Page 1

Use & Installation

Manual

36” Dual Fuel Freestanding Range

965 series // F965 , F965NF

IMPORTANT

Save for local eletrical inspector’s use.

Installer Write Product Serial Number Here before Installing.

Serial Number can be found on the box or on the back of the unit.

Page 2

Table of Contents

Table of Contents................................................................................................................. 2

Safety Requirements ...............................................................................................................3

Ventilation Requirements.......................................................................................................10

Gas Supply Requirements.....................................................................................................13

Type of Gas .......................................................................................................................13

Electrical Requirements.........................................................................................................17

Advance Preparation .............................................................................................................18

Tools and Parts.................................................................................................................. 18

Range Dimensions............................................................................................................. 19

Unpack Range ...................................................................................................................20

Install Leveling Feet and Back Panel .................................................................................20

Install Anti-Tip Device. ........................................................................................................21

Installation Instructions ..........................................................................................................22

Gas Connection .................................................................................................................22

Liquefied Petroleum (Propane) Gas Conversion................................................................26

Electrical Connection .........................................................................................................32

Using the Cooktop..................................................................................................................34

Flame Size .........................................................................................................................34

Proper Burner Adjustments................................................................................................34

Location of the Burners......................................................................................................35

Placement of Burner Heads and Caps...............................................................................35

Cooktop Using Pots and Pans............................................................................................37

Setting Cooktop Controls ...................................................................................................38

Oven Cooking........................................................................................................................38

Setting Oven Clock and Timer ...........................................................................................38

Setting Oven Controls........................................................................................................39

Cooking Instructions...........................................................................................................42

Care and Cleaning.................................................................................................................43

Solutions to Common Problems ............................................................................................47

Page 3

Safety Requirements

IMPORTANT SAFETY NOTICE

READ ALL INSTRUCTION BEFORE INSTALLING AND OPERATING THIS APP LIA NCE

We have prov

read and obey all safety messages.

This is t

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word “DANGER” or “WARNING.”

These words mean:

You can be killed or seriously injured if you don't immediately follow instructions.

You can be killed or seriously injured if you don't follow instructions.

All safety messages will tell you what the potential hazard is, how to reduce the chance of injury, and

he safety alert symbol.

ided many important safety messages in this manual and on your appliance. Always

what can happen if the instructions are not followed.

•

Remove all tape and packaging before using the appliance. Never allow children to play with

packaging material. Do not remove the model/serial plate attached to the appliance.

•

Be sure your appliance is properly installed and grounded by a QUALIFIED TECHNICIAN in

accordance with the National Fuel Gas Code ANSI Z223.1—latest edition in the United States, or in

Canada CAN/CGA B149.1, and CAN/CGA B149.2, and the National Electrical Code ANSI/NFPA No.

70—latest edition in United States, or in Canada CSA Standard C22.1, Canadian Electrical Code,

Part 1, and local code requirements. Install only as per installation instructions provided in the

literature package for this appliance.

3

Page 4

If the in

damage, personal injury or death.

•

•

formation in this manual is not followed exactly, a fire or explosion may result causing property

FOR YOUR SAFETY:

- Do not store or use gasoline or other flammable vapors and liquids in the vicinity of this or any

other appliance.

WHAT TO DO IF YOU SMELL GAS:

- Do not try to light any appliance.

- Do not touch any electrical switch; do not use any phone in your building.

- Immediately call your gas supplier from a neighbor’s phone. Follow the gas supplier’s

instructions.

- If you cannot reach your gas supplier, call the fire department.

− Gas leak

− Gas suppliers recommend that you use a gas detector approved by UL or CSA.

− For more information, contact your gas supplier.

− If a gas leak is detected, follow the “What to do if you smell gas” instructions.

In the State of Massachusetts, the following installation instructions apply:

− Installations and repairs must be performed by a qualified or licensed contractor, plumber, or

gasfitter qualified or licensed by the State of Massachusetts.

− If using a ball valve, it shall be a T-handle type.

− A flexible gas connector, when used, must not exceed 3 feet.

•

Installation and service must be performed by a qualified installer, servicer or the gas supplier.

Ask your dealer to recommend a qualified technician and an authorized repair service. Know how to

shut off gas supply at the meter and disconnect the electrical power to the appliance at the circuit

breaker or fuse box in case of an emergency.

s cannot always be detected by smell.

4

Page 5

• Do not repair or replace any part of the appliance unless specifically recommended in the

manuals. All other servicing should be done only by a qualified technician. This may reduce the risk

of personal injury and damage to the appliance.

•

Proper Installation – The range, when installed, must be electrically grounded in accordance

with local codes or, in the absence of local codes, with the National Electrical Code, ANSI/NFPA 70.

In Canada, the range must be electrically grounded in accordance with Canadian Electrical Code. Be

sure the range is properly installed and grounded by a qualified technician.

•

Disconnect power before servicing.

•

Never modify or alter the construction of the appliance by removing panels, wire covers or any

other part of the product.

•

Injuries may result from the misuse of appliance doors or drawers such as stepping, leaning, or

sitting on the doors or drawers.

•

Overhead range hoods, which operate by blowing a downward air flow on to a range, shall not

be used in conjunction with gas ranges other than when the hood and range have been designed,

tested and listed by an independent test laboratory for use in combination with each other.

•

Ensure that the room is well ventilated by keeping the air intakes open and in good working

order or by installing an extractor hood with discharge pipe. If the appliance is used intensively for a

long time the effectiveness of the ventilation will have to be increased, for example by opening a

window or increasing the power of any electric extractor fan.

•

Flammable materials should not be stored on the appliance or near surface units. This includes

paper, plastic and cloth items, such as cookbooks, plastic ware and towels, as well as flammable

liquids. Do not store explosives, such as aerosol cans, on or near the appliance. Flammable

materials may explode and result in fire or property damage.

5

Page 6

• Maintenance – Keep range area clear and free from combustible materials, gasoline, and other

flammable vapors and liquids.

•

Storage in or o n the Range – Flammable materials should not be stored in an oven or near

surface units.

Do not stor

e items of interest to children in the cabinets above the appliance

or on the backguard of

a range. Children should not be left alone or unattended in the area where appliance is in use. Do

not allow children to climb or play around the appliance. They should never be allowed to sit or stand

on any part of the appliance. Children climbing on the appliance to reach items could be seriously

injured.

•

DO NOT TOUCH THE COOKING SURFACE, THE BURNERS, GRATES OR ANY AREAS

NEAR THEM. Surface burners or appliance may be hot even though flames are not visible. Areas

near surface burners or appliance may become hot enough to cause burns. During and after use, do

not touch, or let clothing or other flammable materials touch these areas until they have had sufficient

time to cool.

•

Do not wear loose-fitting or hanging garments while using the appliance. Do not let clothing or

other flammable materials contact hot surfaces.

•

Smother grease fires with a pan lid, or use baking soda, a dry chemical or foam-type

extinguisher.

•

Use an extinguisher ONLY if:

- You know you have a Class A, B, C ext ing u is h er, and you already know how to operate it.

- The fire is small and contained in the area where it is started.

- The fire department is being called.

- You can fight the fire with your back to an exit.

6

Page 7

• When heating fat or grease, watch it closely. Fat or grease may catch fire if allowed to become

too hot.

•

Use only dry potholders. Moist or damp potholders on hot surfaces may result in burns from

steam. Do not let potholders touch hot heating elements, the flame or burners. Do not use a towel or

other bulky cloth instead of a potholder.

•

Do not heat unopened food containers. Buildup of pressure may cause the container to burst

and result in injury.

•

Stepping, leaning or sitting on this appliance can result in serious injuries and also cause

damage to the appliance.

•

Never use this appliance as a space heater to heat or warm the room. Doing so may result in

carbon monoxide poisoning and overheating of the oven.

•

Know which knob controls which cooktop burner. Visually check that the burner has lit. Then

adjust the flame so it does not extend beyond the edge of the pots and pans.

•

Clean the appliance regularly to keep all parts free of grease that could catch fire. Exhaust fan

ventilation hoods and grease filters should be kept clean. Do not allow grease to accumulate on hood

or filter. Greasy deposits in the fan could catch fire. When cooking food turn the hood, fan on. Refer

to hood manufacturer’s instructions for cleaning.

•

Utensil handles should be turned inward and not extend over adjacent surface burners. To

reduce the risk of burns, ignition of flammable materials, and spillage due to unintentional contact with

the utensil, the handle of the utensil should be positioned so that it is turned inward, and does not

extend over adjacent surface burners.

7

•

Never leave surface burners unattended at high heat settings. Boil overs cause smoke and

greasy spillovers that may ignite, or a pan that has boiled dry may melt.

Page 8

• Do not use aluminum foil to line any part of the appliance. Use aluminum foil only to cover food

during cooking. Improper installation of these liners may result in risk of electric shock or fire.

•

Only certain types of glass, glass/ceramic, ceramic, earthenware, or other glazed utensils are

suitable for appliance service without breaking due to the sudden change in temperature. Check the

manufacturer’s recommendations for appliance use.

•

Do not use decorative surface burner covers. If a burner is accidentally turned on, the

decorative cover will become hot and possibly melt. You will not be able to see that the burner is on.

Burns will occur if the hot covers are touched. Damage may also be done to the range or burners

because the covers may cause overheating. Air will be blocked from the burner and cause

combustion problems.

•

Always use proper flame size. Adjust flame size so it does not extend beyond the edge of the

utensil. The use of undersized utensils will expose a portion of the burner flame to direct contact and

may result in ignition of clothing. Proper relationship of utensil to flame will also improve efficiency.

• Top burner flame size should be adjusted so it does not extend beyond the edg e of th e cook ing

utensil.

•

Use the proper pan sizes. This appliance is equipped with surface units of different sizes. Select

utensils having flat bottoms large enough to cover the surface unit. The use of undersized utensils

will expose a portion of the surface heating unit to direct contact and may result in ignition of clothing.

Proper relationship of utensil to the surface unit will also improve efficiency.

•

Do not use stove top grills on your gas appliance. If you use a stove top grill on a sealed gas

burner, it will cause incomplete combustion and can result in exposure to carbon monoxide levels

above allowable current standards. This can be hazardous to your health.

8

Page 9

TO REDUCE THE RISK OF TIPPING OF THE RANGE, THE RANGE MUST BE SECURED BY

PROPERLY INSTALLED ANTI-TIP DEVICES. TO CHECK IF THE DEVICES ARE INSTALLED

PROPERLY, SLIDE RANGE FORWARD, LOOK FOR ANTI-TIP DEVICE SECURELY ATTACHED

TO WALL.

