Coulter MD II Service manual

COULTER® MD II™ Series Analyzer

789

456

123

_

.

0

TM

â

MD II

Service Manual

PN 4237242C (January 1998)

COULTER CORPORATION

Miami, Florida 33196

®

LEGAL NOTICES

Coulter Corporation makes no representation that, upon furnishing this service manual, the holder of the manual will have

the necessary technical capabilities and know-how to properly troubleshoot and repair any of the equipment specified in the

manual. Coulter Corporation assumes no liability whatsoever, including consequential and incidental damages, resulting

from improper operation of Coulter instruments after maintenance of Coulter instruments has been performed by persons

not employed by Coulter Corporation. Furthermore, Coulter Corporation assumes no liability whatsoever for any personal

injury or property damage resulting from maintenance and/or repair of Coulter instruments performed by persons not

employed by Coulter Corporation.

READ ALL PRODUCT MANUALS AND CONSULT WITH COULTER-TRAINED PERSONNEL

BEFORE ATTEMPTING TO OPERATE INSTRUMENT.

HAZARDS AND OPERATIONAL PRECAUTIONS AND LIMITATIONS

WARNINGS, CAUTIONS, and IMPORTANTS alert you as follows:

WARNING - Might cause injury.

CAUTION - Might cause damage to the instrument.

IMPORTANT - Might cause misleading results.

Coulter Corporation urges its customers to comply with all national health and safety standards such as the use of barrier

protection. This may include, but it is not limited to, protective eyewear, gloves, and suitable laboratory attire when

operating or maintaining this or any other automated laboratory analyzer.

"This Service Manual contains confidential information of Coulter Corporation and its receipt or possession does not

convey any rights to reproduce, disclose its contents, or to manufacture, use, or sell anything it may describe.

Reproduction, disclosure, or use without specific written authorization of Coulter Corporation is strictly forbidden."

Copyright © Coulter Corporation 1995, 1996, 1998

All rights reserved.

REVISION STATUS

Initial Issue A, 8/95

Software Version 1.2

Revision B, 3/96

Software Version 1.3

Updated text for software level 1.3, updated the parts list, added specifications and procedures for the

optional Epson

corrections. The following pages were changed or added: vi, vii-xv, 2-ii, 2-iii, 2.13, 2.2-2, 2.4-5, 2.4-9,

2.4-12, 2.4-13, 3-i, 3.1-2, 3.2-1, 3.2-3, 3.4-1 through 3.4-4, 4.28-1, 4.28-2, 5.1-1, 5.2-1, 7.4-1, 8-i, 8.1-8

through 8.1-7, 8.2-1, 8.2-2, 8.2-4, 8.2-5, 8.2-8, 8.2-9, 8.2-12, A-i, A.1-1, A.2-1 through A.2-4, A.5-1, D-i,

D.1-1, D.1-2, E-i, E.1-1 and INDEX-1 through INDEX-11.

Revision C, 1/98

Released by CN 032060-0248

Software Version 1.3

Reformatted the manual to enhance the online version. Reformatting the manual changed the appearance

of each page, but it did not change the content. Consequently, a revision B manual and a revision C

manual look different but contain the same material.

®

TM-290P Slip Printer, added information about the ISL option, and made minor

This document applies to the latest software listed and higher versions. When a subsequent software version affects the

information in this document, the changes will be summarized on a Notice of Information Update form and will be released

by service memo.

PN 4237242C

i

This document applies to the latest software listed and higher versions. When a subsequent software version affects the

information in this document, the changes will be summarized on a Notice of Information Update form and will be released

by service memo.

