COSMOGAS NOVADENS 24, NOVADENS 24B, NOVADENS 24C, NOVADENS 24P, NOVADENS 34 Instruction Manual

...Page 1

INSTRUCTION MANUAL FOR INSTALLATION

AND MAINTENANCE OF GAS BOILERS

PLEASE READ THE MANUAL CAREFULLY: IT CONTAINS IMPORTANT INFORMATION

REGARDING SAFETY, INSTALLATION, USE AND MAINTENANCE OF THE APPLIANCE

62403425 - R00 07-12-2007_GB-IE

MODELES:

NOVADENS 24 - 24B

NOVADENS 24C - 24P

NOVADENS 34 - 34B

NOVADENS 34C - 34P

Page 2

2

Table of contents

1 - General safety warnings............................................................................................4

1.1 - National installation legislation ..................................................................................................4

2 - GENERAL INFORMATION .......................................................................................5

2.1 - Introduction ............................................................................................................................... 5

2.2 - Description of models ............................................................................................................... 5

2.3 - Manufacturer ............................................................................................................................5

2.4 - Key to symbols used .................................................................................................................5

3 - MAIN COMPONENTS ...............................................................................................6

4 - Functions of the appliance ........................................................................................ 8

4.1 - Intended use and functions of the appliance .........................................................................10

4.2 - Characteristic curves of heating system’s residual head ........................................................ 11

4.3 - Characteristic curve of the domestic side ............................................................................... 11

5 - INSTALLATION ....................................................................................................... 12

5.1 - Opening the packaging ........................................................................................................... 12

5.2 - Dimensions and clearances for installation ............................................................................. 12

5.3 - Choosing the point of installation ............................................................................................ 12

5.4 - Supply and return .................................................................................................................... 13

5.5 - Radiant panel systems (or low temperature systems) ............................................................ 13

5.6 - Domestic hot and cold water ................................................................................................... 13

5.7 - Gas supply .............................................................................................................................. 13

5.8 - Assembling the appliance ....................................................................................................... 14

5.9 - Gas and water connections .................................................................................................... 14

5.10 - Condensation discharge ....................................................................................................... 15

5.11 - Safety relief valve .................................................................................................................. 15

5.12 - Hydraulic connections for boiler with BWR storage tank ...................................................... 16

5.13 - Softener (on request) ............................................................................................................ 16

5.14 - Electrical connections: overview ........................................................................................... 17

5.14.1 - Connecting the power supply cable ........................................................................................17

5.14.2 - Choosing the room thermostat/time-programmable thermostat ..............................................18

5.14.3 - Connecting the room thermostat/time-programmable thermostat ...........................................18

5.14.4 - Installing the outside temperature sensor (on request) ...........................................................18

5.14.5 - CR04 remote time control (optional) .......................................................................................19

5.14.6 - Installation of the CR04 remote time control on the boiler ......................................................19

5.15 - Connecting the boiler to the B70C type water heater (optional) ........................................... 20

5.15.1 - Prevention against Legionnaires disease ...............................................................................20

5.16 - Connecting the boiler to the BWR C type storage tank ....................................................... 21

5.16.1 - Prevention against Legionnaires disease ...............................................................................21

5.17 - Venting systems .................................................................................................................... 22

5.17.1 - “Split 80/80PP” system (polypropylene) ..................................................................................23

5.17.2 - “Split 80/80PP” system: available accessories ......................................................................24

5.17.3 - “Split 80/80PP” system: installation examples ........................................................................25

5.17.4 - “Coaxial 60/100PP” system (polypropylene) ..........................................................................26

5.17.5 - “Coaxial 60/100 PP” system: available accessories ................................................................27

5.17.6 - “Coaxial 60/100PP” system: installation examples ..............................................................28

6 - OPERATING ...........................................................................................................29

6.1 - Operating ................................................................................................................................ 29

6.1.1 - User instructions ........................................................................................................................29

6.1.2 - Filling of the condensation discharge trap .................................................................................29

6.1.3 - Filling the heating system ..........................................................................................................29

6.1.4 - Filling of the secondary heat exchanger of the domestic hot water ..........................................29

6.2 - General warnings concerning gas supply ............................................................................... 29

6.3 - Gas type indicated for the boiler ............................................................................................. 30

6.4 - Converting the boiler from one gas type to another ................................................................ 30

Page 3

3

Table of contents

6.5 - Start-up ................................................................................................................................... 30

6.5.1 - Auto-purging ..............................................................................................................................30

6.6 - Checking and adjusting the gas supply pressure ................................................................... 30

6.7 - Checking the comburant air pressure ..................................................................................... 31

6.8 - Checking and adjusting CO2 levels ........................................................................................ 32

6.9 - Adjusting the heating capacity ................................................................................................ 33

6.10 - Domestic hot water ow rate adjustment .............................................................................. 33

7 - USE ......................................................................................................................... 34

7.1 - Adjusting the domestic hot water ........................................................................................... 34

7.2 - Adjusting the heating system .................................................................................................. 34

7.3 - Thermostatic adjustment ......................................................................................................... 34

7.4 - Climatic adjustment ................................................................................................................. 34

7.4.1 - Climatic adjustment: on which systems? ...................................................................................34

7.4.2 - Climatic adjustment: precautions when making adjustments ....................................................35

7.4.3 - Climatic adjustment: setting of the parameters .........................................................................35

7.4.4 - Climatic adjustment: adjustments of the various climatic zones ...............................................35

7.4.5 - Climatic adjustment: switching on and off the heating service ..................................................35

7.4.6 - Climatic adjustment with room compensation ...........................................................................35

7.5 - Boiler settings (SWITCHES) ................................................................................................... 37

7.6 - Timings of the various functions .............................................................................................. 37

7.7 - Pumps and switch valve blockage protection ......................................................................... 37

7.8 - Anti-freeze protection .............................................................................................................. 37

7.9 - (Empty) ...................................................................................................................................37

7.10 - Energy Saving ....................................................................................................................... 37

7.11 - “Users’ menu” ........................................................................................................................ 38

7.12 - “Installers’ menu” ................................................................................................................... 39

7.13 - Diagnostics ...........................................................................................................................41

7.13.1 - Diagnostics: “L” lock-outs ........................................................................................................42

8 - MAINTENANCE ...................................................................................................... 45

8.1 - General warnings .................................................................................................................... 45

8.2 - Disassembling the casing and accessing internal components .............................................. 45

8.3 - Cleaning of the condensation collecting trap .......................................................................... 46

8.4 - Cleaning the burner and primary heat exchanger (ue gas side) .......................................... 47

8.5 - Correct positioning of the ignition and ionization electrodes .................................................. 47

8.6 - Secondary heat exchanger for the production of d.h.w. .......................................................... 47

8.7 - Replacement of the pump motor ............................................................................................. 48

8.8 - Checking the expansion tank .................................................................................................. 48

8.9 - Dismantling the 3-way valve ................................................................................................... 49

8.10 - Draining the heating side of the appliance ............................................................................ 50

8.11 - Draining the domestic side of the appliance ......................................................................... 50

8.12 - Forcing .................................................................................................................................. 50

8.13 - Auto-purging .......................................................................................................................... 50

8.14 - Fan ........................................................................................................................................ 50

8.15 - Minimum and maximum output ............................................................................................ 50

8.16 - Checking the ionization current ............................................................................................. 50

8.17 - Water temperature gauging sensor ....................................................................................... 51

8.18 - Outside temperature sensor ................................................................................................. 51

8.19 - Functional wiring diagram ..................................................................................................... 52

8.20 - Multiwire wiring diagram ....................................................................................................... 53

9 - TECHNICAL FEATURES ........................................................................................54

10 - EC COMPLIANCE DECLARATION ......................................................................55

Page 4

4

If you smell gas

Close the gas cock.

Ventilate the room.

Do not use any electrical appliances, telephone

included.

Immediately call a qualied technician or the gas board

from another room or building. If you cannot contact

them, call the Fire Brigade.

If you smell pruducts of the combustion

Switch off the appliance.

Ventilate the room.

Call a qualied technician.

Installation, modications

The installation, setting and modication of the gas

appliance must be carried out by qualied technicians,

in compliance with local and national norms and these

instructions.

Never leave any packaging or replaced parts within

the reach of children.

Seal the setting devices after each setting.

It is compulsory to connect the appliance’s discharge

pipe to a chimeney. Failure to observe this rule may

seriously risk the safety of individuals and animals.

Flue pipes must not be modied in any way.

The user, in accordance with these instructions, must

keep the appliance in satisfactory running order and

ensure reliable, safe operating.

The user is responsible for employing a qualified

technician to carry out maintenance work on the

appliance in compliance with local and national norms

and the matters stated in this manual.

We highly recommend arranging a regular maintenance

contract with a qualied technician

The manufacturer cannot be held responsible for any

damage to people, animals or property caused by

incorrect installation or inadequate maintenance.

Use the switches to disconnect the appliance from the

mains before carrying out any cleaning or maintenance

operations.

Do not obstruct the intake/discharge pipe ends.

Explosive or easily inammable products

Do not store or use explosive or easily inflammable

materials such as paper, solvents, paints, etc..., in the

same room as the boiler.

In the event of a breakdown

In the event of breakdown and/or malfunctioning of the

appliance, disconnect it, do not attempt to repair it or

intervene in any way whatsoever. Contact a qualied

technician. If repairs require parts to be replaced, only

original spares must be used. Failure to observe the above

may compromise the appliance’s safety.

Qualied technicians

Qualied technicians are personnel with specic, technical

1 - GENERAL SAFETY WARNINGS

training in the heating system component sector and with

regards to domestic hot water production for public use,

fuel gas systems and electrical systems. These individuals

must have the legally required qualications.

This booklet forms an integral and essential part of

the product and must be carefully kept by the user,

for any future consultation. Ensure that this booklet is

handed over to the new owners and/or installer if the

appliance should change hands or be moved for any

reason whatsoever.

Any optional extras or kit tted subsequently must be

original Cosmogas spares.

This appliance must only be used for the purpose it has

been expressly designed for: heating water for closed

circuit systems for centrally heating public and private

buildings, producing sanitary and domestic hot water

for civil use.

The man ufacture r cannot be held responsible,

contractually or otherwise, for any damage caused by

incorrect installation or use and for failure to comply

with the manufacturer’s instructions or applicable local

and national legislation.

For safety reasons and to safeguard the environment,

all packaging must be disposed of in special sorted

refuge collection centres.

1.1 - National installation

legislation

The installation must be carried out by a registered

compete nt person and be in accordanc e with the

relevant requirements of the current GAS SAFETY

(Installation and Use) REGULATIONS, the BUILDING

REGULATIONS (Scotland)(Consolidation), the LOCAL

BUILDING REGULATIONS, the current I.E.E. WIRING

REGULATIONS and the bye laws of the LOCAL WATER

UNDERTAKING. Where no specic instruction is given

reference should be made to the relevant BRITISH

STANDARD CODES OF PRACTICE. For Ireland install

in accordance with IS 813 “INSTALLATION OF GAS

APPLIANCES”.

