Cosmotec WRA 13-20, WRA 35-45-58-70, WRA 85, ORA 34-43-58-70, WRA 95-A3-A6 Series Manual

...

EN

rev 09.2017

2/34

rev 09.2017 - ©STULZ S.p.A. - all rights reserved

INDEX

1.0 GENERAL INFORMATION

GENERAL INFORMATION

1.1 LIST OF ATTACHED DOCUMENTS

1.2 WARNINGS

1.3 HANDLING AND STORAGE

STORAGE

HANDLING AND TRANSPORTATION

1.4 IDENTIFICATION AND TECHNICAL DATA

LABELS MOUNTED ON THE MACHINE

LEVEL OF PROTECTION

PRINCIPLE OF OPERATION

CONTROL AND SAFETY DEVICES

NOTE FOR WATER CONDENSED CHILLERS

NOTE FOR OIL CHILLERS

SIZE OF CHILLERS

TECHNICAL DATA

CORRECTION FACTORS TABLE

PREVALENCE OF THE STANDARD PUMPS

1.5 INTENDED AND UNINTENDED USE

1.6 SAFETY

1.7 RESIDUAL RISK

2.0 INSTALLATION AND CONNECTIONS

I

N

N

S

S

T

T

A

A

L

L

L

L

A

A

T

T

I

I

O

O

N

N

A

A

N

N

D

D

C

C

O

O

N

N

N

N

E

E

C

C

T

T

I

I

O

O

N

N

S

S

2.1 GENERAL INFORMATION

2.2 HYDRAULIC CONNECTIONS

2.3 ELECTRICAL CONNECTIONS

2.4 OPERATIONS

WORK CONDITIONS TABLE

WATER QUALITIY TABLE

NOTE FOR OIL CHILLERS

3.0 ORDINARY MAINTENANCE

CONTROLS AND

MAINTENANCE

3.1 SPECIAL MAINTENANCE

3.2 COOLANT LEAKS CHECK

3.3 SEARCHING FOR DEFECTS

3.4 DISMANTLING AND DISPOSAL

4.0 GENERAL WARRANTY CONDITIONS

GUARANTEE

AND

DELIVERY

4.1 DELIVERY

3/34

rev 09.2017 - ©STULZ S.p.A. - all rights reserved

1.0 GENERAL INFORMATION

This manual contains all the chiller installation, use and maintenance regulations, highlighting the related

risks and dangers.

It was expressly designed to allow its staff to use it in a safe and secure manner. Read all the information

therein carefully and be careful of the regulations marked with a symbol on the side. If not observed,

they can cause damages to things, people, the environment and the chiller.

The manufacturer is not liable for any improper use of the chiller, for unauthorized changes and for

not following the instructions contained in this manual.

The manual must be kept by the contractor and made available to the staff in charge of installing,

running and maintaining the chiller.

1.1 LIST OF ATTACHED DOCUMENTS

List of documents provided with the chiller:

Manual Part II

Thermostat Manual and Configuration Chart

Pump Manual

Manual of Various Options (if requested by the client)

1.2 WARNINGS

The chiller was designed and built for professional use based on the current regulations (see the declaration

of conformity in the Manual Part II).

The chiller is built with quality materials that underwent laboratory exams to verify its reliability and safety. It

was inspected and put under warranty.

This manual is intended for the following professionals:

INSTALLER is required to verify the correct chiller installation based on the workplace safety regulations and

the instructions contained in this manual.

OPERATOR (or user) is required to know all the workplace safety regulations, the instructions contained in

this manual for its correct use and the ordinary maintenance of the chiller.

MAINTENANCE TECHNICIAN (or assistance technician) authorised by the chiller manufacturer for technical

assistance, special maintenance and repairs.

Qualified staff means those professional figures who, given their training, education and experience as well

as their specific knowledge of the workplace safety and accident prevention regulations, are authorised by

the safety manager to perform the aforementioned activities.

