Coulter MicroDiff Service manual

COULTER®MicroDiff

C

C

®

Field Service

Technical Manual

PNPN 4237161B4237161B (April(April 1993)1993)

CoulterCoulter CorporationCorporation

Miami,Miami, FLFL 33196-250033196-2500

TM

Coulter Corporation makes no representation that, upon furnishing this service manual, the holder of the manual will have the necessary

technical capabilities and know-how to properly troubleshoot and repair any of the equipment specified in the manual. Coulter

Corporation assumes no liability whatsoever, including consequential and incidental damages, resulting from improper operation of

Coulter instruments after maintenance of Coulter instruments has been performed by persons not employed by Coulter Corporation.

Furthermore, Coulter Corporation assumes no liability whatsovever for any personal injury or property damage resulting from

maintenance and/or repair of Coulter instruments performed by persons not employed by Coulter Corporation.

TRADEMARKS

AccuComp, ACCUVETTE, ACCU-ZYME, AQUA-AD, AUTO-CAL, AUTO-CLONE, "CC"

logo,CARDS,CASH,CHANNELYZER,CHEMOTERGE, COMPLETE CELL ANALYSIS,

COULTER, COULTER CHEMISTRY, COULTER CLENZ, COULTER CLONE, THE

COULTER COUNTDOWN, COULTER COUNTER, COULTER CURRENTS,

COULTERAMA, CYTO-STAT, CYTO-TROL, C-ZYME, DACAL, DACOS, "DACOS" logo,

DART, DIFF3, DIFF3 50, DIFF4, DILU-PACK, E.A.SY. 1, EASY 88, EASY 2, EPICS,

FASTECS, 5C,4C,HEMO-CAL,HEMOTERGE,HEMO-W,IsoFlow,ISOLYSE,ISOPET,

ISOTERGE, ISOTON, KEM-O-MAT, "LFI" logo, LANGLEY FORD, LANGLEY FORD

INSTRUMENTS,LEASE-PAK,LYSES, MDADS, MINI-KEM,NANO-SIZER,OMNISORP,

OptiChem, S-CAL, SOMACOUNT, SOMAFIX, SOMATON, STAIN RIGHT, STILL

COUNTING, THROMBOCOUNTER, THROMBO-FUGE, U.V.-ZYME, ZAP-OGLOBIN,

ZAPONIN and ZETAFUGE are trademarks of Coulter Corporation.

HAZARDS AND OPERATIONAL PRECAUTIONS AND LIMITATIONS

WARNINGS, CAUTIONS, and IMPORTANTS alert you as follows:

WARNING: Might cause injury.

CAUTION: Might cause damage to the instrument.

IMPORTANT: Might cause misleading results.

"This Service Manual contains confidential information of Coulter Corporation and its receipt or

possession does not convey any rights to reproduce, disclose its contents, or to manufacture, use, or sell

anything it may describe. Reproduction, disclosure, or use without specific written authorization of Coulter

Corporation is strictly forbidden."

REVISION STATUS

Issue Date Amended Pages Software Level

Draft 5/92

Initial 5/92

A 7/92

B 4/93 2-3, 2-4, 2-9, 2-10, 2-12, 2-15, 3-5, 3-6, Chapter 8 1D

PN 4237161B (April 1993) i

REVISION STATUS

ii PN 4237161A (July 1992)

TABLE OF CONTENTS

1 WARNINGS AND CAUTIONS, 1-1

1.1 GENERAL SAFETY, 1-1

WARNING, 1-1

CAUTION, 1-1

IMPORTANT, 1-1

Note, 1-1

1.2 ELECTRONIC SAFETY PRECAUTIONS, 1-1

1.3 BIOLOGICAL SAFETY, 1-2

2 INSTRUMENT DESCRIPTION, 2-1

2.1 SPECIFICATIONS, 2-1

Dimensions/Weight, 2-1

Power, 2-1

Input, 2-1

Consumption, 2-1

Ambient Operating Temperature, 2-1

Humidity, 2-1

Recommended Reagents, 2-1

Controls and Calibrators, 2-1

Fluid Volumes, 2-2

Interfering Substances, 2-2

2.2 INTRODUCTION TO THE COULTER MicroDiff, 2-2

Function, 2-2

Mode of Operation, 2-2

2.3 DIFFERENTIAL MEASUREMENT, 2-2

2.4 OPERATIONAL OVERVIEW, 2-2

2.5 DILUTER, 2-3

General, 2-3

Count Valve 1 (VL1), 2-5

Dilution Valve 2 (VL2), 2-5

Stepper Motor Driver Card, 2-5

2.6 VENT VALVE VACUUM SENSE CARD, 2-8

2.7 ELECTRONICS ASSEMBLY, 2-8

General, 2-8

Motherboard, 2-9

Linear Power Supply, 2-10

PN 4237161B (April 1993) iii

TABLE OF CONTENTS

Power Supply Components, 2-10

Switching Power Supply, 2-13

Data Acquisition Card, 2-14

Multi Stepper Motor Control Card (MSMC), 2-15

Input Output Resource Adapter Card (IORA), 2-17

Keyboard, 2-18

Display, 2-19

3 MICRODIFF INSTALLATION PROCEDURE, 3-1

3.1 PREINSTALLATION CHECKS, 3-1

Space and accessibility, 3-1

Power Requirements, 3-1

Ambient Temperature and Humidity, 3-1

3.2 INITIAL SETUP, 3-2

Uncrating Instrument, Accessories and

Supplies, 3-2

Reagent Connections, 3-2

Printer Connection, 3-3

Power ON, 3-3

3.3 INSTRUMENT CONFIGURATION, 3-3

3.4 PRELIMINARY OPERATION CHECKS, 3-4

3.5 SETTING AIM FACTORS, 3-5

3.6 CALIBRATION, 3-5

3.7 RUNNING CONTROLS, 3-6

4 SERVICE/REPAIR PROCEDURES, 4-1

4.1 TOOLS AND EQUIPMENT REQUIRED, 4-1

4.2 DRIVER CARD REPLACEMENT, 4-1

Removal, 4-1

Installation, 4-1

4.3 PVAC CARD REPLACEMENT, 4-1

Installation, 4-2

4.4 MOTHERBOARD REPLACEMENT, 4-2

Removal, 4-2

Installation, 4-3

4.5 SYRINGE REPLACEMENT, 4-3

Removal, 4-3

Installation, 4-4

iv PN 4237161A (July 1992)