PN 4237242C

ii

LEGAL NOTICES

REVISION STATUS,i

CONTENTS,iii

1 INTRODUCTION,1.1-1

1.1 MANUAL DESCRIPTION,1.1-1

Scope,1.1-1

Organization,1.1-1

Numbering Format,1.1-1

Special Headings,1.1-1

WARNING,1.1-1

CAUTION,1.1-2

IMPORTANT,1.1-2

ATTENTION,1.1-2

Note,1.1-2

Conventions,1.1-2

1.2 SAFETY PRECAUTIONS,1.2-1

Electronic,1.2-1

Biological,1.2-1

Troubleshooting,1.2-2

CONTENTS

2 INSTRUMENT DESCRIPTION,2.1-1

2.1 SYSTEM OVERVIEW,2.1-1

Description,2.1-1

Software Menu System,2.1-2

Software Tables,2.1-2

Aspirate Table,2.1-5

Power-up Table,2.1-6

2.2 POWER SUPPLY,2.2-1

Overview,2.2-1

AT Power Supply,2.2-1

Inputs,2.2-1

Outputs,2.2-1

Switches,2.2-2

AC Power/Vacuum Relay Card,2.2-2

Inputs,2.2-5

Outputs,2.2-5

Test Points,2.2-5

Jumpers,2.2-5

+24 Volt Switching Power Supply,2.2-6

Inputs,2.2-6

Outputs,2.2-6

Adjustments,2.2-6

Linear Power Supply Card,2.2-6

Inputs,2.2-8

Outputs,2.2-8

PN 4237242C

iii

CONTENTS

Test Points,2.2-8

Jumpers,2.2-8

2.3 FLUIDICS PANEL,2.3-1

Overview,2.3-1

Diluter Panel,2.3-2

Probe/Wipe Traverse Assembly,2.3-4

Peristaltic Pump Assembly,2.3-5

Syringe Assembly,2.3-6

Individual Components Mounted to Fluidics Panel,2.3-7

Cycle Counter and Air Solenoids,2.3-7

Diluent Reservoir,2.3-7

Flex Connect Card,2.3-7

Lyse Pump (PM5),2.3-8

Solenoid Interconnect Card,2.3-8

Vacuum Regulator,2.3-9

2.4 SYSTEM CONTROL,2.4-1

AT Motherboard,2.4-1

Switches and Jumpers,2.4-1

User Resource Adapter (URA) Card,2.4-2

Keypad Controller,2.4-3

Display Controller,2.4-3

CMOS RAM,2.4-3

Diagnostic Data Acquisition Circuit,2.4-4

Utility Timer Circuit,2.4-4

Support Circuits,2.4-4

Inputs,2.4-5

Outputs,2.4-5

Adjustments,2.4-5

Switches and Jumpers,2.4-6

Diluter Resource Adapter (DRA) Card,2.4-6

Motor Controller,2.4-6

Solenoid Controller,2.4-7

Support Circuitry,2.4-7

Inputs,2.4-7

Outputs,2.4-7

Jumpers,2.4-8

Motor/Solenoid Driver Card,2.4-8

Motor Driver,2.4-9

Solenoid Driver,2.4-9

Sensor Control,2.4-9

+24 V POWER ON Signal,2.4-9

+24 V POWERFAIL (PF/PG) Signal,2.4-10

Inputs,2.4-10

Outputs,2.4-10

Test Points,2.4-11

Jumpers,2.4-11

iv

PN 4237242C

2.5 DATA ACQUISITION,2.5-1

Sensor Preamp Adapter (SPA) Card,2.5-1

Inputs,2.5-1

Outputs,2.5-2

Adjustments,2.5-2

Jumpers,2.5-2

Hgb Preamp Card,2.5-3

Inputs,2.5-4

Outputs,2.5-4

Adjustments,2.5-4

Test Points,2.5-4

Vacuum Sensor Card,2.5-4

Inputs,2.5-5

Outputs,2.5-5

Adjustments,2.5-5

Test Points,2.5-6

Sensor Processing Adapter with Diagnostics (SPAD) Card,2.5-6

Power Supply Conditioning,2.5-7

Oscillator Circuit,2.5-7

Control Functions,2.5-7

Octal Digital-to-Analog Converter (DAC),2.5-8

Aperture Signal Processing,2.5-8

Data Acquisition Circuit,2.5-8

Test Pulse Generator,2.5-9

Interrupt Selector,2.5-9

Input,2.5-9

Outputs,2.5-9

Jumper,2.5-10

Adjustments,2.5-10

CONTENTS

PN 4237242C

2.6 PERIPHERALS,2.6-1

Floppy Disk Drive,2.6-1

Display,2.6-1

Keypad,2.6-1

Rear Panel Interface Connectors,2.6-1

3 INSTALLATION PROCEDURES,3.1-1

PART A: INSTRUMENT INSTALLATION

3.1 PREINSTALLATION CHECKS,3.1-1

Space and Accessibility Requirements,3.1-1

Power Requirements,3.1-1

3.2 INITIAL SETUP,3.2-1

Unpack the Instrument,3.2-1

Connect the Reagents,3.2-2

Connect the Printer,3.2-3

Enter the Initial Settings,3.2-4

v

CONTENTS

3.3 INSTRUMENT VERIFICATION,3.3-1

Startup the Instrument,3.3-1

Calibrate the Instrument,3.3-1

PART B: UPGRADE AND OPTION INSTALLATION

3.4 OPTIONAL TICKET PRINTERS,3.4-1

Epson TM-290P Slip Printer,3.4-1

Purpose,3.4-1

Single-Printer Setup Procedure,3.4-1

Two-Printer Setup Procedure,3.4-3

4 SERVICE AND REPAIR PROCEDURES,4.1-1

4.1 GUIDELINES,4.1-1

4.2 ACCESSING THE HIDDEN SERVICE MENU ITEMS,4.2-1

Accessing Service Report,4.2-1

Purpose,4.2-1

Procedure,4.2-1

Accessing Service Diagnostic,4.2-1

Purpose,4.2-1

Procedure,4.2-1

System Reboot,4.2-2

4.3 REMOVING THE TOP COVER,4.3-1

4.4 OPENING THE LOWER CHASSIS,4.4-1

4.5 AT POWER SUPPLY,4.5-1

Tools/Supplies Needed,4.5-1

Removal,4.5-1

Installation,4.5-1

Verification,4.5-2

4.6 AT MOTHERBOARD,4.6-1

Tools/Supplies Needed,4.6-1

Removal,4.6-1

Installation,4.6-2

Verification,4.6-3

4.7 SENSOR PROCESSING ADAPTER WITH DIAGNOSTICS (SPAD) CARD,4.7-1

Tools/Supplies Needed,4.7-1

Removal,4.7-1

Installation,4.7-1

Verification,4.7-2

4.8 USER RESOURCE ADAPTER (URA) CARD,4.8-1

Tools/Supplies Needed,4.8-1

Removal,4.8-1

Installation,4.8-2

Verification,4.8-2

vi

PN 4237242C

4.9 DILUTER RESOURCE ADAPTER (DRA) 1 AND 2 CARDS,4.9-1

Tools/Supplies Needed,4.9-1

Removal,4.9-1

Installation,4.9-2

Verification,4.9-2

4.10 MEMBRANE KEYPAD AND DISPLAY, 4.10-1

Tools/Supplies Needed,4.10-1

Removal,4.10-1

