Page 1

I N S P I R I N G T H E W O R L D ’ S K I T C H E N

30 IN. DUAL FUEL

FREE- STANDING RANGE

CUISINIÈRE AUTOPORTANTE

À BI-COMBUSTIBLE DE 30 PO

COS-305DFSC

IMPORTANT SAFETY INSTRUCTIONS

Carefully read the following Important information redarding installation

safety and maintenance. Keep these instruction for future reference.

INSTALLATION Instructions

INSTRUCTIONS d’installation

Page 2

RANGE SAFETY ...........................................................................................................

I

NSTALLATION REQUIREMENTS ...............................................................................

Tools and Parts ..........................................................................................................

Location Requirements ..............................................................................................

Electrical Requirements .............................................................................................

Gas Supply Requirements .......................................................................................

I

NSTALLATION INSTRUCTIONS ...............................................................................

Step 1 - Unpack Range ...........................................................................................

Step 2 - Install Anti-Tip Bracket ...............................................................................

Step 3 - Make Electrical Connection ........................................................................

Step 4 - Make Gas Connection .................................................................................

Step 5 - Install Range ...............................................................................................

G

AS CONVERSION ...................................................................................................

Step 1 - Adjust the Gas Pressure Regulator .............................................................

Step 2 - Change Burner Oriÿces ...............................................................................

Step 3 - Adjust Burner Flames .................................................................................

Step 4 - Testing Flame Stability ................................................................................

Step 5 - Flame Re-Check ..........................................................................................

Table of Contents

THANK YOU FOR YOUR PURCHASE.

Thank you for your purchase. We know that you have many brands and

products to choose from and we are honored to know that you have decided

to take one of our products into your home and hope that you enjoy it.

COSMO appliances are designed according to the strictest safety and performance

standard for the North American market. We follow the most advanced

manufacturing philosophy. Each appliance leaves the factory after thorough

quality inspection and testing. Our distributors and our service partners are

ready to answer any questions you may have regarding how to install, use and

care for your products. We hope that this manual will help you learn to use the

product in the safest and most effective manner .

If you have any questions or concerns, please contact the dealer from whom you

purchased it, or contact our Customer Support at:

1-888-784-3108.

Please read the important safety instructions before using our product for

4

7

7

8

11

13

16

16

17

18

22

23

25

27

28

29

30

30

INSTRUCTIONS D’INSTALLATION............................................................ 31

your own safety and to reduce the risk of fire or electrical shock, etc.

Please keep this manual for future use.

THANK YOU

2 3

Page 3

Range Safety

Range Safety

Your safety and the safety of others are very important.

We have provided many important safety messages in this manual

and on your appliance. Always read and obey all safety messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can

kill or hurt you and others. All safety messages will

follow the safety alert symbol and either the word

“DANGER,” “WARNING” or “CAUTION.”

These words mean:

An imminently hazardous situation. You

DANGER

WARNING

CAUTION

All safety messages will tell you what the potential hazard is, tell

you how to reduce the chance of injury, and tell you what can

happen if the instructions are not followed.

could be killed or seriously injured if

you don’t immediately follow instructions.

A potentially hazardous situation which, if

not avoided, could result

in death or serious bodily injury.

A potentially hazardous situation

which, if not avoided, may result

in moderate or minor injury.

WARNING

Fire Hazard

If the information in this manual is not followed exactly, a are

or explosion may result causing property damage, personal

injury or death.

- Do not store or use gasoline or other flammable vapors and liquids in

the vicinity of this or any other appliance.

- WHAT TO DO IF YOU SMELL GAS

Do not try to light any appliance.

•

•

Do not touch any electrical switch.

•

Do not use any phone in your building.

•

Clear the room, building, or area of all occupants.

•

Immediately call your gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions.

•

If you cannot reach your gas supplier, call the fire department.

- Installation and service must be performed by a qualified installer,

service agency or the gas supplier.