B.S. Codes of Practice

BS 6891 Gas Installation.

BS 5546 Installation of hot water supplies for domestic

purposes.

BS 5449 Part 1 Forced circulation hot water systems.

BS 6798 Installation of gas red hot water boilers.

BS 5440 Part 1 Flues.

BS 5440 Part 2 Ventilation.

BS 7074 Expansion vessels and ancillary equipment for

sealed water systems.

BS 7593 Treatment of water in domestic hot water central

heating systems.

Page 5

5

2 - GENERAL INFORMATION

2.1 - Introduction

Congratulations!

You have effectively purchased

one of the best products on the

market.

Each single part is built, tested

and assembled, with pride, at the

COSMOGAS factories, thereby

guaranteeing optimum quality

control.

Thanks to on-going research

carried out by COSMOGAS, this

product has been conceived and

is considered to be the best in

its class with regards to respect

for the environment, since it falls

within class 5 (less polluting)

envisaged by technical norm EN

297 (and EN 483) and has an

elevated efciency, 4 star as per

EC Directive 92/42/CEE. Great

importance is also given to the

end of the appliance’s useful life.

All its components can easily

be separated into similar and

completely recyclable parts.

2.3 - Manufacturer

COSMOGAS srl

Via L. da Vinci 16

47014 - Meldola (FC) ITALY

Tel. +39 0543 498383

Fax. +39 0543 498393

www.cosmogas.com

info@cosmogas.com

2.4 - Key to symbols

used

CAUTION!!!

Risk of electric shock: failure to observe

th is war ning may co mpro mise the

smooth running of the appliance or cause

serious damage to individuals, animals

or property.

General danger!

Failure to observe this warning may

compromise the smooth running of the

appliance or cause serious damage to

individuals, animals or property.

Operation symbol

Important indication symbol

NOVADENS XXYYYY

“ “ =

Boiler with exchanger sanitary to partial accumulation;

“A” = Boiler for only heating without integrated pump;

“B” = Boiler which can be combined with BWR C series storage tank;

“C” = Boiler for only heating with integrated pump;

“P” = Boiler with exchanger secondary for D.H.W., to plates;

“0834” = Boiler for low temperature central heating systems.

24 = Boiler with maximum input heat of 25 kW

34 = Boiler with maximum input heat of 34.8 kW

Gas-red, condensing, hot water boiler, with sealed combustion chamber

and pre-mix burner, for heating and domestic hot water production.

2.2 - Description of

models

Page 6

6

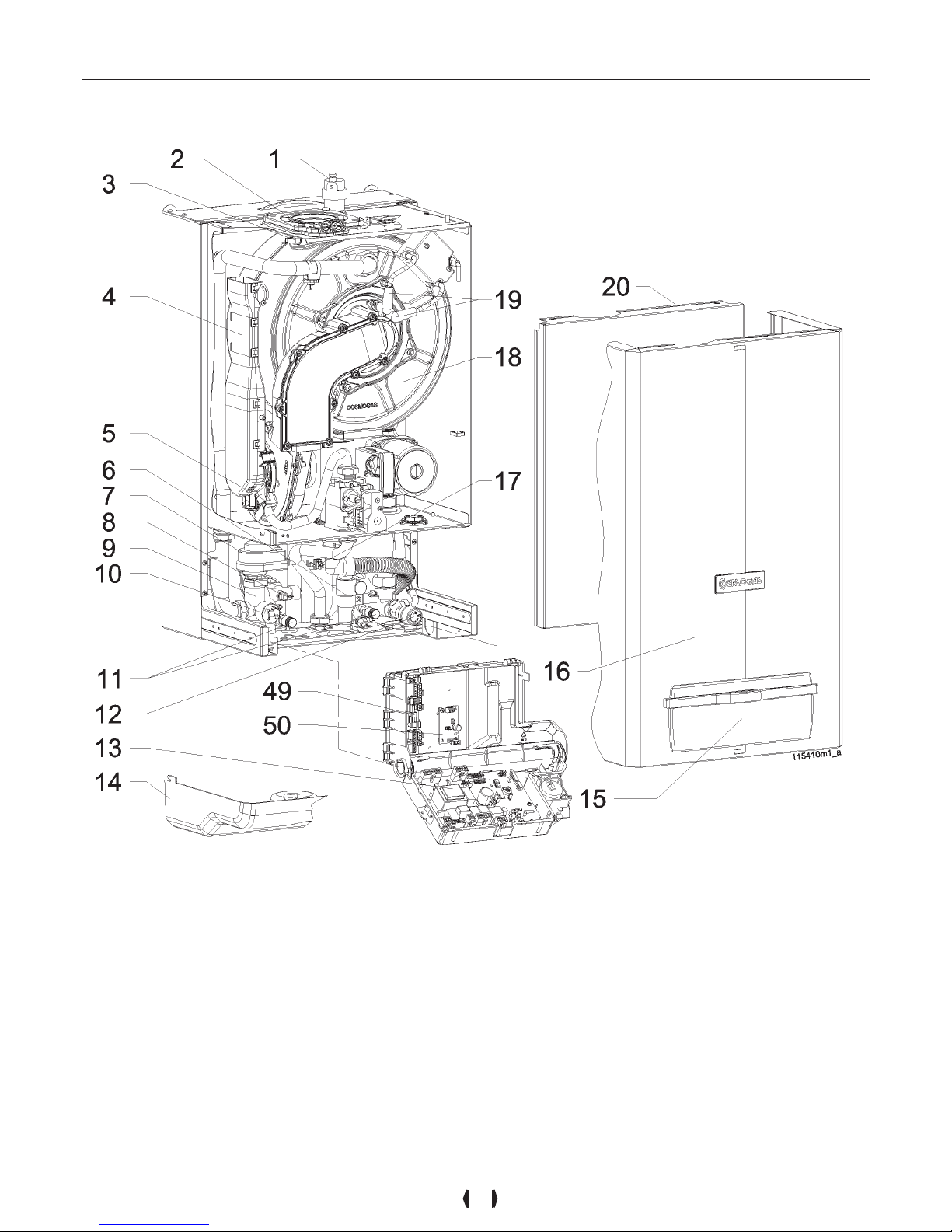

3 - MAIN COMPONENTS

Figure 1 - Internal components of boiler

1 - Automatic air vent

2 - Air intake and ue gas

discharge tting (venting system)

3 - NTC7 ue gas sensor

4 - Air drum

5 - Air/gas mixer

6 - Return unit

7 - 3 way valve

8 - NTC2 d.h.w. outlet sensor

9 - 3 way valve shell

10 - Heating pressure switch

11 - Heating circuit discharge

cock

12 - Safety relief valve

13 - Control board

14 - Lower cover

15 - Door to control box

16 - Casing

17 - NTC3 d.c.w. sensor

18 - Primary heat exchanger

19 - Ignition cables

20 - Door of sealed combustion

chamber

Page 7

7

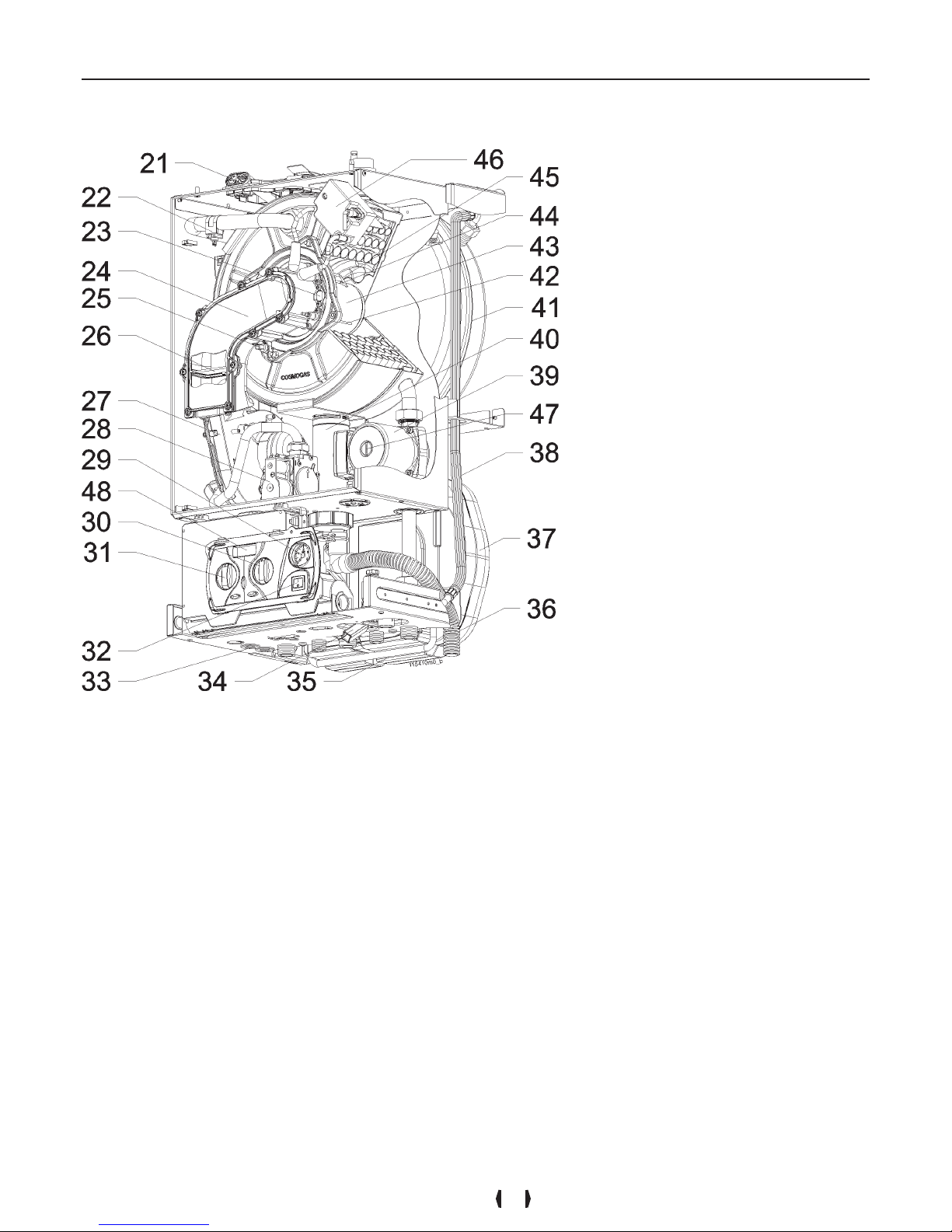

3 - MAIN COMPONENTS

Figure 1 - Internal components of boiler

21 - Combustion analysis tap

22 - NTC1 boiler temperature

sensor

23 - Burner window

24 - Air/gas manifold

25 - NTC6 high temperature limit

sensor

26 - Flue gas ow back

prevention valve

27 - Fan

28 - Gas valve

29 - Pressure gauge

30 - Domestic hot water control

31 - Heating control

32 - On/off power switch

33 - Cable clamp

34 - Filling cock

35 - By-pass pipe (optional)