TABLE OF CONTENTS

4.6 VACUUM PUMP REPLACEMENT, 4-4

Removal, 4-4

Installation, 4-4

4.7 LYSE PUMP REPLACEMENT, 4-5

Removal, 4-5

Installation, 4-5

4.8 LYSE PUMP VERIFICATION/ADJUSTMENT, 4-5

4.9 SWITCHING POWER SUPPLY REPLACEMENT, 4-6

Removal, 4-6

Installation, 4-6

4.10 DISKETTE DRIVE REPLACEMENT, 4-7

Removal, 4-7

Installation, 4-7

4.11 DAC CARD REPLACEMENT, 4-7

Removal, 4-7

Installation, 4-8

4.12 MSMC CARD REPLACEMENT, 4-8

Removal, 4-8

Installation, 4-8

4.13 IORA CARD REPLACEMENT, 4-8

Removal, 4-8

Installation, 4-9

4.14 DISPLAY REPLACEMENT, 4-9

Removal, 4-9

Installation, 4-9

4.15 KEYPAD REPLACEMENT, 4-10

Removal, 4-10

Installation, 4-10

4.16 RED/WHITE BATH/APERTURE COMPONENT

REPLACEMENT, 4-11

Hgb Detector/LED, 4-11

Removal, 4-11

Installation, 4-12

Aperture Electrode Housing

Replacement, 4-12

Removal, 4-12

Installation, 4-13

Bath, 4-13

Removal, 4-13

Installation, 4-14

PN 4237161B (April 1993) v

TABLE OF CONTENTS

CHAPTER 5 INTENTIONALLY OMITTED

6 SCHEMATIC DIAGRAMS, 6-1

CHAPTER 7 INTENTIONALLY OMITTED

8 ILLUSTRATED PARTS LIST, 8-1

8.1 PARTS LIST IN PART NUMBER ORDER, 8-1

8.2 ILLUSTRATED PARTS LISTS, 8-6

APPENDIX A ERROR CODES, A-1

A.1 MicroDiff ERROR CODES, A-1

ILLUSTRATIONS

2.1 Diluter Components, 2-4

2.2 Stepper Motor Driver Card, 2-6

2.3 Motherboard, 2-9

2.4 Linear Power Supply, 2-11

2.5 Regulator Card, 2-12

2.6 Data Acquisition Card, 2-14

2.7 Multi Stepper Motor Control Card, 2-16

2.8 Input/Output Resource Adapter Card, 2-18

8.1 Diluter, 8-6

8.2 Syringe Drive, 8-8

8.3 Linear Power Supply, 8-10

8.4 Bath, Rear View, 8-11

8.5 Bath, Front View, 8-12

8.6 Keypad and Display, 8-13

8.7 Diluent and Count Valve Display, 8-14

8.8 Carriage Assembly, 8-16

TABLES

2.1 Stepper Motor Driver Card Connections, 2-7

2.2 Stepper Motor Driver Card Test Points, 2-8

2.3 Terminal Block Connections, 2-12

2.4 MSMC Jumpers, 2-17

2.5 IORA Jumpers, 2-7

vi PN 4237161A (July 1992)

1.1 GENERAL SAFETY

WARNING

CAUTION

WARNINGS AND CAUTIONS 1

Throughout this manual you will encounter the headings WARNING,

CAUTION, IMPORTANT, and Note. These are provided to inform you

of potentially hazardous situations and important or helpful information.

A WARNING indicates a situation or procedure that, if ignored, can

cause serious personal injury. A WARNING will appear in bolded text

for easy identification.

A CAUTION indicates a situation or procedure that, if ignored, can

cause damage to equipment. A CAUTION also appears in bolded text.

IMPORTANT

An IMPORTANT indicates a situation or procedure that, if ignored can

result in erroneous test results. An IMPORTANT also appears in bolded

text.

Note

A Note contains information that is important to remember or helpful in

performing a procedure.

1.2 ELECTRONIC SAFETY PRECAUTIONS

WARNING

Remove rings and other metal jewelry before performing maintenance

or service on the electronic components of instrument.

PN 4237161A (July 1992) 1-1

WARNINGS AND CAUTIONS

1.3 BIOLOGICAL SAFETY

CAUTION

To prevent damage to delicate electronic components, always be sure

power is OFF before removing or replacing printed circuit boards and

components.

WARNING

To prevent possible injury or biological contamination, service

personnel must wear gloves and eye protection when servicing the

instrument with the doors open.

Use care when working with pathogenic materials. Means must be

available to decontaminate the instrument, provide ventilation, and to

dispose of waste liquid. Refer to the following publications for further

guidance on decontamination.

Biohazards Safety Guide, 1974, National Institute of Health.

Classifications of Etiological Agents on the Basis of Hazards, 3d ed.,

June 1974, Center for Disease Control, U.S. Public Health Service.

In areas of high risk, operator must be trained in person. Telephone

instruction is prohibited.

1-2 PN 4237161A (July 1992)

2.1 SPECIFICATIONS

Dimensions/Weight

Power

INSTRUMENT DESCRIPTION 2

Height 49.5 cm (19.5 in.)

Width 43.2 cm (17 in.)

Depth 40.6 cm (16 in.)

Weight 34 Kg (75 lb)

Input

• 100 Vac (±10%) 50/60 Hz

• 120 Vac (±10%) 50/60 Hz

• 220 Vac (±10%) 50/60 Hz

• 240 Vac (±10%) 50/60 Hz

Consumption

Less than 200 watts

Ambient Operating Temperature

16°C to 32°C (60°F to 90°F)

Humidity

0 to 95% without condensation

Recommended Reagents

COULTER MICRO-PAK (diluent and lytic reagent) P/N 8547007

COULTER CLENZ

Controls and Calibrators

4C®PLUS Cell Control Tri Pac P/N 7547003

®

S-CAL

Calibrator Kit P/N 7547005

®

Cleaning Agent P/N 8546931

PN 4237161B (April 1993) 2-1

INSTRUMENT DESCRIPTION

Fluid Volumes

• Whole Blood Aspirated: 12 µL

• ISOTON

• LYSE S

®

III diluent consumption per cycle: 18.64 mL

®

III Diff reagent consumption per cycle: 415 µL

Interfering Substances

Refer to Product Reference Manual for known interfering substances

2.2 INTRODUCTION TO THE COULTER MicroDiff

Function

The MicroDiff is an automated hematology analyzer for in vitro

diagnostic use in clinical laboratories. The MicroDiff reports a 16

parameter Complete Blood Count, including a six parameter WBC

differential, from whole blood.

Mode of Operation

The MicroDiff has one operating mode. The sample is introduced to the

instrument by removing the cap from the sample tube, presenting the

sample to the aspirator probe, and starting the cycle.

2.3 DIFFERENTIAL MEASUREMENT

The MicroDiff performs WBC differentials from whole-blood samples. It

provides lymphocyte, monocyte and granulocyte percentages and

absolute numbers using Coulter histogram differential technology.

The white blood cells are counted and sized for the WBC histogram in a

single 100-µm WBC aperture.

2.4 OPERATIONAL OVERVIEW

The cycle is started by pressing the 〈ASP〉button on the keypad:

1. The aspirate syringe is driven down to aspirates 12 µL of sample and

a small amount of air.

2. The diluent syringe fills with diluent for the WBC dilution.

3. The bath drains.

2-2 PN 4237161B (April 1993)

OPERATIONAL OVERVIEW

4. The aspirator probe moves to the bath and dispenses the sample into

the bath. The diluent syringe dispenses diluent through the probe

into the bath making a 215:1 dilution.

5. Mixing bubbles from the air pump (PM1) enter the bath to mix the

solution.

6. The aspirate syringe is driven down again to aspirate 100 µl of the

dilution from the bath into the probe, where it is held for the

RBC/Plt dilution.

7. The lyse pump (PM5) dispenses 415 µL of lyse to the bath for a final |

WBC dilution of 251:1 and the sample is mixed again.

8. The WBC solution is drawn through the WBC aperture for 12 s to

count and size the WBCs.

9. After WBC analysis, and just before the WBC sample drains from

the bath, the Hgb reading is taken.

2.5 DILUTER

General

10. The bath is drained and rinsed and Hgb Blank is taken. |

11. The diluent syringe fills with diluent for the RBC/Plt dilution.

12. The 100 µL of the 215:1 solution, stored in the aspirate probe, is

dispensed into the bath with diluent to obtain a final RBC/Plt

dilution of 6250:1.

