COSMOGAS BMS 10/20, BTS 15/29, BMS 15/29, BTS 10/20 Instruction Manual

INSTRUCTION MANUAL

For installation, use and

maintenance for the

MODELS:

BMS & BTS

Direct V ent

Space / Water Heater

Combined Appliance

For Heating and Domestic Hot Water

These instructions MUST be read prior to installation and

left near the appliance when the installation is completed.

Text complies with minimum size requirements.

U.S.A.

62403262R04 -06/02

2

SAFETY INSTRUCTIONS

WARNING: If the information in this manual

is not followed exactly , a fire or explosion

may result causing property damage,

personal injury or death.

— Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this or any other appliance.

— WHAT TO DO IF YOU SMELL GAS

• Do not try to light any appliance.

• Do not touch any electrical switch; do

not use any phone in your building.

• Immediately call your gas supplier

from a neighbor’s phone. Follow the

gas supplier’s instructions.

• If you cannot reach your gas supplier ,

call the fire department.

—Installation and service must be

performed by a qualified installer , service

agency or the gas supplier.

FOR YOUR SAFETY

Do not store or use gasoline or other flammable,

combustible, or corrosive vapors and liquids in

the vicinity of this or any other appliance.

3

These instructions must be read prior to installation. If the information in these instructions

is not followed exactly, a fire or explosion may result, causing property damage, personal

injury, or death.

Hazards and Your Safety - Hot Water Can Scald!

Water temperature over 125°F can cause severe burns instantly, or death from scalds.

Children, disabled, and elderly are at highest risk of being scalded; see instruction manual

before setting temperature at water heater! Feel water before bathing or showering.

Temperature limiting valves are available, see manual.

If there is a smell of gas:

-Turn the gas cock off - Air the room - Do not try to light any appliances - Do not use any

phone in your building - Do not touch any electrical switch - Extinguish any flames - Call

immediately a licensed authorized technician or your local gas company - Follow the gas

supplier’s instructions - If you cannot reach your gas supplier, call the fire department.

If there is a smell of combustion products:

-Turn the unit off - Air the room - Call a licensed authorized technician.

Installation, alterations

Licensed authorized personnel must carry out the installation, calibration or alteration of

the gas apparatus. Flue gas ducts must not be modified in any way. Any replaced part or

packaging parts should never be left within reach of children.

Explosive products or easily inflammable products

Do not keep, use or store explosive materials or easily inflammable materials such as

Gasoline, Adhesives, Solvents, Paint Thinner, Butane, Liquefied Propane, paper, etc., near

the heater.

Maintenance

The user, according to the heater’s operating instructions, has to keep the installation in

good condition and guarantee the reliable, safe operation of the heater. At least once a year

the user must call in a licensed authorized technician for routine maintenance, before

using it for central heating.

Servicing Manual

When the installation and commissioning of the system has been completed, the installer

should instruct the homeowner to save the installation manual near the heater so that

service technicians may refer to it in the future.

Caution: Label all wires prior to disconnection when servicing controls. Wiring errors can

cause improper and dangerous operation. V

ERIFY PROPER OPERATION AFTER SERVICING.

Do not use this appliance if any part has been under water . Immediately call a qualified

service technician to inspect the appliance and to replace any part of the control system

and any gas control, which has been under water.

SAFETY INSTRUCTIONS

4

GENERAL INFORMATION

This instruction manual refers to two types of heaters, the BMS and the BTS.

BMS - this appliance is a wall mounted, direct vent space/water heater

BTS - this appliance is a self standing floor model, direct vent space/water heater

Each type of heater can be of two different input power rating; a 10/20 or 15/29;

10/20 has an input power rating of 87,000 Btu/hr (26 kW)

15/29 has an input power rating of 107,000 Btu/hr (31.6 kW)

BMS 10/20

or

BMS 15/29

or

BTS 10/20

or

BTS 15/29

When referring to this instruction manual, be sure of which type of heater you are

working with. This can be verified by referring to the data plate marked “Space water

heater model” . This data plate is located on the bottom side of the BMS, or on the

inside of the front door (internal side) of the BTS.

Also verify the type of gas for which the heater is set. A label in the front of your heater

states “NA TURAL GAS”, for heaters set to natural gas, or “LP GAS” for heaters set to

LP gas.

5

GENERAL INFORMA TION ...................................................................................................... 4

T ABLE OF CONTENTS .......................................................................................................... 5

GENERAL LA YOUT of the main components of model BMS ............................................... 7

GENERAL LA YOUT of the main components of model BTS................................................ 9

A INST ALLA TION INSTRUCTIONS ..................................................................................... 11

1 Operating and adjusting the output to the radiation system ...................................... 11

2 Location ..................................................................................................................... 11

3 Installation ................................................................................................................. 11

3.1 Installation template ........................................................................................ 12

3.1.1 Clearances for installation ............................................................................ 12

3.2 Safety Relief V alve ........................................................................................... 13

3.3 Heating supply and Return .............................................................................. 1 3

3.3.1 Installation of two heaters............................................................................. 13

3.3.2 Installation of three or more heaters ............................................................ 1 3

3.3.3 Radiant heating installation .......................................................................... 13

3.3.4 Used of glycol................................................................................................ 1 3

3.4 Domestic Hot and Cold water ......................................................................... 1 4

3.5 Water Hardness............................................................................................... 14

3.6 Gas Supply ....................................................................................................... 14

3.6 Gas Supply (cont.)............................................................................................ 15

3.7 Room Thermostat Connection ........................................................................ 15

3.8 Electrical Supply Connection ........................................................................... 1 5

4 VENTING SYSTEMS .................................................................................................. 17

4.1 Concentric Flue (Coaxial) ................................................................................ 17

4.2 Split Flue .......................................................................................................... 1 9

4.3 Chimney Venting .............................................................................................. 1 9

4.4 Venting Locations - Outside Walls (Direct Venting) ......................................... 19

4.5 Kit for air intake/flue discharge ........................................................................ 1 9

4.7 Water Connections for Model BMS .................................................................. 32

4.8 Water Connections for Model BTS................................................................... 33

5 REGULA TING THE DOMESTIC HOT W A TER ............................................................ 40

6 BURNER ................................................................................................................... 40