Installation,4.10-2

Verification,4.10-2

4.11 AC POWER/VACUUM RELAY CARD,4.11-1

Tools/Supplies Needed,4.11-1

Removal,4.11-1

Installation,4.11-1

Verification,4.11-2

4.12 +24 VOLT SWITCHING POWER SUPPLY, 4.12-1

Tools/Supplies Needed,4.12-1

Removal,4.12-1

Installation,4.12-2

Verification,4.12-3

CONTENTS

4.13 LINEAR POWER SUPPLY CARD,4.13-1

Tools/Supplies Needed,4.13-1

Removal,4.13-1

Installation,4.13-2

Verification,4.13-3

4.14 VACUUM SENSOR CARD,4.14-1

Tools/Supplies Needed,4.14-1

Removal,4.14-1

Installation,4.14-2

Verification,4.14-2

4.15 MOTOR/SOLENOID DRIVER CARD, 4.15-1

Tools/Supplies Needed,4.15-1

Removal,4.15-1

Installation,4.15-1

Verification,4.15-2

4.16 SENSOR PREAMP ADAPTER (SPA) CARD,4.16-1

Tools/Supplies Needed,4.16-1

Removal,4.16-1

Installation,4.16-2

Verification,4.16-3

PN 4237242C

4.17 PROBE AND PROBE WIPE,4.17-1

Tools/Supplies Needed,4.17-1

Removal,4.17-1

vii

CONTENTS

Installation,4.17-2

Verification,4.17-3

4.18 PROBE MOTOR, 4.18-1

Tools/Supplies Needed,4.18-1

Removal,4.18-1

Installation,4.18-1

Verification,4.18-1

4.19 TRAVERSE DRIVE BELT,4.19-1

Tools/Supplies Needed,4.19-1

Removal,4.19-1

Installation,4.19-2

Verification,4.19-3

4.20 TRAVERSE MOTOR,4.20-1

Tools/Supplies Needed,4.20-1

Removal,4.20-1

Installation,4.20-2

Verification,4.20-3

4.21 SYRINGE ASSEMBLY, 4.21-1

Tools/Supplies Needed,4.21-1

Removal,4.21-1

Installation,4.21-3

Verification,4.21-4

4.22 PERISTALTIC PUMP MOTOR AND SPOOL, 4.22-1

Tools/Supplies Needed,4.22-1

Removal,4.22-1

Installation,4.22-2

Verification,4.22-2

4.23 VACUUM PUMP,4.23-1

Tools/Supplies Needed,4.23-1

Removal,4.23-1

Installation,4.23-1

Verification,4.23-1

4.24 APERTURE, BATH AND APERTURE ELECTRODE MODULE,4.24-1

Tools/Supplies Needed,4.24-1

Removal,4.24-1

Installation,4.24-2

Verification,4.24-3

viii

4.25 DILUTER PANEL SOLENOIDS,4.25-1

Tools/Supplies Needed,4.25-1

Removal,4.25-1

Installation,4.25-1

Verification,4.25-1

PN 4237242C

4.26 SWEEP-FLOW TUBING,4.26-1

Tools/Supplies Needed,4.26-1

Removal,4.26-1

Installation,4.26-2

Verification,4.26-2

4.27 LATEX GAIN ADJUSTMENT,4.27-1

Tools/Supplies Needed,4.27-1

Procedure,4.27-1

4.28 AIM ADJUSTMENT,4.28-1

Tools/Supplies Needed,4.28-1

Procedure,4.28-1

Optional Procedures,4.28-1

Option 1,4.28-1

Option 2,4.28-2

4.29 HGB PREAMP ADJUSTMENT,4.29-1

Tools/Supplies Needed,4.29-1

Procedure,4.29-1

CONTENTS

4.30 VACUUM ADJUSTMENT,4.30-1

Procedure,4.30-1

4.31 LYSE VOLUME ADJUSTMENT/VERIFICATION,4.31-1

Tools/Supplies Needed,4.31-1

Procedure,4.31-1

5 MAINTENANCE PROCEDURES,5.1-1

5.1 SYSTEM VERIFICATION PROCEDURE (SVP),5.1-1

5.2 PMI RECOMMENDATIONS,5.2-1

Components,5.2-1

Filters,5.2-1

Peristaltic Pump Tubing,5.2-1

Polyurethane Tubing,5.2-1

Syringes,5.2-1

Cleaning,5.2-1

Adjustment Procedures,5.2-2

Verification Procedures,5.2-2

6 SCHEMATICS AND BLOCK DIAGRAMS,6.1-1

6.1 DOCUMENT CONTROL NUMBERS AND DESCRIPTIONS,6.1-1

PN 4237242C

6.2 SCHEMATICS,6.2-1

7 TROUBLESHOOTING,7.1-1

7.1 TROUBLESHOOTING DIAGNOSTICS,7.1-1

Customer Options Available for Troubleshooting,7.1-1

Service Menu,7.1-2

ix

CONTENTS

7.2 GENERATING A SERVICE REPORT,7.2-1

The Screen Display,7.2-1

The Printed Report,7.2-1

AIM Criteria Results,7.2-2

Hgb Data,7.2-3

Sample Results - DO NOT REPORT,7.2-3

7.3 SERVICE DIAGNOSTIC,7.3-1

7.4 TROUBLESHOOTING ERROR MESSAGES,7.4-1

7.5 TROUBLESHOOTING POWER-UP PROBLEMS,7.5-1

8 PARTS LISTS,8.1-1

8.1 MASTER PARTS LISTS,8.1-1

8.2 ILLUSTRATED PARTS,8.2-1

A QUICK REFERENCE INFORMATION,A.1-1

A.1 TOLERANCES, VOLTAGES AND LIMITS,A.1-1

Limits,A.1-1

Adjustments,A.1-1

A.2 SWITCH SETTINGS, JUMPER SETTINGS AND TEST POINTS,A.2-1

AC Power/Vacuum Relay Card,A.2-1

Connectors,A.2-1

Test Points,A.2-1

AT Motherboard,A.2-1

DRA Card,A.2-2

Hgb Preamp Card,A.2-2

Test Points,A.2-2

Linear Power Supply Card,A.2-2

Jumpers,A.2-2

Test Points,A.2-2

Motor/Solenoid Driver Card,A.2-3

Jumpers,A.2-3

Test Points,A.2-3

Sensor Preamp Adapter Card,A.2-4

SPAD Card,A.2-4

URA Card,A.2-4

Vacuum Sensor Card,A.2-4

x

A.3 PRINTER SETTINGS,A.3-1

A.4 FUNCTIONS,A.4-1

Peristaltic Pumps,A.4-1

A.5 MENU TREE,A.5-1

PN 4237242C

B PROCEDURES FOR SPECIAL TOOLS OR SOFTWARE,B.1-1

B.1 PROCEDURES FOR SPECIAL TOOLS OR SOFTWARE,B.1-1

C MESSAGE/ERROR CODE LISTINGS,C.1-1

C.1 INSTRUMENT NON-FATAL ERROR MESSAGES,C.1-1

C.2 INSTRUMENT FATAL ERROR MESSAGES,C.2-1

C.3 AMIBIOS BEEP CODES,C.3-1

D OPTIONAL PRINTERS,D.1-1

D.1 EPSON TM-290P SLIP PRINTER,D.1-1

Specifications,D.1-1

Operator Controls and LEDs,D.1-1

DIP Switch SW1 Settings,D.1-2

Installation Procedure,D.1-2

Printer Self-Test,D.1-2

CONTENTS