•

The rang e will not tip during normal use. However, the range can tip if you apply too much force

or weight to the open door without having the anti-tip bracket fastened down properly.

TIP OVER HAZARD

A child or adult can tip the range and be killed.

Connect anti-tip chain to wall.

Reconnect the anti-tip chain, if the range is moved.

See the installation instructions for details.

Failure to follow these instructions can result in death or serious burns to children and adults.

9

Page 10

Ventilation Requirements

The range should have proper ventilation in order to keep the unit operating properly and maintain the

temperature of immediate surroundings within safe limits. Check your local building codes as they

may vary from the general rules outlined in this guide. It is recommended that a hood be installed

above the range that is rated no less than 400 CFM. This will provide adequate ventilation for this

range. Mounting distance of your ventilation is outlined by the manufacturer of your hood and is

dependent on the total BTU output of your range.

•

Observe all governing codes and ordinances. Do not obstruct flow of combustion and ventilation

air.

•

It is the installer’s responsibility to comply with installation clearances specified on the

model/serial rating plate.

•

For proper operation of a gas appliance, the air necessary for the combustion of the gas must be

able to flow into the room naturally. The air must flow into the room directly through openings in the

outside walls. These openings must have an unobstructed cross-section not less than 2m

kw of power (see total power in kw on the appliance).

•

This opening must be constructed so that it will not be obstructed from inside or outside, and

not be constructed close to the floor. The opening is recommended to be on the side opposite to that

on which the flue gases are discharged.

•

The range should be located for convenient use in the kitchen.

•

Recessed installations must provide complete enclosure of the sides and rear of the range.

3

/h for each

10

Page 11

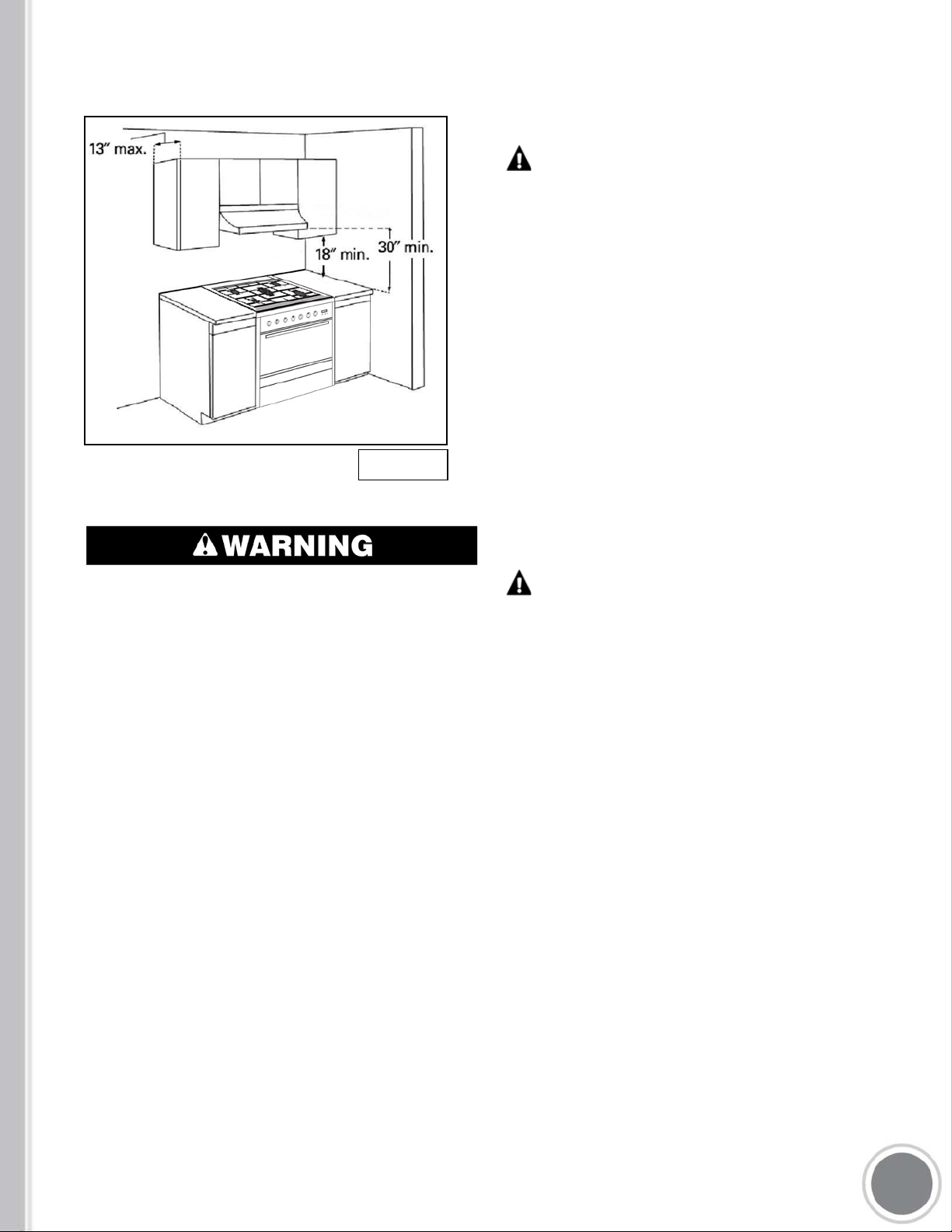

• To eliminate the risk of burns or fire by

•

Avoid placing cabinetry directly above

reaching over heated surface units, cabinet

storage space located above the surface units

should be avoided. If cabinet storage is to be

provided, the risk can be reduced by installing

a range hood or microwave hood combination

with minimum 400 CFM that projects

horizontally a minimum of 5" (12.7 cm) beyond

the bottom of the cabinets. (See Figure 1)

•

If a range hood is installed above the

appliance, maintain a 30” minimum clearance

between cooking surface and bottom of range

hood. The range hood must be connected

directly to flues or to the outside. (See Figure

1)

the appliance when possible. If cabinetry is

used above the cooking surface, use cabinets

no more than 13″ deep. Make sure the wall

coverings, countertop and cabinets around the

appliance can withstand heat up to 200º F

(93°C) generated by the appliance. (See

Figure 1)

•

Cabinet opening dimensions that are

shown must be used. Given dimensions are

minimum clearances. (See Figure 1)

•

Working areas adjacent to the range

should have 18″ minimum clearance between

countertop and cabinet bottom. (See Figure 1)

•

All openings in the wall or floor where

range is to be installed must be sealed.

•

Contact a qualified floor covering installer

to check that the floor covering can withstand

at least 200°F (93°C).

•

Use an insulated pad or ¼" (0.64 cm)

plywood under range if installing range over

carpeting.

•

The floor anti-tip bracket must be

installed. To install the anti-tip bracket shipped

with the range, see “Install Anti-Tip Bracket”

section.

•

Grounded electrical supply is required.

See “Electrical Requirements” section.

•

Proper gas supply connection must be

available. See “Gas Supply Requirements”

section.

11

Page 12

MOBILE HOM

Figure 1

INSTALLATION REQUIREMENTS

•

The installation of this range must

conform to the Manufactured Home

Construction and Safety Standard, Title 24

CFR, Part 3280 (formerly the Federal Standard

for Mobile Home Construction and Safety, Title

24, HUD Part 280). When such standard is not

applicable, use the Standard for Manufactured

Home Installations, ANSI A225.1/NFPA 501A

or with local codes.

In Canada, the installation of this range must

conform with the current standards CAN/CSAA240-latest edition, or with local codes.

E – ADDITIONAL

To avoid damage to your cabinets, check with

your builder or cabinet supplier to make sure

that the materials used will not discolor,

delaminate or sustain other damage. This oven

has been designed in accordance with the

requirements of UL and CSA International and

complies with the maximum allowable wood

cabinet temperatures of 194°F (90°C).

MOBILE HOM

•

When this range is installed in a mobile

home, it must be secured to the floor during

transit. Any method of securing the range is

adequate as long as it conforms to the

standards listed above.

E INSTALL ATIONS REQUIRE:

12

Page 13

Gas Supply Requirements

EXPLOSION

Use a new CSA International approved gas

supply line.

Install a shut-off valve.

Securely tighten all gas connections.

If connected to LP, have a qualified person

make sure gas pressure does not exceed

14" (36 cm) water column.

Examples of a qualified person include:

− Licensed heating personnel

− Authorized gas company personnel

− Authorized service personnel

Failure to do so can result in death,

HAZARD

• Observe all governing codes and

ordinances.

IMPORT

with all local codes and ordinances. In the

absence of local codes, installation must

conform with American National Standard,

National Fuel Gas Code ANSI Z223.1 - latest

edition or CAN/CGA B149 - latest edition.

IMPORT

be conducted according to the manufacturer’s

instructions.

ANT: This installation must conform

ANT: Leak testing of the range must

explosion, or fire.

Type of Gas

NATURAL

− This range is designed for use with

− This range is factory set for use with

GAS :

Natural gas or, after proper conversion,

for use with LP gas.

Natural gas. The model/serial rating

plate has information on the types of

gas that can be used. If the types of

gas listed do not include the type of gas

available,

supplier.

LP GAS CONVERSION:

− Conversion must be done by a qualified

service technician.

− No attempt shall be made to convert

the appliance from the gas specified on

the model/serial rating plate for use

with a different gas without consulting

the serving gas supplier.

check with the local gas

13

Page 14

GAS SUPPLY L

Figure 3

Figure 2

− Provide a gas supply line of ¾" (1.9

cm) rigid pipe to the range location. A

smaller size pipe on longer runs may

result in insufficient gas supply. Pipejoint compounds that resist the action

of LP gas must be used. Do not use

TEFLON®† tape. With LP gas, piping

or tubing size must be ½" (1.3 cm)

minimum. Usually, LP gas suppliers

determine the size and materials used

in the system.