6.1 Changing the Gas Type ................................................................................... 4 0

6.2 Adjusting Gas Flow and Pressure to the Burner............................................. 4 0

7 WIRING DIAGRAMS................................................................................................... 41

B OPERA TING AND MAINTENANCE INSTRUCTIONS for BMS ........................................... 44

9 BMS model; INSTRUCTION FOR USE ...................................................................... 44

9.1 Start-Up Instructions ........................................................................................ 4 4

9.2 Checks Prior to Ignition.................................................................................... 4 4

9.3 Ignition Procedure............................................................................................ 4 4

9.4 Summer-Winter Mode...................................................................................... 4 5

9.5 Adjusting Central Heating................................................................................ 4 5

9.6 Manual Reset High-Limit Thermostat ............................................................. 45

9.7 Resetting the Ignition Module .......................................................................... 4 5

9.8 Heating Circulator Pump ................................................................................. 4 5

9.9 Low water cut-off device................................................................................... 45

T ABLE OF CONTENTS

6

9.10 Shut-Down Procedure ................................................................................... 45

9.11 Maintenance ................................................................................................... 45

9.12 Draining water from the heater ...................................................................... 4 5

C OPERA TING AND MAINTENANCE INSTRUCTIONS for BTS ............................................ 46

10 - BTS model - INSTRUCTIONS FOR USE ............................................................... 46

10.1 Start-Up Instructions ...................................................................................... 4 6

10.2 Checks Prior to Ignition.................................................................................. 4 6

10.3 Ignition Procedure .......................................................................................... 4 6

10.4 Summer-Winter Mode .................................................................................... 4 7

10.5 Adjusting Central Heating .............................................................................. 47

10.6 Manual Reset High-Limit Thermostat ........................................................... 47

10.7 Resetting the Ignition Module ........................................................................ 4 7

10.8 Heating Circulator Pump ............................................................................... 47

10.9 Low water cut-off device................................................................................. 47

10.10 Shut-Down Procedure ................................................................................. 47

10.11 Maintenance ................................................................................................. 47

10.12 Draining water from the heater.................................................................... 4 7

D TROUBLESHOOTING ...................................................................................................... 48

11 Troubleshooting Sequence of Operation to Light the Burner................................... 48

12 Troubleshooting Sequence of Operation for a Call for Heat .................................... 49

E IMPORT ANT INFORMATION FOR THE CUSTOMER ......................................................... 51

F SP ARE PARTS ................................................................................................................ 52

G TECHNICAL FEA TURES .................................................................................................. 53

NOTES................................................................................................................................ 55