E INTELLIGENT SOFTWARE LINK (ISL) OPTION,E.1-1

E.1 ISL OPTION FOR RALS,E.1-1

ISL Description,E.1-1

RALS Installation, Training and Service Responsibilities,E.1-1

Recognizing an MD II Linked to RALS,E.1-1

Servicing an MD II Linked to RALS,E.1-1

TRADEMARKS

PN 4237242C

xi

CONTENTS

ILLUSTRATIONS

2.1-1 Functional Diagram,2.1-1

2.1-2 Software Menu Tree,2.1-3

2.2-1 Top View into Upper Chassis,2.2-3

2.2-2 Top View into Lower Chassis,2.2-4

2.2-3 AC Power/Vacuum Relay Card,2.2-5

2.2-4 Linear Power Supply Card,2.2-7

2.3-1 Fluidics Panel Components,2.3-1

2.3-2 Diluter Panel,2.3-3

2.3-3 Probe-Wipe Traverse Assembly,2.3-5

2.3-4 Peristaltic Pump Assembly,2.3-5

2.3-5 Syringe Assembly,2.3-6

2.4-1 AT Motherboard,2.4-2

2.4-2 URA Card,2.4-5

2.4-3 DRA Card,2.4-8

2.4-4 Motor/Solenoid Driver Card,2.4-12

2.5-1 Sensor Preamp Adapter Card,2.5-3

2.5-2 Vacuum Sensor Card Block Diagram,2.5-5

2.5-3 Vacuum Sensor Card,2.5-6

2.5-4 SPAD Card,2.5-10

3.1-1 System Electrical Connectors,3.1-2

3.2-1 Reagent Connections,3.2-2

3.2-2 System Electrical Connections,3.2-3

3.2-3 CITIZEN GSX-190 Printer settings,3.2-4

3.4-1 Epson TM-290P Slip Printer,3.4-1

3.4-2 DIP Switch, SW1, Location,3.4-2

3.4-3 Printer Connections for a Single Printer,3.4-2

3.4-4 Printer Connections for Two Printers,3.4-4

4.3-1 Top View into Upper Chassis,4.3-1

4.4-1 Top View into Lower Chassis,4.4-1

4.6-1 Card Removal (AT Motherboard, URA, DRAs and SPAD),4.6-1

4.6-2 AT Motherboard,4.6-3

4.8-1 URA Card,4.8-1

4.9-1 DRA Card,4.9-1

4.10-1 Membrane Keypad and Display,4.10-1

4.12-1 +24 V Power Supply,4.12-1

4.13-1 Linear Power Supply Card,4.13-1

4.13-2 Back View of MD II with Rear Panel Door Opened,4.13-2

4.14-1 Vacuum Sensor Card,4.14-1

4.15-1 Motor/Solenoid Driver Card,4.15-2

4.16-1 Sensor Preamp Adapter (SPA) Card and Surrounding Components,4.16-1

4.16-2 Sensor Preamp Adapter Card, 4.16-3

4.17-1 Probe Assembly,4.17-1

4.19-1 Traverse Drive Belt, 4.19-1

4.20-1 Traverse Motor,4.20-1

4.21-1 Syringe Assembly,4.21-2

4.22-1 Peristaltic Pump Motors, 4.22-1

4.24-1 Aperture Bath Assembly,4.24-1

4.26-1 Sweep-Flow Tubing,4.26-1

xii

PN 4237242C

7.2-1 Sample Screen Display,7.2-1

7.2-2 Sample Printed Report,7.2-2

7.2-3 Hgb Results Analysis,7.2-4

7.5-1 Power-Up Troubleshooting Flowchart (part 1 of 2),7.5-1

7.5-2 Power-Up Troubleshooting Flowchart (part 2 of 2),7.5-2

8.2-1 MD II, Lower Chassis, Left Side View (See Table 8.2-1),8.2-1

8.2-2 MD II, Front View (See Table 8.2-2),8.2-2

8.2-3 MD II, Top View into Lower Chassis (See Table 8.2-3),8.2-3

8.2-4 MD II, Upper Chassis (See Table 8.2-4),8.2-4

8.2-5 MD II, Back View (See Table 8.2-5),8.2-5

8.2-6 Traverse Assembly (See Table 8.2-6),8.2-6

8.2-7 Diluter Assembly (See Table 8.2-6),8.2-8

8.2-8 Syringe Assembly (See Table 8.2-8),8.2-10

8.2-9 Peristaltic Pump Assembly (See Table 8.2-9),8.2-12

A.3-1 CITIZEN GSX-190 Printer Settings,A.3-1

A.5-1 Software Menu Tree,A.5-1

D.1-1 Epson TM-290P Slip Printer Control Locations,D.1-1

CONTENTS

PN 4237242C

xiii

CONTENTS

TABLES

2.1-1 Functions the Diluter Table Can Use,2.1-4

2.1-2 Aspiration Cycle,2.1-5

2.1-3 Power-Up Cycle,2.1-6

2.2-1 AT Power Supply Output Connectors,2.2-1

2.2-2 AC Power/Vacuum Relay Card Connectors and Line Input Ranges,2.2-6

2.2-3 Linear Power Supply Card Test Points,2.2-8

2.3-1 Diluter Panel Solenoids and Their Function,2.3-4

2.3-2 Peristaltic Pumps Location and Function,2.3-6

2.3-3 Flex Connect Card Connectors and LEDs,2.3-7

2.3-4 Solenoid Interconnect Card Connectors and LEDs,2.3-8

2.4-1 AT Motherboard Switch and Jumper Settings,2.4-1

2.4-2 URA Card Switch and Jumper Settings,2.4-6

2.4-3 DRA Card Output Connectors,2.4-7

2.4-4 DRA Card Jumper Settings,2.4-8

2.4-5 Motor/Solenoid Driver Card Input Connections,2.4-10

2.4-6 Motor/Solenoid Driver Card Output Connections,2.4-10

2.4-7 Motor/Solenoid Driver Card Test Points,2.4-11

2.4-8 Motor/Solenoid Driver Card Jumper Settings,2.4-11

2.5-1 Sensor Preamp Adapter Card Input Connections,2.5-1

2.5-2 Sensor Preamp Adapter Card Output Connections,2.5-2

2.5-3 Sensor Preamp Adapter Card Jumper Settings,2.5-2

2.5-4 Vacuum Sensor Card Test Points,2.5-6

2.5-5 SPAD Card Input Connections,2.5-9

2.6-1 Pinouts for Serial Ports,2.6-1

3.1-1 Space Requirements,3.1-1

3.1-2 Connectors’ Part Numbers and Line Input Ranges,3.1-2

6.1-1 DCNs and Descriptions for Schematics Included in This Manual,6.1-1

6.1-2 DCNs and Descriptions for Schematics Not Included in This Manual,6.1-1

7.1-1 Diluter Functions Menu Options,7.1-1

7.1-2 Service Menu Options,7.1-2

7.3-1 Service Diagnostic Cycle,7.3-1

7.4-1 Error Messages,7.4-1

8.1-1 Cables,8.1-1

8.1-2 Lower Chassis,8.1-2