INE:

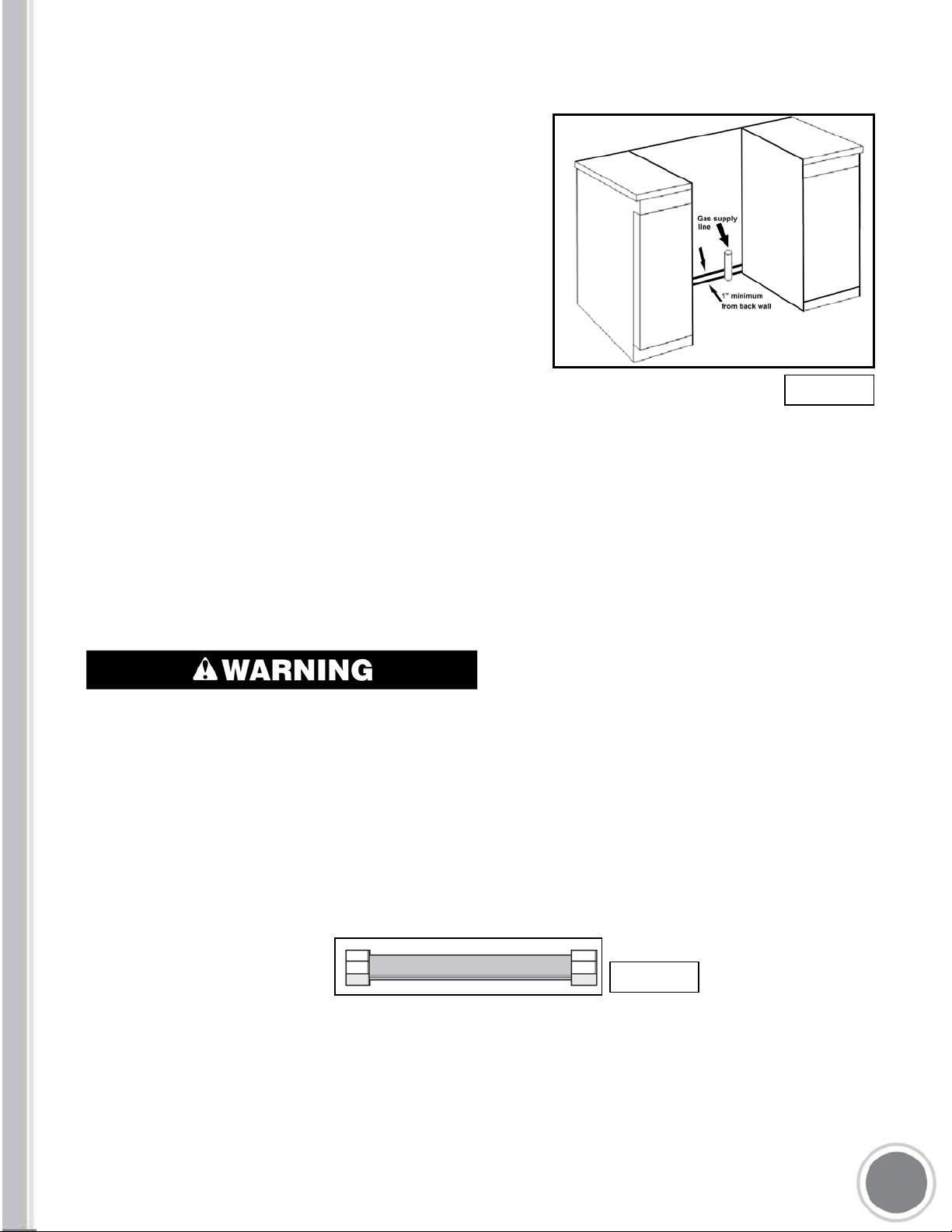

− Gas suppl

opening for this appliance and be a

minimum of 1” from the back wall. (See

Figure 2)

FLEXIBL

Never reuse old flexible connectors. The use of old flexible connectors can cause gas leakage and

personal injury. Always use new flexible connectors when installing a gas appliance. To reduce the

possibility of gas leakage, apply Teflon tape or a thread compound approved for use with LP or

Natural gases to all threaded connections.

E METAL APPLIANCE CONNECTOR:

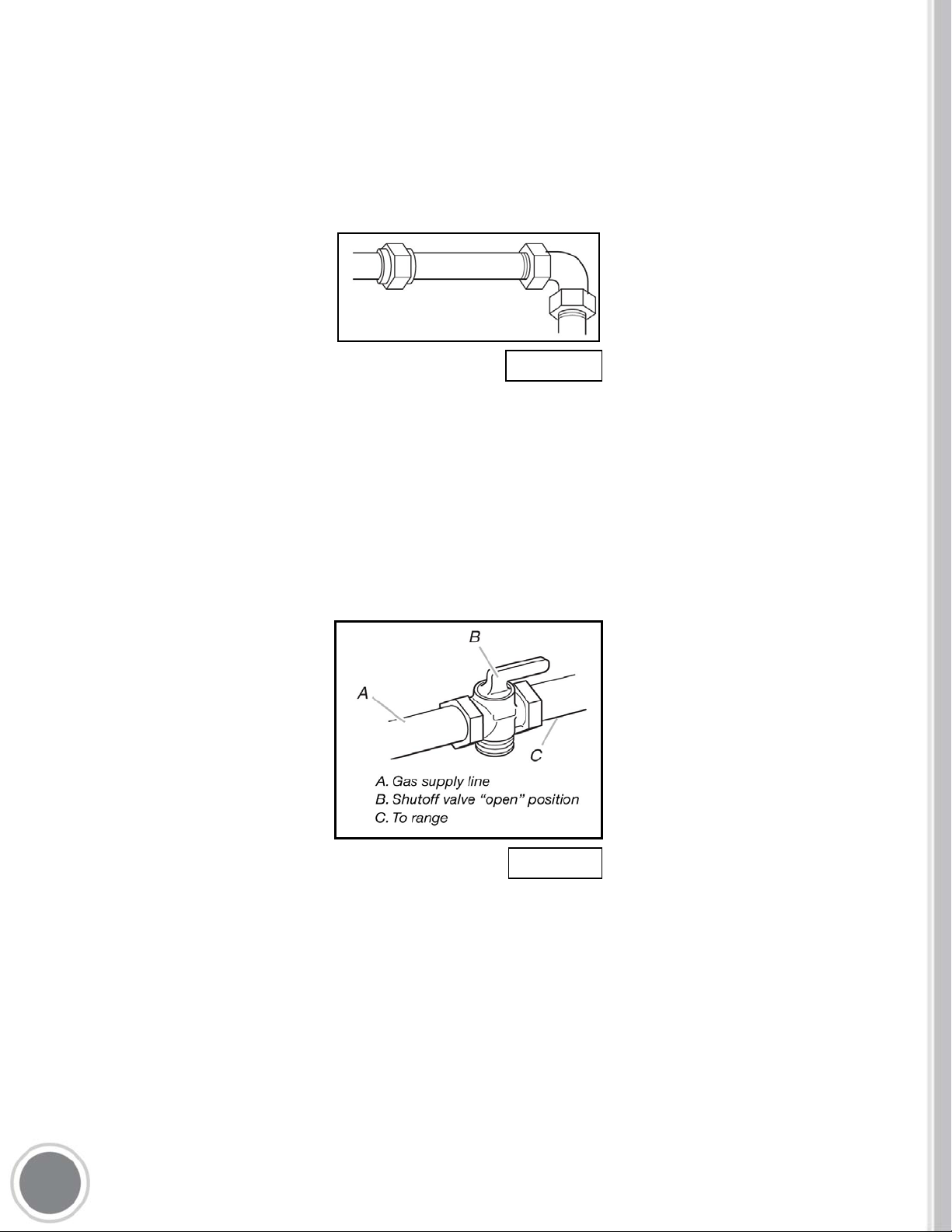

− If loc

al codes permit, a new CSA design-cert if ie d, 4 to 5 f t (1 22 t o 152 .4 cm ) l ong , ½" ( 1. 3 cm)

or ¾" (1.9 cm) I.D., flexible metal appliance connector may be used for connecting range to

the gas supply line. (See Figure 3)

y should be located near the

− A ½" (1.3

inlet to the appliance pressure regulator.

− Do not kink or damage the flexible metal tubing when moving the range.

cm) male pipe thread is needed for connection to the female pipe threads of the

14

Page 15

RIGID PIPE

Figure 4

Figure 5

− The rigid pipe connection requires a combination of pipe fittings to obtain an in-line connection

CONNECTION:

to the range. The rigid pipe must be level with the range connection. All strains must be

removed from the supply and fuel lines so range will be level and in line. (See Figure 4)

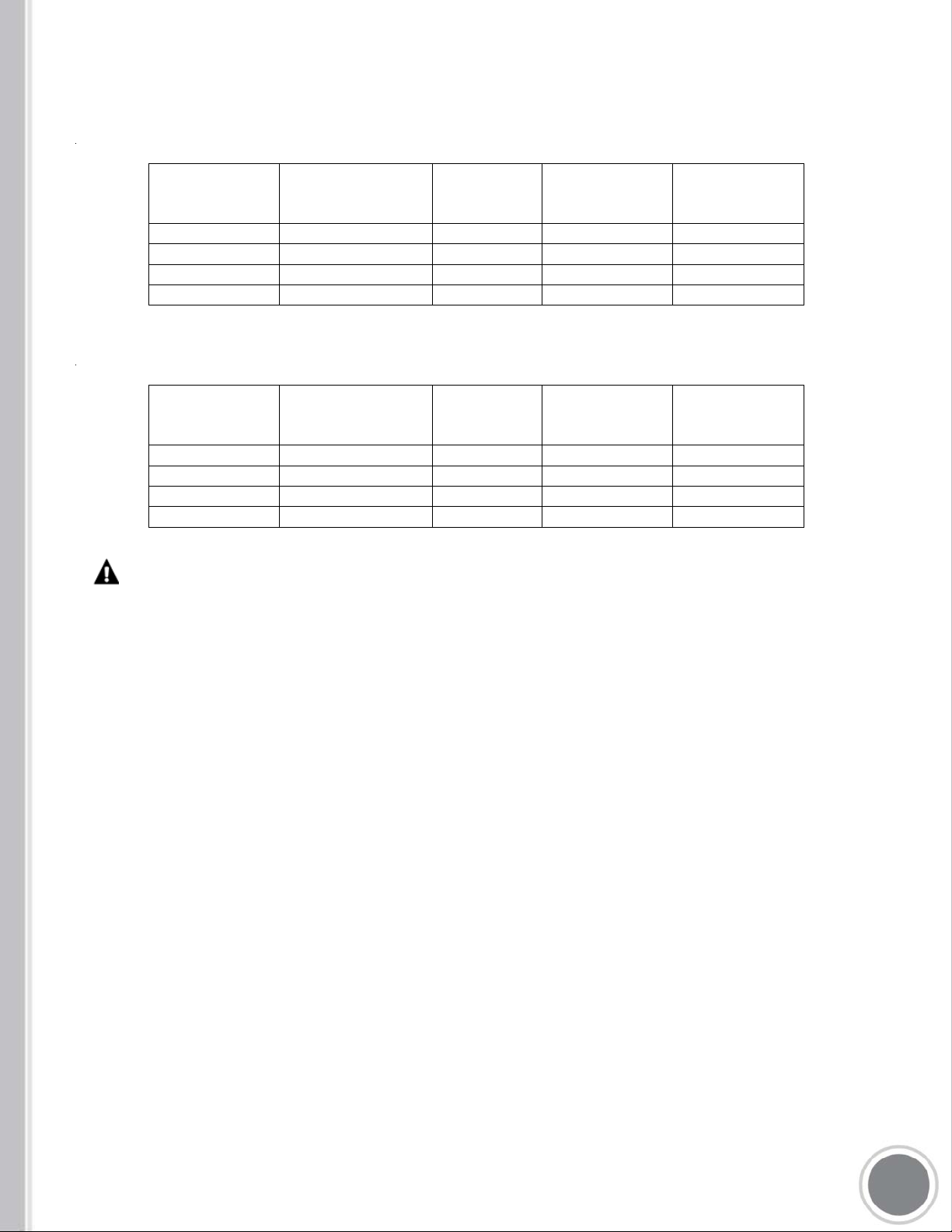

MUST INCLUDE A

− The supply line must be equipped with a manual shutoff valve. This valve should be located in

the same room but external to the range in an easily accessible location. It should be in a

location that allows ease of opening and closing. Do not block access to shutoff valve. The

valve is for turning on or shutting off gas to the range. (See Figure 5)

− Be sure you know where and how to shut off the gas supply to the range.

