New Cosmos PS-7

User Manual

Includes:

Product Manual

Administrator Manual

Pyrolyzer Manual

2

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

© DOD Technologies, INC

675 Industrial Drive Bldg. A.

Cary, IL 60013

Phone 815.788.5200 • Fax 815.788.5300

3

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

Table of Contents

Chapter 1 – Introduction ........................................................................................................................................ 5

1.1 Explanation of Symbols .................................................................................................................................................... 5

Chapter 2 – Safety Instructions ............................................................................................................................. 6

Chapter 3 – Contents of This Package .................................................................................................................. 7

3.1 End of Line Filter Use ............................................................................................................................................................ 8

Chapter 4 – System Flow Diagram ........................................................................................................................ 9

Chapter 5 – Description ....................................................................................................................................... 10

5.1 Components on the Main Unit ........................................................................................................................................... 10

5.2 Details of the Key Switch Section ...................................................................................................................................... 12

5.3 Details of the LCD Screen Display ..................................................................................................................................... 13

Chapter 6 – Installation and Wiring ..................................................................................................................... 14

6.1 Installing the Main Unit ...................................................................................................................................................... 15

6.2 Wiring Instructions ............................................................................................................................................................. 16

Chapter 7 – Operation .......................................................................................................................................... 18

7.1 Operation Procedures ......................................................................................................................................................... 18

7.2 Gas Alarm Operating Instructions ..................................................................................................................................... 30

7.3 Trouble Alarm Operating Instructions ............................................................................................................................... 32

7.4 Test Mode Settings and Operating Instructions .............................................................................................................. 33

7.5 Maintenance Mode Settings and Operating Instructions ................................................................................................ 34

Chapter 8 – Maintenance and Inspection ............................................................................................................ 35

Chapter 9 – replacing Consumables.................................................................................................................... 38

9.1 Replacing the Filter Element (FE-1) ................................................................................................................................... 38

9.2 Attach/Replacing the Sensor Unit ..................................................................................................................................... 39

9.3 Replacing the Sampling Unit.............................................................................................................................................. 41

Chapter 10 – Troubleshooting ............................................................................................................................. 44

Chapter 11 – Specifications ................................................................................................................................. 45

Chapter 12 – Warranty ......................................................................................................................................... 46

Chapter 13 – Detection Principles ....................................................................................................................... 46

13.1 Electrochemical Sensor ................................................................................................................................................... 46

13.2 Hot-wire Semiconductor Sensor ..................................................................................................................................... 47

13.3 Galvanic Cell Sensor ......................................................................................................................................................... 47

Chapter 14 – Glossary .......................................................................................................................................... 48

Administrator Manual ........................................................................................................................................... 49

Chapter 1 – Passwords ........................................................................................................................................ 50

1.1 Password Protected Settings ............................................................................................................................................ 50

1.2 Releasing the Password Lock ............................................................................................................................................ 50

Chapter 2 – Changing Settings ............................................................................................................................ 51

4

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

2.1 Span Adjustment ................................................................................................................................................................ 51

2.2 21Vol% Adjustment ............................................................................................................................................................ 52

2.3 Changing Setting Values .................................................................................................................................................... 53

2.4 Changing the Alarm Settings ............................................................................................................................................. 55

Pyrolyzer Manual .................................................................................................................................................. 57

Chapter 1 – Attach/Replacing the Pyrolyzer ....................................................................................................... 58

5

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

Chapter 1 – Introduction

Thank you for purchasing the extractive COSMOS Gas Detector Model PS-7.

This Gas Detector is designed to detect the leakage of toxic and combustible gases. It is designed to display

the concentration level of detected gases on the main unit and output that information externally as an

analog signal. When a preset warning level of gas is detected, the warning lamp (ALARM lamp) on the main

unit starts to blink, the external contact output is activated, and the amount of leaking gas is monitored.

The sensor unit and sampling unit used in the Gas Detector can be replaced without the use of tools. Regular

replacement of these components eliminates the need to perform calibration on-site. To ensure correct

operation, read this manual carefully before attempting to install or operate the Gas Detector.

1.1 Explanation of Symbols

This manual uses the following symbols. Their meanings must be understood and observed to ensure safe

operation of the unit.

Danger:

Indicates an impending hazardous situation that, if not avoided, will result in serious

injury or death.

Warning

Indicates a potentially hazardous situation that, if not avoided, could result in serious

injury or death.

Caution

Indicates a potentially hazardous situation that, if not avoided, could result in minor

injury or physical damage.

Note

Indicates operational advice and/or instructions.

6

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

Chapter 2 – Safety Instructions

Read and understand the following information to ensure that the Gas Detector is used correctly. The Gas

Detector must always be used in accordance with relevant laws and regulations, and all wiring, installation,

and other work associated with the Gas Detector must be performed by qualified personnel.

Warning

• When the Gas Detector detects a gas leak, carry out the procedures stipulated by

your company in response to gas leaks.

• The Gas Detector must be grounded to prevent electric shock.

• The Gas Detector is not explosion-proof. It must be installed in a safe location.

Caution

• Do not disassemble or modify the unit or change its construction or circuitry in

any way. Doing so may impair the unit's performance.

• The Gas Detector is not drip-proof and must be installed in a location free from

spattering water.

• The unit must be used in accordance with prescribed laws and regulations.

• Please turn the power switch located on the front of the base unit OFF when

attaching or removing the main unit. If this is done with the switch left ON, the unit

may become damaged, or give false alarms.

7

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

Chapter 3 – Contents of This Package

The following components are included with the standard Gas Detector unit. Ensure that all components are

present before attempting to use the unit. Every effort is made to ensure that the unit is packed correctly, but

if any components are damaged or missing, contact your local authorized distributor.

*1 2 sticks are provided with each system.

NOTE:

1. The sensor unit is not bundled with the Gas Detector and must be purchased separately.

2. When it is with DeviceNet unit, the contents are as described in the DeviceNet Unit Instruction manual

IMPORTANT NOTICE - If using the PS-7 for absorbent / corrosive gases such as HCl, HF, Cl2, HBr, etc. You

must remove the internal filter and install #2-800-013 OR #60009 Corrosive Filter at the end of the sample

line.

Teflon FEP sample tubing must be used in conjunction with the corrosive filter when monitoring for corrosive

/ absorbent gases. 1/4 OD x 3/16” ID

See Chart on next page

Description

Quantity

PS-7 Gas Detector

1

Male connector ¼” NPT

2

Filter elements (FE-1, 12 pcs.)

(For MF-50 Filter Unit)

1

Fuse (0.5 A)

1

Mounting screws (M4 8)

2

Stick for Test

2

*

1

Operation Manual

1*2

Operation Manual

1*2

8

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

3.1 End of Line Filter Use

PN: 780248

PN: 60009

PN: 2-800-013

Use with

Use with:

Use with:

AsH3

BCl3

BCl3

COCl2

Bf3

Bf3

C4F8

Cl2

Cl2

C5F8

DCS

DCS

B2H6

HBr

HBr

H2S

HCl

HCl

H2Se

HF

HF

GeH4

SiCl4

SiCl4

CH4

SiF4

SiF4

IPA

WF6

WF6

CH2F2

POCl3

POCl3

CH4

Hydrazine

Hydrazine

CHF3

NH3

NH3

CO

O3

O3

H2

NF3

PH3

SiH4

O2

9

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

Chapter 4 – System Flow Diagram

Figure 1 System flow diagram

GAS OUT

Rc 1/4

LCD Display

Maintenance

switch

P

Pump

Sensor

Flow

sensor

MF-50 (Dust filter)

GAS IN

Rc 1/4

GAS IN

Rc 1/4

Controller

F1

ZA1

ZA2

ZC

TA

TC

Power

DC 24V

TB

1st level warning

2nd level warning

Common

Trouble

warning

Warning contact capacity (ZA1orZA2-ZC)

(Rated load: 125 V AC or 30 V DC

0.5-A resistance load)

Trouble output (TA-TC)

(Rated load: 30 V DC 30-mA

resistance load)

Gas alarm contact output

(N/O)

PW

Jack

(4-conductor shielded cable)

+

-

+

-

TB

FS

Sampling Unit

P

N

G

H

E

SW

SW

TR

AL

Key

Analog Output

4 to 20 mA DC

Trouble warning output

(N/C)

CPU Board

Warning

Pay special attention to the polarity of the trouble warning output. As the circuit protection

diodes are internalized, if the polarity is reversed, the trouble warning 1 Pull back

not be output.