13. Mixing bubbles from PM1 enter the bath to mix the solution.

14. The RBC/Plt dilution is drawn through the RBC/Plt aperture for 12 s

to count and size the RBCs and Plts.

15. The bath is drained and rinsed.

16. The aperture is zapped, and the system is prepared for the next test |

sequence.

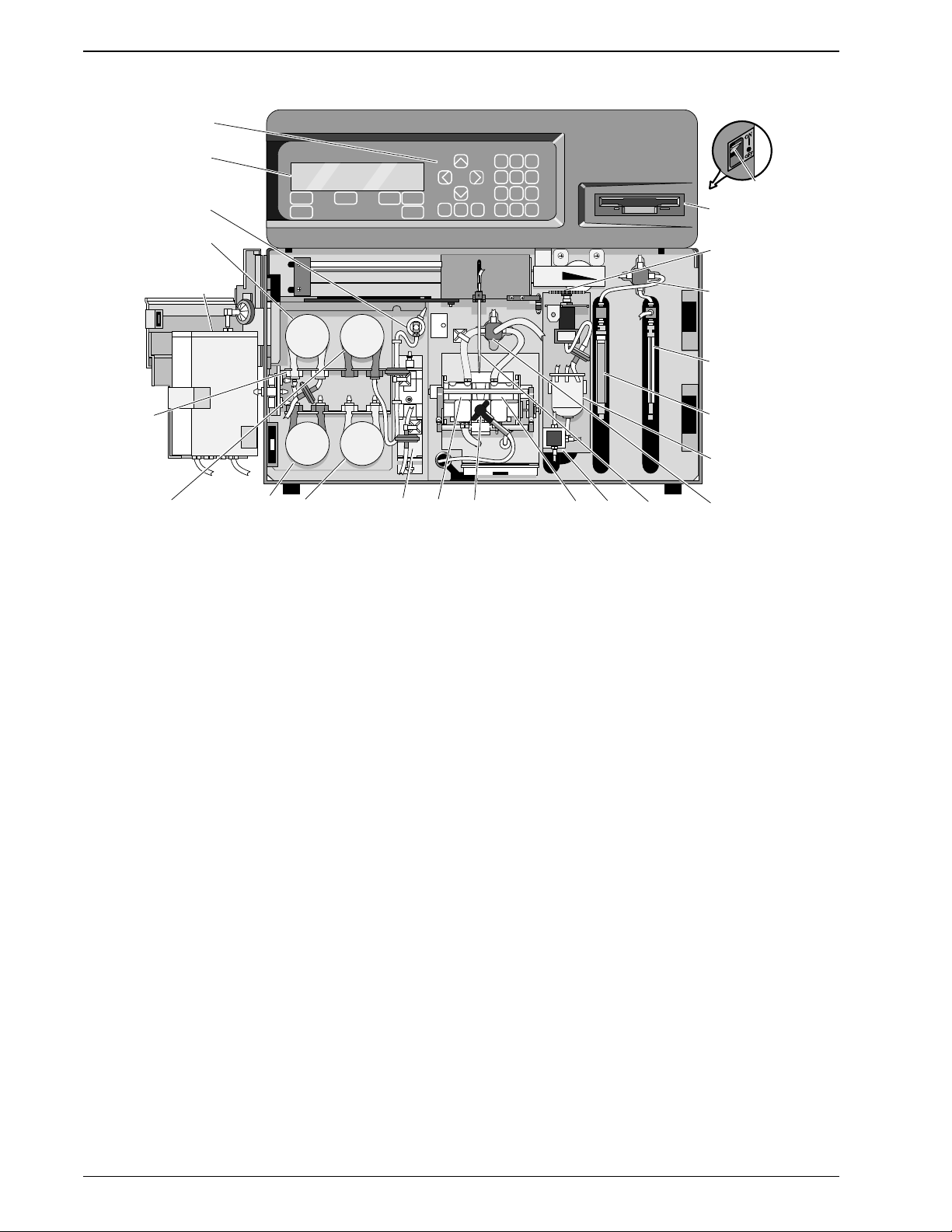

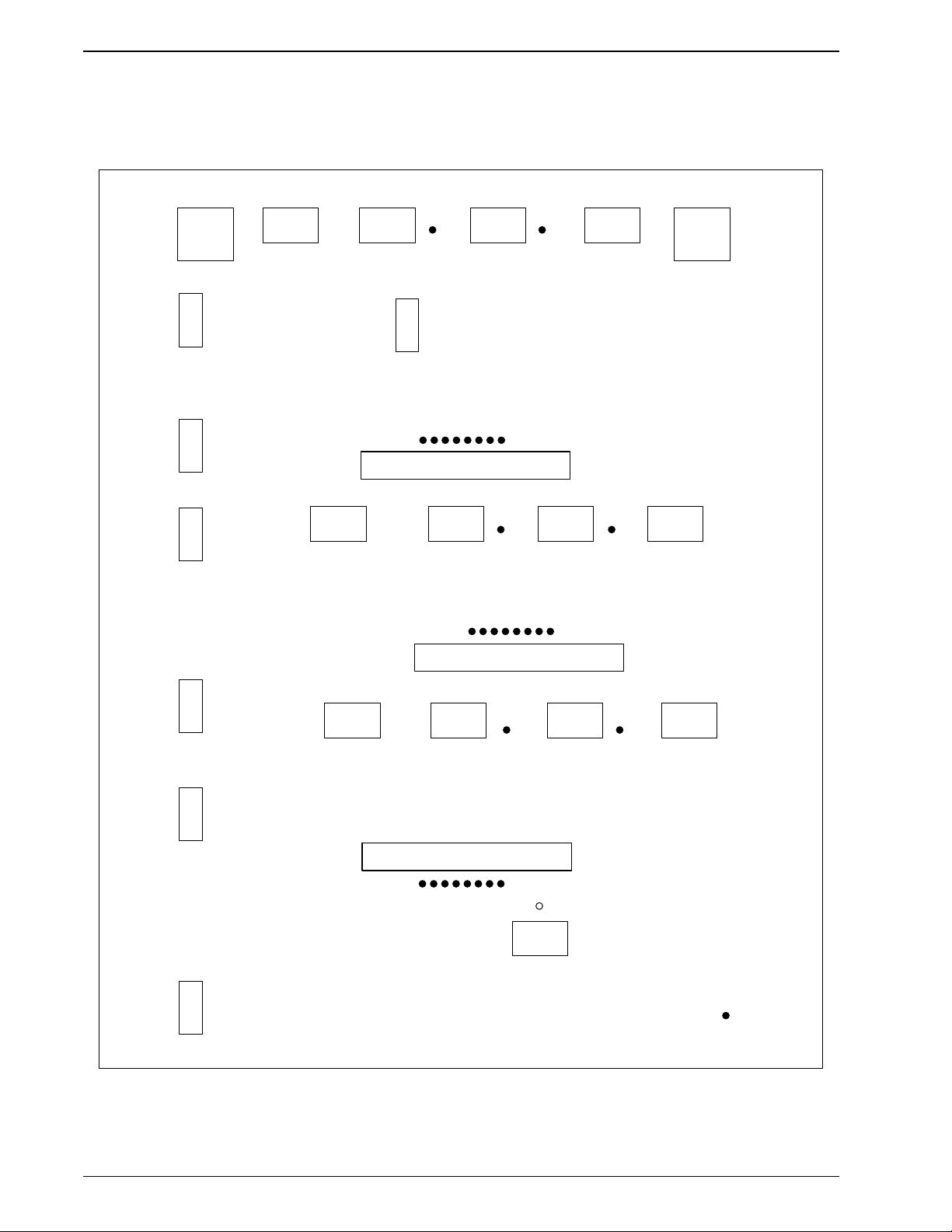

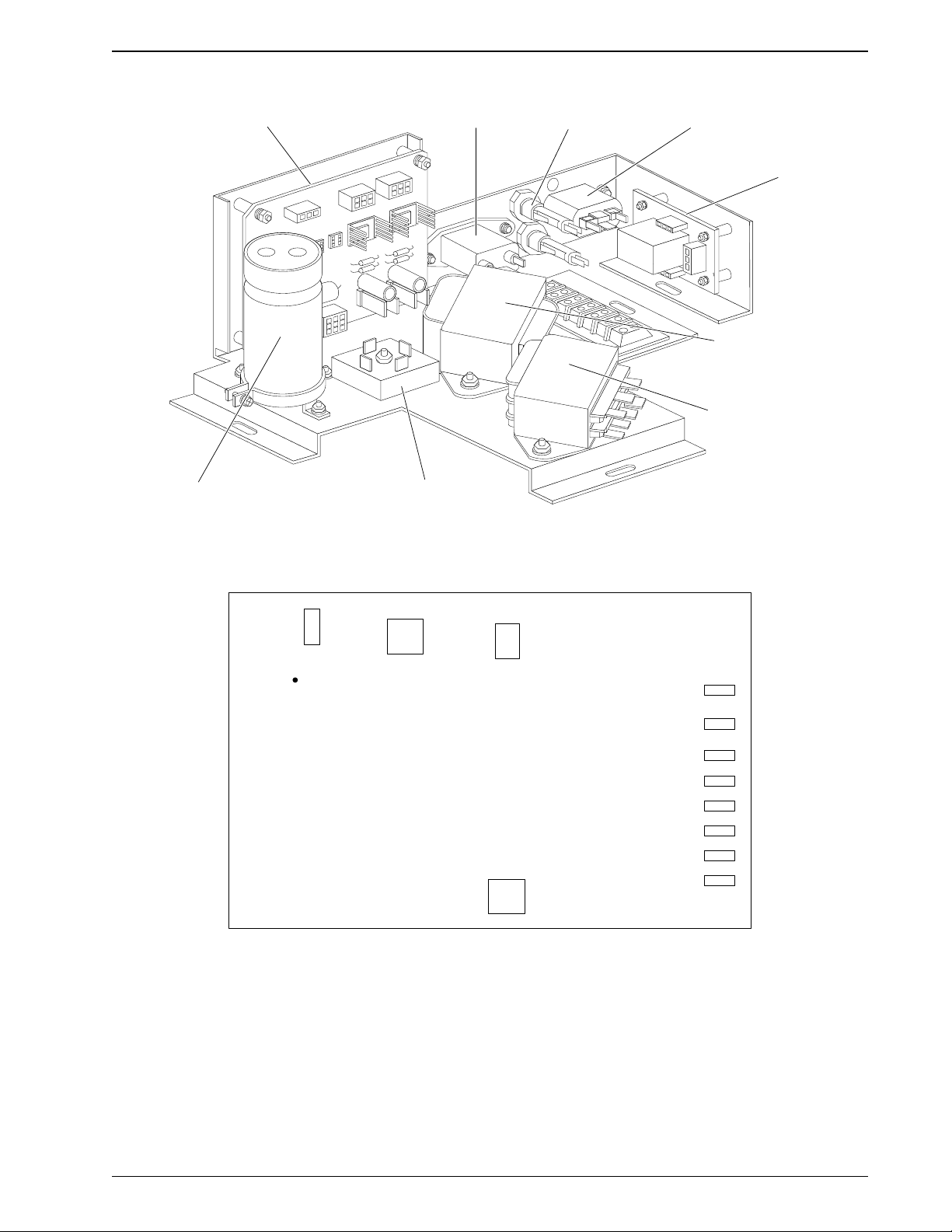

The diluter section of the MicroDiff processes the sample for analysis.

The locations of the components are illustrated in Figure 2.1.

PN 4237161B (April 1993) 2-3

INSTRUMENT DESCRIPTION

2

1

18

20

3

10

ON/OFF

SWITCH

19

9

222117

1. LCD DISPLAY

2. KEYPAD

3. DISK DRIVE

4. ASPIRATOR PROBE

5. ASPIRATION SYRINGE

6. DILUENT SYRINGE

7. VL2 DILUENT VALVE

8. LYSE PUMP PM5

9. LYSE DECTECTOR

10. VACUUM REGULATOR

11. VACUUM ISOLATOR

12. VL1 COUNT VALVE

13. BATH-WBC APERTURE

14. BATH-RBC APERTURE

15. HGB LED

16. LV3 DRAIN SOLENOID

17. AIR PUMP PM1

18. LV4 AIR MIX SOLENOID

19. DILUENT RESERVOIR

20. DILUENT PUMP PM2

21. RINSE PUMP PM3

22. WASTE PUMP PM4

7

5

6

11

124161315148

7161-01

Figure 2.1 Diluter Components|

The MicroDiff uses two syringes driven by stepper motors to aspirate

sample and deliver diluent. The syringe volumes are:

• Aspirate syringe 100 µL

• Diluent syringe 5000 µL

The instrument uses four stepper motor driven peristaltic pumps to

generate mixing bubbles, drain the bath, deliver rinse to the bath, and

draw diluent from diluent pack into the diluent reservoir.

Two stepper motor driven switching valves, Count Valve 1 and Dilution

Valve 2, control the flow and direction of the fluidics and pneumatics.

2-4 PN 4237161B (April 1993)

Count Valve 1 (VL1)

The count valve is a three-position valve that routes count vacuum to the

WBC and RBC apertures.

Dilution Valve 2 (VL2)

The dilution valve is a four-position valve that:

• Routes diluent to the bath through the aspirate probe.

• Provides a path to the diluent supply to fill diluent syringe.

• Routes the sweep flow diluent from the diluent reservoir through

the sweep flow can to the RBC aperture.

Stepper Motor Driver Cards

Two Stepper Motor Driver cards, in the Diluter, provide the drive voltage

to the stepper motors, the opto switches, the lyse pump, solenoids, and

the cycle counter.