SHUTOFF VALVE:

15

GAS PRESSURE REG

− The pressure regulator must be connected in series with the manifold of the appliance and

must remain in series with the supply line regardless the type of gas being used.

− For proper operation, the gas pressure regulator supplied with this range must be used. The

inlet pressure to the regulator should be as follows:

ULATOR:

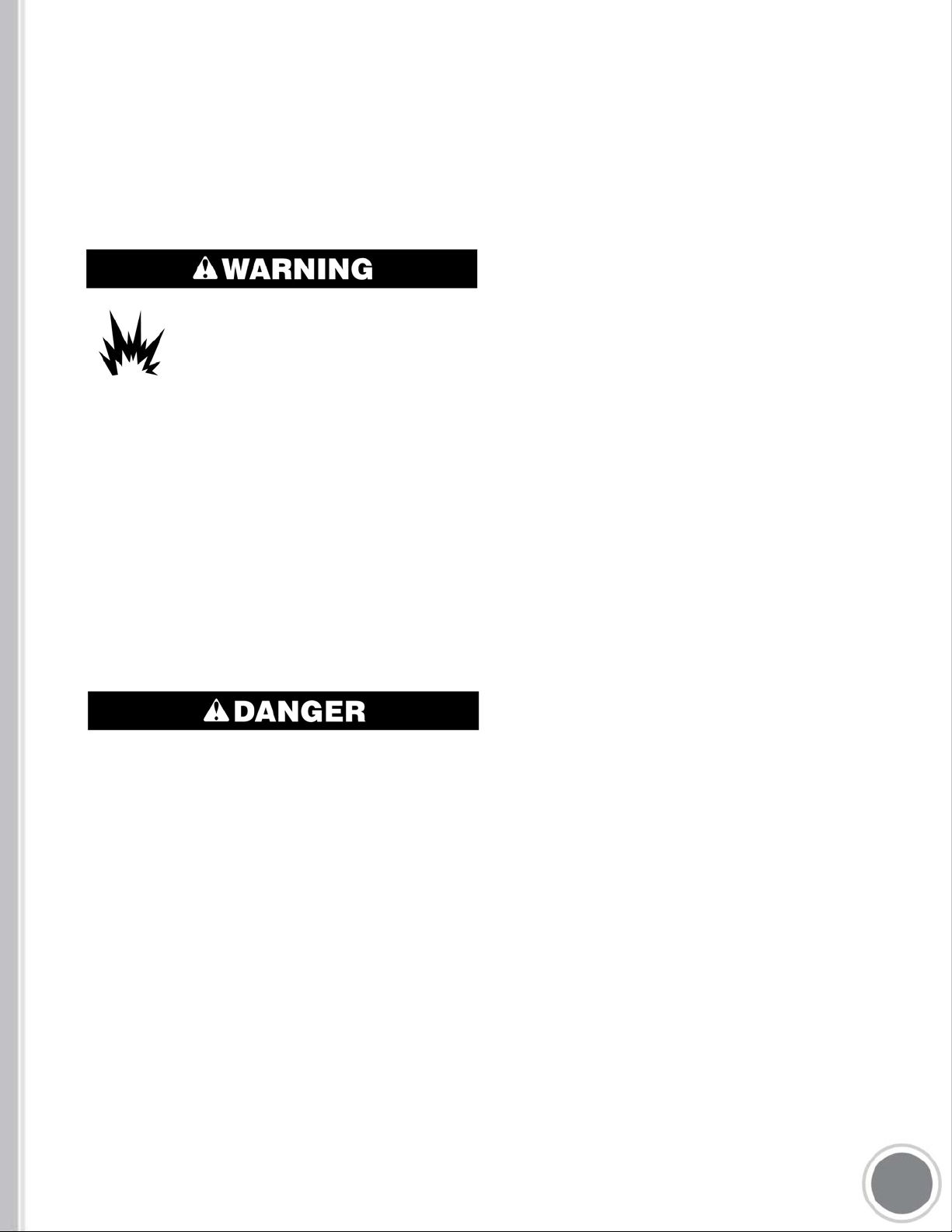

Page 16

NATURAL GAS

NATURAL GAS NOZZLES

LIQUID PERTROLEUM (LP) GAS NOZZLES

BURNER POSITION NOZZLE

Auxiliary Front Right 1 x 1.10 4” 14”

Semi-Rapid Rear Left & Right 2 x 1.29 4” 14”

Rapid Front Left 1 x 1.45 4” 14”

Triple Ring Center 5 x 0.99 4” 14”

LIQUID PETROL

BURNER POSITION NOZZLE

Auxiliary Front Right 1 x 0.70 10” 14”

Semi-Rapid Rear Left & Right 2 x 0.80 10” 14”

Rapid Front Left 1 x 0.89 10” 14”

Triple Ring Center 5 x 0.56 10” 14”

DIAMETER

EUM (LP) GAS

DIAMETER

MINIMUM

PRESSURE

MINIMUM

PRESSURE

• Contact your local gas supplier if you are not sure about the inlet pressure.

MAXIMUM

PRESSURE

MAXIMUM

PRESSURE

BURNER INPUT REQUIREM

− Input ratings shown on the model/serial rating plate are for elevations up to 2,000 ft (609.6 m).

− For elevations above 2,000 ft (609.6 m), ratings are reduced at a rate of 4% for each 1,000 ft

(304.8 m) above sea level (not applicable for Canada).

GAS SUPPLY PRESSURE TEST

Line pressure testing above ½ psi gauge (14" WCP):

• The range and its individual shutoff valve must be disconnected from the gas supply piping

system during any pressure testing of that system at test pressures in excess of ½ psi (3.5

kPa).

Line pressure testing at ½ psi gauge (14" WCP) or lower:

• The range must be isolated from the gas supply piping system by closing its individual

manual shutoff valve during any pressure testing of the gas supply piping system at test

pressures equal to or less than ½ psi (3.5 kPa).

ENTS:

ING:

16

Page 17

Electrical Requirements

instructions in the “Electrical Connection”

section. If you wish to install this appliance

directly to the main (without a plug), it m ust be

installed by a qualified service technician.

Electrical Shock Haz ard

Do not use an extension cord.

Failure to follow these instructions can

result in death, fire, or electrical shock.

• Any additions, changes or conversions

required in order for this appliance to

satisfactorily meet the application needs must

be made by a qualified service technician in

accordance with the manufacturer’s

instructions and all codes and requirements of

the authority having jurisdiction. Failure to

follow the instructions could result in serious

injury or property damage. The qualified

agency performing this work assumes

responsibility for the conversion.

•

DO NOT operate this appliance using a

2-prong adapter or an extension cord. If a 2prong wall receptacle is the only available

outlet, it is the personal responsibility of the

consumer to have it replaced with a properly

grounded 4-prong wall receptacle installed by

a qualified electrician.

•

Severe shock, or damage to the range

may occur if the range is not installed by a

qualified installer or electrician.

•

This appliance features a pilotless

electric ignition for energy savings and

reliability. It operates on a 220-240V/50-60Hz

- 35 Amp po wer supply.

17

• This appliance is not supplied with a plug.

If you wish to install this appliance with a plug,

it must installed by a qualified service

technician. The plug must be a 4-prong, 3phase plug that is designed specifically for

freestanding ranges.

• This appliance can be installed directly to

the main (without a plug). To do so, follow

•

A separate circuit, protected by a 15 amp

time delay fuse or circuit breaker, is required.

•

For personal safety, the appliance must

be properly grounded.

•

See the “Installation Instructions”

packaged with this appliance for complete

installation and grounding instructions.

Page 18

Advance Preparation

Tools and Parts

Gather the required tools and parts before starting installation.

Read and follow the instructions provided with any tools listed here.

■ Tape measure

■ Phillips

■ Flat blade screwdriver

■ 1/8” flat bla de screwdriver

■ Level

■ Hand or electric drill

■ Wrench or pliers

■ Pipe wrench

■ 1 5/16" combination wrench

■ Marker or pencil

■ Pipe-joint compound resistant to LP gas

■ 3/16” (4.8 mm) carbide-tipped masonry drill

bit (for concrete/ceramic floors)

■ Noncorrosive leak-detection solution

FOR LP/NATURAL GAS CONVERSIONS:

■ 1/2" Combination wrench

screwdriver

PARTS SUPPLIED:

Check that

■ 5 - Burner caps

■ 3 - Burner grates

2 - Oven racks

■

■

1 - Baking Tray

4 adjustable legs / rubber pegs

■

Gas Pressure Regulator

■

■ Anti-tip Device (explained on page 21)

■ 2 plastic anchors

■ 2 screws

The anti-tip device must be securely

mounted to the wall.

PARTS NEEDED

Check local codes and consult gas supplier.

all parts are included.

■ 1/4" (6 m m) nut driver

■ 9/32" (7 mm) nut driver

■ Masking tape

Check existing gas supply and electrical

supply. See “Electrical Requirements” and

“Gas Supply Requirements” sections.