WARNING: Gas leaks cannot always be detected by smell.

Gas suppliers recommend that you use a gas detector approved

by UL or CSA.

For more information, contact your gas supplier.

If a gas leak is detected, follow the “What to do if you smell

gas” instructions.

4 5

Page 4

Range Safety

In the State of Massachusetts, the following installation

instructions apply:

Installations and repairs must be performed by a qualified or

•

licensed contractor, plumber, or gasfitter qualified or licensed by

the State of Massachusetts.

If using a ball valve, it shall be a T-handle type.

•

A flexible gas connector, when used, must not exceed 3 feet.

•

State of California Proposition 65 Warnings:

WARNING: This product contains one or more chemicals known

to the State of California to cause cancer.

WARNING: This product contains one or more chemicals known to

the State of California to cause birth defects or other reproductive

harm.

WARNING

ip Over Hazard

T

Installation Requirements

TOOLS AND PARTS

Gather the required tools and parts before starting installation. Read and follow

the instructions provided with any tools listed here.

TOOLS NEEDED

Tape measure

•

Flat-blade screwdriver

•

Phillips screwdriver

•

Level

•

Cordless electric drill

•

Hammer

•

Wrench or pliers

•

Pipe wrench

•

10" Adjustable Wrenches (2)

•

or LP/Natural Gas Conversions

F

½" Combination wrench

•

7 mm combination wrench

•

PARTS SUPPLIED

3/8" nut driver

•

¼" nut driver

•

1/8" (3.2 mm) drill bit (for wood floors)

•

Marker or pencil

•

Masking tape

•

Pipe-joint compound resistant to LP gas

•

a/16" carbide-tipped masonry drill bit

•

(for concrete ceramic floors)

Noncorrosive leak-detection solution

•

7 mm nut driver

•

A child or adult can tip the range and be killed.

Connect anti-tip bracket to rear range foot.

Reconnect the anti-tip bracket, if the range is moved.

Failure to follow these instructions can result in death or serious

burns to children and adults.

6 7

d

c

a 16 x 1 5/8" Screws (2)

b Anti-tip Bracket

OTE: The Anti-tip bracket must be securely mounted to the subfloor.

N

Depending on the thickness of the flooring, longer screws may be

required to anchor the anti-tip bracket to the subfloor. Longer screws are

available from your local hardware store.

c Regulator

d Gas Pipe Adapter

with Washer

Page 5

Installation Requirements

Installation Requirements

PARTS NEEDED

Check local codes and consult gas supplier. Check existing gas supply and

electrical supply. See “Electrical Requirements” and “Gas Supply

Requirements” sections.

Gas Supply Line Kit (Supply line and 2 adapters)

•

LOCATION REQUIREMENTS

VENTILATION

IMPORTANT: Observe all governing codes and ordinances. Do not obstruct

flow of combustion and ventilation air.

It is the installer’s responsibility to comply with installation clearances if

•

specified on the model/serial rating plate. The model/serial rating plate is

located on the left-hand side of the oven frame. Open oven door to view

label. See label on back panel of range for additional element and oven

power ratings.

a

a Rating Plate

GENERAL

The range should be located for convenient use in the kitchen.

•

Recessed installations must provide complete enclosure of the sides and

•

rear of the range.

To eliminate the risk of burns or fire by reaching over heated surface units,

•

cabinet storage space located above the surface units should be avoided. If

cabinet storage is to be provided, the risk can be reduced by installing a

range hood or microwave hood combination that projects horizontally a

minimum of 5" (12.7 cm) beyond the bottom of the cabinets.

All openings in the wall or floor where range is to be installed must be sealed.

•

Do not seal the range to the side cabinets.

•

Grounded electrical supply is required. See “Electrical Requirements” section.

•

Proper gas supply connection must be available. See “Gas Supply

•

Requirements” section.

