Page 1

62417003 - R00 07-12-2007_GB-IE

MODELS:

NOV ADENS 24 - 24B

NOV ADENS 24C - 24P

NOV ADENS 34 - 34B

NOV ADENS 34C - 34P

NOV ADENS 45A - 45C

USERS’ MANUAL FOR GAS BOILERS

PLEASE READ THE MANUAL CAREFULLY: IT CONTAINS IMPORTANT INFORMATION

REGARDING SAFETY, INSTALLATION, USE AND MAINTENANCE OF THE APPLIANCE

Page 2

2

T able of contents

1 - GENERAL SAFETY WARNINGS........................................................................... 3

2 - GENERAL INFORMATION ..................................................................................... 4

2.1 - Introduction ............................................................................................................................... 4

2.2 - Description of models ............................................................................................................... 4

2.3 - Manufacturer ............................................................................................................................. 4

2.4 - Key to symbols used ................................................................................................................. 4

2.5 - Warranty ................................................................................................................................... 4

3 - USE.......................................................................................................................... 5

3.1 - Check that the cocks are open .................................................................................................. 5

3.2 - Check heating system pressure ................................................................................................ 5

3.3 - Overview...................................................................................................................................5

3.4 - Displays.................................................................................................................................... 6

3.5 - St art-up procedure .................................................................................................................... 6

3.6 - “Users’ menu”............................................................................................................................ 6

3.7 - Summer mode .......................................................................................................................... 7

3.8 - Winter mode .............................................................................................................................7

3.9 - Adjusting the heating temperature .............................................................................................7

3.10 - Adjusting the heating temperature with climatic adjustment......................................................7

3.1 1 - Domestic hot water temperature adjustment ............................................................................ 8

3.12 - Room temperature adjustment ................................................................................................ 8

3.13 - Errors and alarms ................................................................................................................... 8

3.14 - Pressure gauge ......................................................................................................................8

3.15 - Shutdown procedure ............................................................................................................... 9

3.16 - Precautions against freezing ................................................................................................... 9

3.17 - Flue gas discharge ................................................................................................................. 9

3.18 - Operating anomalies............................................................................................................... 9

3.19 - Remote control (on request) .................................................................................................. 10

4 - Warranty................................................................................................................. 11

4.1 - General warranty conditions ....................................................................................................11

4.2 - Instructions for filling in the warranty card ................................................................................. 11

4.3 - Warranty limits......................................................................................................................... 11

Page 3

3

If you smell gas

l Close the gas cock.

l Ventilate the room.

l Do not use any electrical appliances, telephone

included.

l Immediately call a qualified technician or the gas

board from another room or building. If you cannot

contact them, call the Fire Brigade.

If you smell product of the combustion

l Switch off the appliance.

l Ventilate the room.

l Call a qualified technician.

In the presence of water leaks

l Switch off the appliance.

l Close the central water mains cock.

l Call a qualified technician.

Explosive or easily inflammable products

Do not store or use explosive or easily inflammable

materials such as paper, solvents, paints, etc..., in

the same room as the boiler.

In the event of a breakdown

In the event of breakdown and/or malfunctioning of the

appliance, disconnect it, do not attempt to repair it or

intervene in any way whatsoever. Cont act a qualified

technician.

Qualified technicians

Qualified technicians are personnel with specific,

technical training in the heating system component

sector and with regards to domestic hot water

production for public use, fuel gas systems and

electrical systems. These individuals must have the

legally required qualifications.

1 - GENERAL SAFETY WARNINGS

FThis booklet forms an integral and essential

part of the product and must be carefully kept

by the user, for any future consult ation. Ensure

that this booklet is handed over to the new

owners and/or installer if the appliance should

change hands or be moved for any reason

whatsoever.

FThe installation, setting and modification of

the gas appliance must be carried out by

qualified technicians, in compliance with local

and national norms and the instructions in the

installation and maintenance manual.

FFlue pipes must not be modified in any way.

FThe user, in accordance with these instructions,

must keep the appliance in satisfactory running

order and ensure reliable, safe operating.

F The user is responsible for employing a

qualified technician to carry out maintenance

work on the appliance in compliance with local

and national norms and the matters stated in

the installation and maintenance manual. We

highly recommend arranging a regular

maintenance contract with a qualified

technician.