T ABLE OF CONTENTS

7

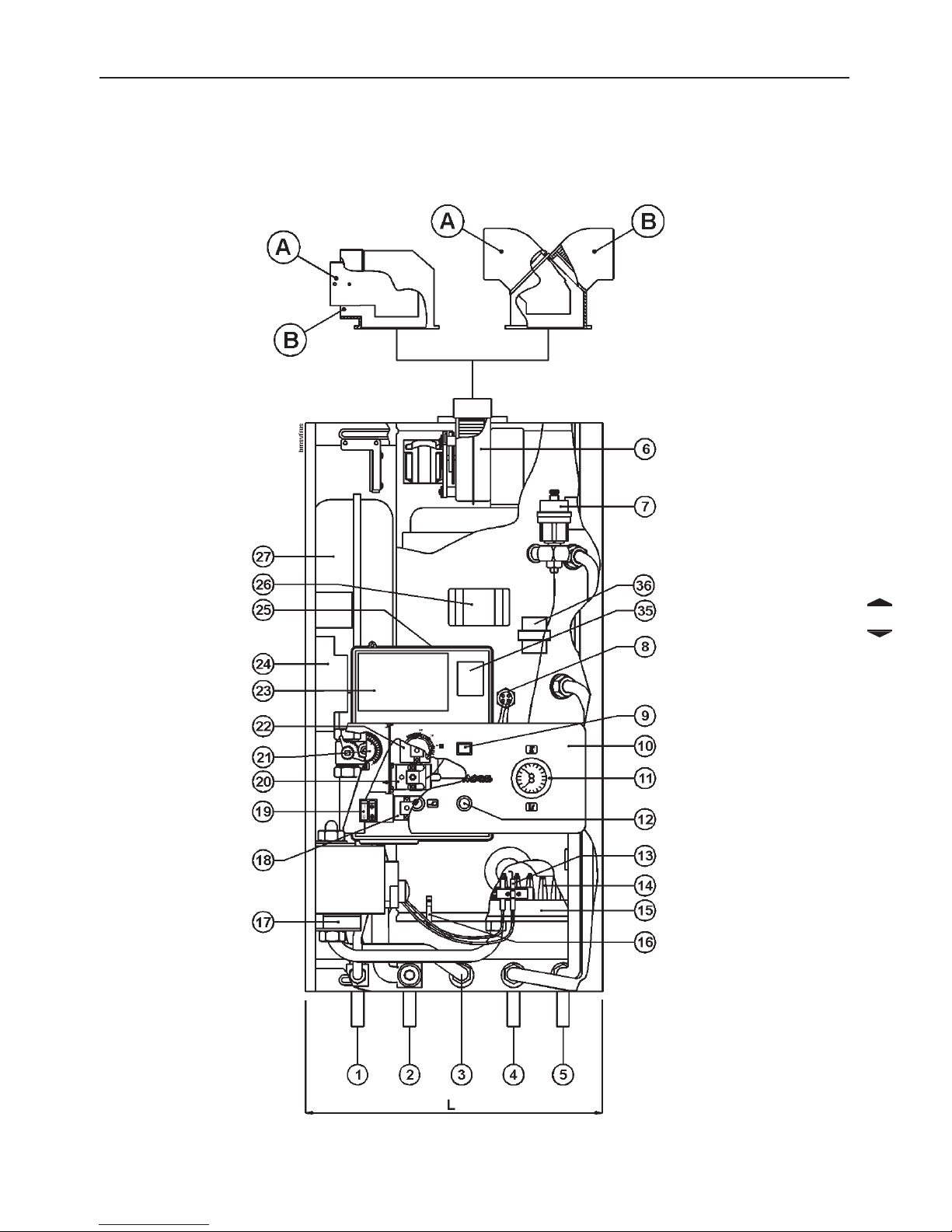

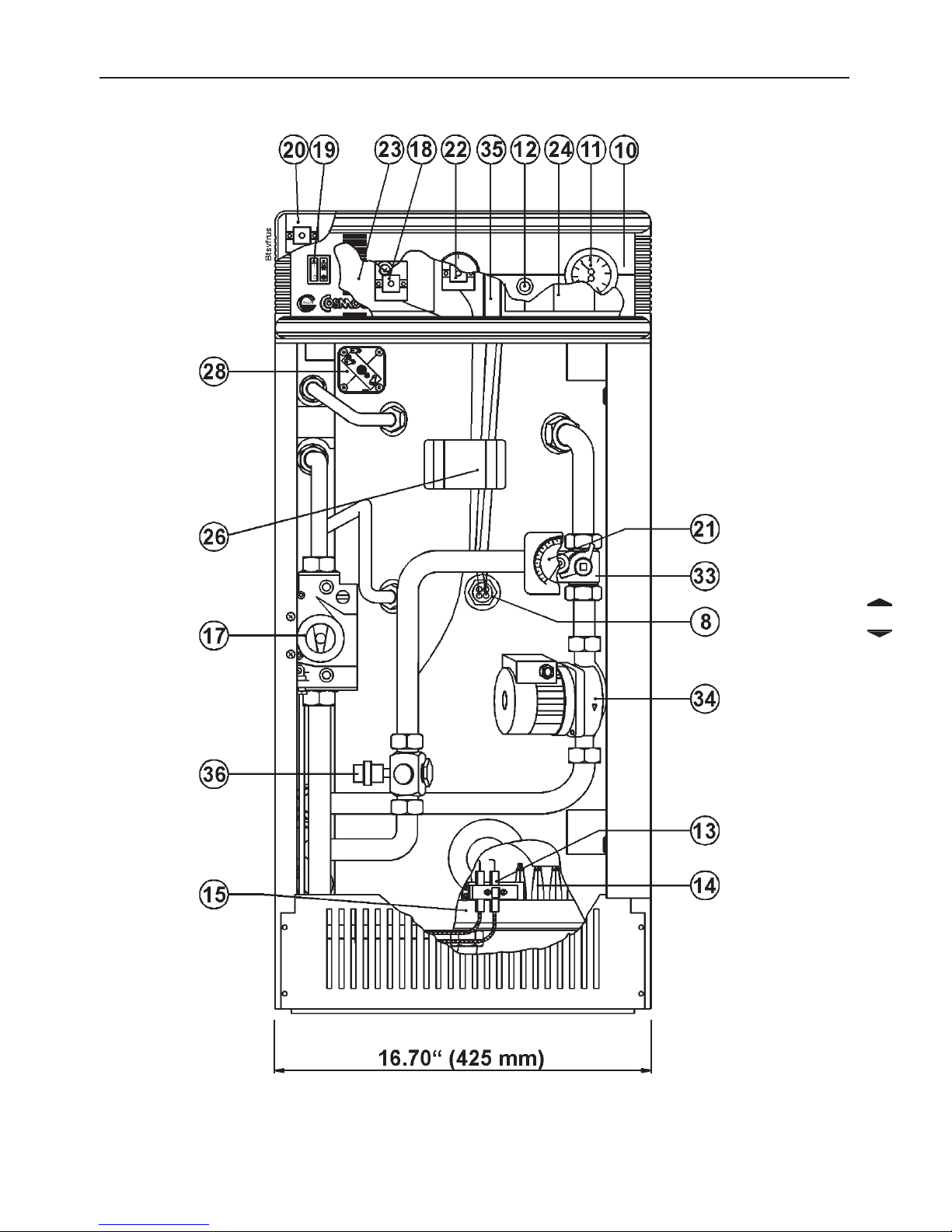

GENERAL LA YOUT of the main components of model BMS

Figure 1 - BMS Front view

Coaxial discharge

Split discharge

A = Flue discharge

B = Air intake

8

GENERAL LA YOUT of the main components of model BMS

Figure 2 - BMS Side and top views

1 Central heating supply

2 Central heating return

3 Gas inlet

4 Domestic hot water outlet

5 Cold water inlet

6 Flue gas discharge fan

7 Automatic air vent

8 Thermostat bulb pocket

9 Gas valve service switch

10 Instrument panel

11 Temperature-pressure gauge

12 Failure lamp indicator

13 Ignition and detection electrodes

14 Burner

15 Gas manifold

16 Exchanger shell clamps

17 Gas valve

18 High limit thermostat

19 Power and circulator pump switches

20 Domestic hot water priority

thermostat

21 Central heating regulation knob

22 Heater temperature control

23 Electrical control board

24 Ignition module

25 Electrical plastic cover

26 Electrical junction box

27 Expansion tank

28 Pressure switch

29 Domestic water heat exchanger

30 Heat exchanger

31 Turbulator

32 Support bracket

33 Central heating regulation valve

34 Circulator pump

35 Transformer

36 Low water cut-off

9

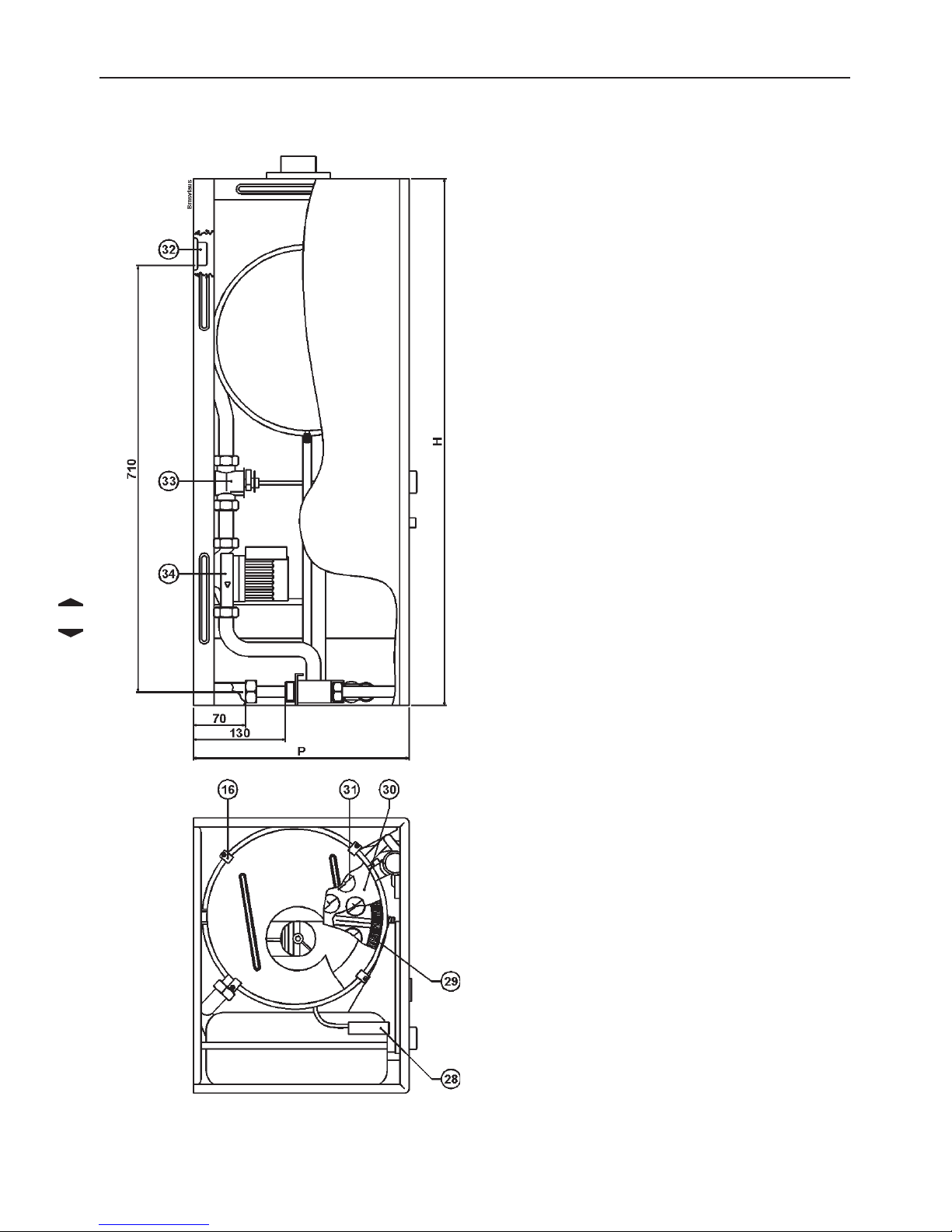

GENERAL LA YOUT of the main components of model BTS

Figure 3 - BTS Front view

10

GENERAL LA YOUT of the main components of model BTS

1 Central heating supply

2 Central heating return

3 Gas inlet

4 Domestic hot water outlet

5 Cold water inlet

6 Flue gas discharge fan

7 Automatic air vent

8 Thermostat bulb pocket

9- 10 Instrument panel

11 Temperature-pressure gauge

12 Failure lamp indicator

13 Ignition and detection electrodes

14 Burner

15 Gas manifold

16 - 17 Gas valve

18 High limit thermostat

19 Power and circulator pump switches

20 Domestic hot water priority

thermostat

21 Central heating regulation knob

22 Heater temperature control

23 Electrical control board

24 Ignition module

25 - 26 Electrical junction box

27 Expansion tank

28 Pressure switch

29 - 30 - 31 - 32 - 33 Central heating regulation valve

34 Circulator pump

35 Transformer

36 Low water cut-off

A Flue discharge

B Air intake

Figure 4 - BTS side view

11

A INSTALLATION INSTRUCTIONS