Caution

The analog output source is not insulated from the power source. In case it is used in

combination with other types of devices, the analog signal must be isolated from flowing into

the power sources of the other devices.

10

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

Chapter 5 – Description

5.1 Components on the Main Unit

No.

Description

Function

1

POWER lamp

(Green) Power lamp. Illuminates during regular monitoring

operations.

2

TROUBLE lamp

(Yellow) The lamp blinks when trouble occurs.

3

ALARM lamp

(Red) The lamp blinks when the concentration level of detected

gas exceeds that of the preset alarm level.

4

LCD display

Warning displays, detected gas levels, bar graphs of gas levels,

trouble states, maintenance modes, test mode, flow sign are all

shown on the LCD display.

5

Key switches (inside)

Switches to carry out the various settings.

6

Filter unit (MF-50)

Incorporates a filter element (FE-1) that prevents dust from

entering the gas inlet and tubes leading to the sensor.

7

Operation section cover

Lift up gently to use key switches.

8

Front panel

Contains the main board.

9

Sampling unit

The pump is contained inside the sampling unit.

10

Main body cover

The cover protecting the sensor unit.

11

Latches

Latches to attach the main unit onto the base unit.

12

Locked/unlocked line

A line (mark) to show the return position of the latch.

11

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

No.

Description

Function

13

Fuse

125 V, 0.5 A

14

Base unit power switch

The power switch for the base unit.

15

Mounting holes

Screw holes (5.5) for wall mounting.

16

Terminal strip

Used to connect external wiring.

17

Main unit power switch

The power switch for the main unit.

18

Maintenance switch

A switch that is set to regular, maintenance mode 1 (MNT1) or

maintenance mode 2 (MNT2).

19

Connector for the pyrolyzer

A connector to provide power to the pyrolyzer when one is being

used. (CDP-7 type).

20

Gas inlet

Aspiration inlet for sampled gas. A filter unit (MF-50) is attached.

21

Gas outlet

Exhaust outlet for sampled gas.

22

Cable entry

A hole for incoming cables.

12

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

5.2 Details of the Key Switch Section

No.

Description

Display

Function

1

Span adjustment

switch

SPAN

To carry out 21vol% adjustments.

(For the COS-7 oxygen sensor unit.)

2

Zeroing switch

ZERO

To carry out zeroing.

(For the CHS-7 flammable gas sensor unit or CDS-7 toxic gas

sensor unit.)

3

Alarm point set switch

AL

Used to check the values of various alarm settings.

4

Communications

switch

COMM.

Sends sensor unit information to the main unit after initial

start-up, etc.

5

Up/down switch

UP

DOWN

Used to change the values of the test output, etc.

6

Connector to check

analog output

CP

A connector employed specially to check the analog output

from the main unit (4- 20 mA).

7

Test switch

TEST

Used to set to test mode.

8

Special command

switch

(None)

Used to change the values of various settings.

(For administrative use.)

13

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

5.3 Details of the LCD Screen Display

No.

Meaning

1

Shows the detected gas concentration (with units).

2

Lights when the flow rate is decreasing. (Also, see no. 6 below.)

3

These light when the detected gas concentration exceeds that of the preset alarm level.

4

Lights on when there is sensor trouble, or when a sensor is inserted incorrectly.

5

Lights on when the pyrolyzer is disconnected.

6

Shows the flow rate of the sampling gas.

Fast rotating display: When flowing at normal rate (0.5 L/min).

Slowly rotating display: (Showing that it is clogged) When the load on the pipe is high.

No rotation: (Warning that the flow rate is decreasing) When the flow rate has decreased.

7

Bar graph of gas concentration. One division is 5% of a full-scale value.

When the bar extends to the far right, it is at full scale.

8

Shows the values of various settings. (For administrative use.)

9

Lights while in test mode.

10

Lights while in either maintenance mode 1 (MNT1) or mode 2 (MNT2).

14

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

Chapter 6 – Installation and Wiring

Warning

• The Gas Detector is not explosion-proof. It must be installed in a safe location.

• When detecting highly adsorbent gases remove the internal filter and install proper

end of line filter (see page 8)

• The sample distance on the PS-7 is 50 feet for non-absorbent gases and 30 feet for

absorbent gases. FEP TEFLON tubing must be used with absorbent gases.

Caution

• The Gas Detector should be installed in a location free from shock and vibration, and

away from sources of high frequencies or magnetism.

• Do not use the gas collector hood when detecting gas concentrations in narrow spaces

such as ducts.

• Do not install the Gas Detector in locations where the temperature may exceed 40°C or

dew condensation or sudden temperature fluctuations may occur.

• The Gas Detector is not drip-proof.

• The pressure difference between the gas inlet/exhaust ports and the ambient

atmosphere must be within 1 kPa. The pressure difference between the inlet port and

exhaust port must be such that the inlet port is a negative pressure of 1 kPa or less.

• Install the Gas Detector vertically. (Inlet port and exhaust port must be in downward

direction.)

• Locate the detector tip (the tip of the gas sampling pipe) to be appropriate for the

specific gravity of the gas to be detected. It must also be placed in a location where the

target gases are likely to accumulate.

Type of gas

Installation height

Heavier than air

Not more than 30 cm above floor level

Equivalent to air

75 to 150 cm above floor level

Lighter than air

Near the ceiling

15

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

6.1 Installing the Main Unit

1. Determine the installation point and

attach the base unit using two M4 8

screws.

`

2. Run a cable through the cable entry

(the cutout hole near the bottom of

the base unit) and connect to the

terminal board. (Refer to 6.2 Wiring

Instructions.)

3. To attach the sensor unit, refer to 9.2

Attach/Replacing the Sensor Unit. To

attach it after attachment of the base

unit, proceed to step 4.

4. Remove the protective seal before

attaching the main unit.

5. Pull back the latches on both the left

and rights sides of the bottom of the

base unit, and attach the main unit

inserting from the top side first.

6. Push both the latches on the left and

right-hand sides of the base unit

back in until the locked/unlocked line

can be seen

2 Attach in line with the rails

1 Pull the latches on both sides forward

16

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

NOTE: The protection seal on the base unit is to protect the connector and internal piping when attaching the

base unit. This seal is not necessary after the main unit is attached. Please dispose of it properly in

accordance with company disposal regulations.

If multiple units are to be mounted in a row, ensure that there is enough space between each unit (at least 3

cm on either side is recommended) to allow the main unit to be removed and reattached.

6.2 Wiring Instructions

Terminal Board

Sign

Polarity

Function

TB1

P

+

Power supply (24 V DC)

N

- G +

Gas concentration output (4-20 mA DC)

H

-

E

Ground

TB2

ZA1

Gas alarm contact output (1st level)

(no voltage contact 1a)

Rated load: 125 V AC or 30 V DC, 0.5-A resistance load

ZA2

Gas alarm contact output (2nd level)

(no voltage contact 1a)

Rated load: 125 V AC or 30 V DC, 0.5-A resistance load

ZC

ZA1, ZA2 common

TA

+

Trouble alarm

(Open collector: N/C)

Rated load: 30 V DC, 30-mA resistance load

TC

-

Trouble alarm common

Warning

Be sure to push the latches back as far as they will go. If the latches are not back behind the

locked/ unlocked line, normal gas detection will not be performed.

17

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

Warning

• Be especially careful regarding the polarity of the trouble alarm (TA: plus, TC:

minus.) as the circuit protection diodes are internalized, if the polarity is reversed,

the trouble warning signal will not be output.

• To avoid electric shock, always disconnect the power supply before performing

any wiring operations.

• Ensure that the unit is properly grounded.

Caution

• Do not lay cables near sources of electrical noise, such as high-capacity

transformers, motors or power supplies.

• Ensure that the cables on the external device side and the gas detector side are

correctly connected.

18

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

Chapter 7 – Operation

7.1 Operation Procedures

Carry out operations in the following manner. Refer to the items inside each box for more detailed

instructions (listed from the next page)

19

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

Proceed with operation in the following manner:

1. Verify that the power supply voltage (the voltage between the P and N of the terminal block) is 24 VDC

10%.