FThe manufacturer cannot be held responsible

for any damage to people, animals or property

caused by inadequate maintenance.

FDo not obstruct the ends of the venting pipes .

FThe technician will explain the functioning,

use of the appliance and use of the system to

the user.

FThe user must be familiar with filling and

discharge procedures for the boiler, and the

control and eventual adjustment of water

pressure in the heating circuit.

FThe user must be familiar with the

procedures for fully optimizing the

conservation of energy and avoiding waste

of the entire heating system.

FRegularly check the system pressure using

the pressure gauge “13” (see figure 1) to

ensure a reading between 1 and 1.5 bar.

FWait a few minutes after opening the gas

supply cock before starting the boiler up.

FDo not leave the boiler switched on

unnecessarily if it is not going to be used for

long periods; in such situations, close the gas

cock and disconnect from the electricity

mains supply . Consult section 3.16 if there is

a risk of freezing.

FDo not touch the flue gas discharge pipe,

during and for some time after operations, as

it is very hot.

Page 4

4

2 - GENERAL INFORMATION

2.1 - Introduction

Congratulations!

Y ou have ef fectively purchased one

of the best products on the market.

Each single part is built, tested and

assembled, with pride, at the

COSMOGAS factories, thereby

guaranteeing optimum quality

control.

Thanks to on-going research

carried out by COSMOGAS, this

product has been conceived and is

considered to be the best in its

class with regards to respect for

the environment, since it falls within

class 5 (less polluting) envisaged

by technical norm EN 297 (and EN

483) and has an elevated efficiency ,

4 stars as per EC Directive 92/42/

EEC. Great importance is also

given to the end of the appliance’s

useful life. All its components can

easily be separated into similar and

completely recyclable parts.

2.3 - Manufacturer

COSMOGAS srl

Via L. da Vinci 16

47014 - Meldola (FC) IT AL Y

T el. +39 0543 498383

Fax. +39 0543 498393

www.cosmogas.com

info@cosmogas.com

2.4 - Key to symbols

used

General danger!

Failure to observe this warning may

compromise the smooth running of the

appliance or cause serious damage to

individuals, animals or property .

l Operation symbol

F Important indication symbol

2.5 - W arranty

See section 4

NOVADENS XXYYYY

“ “ =

Boiler with exchanger sanitary to partial accumulation;

“A” = Boiler for only heating without integrated pump;

“B” = Boiler which can be combined with BWR C series storage tank;

“C” = Boiler for only heating with integrated pump;

“P” = Boiler with exchanger secondary for D.H.W., to plates;

“0834” = Boiler for low temperature central heating systems.

24 = Boiler with maximum input heat of 25 kW

34 = Boiler with maximum input heat of 34.8 kW

Gas-fired, condensing, hot water boiler, with sealed combustion chamber

and pre-mix burner, for heating and domestic hot water production.