18

Page 19

Range Dimensions

Figure 6

• Avoid placing cabinetry directly above the appliance when possible. If cabinetry is used above

the cooking surface, use cabinets no more than 13″ deep. Make sure the wall coverings, countertop

and cabinets around the appliance can withstand heat up to 200º F (93°C) generated by the

appliance. (See Figures 1 and 6)

•

Cabinet opening dimensions that are shown must be used. Given dimensions are minimum

clearances. (See Figures 1 and 6)

•

Working areas adjacent to the range should have 18″ minimum clearance between countertop

and cabinet bottom. (See Figures 1 and 6)

19

Page 20

Unpack Range

Install Leveling Feet and Back Panel

Excessive Weight

Tip Over Hazard

A child or adult can tip the range and be killed.

Use two or more people to move and install range.

Failure to follow these instructions can result in death or serious burns to children and adults.

1.

Remove shipping materials from the

range. DO NOT remove protective film

covering the appliance.

2. Remove oven racks and parts package

from inside oven.

3. Place range on its back; take four (4) Lshaped cardboard corners from the

carton. Stack one cardboard corner on

top of another. Repeat with the other 2

corners.

Hazard

6. Install the

The leveling feet can be found in one of

the boxes that was inside the oven.

7. Place cardboard or hardboard in front

of range. Using 2 or more people,

stand range back up onto cardboard or

hardboard.

8.

Remove the protective film covering the

appliance.

leveling feet one at a time.

4. Place the four (4) L-shaped cardboard

corners lengthwise on the floor behind

the range to support the range when it

is laid on its back.

5. Using 2 or more people firmly grasp the

range and gently lay it on its back on

the cardboard corners.

9. The stainless steel back panel can now

be installed. Place panel into the

grooves on the top rear of the range.

Then affix the panel to the range using

the screws provided.

20

Page 21

Install Anti-Tip Device (Chain)

Tip Over Hazard

A child or adult can tip the range and be killed.

Connect anti-tip bracket to rear range foot.

Reconnect the anti-tip bracket, if the range is moved.

Failure to follow these instructions can result in death or serious burns to children and adults.

The range is supplied with an antitilting chain to prevent the

appliance from tilting forward and

accidental damage to the gas pipe.

Take the wall anchor with hook and

make an adequate hole in the wall

behind, at the same height as the

chain. Insert the wall anchor into

the hole and screw in the hook until

it is firmly fixed to the wall. Connect

the chain to the hook.

21

Page 22

Installation Instructions

Gas Connection

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shut-off valve.

Securely tighten all gas connections.

If connected to LP, have a qualified person make sure gas pressure does not exceed 14" (36

cm) water column.

Examples of a qualified person include: licensed heating personnel, authorized gas company

personnel, and authorized service personnel.

Failure to do so can result in death, explosion, or fire.

This appliance i

connected with gas supply line. The gas connection is a male ½” BSP and is located roughly 2 ¼”

from the right and 22” from the ground. The hose needs to be free of kinks or other deformation that

would inhibit its ability to supply gas to the unit or susceptible to a gas leak. Line should also be free

from contact with a moving part such as a drawer, so that it does not become obstructed or damaged.

INSTALLING THE PRESSURE REGUL ATOR

• This appliance is set for natural gas and is designed to operate at 5” water column pressure. The

gas supply is required to provide a minimum of 4” to a maximum of 14” water column pressure to the

appliance regulator.

s outfitted from the factory to be used with ONLY one type of gas. This range is to be

22

Page 23

NATURAL GAS NOZZLES

BURNER POSITION NOZZLE

MINIMUM

MAXIMUM

DIAMETER

Auxiliary Front Right 1 x 1.10 4” 14”

Semi-Rapid Rear Left & Right 2 x 1.29 4” 14”

Rapid Front Left 1 x 1.45 4” 14”

Triple Ring Center 5 x 0.99 4” 14”

• If the appliance i

provide a minimum of 10” to a maximum of 14” water column to the cooktop regulator.

BURNER POSITION NOZZLE

Auxiliary Front Right 1 x 0.70 10” 14”

Semi-Rapid Rear Left & Right 2 x 0.80 10” 14”

Rapid Front Left 1 x 0.89 10” 14”

Triple Ring Center 5 x 0.56 10” 14”

•

The gas supply line must be equipped with an approved manual shut-off valve. The shut-

s converted for liquid pretroleum (LP) gas, the LP gas supply is required to

LIQUID PETROLEUM (LP) GAS NOZZLES

DIAMETER

PRESSURE

MINIMUM

PRESSURE

PRESSURE

MAXIMUM

PRESSURE

off valve must be in an easily accessible location in the same room as the appliance. Do not

block access to the shutoff valve. Be sure you know how and where to shut off the gas

supply to the range.

1) The gas inlet i

2 ½” in from the right hand side of the appliance. Make gas connection through rear wall, or on

cabinet floor at rear. Install the house gas supply at least 1” from the back wall.

2) When installing, fit a safety valve at the end of the pipeline. The appliance leaves the factory

tested and set for natural gas. Make sure that the type of gas to be supplied to the appliance is

the same as that shown on the label affixed to the rear of the appliance. (See Figure 12)

3) Make the connection to the gas system using a rigid ½” or ¾” metal pipe and regulation unions, or

with a stainless steel hose complying with the local standard. If metal hoses are used, take care

that they do not come into contact with mobile parts and are not crushed.

4) The gas intake connection of the appliance has a “male thread.” When making the connection,

s located 6” down from the top of the appliance at the rear on the right side and

23

take care not to apply stresses of any kind to the appliance. Over- tightening may crack the

regulator resulting in a gas leak and possible fire or explosion.

Page 24

5) Once reg

Figure 12

gas to move through the gas line.

ulator is in place, open the shutoff valve in the gas supply line. Wait a few minutes for

6) After c

position and check the system for leaks with a manometer. If a manometer is not available, turn

on the gas supply and use a liquid leak detector (or soap and water) at all joints and connections

to check for leaks.

TESTING

Do not use a flame to check for leaks from gas connections. Checking for leaks with a flame may

result in a fire or explosion.

•

•

onnecting the appliance to the gas supply, make sure all burners knobs are in the OFF

FOR LEAKS

Tighten all connections if necessary to prevent gas leakage in the range or supply line.

Check alignment of control knob valves after connecting the range to the gas supply to be

sure the range manifold pipe has not moved. A misalignment could cause the valve stems to rub on

the control panel, resulting in a gas leak at the valve.

•

Disconnect this range and its individual manual shutoff valve from the gas supply piping

system during any pressure testing of that system at test pressures

14" water column).

in excess of 1/2 psi (3.5 kPa or

24

Page 25

• Isolate the range fr om the gas supply piping system by closing its individual manual shutoff

Figure 13

Figure 14

valve during any pressure testing of the gas supply piping system at test pressures equal to or less

than 1/2 psi (3.5 kPa or 14" water column).

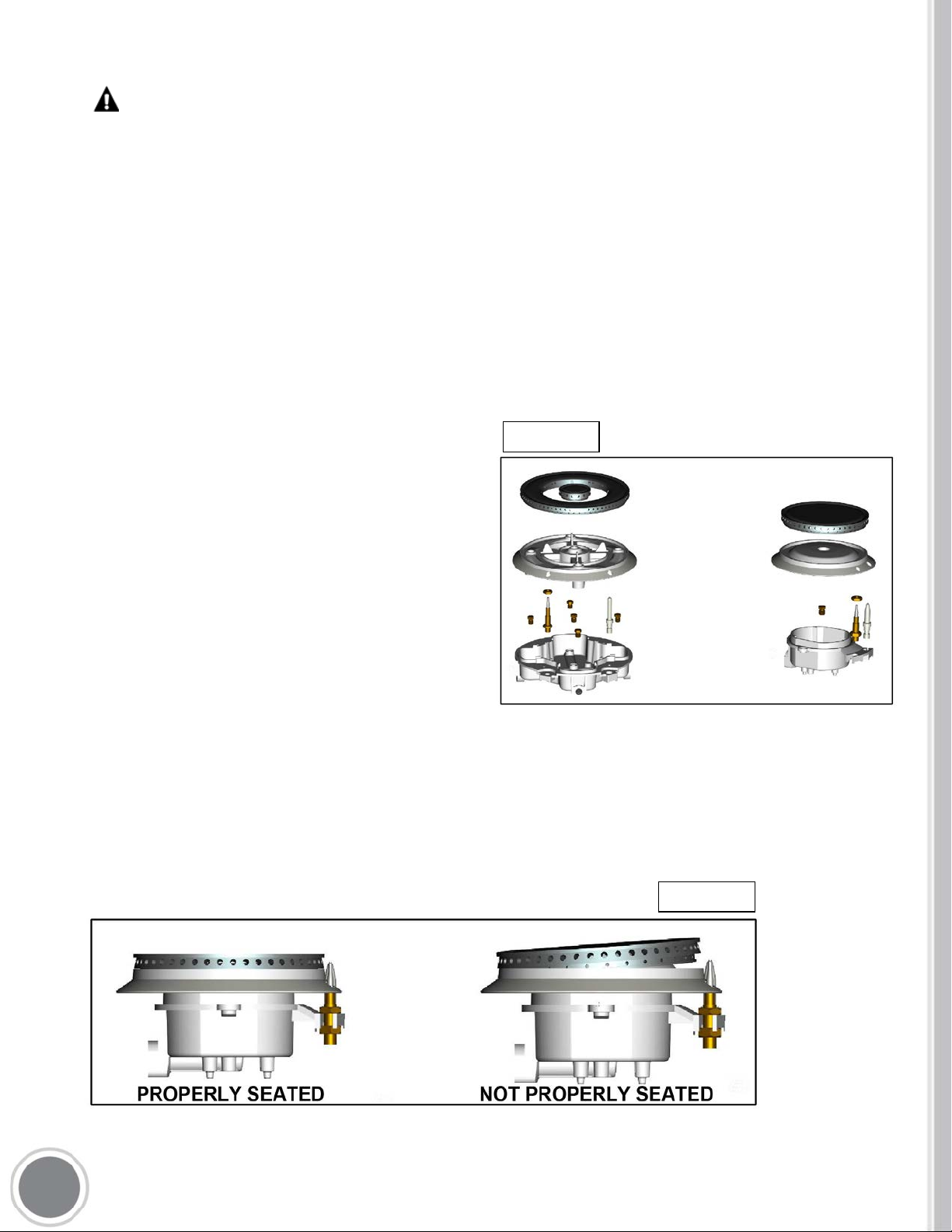

ASSEMBLY OF THE

The electrode of the electronic ignition system is positioned above the surface of the burner base. Do

not remove a burner cap or touch the electrode of a burner while another is turned on. Damage or

electrical shock may occur.