1 Operating and adjusting the

output to the radiation system

The COSMOGAS heater can be installed in

any domestic or light commercial building

where the maximum BTU/H required is not

greater than 88,800 BTU/H.

The unit has a internal mixing valve (heating

side only) that can be adjusted to regulate

the supply water temperature delivered to

the heating system.

The heating system will not receive any water

unless the water temperature inside of the

heater is at a minimum of 140°F. The heater

built-in domestic hot water priority thermostat

will cease the power to the circulator until

the temperature is greater than 140°F.

2 Location

This space/water heater unit is not intended for

outdoor installation. Choose a location centralized

to the piping system along with consideration to

the vent pipe length. Additionally, you will need to

place the space/water heater so that the controls,

drain, inlet/outlet, and gas valve are easily

accessed. Also, care must be exercised when

choosing the location of this appliance, where

leakage from the safety relief valves, leakage from

related piping, or connections, will not result in

damage to the surrounding areas, or to the lower

floor of the building.

No valve is to be placed between the safety relief

valves and the heater. The discharge from the

temperature and pressure relief valve must be

conducted to a suitable place for disposal. No

reducing coupling or other restriction shall be

installed in the discharge line. The discharge line

should allow complete drainage of both valve and

line.

3 Installation

The installation must conform to local codes and

ordinances or, in the absence of local codes, the

National Fuel Gas Code ANSI Z 223.1/NFPA 54

- 1984. When installed the appliance must be

electrically grounded in accordance with the

National Electrical Code, ANSI/NFPA No.70 -

1987.

For Canada, the installation should conform to

CGA B149.1 INST ALLA TION CODES and/or local

installation codes.

The gas supply piping system should be tested

before the heater is connected.

The heater, (complete with all its parts: external

jacket, intake and discharge flue pipes, etc.), must

be installed leaving a distance of at least 10 cm,

(4”), from sidewalls and ceiling.