2.2 - Description of

models

Page 5

5

3 - USE

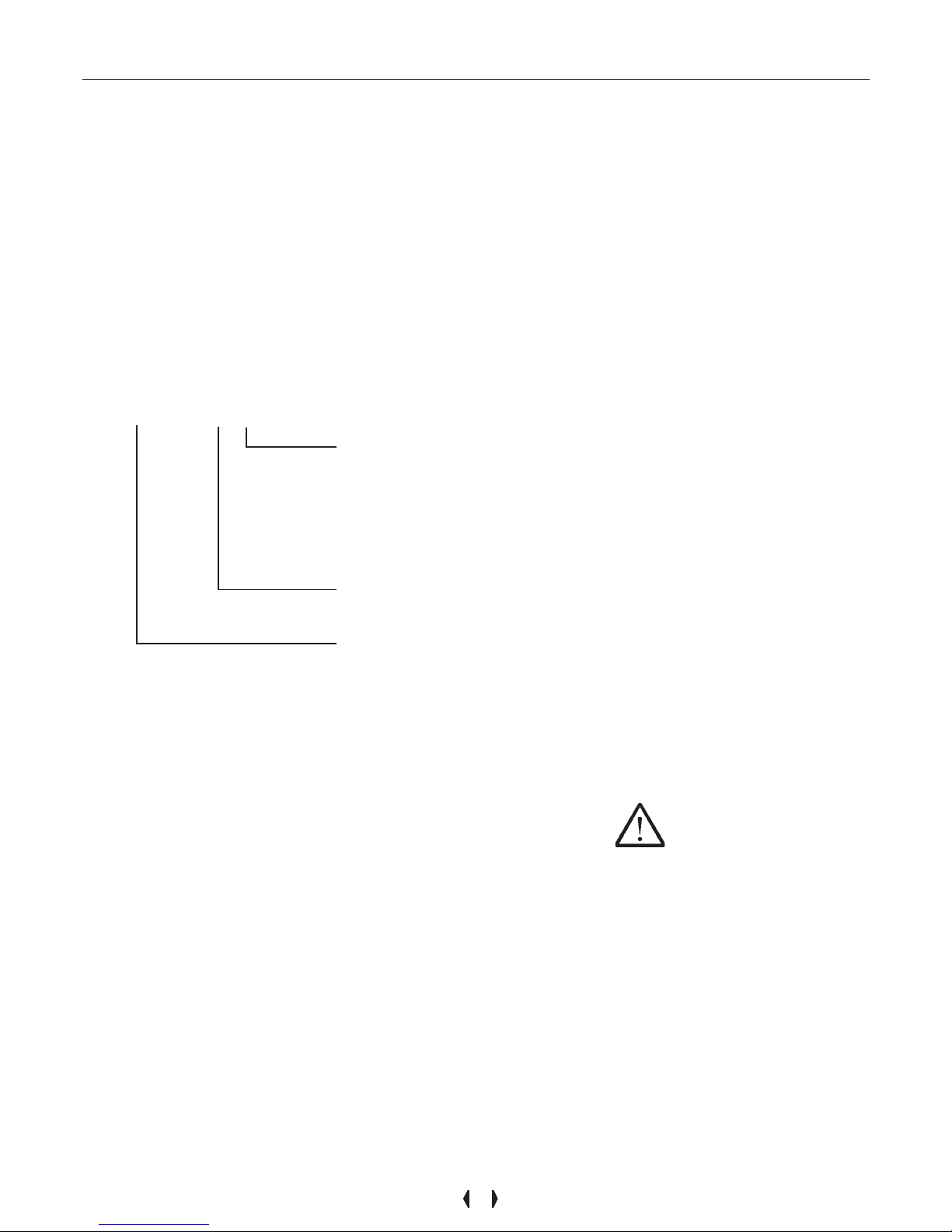

Figure 1 - Instrument panel

3.1 - Check that the

cocks are open

- The gas cock must be open;

- any supply and return valves must be

open;

- any hot and cold water valves must be

open.

3.2 - Check heating

system pressure

If the pressure inside the heating circuit

falls below 0.5 bar, the appliance

switches off and the display 1 as per

figure 1, shows to indicate

that it is necessary to restore the correct

pressure. Proceed as follows:

l open the filling cock (see figure 5)

turning it in a counter-clockwise

direction;

l check the pressure on the pressure

gauge “13” of figure 1, it must reach a

pressure of 1.5 bar and the indication

must disappear;

l close the filling cock (see figure 5)

turning it in a clockwise direction.

CAUTION!!! During normal

operations, the filling cock (see

figure 5) must always remain in the

closed position.

If, with time, the pressure drops, restore

the correct value. This operation may

have to be repeated several times

during the first month of operations to

remove any gas bubbles present.

3.3 - Overview

The boiler is pre-set with standard

parameters. However , it is possible to

make a number of changes or consult

the parameters by means of using the

“Users’ Menu” (see section 3.6).

During functioning display “1” of figure 1

displays the status of the boiler and

display “2” (see figure 1) shows the

value of the parameter. The various

operating statuses are shown in the

table in figure 2.

Within the “Users’ Menu” (see section

3.6) it is possible to check the last

lock-outs or errors which have occurred.

In addition to the operating modes, the

instrument panel provides important

information on the current functioning of

the boiler, via the indicators “3”, “4”, “5”

and “6” of figure 1. In particular:

- the indicator “3” displays whether the

burner is functioning (on) or whether it is

off (blinking);

- the indicator “4” displays whether the

domestic hot water service is on or off;

- the indicator “6” displays whether a

heating service request is active (on) or

nor (off).

1 - Parameter display .

2 - Display of values adopted by parameters.

3 - Burner status indicator . On = burner on, flashing = burner off.