1. Place burner heads ov

Make sure the hole in the burner head is

properly aligned with the electrode in the

burner base. (See Figure 13)

2. Place the burner

Make sure that the burner caps are

properly seated on the burner head. (See

Figure 14)

BURNERS

er the burner base.

caps on the burner heads.

3. O per ation of

tested after the range and supply line have

been carefully checked for leaks and the

range has been connected to the electrical

power. To check igniters, push and turn a

sounds), but only the burner turned to LITE

will light.

the electric igniters should be

25

Page 26

Liquefied Petroleum (Propane) Gas Conversion

Failure to make the appr

damage.

The conversion must be performed by a qualified service technician in accordance with

the kit instructions and all local codes and requirements. Failure to follow instructions could

result in serious injury or property damage. The qualified agency performing this work

assumes responsibility for the conversion.

This appliance can be used with Natural Gas or LP/Propane Gas. It is shipped from the factory

for use with Natural Gas. A kit for converting to LP gas (Not Included) can be purchased from

http://www.cosmoappliances.com. The kit is marked "Cosmo LP Conversion Kit (Your model

number)". If you have trouble locating the correct kit, please contact us.

When the range is converted for Liquid Petroleum (LP) Gas, the LP gas supply is required to provide

a minimum of 10” to a maximum of 14” water column to the range regulator.

opriate conversion can result in serious personal injury and property

A. ADJUST THE REGULAT

− Disconnect all electri

− Shut off the gas supply to the appliance by closing the manual shut-off valve.

− Adjust the pressure regulator by doing the following:

OR

cal power at the main circuit breaker or fuse box.

26

Page 27

1) Unscrew the regulator cap with t he wrench.

Figure 15

Figure 16

Figure 18

4) Reverse the r

etainer pin and put back into

(See Figure 15)

2) This is how the retainer pin looks for

Natural Gas usage. (See Figure 16)

the regulator cap. This is how the regulator

pin looks for LP gas usage. (See Figure 18)

5) Screw the regulator cap back into the

3) Remove the r

regulator and re-attach the regulator to the

nipple and flare union. (See Figures 12 and

19)

etainer pin. (See Figure 17)

Figure 19

27

Figure 17

Page 28

B. CHANGE BURNER NOZZLES

LIQUID PRETR OLEUM (LP) GAS NOZZLES

Figure 20

TRIPLE RING BURNER

5 NOZZLES

AUXILARY BURNER

1 NOZZLE EACH

NOZZLES

Figure 21

INSTALLATION

TIP: First remove all nozzles and then start replacing them. This will help to prevent

the possibility that some may not be replaced.

1) Remove the burner g

rates, burner caps and burner heads.

2) Using a 7mm nut driver, remove the burner nozzles.

SEMI-RAPID BURNER

RAPID BURNER

BURNER POSITION NOZZLE

DIAMETER

MINIMUM

PRESSURE

MAXIMUM

PRESSURE

Auxiliary Front Right 1 x 0.70 10” 14”

Semi-Rapid Rear Left & Right 1 x 0.80 10” 14”

Rapid Front Left 1 x 0.89 10” 14”

Triple Ring Center 5 x 0.56 14”

10”

IMPORTANT: Carefully read and observe each nozzle label for correct location.

3) Install the proper nozzles in the exact locations as noted in the illustrations above and the

table below. (See Figures 20, 21 and table above)

4) Replace the burner bases, heads, caps and top grates. Make sure burner caps are properly

seated on the burner head.

28

Page 29

C. ADJUST BURNER FLAMES

1) Turn all burners on highest setting and

check the flames. They should be blue

in color and may have some yellow

tipping at the ends of the flame when

using LP gas. Foreign particles in the

gas line may cause an orange flame at

first, but this will soon disappear.

2) Turn the ra

while observing the flame.

3) Adjustment

other burners in operation on a medium

setting. This prevents the upper row of

flames from being set too low, resulting

nge burner knob to “LO”

s must be made with two

4) To adjust

insert a screwdriver through the access

hole in valve shaft as shown. Make the

adjustment by slowly turning the screw

until flame appearance is correct. (See

Figures 22 and 23)

− If the f

open the valve more than the original

setting.

− If the flames are too large, close the

valve more than the original setting.

the flame, remove the knobs;

lames are too small or fluttered,

in the flame being extinguished when

other burners are turned on.

Figure 22 Figure 23

29

Page 30

TESTING FL

AME STABILITY

Test 1——Turn t

increase the flame size and test again.

Test 2——With the burner on “LO”, open and close the cabinet door under the range. If the flame is

extinguished by the air currents created by the door movement, increase the flame height and test

again.

D. FLAME RE-CHECK

After the adjustment is made, turn all burners off. Ignite each burner individually. Observe the flame

at the “HI” position. Rotate the knob to the lowest setting and be sure that the flame size decreases

as the knob is rotated counter-clockwise.

Adjust the hei

approximately ¼" (0.64 cm) high.

he knob from “HI” to “LO” quickly. If the upper row of flames goes out at this setting,

ght of top burner flames. The range “low” burner flame should be a steady blue flame

Once the conversion has been completed and has passed testing, fill out the conversion

sticker and include your name, organization and the date conversion is made. A pply the

sticker near the appliance gas inlet opening to alert others in the future that this appliance has

been converted. If converting back to Natural Gas, please remove the sticker so others know

that the appliance is set to use its original gas.

30

Page 31

Electrical Connection

ELECTRICAL SPECIFICATIONS

SYSTEM

Upper Heating Element

2200W

Bottom Heating Element

1800W

Grill Heating Element

2900W

Convection Heating Element

2 x 1550W

Ventilator Motor

2 x 30W

Cooling Fan

11W

Electrical Shock Hazard

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death, fire, or electrical shock.

Electrical connection must be performed by a qualified service technician in accordance with

the kit instructions and all local codes and requirements.

• This appliance is not supplied with a plug and needs to be connected directly to the electrical

mains.

• If you wish to install this appliance with a plug, it must installed by a qualified service technician.

The plug must be a 4-prong, 3-phase power plug that is designed specifically for ranges and ovens.

Electrical Requirements: 220-240V/50-60Hz, 35 Amps

Oven Light

2 x 25W

31

Page 32

BEFORE MAKING THE ELECTRICAL CONNECTION, MAKE SURE THAT:

• The safety circuit-br eaker and the electrical system are able to with stand the load of the

appliance. See rating label on back of range.

• Rating plate is located on back of range should you need to verify any of the electrical

requirements.

• The power supply system has a ground connection in good working order in accordance with the

regulations in force.

• The electrical socket is easily accessible with the appliance installed. In all cases, the power

supply lead must be positioned so that it does not reach a temperature of 50

o

C above the room

temperature at any point.

• The manufacturer is not liable for any direct or indirect damage caused by faulty installation or

connection. It is therefore necessary that all installation and connection operations are carried out by

qualified personnel complying with the local and general regulations in force.

CONNECTIO

1) This appli

2) Follow the diagram below to know how to connect the freestanding range wir es to the

electrical main wires of the home. (See Figure 24)

N OF THE RANGE WIRES TO THE MAINS

ance is equipped with the following wires:

One Black Wire, One Red Wire (L1 and L2 - Liv

•

•

One Yellow /Green (Ground)

e)

32

Page 33

3) The two black wires can be connected to the electrical main wires of the home in one of the

Figure 24

following three configurations:

• Config

• Configuration 2: L1 to L1 and L2 to L3

• Configuration 3: L1 to L2 and L2 to L3

uration 1: L1 to L1 and L2 to L2

33

4) Never us

5) After

into contact with parts subject to heating.

e reductions, shunts, or adaptors which can cause overheating or burning.

carrying out the connection to the mains, check that the supplying cable does not come

Page 34

Using the Cooktop

Figure 25

Flame Size

• For most cooking, start on the highest control setting and then turn to a lower one to complete the

process. The size and type of utensil used and the amount of food being cooked will influence the

setting needed for cooking.

• For deep fat fry

too cool, the food will absorb the fat and be greasy. If the fat is too hot, the food will brown so quickly

that the center will be undercooked. Do not attempt to deep fry too much food at once as the food will

neither brown nor cook properly.

•

Never extend the flame beyond the outer edge of the utensil. A higher flame simply wastes heat

and energy, and increases your risk of being burned by the flame. (See Figure 25)

ing, use a thermometer and adjust the surface control knob accordingly. If the fat is

Proper Burner Adjustments

• The color of t

visible in a well-lighted room. Each cone of flame should be steady and sharply defined.

• Adjust or cl

Cleaning”. (See Figures 22 and 23)

he flame is the key to proper burner adjustment. A good flame is clear, blue and hardly

ean burner if flame is yellow-orange. To clean burners, see instructions under “Care and