DANGER

SITUATIONS WHERE THERE IS A RISK OF

ACCIDENT FOR THE OPERATOR

AND THE RISK OF DAMAGE TO THE CHILLER

ATTENTION

INFORMATION OR WARNING TO BE CAREFUL

WHEN COMPLETING A PROCEDURE OR

COMMAND

INFORMATION

IMPORTANT INFORMATION

4/34

rev 09.2017 - ©STULZ S.p.A. - all rights reserved

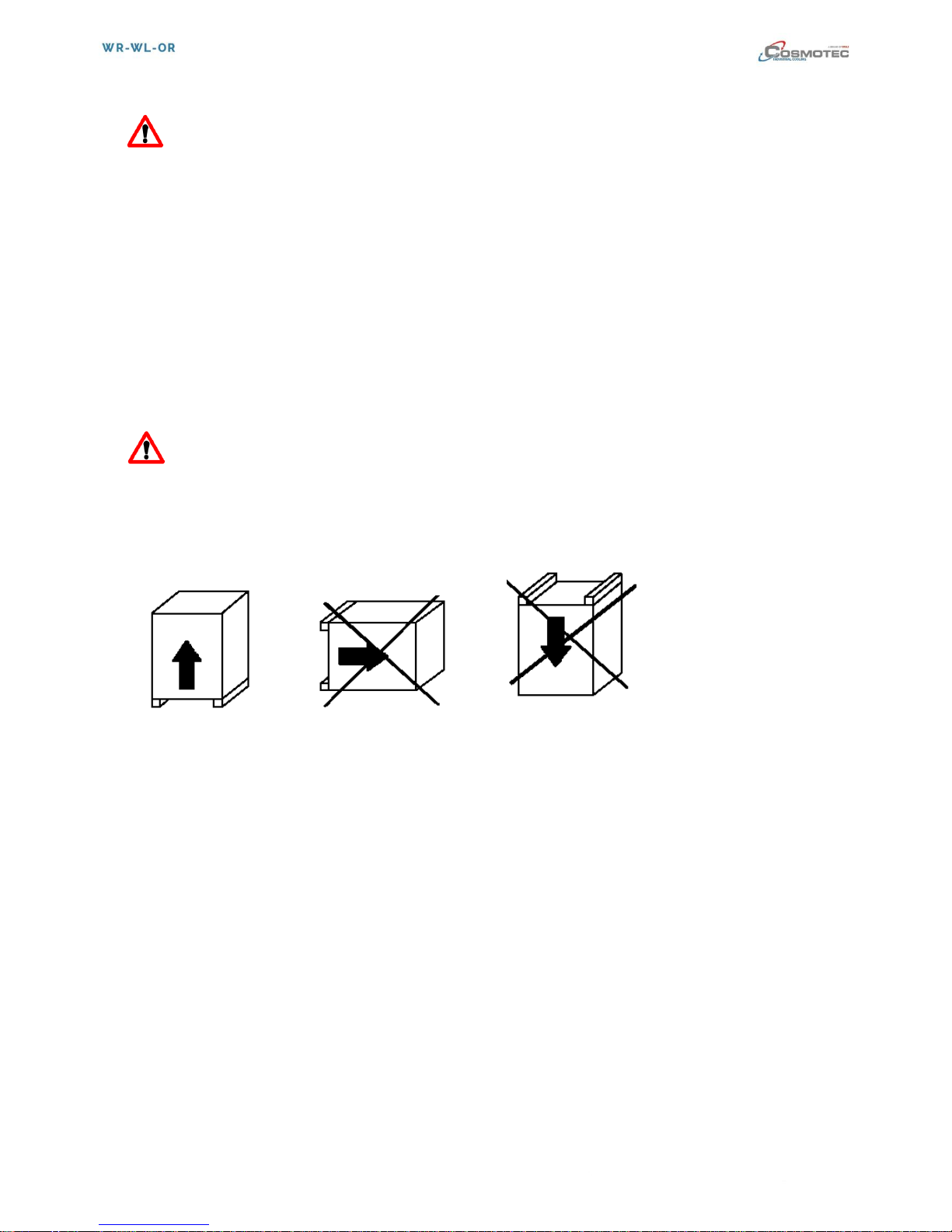

1.3 ACCEPTANCE, HANDLING AND STORAGE

ATTENTION The chiller must be transported and moved without liquid(s) in the tank(s) (only for

models with a tank).

STORAGE

The chillers are packaged using standard packaging (unless otherwise agreed).

Loading and unloading must be done indoors.