4 - Domestic hot water service status indicator. On = d.h.w. on, Off = d.h.w. off.

5 - Indicator of decimal of value displayed.

6 - Heating service status indicator. On = heating on, Of f = heating off.

7 - Heating temperature and start control.

8 - Key for decreasing parameter values.

9 - Key for resetting shutdowns and for scrolling the list of parameters.

10 - Key for increasing parameter values.

1 1 - Domestic hot water temperature and start control.

12 - On/off power switch.

13 - Heating circuit pressure gauge.

Page 6

6

3 - USE

Figura 2 - Parameters displayed during functioning

P ARAMETER DESCRIPTION ON DISPLA Y “2” (figure 1)

Boiler on stand-by or on hold (no heating or hot water request

exists)

Anti-freeze function active

Caution!!! Domestic hot water active for more than 120 minutes

(turn domestic hot water to OFF position in order to reinstate

heating). Check that there are no leaking taps. If the problem

persists, contact a professionally qualified technician

Caution!!! System pressure too low, fill system follow section

3.2.

Domestic hot water service on

Heating service on

Boiler in lock-out mode. To reset it, press the

button. If

the lock-out occurs frequently, cont act a professionally qualified

technician.

Boiler fault. Contact a professionally qualified technician

Auto-purging procedure in progress . It will end within 2 minutes

Boiler temperature (°C)

Boiler temperature (°C)

Boiler temperature (°C)

No display

Domestic hot water temperature (°C)

Heating temperature (°C)

Lock-out code (see installation and

maintenance manual)

Error code (see installation and maintenance

manual)

Boiler temperature (°C)

POSSIBLE DISPLAYS

3.4 - Displays

During normal operations, the parameters’ display “1” and the values’

display “2” (see figure 1) remain permanently on (if the ”Energy Saving” mode

has not be activated).

The parameters which can be displayed

are shown with their meaning in the

table shown in figure 2.

3.5 - Start-up

procedure

l Open the gas cock;

l switch on electric power to the boiler;

l If the display shows code 21, it

means that the polarity has not been

observed between phase and neutral;

l on initial start-up, the appliance carries

out an auto-purging cycle lasting two

minutes. This is indicated by the

appearance of on the display;

l wait two minutes until the end of the

auto-purging cycle;

l turn knob “7” of figure 1 until it reaches

the heating temperature desired. Turn

knob “1 1” of figure 1 until it reaches the

domestic water temperature desired.

The flame control appliance will start-up

the burner.

If the burner fails to ignite within 5

seconds, the boiler will automatically

attempt ignition another three times, after

which if it fails to start-up, it will shut down

and the display will show 01.

Press the button in order to re-set

normal operating conditions. The boiler will

automatically attempt another start-up.

CAUTION!!! If the appliance

frequently shuts down, contact a

qualified technician to restore normal

running conditions.

Now the boiler will continue to operate in

relation to the service requested and will

indicate the following on display “1”:

if a domestic water request is active;

if a heating request is active;

if there is no domestic water or heating

request active.

3.6 - “Users’ menu”

Entry into the “Users’ Menu” is shown

by display “1” blinking. In order to access

the “Users’ menu” just:

l press the button for 2 seconds

until the display starts to blink;

l press and release the button

several times until the parameter

desired is displayed;

l by means of the or keys,

it is possible to change the value of

the parameter;

l press in order to confirm the

amended data and pass onto the next

parameter;

l Once you have reached the end of the

menu, on the last , the display

“1” stops blinking indicating exit from

the “Users’ menu”.

If no key is pressed for more than 60

seconds, one automatically exists the

menu. Any change in the p arameters not

confirmed using the button, will

be lost.

In this menu it is possible to consult and/

or change the parameters indicated in

figure 3.

Page 7

7

3 - USE

Figure 3 - Parameters within the “Users’ Menu”

“USERS’ MENU”

Adjustment of the gradient of the line as per figure 4. Visible only with climatic adjustment active.

(See installation and instruction manual).

Adjustment of “Minimum heating temperature”.

Visible only with climatic adjustment active. (See

installation and instruction manual).

Adjustment of “Maximum heating temperature”.

Visible only with climatic adjustment active. (See

installation and instruction manual).

