALVEDUAL ACTION PINCH VALVESOLENOIDMINI PINCH VALVE

7187001A

19

1613

ROCKER BED

DILUTER BASE (IN FRONT OF THE ROCKER BED)

MF13

46

MF11

363534333231

30

43384044

474648

49

29

28

24

23

221820

1514

7

4

32

1

5

6

10 12 11

22

25

24

58

69

68

77

88

59

54

52

26

82

55

21

58 57

56

53

13

51

15

52

17 53

41

54

44 55

45

56

57

48

60

49

61

50

65

BSV

7985

81 76

78

83

74

73

34 64 27 26 36 23

9

30 62 63 37 59 28

29

86

TOP

87

BOTTOM

Table 7 Solenoids

Solenoid Function Action

continued

GENERAL

1

SL81 Level sense MF1

Figure 3 illustrates solenoid and pinch valve locations.

20 PN 4237187A (November 1993)

Figure 3 Pinch Valve and Solenoid Locations

2.1 GENERAL INFORMATION

For optimum performance of your COULTER®STKS with Reticulocyte

Analysis, you must calibrate the CBC parameters. The WBC differential

parameters are calibrated at the factory; they do not require calibration in

the laboratory.

CALIBRATION 2

Your laboratory is responsible for the final calibration of the CBC

parameters, for recording the calibration factors, and for establishing

reference values for ramp-pulse and precision-pulse tests. Coulter

recommends S-CAL

alternative to whole-blood calibration.

Calibrate the CBC parameters:

• At installation

• After the replacement of any component that involves the dilution

characteristics (such as the BSV), or the primary measurements

(such as the apertures)

• When advised to do so by your Coulter Service representative

Daily quality assurance programs monitor ongoing instrument and

system performance. However, we recommend that you verify the status

of instrument calibration quarterly, and/or when controls begin to show

evidence of unusual trends, or when controls exceed the manufacturer’s

defined acceptable limits.

®

calibrator, or an exact equivalent, as an acceptable

2

CALIBRATION

• Although the instrument is relatively insensitive to minor room

temperature changes, perform calibration when the room

temperature is stable and within the normal ambient temperature

range. If the average ambient room temperature changes more than

10°F from the calibrating temperature, it is advisable to verify

calibration and to recalibrate if necessary.

• In the normal process of tracking data for an extended period of

time, your laboratory can make a specific decision to recalibrate a

given parameter. Never adjust to a specific value for an individual

sample.

PN 4237187A (November 1993) 21

CALIBRATION

2.2 PRECALIBRATION STEPS

CALIBRATION

• If a problem or malfunction occurs while performing these

procedures, see the Troubleshooting procedures later in this

manual. If the corrective procedures fail to eliminate the problem,

call Coulter Customer Operations immediately.

Before calibrating, perform the following procedures in the order given.

1. Follow a, b or c as it applies to your instrument.

a. If the instrument is in the shutdown condition, and you

routinely shut down the instrument for a minimum of 30

minutes every 24 hours in COULTER CLENZ

go to step 2.

®

cleaning agent,

2

b. If you routinely use COULTER CLENZ cleaning agent, but you

are beginning calibration after processing patient samples, shut

down the instrument in the cleaning agent for 30 minutes to

assure optimum aperture cleanliness before proceeding.

CAUTION

Do not aspirate bleach; bleach can damage the flow cell.

c. If you do not routinely use COULTER CLENZ cleaning agent,

perform the Bleach the Apertures procedure in Chapter 3.

2. Check the reagent containers for:

a. Sufficient quantity

b. Not beyond expiration date

c. No precipitates, turbidity, particulate matter, or unusual color

d. Proper connections between the Diluter and the reagent

containers

22 PN 4237187A (November 1993)

PRECALIBRATION STEPS

WARNING

The contents of the waste container and its associated tubing can

include residual biological material and must be handled with care.

Avoid skin contact and clean up spills immediately. Dispose of the

contents of the waste container in accordance with acceptable

laboratory procedures.

3. Check the waste container for:

a. Sufficient capacity

b. Proper connections

4. Perform the startup procedures, including a quality-control check,

as described in the Operator’s Guide, PN 4237188. Verify that the

following are acceptable: background count, reproducibility,

carryover, and control recovery.

Reproducibility Check, CBC/Diff

Before you calibrate the STKS with either the S-CAL Kit or whole blood,

perform a 10-sample reproducibility study on the CBC parameters in the

Primary mode. You can also perform this study if you need to check

instrument precision for the CBC or diff parameters.

In the Secondary mode, when you perform a Reproducibility check, do

not cycle more than eight samples per tube. If you are running 31

samples, use four separate vials.

2

CALIBRATION

Sample Requirements

Collect enough blood for 10 cycles from a single donor who:

• Is receiving no medication.

• Has normal hematologic parameters, with a WBC count of 10,000

±1,000.

• Has normal erythrocyte, leukocyte and platelet morphology and

PN 4237187A (November 1993) 23

CALIBRATION

• If you want to check the diff parameters, with diff values of

Neutrophils 40 to 72%

Lymphocytes 17 to 45%

Monocytes 4 to 12%

Eosinophils 0 to 10%

Basophils 0 to 1%

Procedure, Primary Mode

CALIBRATION

2

1. At the Diluter, press

PRIME APERT to activate the pneumatics.

2. At the Analyzer:

a. In SYSTEM CONFIGURATION, be sure that the BLOOD

DETECTOR is set to ENABLED.

b. In SYSTEM RUN, verify that the # aspirations/tube is 1.

3. At the DMS, select

Special Functions

Calibration

Reproducibility

If data remains from a previous study, press Delete Table.

4. Cycle one sample of normal whole blood in the Primary mode.

CAUTION

Do not pierce a specimen tube more than five times; additional piercing

can obstruct or clog the needle.

5. At the Analyzer, set the number of aspirations per tube to 5.

6. Aliquot the well-mixed normal whole-blood sample into two redtopped tubes.

a. Place the tubes into consecutive positions in a cassette, place

the cassette in the loading bay, and press

START/CONT.

b. Monitor the system for normal sample flow.

24 PN 4237187A (November 1993)

Loading...

Loading...