Standard packaging does not protect the chiller from rain and inclement weather

Standard packaging is not suitable for transportation by boat

Standard packaging is not suitable for transportation by air

The environmental conditions for storage are the following:

-min ambient temperature -10°C for R134a/ R407C/ R404A/ R410A

-max ambient temperature +60°C for R134a

-max ambient temperature +50°C for R407C/R404A

-max ambient temperature +45°C for R410A

- max humidity UR 90%

HANDLING AND TRANSPORTATION

The chiller must be lifted safely without inclining it and laying it on its side using the appropriate

equipment with the following characteristics:

-adequate capacity to lift the load

-the load must be balanced to avoid impact

-do not do any brusque and/or violent movements

-do not place other objects on the chiller

Examples:

5/34

rev 09.2017 - ©STULZ S.p.A. - all rights reserved

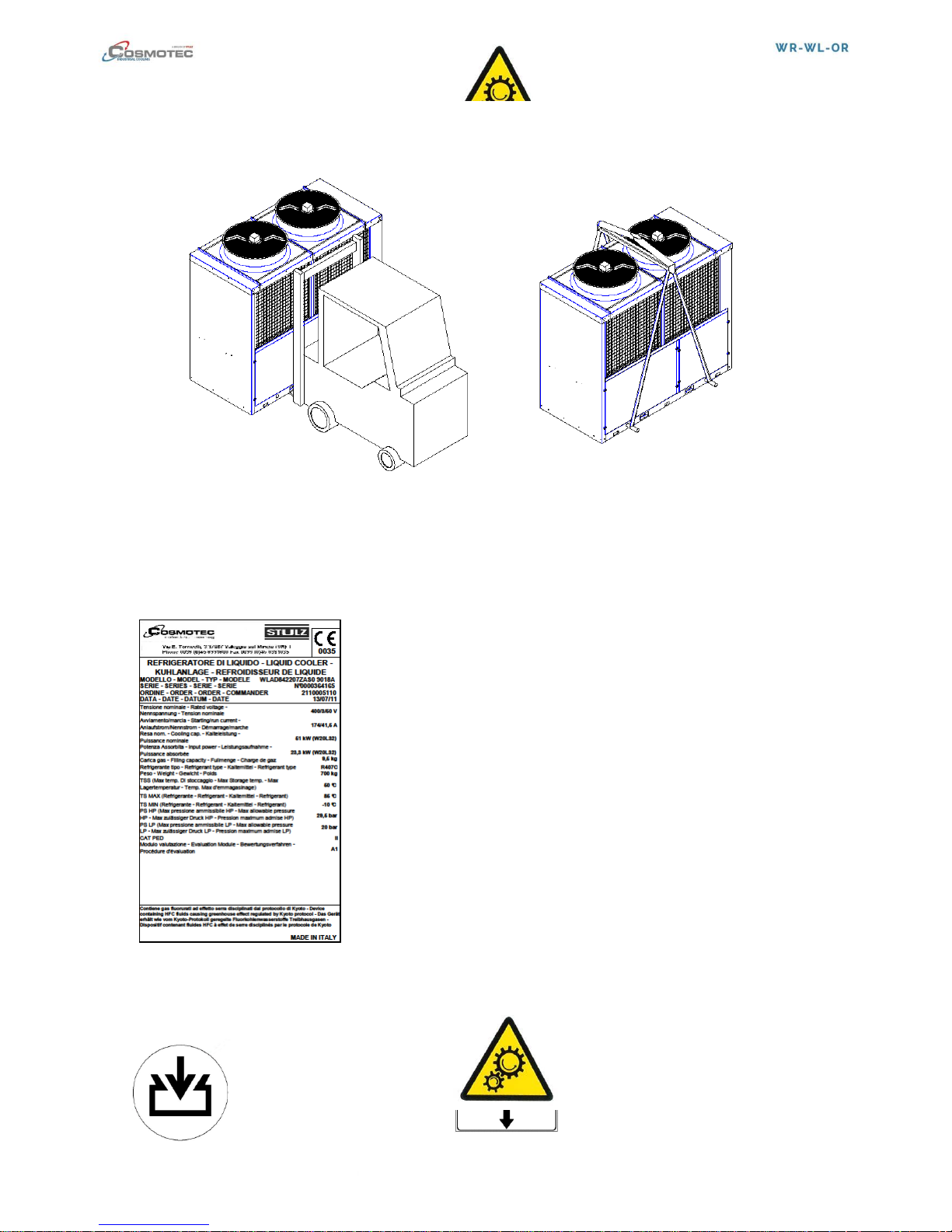

1.4 IDENTIFICATION AND TECHNICAL DATA

The chiller is identified with a technical data label that includes the following information:

TYPE OF LIQUID TO CHILL:

Ex. WRA3541N07C000 water (water solutions +

additives)

Ex. WLAD842207C000 water (water solutions +

additives)

Ex. ORA9542207C000 oil (see note for oil chillers in chap.