DIMENSIONS

Product/Opening

Opening dimensions shown are for 25" (64.0 cm) countertop depth, 24" (61.0

cm) base cabinet depth and 36" (91.4 cm) countertop height.

a

5.9" (15 cm)

Min.

Min. 24" (60.9 cm)

Max. 30" (77 cm)

c

a

b

Dimension

30" (76 cm)

29 7/8" (75.9 cm)

TEMPERATURE

IMPORTANT: Some cabinet and building materials are not designed to

withstand the heat produced by the oven for baking and self-cleaning. Check

with your builder or cabinet supplier to make sure that the materials used will

not discolor, delaminate or sustain other damage.

Contact a qualified floor covering installer to check that the floor covering

•

can withstand at least 200°F (93°C).

Use an insulated pad or ¼" (0.64 cm) plywood under range if installing range

•

over carpeting.

8 9

c

ed

d

e

25" (63.5 cm)

36" (91.4 cm)

37 3/4" (96 cm)

b

N

OTE: Range can be raised approximately 1" (2.5 cm) by adjusting the leveling

legs. Front of door and drawer may extend farther forward depending on styling.

Page 6

Back of Range

a

b

c

a

Access Panel to Electrical

Supply Connection

b

Power Cord Opening

c

Recessed area

P

ower Supply

IMPORTANT: An electrical outlet in the floor, may be either recessed or surface

mounted, but an electrical outlet in the wall must be recessed to make the

connection. For Direct Wiring, the electrical box should be mounted to the wall.

a

b

e

d

g

h

c

f

a

30" (76 cm)

b

11½" (29.2 cm)

c

6" (15.2 cm)

d

7¼" (18.4 cm)

e

3" (7.6 cm)

f

17½" (44 cm)

g

Recommended Location for

Electrical Outlet

h

Recommended Location

for Gas Supply Connection

Installation Requirements

8

9

ELECTRICAL REQUIREMENTS

IMPORTANT: Use a 3-wire, UL listed, 30-amp minimum supply cord (pigtail);

or if local codes do not permit grounding through the neutral, use a 4-wire UL

listed, 30-amp minumum power supply cord rated at 250 volts and intended

for use with ranges.

If codes permit and a separate ground wire is used, it is recommended that

a qualified electrical installer determine that the ground path is adequate

and wire gauge is in accordance with local codes.

To properly install your range, you must determine the type of electrical

connection you will be using and follow the instructions provided for it here.

•

Range must be connected to the proper electrical voltage and frequency as

specified on the model/serial number rating plate. All models are dual rated,

and designed to be connected to either 120/240V or 120/208V AC, 60Hz,

single-phase, 3-wire or 4-wire, power supply.

Voltage and

Frequency

Amps Circuit Required

240V, 60 Hz 20A

25 Amp Circuit

208V, 60 Hz 17.4A

20 Amp Circuit

•

When a 4-wire, single-phase 120/240 volt, 60 Hz., AC only electrical

supply is available, a 25-amp maximum circuit protection is required (or, if

specified on the model/serial rating plate, when a 4-wire, single phase

120/208 volt 60 Hz., AC only electrical supply is available, a 20-amp

maximum circuit protection is required).

•

For direct wire installations, install a suitable conduit box (not furnished).

An appropriately sized, UL conduit connector must be used to correctly

attach the conduit to the junction box.

I

MPORTANT: Local Codes may vary; installation electrical connections

and grounding must comply with all applicable local codes.

If local codes permit grounding through the electrical supply neutral, connect

both the white neutral wire and the green ground wire from the oven to the

white neutral electrical supply wire.

ELECTRICAL REQUIREMENTS - U.S.A. ONLY

Do not use an extension cord.

Be sure that the electrical connection and wire size are adequate and in

conformance with the National Electrical Code, ANSI/ NFPA No. 70-latest

edition and all local codes and ordinances.