36 - Condensation discharge pipe

37 - Secondary heat exchanger for

domestic hot water

38 - Expansion tank connection pipe

39 - Circulator pump

40 - Condensation discharge trap

41 - Expansion tank

42 - Ionization electrode

43 - Burner

44 - Right ignition electrode

45 - Left ignition electrode

46 - Spark generator

47 - Screw cap for unblocking

pump

48 - Display

49 - Electric connections board

50 - Opentherm interface board

(optional)

Page 8

8

4 - FUNCTIONS OF THE APPLIANCE

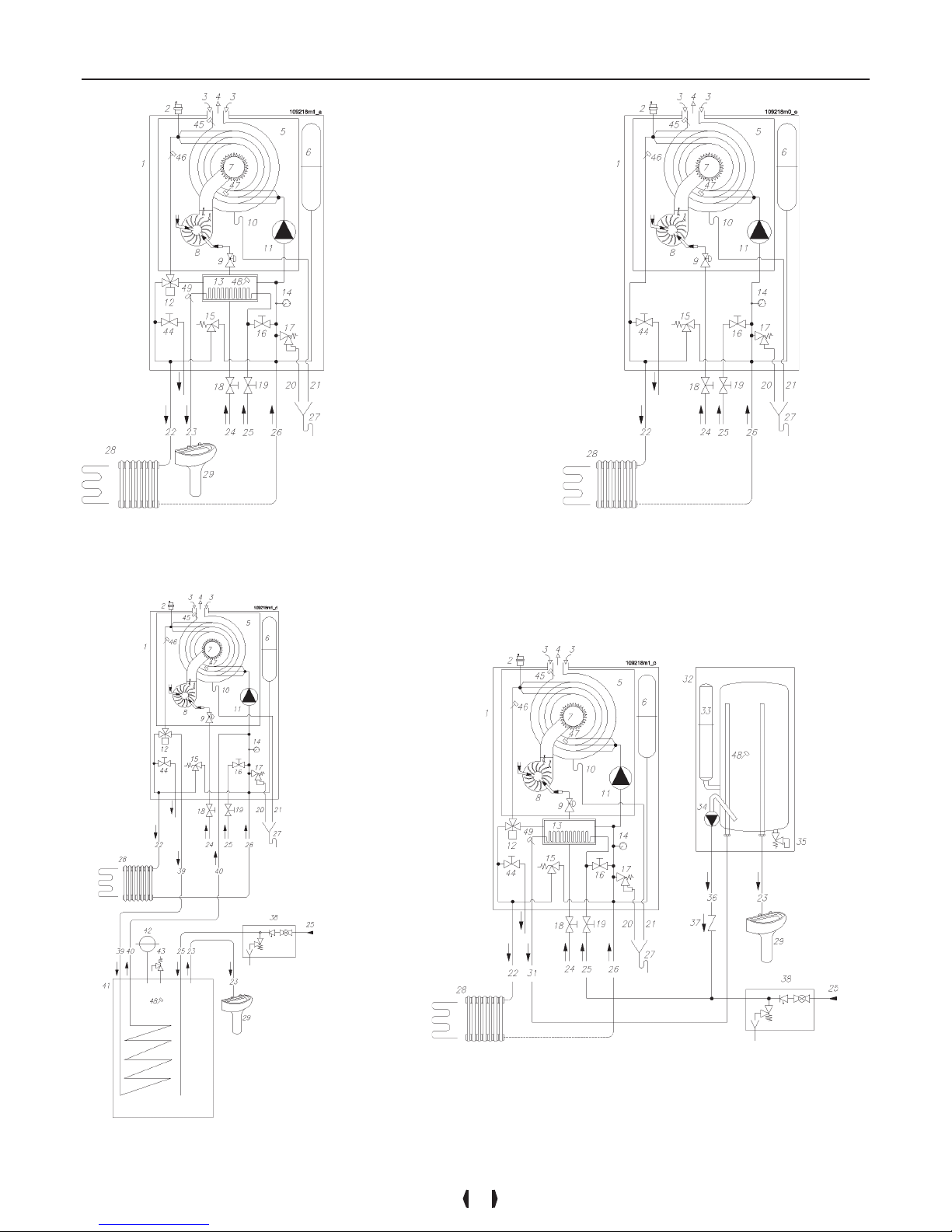

Figure 2 - Hydraulic diagram

NOVADENS 24 or 24P

NOVADENS 34 or 34P

Figure 3 - Hydraulic diagram

NOVADENS 24C

NOVADENS 34C

(for settings, see section 5.5)

Figure 5 - Hydraulic diagram

NOVADENS 24 or 24P

NOVADENS 34 or 34P

connected to B70 type storage

tank

(for settings, see section 5.15)

Figure 4 - Hydraulic diagram

NOVADENS 24B

NOVADENS 34B

Page 9

9

Key to gures 2, 3, 4 and 5:

1 = COSMOGAS boiler NOVADENS model

2 = automatic air vent

3 = air intake

4 = ue discharge

5 = sealed combustion chamber

6 = expansion tank

7 = burner

8 = fan

9 = gas valve

10 = condensation discharge trap

11 = circulator pump

12 = 3-way valve

13 = secondary heat exchanger for d.h.w.

14 = pressure gauge

15 = by-pass valve (optional)

16 = lling cock

17 = safety relief valve

18 = gas cock

19 = cold water inlet cock

20 = safety relief valve discharge (optional)

21 = condensation discharge

22 = heating supply pipe

23 = domestic hot water outlet

24 = gas inlet

25 = cold water inlet

26 = heating return pipe

27 = trap funnel (optional)

28 = heating system for radiators or radiant panel-type heating system (to be tted by installer)

29 = domestic hot water system (to be tted by installer)

30 = ------------------

31 = re-circulation supply pipe for water heater loading (to be tted by installer)

32 = B70 type storage tank (optional)

33 = expansion tank

34 = circulator pump

35 = safety rilief valve

36 = re-circulation return pipe for water heater loading (to be tted by installer)

37 = check valve (to be tted by installer)

38 = hydraulic safety unit complying with EN 1487 (to be tted by installer)

39 = water heater lling supply pipe (to be tted by installer)

40 = water heater lling return pipe (to be tted by installer)

41 = BWR type storage tank (optional)

42 = expansion tank

43 = safety relief valve

44 = heating system discharge cock

45 = NTC7 = ue gas sensor

46 = NTC1 = boiler temperature sensor

47 = NTC6 = high temperature limit sensor

48 = NTC3 = domestic cold water sensor/storage tank sensor

49 = NTC2 = domestic hot water outlet sensor

4 - FUNCTIONS OF THE APPLIANCE

Page 10

10

4.1 - Intended use

and functions of the

appliance

This condensation-type gas appliance,

is designed to be used for central

heating and producing domestic hot

water for civil use.

Fit the boiler to the system according

to the most suitable residual curve

head (see gures 6 and 7).

The maximum output heat is always

guaranteed for the production of

domestic hot water since, on each

request, the heating service switches

off.

Follow the specic procedure in

section 9.13 for the adjustment of the

domestic hot water temperature.

Depending on the model chosen, the

following system types can be created:

A- NOVADENS -- ” “. By means of

this boiler, a system can be created

for the production of instant domestic

hot water and a heating system

with heating elements functioning at

temperatures ranging between 30°C

and 80°C. An example of this type of

system is shown in gure 2.

B- NOVADENS -- “B”. By means of

this boiler, a system can be created

for the production of domestic hot

water using a storage tank, BWR or

equivalent model and a heating system

with heating elements functioning at

temperatures ranging between 30°C

and 80°C. An example of this type of

system is shown in gure 4.

C- NOVADENS -- “C”. By means of

this boiler, a system can be created for

the only heating with heating elements

functioning at temperatures ranging

between 30°C and 80°C. An example

of this type of system is shown in gure

3.

In this model is moreover possible to

connect, also after the installation,

en storage tank model BWR lled

up through one external valve to the

boiler.

D- NOVADENS -- “P”. By means of

this boiler, a system can be created

for the production of instant domestic

hot water and a heating system

with heating elements functioning at

temperatures ranging between 30°C

and 80°C. An example of this type of

system is shown in gure 2.

All the boiler versions described

previously can be connected to a

room thermostat for the setting of

the heating. Or, so as to improve

the quality of the heating service,

it is possible to connect an external

temperature sensor (Climatic heat

adjustment) so as to automatically

set the supply temperature in relation

to the external temperature; the

room thermostat, in this case, can

make a compensation of the room

temperature. The room compensation

can be of an ON /OFF type or twostage.

For further information on the Climatic

heat adjustment, refer to section 7.4.

For take advantage of the rendering

characteristics of boiler, it is

advised to connect it to the CR04

cronothermostat, (see chapter

5.14.5), what it will regulate the

temperature of supply to the

radiators in continuous and linear

way, to maintain the temperature

environment planned.

The boiler must be connected to

a heating system and a domestic

hot water supply, with compatible

specications, performance and

power rating.

Before installation, thoroughly ush

the heating and plumbing systems

of any residue or impurities which

might compromise the smooth

running of the boiler.

This boiler is not designed for

outside installation.

Choose a sheltered place where

it is protected from atmospheric

elements including frost.

Refer to gure 9 for minimum

clearance distances for installation

and future maintenance.

4 - FUNCTIONS OF THE APPLIANCE

E- NOVADENS -- “0834”. By means

of this boiler, a system can be created

for the production of instant domestic

hot water and a heating system

with heating elements functioning at

temperatures ranging between 20°C

and 45°C. An example of this type of

system is shown in gure 2.

F- NOVADENS -- “B0834”. By means

of this boiler, a system can be created

for the production of domestic hot

water using a storage tank, BWR or

equivalent model and a heating system

with heating elements functioning at

temperatures ranging between 20°C

and 30°C. An example of this type of

system is shown in gure 4.

G- NOVADENS -- “C0834”. By means

of this boiler, a system can be created

for the only heating with heating

elements functioning at temperatures

ranging between 20°C and 45°C.

An example of this type of system is

shown in gure 3.

In this model is moreover possible to

connect, also after the installation,

en storage tank model BWR lled

up through one external valve to the

boiler.

H- NOVADENS -- “P0834”. By means

of this boiler, a system can be created

for the production of instant domestic

hot water and a heating system

with heating elements functioning at

temperatures ranging between 20°C

and 45°C. An example of this type of

system is shown in gure 2.

In all the boiler versions described

previously, connection of the domestic

hot water service is not indispensable;

if the boiler is required solely for central

heating purposes, it is sufcient to

connect the cold water pipe so as to ll

the heating system and close the tting

of the d.h.w. outlet.