Adjustment of the parallelism “b” of the line as per

figure 4. Visible only with climatic adjustment

active. (See installation and instruction manual).

Display of calculated heating temperature (if

climatic adjustment active) or display of temperature set via the control “7” as per figure 1.

Display of domestic hot water temperature set via

the control “11” as per figure 1.

Display of last error registered.

Display of last block which occurred.

Setting range: 0.1-5.0

Setting range: 20°C-60°C for radiant panels, 30°C - 60°C

for radiators.

Setting range: 45°C for radiant panels, 80°C for radiators.

Only display . The regulation is carried out using the control

“7” as per figure 1. It can adopt values ranging between 10°C and +10°C

Only display. It can adopt values ranging between 20°C

and 80°C

Only display. It can adopt values ranging between 40°C

and 70°C

Only display. It can adopt the values indicated in the

installation and maintenance manual

Only display. It can adopt the values indicated in the

installation and maintenance manual

PARAMETER DESCRIPTION INFORMATION ON DISPLAY “2”

3.7 - Summer mode

To disable the heating functions for a

prolonged period, leaving only the

domestic hot water function, switch the

heating temperature to minimum, until the

wording OFF appears, by turning knob “7”

of figure 1.

3.8 - Winter mode

In Winter mode, by means of the pump ,

the boiler sends the water to the system

at the temperature set using knob “7” of

figure 1.

When the temperature inside the boiler

reaches the temperature set, the burner

starts to modulate the flame so as to

reduce the output to a minimum. If the

temperature rises further, the burner shut s

down.

Simultaneously, the pump which sends

the water to the system is switched on

and off by the room thermostat. This can

be noted, because indicator “6” of figure

1 switches on and off in correspondence

with the on and off of the pump.

At first the pump may make a noise. This

is due to the presence of residual air in

the hydraulic system which will soon

disappear on its own.

We recommend keeping the temperature

set using knob “7” at the point shown by

the symbols on the panel for a rational

use of the boiler. If it is a p articularly cold

Winter and it is difficult to maintain the

desired temperature, turn knob “7” to

gradually higher values.

3.9 - Adjusting the

heating temperature

To set the heating temperature, turn

control knob “7” of figure 1. As soon as

the knob is touched, will blink on

display and the temperature being set will

appear on display “2”. As a rule, it is

sufficient to turn control knob “7” to the

half-way position. If it is a particularly cold

Winter, progressively increase the

temperature by rotating control “/”.

3.10 - Adjusting the

heating temperature

with climatic

adjustment

The adjustment of the heating

temperature, in the event that climatic

adjustment has been set, is carried out

by turning control “7” as per figure 1. As

soon as the control is touched, display

“1” show a flashing and display “2”

shows the value in °C of translation on a

parallel with the adjustment curve (see

figure 4, detail “b”. As a rule, it is sufficient

to adjust control “7” to the half-way

position. If the Winter is particularly rigid,

progressively increase the temperature

using control “7” until the temperature

inside the rooms is satisfactory. If the

comfort produced by the climatic

adjustment is not satisfactory (too hot,

too cold, room temperature not constant)

Page 8

8

3 - USE

Outside temperature (°C)

Supply temperature (°C)

Figure 4 - Graphs of the climatic adjustment for high temperature

systems

Outside temperature (°C)

Supply temperature (°C)

OA = Inclination of the line

Ob = Minimum heating

temperature

Oc = Maximum heating

temperature

br = “Fix point” of the angle

fulcrum of the line

b = parallel shift of the line

(possible using control “7” of

figure 1)

just enter the users’ menu and adjust the

parameters corresponding to figure 4. It

is necessary to consider that the thermal

inertia of a dwelling is extremely high,

therefore each time you make a change,

wait at least 24 hours to see the result.

3.11 - Domestic hot

water temperature

adjustment

To adjust the domestic hot water, turn

control knob “1 1” of figure 1. As soon as

the knob is touched, will blink on

display “1” and the temperature being set

will appear on display “2”. It is advisable

to set this value at 50°C-55°C; if a storage

tank is present, the temperature can arrive

at 60°C-65°C.

3.12 - Room

temperature

adjustment

It is necessary to install a timeprogrammable thermostat for an optimum

setting of the room temperature and thus

satisfactory energy saving; this is a

device capable of switching on and off and/

or raising and lowering the room

temperature, in relation to certain set

times. Contact a qualified technician for

the installation of this device.