2. Switch the base unit power ON.

Warning

• Verify that the power supply voltage is 24 V DC 10%.

• Before operating the Gas Detector, verify that the sensor unit correctly displays the

type of gas to be detected and the full-scale value.

Warning

• Before Turning the power on, check that all connections are correct. Refer to 6.2

Wiring Instructions and the separate delivery specifications if available.

20

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

3. Analog adjustment in maintenance mode 2

- The analog output of the main unit changes when the maintenance switch is set to 2.

- Adjustment should be carried out based on the following instructions as the analog output also

differs depending on the sensor unit being used. For details regarding maintenance modes, refer

to 7.5 Maintenance Mode Settings and Operating Instruction.

Toxic gas sensor unit: CDS-7

Combustible gas sensor unit: CHS-7

Oxygen sensor unit: COS-7

(Value when at full scale 25vol%)

Oxygen sensor unit: COS-7

(Value when at full scale 50vol%)

*MUST BE ADJUSTED

1. Pull back to open

2. Move knob to the right to set to maintenance

mode 2 (MTN2)

1. Pull back to open

2. Move knob to the right to set to maintenance

mode 2 (MTN2)

Analog adjustment volume for maintenance mode 2

Analog adjustment volume for maintenance mode 2

The tester tests the current range.

G=plus

H=minus

The tester tests the current range.

G=plus

H=minus

21

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

Measure the analog output (current) of “G” and “H”

on the terminal board TB1 using a tester, etc.

If it falls within the range shown below, go on to

the next step.

If it is not within the range shown below,

use the analog adjustment volume for maintenance

mode 2 to bring it into this range.

Model Type: Adjustment Range:

CDS-7 3.92 – 4.08 mA

CHS-7 3.92 – 4.08 mA

COS-7 17.32 – 17.48 mA

Measure the analog output (current) of “G” and “H”

on the terminal board TB1 using a tester, etc.

Adjust it to within the range of 10.64 to 10.80 mA by

using analog adjustment volume for maintenance

mode 2.

For toxic gas sensor unit: CDS-7

OR

combustible gas sensor unit: CHS-7

Oxygen sensor unit: COS-7

(When full scale value is 50vol%)

Set analog output to 10.7mA as the regular oxygen

concentration is 21%

Oxygen Sensor Unit: COS-7

(When full scale value is 25vol%)

Set analog output to 17.4mA as the regular oxygen

concentration is 21%

22

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

1. Pull back to open

2. Move knob to center to set to normal mode

1. Pull back to open

2. Move knob to center to set to normal mode

4. If the sensor unit is not attached, refer to 9.2 Attach / Replacing the Sensor Unit, and attach the sensor

unit.

5. Switch the main unit power ON

*Refer to 6.1 installing the main unit:

23

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

6. Begin self-diagnosis after the front lamp and the LCD screen have been on for over one second.

7. When “Good” is displayed at the bottom right of the LCD screen, it will go into initial power delay mode

(POWER lamp blinks) for 30 seconds. It will then return to normal operation state, and the POWER

lamp will come on. The detected gas concentration will be displayed in the middle of the screen.

POWER lamp (Green)

Blinks (30 Secs) - ON

The TROUBLE lamp (Yellow) will

blink.

Also [SENS] will be displayed at

the top of the LCD screen and Err

on the bottom right

Open the cover on the operation

section of the main body and hold

down the key switch “COMM” for

over one second

When using the main detector for the first time, or when a new sensor unit with

different settings (sensor units for which the target gases and full-scale values, etc.,

are different) has been attached:

When the sensor unit has been replaced, or when a sensor unit with the same settings

(sensor units for which the target gases and full-scale values etc. are the same) has

been attached:

24

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

8. Check the various setting values

- The values of the various settings can be checked by pressing the up/down switch, “” or “” on

the main unit. The setting values are displayed in the bottom right hand corner of the LCD Screen.

NOTE: They may sometimes be difficult to distinguish due to the types of alphabet letters used.

The values of alarm settings can be checked by pressing the alarm setting switch “AL”.

“AL1 displayed” “AL2 displayed” “Normal” “AL1 displayed” (Repeat)

The percentage of the full-scale value for the current alarm values will be displayed in the bottom right hand

corner of the LCD screen (in units of 1%), and the alarm set value at the current gas concentration is displayed

in the middle of the screen.

LCD Display

Screen

Default value

Explanation of the default value

A1 **

Toxic: CDS-7

Combustible: CHS-7

A1 10

10% of F.S.

Oxygen: COS-7

A1 72

72% of F.S.

A2 **

Toxic: CDS-7

Combustible: CHS-7

A2 20

20% F.S.

Oxygen: COS-7

A2 76

76% of F.S.

LCD Screen

Display

The function to be set

Remarks

Default value

Toxic : CDS-7

Combustible: CHS-7

Oxygen:

COS-7

d1 **

Time delay1

Time delay (secs.) of the gas alarm contact

(1st level)

d1 0

d1 0

d2 **

Time delay2

Time delay (secs.) of the gas alarm contact

(2nd level)

d2 0

d2 0

az

Analog output (base)

(*For our maintenance purposes only)

-

-

as

Analog output (span)

(*For our maintenance purposes only)

-

-

zs *

Zero suppression, or 21vol%

suppression

Displays the percentage of the full-scale

value (rounded to the percent)

zs 5

zs 2

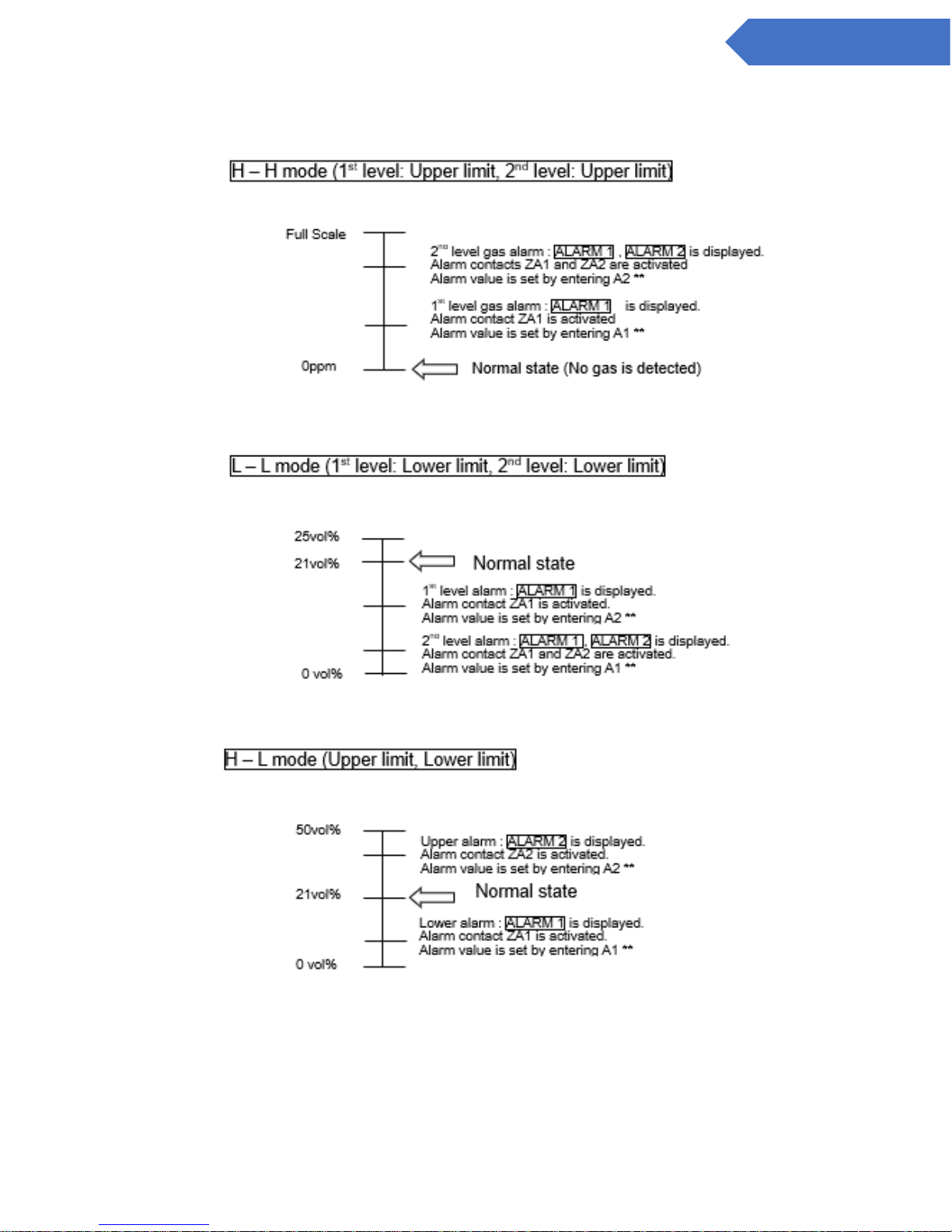

H-H

L-L

H-L

Alarm mode

1st: Upper limit, 2nd: upper limit warning

1st: Lower limit, 2nd: lower limit warning

1st: Upper limit, 2nd: lower limit warning

H-H

L-L

Con *

Pyrolyzer failure alarm

0: Off 1: On

Con 0

Con 0

CG **

Calibrated gas concentration

(*For our maintenance purposes)