All the NOVADENS -- or NOVADENS

--0834 model boilers, can also be

connected subsequently for the

installation of a B70 C series storage

tank (see gure 5)

Page 11

11

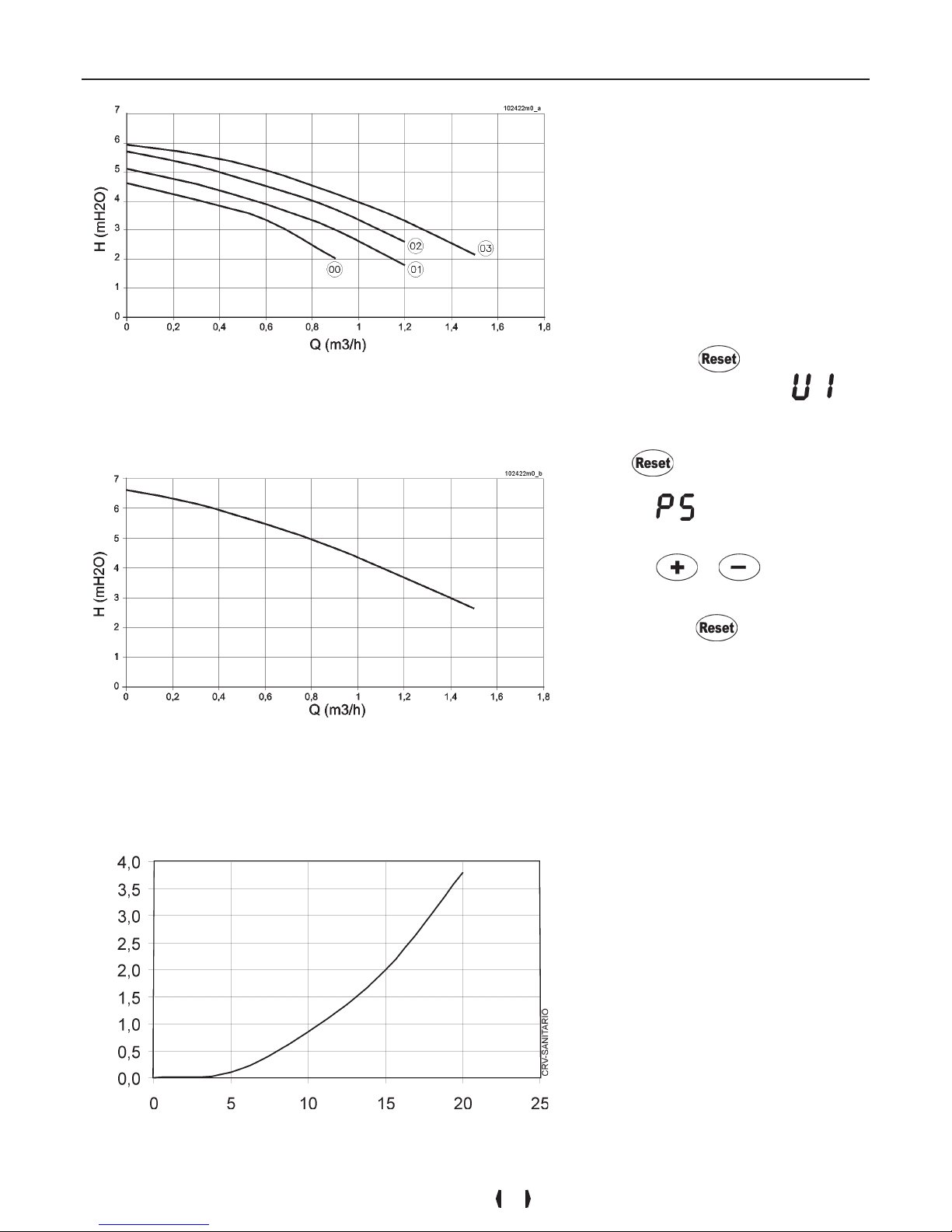

4.2 - Characteristic

curves of heating

system’s residual

head

Each standard boiler is tted with its

own specic circulator pump. The

residual head at the boiler connections

is shown in graph form in gures 6.

On demande, we can supply the boiler

with a 7 m head pump (see g.7).

The diagram comprises 4 curves which

can be selected from the control panel,

in the following manner:

press the button for 12

seconds until parameter is

displayed (the display panel will start

to blinking);

continually press and release the

button in order to scroll

through the list of parameters until

the parameter is displayed;

once the parameter has been

identied, it can be changed using

the or key;

choose the desired value of the

pump speed;

Press the button in order to

conrm the modied data and exit

from the menu;

4.3 - Characteristic

curve of the

domestic side

Every boiler offers certain resistance

to the passage of the domestic water

(see graph ow/pressures of gure

8). The installer or the engineer must

take account of this in order to ensure

the correct domestic water ow to the

utilities.

Figure 6 - Curve of the pump with 6 metres head

Figure 7 - Curve of the pump with 7 metres head

Figure 8 - Curve of the of pressure for the domestic side.

4 - FUNCTIONS OF THE APPLIANCE

Pressure (bar)

Flow (l/min)

Page 12

12

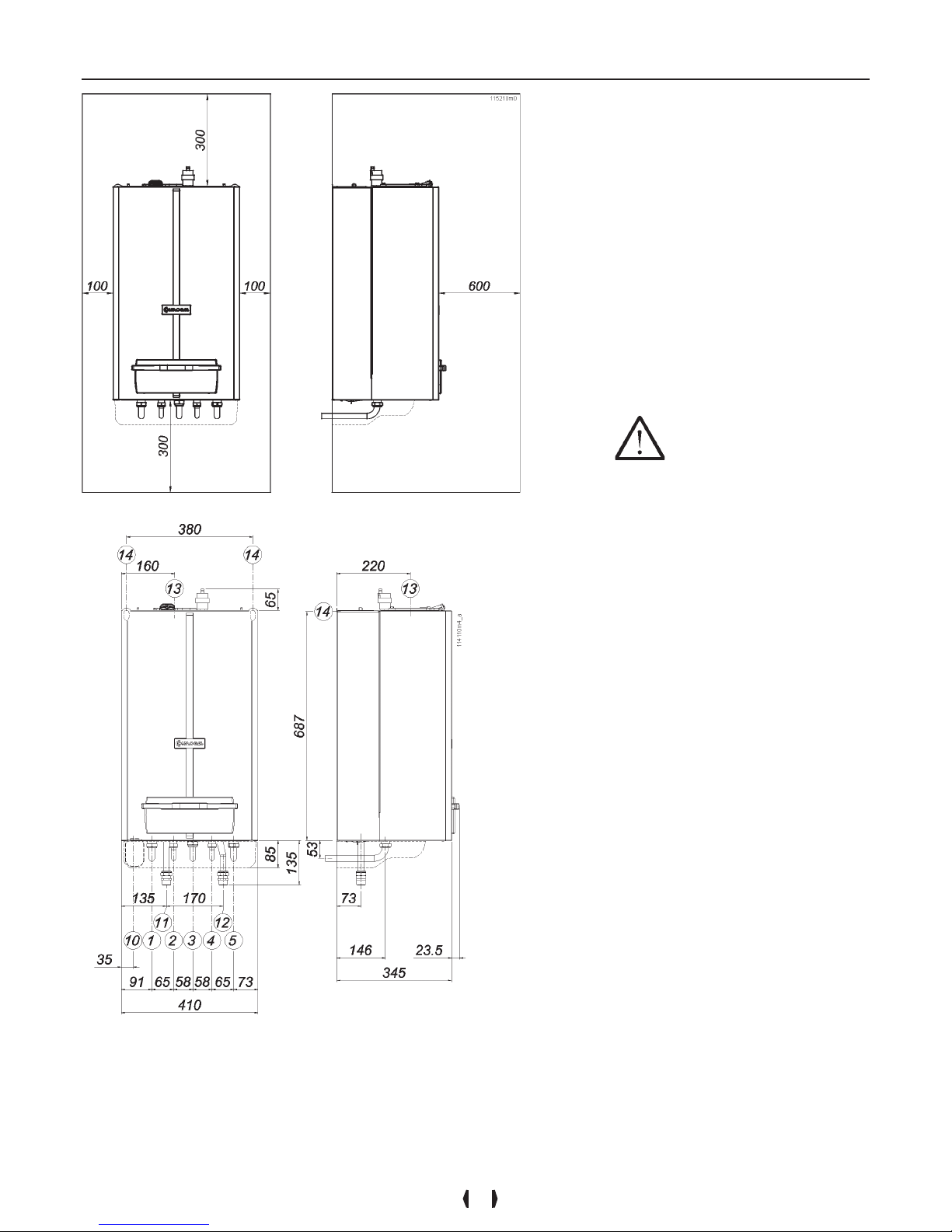

5.1 - Opening the

packaging

The appliance is supplied in a box. Open

it up following the instructions given on

the closing aps.

5.2 - Dimensions

and clearances for

installation

Leave an area free around the boiler for

carrying out installation or maintenance

activities, as shown in gure 9.

5.3 - Choosing the

point of installation

CAUTION!!! The boiler must

be installed exclusively on a solid,

vertical wall able to bear its weight.

The appliance must be installed

indoors, or protected from atmospheric

agents including rain, wind, sun and

especially frost.

When choosing the room and position

for installation, account must be taken

of the following factors:

- the connection of ue gas discharge/

air intake pipes;

- the connection of gas supply pipe;

- the connection to the water mains;

- connection of the system to the

central heating;

- the connection to the domestic hot

water system;

- electrical connections;

- the connection of the discharge for

condensation produced by the boiler;

- electrical connection to the room

thermostat;

- possible connection of the safety

relief valve discharge;

- possible connection of the external

temperature sensor;

Figure 9 - Minimum clearance distances

1 = 3/4” (models 24) and

1” (models 34) heating supply

2 = 1/2” domestic hot water

(absent in NOVADENS B and C models)

3 = 3/4” gas

4 = 1/2” domestic cold water

5 = 3/4” (models 24) and 1” (models 34)

heating return

10 = area for power supply cable

11 = BWR supply pipe

(present only on NOVADENS B models)

12 = BWR return pipe

(present only on NOVADENS B models)

14 = positions available for boiler support

5 - INSTALLATION

Figure 10 - Boiler dimensions and ttings’ distances

Page 13

13

5.4 - Supply and

return

CAUTION!!! This boiler is

equipped with a safety relief valve

set at 3 bar. Therefore it must not be

installed with a radiator positioned

at a manometric high higher

than 30 m.

CAUTION!!! COSMOGAS

cannot be held responsible for any

damage caused by incorrect use of

additives in the heating system.

CAUTION!!! The system

downstream from the appliance

must be made of materials which

can withstand temperatures up to

97°C. Otherwise (e.g. plastic piping)

the boiler must be tted with a

device to cut out the pump when

it reaches the maximum permitted

temperature.