Installation of the BTS combi directly on combustible

flooring such as carpeting shall be installed on a

metal or wood panel extending behind the full width

and depth of the appliance by at least 3”, (76.2

mm), in any direction or, if the appliance is installed

in an alcove or closet, the entire floor shall be

covered by the panel.

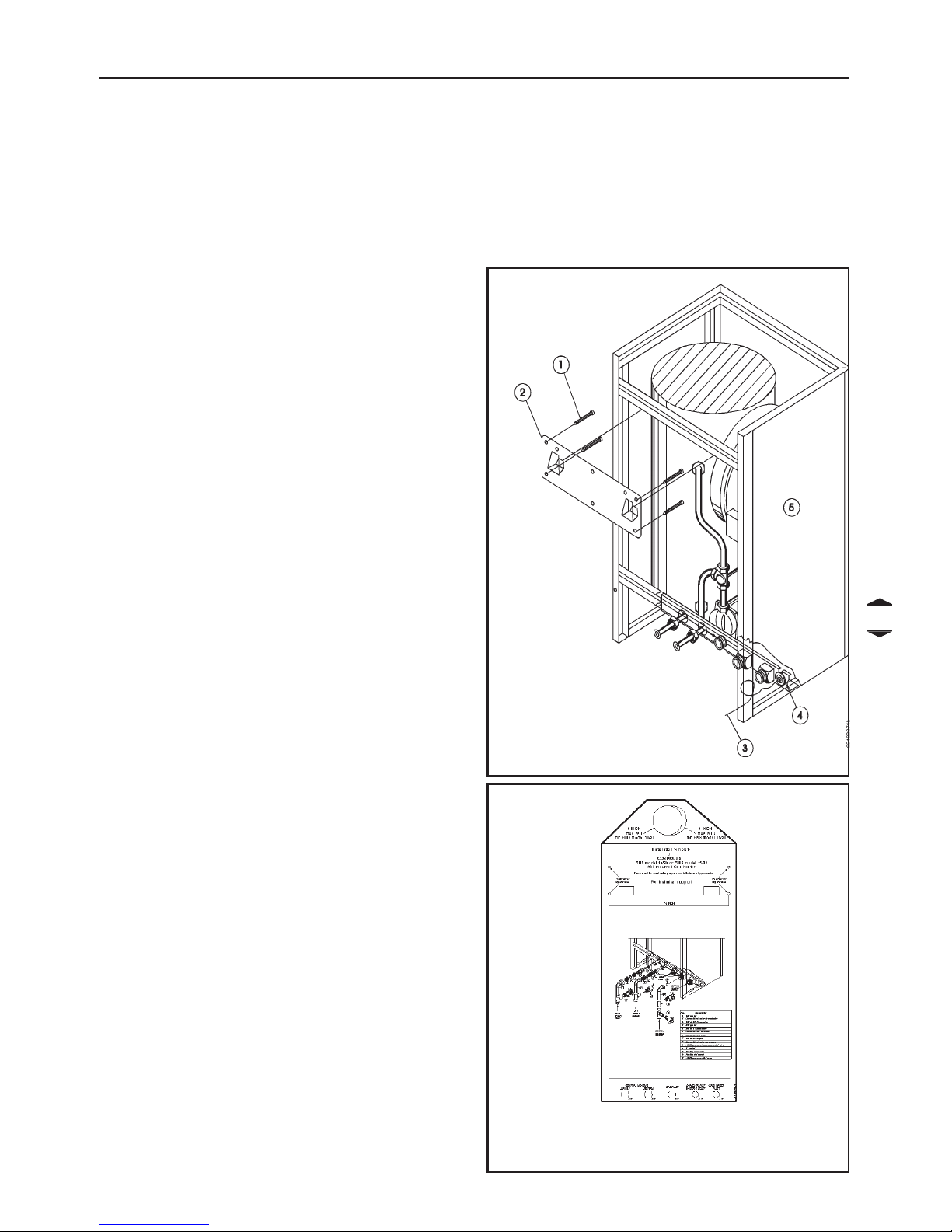

Figure 5 - Installation template, Only

for model BMS

Figure 4A

12

3.1 Installation

template

ONL Y model BMS is provided

with an installation template

to facilitate proper installation

alignments (See figure 5

below).

3.1.1 Clearances for

installation

The figures 5A and 5B show the

proper distances to keep from

any obstacle pertaining to the

support bracket (2) or to the wall.

The procedure for installing the

BMS is as follow:

1) - Take the support bracket (2)

and choose a position with proper

clearances, as per Figures 5A &

5B. A minimum clearance of 40”

(1000mm) is required from the

front of the heater.

WARNING: Please take caution

when choosing a mounting

surface for the heater. The

weight of the heater with water

is approximately 165 lbs. Make

certain that the wall can support

such weight.

2) Screw the bracket to the wall.

The screws MUST screwed in

correspondence of the 16"

vertical studs (see figures 4A and

5A)

3) Place the template onto the

support bracket and make all

rough-in holes for the piping to

the heater. The hole for the

coaxial flue vent kit discharge may

also be cut at this time.

4) Install the heater on the support

bracket and secure all of the

connections.

Figure 5A - Clearances for model BMS

Figure 5B - Clearances for model BTS

A INST ALLA TION INSTRUCTIONS

13

A INSTALLATION INSTRUCTIONS

3.2 Safety Relief Valve

An ASME approved safety relief valve, (set at

30 psi), must be installed in a vertical

position on the outlet side of the central

heating system, and as close as possible

to the heater. There must be no valves

between the safety relief valve and the heater.

Manually operate the safety relief valve at

least once a year to ensure proper operation.

Precaution must be taken prior to operating

the safety relief valve, to avoid contact with

hot water coming out of the safety relief valve

and to prevent water damege.

If the safety relief valve discharges

periodically, this may be due to thermal

expansion in a closed water supply system.

Contact the water supplier or local plumbing

inspector on how to correct this situation.

Do not plug the safety relief valve.