A copy of the above code standards can be obtained from:

National Fire Protection

Association One Batterymarch

Park

Quincy, MA 02269

Installation Requirements

NOTE: 24" (61.0 cm) minimum clearance required when bottom of wood or metal

cabinet is covered by not less than ¹/₄" (0.64 cm) flame retardant millboard

covered with not less than No. 28 MSG sheet steel, 0.015" (0.4 mm) stainless

steel,

0.024" (0.6 mm) aluminum or 0.020" (0.5 mm) copper. 30" (76.2 cm) minimum

clearance between the cooking and the bottom of an uncovered wood or metal

cabinet.

10 11

Page 7

WARNING

10

E

lectrical Shock Hazard

The electrical power to the oven branch circuit must be shut off

while line connections are being made.

Do not use an extension cord with this appliance.

Electrical ground is required on this appliance. The free end of the

green wire (the ground wire) must be connected to a suitable

ground. This wire must remain grounded to the oven.

If cold water pipe is interrupted by plastic, non metallic gaskets,

union connections or other insulating materials, DO NOT use for

grounding.

DO NOT ground to a gas pipe.

DO NOT have a fuse in the NEUTRAL or GROUNDING circuit. A

fuse in the NEUTRAL or GROUNDING circuit could result in an

electrical shock.

Check with a qualified electrician if you are in doubt as to whether the

appliance is properly grounded.

Failure to do so could result in death, fire or electric shock.

ELECTRICAL REQUIREMENTS - CANADA ONLY

Electrical Shock Hazard

Disconnect power before servicing.

Plug into a grounded outlet.

Do not use an extension cord.

Failure to do so can result in death, fire, or electrical shock.

Be sure that the electrical connection and wire size are adequate and in

conformance with CSA Standard C22.1, Canadian Electrical Code, Part 1 latest edition, and all local codes and ordinances.

Installation Requirements

WARNING

A copy of the above code standards can be obtained from:

Canadian Standards

Association 178 Rexdale Blvd.

Toronto, ON M9W 1R3

CANADA.

•

Check with a qualified electrical installer if you are not sure the range is

properly grounded.

•

This range is equipped with a CSA International Certified Power Cord

intended to be plugged into a standard 14-50R wall receptacle. Be sure the

wall receptacle is within reach of range’s final location.

•

Do not use an extension cord.

GAS SUPPLY REQUIREMENTS

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shut-off valve.

Securely tighten all gas connections.

If connected to LP, have a qualified person make sure gas

pressure does not exceed 14" (36 cm) water column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion or fire.

Observe all governing codes and ordinances.

Installation Requirements

WARNING

12 13

Page 8

12

IMPORTANT: This installation must conform with all local codes and

ordinances. In the absence of local codes, installation must conform with

American National Standard, National Fuel Gas Code ANSI Z223.1 - latest

edition or CAN/CGA B149 – latest edition.

I

MPORTANT: Leak testing of the range must be conducted according to

the manufacturers instructions.

TYPE OF GAS

Natural gas:

This range is design-certified by CSA International for use with Natural gas or,

after proper conversion, for use with LP gas.

•

This range is factory set for use with Natural gas. See “Gas Conversions”

section. The model/serial rating plate located on the right side oven door

trim has information on the types of gas that can be used. If the types of gas

listed do not include the type of gas available, check with the local gas supplier.

L

P gas conversion:

IMPORTANT: Conversion must be done by a qualified service technician.

No attempt shall be made to convert the appliance from the gas specified on

the model/serial rating plate for use with a different gas without consulting the

serving gas supplier. See “Gas Conversions” section.

GAS SUPPLY LINE

Provide a gas supply line of ¾" (1.9 cm) rigid pipe to the range location. A

smaller size pipe on longer runs may result in insufficient gas supply. Pipe-joint

compounds that resist the action of LP gas must be used. With LP gas, piping

or tubing size can be ½" (1.3 cm) minimum. Usually, LP gas suppliers determine

the size and materials used in the system.