Thoroughly wash out the system,

before connecting the heating pipes,

to ush out any deposits (hemp,

radiator casting residue, etc.) which

might damage the appliance. Thorough

ushing is also required when

replacing an appliance.

Figure 10 illustrates the position of the

supply and return pipes.

Install a metallic mesh lter on the

return pipe to prevent any residue

from the system returning to the

boiler.

Do not use the appliance for adding

any type of additive to the system.

5.5 - Radiant

panel systems (or

low temperature

systems)

CAUTION!!! When the boiler

is installed in a low temperature

system, it is indispensable to set

the switch 6 in the ON position (see

chapter 7.5).

By means of this setting, the boiler will

set the temperature towards the supply

of a temperature between 20°C and

45°C. No setting operation from the

control panel (even by means of the

climatic setting) will be able to supply

water at a temperature higher than

45°C.

CAUTION!!! If the boiler

is installed in a radiant panel

heating system with plastic

piping, precautions must be taken

against corrosion caused by water

oxygenation: check that the system

has plastic piping with a permeability

to oxygen of no higher than 0.1 g/m3

at 40°C. If the piping does not comply

with these specications, the radiant

panel circuit must be isolated from the

boiler by a plate heat exchanger.

5.6 - Domestic hot

and cold water

CAUTION!!! If the water

hardness is greater than 25°F, we

recommend installing a softener

with lter (see section 5.13).

Figure 10 illustrates the positioning of

the domestic hot and cold water pipes.

For servicing purposes, install a cutoff cock upstream from the cold water

inlet.

Connection of the domestic hot water

service is not indispensable; if the

boiler is required solely for central

heating purposes, it is sufcient to

connect the cold water pipe so as to

ll the heating system and close the

d.h.w. outlet.

5.7 - Gas supply

CAUTION!!! It is forbidden to

use a different gas to that stated for

the boiler.

CAUTION!!! Check that the

gas type and the pressure of the

gas supplied correspond with those

required for the boiler.

There are two possible situations:

A - the gas type and the supply

pressure match those of the boiler

setting. In this case proceed with

connections;

B - the gas type and the supply

pressure do not match those of the

boiler setting. In this case, the boiler

must be converted to the type of gas

and supply pressure available.

A special conversion kit is available on

request from your salesman or direct

from COSMOGAS.

Before installation, we recommend

thorough ushing of the gas supply

pipe.

An on-off cock must be installed on

the gas supply pipe.

To avoid damaging the gas control

unit of the appliance, carry out a

leak test at a pressure of no greater

than 50 mbar.

If testing of the gas system must

be carried out at a pressure nigher

than 50 mbar, use the cock situated

immediately upstream from the

boiler, to isolate the same from the

system.

Figure 10 shows the position of the

appliance gas tting.

The sections of piping making up

the gas supply system must always

provide sufcient gas to cover the

required maximum.

5 - INSTALLATION

Page 14

14

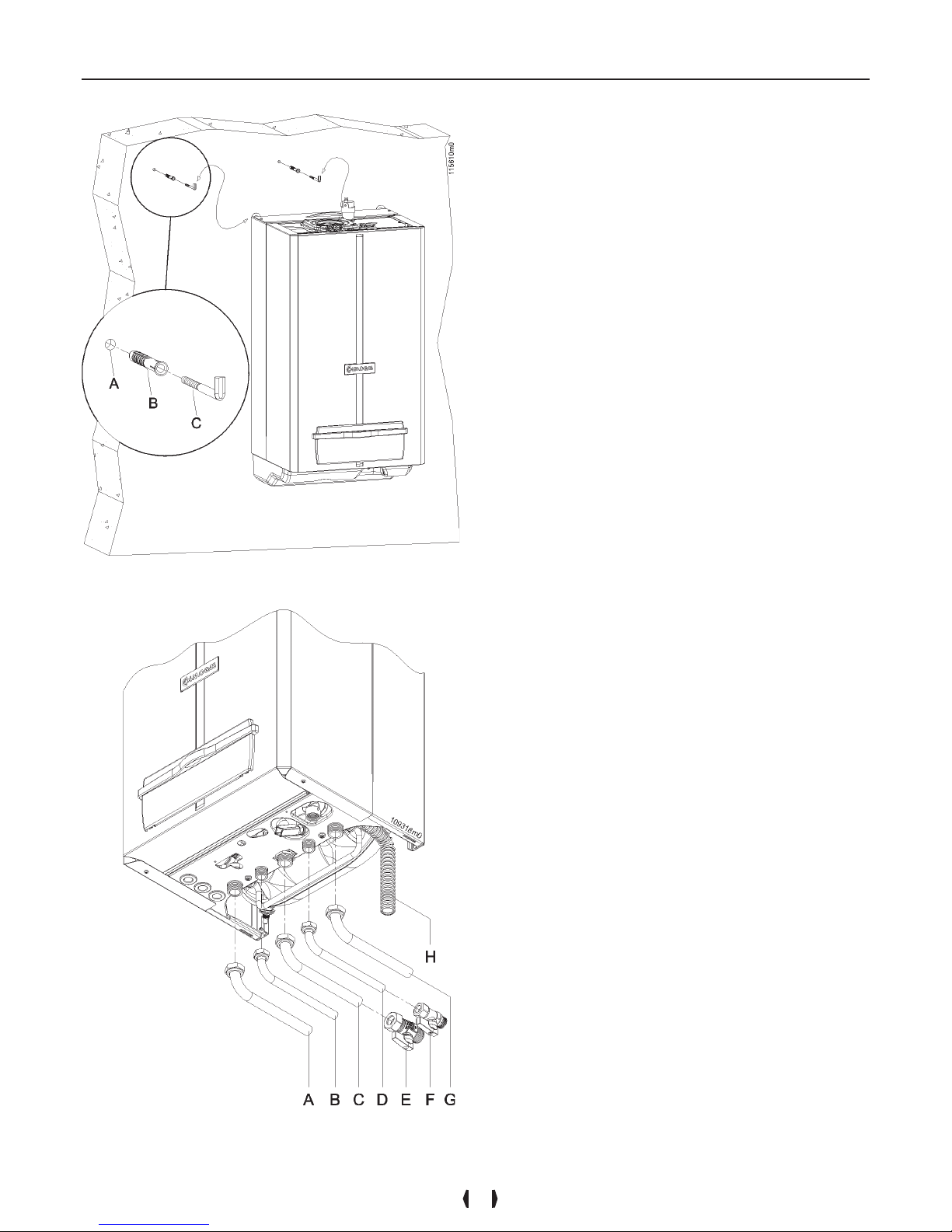

Figure 12 - Gas and water connections

5.8 - Assembling

the appliance

Refer to gure 11:

place the paper template, provided

with the appliance, against the wall;

ensure that the template is square

with the room;

mark holes for the wall dowel plugs

and the hydraulic ttings;

remove the paper template;

drill the holes “A” and insert the wall

dowel plugs “B”;

carry out the hydraulic and gas

connections for the boiler;

hang the boiler on the dowel plugs

“C”;

carry out the hydraulic connections.

5.9 - Gas and water

connections

The boiler comes supplied with the

standard ttings illustrated in gure 12,

where:

A = heating supply

B = domestic hot water

C = gas inlet

D = domestic cold water

E = gas inlet cock (EN 331

type approved)

F = domestic cold water cock

G = heating return

H = condensation discharge

pipe

5 - INSTALLATION

Figure 11 - Support dowel plugs

Page 15

15

5 - INSTALLATION

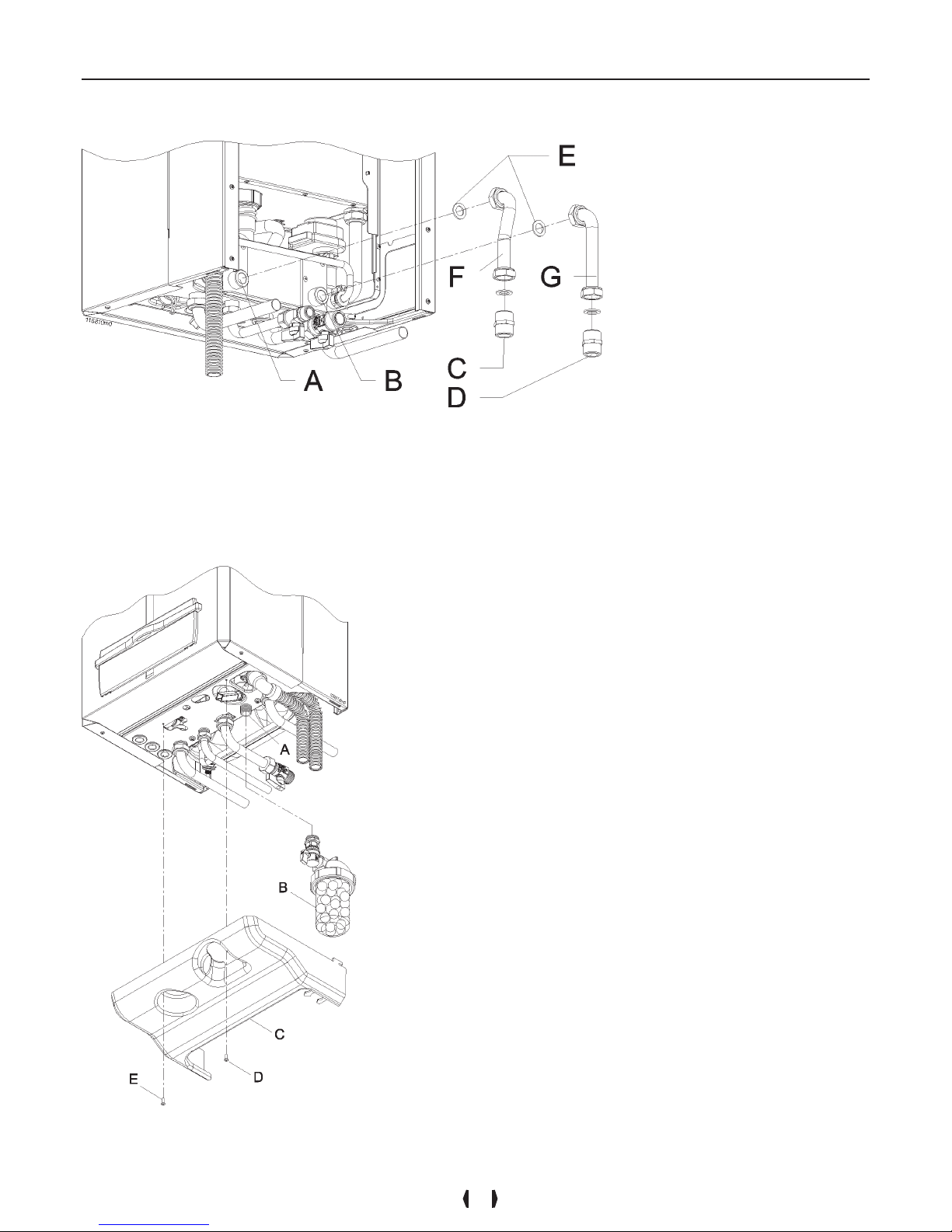

Figure 13 - Connection of the discharge safety

valve “A” (pipe “A” is optional) and condensation

discharge “B”

Figure 14 - Trap funnel “F” (on request)

5.10 - Condensation

discharge

The boiler is equipped internally with a trap for

the evacuation of condensation (see gure 1,

detail 40) and so as to prevent the leakage of

combustion products, whose end corresponds

with pipe “B” shown in gure 13. This end

must be conveyed to another smell-control trap

(gure 14, detail “F”) so as to prevent the return

of bad smells in the room (the smell-control trap

“F” is supplied upon request).