3.3 Heating supply and Return

The central heating supply and return pipes

are marked with different colored caps,

(supply red and return blue).

If there are any heating elements above

heater level, it is advisable to install a check

valve on the supply pipe to prevent “natural

circulation” phenomena from occurring.

If the heater is to be connected to an existing

system it is advisable to wash out and

remove any deposits from inside the existing

pipes, and install a filter at the lowest point

to trap any additional impurities when it is

running.

This equipment is designed for use in a

closed loop system.

Installation schematics are found in figures

23 to 28.

WARNING !!! All the schematics in figures

23 to 28 are only samplesl. Safety apparatus,

pipe diameters, and auxiliary accessories,

must be verified by a qualified personnel only

and in accordance with the national and/or

local codes.

3.3.1 Installation of two heaters

Iinstalling two heaters in parallel. Follow the

schema in the figure 23

3.3.2 Installation of three or more

heaters

Installing three or more heaters in parallel.

Follow the schema in the figure 24

3.3.3 Radiant heating installation

When the heater is used in conjuction with

radiant heating, it is imperative that the tubing

contains an oxygen diffusion barrier. If you

are unsure whether or not the tubing has a

barrier, a heat exchanger must be used to

protect the heater from oxygen corrosion

(See figure 25). This situation will also occur

if the heater is used on an open-loop system

where new, cold-fill water is introduced into

the system. The oxygen will remove itself

from solution and react chemically with the

ferrous components (i.e. steel), causing

them to rust and corrode. THIS TYPE OF

FAILURE IS NOT COVERED BY THE

WARRANTY!

3.3.4 Used of glycol

If glycol is used with the heater, the glycol

must be recognized as safe or approved by

the United States Food and Drug

Administration for food contact as listed in

Code of Federal Regulations, title 21, part

182 of the Food Additive Regulations. Any

additives introduced into the heating system

must be recognized as safe by the United

States Food and Drug Administration. If a

non-approved additive is used, it can cause

serious health problems or possibly

death.The pressure of the heating system

side of the heater must be fitted with devices

(automatic water feed/pressure reducing

valve not to exceed 30 psi) arranged to

function automatically in order to maintain

the pressure of the heating side at a level

below that of the potable water leaving the

heat exchanger.

14

3.4 Domestic Hot and Cold water

The domestic hot water flow restrictor must be

installed on the cold water inlet, (Refer to figure

25, 26, 27 and 28).

For servicing purposes, install a shut-off

valve upstream from the cold water inlet.

The heater’s thermostat can be regulated to

provide domestic hot water between 100°F

and 180°F. Water temperature over 125°F

can cause severe burns instantly. Since it is

required that the heater water temperature

reach above 140°F in order for the heating

system side of the unit to operate, it is

imperative that a mixing valve be installed

external of the heater to further regulate

the temperature of the domestic hot water

(See figures 23, 25, 26, 27 and 28). Failure

to install a domestic side mixing valve will

result in severe burns!

Piping and components connected to the

water heater for space heating shall be

suitable for use with potable water, and shall

not be connected to any heating system or

components previously used with a nonpotable water heating appliance.

The domestic hot water circuit needs an

ASME approved pressure relief valve, set at

150 psi, installed as close as possible to

the heater. There must be no valves

between the relief valve and the heater . The

relief valve discharge pipe must not be

restricted or plugged.

3.5 Water Hardness

In hard water areas (above 150 p.p.m), it is

recommended that a suitable water

treatment device (softener with filters) be

installed. Excessive buildup of minerals in

the heat exchanger can cause a nonwarranty failure. Water hardness can be

determined by using the standard test or by

checking with your local water authority.

Toxic chemicals, such as used for heater

treatment, should not be introduced into the

potable water used for space heating.

3.6 Gas Supply

Before making any gas connections, verify

that the heater is being supplied with same

gas type as indicated on the rating plate.

The rating plate is located on the front of the

BMS, and is located on the front door of the

BTS. This heater has orifices which will

operate at an altitude of up to 2,000 feet.

For installations in higher elevations, downrate the heater by 10%.

Install a manual gas cock outside of the

heater. Refer to Figures 1 and 3, item 3, for

the gas inlet location of the heater.

Gas piping to the heater must be sufficient

to guarantee a supply of gas to meet

maximum requirements. See Table 1 for

max. and min. values of gas pressure (Back

of manual).

All piping must comply with local codes

and ordinances or with the National Fuel

Gas Code, (ANSI Z223.1 NFPA No. 54),

whichever applies.

The appliance and its individual shutoff

valve must be disconnected from the gas

supply piping system during any pressure

testing of that system at test pressures in

excess of ½ psig, (3.5 kPa).

The appliance must be isolated from the

gas supply piping system by closing its

individual manual shutoff valve during any

pressure testing of the gas supply piping

system at test pressures equal to or less

than ½ psig, (3.5 kPa).

A INST ALLA TION INSTRUCTIONS

15

A INSTALLATION INSTRUCTIONS

Length of Gas Pipe Capacity of Gas Pipe Size in MBTUH

1/2" 3/4" 1" 1 1/4"

10'

132 278 520 1050

20'

92 190 350 730

30'

73 152 285 590

40'

63 130 245 500

50'

115 215 440

75'

93 175 360

100'

79 150 305

150'