CG 40

CG 84

nEt *

The existence of DeviceNet unit

0: Non-existent 1: Existent

nEt 0

nEt 0

F ***

Display offvalue

(*For our maintenance purposes)

-

FL ***

Displays rate of flow

Shows the current rate of flow (mL/min)

-

P ***

Sensor unit output

(*For our maintenance purposes)

-

At *

Auto 21vol% adjustment

0: No 1: Yes

At 1

25

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

Alarm point setting switch

Up/Down Switch

Center of the

screen

Bottom right of the

screen

9. Verifying the sampling flow rate (Check flow rate)

- Check to see that the flow rotation rate is high, and the TROUBLE lamp (yellow) is off.

- If the flow rotation is high, then it is flowing at the designated rate (0.5 L/min).

NOTE:

Clogged Display

• Slowly rotating flow rate

A “Clogged Display” will be shown when the load on

the pips is high. This could mean:

• The pipes are clogged

• The filter is clogged

• The load is too high

Monitoring of gas concentration will continue even

when the “Clogged Display” is shown.

Warning that flow rate is decreasing

• No Rotation

• FLOW is displayed on the LCD Screen

• TROUBLE lamp (Yellow) blinks

• Trouble warning is activated

When the flow is not at the designated rate, a

warning that the flow rate is decreasing is output.

Rotates Quickly

TROUBLE lamp (yellow) Off

Stops Rotating

26

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

10. Verifying airtight seal

Disconnect the gas sampling pipe from the gas inlet and block the inlet with

a finger completely.

The flow rotation rate will then slow. By keeping the inlet blocked, it will

eventually stop. Then, check to make sure the TROUBLE lamp (Yellow) is

blinking.

(The warning that the flow rate is decreasing is generally set to a delay time

of 10 seconds)

FLOW will be displayed on the LCD screen.

If the flow rate rotation stops and the TROUBLE lamp (Yellow) does not come

on – please check to ensure the sensor unit is properly attached to the main

unit (Refer to 9.2 Attach / Replacing the Sensor Unit) Also check to ensure

that the latches at the bottom of the base unit are correctly locked back

behind the locked / unlocked line.

When the pipes have been returned to normal, recheck to see that the flow rotation rate is high.

11. Adjusting the Zero/21 vol% setting (Zeroing for the CDS-7, CHS-7, and 21vol% adjustment for the

COS-7)

After power is applied to the main unit, and the appropriate time has passed (depending on the type of

sensor unit), press the appropriate key switch from the below table. Then, be sure to do a

readjustment to increase precision.

Sensor Unit

Initial

adjustment

Readjustment

Zero / 21ol% adjustment key switch

Toxic gas sensor unit

CDS-7

30 minutes after

power ON

24 hours after power

ON

Maintenance mode1 or 2

+ ZERO switch *1

Oxygen sensor unit

COS-7

Maintenance mode1 or 2

+ SPAN switch*2

Combustible gas sensor

unit CHS-7

1 day after power

ON

7 days after power

ON

Maintenance mode1 or 2

+ ZERO switch *1

NOTE: Factors such as the atmosphere of the installation location may cause the Zero/21 vol% setting to take

longer to stabilize (the time until re-adjustment) than the time indicated in the above table.

Block the inlet

27

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

Zeroing

Toxic Gas Sensor Unit: CDS-7

Combustible Gas Sensor Unit: CHS-7

21vol% Adjustment

Oxygen Sensor Unit: COS-7

1. Set to maintenance mode (MNT1 or MNT2)

Left: Maintenance 1 (MNT1)

Center: Normal Mode

Right: Maintenance 2 (MNT2)

*For details regarding maintenance modes, refer to

7-5 Maintenance Mode Settings and Operating

1. Set to maintenance mode (MNT1 or MNT2)

Left: Maintenance 1 (MNT1)

Center: Normal Mode

Right: Maintenance 2 (MNT2)

*For details regarding maintenance modes, refer to

7-5 Maintenance Mode Settings and Operating

2. Hold down the ZERO Key for over a second.

It is complete when the POWER lamp (Green)

blinks once.

2. Hold down the SPAN Key for over a second.

It is complete when the POWER lamp (Green)

blinks once

3. Set back to normal mode (Center)

3. Set back to normal mode (Center)

Be sure to do a readjustment after the appropriate

time has passed to increase precision.

Poisonous gas sensor unit: After 24 Hours

Flammable gas sensor unit: After 7 Days

Be sure to do a readjustment after the appropriate

time has passed to increased precision.

Oxygen Sensor Unit: After 24 Hours

28

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

12. Affix the seal showing target gases to be detected in a clearly visible place on the front of the main

body.

Normal operation state

Warning

Zeroing and 21vol% adjustment must be carried out in a clean environment. If they are done

in a gas-filled environment, the correct level of gas concentration detected will not be given.

POWER lamp (Green): On

TROUBLE lamp (Yellow): Off

ALARM lamp (Red): Off

Flow rate: High rotation

Detected gas

concentration level

Seal showing target gases

to be detected

29

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

Normal Trouble

Gas alarm

(1st stage)

Gas alarm (2nd

stage)

LED

Green light

Yellow blink

Red blink

Red blink

LCD screen

FLOW

SENS

CONV

ALARM1

ALARM1

ALARM2

Alarm contact

(ZA1)

OFF OFF

ON ON

Alarm contact

(ZA2)

OFF OFF OFF

ON

Trouble alarm

(TA)

ON

OFF

ON ON

30

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

7.2 Gas Alarm Operating Instructions

When the concentration level of detected gas exceeds that of the preset alarm level, the alarm contacts are

activated after a set time delay, the ALARM lamp (red) blinks, and ALARM1 or ALARM2 is displayed on the

LCD screen.

* During the alarm time delay, ALARM1 or ALARM2 blinks on the LCD screen, but the alarm contacts are not

activated, and the ALARM lamp (red) does not blink.

When the concentration of detected gas drops back below the preset alarm level, it will automatically return

to normal.

Gas Alarm (1st Level)

Alarm 1

Gas Alarm (2nd Level)

Alarm 2

*When the 2nd level gas alarm is activated, both the

ALARM1 and ALARM2 will turn on.

○: On : Blinking ●: Off

Alarm level

LCD Screen

POWER

Lamp (Green)

TROUBLE

Lamp

(Yellow)

ALARM

Lamp

(Red)

Remarks

1

Gas alarm (1st level)

ALARM 1

○

●

2

Gas alarm (2nd level)

ALARM 1, ALARM 2

○

●

The ALARM lamp (red) will blink with the gas

alarm (1st level), or gas alarm (2nd level)

31

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

NOTE: The relationship between 1st level and 2nd level alarm values of each alarm mode is as follows:

32

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

7.3 Trouble Alarm Operating Instructions

The trouble alarm will be activated in the following situations. (The open collector will be ON in normal mode,

and OFF during trouble or when the power is disconnected.) The TROUBLE lamp (yellow) will blink, and analog

output will drop to below 0.6 mA. When the problem is remedied, the trouble alarm will automatically return to

normal.

1. Decrease in the rate of flow

When the flow is not at the designated rate, it is assumed that it is decreasing. FLOW Is

displayed on the LCD screen, and the flow rate rotation stops. Causes for a decrease in flow

rate can include the clogging of filter elements, the clogging of pipes, the load being too high,

deterioration of the pumps, etc.