8.1-3 Peripherals and Support,8.1-5

8.1-4 Upper Chassis,8.1-6

8.1-5 Miscellaneous Hardware,8.1-7

8.2-1 MD II, Lower Chassis, Left Side View (See Figure 8.2-1),8.2-1

8.2-2 MD II, Front View (See Figure 8.2-2),8.2-2

8.2-3 MD II, Top View into Lower Chassis (See Figure 8.2-3),8.2-3

8.2-4 MD II, Upper Chassis (See Figure 8.2-4),8.2-4

8.2-5 MD II, Back View (See Figure 8.2-5),8.2-5

8.2-6 Traverse Assembly (See Figure 8.2-6),8.2-7

8.2-7 Diluter Assembly (See Figure 8.2-7),8.2-9

8.2-8 Syringe Assembly (See Figure 8.2-8),8.2-11

8.2-9 Peristaltic Pump Assembly (See Figure 8.2-9),8.2-13

A.1-1 Calibration Factor Limits,A.1-1

A.1-2 Amplifier Noise Limits,A.1-1

xiv

PN 4237242C

CONTENTS

A.1-3 Adjustments,A.1-1

A.2-1 AC Power/Vacuum Relay Card Connectors and Line Input Ranges,A.2-1

A.2-2 AT Motherboard Switch and Jumper Settings,A.2-1

A.2-3 DRA Card Jumper Settings,A.2-2

A.2-4 Linear Power Supply Card Jumper Settings,A.2-2

A.2-5 Linear Power Supply Card Test Points,A.2-2

A.2-6 Motor/Solenoid Driver Card Jumper Settings,A.2-3

A.2-7 Motor/Solenoid Driver Card Test Points,A.2-3

A.2-8 Sensor Preamp Adapter Card Jumper Settings,A.2-4

A.2-9 URA Card Switch and Jumper Settings,A.2-4

A.2-10 Vacuum Sensor Card Test Points,A.2-4

A.4-1 Peristaltic Pumps Location and Function,A.4-1

C.1-1 Non-fatal Error Messages,C.1-1

C.2-1 Fatal Error Messages,C.2-1

C.3-1 AT Motherboard AMIBIOS Beep Codes,C.3-1

D.1-1 DIP Switch SW1 Position Settings,D.1-2

D.1-2 DIP Switch SW1 Settings for International Character Sets,D.1-2

PN 4237242C

xv

CONTENTS

xvi

PN 4237242C

1 INTRODUCTION,1.1-1

1.1 MANUAL DESCRIPTION,1.1-1

Scope,1.1-1

Organization,1.1-1

Numbering Format,1.1-1

Special Headings,1.1-1

WARNING,1.1-1

CAUTION,1.1-2

IMPORTANT,1.1-2

ATTENTION,1.1-2

Note,1.1-2

Conventions,1.1-2

1.2 SAFETY PRECAUTIONS,1.2-1

Electronic,1.2-1

Biological,1.2-1

Troubleshooting,1.2-2

CONTENTS

1

PN 4237242C

1-i

CONTENTS

1-ii

PN 4237242C

1.1 MANUAL DESCRIPTION

Scope

This manual provides the reference information and procedures necessary for servicing and

maintaining the COULTER

This manual is to be used in conjunction with the appropriate customer documents and does

not contain information and procedures already covered in those documents. There are five

COULTER

r Host Transmission Specification, PN 4237198

r Operator's Guide, PN 4237235

r Quip-Tip Card, PN 4237277

r Reference, PN 4237236

r Training Guide, PN 4237271.

Organization

The material in this manual is organized into eight chapters. Chapter 1 includes a brief

description of this manual and essential safety information. Chapter 2 introduces the

COULTER MD II Series analyzer, hereafter referred to as the MD II or the instrument, and

describes how it functions. Chapters 3 through 5 contain the procedures for installing,

repairing and maintaining the instrument. Chapters 6 through 8 contain information required

for servicing the instrument: schematics, troubleshooting tables and a parts list. Appendices A

through C contain quick reference tables showing: instrument limits, instrument

adjustments, switch and jumper settings, and error messages/codes, and also procedures for

using the Service Diagnostics diskette.

®

MD II™ Series analyzer customer documents available for reference:

®

MD II™ Series analyzer.

1

INTRODUCTION

1

Numbering Format

Each chapter of this manual is further divided into topics, which are numbered sequentially,

beginning at one. The numbering format for the topic heading, which is called the primary

heading, is chapter number, decimal point, topic number. For example, the primary heading

number for the fifth topic covered in Chapter 2 is 2.5.

The page, figure and table numbers are tied directly to the primary heading number. For

example, Heading 2.5 begins on page 2.5-1, the first figure under Heading 2.5 is Figure 2.5-1,

and the first table under Heading 2.5 is Table 2.5-1.

Note: Primary headings always begin on the top of a right-hand page.

Special Headings

Throughout this manual WARNING, CAUTION, IMPORTANT, Attention and Note headings

are used to indicate potentially hazardous situations and important or helpful information.

WARNING

WARNING

A

injury. The word

manual.

indicates a situation or procedure that, if ignored, can cause serious personal

WARNING

is boldfaced in the printed manual and is red in the online

PN 4237242C

1.1-1

INTRODUCTION

MANUAL DESCRIPTION

CAUTION

A CAUTION indicates a situation or procedure that, if ignored, can cause damage to

equipment. The word CAUTION is boldfaced in the printed manual and is red in the online

manual.