G

as Shut-off Valve:

•

The gas supply line must be equipped with a manual shutoff valve. This valve

should be located in the same room but external to the range. It should be

in a location that allows ease of opening and closing. Do not block access

to shutoff valve. The valve is for turning on or shutting off gas to the range.

a b c

a Gas Supply Line

b Shutoff Valve “Open” Position

c Flexible/Rigid Gas Line to Range

Installation Requirements

13

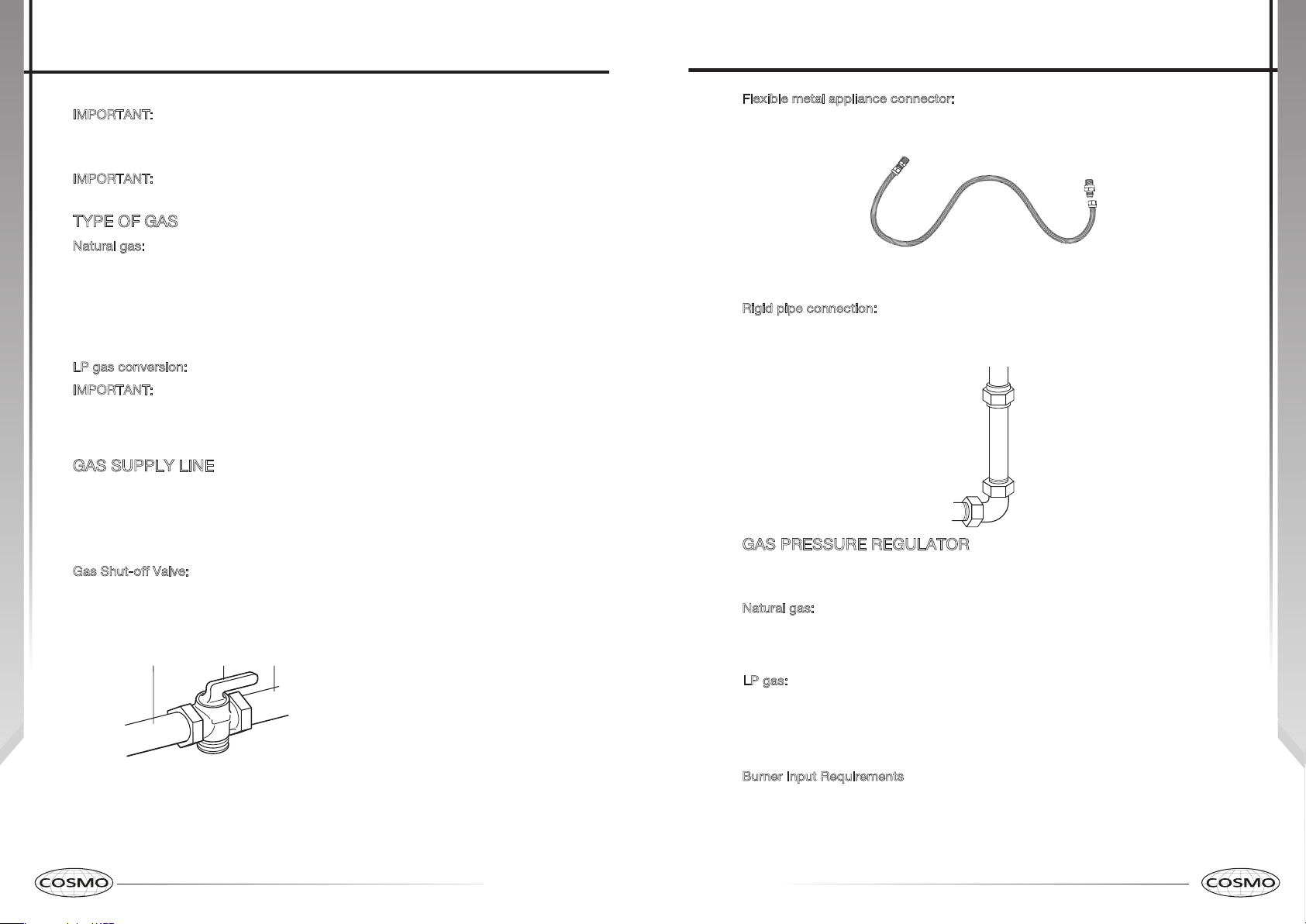

Flexible metal appliance connector:

•

If local codes permit, a new CSA design-certified, 4 - 5 ft (122 - 152.4 cm) long,

1/2" (1.3 cm) or 3/4" (1.9 cm) I.D., flexible metal appliance connector may

be used for connecting range to the gas supply line.

•

A ½" (1.3 cm) male pipe thread is needed for connection to the female

pipe threads of the inlet to the appliance pressure regulator.

•

Do not kink or damage the flexible metal tubing when moving the range.

R

igid pipe connection:

The rigid pipe connection requires a combination of pipe fittings to obtain an

in-line connection to the range. The rigid pipe must be aligned with the range

connection. All strains must be removed from the supply and fuel lines so

range will be level and in line.

GAS PRESSURE REGULATOR

The gas pressure regulator supplied with this range must be used. The inlet

pressure to the regulator should be as follows for proper operation:

N

atural gas:

Minimum pressure: 5" WCP

Maximum pressure: 14" WCP

L

P gas:

Minimum pressure: 11" WCP

Maximum pressure: 14" WCP

Contact local gas supplier if you are not sure about the inlet pressure.

B

urner Input Requirements

Input ratings shown on the model/serial rating plate are for elevations up to

2,000 ft (609.6 m).

For elevations above 2,000 ft (609.6 m), ratings are reduced at a rate of 4% for each

1,000 ft (304.8 m) above sea level (not applicable for Canada).

Installation Requirements

14 15

Page 9

14

GAS SUPPLY PRESSURE TESTING

Line pressure testing above 0.5 psi gauge (14. WCP)

The range and its individual shutoff valve must be disconnected from the gas

supply piping system during any pressure testing of that system at test

pressures in excess of 0.5 psi (3.5 kPa).

L

ine pressure testing at 0.5 psi gauge (14" WCP) or lower

The range must be isolated from the gas supply piping system by closing its

individual manual shutoff valve during any pressure testing of the gas supply

piping system at test pressures equal to or less than 0.5 psi (3.5 kPa).

I

MPORTANT: This appliance shall be installed only by authorized persons

and in accordance with the manufacturer’s installation instructions, local

gas fitting regulations, municipal building codes, electrical wiring

regulations, local water supply regulations.

STEP 1 - UNPACK RANGE

Excessive Weight Hazard

Use two or more people to move and install range. Failure to

do so can result in back or other injury.

1. Remove shipping materials, tape and film from the range. Keep

cardboard bottom under range. Do not dispose of anything until the

installation is complete.

2

. Remove oven racks and parts package from oven and shipping materials.

3

. To remove cardboard bottom, first take 4 cardboard corners from the

carton. Stack one cardboard corner on top of another. Repeat with the

other 2 corners. Place them lengthwise on the floor behind the range to

support the range when it is laid on its back.

4

. Using two or more people, firmly grasp the range and gently lay it on its

back on the cardboard corners.

5

. Remove cardboard bottom.

N

OTES:

•

The leveling legs can be adjusted while the range is on its back.

•

To place range back up into a standing position, put a sheet of cardboard

or hardboard on the floor in front of range to protect the flooring. Using two

or more people, stand range back up onto the cardboard or hardboard.

Installation Requirements

Installation Instructions

WARNING

WARNING

STEP 2 - INSTALL ANTI-TIP BRACKET

Tip Over Hazard

A child or adult can tip the range and be killed.

Connect anti-tip bracket to rear range foot.