2.4 Operations)

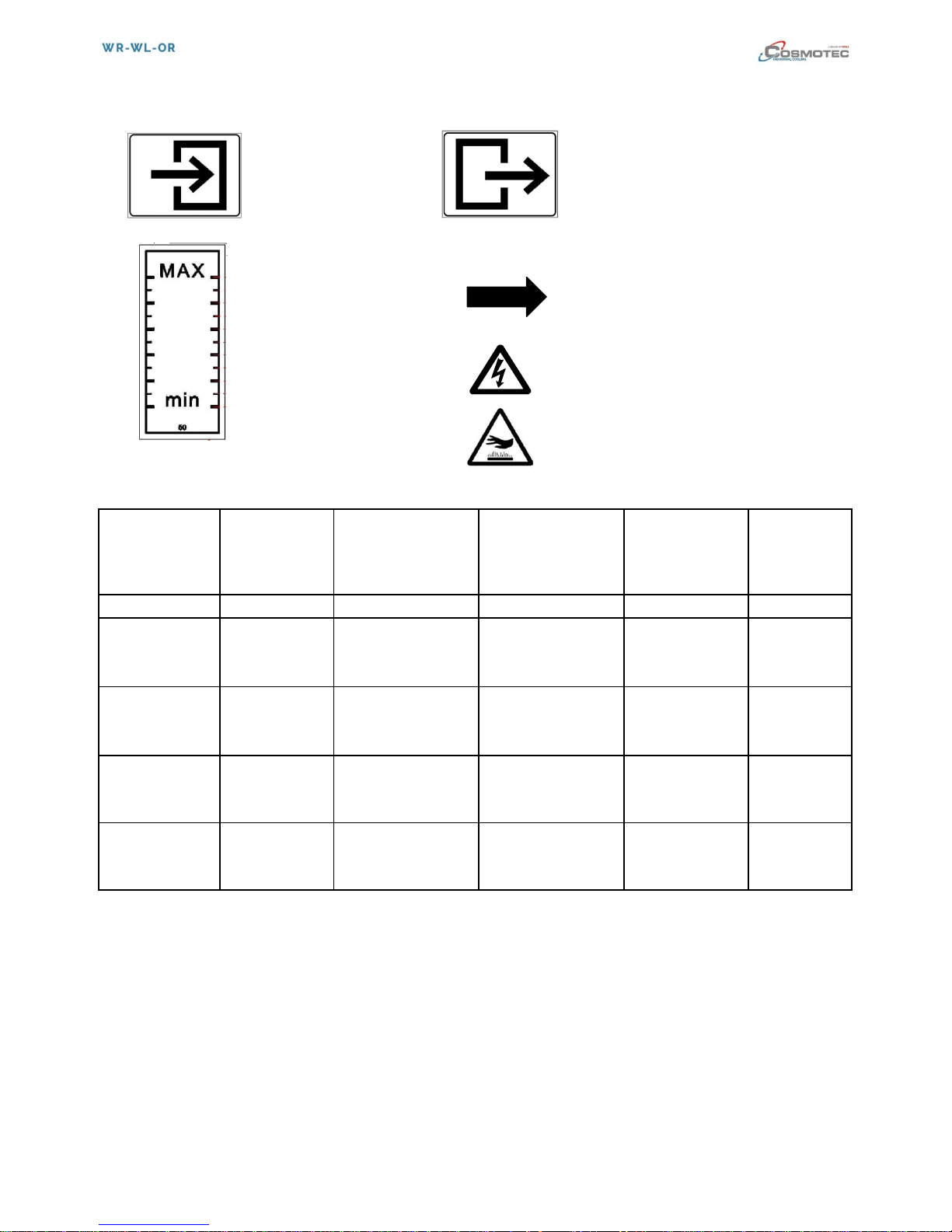

LABELS MOUNTED ON THE MACHINE:

MOVING PARTS HAZARD

FILING UNLOADING

TANK TANK

6/34

rev 09.2017 - ©STULZ S.p.A. - all rights reserved

INCOMING OUTGOING

FLUID FLUID

CHILLER CHILLER

TANK LEVEL ROTATION DIRECTION

ENGINES

RISK OF TENSION

ATTENTION! HOT SURFACES

LEVEL OF PROTECTION

SERIES

MODELS

INSTALLATION

POWER

CONTROL

PANEL

PROTECTION

(mounted on the

machine)

ENGINE

PROTECTION

(from the

external

environment)

WLA Compact

ALL

INDOOR

230/1/50-60

IP 21

IP 21

WRA Vertical +

ORA O-FLOW

WRA 13-20-35-

45-58-70-85

ORA 20-34-43-

58-70

INDOOR

230/1/50-60

400/3/50 460/3/60

IP 21

IP 21

WRA Vertical +

ORA O-FLOW

WRA 95-A3-

A6-A8-B4-B8-

C2-C8-D8

ORA 95-A3-A6

OUTDOOR

400/3/50 460/3/60

IP54

IP 44

WLA Precision

ALL

OUTDOOR

400/3/50 460/3/60

IP54

IP 44

WLA Precision

R410A

ALL

OUTDOOR

400/3/50 460/3/60

IP54

IP 44

The IP (International Protection) code is a convention defined in EN 60529 standard (implemented

by CEI as CEI 70-1 standard) to identify the degree of protection provided by enclosures for

electrical and electronic equipment against the penetration of external agents in solid or liquid form.

PRINCIPLE OF OPERATION

The chiller is designed to chill liquids and is suitable for industrial environments. Its use allows the

temperature of the liquid to chill to be controlled.

The principle of operation is the following:

The compressor compresses coolants, bringing it to a high pressure and temperature; the gas passing

through the condenser is chilled and liquefied, releasing heat into the environment. Pushed toward the filing

system or valve, the liquid gas drops in pressure which helps its evaporation, which occurs in the evaporator,

in contact with the liquid coming from the catchments that is chilled.

7/34

rev 09.2017 - ©STULZ S.p.A. - all rights reserved

CONTROL AND SAFETY DEVICES

- Safety pressure switch: It stops the compressor operation when the internal pressure of the circuit

exceeds the calibration level - (High pressure switch)

- Safety valve (when installed): It vents the internal pressure of the circuit to the atmosphere if there

would be an abnormal increase in pressure with the equipment in operation or switched off

NOTE FOR WATER CONDENSED CHILLERS

For chillers WRW, WLW AND ORW with a water condenser in the heat exchanger, follow the following

instructions:

Condensation condenser temperature water entering to the exchanger operation limits. Min/Max 10-30°C.

Recommended filtering level μm 500.

The minimum capacity is suggested in the technical chart attached to the machine and varies to vary the

required chiller capacity or for any special client requests, which are occasionally analyzed by the technical

office.

The adjustment of the water pressure valve on the water side is done when it is inspected in the plant. For

any problems/questions, contact aftersales.

A short discussion about the heat exchangers used to condense the water chiller:

Load loss

The load loss values that are found in the heat exchangers can be estimated at a minimum of 0.1 bar and a

maximum of 0.5 bar.

Dirtiness and Corrosion

To increase the efficiency of the exchangers, reduce, or avoid, build-ups due to materials in the liquids, for

example, mud, sand, etc, which often occurs in exchangers powered by rainwater, cooling towers, river

water, lake water, etc. They are not suited for salt water.

Dirtying due to carbonate would seem to be different since, as is known, they cannot be influenced by the

operation of the exchanger's temperature: precipitation starts when the water that is contained therein

exceeds the threshold of 45°C.

The heat exchangers are clean with suitable fluids for this purpose. Problems of corrosion are limited given

the specific resistance of the materials used for construction.

8/34

rev 09.2017 - ©STULZ S.p.A. - all rights reserved

SIZE OF WLA COMPACT

L P H K J O IN/OUT

UNI ISO228

WLA 14-20

604

480

388

56

54

90

½ ”G

WLA 28-41-45

807

494

504

70

54

90

½ ”G

MOD.