IMPORTANT

An IMPORTANT indicates a situation or procedure that, if ignored can result in erroneous

test results. The word IMPORTANT is boldfaced in the printed manual and is red in the

online manual.

ATTENTION

An ATTENTION contains information that is critical for the successful completion of a

procedure and/or operation of the instrument. The word ATTE NTION is boldfaced in the

printed manual and is red in the online manual.

Note

A Note contains information that is important to remember or helpful in performing a

procedure.

Conventions

This manual uses the following conventions. An example is given below each convention.

r Italics indicate screen messages.

The MD II screen displays ERROR CODE (018) Copy Protection Violation when the

instrument detects the wrong resource files on the Program Disk.

r Courier font indicates text that you have to type.

When the instrument prompts you for a password, type 123.

r Bold, all uppercase text indicates a menu option for you to select. The item number key

next to the menu item next to it, indicates the item number key you have to press to

select the menu option. The menu item is displayed on the screen but only the item

number key is on the instrument’s keypad.

From the Main Menu select

r Select menu item tt sub-menu item indicates the software options you have to select, as

well as the order in which you should select them.

From the Main Menu, select

7 SERVICE DIAGNOSTICS.

r In the online manual, blue, underlined text indicates a link to additional information. To

access the linked information, select the blue, underlined text.

5 SPECIAL FUNCTIONS.

5 SPECIAL FUNCTIONS tt 4 SUPERVISOR tt

1.1-2

PN 4237242C

1.2 SAFETY PRECAUTIONS

Electronic

INTRODUCTION

SAFETY PRECAUTIONS

1

WARNING

causing personal injury from electronic shock. Remove rings and other metal jewelry before performing

maintenance or service on the electronic components of the instrument.

CAUTION

components is performed while power is ON, damage to components may occur. To prevent damage to

delicate electronic components, always make sure power is OFF before removing or replacing printed circuit

cards and components.

CAUTION

add-in circuit cards and other electronic components. Perform any procedures where there is a possibility

of ESD damage, at an ESD workstation or wear an antistatic wrist strap attached to a metal part of the

chassis that is connected to an earth ground.

Risk of personal injury. Rings or other jewelry can contact exposed electronic components

Risk of damage to electronic components. If removal/replacement of printed circuit card or

Risk of damage to electronic components. Electrostatic discharge (ESD) can damage disk drives,

Biological

WARNING

while servicing the instrument with the doors open, they may become injured or contaminated. To prevent

possible injury or biological contamination, service personnel must wear gloves, a laboratory coat and eye

protection when servicing the instrument with the doors open

Use care when working with pathogenic materials. Means must be available to decontaminate

the instrument, provide ventilation, and to dispose of waste liquid. Refer to the following

publications for further guidance on decontamination.

Risk of personal injury or contamination. If service personnel do not properly shield themselves

PN 4237242C

Biohazards Safety Guide, 1974, National Institute of Health.

Classifications of Etiological Agents on the Basis of Hazards, 3d ed., June 1974, Center

for Disease Control, U.S. Public Health Service.

1.2-1

INTRODUCTION

SAFETY PRECAUTIONS

Troubleshooting

Bring the following warning to the customer's attention before advising the customer to

perform any maintenance, troubleshooting, or service procedures on their instrument.

WARNING

performing service, maintenance and troubleshooting procedures, residual fluids in the instrument could

injure or contaminate them. Coulter recommends that barrier protection, such as appropriate safety

glasses, laboratory coat, and gloves be worn throughout the performance of service, maintenance and

troubleshooting procedures to avoid contact with cleaners and residual fluids in the instrument.

WARNING

performing adjustment and measurements with the power ON, injury could result. Only Coulter-trained

Service personnel should service this instrument.

Risk of personal injury or contamination. If operators do not properly shield themselves while

Risk of personal injury. If non-Coulter-trained personnel attempt to service the instrument by