2. Sensor trouble

SENS. will be displayed on the LCD screen in the following situations:

• When the base output of the sensor unit has decreased significantly

• When the sensor has been disconnected. (For combustible gas sensor unit: CHS-7.)

3. When a sensor unit has been inserted wrong

The settings, full scale values, and target gases to be detected are recorded in a detector after

its first use. When a sensor unit with different settings information is inserted, this is

determined to have been inserted wrong, and SENS. is displayed on the LCD screen. The

concentration of the detected gases is displayed as: ‘’- - - -”

4. Disconnection of the pyrolyzer

When the pyrolyzer has been disconnected after used, CONV. is displayed on the LCD screen.

5. Disconnection of the power source

When the power source has been cut, all lamps (green, yellow, and red) will turn off, and all

operations will cease.

6. A blown fuse

When a fuse has blown, or is disconnected, the power source becomes cut, and all lamps (green,

yellow, and red) will turn off, and all operations will cease

NOTE: When the trouble alarm is activated while using the oxygen sensor unit COS-7, the analog output is

reduced to less than 0.6 mA. When the host system setting is the lower limit alarm, trouble will occur if the

analog output from the main unit drops to less than 0.6 mA within one second from the time that the lower

limit alarm is not activated. To avoid this, set it so that the lower alarm limit is not activated.

○: On : Blinking ●: Off

Type of trouble

LCD display

POWER

Lamp

(green)

TROUBLE

Lamp

(yellow)

ALARM

Lamp (red)

Remarks

1

Decrease in rate of

flow

FLOW

○ ●

The flow rate rotation is

stopped

2

Sensor trouble

SENS.

○ ●

3

Incorrect insertion of

the sensor unit

SENS.

○ ●

The gas concentration display

shows “- - - -”

4

Pyrolyzer failure

CONV.

○ ●

5

Disconnection of the

power source

(Nothing)

● ● ●

6

Blown fuse

(Nothing)

● ● ●

33

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

7.4 Test Mode Settings and Operating Instructions

1. Settings

Press the “TEST” key switch on the front of the main unit.

When this is pressed once, it will go into test mode. When it is pressed again, it will return to

normal mode.

*Test mode will automatically be released after 10 minutes.

2. Operating Instructions

TEST is displayed on the LCD screen.

In test mode, the value of the analog output (4-20 mA) can be set to units of 0.16 mA (1% units of

the full-scale value).

The value of the analog output can be changed using the “UP/DOWN” keys.

Can be set with the UP/DOWN

keys.

Press with the stick for test.

When pressed once, it will go into

test mode, when pressed again it

will return to normal.

Caution

The alarm check conducted with the test switch will also activate the gas alarm contacts.

For this reason, if alarm contacts are used for interlocking with external devices, verify that

the interlock be released prior to conducting the alarm test.

Be sure to conduct alarm testing after changing settings in either maintenance mode. (Refer

to 7.5 Maintenance Mode Settings and Operating Instructions.) Also, conduct inspections on

the gas detection devices only after informing those involved.

34

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

7.5 Maintenance Mode Settings and Operating Instructions

1. Settings

There are two types of maintenance modes. (See the table below for the functions of each)

Set the maintenance switch at the bottom of the from of the main unit to 1 [left], or 2 [right]

Either MNT1 or MNT2 will be displayed on the LCD Screen

Move the maintenance switch to the center position to return to normal mode

Set to maintenance mode.

LEFT: Maintenance Mode 1

CENTER: Normal Mode

RIGHT: Maintenance Mode 2

2. Operating instructions

When on maintenance mode 1, neither the gas alarm contacts, nor the trouble alarm are activated.

When on maintenance mode 2, neither the gas alarm contacts, nor the trouble alarm are activated.

And the analog output will be fixed to either 4.0 mA or 17.4 mA.

In both maintenance modes, the trouble lamp (yellow) blinks, and the concentration value of detected gas is

displayed on the LCD screen.

Alarm contacts

Trouble alarm

Analog output

TROUBLE

Lamp (yellow)

LCD screen

Maintenance mode

1

Not activated

(Fixed OFF)

Not activated

*(Fixed ON)

Output based on the

concentration value

of the detected gas

Blinks

Concentration

value of

detected gas

Maintenance mode

2

Not activated

(Fixed OFF)

Not activated

*(Fixed to ON)

Fixed to 4mA or 17.4

mA.

Blinks

Concentration

value of

detected gas

Caution

*1 In both maintenance mode, the trouble alarm is activated when the power source is

switched off on the main unit. (Trouble alarm: OFF)

*2 The analog signal may change when the power source is switched off on the main unit.

Warning

Be sure to check that it is set to normal mode (center) during regular operations (monitoring

gas concentration.) When regular operations are carried out in maintenance modes 1 or 2,

the alarm contacts and trouble alarms will not work. In maintenance mode 2, the analog

signal will not change from 4 mA.

35

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

NOTE: Both maintenance modes 1 and 2 function only on the base unit. Even when there is no main unit,

analog output of 4mA is possible on maintenance mode 2, which enables a loop check during setup.

Chapter 8 – Maintenance and Inspection

• The Sensor Modules do not normally require gas calibration to be performed on site. Gas calibration

of the sensor module is performed by New Cosmos at the time the sensor is manufactured.

• The CDS sensors (electrochemical) have a life of 2 or more years depending on the specific sensor.

CDS sensors are labeled with a manufacture date. All CDS sensors must be gas tested or replaced

every 16 months from the manufacture date or 12 months from the install date, whichever comes first.

• CDS sensors also have an “install by date”. If a sensor is installed after the “install by date” monitor

the sensor in maintenance mode 2 (MNT 2) to ensure the sensor is stable and not drifting before

placing the PS-7 in the run position. The actual time for the sensor to stabilize will vary based on the

sensor type. Once stable the sensor is ready to use.

• CHS sensors have a stated service life of 5-7 years based on the type of sensor. The actual life of the

sensor can exceed the stated service life. CHS sensors should be gas tested on an annual basis.

• The following table provides an inspection timetable for various components of the Gas Detector unit.

Periodic inspections refer to inspections that should be performed every twelve months by either the

user or an authorized representative of New Cosmos.

Frequency and Content of Inspections

Content of Inspection

When starting up or

relocating

Periodic inspection

Every 12 months

1. Gas concentration indicator

inspection

○

○

2. Sampling flow rate inspection

○

○

3. Inspection of airtight seal of internal

assembly

○

○

4. Replacement of filter element

Will vary based on sampling condition

5. Pipe line inspection

○

6. Gas testing or replacement of sensor

○

○

7. Loop inspection using Test switch

○

Important

36

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

1. Gas concentration indicator inspection

Verify that the gas concentration value is indicated on the LCD screen and the unit is functioning

normally.

2. Sampling flow rate inspection (Flow rate inspection)

Check that the flow rate on the LCD screen is rotating quickly. (Refer to 7.1 Operation Procedures (9)).

If the flow rate is rotating slowly or has stopped, check the filter element, and replace if clogged or

dirty. (See 9.1 Replacing the Filter Element.) If it still is not right after replacing the filter element, check

to make sure the pipes are not clogged, or the load is not too high, etc.

3. Inspection of airtight seal

Carry out an inspection of the airtightness of the internal assembly while

referring to 7.1 Operation Procedures (10).

4. Replacement of filter element

Check to ensure the filter elements are not clogged or dirty at least once every 6 months and replace if

necessary. Filter elements can get dirtier easier depending on the surrounding environment. When the

display shows that the filter is clogged (the flow rate is on slow rotation), check the filter element and

change if necessary. (Refer to 9.1 Replacing the Filter Element FE-1)

5. Pipe inspection

Inspect the gas sampling pipe at startup or when the installation has been augmented or relocated. If

the pipe is not correctly connected, it will not be possible to maintain the required sampling flow rate

or to take gas samples from the target location.

6. Attachment and replacement of sensor unit

Install a new sensor unit at startup. CDS and CHS Sensors should be gas tested or replaced at 12

month intrevals. (Refer to 9.2 Attach/Replacing the Sensor Unit on page 39 and 41.)