(mm)

9/34

rev 09.2017 - ©STULZ S.p.A. - all rights reserved

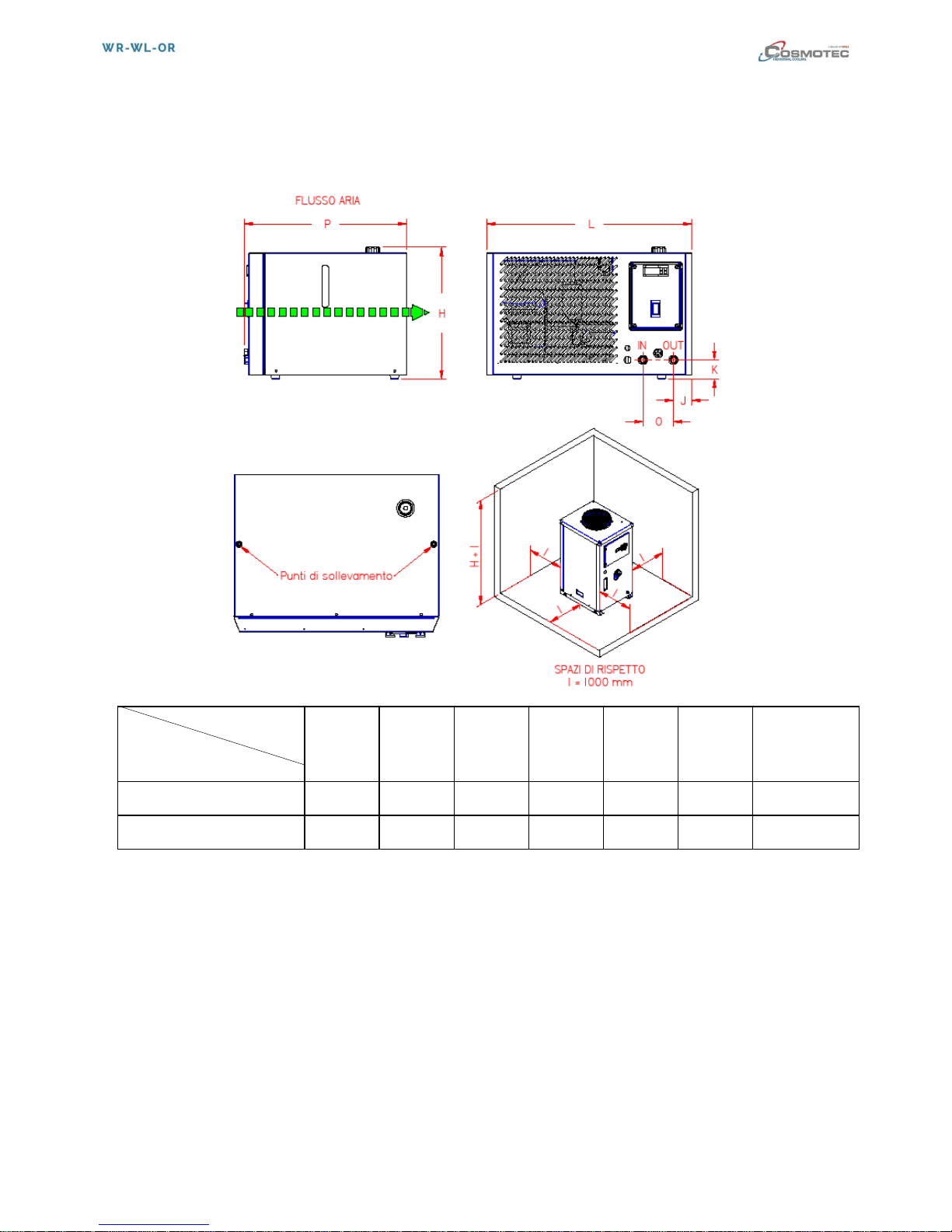

WRA VERTICAL + ORA O-FLOW SIZE

L P H K J O IN/OUT

UNI ISO228

WRA 13-20

480

525

686

87

59

72

½ ”G

MOD.

(mm)

10/34

rev 09.2017 - ©STULZ S.p.A. - all rights reserved

L P H K J O IN/OUT

UNI ISO228

ORA 20

420

580

720

90

54

72

½ ”G

WRA 35-45-58-70

ORA 34-43-58-70

570

740

1146

135

85

130

¾ ”G

WRA 85

570

740

1220

135

85

130

¾ ”G

WRA 95-A3-A6

ORA 95-A3-A6

735

926

1500

142

121

130

1 ”G

WRA A8-B4-B8-C2

900

1200

1930

165

170

150

1 ¼”G

WRA C8–D8

1250

1250

2000

190

170

150

1 ½”G

MOD.