DILUTER

Stepper Motor Driver Card 1 drives the following components:

• Diluent Pump • Air Pump

• Rinse Pump • Waste Pump

• Lyse Pump • Air Mix Solenoid

• Diluent Reservoir Sensor • Lyse Level Sensor

• Cycle Counter

Stepper Motor Driver Card 2 drives the following components:

• Dilution Valve • Dilution Valve Home Opto Switch

• Traverse Motor • Traverse Home Opto Switch

• Count Valve Motor • Count Valve Opto Switch

• Aspirate Syringe Motor • Aspirate Syringe Opto Switch

• Diluent Syringe Motor • Diluent Syringe Opto Switch

• Vacuum Pump ON • Power ON

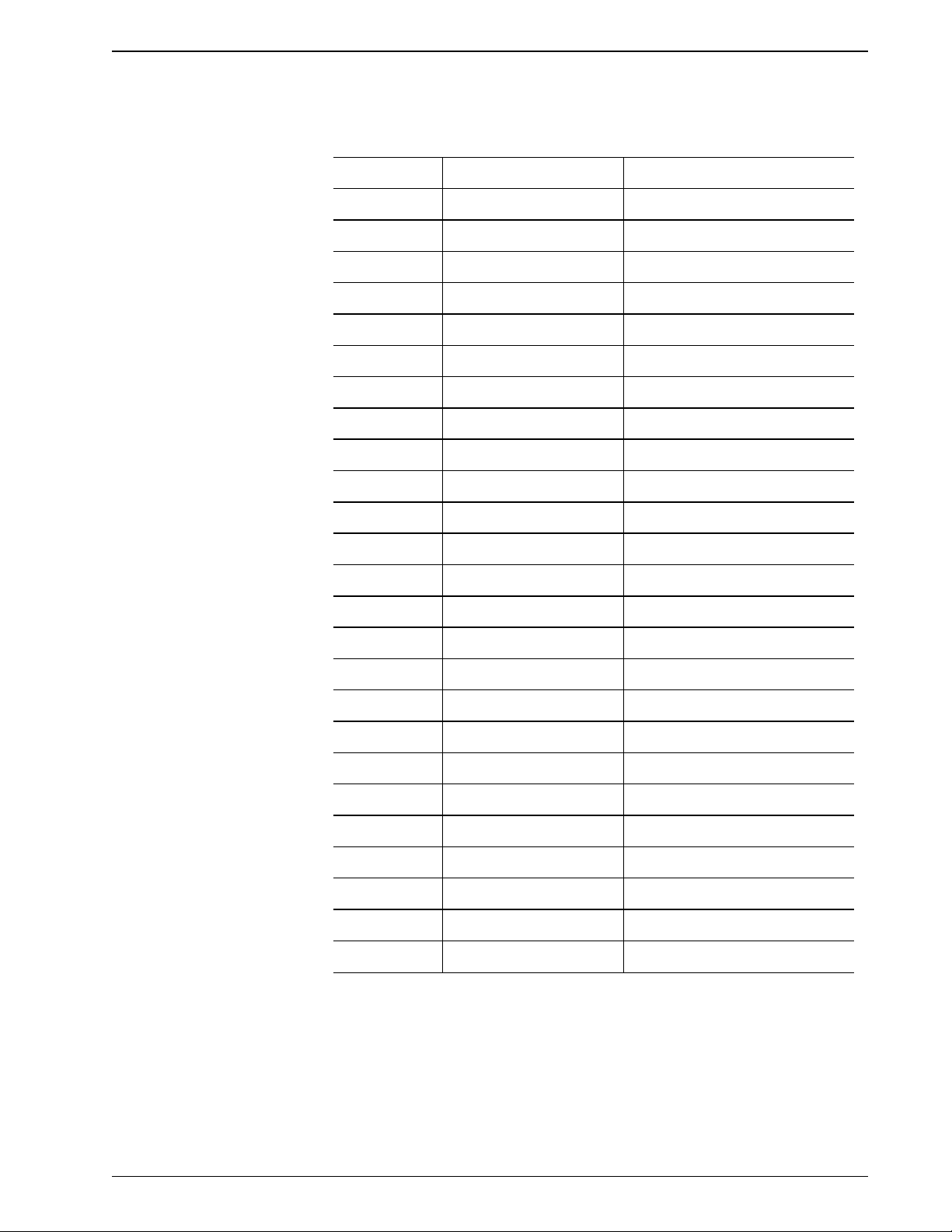

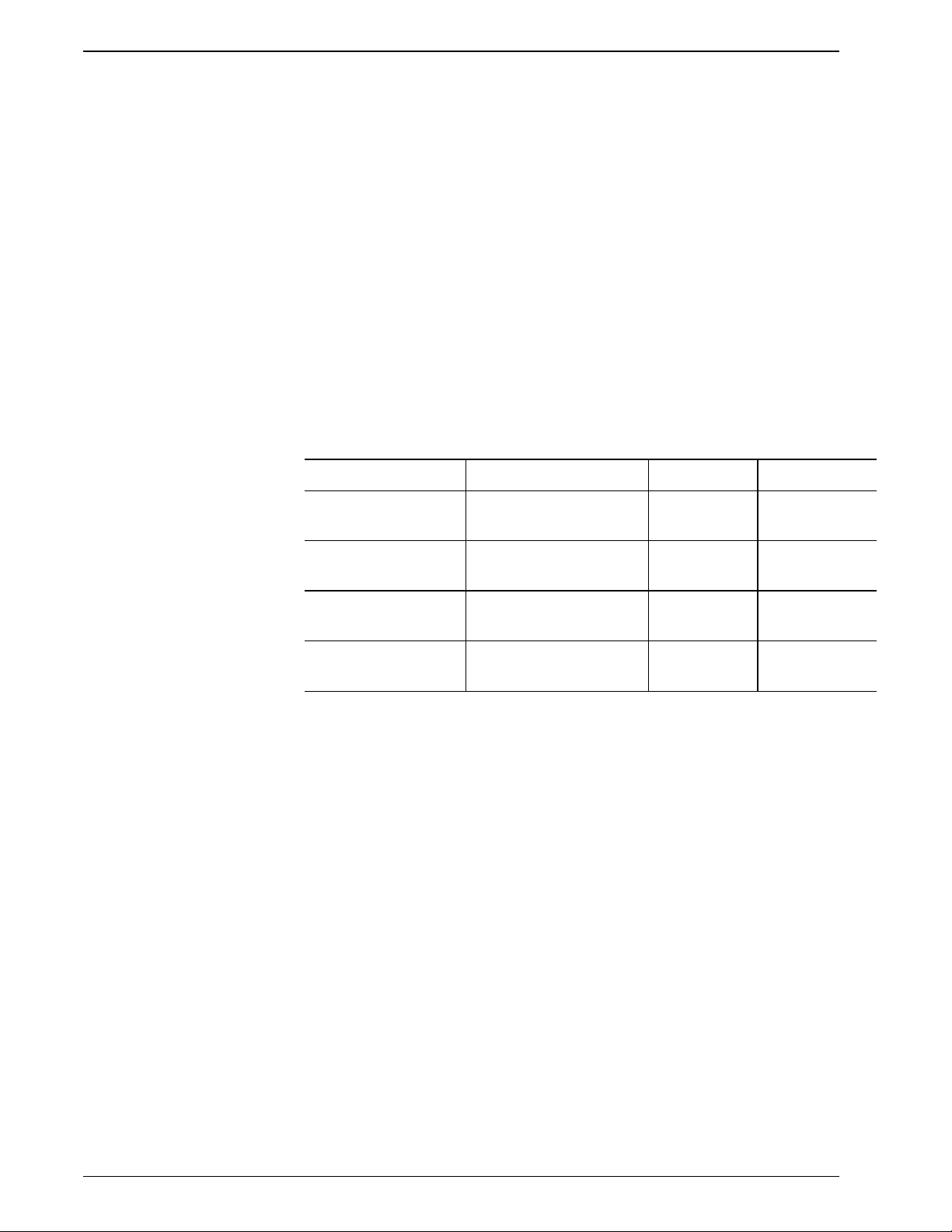

The location of the electrical connections and test points on the Stepper

Motor Driver Cards is shown in Figure 2.2. Tables 2.1 and 2.2 list the

connectors and test points.