64 120 250

Additional length

to be added for

1.3' 1.7' 2.2' 2.7'

each bend or tee

3.6 Gas Supply (cont.)

A Electrical supply

connection

B Room thermostat

connection

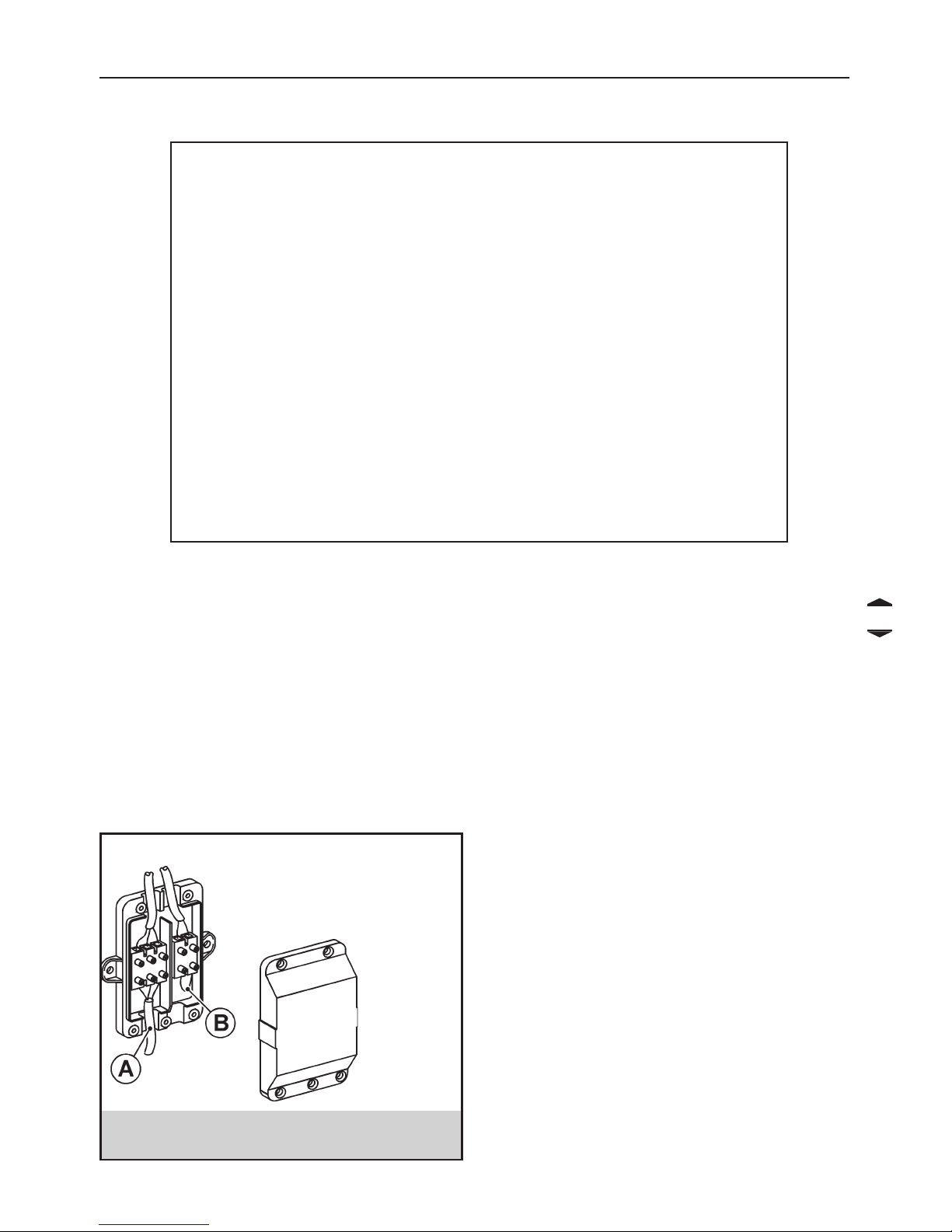

Figure 6 - Connecting the room

thermostat and electrical supply

3.7 Room Thermostat Connection

This is installed by removing the electrical junction

box cover indicated in fig.6, (see fig.1 and 3, item

26), and connecting the two wires of the room

thermostat, or zone valve control thermostat, to

the low voltage terminals, (figure 6, item B). NOTE:

first remove factory installed jumper from

terminals. The room thermostat must always

be located in a point of the house where the

temperature is not subject to sudden changes.

3.8 Electrical Supply Connection

The heater must be connected to a 115V

60Hz, single phase electrical supply fused

to 15 amps,

Grounding is required as well as the

installation of a main emergency switch

immediately upstream from the heater.

An electrical junction box (see figures 1

and 3, item 26) is provided for connections

for both the line voltage of 1 15V 60 Hz (See

figure 6 item A) , and the room thermostat

at low voltage of 24Vac (See figure 6 item

B).

The cable wire of the line voltage must be

insered into the heater, through the p asscable positioned in the side of the idraulic

connections (see figure 6A and 6B).