(mm)

11/34

rev 09.2017 - ©STULZ S.p.A. - all rights reserved

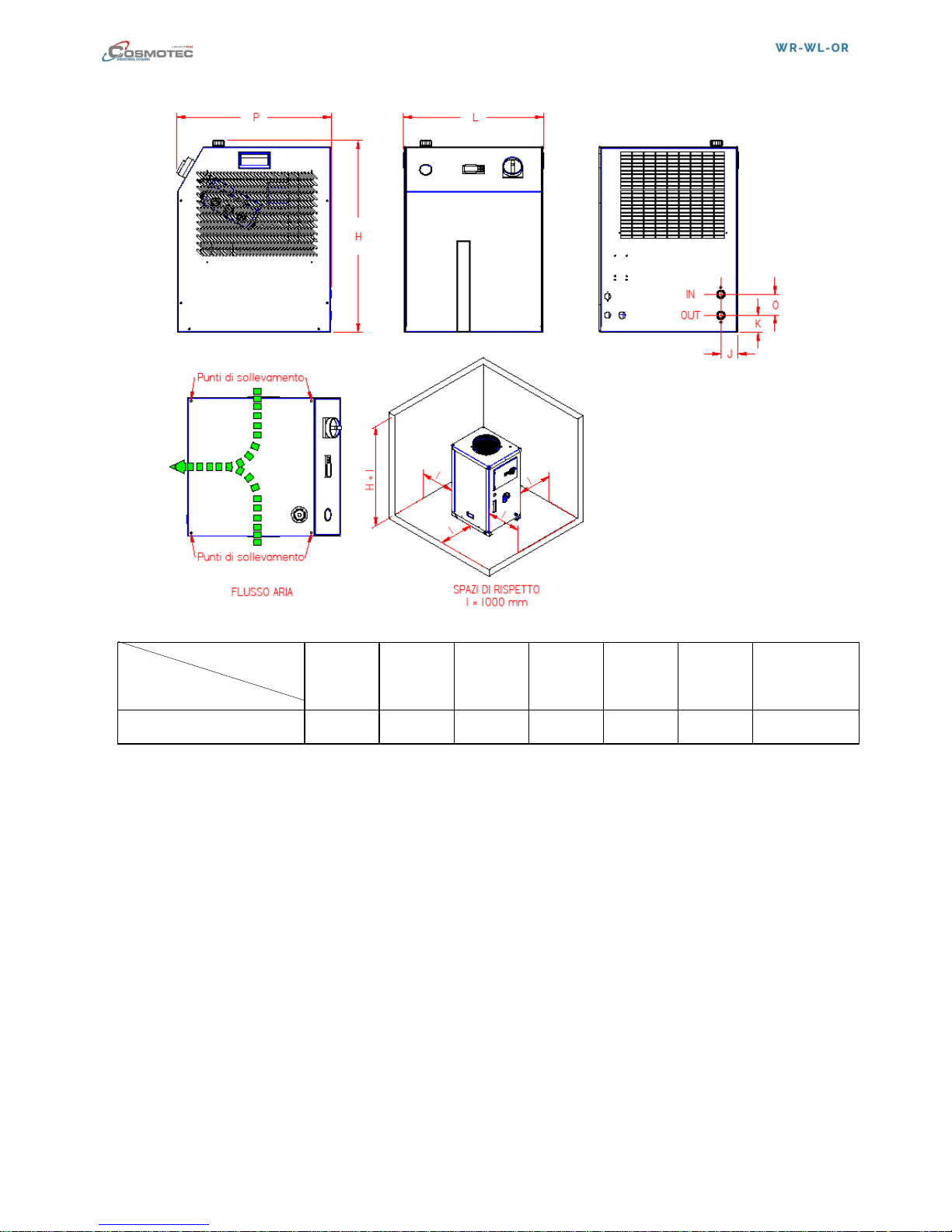

SIZE OF WLA PRECISION

L P H K J O IN/OUT

UNI ISO228

WLA B8-C2

700

1650

1450

615

98

150

1 ¼”G

WLA C8-D8

1140

2000

1820

615

98

150

1 ½”G

WLA G2-H8

1140

2000

1820

615

98

150

1 ½”G

SIZE OF WLA PRECISION R410A

MOD.

(mm)

Loading...

Loading...