7. Loop inspection using Test switch

By pressing the “TEST” key switch on the front of the main unit with a long thin tip, such as that of a

ball point pen, the analog output value can be set at will, so please check the host system. When

“TEST” is pressed again, output returns to normal. (Refer to 7.4 Test Mode Settings and Operating

Instructions)

37

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

Caution

The alarm check conducted with the Test switch will also activate the gas alarm contact. For

this reason, if alarm contacts are used for interlocking with external devices, be sure to check

that the interlock be released prior to conducting the alarm test. Also, be sure to carry out alarm

testing with the test switch after setting in maintenance mode. (Refer to 7.5 Maintenance Mode

Settings and Operating Instructions.)

Relevant personnel should also be notified of the inspection in advance.

38

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

Chapter 9 – replacing Consumables

• The Gas Detector is designed to allow users to replace consumables.

• Contact your local dealer to purchase consumables, or if further instruction is needed regarding their

installation and replacement.

9.1 Replacing the Filter Element (FE-1)

Use the following procedure to replace the filter element if it becomes dirty or clogged.

White arrow: Rotation Direction to loosen the fastening nut.

Return the filter unit gas intake to its original position and tighten the fastening nut to secure the gas

sampling pipe. DO NOT forget to place the O-Ring beneath the new filter.

Loosen the fastening nut of the filter unit

(MF-50) and remove the gas sampling

pipe.

Main body side of the filter unit

O-ring

Replace with a new filter element (FE-1)

Suction hole in the filter unit

Fastening Unit

Don’t forget the O-Ring!

Rotation direction to tighten the fastening nut

39

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

9.2 Attach/Replacing the Sensor Unit

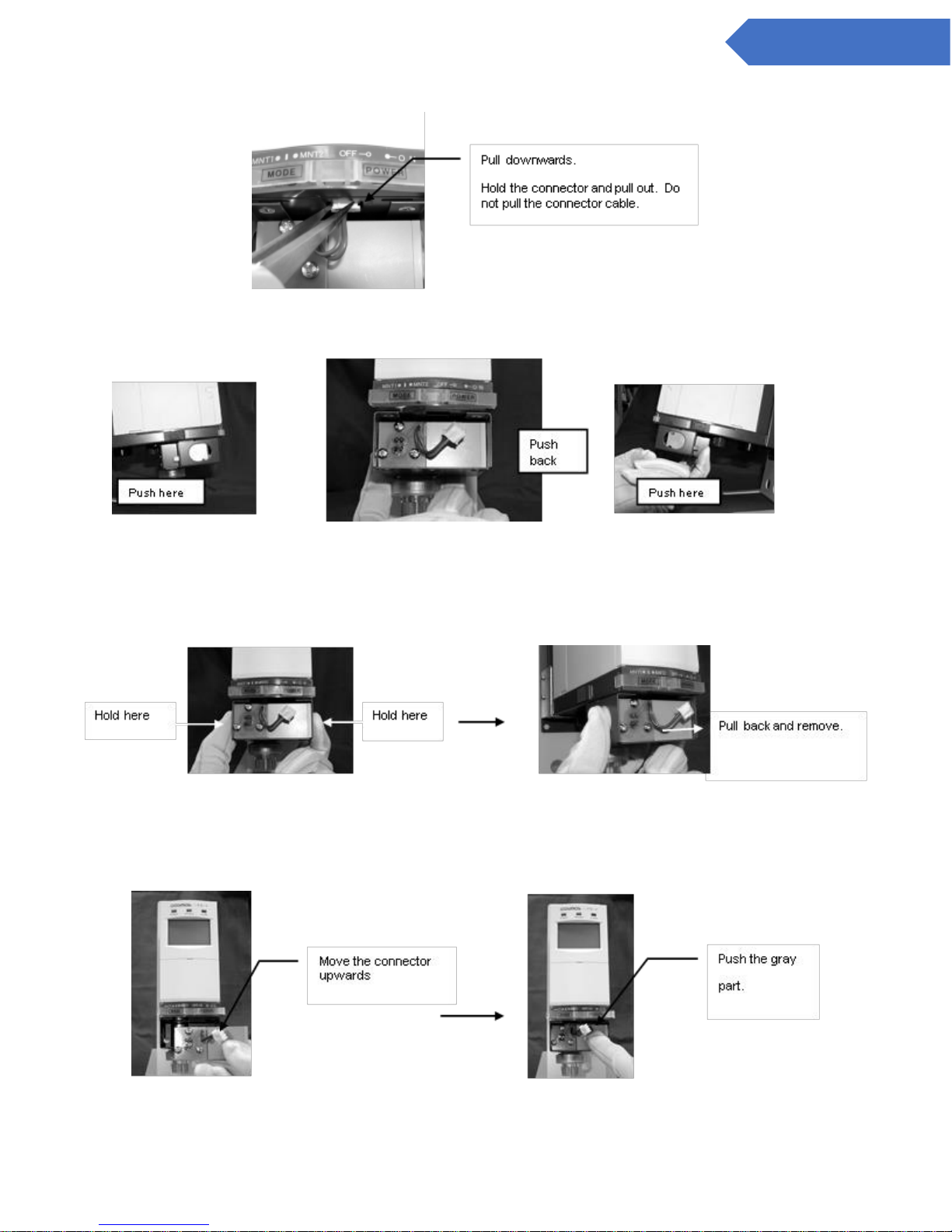

1. Turn off the power source to the main unit

2. Pull the two latches at the bottom of the base unit back, and (while they are still pulled back) release

the main unit, pulling from the top.

3. Press back while pushing on the middle of the upper section of the main body cover with your thumb

and remove the cover

Warning

Verify that the detected gas type and the full-scale value of the new sensor unit are the same

as the sensor unit being replaced. Be sure to check that its expiration date has not passed.

(There is no expiration date displayed for the Combustible Gas Sensor Unit CHS-7.)

Caution

• The sensor unit should be gas tested or replaced at 12-month intervals.

• Turn off the power source before carrying out any replacements.

However, when the power switch to the main unit is turned off to replace the sensor unit, the

trouble alarm output (open collector) is also turned off. If alarm contacts are used for

interlocking with external devices, verify that the interlock be released prior to conducting

the alarm test.

40

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

4. Insert a finger in the gap between the main body and the top of the sensor unit and pull back slightly.

Then grasp the sides of the sensor unit and pull out.

5. Insert the new sensor unit, then reattach the main body cover.

Push in as far as it will go with the palm of your hand

6. Pull back the latches on both the left and right sides of the bottom of the base unit and attach the

main unit.

The axis is here (fulcrum).

Remove by turning.

Warning

If the sensor unit is improperly attached, it will not be made airtight and will fail to detect gas

correctly. Be sure to attach it in as far as it will go.

Pull out grasping the sides

Insert a finger and pull slightly

41

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

7. Push both the latches on the left, and right-hand sides of the base unit back in until locked/unlocked

line can be seen.

After power is applied to the main unit, and the appropriate time has passed (depending on the type of sensor

unit). Refer to page 26, #11 for proper zero adjustment of the sensor.

NOTE: CDS sensors do contain electrolyte and proper disposal in accordance with local regulations is

required.

9.3 Replacing the Sampling Unit

Locked/unlocked line

Latch

Push both latches back in.

Warning

Be sure to return the latches right back in. If the latches are not behind the locked/unlocked

line, gas detection will not work properly.

Caution

Always turn OFF the power supply before attempting to replace the sampling unit.

However, if the power switch to the main unit is turned off to replace the sampling unit, the

trouble alarm output (open collector) will also turn off. If alarm contacts are used for

interlocking with external devices, verify that the interlock be released prior to replacing the

unit.

42

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

1. Remove the sensor unit as described in 9.2 Attach/Replacing the Sensor Unit.

2. Press back while pushing on the lower section of the main body cover with both thumbs and remove

the front panel.

3. Remove the two connectors on the back of the front panel

4. Connect the two front panel connectors to the new sampling unit and reattach the front panel. After

inserting the sensor unit, reattach the main body cover.

The axis is here (fulcrum)

Direction to push with thumb

The position to push from. Push the

lower section of the front panel with

both thumbs and remove.

The position to push from.

43

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

*Be careful not to pinch the cables.

The following is the same as the procedure from step 6 onward in 9.2 Replacing the Sensor Unit.