In particular, the condensation disposal system

must:

for premises used for dwelling purposes or

ofce purposes with a number of occupants

greater than 10, be connected to the

domestic waste disposal system by means of

an appropriate trap with separation capable

of preventing the pressurization of the system

and preventing the return of bad smells

from the sewer (detail “F” of gure 14). If

the premises for ofce use has a number of

occupants less than 10, before connection

with the domestic waste discharge, it is

advisable to t a condensation neutralizer

(see section 10 for the acidity value of the

condensation and the quantity);

be carried out with a pipe with an internal

diameter equal to or greater than 13 mm;

be installed in such a way so as to avoid the

freezing of the liquid, therefore take care with

any external stretches; discharge into gutters

or rain collectors is forbidden;

present a continual slope towards the point

of discharge; avoid high points, which could

place the pipe under pressure;

5.11 - Safety relief valve

The boiler is protected against overpressure, by

a safety relief valve set at 3 bar (see gure 1,

detail 12).

The safety relief valve discharge must be

connected to pipe “A” (see gure 13) with a

minimum internal diameter of 13 mm; pipe “A”

must then be led to the smell-control trap (detail

“F” of gure 14). This discharge with trap must

provide protection against overpressure in the

event of the valve opening and must indicate to

the user that this intervention has taken place.

Pipe “A” shown in gure 13 and the smellcontrol trap “F” shown in gure 14 are on

request.

CAUTION!!! If the safety relief valve

is not connected to the discharge, opening

of the valve could cause harm to individuals,

animals or property.

Page 16

16

Reference of Figure 17

A = Box tool’s control

B = stirrup of block

C = toward of opening

C = Cover

D = xing screws

E = Cover electrical

connexion board

F = toward of opening “E”

cover

G = Power supply cable

(not included)

H = Room thermostat cable

(not included)

Figure 16 - Softener with lter

5.12 - Hydraulic

connections for

boiler with BWR

storage tank

The NOVADENS -- B or NOVADENS -B0834 model boiler must be connected

to a storage tank for the production of

domestic hot water.

For this purpose, connection ttings to

the storage tank have been provided

for. For the preparation, operate as

follows (refer to gure 15):

mount pipe “F” to tting “A”;

mount pipe “G” to tting “B”;

mount ttings “C” and “D”

respectively to “F” and “G”;

Take care to insert the appropriate

gasket in each coupling.

5.13 - Softener (on

request)

If the boiler is to be installed in a

geographic area where the domestic

water hardness exceeds 25°F (250

mg/l), a softener must be installed on the

cold water supply (see gure 16, detail

“B”), so as to safeguard the appliance

from any blockage in the domestic water

circuit.

In order to facilitate installation, a softener

may be request to COSMOGAS, with a

specic installation kit.

5 - INSTALLATION

A = BWR return pipe

B = BWR supply pipe

C = BWR return tting

D = BWR supply tting

E = gaskets

F = service pipe

G = service pipe

Figure 15 - Hydraulic connections for boiler with BWR type

storage tank

Page 17

17

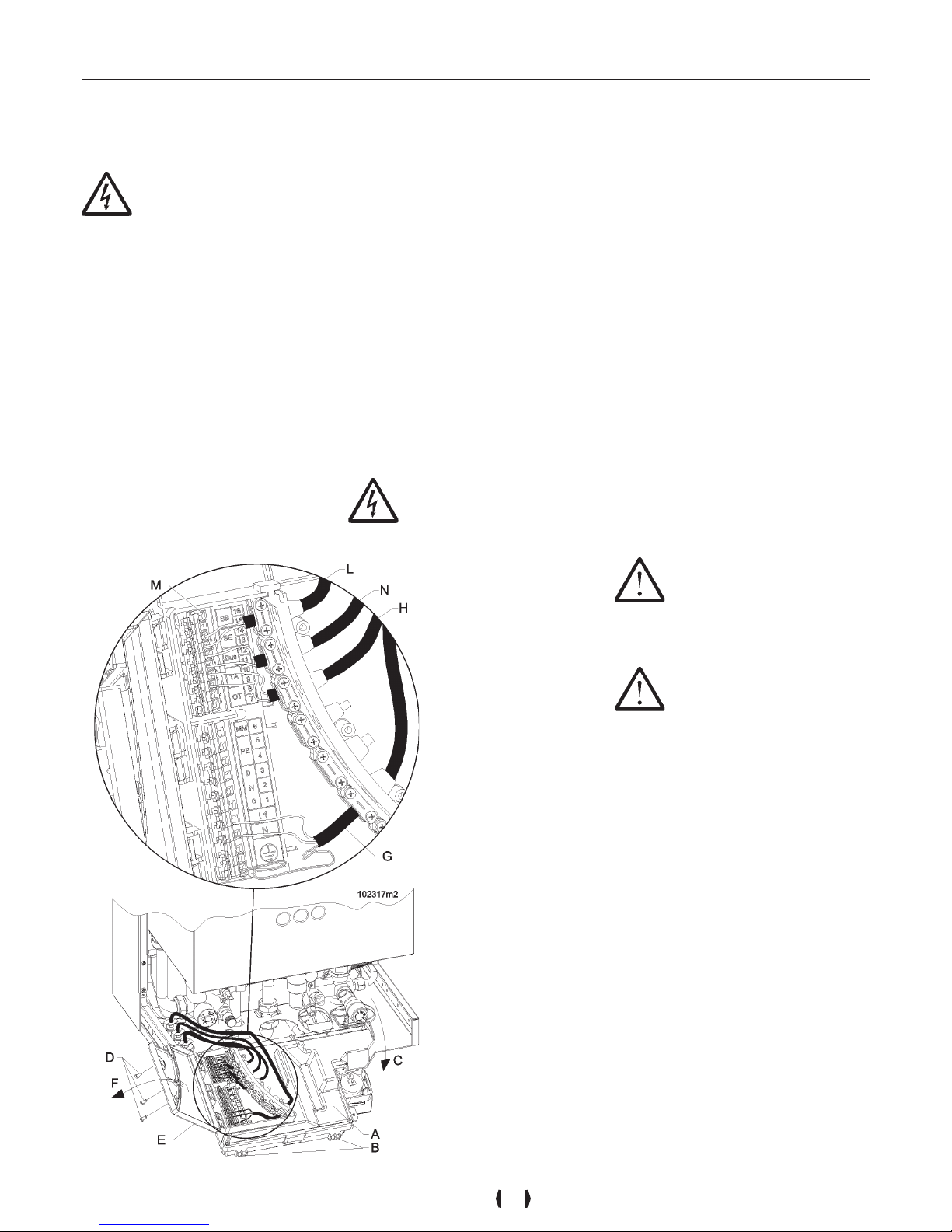

5.14 - Electrical

connections:

overview

CAUTION!!! The appliance

is only electrically safe when it is

correctly connected to an efciently

earthed system, carried out in

compliance with current safety

standards.

This is an essential safety requirement

which must be checked. If in doubt,

have the electrical system thoroughly

checked by a qualied technician.

Have a qualied technician

check that the electrical system is

adequate for the electric power,

indicated on the rating plate,

required by the boiler.

The boiler must be connected to the

mains electricity by connection using

movable plug. Do not use adapters,

multiple plugs or extensions, etc.

The boiler must be connected to

5 - INSTALLATION

the mains electricity by a threepole electrical cable with double

insulation and a minimum cross

section of 1.5 mm2, resistant to

a minimum temperature of 70°C

(feature T).

To connect the boiler to the mains

electricity, use a bipolar switch with

a contact opening distance of at

least 3mm, near to the appliance, in

compliance with current standards

on the subject.

Respect the polarity between live

and neutral when connecting the

boiler.

Ensure that heating and water

piping is not used as earth plates for

the electric and telephone systems.

This piping is completely unsuitable

for this purpose and, in addition,

could rapidly lead to serious

corrosion damage to the boiler,

piping and radiators.

CAUTION!!! The boiler is

not provided with any protection

against lightening strikes.

5.14.1 - Connecting

the power supply

cable

To connect the electrical power supply

cable, proceed as follows (refer to

gure 17):

use a three-pole cable with double

insulation and a minimum cross

section of 1.5 mm2;

remove the boiler casing following

the instructions given in section 8.2;

to rotate the panel "A" toward the

front of the boiler acting on the

stirrups "B";

remove the screw “D” and open the

cover “E”;

lay the power supply cable “A” as

shown in gure 17;

strip the cable being careful to leave

the earth wire (yellow green) 20 mm

longer than the other two;

connect the yellow green cable to

the earth terminal (terminals “G”);

connect the brown cable to terminal

L1 (terminals “G”);

connect the blue cable to terminal N

(terminals “G”).

CAUTION!!! If the “L1” phase

conductor is inverted with

the neutral “N” conductor,

the boiler will lock-out,

displaying error code E21.

CAUTION!!! If the earthing

system is not efcient,

the boiler will lock-out,

displaying error codes L05,

E42 or E23 (depending

on the entity of the

inefciency).

Figure 17 - Electrical connections

Page 18

18

5 - INSTALLATION

Figure 18 - Correct positioning of the room thermostat/timeprogrammable thermostat

5.14.2 - Choosing

the room

thermostat/timeprogrammable

thermostat

The boiler is designed to function

with any type of room or timeprogrammable thermostat which

has contacts for the boiler cable

connections, and the following

features:

- open/closed (ON/OFF);

- clean (not powered);

- closed when heating is required;

- electrical specications 24Vac, 1A.

5.14.3 - Connecting

the room

thermostat/timeprogrammable

thermostat

Install the room thermostat in a part

of the house where the temperature

is as near to average as possible and

in any event not an area subject to

sudden temperature changes, away

from outside windows or doors (see

gure 18).

To connect the room thermostat cable,

proceed as follows (refer to gure 17):

use a bipolar cable with a minimum

cross section of 1.5 mm2 which

leads from the boiler to the room

thermostat/time-programmable

thermostat;

remove the boiler casing according

to the instructions given in section

8.2;

lay the electrical cable “H” exactly as

shown in gure 17;

get the cable to pass via a free cable

clamp, not used by other wires;

connect the 2 ends of the cable to

the “TA” terminals (see gure 17,

detail “M”).