1.2-2

PN 4237242C

2 2 INSTRUMENT DESCRIPTION,2.1-1

2.1 SYSTEM OVERVIEW,2.1-1

Description,2.1-1

Software Menu System,2.1-2

Software Tables,2.1-2

Aspirate Table,2.1-5

Power-up Table,2.1-6

2.2 POWER SUPPLY,2.2-1

Overview,2.2-1

AT Power Supply,2.2-1

Inputs,2.2-1

Outputs,2.2-1

Switches,2.2-2

AC Power/Vacuum Relay Card,2.2-2

Inputs,2.2-5

Outputs,2.2-5

Test Points,2.2-5

Jumpers,2.2-5

+24 Volt Switching Power Supply,2.2-6

Inputs,2.2-6

Outputs,2.2-6

Adjustments,2.2-6

Linear Power Supply Card,2.2-6

Inputs,2.2-8

Outputs,2.2-8

Test Points,2.2-8

Jumpers,2.2-8

CONTENTS

2

2.3 FLUIDICS PANEL,2.3-1

Overview,2.3-1

Diluter Panel,2.3-2

Probe/Wipe Traverse Assembly,2.3-4

Peristaltic Pump Assembly,2.3-5

Syringe Assembly,2.3-6

Individual Components Mounted to Fluidics Panel,2.3-7

Cycle Counter and Air Solenoids,2.3-7

Diluent Reservoir,2.3-7

Flex Connect Card,2.3-7

Lyse Pump (PM5),2.3-8

Solenoid Interconnect Card,2.3-8

Vacuum Regulator,2.3-9

2.4 SYSTEM CONTROL,2.4-1

AT Motherboard,2.4-1

Switches and Jumpers,2.4-1

User Resource Adapter (URA) Card,2.4-2

Keypad Controller,2.4-3

Display Controller,2.4-3

CMOS RAM,2.4-3

PN 4237242C

2-i

CONTENTS

Diagnostic Data Acquisition Circuit,2.4-4

Utility Timer Circuit,2.4-4

Support Circuits,2.4-4

Inputs,2.4-5

Outputs,2.4-5

Adjustments,2.4-5

Switches and Jumpers,2.4-6

Diluter Resource Adapter (DRA) Card,2.4-6

Motor Controller,2.4-6

Solenoid Controller,2.4-7

Support Circuitry,2.4-7

Inputs,2.4-7

Outputs,2.4-7

Jumpers,2.4-8Motor/Solenoid Driver Card,2.4-8

Motor Driver,2.4-9

Solenoid Driver,2.4-9

Sensor Control,2.4-9

+24 V POWER ON Signal,2.4-9

+24 V POWERFAIL (PF/PG) Signal,2.4-10

Inputs,2.4-10

Outputs,2.4-10

Test Points,2.4-11

Jumpers,2.4-11

2.5 DATA ACQUISITION,2.5-1

Sensor Preamp Adapter (SPA) Card,2.5-1

Inputs,2.5-1

Outputs,2.5-2

Adjustments,2.5-2

Jumpers,2.5-2

Hgb Preamp Card,2.5-3

Inputs,2.5-4

Outputs,2.5-4

Adjustments,2.5-4

Test Points,2.5-4

Vacuum Sensor Card,2.5-4

Inputs,2.5-5

Outputs,2.5-5

Adjustments,2.5-5

Test Points,2.5-6

Sensor Processing Adapter with Diagnostics (SPAD) Card,2.5-6

Power Supply Conditioning,2.5-7

Oscillator Circuit,2.5-7

Control Functions,2.5-7

Octal Digital-to-Analog Converter (DAC),2.5-8

Aperture Signal Processing,2.5-8

Data Acquisition Circuit,2.5-8

Test Pulse Generator,2.5-9

Interrupt Selector,2.5-9

Input,2.5-9

2-ii

PN 4237242C

Outputs,2.5-9

Jumper,2.5-10

Adjustments,2.5-10

2.6 PERIPHERALS,2.6-1

Floppy Disk Drive,2.6-1

Display,2.6-1

Keypad,2.6-1

Rear Panel Interface Connectors,2.6-1

ILLUSTRATIONS

2.1-1 Functional Diagram,2.1-1

2.1-2 Software Menu Tree,2.1-3

2.2-1 Top View into Upper Chassis,2.2-3

2.2-2 Top View into Lower Chassis,2.2-4

2.2-3 AC Power/Vacuum Relay Card,2.2-5

2.2-4 Linear Power Supply Card,2.2-7

CONTENTS

2

2.3-1 Fluidics Panel Components,2.3-1

2.3-2 Diluter Panel,2.3-3

2.3-3 Probe-Wipe Traverse Assembly,2.3-5

2.3-4 Peristaltic Pump Assembly,2.3-5

2.3-5 Syringe Assembly,2.3-6

2.4-1 AT Motherboard,2.4-2

2.4-2 URA Card,2.4-5

2.4-3 DRA Card,2.4-8

2.4-4 Motor/Solenoid Driver Card,2.4-12

2.5-1 Sensor Preamp Adapter Card,2.5-3

2.5-2 Vacuum Sensor Card Block Diagram,2.5-5

2.5-3 Vacuum Sensor Card,2.5-6

2.5-4 SPAD Card,2.5-10

TABLES

2.1-1 Functions the Diluter Table Can Use,2.1-4

2.1-2 Aspiration Cycle,2.1-5

2.1-3 Power-Up Cycle,2.1-6

2.2-1 AT Power Supply Output Connectors,2.2-1

2.2-2 AC Power/Vacuum Relay Card Connectors and Line Input Ranges,2.2-6

2.2-3 Linear Power Supply Card Test Points,2.2-8

PN 4237242C

2.3-1 Diluter Panel Solenoids and Their Function,2.3-4

2.3-2 Peristaltic Pumps Location and Function,2.3-6

2.3-3 Flex Connect Card Connectors and LEDs,2.3-7

2.3-4 Solenoid Interconnect Card Connectors and LEDs,2.3-8

2-iii

CONTENTS

2.4-1 AT Motherboard Switch and Jumper Settings,2.4-1

2.4-2 URA Card Switch and Jumper Settings,2.4-6

2.4-3 DRA Card Output Connectors,2.4-7

2.4-4 DRA Card Jumper Settings,2.4-8

2.4-5 Motor/Solenoid Driver Card Input Connections,2.4-10

2.4-6 Motor/Solenoid Driver Card Output Connections,2.4-10

2.4-7 Motor/Solenoid Driver Card Test Points,2.4-11

2.4-8 Motor/Solenoid Driver Card Jumper Settings,2.4-11

2.5-1 Sensor Preamp Adapter Card Input Connections,2.5-1

2.5-2 Sensor Preamp Adapter Card Output Connections,2.5-2

2.5-3 Sensor Preamp Adapter Card Jumper Settings,2.5-2

2.5-4 Vacuum Sensor Card Test Points,2.5-6

2.5-5 SPAD Card Input Connections,2.5-9

2.6-1 Pinouts for Serial Ports,2.6-1

2-iv

PN 4237242C

2.1 SYSTEM OVERVIEW

Description

The MD II instrument is an automated hematology analyzer and leukocyte differential

counter For In Vitro Diagnostic Use in clinical laboratories. It is contained in one unit, with

additional space needed only for the external Printer(s), the reagents, and if used, a waste

container. The MD II is marketed as four distinct instruments; the 8 parameter and 10

parameter instruments which do not generate histograms, and the 16 parameter and 18

parameter instruments which do generate histograms. The 16 and 18 parameter instruments

have additional hardware allowing them to generate histograms.