PN 4237161B (April 1993) 2-5

INSTRUMENT DESCRIPTION

MOTOR DRIVER CARD

J18

J

3

0

J

2

9

J

2

8

J19 J20 J21 J22

TP4 TP5

J

3

1

T

T

T

T

T

T

P

P

P

9

8

7

T

T

P

P

P

P

P

1

1

1

1

6

3

2

1

0

J17

J12 J13 J14 J15

TP14 TP15

T

T

T

T

T

T

T

P

P

P

1

1

1

9

8

7

T

P

P

P

P

P

1

2

2

2

2

6

3

2

1

0

J10

J23

J

2

7

J5 J6 J7 J8

TP24 TP25

J

2

6

J3

T

T

T

T

T

P

2

8

T

P

P

P

P

P

2

2

2

3

3

9

7

6

3

1

J

2

TP3

T

T

P

P

3

3

2

0

J1

TP34

5

7161-02

Figure 2.2 Stepper Motor Driver Card

2-6 PN 4237161B (April 1993)

Table 2.1 Stepper Motor Driver Card Connections

Connector Driver 1 Driver 2

J1 +24 Volts +24 Volts

J3 MSMC 1 J1 MSMC 2 J1

J5 Not Used Count Valve Motor

J6 Not Used Count Valve Opto

J7 Not Used Traverse Opto

J8 Not Used Traverse Motor

J10 MSMC 1 J2 MSMC 2 J2

J12 Air Mix Motor Diluent Valve Motor

J13 Not Used Diluent Valve Opto

J14 Diluent Level Sense Not Used

DILUTER

J15 Diluent Fill Motor Not Used

J17 MSMC 1 J3 MSMC 2 J3

J18 Resistor Bank Resistor Bank

J19 Rinse Motor Aspirate Syringe Motor

J20 Not Used Aspirate Syringe Opto

J21 Lyse Level Sense Diluent Syringe Opto

J22 Waste Motor Diluent Syringe Motor

J23 Resistor Bank Resistor Bank

J25 Not Used Not Used

J26 Not Used Iso Chamber VentValve

J27 Air Mix Solenoid Vacuum Sense Vent Valve

J28 Cycle Counter Vacuum Pump ON Signal

J29 Lyse Pump Drain Solenoid

J30 Not Used Power ON to Relay Card

J31 Not Used +12 Volts

PN 4237161B (April 1993) 2-7

INSTRUMENT DESCRIPTION

Table 2.2 Stepper Motor Driver Card Test Points

Test Points Driver 1 Driver 2

TP3 Ground Ground

TP4 Not Used Aspirate Syringe Opto

TP5 Lyse Level Sense Diluent Syringe Opto

TP6 - TP13 Stepper Motor Phases Stepper Motor Phases

TP14 Not Used Diluent Valve Opto

TP15 Diluent Level Sense Not Used

TP16 - TP23 Stepper Motor Phases Stepper Motor Phases

TP24 Not Used Count Valve Opto

TP25 Not Used Traverse Opto

TP26 - TP33 Stepper Motor Phases Stepper Motor Phases

TP34 +24 Volts +24 Volts

2.6 VENT VALVE VACUUM SENSE CARD

The Vent Valve Vacuum Sense Card (VVVS) is responsible for

monitoring the 6-in. Hg of vacuum used for count, venting the isolator

chamber when in drains, and venting the vacuum transducer to obtain

an atmosphere offset.

The output of the VVVS goes to the IORA card. the voltage for 6 in. Hg

of vacuum is 4.286 volts plus the measured atmosphere offset voltage.

2.7 ELECTRONICS ASSEMBLY

General

The Electronics Assembly of the MicroDiff is contained in a hinged

compartment at the top of the instrument. It consists of the following

subassemblies:

• Motherboard with 80386 microprocessor

• 200 watt switching power supply

• Front panel with keypad and LCD display

• 1.44 MB 3½in. floppy disk drive

• Data Acquisition Board (DAC)

• Multi Stepper Motor Controller Card (MSMC)

• Analog/Peripheral Board (IORA)

• Vacuum Sensor Amp Board (PVAC)

2-8 PN 4237161B (April 1993)