CAUTION!!!

Si n c e t h e cabl e s of t he r o om

the r m o st a t/ t im e - pr o gr a mm a bl e

thermostat are subject to low safety

voltage (24Vcc), they must run through

ducts different from the 230Vac power

supply cables.

5.14.4 - Installing the

outside temperature

sensor (on request)

Install the outside temperature sensor

outside the house, on a wall facing

NORTH or NORTH-EST, at a height

of between 2 and 2.5 metres from the

ground; on buildings with several oors,

install near the upper half of the second

oor. Do not install the sensor above

doors, windows or ventilation outlets nor

directly under balconies or gutter pipes

Do not plaster the external temperature

sensor. Do not install the sensor on walls

without overhangs, or not protected from

rain.

If the sensor is installed on a wall still

to be plastered, it is necessary to install

it with an adequate shim or remove it

before plastering.

To connect the cable of the outside

temp e r a t ur e s e ns o r, p r o c e ed a s

follows:

lay a bipolar electrical cable with a

minimum section of 1.5mm2 which

leads from the boiler to the external

temperature sensor. The maximum

length permitted is 20 m. For longer

lengths, up to 100 m, it is necessary to

use a shielded cable with an earthed

shield;

CAUTION!!!

Since the cables are subject to low

safety voltage (24Vcc), they must

run through ducts different from the

230Vac power supply cables.

connect the bipolar cable to

terminals SE as shown in gure 17,

detail “F”;

connect the bipolar cable to the ends

of the external temperature sensor.

Set the boiler so that it detects the

outside temperature sensor, as follows:

press down the button for 12

seconds until the display blinking and

shows ;

then press and release the button

several times until the following

parameter appears ;

using the and keys,

change the parameter value

from 00 to 01 or 02 in relation to

the type of climatic heat adjustment

desired (see section 7.4);

press the button repeatedly

until exiting the menu; the display will

no longer ash.

Page 19

19

5 - INSTALLATION

5.14.5 - CR04

remote time control

(optional)

The CR04 time control is a room

thermostat capable of interacting

with the boiler, adjusting the room

temperature in a modulating manner

and not by steps. This device is

really a genuine heat regulator

capable of operating, or otherwise,

with the outside temperature sensor

and therefore of adjusting the room

temperature in an optimum manner. If

the boiler has been factory purchased

without this device, it is rst of all

necessary to t an “Opentherm”

interface board as described in the

following section.

If the boiler has been purchased

inclusive of the remote control, it

means that the “Opentherm” board has

already been installed on the boiler

and it is only necessary to install the

remote control as follows:

Install the CR04 remote control in

a point of the building where the

temperature is as close to that

characteristic of the house and in any

event in an area not subject to sudden

temperature changes, far away from

windows and doors which directly

connect with outdoors (see gure 18).

In order to connect the room

thermostat cable, proceed as follows

(refer to gure 17):

use a bipolar cable with a minimum

cross section of 1.5 mm2 which

leads from the boiler to the CR04

remote control. The cable must

also be protected by means of the

earthing of the protection and the

maximum length permitted is 100

metres;

dismantle the casing and access the

electrical terminal board, following

the specic instructions in section

8.2;

connect the 2 ends of the cable to

the “OT” terminals of the boiler (see

gure 17).

connect the other 2 ends of the

cable to the terminals of the remote

control (follow the instructions on the

remote control).

CAUTION !!!

Since the cables of the remote control

are subject to extremely low security

voltage (24Vcc), they must pass

through ducts differen t from the

230Vac supply cables.

Once the remote control has been

connected, all the room temperature

adjustmen ts and domestic water

tempe rat ure operati ons must be

carried out directly on the same.

Accordingly, remember to closely

follow the instructions contained on

the CR04 remote control.

5.14.6 - Installation

of the CR04 remote

time control on the

boiler

If the boiler has been purchased with

the CR04-type time control, in order

to enable the same it is necessary to

install the “Opentherm” interface board

on the boiler following the instructions

contained on the remote control.

Page 20

20

5.15 - Connecting

the boiler to the

B70C type water

heater (optional)

The boiler can be immediately or

subsequently connected to a B70C

type storage tank manufactured by

Cosmogas.

The water connection must be carried

out as per gure 19.

For the electrical connection, proceed

as follows (refer to gure 21):

disconnect the electricity supply to

the boiler;

access the internal components and

the electrical components of the boiler,

following the specic section 8.2;

move the switch 1 to position “B”

(ON);

Remove the cable from the sonde “17”

of gure 1;

lay the bipolar cable with a minimum

1.5mm2 section which goes from the

boiler to the temperature sensor of

the water heater and connect it on

the boiler to terminals “15” and “16”

(SB);

Figure 19 - Hydraulic connection to B70C storage tank type

1 COSMOGAS boiler

2 B70C type storage tank (on

request)

3 Gas supply

4 d.h.w. supply to water heater (to

be tted by the installer)

5 d.h.w. outlet

6 Cold water

7 Safety relief valve

9 Check valve (to be tted by

installer)

10 Recirculation for storage tank

loading (to be tted by installer)

11 Storage tank loading pump

12 Temperature sensor

13 Hydraulic safety unit (to be tted

by installer)

14 Heating supply

15 Heating return

5 - INSTALLATION

connect the other end of the cable to

the temperature sensor of the water

heater;

insert the probe of the temperature

sensor into the socket “12” as shown

in gure 19.

CAUTION!!! Since the cables

are subject to low safety voltage

(24Vcc), they must run through

ducts different from the 230Vac

pump power supply cable.

connect a three-pole double insulated

electrical cable (Live, Neutral and

Earth), with a minimum cross section

of 1.5m m2 which is resis tant to

a minimum tempera ture of 70°C

(feature T) to terminals “3” and “5” and

to the earth connection, and connect

the other end of the cable directly to

the pump of the storage tank (see

gure 19, detail “11”);

5.15.1 - Prevention

against

Legionnaires

disease

If the boiler is connected to a storage

tank for the preparation of domestic hot

water, a disinfection cycle is envisaged

against Legionnaires bacteria. This

cycle anticipates taking the storage

tank to a temperature of 60°C

(temperature at which said bacteria

die) at least once a week. Therefore,

the water (at certain times) may reach

the user at a higher temperature than

that set on the knob on the specic

control.

The rst time the boiler is started up,

the anti-Legionnaires cycle is also

started after 2 hours of running.

Page 21

21

5.16 - Connecting the

boiler to the BWR C

type storage tank

Only the NOVADENS -- B and

NOVADENS -- B0834 model boilers

can be connected to a BWR type

storage tank.

The water connection must be carried

out as per gure 20.

For the electrical connection, proceed as

follows (refer to gure 21):

disconnect the electricity supply to the

boiler;

access the internal components and

the electrical components of the boiler,

following the specic section 8.2;

move switch 1 to position “B” (ON);

Remove the cable from the sonde “17”

of gure 1;

lay the bipolar cable with a minimum

1.5mm2 section which goes from the

boiler to the temperature sensor of the

storage tank and connect it on the boiler

to terminals “15” and “16” (SB);

connect the other end of the cable to

the temperature sensor of the storage

tank;

insert the probe of the temperature

sensor into the socket of the storage

tank (see gure 20, detail 14).

5.16.1 - Prevention

against Legionnaires

disease

See chapter 5.15.1.

Figure 20 - hydraulic connection to BWR C type storage

tank

1 COSMOGAS boiler

2 3 4 Gas supply

5 6 Connection for lling the heating

system (to be carried out by the

installer)

7 BWR C type storage tank

8 Domestic hot water outlet

9 Cold water inlet

10 Supply and return for storage

tank loading

11 Hydraulic safety unit (to be tted

by installer)

12 Supply pipe to heating system

13 Retur n pipe from heat i n g

system

14 Temperature sensor socket

Figure 21 - Electrical connection to a B70C or BWR C type water heater

5 - INSTALLATION

Page 22

22

5 - INSTALLATION

5.17 - Venting systems

CAUTION!!! All venting systems

must be connected in compliance with

current national and local standards.

CAUTION!!! Under determinate

conditions, the temperature of the

appliance’s ue gases may reach 110°C.

Therefore, use plastic piping capable of

resisting this temperature.

CAUTION!!! This is a

“condensation-type” appliance. In order

to create the ue gas discharge, use

materials in AISI 316L stainless steel or

plastic materials in polypropylene, so as

to avoid corrosion due to the acidity of

the condensation.

Remember that this type of appliance must

have discharge and intake pipes supplied by

the appliance manufacturer.

Any other types of pipe must be approved.

The approved types of ue gas discharge

system are given in the table of technical

features at the end of the manual, under the

heading “type”, and on the boiler rating plate,

again under the heading “type”. The symbols

used to dene the type of discharge system

are as follows(see also g.22):

- C13, coaxial through vertical wall;

- C33, coaxial through the roof;

- C43, separate with discharge in the

chimney, intake through another same

channel;

- C53, separate discharge through roof and

intake through wall, or in two places with

potentially different pressure;

- C63, the boiler can be tted to approved

intake and discharge pipes of another

manufacturer;

- C83, separate with intake through the wall,

or another point, independent of venting for

other appliances, with discharge into the

chimney ue.

During operation, especially in Winter,

again due to high efciency, the boiler may

discharge white smoke. This is a purely

natural phenomenon and not a reason for

concern, as it is steam from the gas fumes

condensing on contact with the outside air.

Figure 22 - Approved discharge/intake systems

Page 23

23

5.17.1 - “Split 80/80PP”

system (polypropylene)

The standard appliance is not supplied with

ttings for connecting ue gas discharge outlets/

air intakes. A special kit is available on request

for connecting the boiler to the “split 80/80PP

system”, to be installed following gure 23.

Fitting “A” can freely turn 360 degrees, thereby

guaranteeing optimum installation versatility.

It is advisable to install AISI 316L type

stainless steel pipes or polypropylene pipes

on the ue gas discharge side, which are more

resistant to the formation of condensation.

Take particular care when installing piping

through a wall to the outside; install the pipes

in sheathing so that they can be easily slipped

out for access during routine maintenance.

Horizontal sections must always be pitched by

at least 2% towards the condensation drainage

system.

The boiler comes supplied with a condensation

collector which must be tted to a discharge

pipe (see

section 5.10).

CAUTION!!! This condensation

drainage system is designed to empty all the

liquid produced by one single appliance. If

installing more than one boiler, each must be

equipped with its own drainage system.

The ue gas discharge/air intake systems can

be extended up to the maximum distance given

in section 9 at the end of the manual. Each

90° elbow has an equivalent loss of 1 metre of

straight pipe. Each 45° elbow has an equivalent

loss of 0.5 m of straight pipe.