16

A INST ALLA TION INSTRUCTIONS

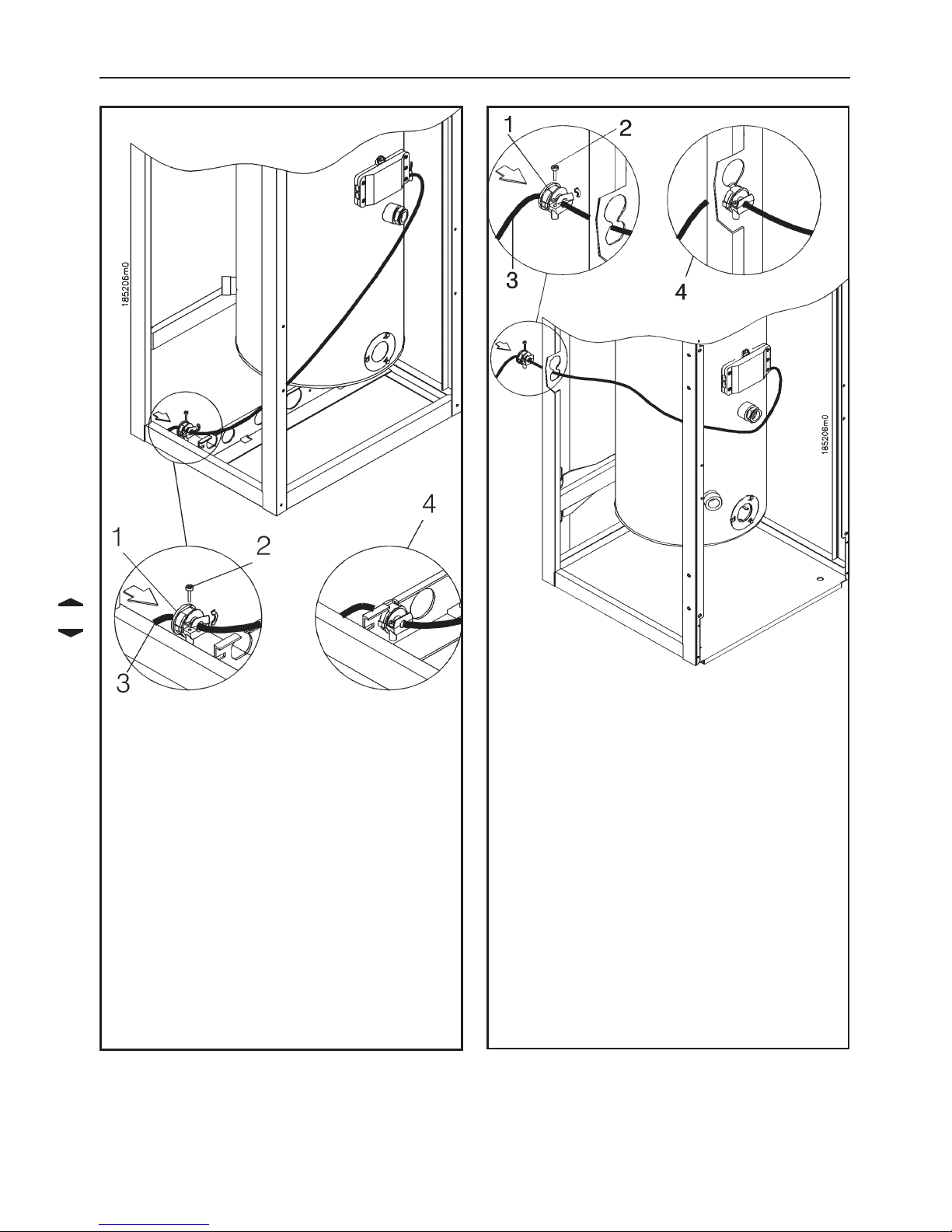

Figure 6A - Installation of the electrical

supply cable on the model BMS

a) Remove or loosen screw (2)

b) Pop- out the passage tunnel for the

supply cable. Pass the supply cable

through the passage (1)

c) Connect the supply cable to the

junction box

d) Tighten screw (2);

e) Re-insert the passage tunnel into its

position (4).

f) Feed wire to junction box and connect

as shown in Figure 6.

Figure 6B - Installation of the electrical

supply cable on the model BTS

a) Remove or loosen screw (2)

b) Pop- out the passage tunnel for the

supply cable. Pass the supply cable

through the passage (1)

c) Connect the supply cable to the

junction box

d) Tighten screw (2);

e) Re-insert the passage tunnel into its

position (4).

f) Feed wire to junction box and connect

as shown in Figure 6.

17

A INSTALLATION INSTRUCTIONS

4 VENTING SYSTEMS

This heater can be fitted with either a

concentric or split type venting system.

Particular attention must be taken when

installing the vent pipes that go through the

wall to the outside. It must always be

possible to carry out routine maintenance

operations of the flue. The vent pipe must

be installed in such a way that it can be

removed, if needed, in the future. Hence, a

suitable sheath should be prepared in which

to insert the vent pipe. Both venting systems

are suitable for venting through a wall 1” to

24” thick.

The connection of the vent air intake system

to the heater can turn 360°, which means in

all directions, making installation extremely

easy.

To turn it just loosen the securing screws on

the base of the vent elbow where it attaches

to the heater, turn to desired position, then

tighten the screws without forcing them.

You must place the terminal in an open area,

and follow the following guidelines:

• Make certain that exhaust gas does not

re-circulate back into the intake pipe.

• Never vent into a walkway or patio area,

or an alley , or otherwise public area less than

7ft from the ground level. This is to prevent

anyone from walking into the vent;

• Never vent over or under a window or over

a doorway;

• Never install a heat saver or similar

product to capture waste heat from exhaust;

• Always have vent 1ft above ground level,

away from shrubs and bushes.

• Follow local gas codes in your region or

refer to National Fuel Gas Code, or Can

B149.1 INST ALLATION CODES.

• Always have vent at least 3ft from an

inside corner of outside walls.

• Maintain at least 4ft clearance to electric,

gas meters and exhaust fans.

• Always place screens in all openings in

intake and exhaust to prevent foreign matter

from entering the heater.

• The vent terminals, (concentric, split type

exhaust), must be a minimum of 1ft above

the ground level.

• If split type vent will be venting into a

chimney, make certain that no other

appliances are vented into it. This powervented heater must not share a chimney . Vent

exhaust terminal should be inserted into, but

not beyond, inner wall of chimney.

Do not vent into transient pipe. Warranty will

be void.

CAUTION! - Take all precautionary measures

to allow the angle of the flue to run down slightly

to the outside, NEVER rising. Anticipate for

all horizontal pipes, an inclination of 1/4” per

foot toward the discharge. If a vertical pipe

follows a horizontal one, place a condensation

discharge fitting in the lowest part of the vertical

pipe. A condensation discharge pipefitting

must also be used for vertical discharge pipe

installations directly from the heater with a pipe

whose length is more than 10”.

During normal operating conditions, the

heater will have exhaust gases exiting

from the flue pipe. The smoke will be

heavier on some days than on others. This

is due to the outdoor weather conditions

(the temperature, humidity, etc.), and is

extremely common.

4.1 Concentric Flue (Coaxial)

The (Coaxial) concentric vent, (air inlet and

flue outlet), system consists of 2 pipes: the

outer one for fresh air intake, the inner pipe

for flue exhaust discharge.

With optional pipe, it is possible to increase

the overall length up to 15ft (4.5 m).

There are also 90° concentric elbows

available, if they are installed, there will be a

loss of draught equal to that caused by 3ft,

(1 m), of straight pipe.

Connections between the various parts must

be secured by using self-tapping screws,

(see fig.9). The vents stainless steel end

terminal must always come completely out

of the outer pipe. If for any reason the intake

grid is blocked, the heater will not receive

enough air for combustion and the burner

would fail to ignite.

Loading...

Loading...