5. Pull back the latches on both the left and rights sides of the bottom of the base unit, and attach the

main unit inserting from the top side first.

6. Push both the latches on the left, and right-hand sides of the base unit back in until the

locked/unlocked line can be seen

NOTE: Please return used sampling units back to your authorized dealer.

Main body cover

The axis is here

(fulcrum)

The axis is here

(fulcrum).

Front panel

Warning

If used when not inserted properly, the sensor unit will not be airtight, and will therefore not

detect gases properly. Be sure to attach it on as far as it will go

Also, when connecting the sampling unit with the front panel, be careful that the connector

cables are not pinched by the case.

Also, when attaching the front panel onto the sampling unit, be careful that the connector

cables are not pinched by the case.

44

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

Chapter 10 – Troubleshooting

If a problem occurs, check the following before contacting a service or sales representative.

Problem

Cause

Remedy

Reference

The POWER lamp (green) does not

come on when the power is turned

on

The power switch on the base

unit is turned OFF.

Turn the power switch to the

base unit ON.

7.1 Operation procedures

The power switch on the main

unit is turned OFF.

Turn the power switch to the

main unit ON.

7.1 Operation procedures

Wiring is not properly

connected.

Check wiring and tighten

terminal connections.

6.2 Wiring Instructions

The connector harness is not

connected properly.

Check and reattach the

connector.

9.3 Replacing the Sampling Unit

The fuse has blown.

Replace the fuse.

5 Description

The TROUBLE lamp (yellow) is

blinking

The filter element is clogged.

Replace the filter element.

9.1 Replacing the Filter Element FE-1

Pump is defective.

Replace the pump unit.

9.3 Replacing the Sampling Unit

Gas sampling pipe is blocked.

Remove the blockage.

The connector harness is not

connected properly.

Check and reattach the

connector.

9.3 Replacing the Sampling Unit

A sensor with different setting

has been inserted.

Change the settings on the

main unit or change the

sensor.

7.1 Operation procedures

Defective sensor unit.

Replace the sensor unit.

9.2 Attach/Replacing the Sensor Unit

Sensor unit is not installed.

Install the sensor unit.

9.2 Attach/Replacing the Sensor Unit

The output of the flow sensor

was not stable when power

was turned on.

Turn the power on and leave

for about 30 minutes until it

stabilizes.

7.1 Operation procedures

The “__” indication and the detected

gas concentration value blink

alternately.

It is set to either maintenance

mode 1 or 2.

Set to normal mode (center).

7.5 Maintenance Mode Settings and

Operating Instructions

There is no electrical output from

the alarm contacts.

It is set to either maintenance

mode 1 or 2.

Set to normal mode (center).

7.5 Maintenance Mode Settings and

Operating Instructions

Wiring is not properly

connected.

Check wiring and tighten

terminal connections.

6.2 Wiring Instructions

The analog output won’t change

from 4mA.

The maintenance switch is set

to 2.

Set to normal mode (center).

7.5 Maintenance Mode Settings and

Operating Instructions

Contact your local dealer if none of the above procedures remedy the problem or if the problem is not listed.

45

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

Chapter 11 – Specifications

Model

PS-7

Principle

Electrochemical sensor, hot-wire semiconductor sensor, galvanic cell sensor

Sampling method

Pump suction type (0.5 L/min, suction flow automatically controlled)

Gas sampling pipe*1

Teflon OD6/ID4 mm, maximum tube length 20 m.

Concentration display

4-digit digital LCD display(incl. units)20-segment bar graph

Alarm settings

As per specifications

Alarm accuracy

• Combustible gas 25% of preset alarm point under identical conditions

• Toxic gas 30% of preset alarm point under identical conditions

• Oxygen deficiency 1 vol% under identical conditions

Response time

• Combustible gas Within 30 secs using test gas concentration 1.6 times that of preset alarm point

• Toxic gas Within 60 sec. using test gas concentration 1.6 times that of preset alarm point

• Oxygen deficiency Within 5 sec. to reach 18 vol% reading (at 20 2C) from an atmosphere

concentration of 10 vol%

(Gas sampling pipe length and communication times not included in any of the above.)

Alarm display

• Gas alarm (1st and 2nd stage)

ALARM lamp (red) blinking: LCD display ALARM1 or ALARM2 is displayed

• Trouble alarm

Decreased rate of flow

TROUBLE lamp (yellow): LCD display FLOW displayed: The flow rate rotation is stopped

Sensor trouble

TROUBLE lamp (yellow) blinking: LCD display SENS. is displayed

The sensor unit is inserted incorrectly

TROUBLE lamp (yellow): LCD screen SENS. is displayed

Pyrolyzer is disconnected

TROUBLE lamp (yellow) blinking: LCD screen CONV. is displayed

External output

• Analog output

4-20mA DC (common negative with power supply)

*Resistance for detecting current to be less than 300Ω including circuit resistance.

• Alarm contacts (1st and 2nd stages)

1a no-voltage contact/auto reset

*Rated load: 125 V AC or 30 V DC, 0.5-A resistance load

• Trouble alarm

Open collector/auto return/auto reset

(Normal close: Normally ON, during trouble OFF, and OFF during shut-off of power supply.

*Rated load: 30 V DC, 30mA resistance load

Activated by decline of flow rate, sensor error, when the sensor unit has been inserted incorrectly, pyrolyzer

is disconnected, power off, or blown fuse.

The analog output is smaller than 0.6 mA, and the gas alarm is not activated.

Applicable cable

Shielded control cable (8 to 11 mm dia.) x2

Cable length

Maximum length not exceeding 500 m

Operating Temp

0-40C (avoid radical temperature fluctuation), 30-85% RH (no dew condensation)

Power requirement

24 V DC 10%

Power consumption

Approximately7 W (Approximately 10 W with convertor attached)

Dimensions

W62 H124 D143 mm (projected portion excluded)

Weight

Approximately 1.0 kg

Installation

Wall mount type

46

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

*1 Teflon tubing is recommended. However, this may differ if the unit is to be used to detect highly adsorbent

gases. Contact your authorized dealer for information and assistance. For product improvement purposes,

the preceding specifications may be subject to change without notice. Any specifications issued separately

take precedence over those stated above.

Chapter 12 – Warranty

New Cosmos Electric Company Limited, warrants its gas detection products against any defects in materials

and workmanship under normal use and operating conditions, for a period of one year from the date of

purchase. (Except toxic and oxygen sensor unit)

All obligations and liabilities under this product warranty are limited to repairing or replacing at the

manufacturer’s option of the allegedly defective items returned to us, with carrier charges prepaid. All repairs

and replacements are made subject to our factory inspection of the returned items.

No liability is accepted for the consequential damages or reinstallation labor. Defects as defined in the above

shall not include decomposition by chemical reaction (including corrosion).

New Cosmos Electric Company Limited, shall not assume responsibility for contingent liability arising from

alleged failure of any of its products and accessories.

Chapter 13 – Detection Principles

13.1 Electrochemical Sensor

In an electrochemical method, electrolytic reactions are carried out selectively on target composite gases,

and the ensuing electrolytic current is measured by a gas sensor.

The gas sensor consists of three electrodes (active, reference, and counter electrodes), electrolyte, and a

potentiostat circuit. The electrode is a gas permeable membrane (to permeate gas and not electrolyte)

treated with a catalyst. When SiH4 contacts the active electrode, the following reaction occurs on the

electrode:

SiH4+4H2O→H4SiO4+8H++8e− (1)

while the following reaction occurs on the counter electrode:

2O2+8H++8e−→4H2O (2)

and current flows to the external circuit. To make the reaction selective and the generated current

porportional to the concentration of SiH4, the potential of the active electrode is detected by the reference

electrode and, during the electrolysis reaction, the active electrode is maintained at a constant potential by

the potentiostat circuit. (Refer to the following illusration.)

47

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

13.2 Hot-wire Semiconductor Sensor

In the hot-wire semiconductor method, a semiconductor sensor is designed to measure the change of

electrical conductivity initiated by adsorption of the electrons of combustible gases onto the surface of a

metal oxide semiconductor heated with a platinum filament. When the semiconductor adsorbs these

electrons, the electron concentration increases and the conductivity of the semiconductor rises. As a result,

the temperature of the semiconductor declines, and the resistance of the platinum filament decreases. This

change is measured as a deviation voltage with a Wheatsone bridge.