CAUTION!!! Mechanically secure the

joints between the different components of

the ue gas discharge and intake pipes with

xing screws or equivalent systems. See

gure 25.

CAUTION!!! During operation, the

temperature of the discharge pipe can exceed

110°C. Insert protective heat insulating

sheathing if it has to pass through walls

which are vulnerable to such temperatures.

CAUTION!!! Leave a minimum gap of

1 metre between the air intake and ue gas

discharge terminals if they are located on the

same wall.

Figure 25 - Fixing the ue gas discharge and air intake

pipes

5 - INSTALLATION

Figure 23 - Installation of “split 80/80 PP” system

Figure 24 - Dimensions

Page 24

24

5 - INSTALLATION

5.17.2 - “Split 80/80PP”

system: available

accessories

Some of the most commonly used accessories for

installing the split system of ue gas discharge/air intake

80/80PP are listed below; a much wider range however

can be found in the special catalogue:

(the number after the code refers to the part in the

following drawings)

62617053 - No. 9 chimney cap draft damper for the

roof

62617244 - No. 12 90° elbow M/F in PP

62617255 - No. 29 ashing for roofs pitched between

15° and 25°

62617236 - No. 11 extension M/F in PP

62617248 - No. 18 anti-extraction clamp for PP

extensions

62617240 - No. 14 exible M/F pipe in PP L=20m

62617241 - No. 16 spacer for exible pipe

62617238 - No. 17 telescopic joint in PP

62617242 - No. 15 T tting in PP

Page 25

25

5 - INSTALLATION

5.17.3 - “Split

80/80PP” system:

installation

examples

Two installation examples can be seen

in gure 26:

- discharge into chimney with collection of

condensation at base of the chimney.

The hor izontal part of the flue gas

discharge side must be pitched towards

the “T” with condensation collection.

The intake must be pitched outward to

prevent rainwater entering.

- discharge directly outside with the

pipes of the boiler with collection of

condensation inside the boiler itself.

The intake must be pitched outward to

prevent rainwater entering.

A separate type flue gas discharge

example can be seen in gure 27 where

the discharge of the ue gases is carried

out with plastic exible pipes, for piping

of technical pits.

All the condensation produced in the

vertical pipe is conveyed inside the

boiler

The intake must be pitched outward to

prevent rainwater entering.

Figure 26 - Installation example “Split 80/80 PP” system

Figure 27 - Installation example “Split 80/80 PP” system

Page 26

26

5.17.4 - “Coaxial

60/100PP” system

(polypropylene)

The standard appliance is not

supplied with ttings for connecting

ue gas discharge outlets/air intakes.

A special kit is available on request

for connecting the boiler to a “coaxial

60/100PP” system, to be installed as

shown in gure 28, where the vertical

discharge is shown on the left under

letter “A” and the horizontal discharge

on the right under letter “B”:

CAUTION!!! Scrupulously

follow the installation steps for the

coaxial pipe as illustrated in gure 26.

In particular, it is necessary to

insert the coaxial pipe “C” inside elbow

“A”;

secure the outer pipe with stainless

steel self-tapping screws “B”.

CAUTION!!! After the above

operations, check that the end of

the discharge/intake faces outwards

with the tolerances shown in gure

31.

Take particular care when installing

piping through a wall to the outside;

install the piping in sheathing so that

it can be easily slipped out for access

during routine maintenance.

Horizontal sections must always be

pitched by at least 2% towards the

boiler.

The ue gas discharge/air intake pipe

can be extended up to the maximum

distance given in the table in section

9 at the end of the manual.

5 - INSTALLATION

Figure 28 - Installation of the vertical coaxial system (A) or

the horizontal coaxial system (B)

A

B

Figure 29 - Pre-installation gures and distances between

holes for coaxial discharge system

Figure 30 - Positioning of the coaxial pipe

Page 27

27

5 - INSTALLATION

5.17.5 - “Coaxial 60/100

PP” system: available

accessories

The following accessories are available, on request,

for installing the ue gas discharge/air intake system

60/100:

(the number after the code refers to the part in the

following drawings)

62617255 - No. 2 ashing for roofs pitched between

15° and 25°

62617234 - No. 1 Coaxial elbow 90° M/F PP

62617252 - No. 6 Coaxial elbow 45° M/F PP

62617231 - No. 7 Coaxial extension L 1m PP

62617250 - No. 3 Coaxial roof end piece PP

62617232 - No. 5 Coaxial wall end piece PP

Page 28

28

5 - INSTALLATION

5.17.6 - “Coaxial

60/100PP” system:

installation

examples

When a coaxial discharge is installed

(see gure 31), whether it is vertical or

horizontal, it is indispensable to slope the

discharge pipe upwards so as to get the

condensation to ow inside the boiler.

Figure 31 - Installation examples for the coaxial pipe

Page 29

29

6.1 - Operating

Before starting the appliance up, it is

necessary to carry out the following.

6 . 1 . 1 - U s e r

instructions

The user must be correctly instructed

on how to operate the appliance, in

particular:

Make sure that the user has the

instruction and users’ manual and all

other documentation included in the

packaging.

Make sure the user is informed of

all the special measures to be taken

for discharging ue gases, and that

these must not be modied.

Inform the user with regards to

adjusting the water pressure in the

system and all necessary measures

for lling and bleeding air.

Correctly inform the user on how to

adjust temperatures, controls/room

thermostats and radiators to save

energy.

6.1. 2 - F illi n g o f

the condensation

discharge trap

The trap is positioned inside the boiler

(see gure 1, detail 40), and must be

lled with water in order to create the

head capable of avoiding the leakage of

the ue gases from the pipe “36” of gure

1. Proceed as follows for this purpose:

disconnect the ue gas discharge

tting from opening “2” as per gure

1;

6 - OPERATING

remove the tube previously

connected and check that there are

no water leakages.

6.2 - General warnings

c o n c e r n i n g g a s

supply

When starting up the boiler for the rst

time, have qualied technicians check

the following:

That the boiler is powered by the

type of fuel it is designed to use.

That the gas supply pressure (with

boiler on and boiler off) is within

the maximum and minimum values

given in the table in section 9 at the

end of the manual.

That the gas supply system is

provided with all the safety devices

and controls required under current

national and local legislation.

That the ue gas discharge terminal

and the air intake terminal are free

from any blockages.

That the condensation discharge

connection is connected.

CAUTION !!! If you smell

gas:

A - Do not use any electrical

appliance, including

telephones or any object

which might cause sparks;

B - Immediately open doors and

windows to produce a current

of air to rapidly clear all gas

from the room;

C - Immediately call, from

another room or from a

neighbour’s house, a qualied

technician or the gas board. If

you cannot contact them, call

the Fire Brigade.

Figure 32 - Bleed screws of

the secondary heat exchanger

from the central opening (ue

gas discharge), slowly pour in

approximately 100 cm3 (a glass full)

of water;

re-connect the ue gas discharge

tting;

6.1.3 - Filling the

heating system

If at the time of switching on the power

to the boiler, FILL appears on the

display, it means that it is necessary

to ll the heating system. Proceed as

follows:

The heating system must only be

lled with clean water from the mains

supply.

CAUTION!!! The addition

of any chemical substance, such

as anti-freeze, must be carried

out according to the product

instructions. These substances

must never be inserted directly into

the boiler.

Open the automatic air vent a

couple of turns (see gure 1, detail

“1”) situated at the top of the boiler.

Open the supply cock located under

the boiler (see gure 1, detail “34”)

and proceed to ll the system and

appliance to about 1.5 bar (FILL

disappears from the display).

Check that there is no water leaking

from the ttings.

Close the supply cock (see gure 1,

detail “34”);

Purging the air from the radiators.

Check the pressure gauge reading

of the boiler once again. If it has

dropped, re-ll again until its reads

1.5 bar

6.1.4 - Filling of the

secondary heat

exchanger of the

domestic hot water

Once the heating circuit has been lled, it

is also necessary to carry out the lling of

the secondary heat exchanger. Proceed

as follows:

connect a rubber tube to the

pressure coupling “A” shown in

gure 32 and take it to the discharge

of a sink or similar;

loosen screw “A” as shown in gure

32 until you hear the air escape and

wait until just water runs out;

tighten screw “A” once again as

shown in gure 32;

A

Page 30

30

Figure 33 - Gas valve

C - Service pressure probe

D - Gas inlet pressure probe

E - CO2 adjusting screws

6.3 - Gas type

indicated for the

boiler

On the front of the boiler there is a

label indicating the type and supply

pressure of gas to be used for the

boiler.

The boiler can have one of the

following two labels:

2H-G20-20mbar

NATURAL GAS

means that the appliance should be

used with gas type H of the second

family (natural gas), at a supply

pressure of 20 mbar.

3P-G31-30mbar

L.P. Gas

means that the appliance should be

used with gas type P (Propane also

known as L.P.Gas) of the third family,

at a xed supply pressure of 30 mbar

6.4 - Converting the

boiler from one gas

type to another

Conversion of the appliance to use

another type of gas must be carried out

by a qualied technician.

If the gas available is not of the type to

be used with the appliance, it must be

converted. Special conversion kits are

available for this purpose.

6.5 - Start-up

Open the gas cock.

Swit ch on el ectri c powe r to the

boiler.

If the display shows code E 21, it

means that the polarity has not been

observed between phase and neutral.

Therefore it is necessary to rotate

them.

Upon start-up, an F is shown for 2

minutes during which the purging

of the plant takes place. If you wish

to by-pass this stage, just press the

keys + and - together until a blinking

F appears. Then press the RESET

button.

Rotate the controls “30” and “31”

shown in figure 1 to the desired

temperature.

The heating service will only start up

when the room thermostat calls for

heating. If an external temperature

sensor is connected, check that the

temperature calculated is higher than

the minimum running temperature

(see section 7.4).

If the pump indicator is illuminated but

the pump (see gure 1 detail “39”) is

not running, try releasing it using the

special screw (remove the screw “47”

shown in gure 1 and turn the screw

underneath).

If the pump indicator is illuminated but

the radiators do not heat up, repeat air

bleeding operations on both the boiler

and the radiators.

6.5.1 - Auto-purging

Each time the power supply to the

appliance is switched on, a procedure

for the auto-purging of the air in the

plant commences, lasting 2 minutes.

The procedure involves the switching on

and off of the pump in order to facilitate

the evacuation of the air. Before starting

the procedure up, ensure that you have

opened the automatic air vent (detail “1”

of gure 1).

6.6 - Checking and

adjusting the gas

supply pressure

The gas supply pressure must match

that given in the table in section 9

at the end of this manual. Check as

follows:

close the gas cock;

access the internal components of

the boiler following the procedure in

section 8.2;

loosen the pressure connection “D”

(see gure 33);

connect a pressure gauge with a

denition of at least 0.1 mbar (1

mmH2O);

open the gas cock;

check that the pressure does not