34

Page 35

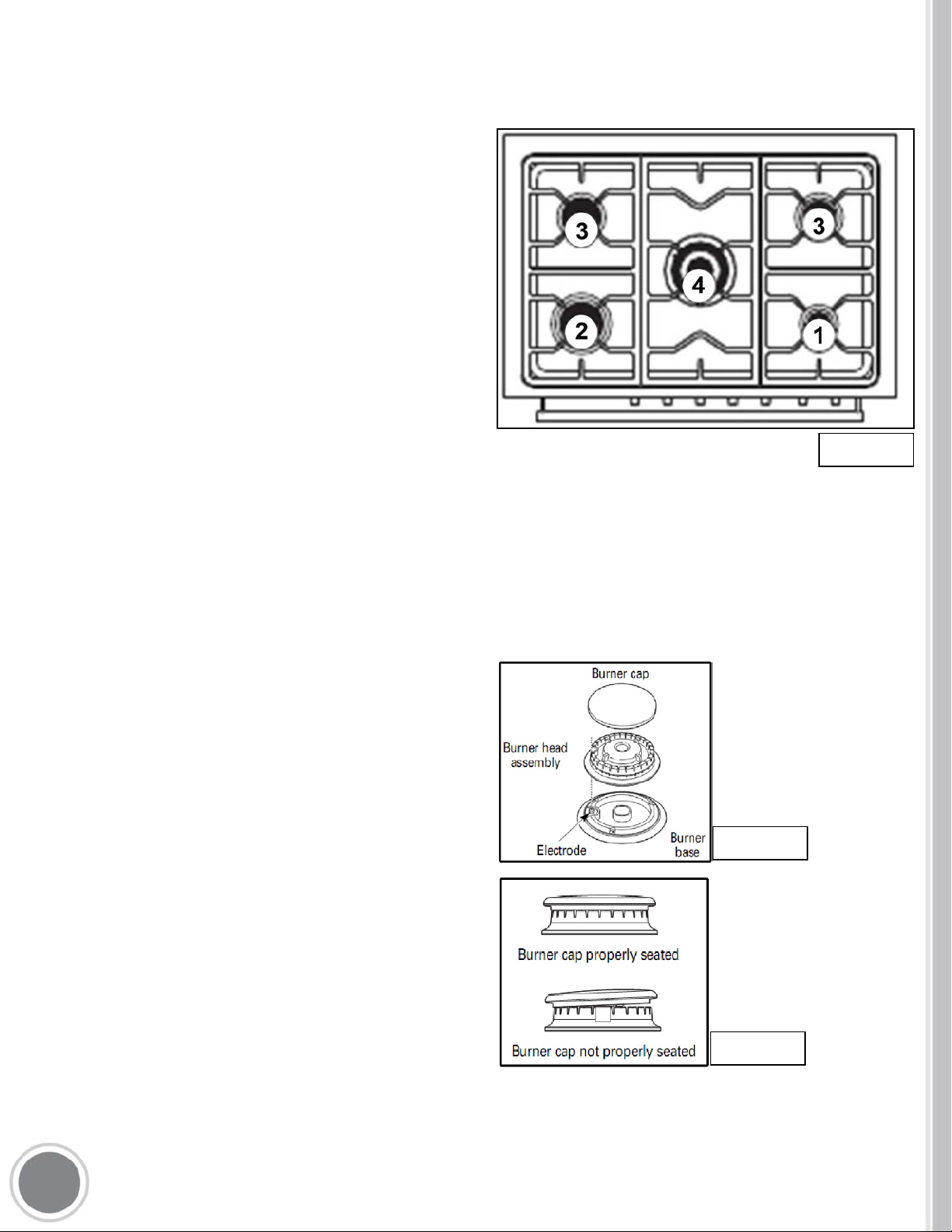

Location of the Burners

Figure 27

Figure 26

1. Auxil

2. Rapid burner ( Front left) – 8,500 BTU

3. Semi-rapid burners (Rear left and right) –

4. Triple-ring burner – (Center) 18,000 BTU

iary burner (Front right) - 5,000 BTU

7,000 BTU

Placement of Burner Heads and Caps

1) Place a burner cap on each burner

4) Do not service the sealed burner

head, matching the cap size to the

head size. The cap for each burner

has an inner locating ring which centers

the cap correctly on the burner head.

Be sure that all the burner caps and

burner heads are correctly placed

BEFORE using your appliance. (See

Figure 27)

2) Make sur

aligned and level. (See Figure 28)

3) Turn t

light. If the burner does not light,

contact a qualified service center.

e each burner cap is properly

he burner on to determine if it will

yourself.

Figure 28

35

Page 36

Cooktop Using Pots and Pans

BURNER

MINIMUM DIAMETER OF PAN

MAXIMUM DIAMETER OF PAN

Rapid (front left)

178 mm (7 inches)

254 mm (10 inches)

Semi-Rapid (rear left and right)

152 mm (6 inches)

203 mm (8 inches)

Auxiliary (front right)

76 mm (3 inches)

178 mm (7 inches)

Triple-Ring (center)

203 mm (8 inches)

330 mm (13 inches)

Do not place plastic items such as salt and pepper shakers, spoon holders or plastic

wrappings on top of the appliance when it is in use. These items could melt or ignite. Potholders,

towels or wood spoons could catch fire if placed too close to a flame.

Note: Always use a utensil for its intended purpose. Follow manufacturer’s instructions. Some

utensils were not made to be used in the oven or on the cooking surf ace.

Regardless

prepared. Select a burner and flame size appropriate to the pan. Never allow flames to extend

beyond the outer edge of the pan.

For lower gas c

suitable for the burners, as shown in the table below. Check for flatness by rotating a ruler across the

bottom of the pan. There should be no gaps between the pan and ruler. As soon as a liquid comes

to a boil take care to turn the flame down to a level that will just keep it simmering. (See Figure 29)

Specialty pans

recommended cookware requirements.

of size, always select a utensil that is suitable for the amount and type of food being

onsumption and better efficiency: Use only flat-bottomed pans of dimensions

Figure 29

(lobster pots and pressure cookers) may be used but must conform to the

During cooking processes involving fats or oils, watch your foods carefully because these

substances may catch fire if brought to high temperatures.

36

Page 37

Setting Cooktop Controls

SYMBOLS

Figure 30

IGNITION A

1. To obtain a f

2. To light a burner, press the knob of the

3. After

ND OPERATION OF THE GAS BURNERS

lame more easily, light the

burner before placing a cooking utensil

on the burner grate.

burner fully down and turn it counterclockwise to the “maximum flow”

setting symbol:

lighting the flame, keep the knob

pressed down for about 10 seconds.

This is necessary to heat up the

. (See Figure 30)

5. If the burner fails to ignite, wait one

minute for the gas to dissipate before

attempting to reignite. At this moment

it is possible to adjust the flame

intensity by rotating the knob counterclockwise to the desired position.

6. In the ins

place a lit match near the burner and

proceed as already described. If the

burner does not light after a few

attempts, check that the “burner cap”

and “flame cap” are correctly positioned.

tance of a power outage,

37

thermocouple and activate the safety

valve, which would otherwise cut off the

gas flow.

4. Check tha

the control knob to adjust the flame as

required:

t the flame is even and turn

. (See Figure 30)

ALWAYS USE CAUTION WHEN LIGHTING BURNERS MANUALLY.

7. To turn

knob clockwise to the:

Always lower or turn off the flame

before removing pans from the burners,.

(See Figure 30)

off the flame, turn the control

● symbol.

Page 38

Setting Oven Clock and Timer

Oven Cooking

Figure 31

DIGITA

This

with 3 control buttons. When first connected to

power (or after a power outage) the screen will

display ’12:00’ and the bar above the

symbol will flash. (See Figure 31)

ADJUS

To set the correct time, press the + or – button

to advance forward or backward until the

correct time is displayed. When finished you

can press the function button, otherwise wait 5

seconds it will stay at the set time. (See

Figure 31)

MANUAL O

L CLOCK

model has a digital display 24 hour clock

TING THE CLOCK

PERATION

COOKING WITH THE TIMER

By s

electing the desired end time, cooking

time, temperature and cooking mode you can

set the oven to cook your dish automatically.

(See Figure 31)

1) Press

2) Press the function button until the bar

3) Set the temperature and cooking mode

the function button until the bar

above the

press + or – to set the cooking time.

above the

press + or – t o set the desired end time.

using the thermostat and selector

knobs.

symbol flashes, then

symbol flashes, then

Press t

operation.

he function button to select manual

38

Page 39

Setting Oven Controls

Figure 32

Figure 33

KNOB SETTINGS

New knob design now features oven controls directly on the

knob. Simply twist to desired setting to set that cooking

mode. (see below for modes)

Selection of cooking temperature is carried out by turning the knob clockwise to the required

temperature. The warning light will illuminate during the heating process. Once the oven

reaches desired temperature, the light will go out. Regular flashing means that the oven

temperature is being maintained at the programmed level.

DEFROST (Bottom fan)

All types of food can be defrosted by circulating air at room temperature: cakes, cream, fruit, etc.

For foods such as: meat, fish, and bread you will want to set the fan temperature to 175-200° C

(347-392° F).

CONVECTION BAKE (Cooking element & Fan)

39

THERMOSTAT SELECTOR SWITCH FROM 60° C (140° F) TO MAX

This method allows even-heat multi-rack cooking for various types of foods with the appropriate

cooking times for each dish. The oven must be preheated before the foods are placed inside.

Use the ‘Fan Forced’ function to operate.

Page 40

CONVECTION BROIL (Grill element and Fan)

THERMOSTAT SELECTOR SWITCH FROM 60° C (140° F) TO 200° C (392° F)

Best used for grilling meats, vegetables, and poultry. Preheat the oven, place food on a grilling

rack or backing tray and place in the middle of the oven. Other racks can be used

simultaneously using this method.

HIGH BROIL (Grill Element)

THERMOSTAT SELECTOR SWITCH FROM 60° C (140° F) TO MAX

The use of the grill element is best reserved for: melting cheese, toasting, and browning. The

cooking time should be no longer than 5 minutes. To operate, please select Full Grill Function

along with the temperature.

LOW BROIL (UPPER ELEMENT COOKING)

THERMOSTAT SELECTOR SWITCH FROM 60° C (140° F) TO MAX

This is best used to brown select dishes at the end of cooking.

PIZZA (Lower element and Fan)

THERMOSTAT SELECTOR SWITCH FROM 60° C (140° F) TO MAX

Ideal for pastries and cakes with wet covering and little sugar and damp desserts in moulds.

Excellent results can also be achieved in completing cooking at the bottom and with dishes

requiring heat in the lower area in particular. The plate is best inserted at bottom level.

40

Page 41

BAKE (Upper and Lower element)

THERMOSTAT SELECTOR SWITCH FROM 60° C (140° F) TO MAX

The heat is provided from the top and bottom elements. The oven must be preheated before the

food is placed inside. Static cooking provides optimum results with: cakes, pizzas, bread and for

gentle slow cooking of casseroles. Characteristics of static cooking: heat provided from above

and below, cooking is possible only on middle shelf and should be centrally located in the oven.

LIGHT - LIGHT INDICATOR

The lamp of the oven is on. During oven operation the lamp will always remain on.