This boiler is suitable for being connected

to devices of this type.

3.13 - Errors and

alarms

The boiler control device carries out

numerous checks.

When it detects a malfunction, it shuts

down the appliance and displays the

reason for the shut down on the display .

The boiler may stop as a result of two

different series of shutdowns:

and followed by the number

identifying the shutdown.

The shutdowns identified by can be

re-set by pressing . If the boiler fails

to re-start, or if it shuts down frequently,

contact a qualified technician.

The shutdowns identified by cannot

be re-set unless the cause of the problem

is eliminated. In such cases, it is

necessary to contact a qualified

technician.

The alarms shown on the display by

means of

, do not block the boiler, but

alert the user to the fact that a system

anomaly is underway . E.g. domestic hot

water cock leak.

In this event, if you wish to reinstate the

heating function, you must turn control

knob “11” to zero and eliminate the water

leak.

3.14 - Pressure

gauge

The pressure gauge (detail “13” of figure

1) is a device which indicates the pressure

of the water within the heating circuit.

Page 9

9

3 - USE

3.15 - Shutdown

procedure

If the boiler is to be shutdown for a

relatively short time and there is no risk

of freezing, simply disconnect from the

mains the switch “12” of figure 1.

If there is a risk of freezing during your

absence, leave the boiler connected to

the mains and the gas open and carry

out the procedure for the shutdown of the

services, turning both knobs “7” and “11”

of figure 1 to OFF .

Now the two services of the boiler are

switched off. On reaching a boiler

temperature of 7°C, the heating pump

automatically switches on. If the

temperature falls further to under 2°C, the

burner will also switch on, so as to protect

the system and the boiler itself from the

effects of freezing weather conditions.

If the boiler is not used for a long period of

time, we suggest emptying it. Contact a

professionally qualified technician.

3.16 - Precautions

against freezing

If you leave the dwelling, disconnect the

gas and electricity supply, since the

appliance is not protected against

freezing. If it is switched off and runs the

risk of being exposed to temperatures

below zero, it is necessary to empty the

appliance. Contact a professionally

qualified technician.

CAUTION!!! It is absolutely

forbidden to introduce chemical

additives, such as anti-freeze or

others, into the domestic water

circuit.

3.17 - Flue gas

discharge

Due to its high efficiency and low pollution

levels, this boiler is considered to be

ecological. Therefore, white smoke may

be discharged from the discharge pipe,

under specific atmospheric and operating

conditions. There is no cause for alarm

as it is only steam which condenses on

contact with the outside cold air .

3.18 - Operating

anomalies

If the boiler fails to start, check that:

FThe gas supply is open;

Fthe boiler power supply switch is on;

Fthe heating temperature control knob

“7” is in the position suggested by the

symbols;

Fthe boiler is not in lock-out mode.

Press the button to re-start it;

Fthe room thermostat is set to a higher

temperature than that of the room where

it is installed and that it is programmed

to call for heating at that time;

If during winter operations, there is

hot water but no heating, check that:

FThe room thermostat is set to a higher

temperature than that of the room where

it is installed and that it is programmed

to call for heating at that time;

Fany valves installed on the supply and

return connections are open;

Fopen the radiator cocks to purge air;

CAUTION!!!

If after these checks, the system is

still cold, do not attempt any repairs

yourself but contact a qualified

technician.

Figure 5 - Filling cock

OPEN CLOSE

Page 10

10

3 - USE

A - Heating adjustment knob

B - RESET key

C - Domestic hot water adjustment knob

D - Green light (for indications, see section 3.19)

E - Red light (for indications, see section 3.19)

Figure 6 - Remote control

3.19 - Remote control

(on request)

If the boiler is connected to the remote

control, the heating temperature adjustment and domestic hot water temperature adjustment functions are performed

directly on the remote control as

indicated below:

- the adjustment of the heating is carried

out directly using knob “A” as per figure

6;

- the adjustment of the domestic hot water

is carried out directly using knob “C” as

per figure 6.

Furthermore, it is possible to reset any

alarms by pressing the RESET key (see

figure, 6 detail “B”).