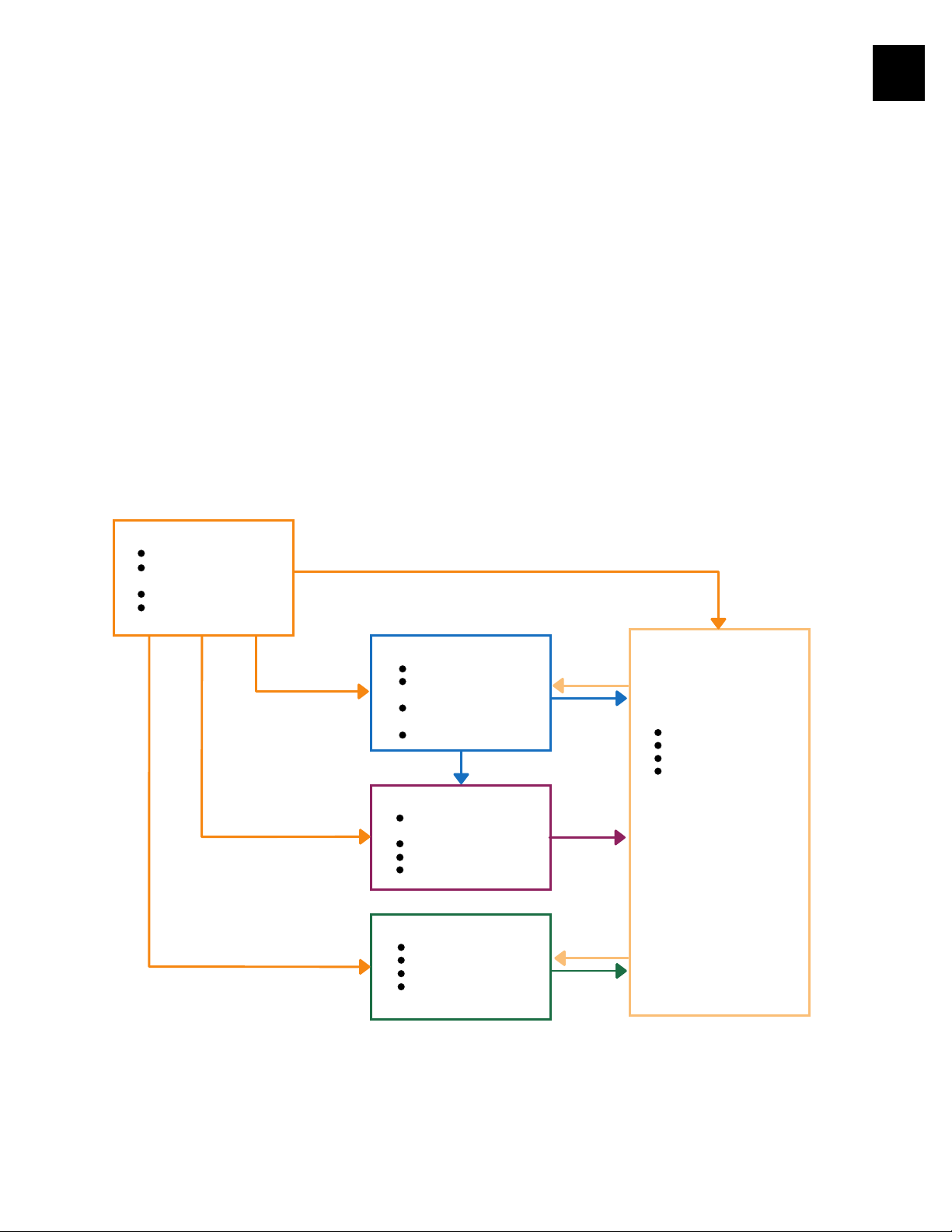

Since the MD II is housed in one unit with indistinct physical sections, it is easier to envision

it as a set of functional or logical sections. Using this concept, the description of the unit is

divided into five sections: Power Supply, System Control, Fluidics Panel, Data Acquisition

and Peripherals.

See Figure 2.1-1 for a diagram of these sections and their relationships.

Figure 2.1-1 Functional Diagram

2

INSTRUMENT DESCRIPTION

2

POWER SUPPLY

AT POWER SUPPLY

AC POWER/VACUUM

RELAY CARD

+24 V POWER SUPPLY

LINEAR POWER SUPPLY

CARD

7242001A

FLUIDICS PANEL

DILUTER PANEL

PROBE WIPE/TRAVERSE

ASSEMBLY

PERISTALTIC PUMP

ASSEMBLY

SYRINGE ASSEMBLY

DATA ACQUISTION

SENSOR PREAMP

ADAPTER CARD

Hgb PREAMP CARD

VACUUM SENSOR CARD

SPAD CARD

PERIPHERALS

FLOPPY DISK DRIVE

DISPLAY

KEYPAD

REAR PANEL INTERFACE

CONNECTORS

SYSTEM CONTROL

AT MOTHERBOARD

URA CARD

DRA1 AND DRA2 CARDS

MOTOR/SOLENOID

DRIVER CARD

PN 4237242C

2.1-1

INSTRUMENT DESCRIPTION

SYSTEM OVERVIEW

The MD II cycle begins with the presentation of a whole-blood sample to a self-washing

aspirate probe. The MD II then aspirates 12 µL of blood, dilutes and analyzes the sample and

makes the results available to a Liquid Crystal Display (LCD) and Printer. Instrument

intelligence is provided by a program loaded at power ON from a diskette. Interaction with

the instrument is largely through use of a menu system displayed on the 4-row by 40-column

LCD and a numeric keypad, with select functions provided through dedicated keys.

Software Menu System

Figure 2.1-2 shows the software menu tree. This is the same menu tree that is shown and

described in the customer documentation except that the three hidden menu items for service

personnel are added. These hidden items, shown in bold on the diagram, are not shown on

the instrument’s display nor in the customer’s documentation. Quick steps to access these

hidden items are in Heading 4.2, ACCESSING THE HIDDEN SERVICE MENU ITEMS.

Software Tables

Instrument cycling is accomplished using diluter tables. A diluter table is a collection of

software functions. The software function performs the action requested by the table, by

enabling the appropriate electrical drivers. The table determines specifics, such as when to

perform a certain action, and for how long. For instance, to drain a bath, a solenoid valve

must be opened to open a fluid path to waste. The diluter table specifies when this valve

opens and for how long. On the MD II, a peristaltic pump is used to move waste fluids. The

function to turn the pump stepper motor on is given the step rate and the total number of

steps. The diluter table also specifies some functions that are electronic in nature. Taking a

Hgb reading and accumulating aperture data are two such functions.

This table method allows for simple changes in the diluter cycles. Since the main software

does not need to be changed, only specific numbers in a specific diluter table change. All the

other tables are unchanged, which would not be true if a change was made to the software

function.

2.1-2

PN 4237242C

Loading...

Loading...