Motherboard

SERIAL 1

SERIAL 2

3

5

2

4

1 PARALLEL

FLOPPY DISK

SWITCH

BATTERY

IDE HARD DISK

80387SX

4

1

4MX9 SIM M

SUPPORT

JUMPER

8742

27512

RESET

SPEAKER

KEYLOCK

IDE ACTIVITY

SXCAT DIAGRAM

7161016A

TURBO

LED

TURBO

SWIT CH

ELECTRONICS ASSEMBLY

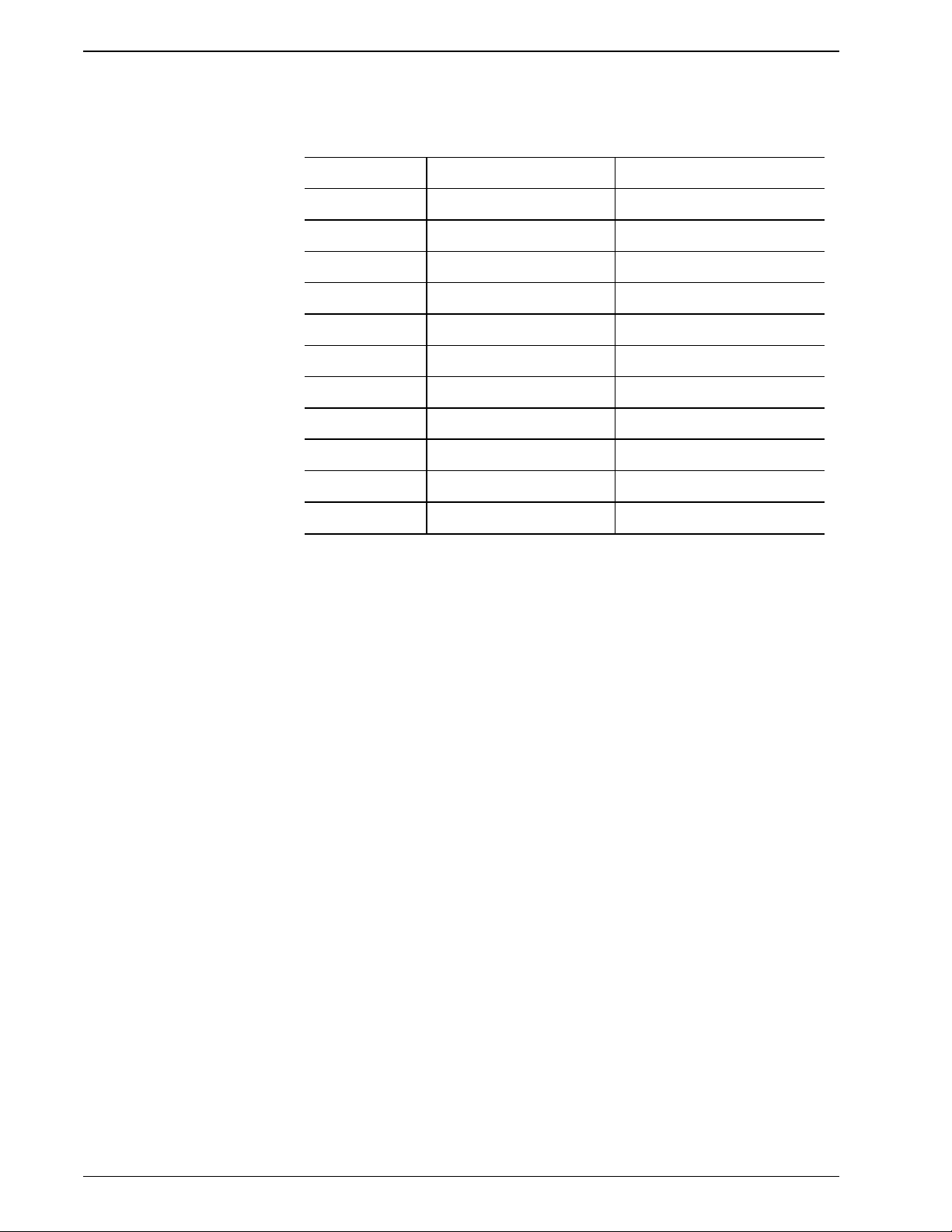

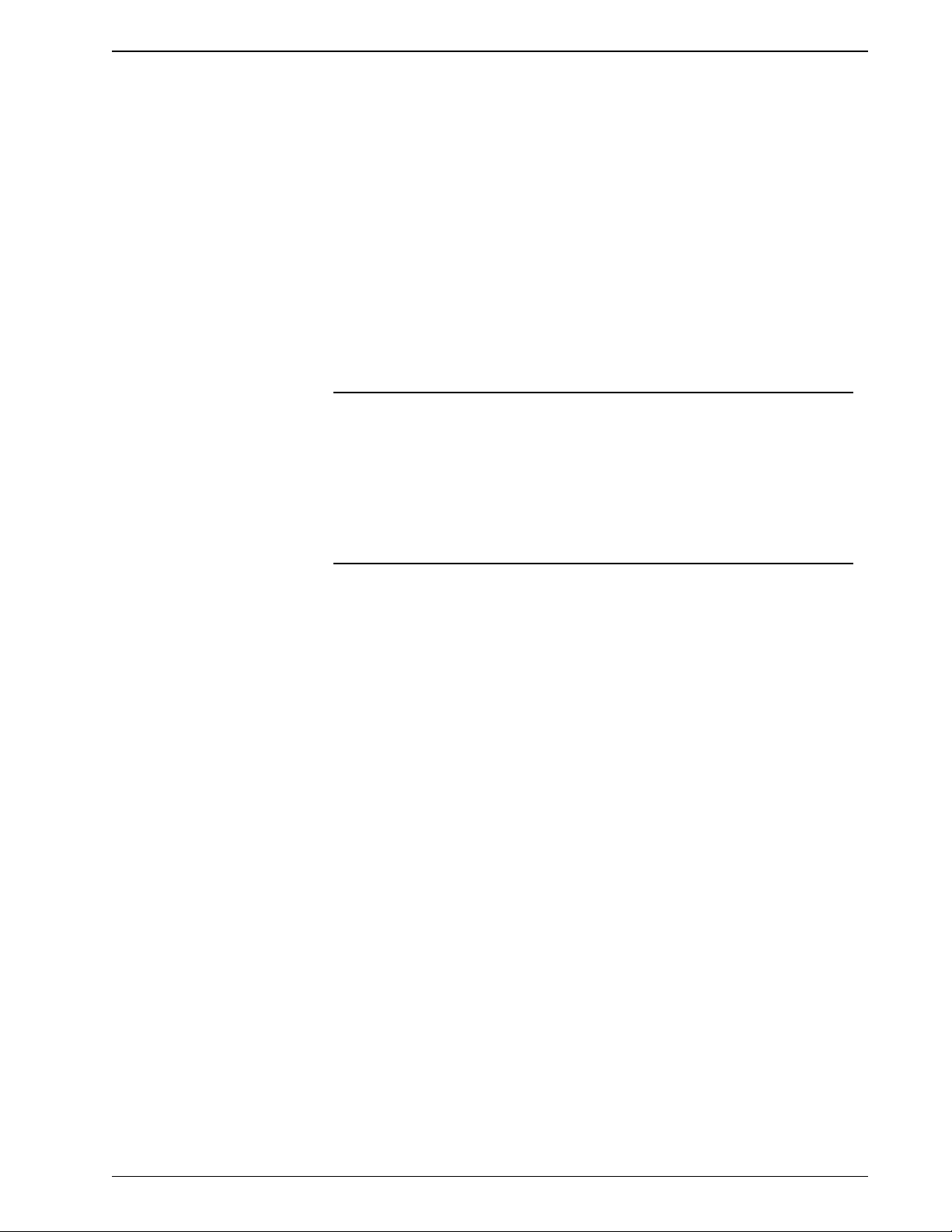

The Motherboard (Figure 2.3) is an AT compatible 80386 computer. The

disk controller and serial I/O port are resident on the board. Program

software is not resident in EPROMs on the motherboard. The program is

loaded from the diskette drive into the computer’s memory.