41

Page 42

Cooking Instructions

Setting:

Food:

Rack Level

(See Figure 33)

Temperature

(Fahrenheit):

Time (m ins):

Lasagna

2-3

410-450

30

Oven-Baked

Pasta

2-3

410-450

40

Roast Veal

2

350-400

30-40/lb

Beef

2

410-460

30-40/lb

Pork

2

340-400

30-40/lb

Chicken

2

340-400

45-60

Duck

2

340-400

45-60

Goose/Turkey

1

280-340

45-60

Lamb

2

340-400

15/lb

Fish

1-2

340-400

Depends on

dimension

Pizza

1-2

410-450

40-45

Short Pastry

1-2

340-400

15-20

Fruit Cake

1-2

340-400

20-30

Browning

3-4

140

5

Lasagna

2-3

375-410

20-25

Pasta

Roast Veal

2

300-350

65-90

Beef

2

350-375

65-90

Pork

2

300-325

70-100

Chicken

2

350

70-90

Duck

2

325-350

100-160

Goose/Turkey

2

300-325

160-240

Lamb

2

300-350

100-130

Fish

2-3

300-350

Depends on

dimension

Pizza

2-3

410-475

30-50

Sponge Cake

2-3

375-425

25-35

Fruit Cake

2-3

350-375

40-50

Bread

1-2

425-475

7

Setting:

Food:

Rack Level

(See Figure 33)

1st Side Cook

Time (m ins):

2nd Side Cook Time

(mins):

Pork Chops

4

7-9

5-7

Fillet (Pork)

3

9-11

5-9

Fillet (Beef)

3

9-11

9-11

Liver

4

2-3

2-3

Veal

4

7-9

5-7

Chicken

3

9-14

9-11

Sausages

4

7-9

5-6

Meatballs

4

7-9

5-6

Fish Fillet

4

5-6

3-4

Toast

4

2-4

2-3

Traditional

Cooking

(add time for

preheat)

Convection

Cooking

(add time for

preheat)

Grill Cooking

Oven-Baked

2 375-410 25-30

42

Page 43

Care and Cleaning

Figure 34

ELECTRICAL SHOCK HAZARD

BURN HAZARD

To avoid possible burns use care when cleaning the appliance.

DO NOT attempt to clean the appliance whenever the oven or burner heads are still hot.

To avoid possible burns DO NOT attempt any of the following cleaning instructions

before turning OFF ALL of the surface burners and allowing them to cool.

IMPORTANT: Always follow label instructions on cleaning products.

• Control Knobs

− For general cleaning, use hot, soapy water and a cloth.

− For more difficult soils and built-up grease, apply a liquid detergent directly onto the

soil. Rinse with a damp cloth and dry.

− DO NOT use steel wool or acidic cleaners on the knobs as they can scratch.

• Burner

Grates

− Clean burner grates in the dishwasher and dry upon removal.

− Please note that the grates are equipped with rubber pads on the feet that come into

contact with the range to avoid scratches. After cleaning it is important to verify that

these rubber pads are still there. Should they come off, they can be reapplied using

heat resistant adhesive.

− Grates should be positioned correctly over the burners as shown. (See Figure 34)

43

Page 44

• Burner Caps

− To clean the burner caps, lift the burner cap off the burner head. Clean heavy soils with

an absorbent cloth.

− Rinse with a clean, damp cloth and immediately thoroughly dry including the bottom

and inside of the cap.

− Do not use harsh abrasive cleaners. They can scratch the cap.

− DO NOT PUT BURNER UNITS I N THE DIS HWASHER

• Burner Heads

− The holes in the burners of your appliance MUST be kept clean at all times for proper

ignition and a complete, even flame. Remove any food from between the burner slots

using a small nonabrasive brush like a toothbrush and afterwards wipe using a damp

cloth.

− To remove deposits from the burner cavities, remove the cap and separate the two parts.

Clean the burner holes routinely with a small gauge wire or needle and especially after

bad spillovers which could clog these holes.

− After cleaning, put the two parts back together and return them correctly to their position,

making sure they are seated and level.

− DO NOT PUT BURNER UNITS I N THE DIS HWASHER

• Stainless Steel

− Clean stainless steel with hot, soapy water and a dishcloth. Rinse with clean water and a

cloth.

− Do not use cleaners with high concentrations of chlorides or chlorines. Do not use harsh

scrubbing cleaners. Only use kitchen cleaners that are especially made for cleaning

stainless steel.

• Inside O

− This appliance does NOT have a self-cleaning feature.

− DO NOT attempt to clean the appliance whenever the oven is still hot.

− Use an appropriate cleaning product designed specifically to clean the inside of ovens.

− IMPORTANT: Al ways follow label instruct ions on cleaning products.

ven

44

Page 45

• Cleaning Interior Lower Grill Element

− To remove the element, support one side with your hand while removing the retainer

with the other.

− When cleaning, make sure not to apply excessive force on the element as it is fragile.

− Reposition the element and secure the retainer back in place.

− DO NOT use the oven with the grill element hanging down – it must be repositioned after

cleaning.

• Oven Door Exterior

− Use a glass cleaner and a soft cloth or sponge.

− Apply glass cleaner to soft cloth or sponge, not directly on panel.

• Removing and Cleaning the Oven Door

For normal range use, it is not suggested to remove the oven door. However, if removal is

necessary, make sure the oven is off and cool. The oven door is heavy. Follow these

instructions.

− Open the door fully.

• Lift up and turn the small levers located on the two hinges.

• While holding the door on each side, close it approximately half way.

• While in this position release the door by pressing clamps ‘F’ (see illustration below)

and pull the door towards you. (See Figure 35)

− To replace the door, perform the reverse of the above procedure.

Figure 35

45

Page 46

• Changing the Interior Oven Light Bulb

Figure 36

ELECT

RICAL SHOCK HAZARD

− Ensure that the appliance is switched off before replacing the lamp to avoid possible

electric shock.

− Remove the glass cover by turning counter clockwise. (See Figure 36)

− Replace bulb with a high temperature bulb able to withstand 600 degrees and that meets

the following criteria:

• 240V

• 25W

• Type: E-14

46

Page 47

Solutions to Common Problems

IMPOR

Before calling for service, review this list. It may save you both time and expense. This

list includes common experiences that are not the result of defective workmanship or

material in your appliance.

Electrical Shock Hazard

Plug into a grounded 3 prong outlet.

Do not remove ground prong.

Do not use an adapter.

Do not use an extension cord.

Failure to follow these instructions can result in death, fire, or electrical shock.

NOTHING WILL OPERATE

■ Is the electrical supply disconnected?

TANT

Verify that electrical wires are connected to the mains properly. See “Electrical Connection”

section. If the problem continues, contact a qualified technician.

■ Household fuse blown or circuit breaker tripped?

Replace the fuse or reset the circuit breaker. If the problem continues, contact a qualified

technician.

■ Is the main or regulator gas shutoff valve in the off position?

See “Gas Connection” section.

■ Is the range properly connected to the gas supply?

Contact a qualified technician. See “Gas Connection” section.

SURFA

■ Is this the first time the surface burners have been used?

Turn on any one of the surface burner knobs to release air from the gas lines.

■ Is the control knob set correctly?

Push in knob before turning to a setting.

CE BURNERS WILL NOT OPERATE

47

Page 48

■ Are the burner ports clogged?

See “Care and Cleaning” section.

SURFACE

■ Are the burner ports clogged?

See “Care and Cleaning” section.

■ Are the burner caps positioned properly?

See “Placement of Burner Heads and Caps” section.

■ Is propane gas being used?

The range may have been converted improperly. Contact a qualified service technician. See

“Liquid Petroleum (Propane) Gas Conversion” section.

SURFACE

■ Is the burner wet?

Let it dry.

EXCES

■ Is the cookware the proper size?

Use cookware about the same size as the surface cooking area, element or surface burner.

BURNERS ARE UNEVEN, YELLOW AND/OR NOISY

BURNER MAKES POPPING NOISES

S HEAT AROUND COOKWARE ON COOKI NG SURFACE

Cookware should not extend more than ½" (1.3 cm) outside the cooking area.

COOKTOP COOKING RESULTS NOT WHAT EXPECTED

■ Is the proper cookware being used?

See “Surface Cooking Utensils” section.

■ Is the control knob set to the proper heat level?

See “Setting Surface Controls” section.

■ Is the range level?

Level the range. See the “Unpack Range / Install Leveling Feet and Back Panel” section.

OVEN WILL NOT OPERATE

■ Are the oven controls set correctly?

See “Setting Oven Controls” section.

48

Page 49

COOLING FAN RUNS DURING BAKING AND BROI LI NG

■ It is normal for the fan to automatically run while the oven is in use and for s ome time after to

cool.

OVEN T

■ Was the oven preheated?

See “Cooking Instructions” section.

■ Are the racks positioned properly?

See “Cooking Instructions” section.

■ Is there proper air circulation around bakeware?

See “Cooking Instructions” section.

■ Is the batter evenly distributed in the pan?

Check that batter is level in the pan.

■ Is the proper length of time being used?

Adjust cooking time.

■ Has the oven door been opened while cooking?

Oven peeking releases oven heat and can result in longer cooking times.

■ Are baked items too brown on the bottom?

Move rack to higher position in the oven.

■ Are pie crust edges browning early?

EMPERATURE TOO HIGH OR TOO LOW

Use aluminum foil to cover the edge of the crust and/or reduce baking temperature.

NO SPARK WHEN LIGHTING BURNER

■ Electrical supply - The electrical wires or the plug are not connected well.

Connect with electrical power again. If the problem continues, contact a qualified technician.

■ Burner - The burner is not installed correctly.

Install the burner again. See “Placement of Burners and Caps” section.

■ Spark pin - Ignition electrode and the hole are not placed well.

Install the burner again. See “Placement of Burners and Caps” section.

THE FIRE GOES OUT ONCE RELEASING THE KNOB

■ Safet y valve - Knob not pressed down long enough.

Press and turn the knob again and keep 3 to 5 seconds after the burner has been lit.

BURNER WON’T IGNITE OR BURNS UNEVENLY

49

Page 50

■ Gas valve - The valve is not open.

Make sure the valve is completely open.

■ Gas pipe - There may be air in the gas pipe.

Ignite repeatedly until flame catches.

■ Burner cap

− The burner cap is not placed correctly.

o Replace the burner cap.

− Some holes in the lid are stocked.

o Clean the holes of the lid.

■ Spark pin - The spark pin is wet or contaminated by t he food.

Clean and dry the spark pin..

■ Gas connecting pipes - The gas connecting pipes are stocked or squashed.

Contact a qualified technician. Adjust or change the connecting pipes.

THE FLAME GOES OUT DURING OPERATION

■ Thermocouple

− The safety device is contaminated.

o Clean the thermocouple.

− The flame is so little that it can’t touch the thermocouple

o Adjust the flame a little bigger. See the “ Pr oper Burner Adjustments” section.

STRAN

■ Gas leaking -

GE SMELL

Contact a qualified technician

− The gas supply pipe

o The main burner is not lit.

− Change the gas supply pipe.

o Ignite again after there is no strange smell.

is old and broken.

50

Page 51

WARRANTY AND SERVICE

For full warranty details on this product please visit:

http://www.cosmoappliances.com/warranty

TO RECEIVE WARRANTY SERVICE, YOUR

PRODUCT MUST BE REGISTERED. TO REGISTER, VISIT:

WWW.COSMOAPPLIANCES.COM/WARRANTY

Loading...

Loading...