Figure 9

13.3 Galvanic Cell Sensor

The galvanic cell sensor consists of noble metal (Pt, Ag) electrode, a base metal (Pb) electrode, and

electrolyte. The noble metal electrode contacts the air through a Teflon membrane.

Since a potential difference is produced between the two electrodes, the following reaction occurs when a

load resistor is connected:

Noble metal electrode O2+2H2O+4e−→4OH−

48

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

Base metal electrode 2Pb→2Pb

2

+

+4e−

As a result, a current proportional to the concentration of oxygen in the air flows from the noble metal

electrode to the base metal electrode through an external circuit. Since the current generated is dependent on

temperature, a thermistor is used to compensate for the atmospheric temperature changes.

Figure 10

NOTE: The galvanic cell sensor gives an output according to the partial pressure of the oxygen in the air (the

oxygen concentration is usually 21vol%.) Therefore, when the atmospheric pressure changes, the partial

pressure of the oxygen will change, and when there is no change in the oxygen concentration (21vol%), this

may effect the output values from the sensor.

Chapter 14 – Glossary

Gas Detector

Detects the gas concentration level, and converts it into an electric signal.

Target Gases for

detection

The target gases for which the gas concentration level is detected, and indications

or warnings are given.

Detection range

The concentration range within which the level of target gases can be detected, and

indications or warnings given.

Alarm delay

The time between when a level of gas concentration higher (or lower) than the

preset alarm values come into contact with the gas detector, and when the alarm

goes off.

Explosion-proof

constructions

Construction to ensure that electrical components do not become an ignition source

and do not ignite surrounding flammable air.

Maintenance

inspection

Inspections conducted to ensure that the instrument is able to continue carrying out

the functions demanded of it.

Part of this terminology list is quoted from gas detection monitor terminology definitions from the Industrial

Gas Detectors Monitor Association.

49

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

Administrator Manual

• Operate this unit only after reading and fully understanding the content of this manual.

• This Operation Manual was written for administrator use. Instructions for the basic operations of this

unit are provided separately in the standard Operation Manual. Refer to the Operation Manual when

necessary.

50

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

Chapter 1 – Passwords

Some of the settings on this unit (alarm settings, etc.) are password protected.

This Operation Manual explains the following items:

• Passwords

• Changing settings

1.1 Password Protected Settings

Span Adjustment

Refer to 2.1 Span Adjustment

21vol% adjustment

Refer to 2.2 21Vol% Adjustment

The values of various settings

Refer to 2.3 Changing Setting Values

The values of alarm settings

Refer to 2.4 Changing the Alarm Settings

1.2 Releasing the Password Lock

Press these key switches in the following order.

1. ZERO switch

2. UP switch

3. Special command switch

4. DOWN switch

The password lock is released when the

POWER lamp (green) blinks once.

The password lock is automatically reactivated

10 minutes after it has been released.

Warning

Important tasks, such as changing alarm settings, span adjustment, etc., can be carried out

once the password lock is released. Take the utmost care regarding confidentiality of the

password.

51

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

Chapter 2 – Changing Settings

2.1 Span Adjustment

Toxic Gas Sensor Unit: CDS-7

Combustible Gas Sensor Unit: CHS-7

1. Set to maintenance mode

(MNT1 or MNT2)

Left: Maintenance 1 (MNT 1)

Center: Normal Mode

Right: Maintenance 2 (MNT 2)

2. Release the password Lock (Refer to 1.2 Releasing the Password Lock

3. Press the SPAN switch.

4. Let the calibration gas through

5. Use the UP/DOWN switch

to adjust the

concentration indication

on the screen to that of

the calibration gas

concentration

6. Once adjustments have been done, press the SPAN switch again. The SPAN indication in the

bottom right of the LCD screen will go off, and the span adjustment will be completed.

52

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

7. Remove the calibration gas, check that the detected gas concentration is under that of the alarm

value and restore to the normal mode (by switching the maintenance switch to the center).

2.2 21Vol% Adjustment

Oxygen Sensor Unit: COS-7

1. Set to maintenance mode (MNT1 or MNT2).

Left: Maintenance 1 (MNT 1)

Center: Normal Mode

Right: Maintenance 2 (MNT 2)

2. Release the password lock. (Refer to 1-2 Releasing the Password Lock)

3. Press the SPAN Switch

4. Let the calibration gas through

5. Use the UP/DOWN switch to adjust the concentration indication on the screen to that of the

calibration gas concentration.

6. When the adjustment is completed, press the SPAN switch again. The SPAN indication in the

bottom right corner of the LCD screen will then disappear, and the 21vol% adjustment is complete.

53

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

7. Remove the calibration gas and confirm that no alarm is displayed( ALARM 1 , ALARM 2 is not shown).

Then, restore to the normal mode by switching the maintenance switch to the center.

2.3 Changing Setting Values

Some of the setting values of the unit can be changed. Those that can be changed are listed in the table

below. The method for changing them is explained here.

1. Release the password lock. (Refer to 1.2 Releasing the Password Lock.)

2. Press the UP/DOWN switch (“” or “”)

until the setting you wish to change ( “LCD

Screen Indication” in the table below ) is

displayed at the bottom right of the LCD

displays.

3. Then press the special command switch, and

the setting to be changed ( “LCD Screen

Indication” in the table below ) and “—“ will

flash alternately.

4. Change the value by using the UP/DOWN switches (“” or “”). When you are done, press the

special command switch again, and the alternating display in the bottom right corner of the LCD

display will become constant. The process is now finished.

54

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

LCD Screen

Indication

The function

to be set

Remarks

Default value

Adjustable

Range

Toxic: CDS-7

Combustible:

CHS-7

Oxygen:

COS-7

Each time the UP switch is pressed, it will move down the table to the next item.

When the DOWN

switch is pressed, it will move up one.

d1 **

Time delay 1

Time delay (secs.) of the gas

alarm contact (1st level)

d1 0

d1 0

0 to 99 sec

d2 **

Time delay 2

Time delay (secs.) of the gas

alarm contact (2nd level)

d2 0

d2 0

0 to 99 sec

az

Analog

output (base)

(*For our maintenance

purposes only)

as

Analog

output (span)

(*For our maintenance

purposes only)

zs *

Zero

suppression,

or 21vol%

suppression

Displays the percentage of the

full-scale value (rounded to the

percent)

zs 5

zs 2

0 to 30%

H-H

L-L

H-L

Alarm mode

1st: upper limit, 2nd : upper

limit warning

1st : lower limit, 2nd : lower

limit warning

1st : upper limit, 2nd: lower

limit warning

H-H

L-L

H-H

L-L

H-L

Con *

Pyroletic

converter

failure alarm

0: Off 1: On

Con 0

Con 0

0 or 1

CG **

Calibration

gas

concentration

(*For our maintenance

purposes only)

CG 40

CG 84

nEt *

The existence

of a

DeviceNet

unit

0: Non-existent 1: Existent

nEt 0

nEt 0

0 or 1

F ***

Display of f

value

Calibration gas type in lower

right of LCD

f value in center of LCD

(Depending on the sensor unit)

FL ***

Displays rate

of flow

Shows the current rate of flow

(mL/min)

(Depending on the rate of flow)

P ***

Sensor unit

output

(*For our maintenance

purposes)

--

At *

Auto 21vol%

adjustment

0: Off 1: On

--

A t 1

0 or 1

Type of sensor unit (Normal

display)

(Depending on the sensor unit)

55

DC-ITD-PS7MAN01.A www.dodtec.com

JAN 2019 815-788-5200

PS-7 Manual

2.4 Changing the Alarm Settings

The values of alarm settings on this unit can be changed. The method for changing them is explained here.

1. Release the password lock. (Refer to 1.2 Releasing the Password Lock.)

2. Press the AL switch until the alarm setting

to be changed is displayed on the LCD

display. (The bottom right of the screen, as in

the table below.) The alarm setting for the

actual gas concentration is displayed in the

middle of the screen, and the percentage of

the full-scale value is displayed in the

bottom right corner

LCD Display

Indication

(Lower right)

Default value

Explanation of the

default value

Adjustable Range

A1 **

Toxic : CDS-7

Comb. : CHS-7

A1 10

10% F.S.

0 to 100% F.S.

Oxygen: COS-7

A2 72

72% F.S.

A2 **