Figure 2.3 Motherboard

Switch |Description |

SW1-1 |Close (On) to enable Onboard Battery. |

Open (Off) to enable Offboard Battery. |

SW1-2 |Close (On) to Enable Battery. |

Open (Off) to Disable Battery. |

Must be closed for normal system operation. |

SW1-3 |Close (On) for additional wait states on IDE interface. |

Open (Off) for no additional wait states. |

SW1-4 |Close (On) for Color Adapter. |

Open (Off) for Monochrome Adapter. |

This switch setting does not matter when using VGA or |

PN 4237161B (April 1993) 2-9

EGA adapters. |

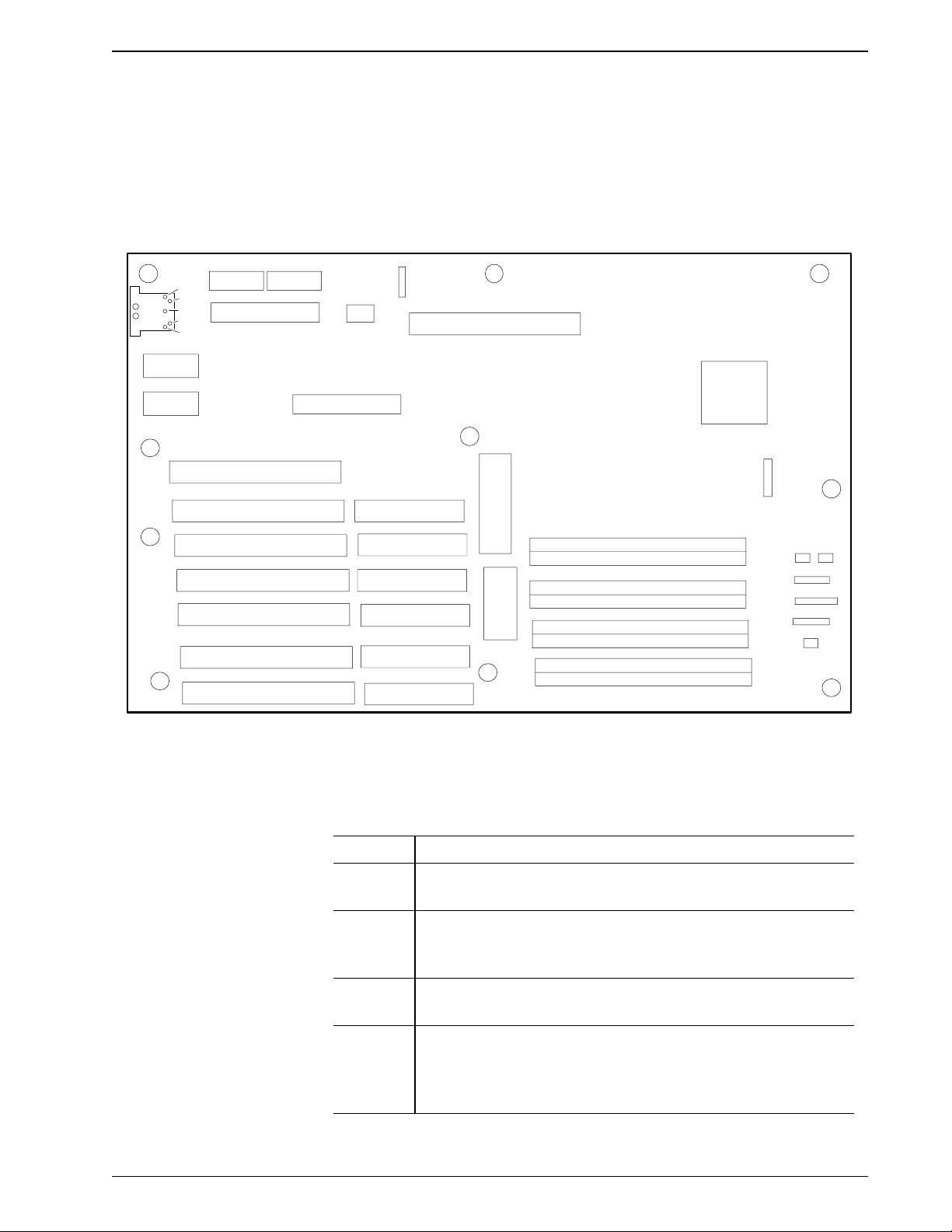

Linear Power Supply

ELECTRONICS ASSEMBLYINSTRUMENT DESCRIPTION

The Linear Power Supply (Figure 2.4) is a self contained unit located

below the Computer Chassis at the bottom of the Main Chassis

Assembly. The unit is accessible with the hinged electronics

compartment open. The Power Supply provides all the necessary dc and

ac voltages to operate the unit. The supplied voltages are:

• ±15 Vdc for the analog circuitry

• +24 Vdc for the stepper motors and pneumatic solenoids

• +240 Vdc to generate aperture current and zap volts

• 0.02 amp constant current source for the Hgb LED.

The unit supplies dc power to the following assemblies:

• DATA ACQ and IORA Boards located in the electronics

compartment.

• PVAC Board, and the Hgb LED assembly located in the diluter

panel.

• Motor Driver boards located in the Main Chassis.

The unit also supplies the ac power for the Vacuum Pump, Switching

Power Supply, and the 24-volt Power Supply.

Power Supply Components

Power Supply Board: This board consists of rectifiers; filters and

regulators for ±15 V and +240 V; a constant current source for the Hgb

LED; connectors for all inputs, outputs and test points.

Power Transformer T1: T1 provides stepped down ac power to the power

supply board for the +15 volt supply, the -15 volt supply, the 240 volt

supply and the constant current source for the Hgb LED supply which is

driven from the +15 volt supply.

24V Power Transformer T2: T2 provides stepped down ac voltage for the

+24v Power Supply.

2-10 PN 4237161B (April 1993)

ELECTRONICS ASSEMBLY

FUSE HOLDERREGULATOR CARD

LINE FILT ER

OUTLET

RELAY CA RD

24V TRANSFORMER

MAIN TRANSFORMER

BRIDGE RECTIFIER

24V FILTER CAPACITOR

7161-04

J

2

TP9

APP C URRE NT

Figure 2.4 Linear Power Supply

J3

J4

J1

Figure 2.5 Regulator Card

Hgb

Hgb Ref.

+15

Gnd

-15

Gnd

240V Gnd

240V

TP7

TP6

TP5

TP4

TP3

TP8

TP2

TP1

7161-05

PN 4237161B (April 1993) 2-11

ELECTRONICS ASSEMBLYINSTRUMENT DESCRIPTION

+24 Rectifier and Filter: Provides +24 Vdc for motors and solenoids.

Vacuum Pump Solid State Relay: Connects the input ac voltage to the

vacuum pump.

+24-V Relay: Connects the input ac voltage to the +24-Volt power

transformer. The signal to operate the relay comes from the MSMC Card

through the motor driver.

AC Line Filter: Filters the input ac voltage before going to the

transformers and switching power supply.

Fuses: Control the ac line voltage to the input of the instrument.

Terminal Block: Provides ac line voltage selection (see Table 2.3).

Table 2.3 Terminal Block Connections

Input Voltage Relay Card AC Wire Position Jumper

100 White

Black

120 White

Black

220 White

Black

240 White

Black

1

4

1

6

1

4|

1

6|

1&2

3&4

1&2

5&6

2&5

2&5

The Power Transformer T1 has three secondaries that provide ac voltage

to all the supplies. The high voltage winding is surrounded by an

electrostatic shield to reduce noise induced by the ac line. All the

secondary windings of the transformer are internally fused.

The ac voltage is then distributed to the power supply card where the ac

is full wave rectified, filtered, and regulated. The regulated supplies are

protected against overload and short circuit by current foldback and

thermal shutdown.

Two input signals to the Power Supply Card come from the DAC Card.

These signals are the aperture current ON command and aperture

current control. The aperture current ON command turns on the high

voltage regulator when aperture current is required.

The aperture current control is a signal between 0 and 5 Volts that

controls the output of the high voltage regulator. The output of this

regulator controls the gain of the pre-amp section on the DAC Card.

The Power Supply has two fuses, F1 and F2, rated at 2.0 A for 100 Vac to

120 Vac or 1.0 Amps for 200 Vac to 240 Vac.|

2-12 PN 4237161B (April 1993)

Switching Power Supply

The Switching Power Supply is in the top chassis and provides +5 Vdc

and +12 Vdc to the CPU and associated electronics. The switching

supply also has the POWER ON switch for the system and a cooling fan.

The ac input voltage is switch selectable for 90 Vac to 130 Vac or 180

Vac to 260 Vac. The voltages developed are plus and minus 5 volts and

plus and minus 12 volts.

There are 5 connectors coming from the Switching Power Supply. A label

on the Switching Power Supply list the voltage and current for each

connector and connector pin.

The power connectors P4 and P5 must not be switched!! If they are

reversed the computer motherboard may be damaged. P4 should be

towards the rear of the board and P5 towards the front. Another way to

check proper connection is thatthecommonblackwiresfor each of the

connectors will be next to each other in the middle .

ELECTRONICS ASSEMBLY

CAUTION

Data Acquisition Card

The destination of the Switching Power Supply connectors are:

P1 Spare

P2 Spare

P3 Diskette Drive

P4 Computer Motherboard P1

P5 Computer Motherboard P2

The Data Acquisition Card (DAC) (Figure 2.6) performs the following

functions:

• Pre-Amp for RBC/PLT/WBC • Aperture Current Control

• Aperture Cleaning Circuit • RBC/WBC Editing

• Thresholding for RBC/PLT/WBC • PLT Processing

• RBC/WBC Counting • Interface to the AT bus

• Aperture Integrity Monitor • RBC/PLT/WBC Analog to

Digital conversion

PN 4237161B (April 1993) 2-13

Loading...

Loading...