Two indication lights are present on the

remote control, and have the following

meaning:

- green light on: heating service on and

correct communication between boiler

and remote control;

- green light blinking every 7 seconds:

correct communication between boiler

and remote control;

- red light on: boiler in lock-out status. It

is possible to re-activate it by pressing

the RESET key (see figure 6, detail “B”).

If the lock-out occurs frequently,

contact a professionally qualified

technician;

- red light blinking: boiler in lock-out for

more than 5 minutes. It is possible to

re-activate it by pressing the RESET

key (see figure 6, detail “B”). If the lockout occurs frequently, contact a

professionally qualified technician;

- green light and red light blinking: heating

pressure anomaly (see section 3.2).

In order to check the type of lock-out

corresponding to the light illuminated,

check the error type on the boiler and refer

to the sections “LOCK-OUTS” and

“ERRORS” in the installation manual.

Page 11

11

4.1 - General

warranty conditions

COSMOGAS guarantees that all its

products are free from manufacturing

and material defects for 24 months from

the testing and inspection date of the

first start-up. Within the aforementioned period, COSMOGAS will

repair or replace any manufactured

parts found to be defective, excluding

any defects caused by normal wear and

tear during operations. Any transport

and handling costs for replaced parts

are at the customer’s expense. The

warranty does not cover compensation

for any type of damage which may

occur to people or property . The faulty

materials replaced under warranty are

the property of COSMOGAS and must

be returned free of charge to our factory ,

within 30 days of their replacement,

otherwise COSMOGAS will issue an

invoice covering the cost of the replaced

material.

All COSMOGAS products are subject

to reserved ownership agreement until

the purchased appliance has been fully

paid for .

4.2 - Instructions for

filling in the warranty

card

l The installer must stamp the

warranty certificate.

l Always request the intervention of

one of our authorized technicians for

the initial start-up and testing of the

appliance; a list is enclosed with the

instruction manual or can be found in

the Y ellow Pages under "Gas

boilers".

l The technician will collect the

warranty certificate and forward it to

COSMOGAS.

4.3 - W arranty limits

The warranty is invalid:

- if the appliance is

not installed by

qualified technicians;

- if the appliance is not installed in

compliance with COSMOGAS

instructions and/or those established by

national and/or local standards in force;

- the running and/or maintenance of the

system is not carried out in compliance

with these instructions and/or national

and/or local standards in force;

- damage to the product has been

caused by voltage fluctuations;

- damage to the product has been

caused by the use of too hard, too acid

or over oxygenated water;

- damage to the product has been

caused by thermal shock, defective

chimneys and/or flue gas discharge and

air intake piping;

- the product has anomalies not

dependent on COSMOGAS;

- the boiler has been tampered with due

to adaptation work, repair work and

replacement work using non-original

parts;

- the repair work has been carried out

by unauthorized personnel;

- the warranty certificate is not

forwarded to COSMOGAS within 15

days of the date of initial start-up.

COSMOGAS cannot be held

responsible for any accident, including

those caused by the user, any

compensation which does not concern

boiler parts with recognized

manufacturing defects being excluded.

Court of competent jurisdiction: Forlì,

IT ALY.

4 - W arranty

Page 12

The appliance has been installed by qualified

technicians in possession of the legally required

qualifications, in compliance with the

instructions contained in this manual, on the

installation and maintenance manual and follow

national and/or local standards in force.

Date______________________________

INSTALLER (Stamp)

The appliance has been tested and inspected

for initial start-up purposes by qualified

technicians in possession of the legally required

qualifications, in compliance with the

instructions contained in this manual, on the

installation and maintenance manual and follow

national and/or local standards in force, with the

following results:

POSITIVE q NEGATIVE q

SERVICE CENTRE (Stamp)

Comments________________________________________________________________________

___________________________________________________________________________________

Service Centre signature

_________________________

User signature

_________________________

W ARRANTY CERTIFICATE

FOR “COSMOGAS” APPLIANCES

Warranty valid 24 months

Date______________________________

Comments________________________________________________________________________

___________________________________________________________________________________

TO BE COMPLETED BY THE INSTALLER

TO BE COMPLETED BY THE SERVICE CENTRE

Signature ________________

Page 13

Page 14

Page 15

Page 16

COSMOGAS s.r .l.

Via L. da Vinci 16 - 47014

MELDOLA (FC) ITAL Y

info@cosmogas.com

www .cosmogas.com

Loading...

Loading...