Reconnect the anti-tip bracket, if the range is moved.

Failure to follow these instructions can result in death or serious

burns to children and adults.

IMPORTANT: An anti-tip bracket kit is included with the range. The anti-tip bracket

uses either the right or left rear leveling leg to secure the range to the floor.

1. Remove the anti-tip bracket from where it is taped inside the oven or storage

drawer.

2.

NOTE: The anti-tip bracket can be installed on either the left-hand side or

right-hand side of the opening.

3. Place the anti-tip bracket onto the floor so that the distances from the

center of the bracket to the center line and to the wall is correct for your

model.

•

Center of Opening to Center of Bracket: 13½" (34.3 cm)

•

4. Drill two 1/8" (3 mm) holes through the mounting holes in the anti-tip

bracket and into the floor.

NOTE: Contact a qualified floor covering installer for the best procedure

for drilling mounting holes through your type of floor covering.

5. Using the two screws provided, secure the anti-tip bracket to the floor.

NOTE: A rear leg of the range will be centered within the anti-tip bracket

when it is moved into its final position.

Installation Instructions

Determine and mark centerline of the opening where the unit will be installed.

Wall to Top of Bracket - 3 5/16" (8.e cm)

16 17

Page 10

Installation Instructions

Installation Instructions

DIRECT WIRE - U.S.A ONLY

STEP 3 - MAKE ELECTRICAL CONNECTION

After reading the requirements for each connection method, follow the

electrical connection instructions specific to your situation.

POWER SUPPLY CORD - CANADA ONLY

WARNING

Electrical Shock Hazard

Plug into a grounded outlet.

Do not use an extension cord.

Failure to do so can result in death, fire, or electrical shock.

1. Plug into a standard 14-50R grounded wall receptacle.

2

. Go to STEP 4 - MAKE GAS CONNECTION.

WARNING

Electrical Shock Hazard

Disconnect power before servicing.

Improper connection of aluminum house wiring and copper

appliance leads can result in an electrical hazard or fire. If the home

has aluminum wiring, only use connectors designed and UL listed

for joining copper to aluminum and precisely follow the

manufacturer's recommended procedure. Aluminum-to-Copper

connections must conform with local codes.

Use 10 gauge copper or aluminum wire.

Electrically ground range.

Failure to do so can result in death, fire or electrical shock.

Be sure your appliance is properly installed and grounded by a qualified

technician. Ask your dealer to recommend a qualified technician or an

authorized repair service.

This range is manufactured with a neutral (white) power supply wire and a

cabinet-connected green (or bare) ground wire twisted together.

After making sure that the power has been turned off, connect the flexible

conduit from the range to the junction box using a UL listed conduit connector.

The Grounded Neutral and Ungrounded Neutral Graphics on the following

pages and the instructions provided, present the most common way of

connecting ranges. Your local codes and ordinances, of course, take

precedence over these instructions. Complete electrical connections according

to local codes and ordinances.

18 19

Page 11

Installation Instructions

Installation Instructions

3-WIRE CONNECTION (GROUNDED NEUTRAL) - U.S.A. ONLY.

WARNING

Electrical Shock Hazard

Grounding through the neutral conductor is prohibited for new

branch-circuit installations (1996 NEC); mobile homes; and

recreational vehicles, or in an area where local codes prohibit

grounding through the neutral conductor. For installations where

grounding through the neutral conductor is prohibited, see the

Ungrounded Neutral graphic.

Use grounding terminal or lead to ground unit.

Connect neutral terminal or lead to branch circuit neutral in

usual manner.

Failure to do so could result in death, fire or electric shock.

3-Wire Cable from Home Power Supply

IMPORTANT: Use the 3-wire cable from home power supply where local codes

permit a 3-wire connection.

1

. Disconnect power.

rounded Neutral

G

a

i

2.

Connect the 2 black wires

.

3

Connect the 2 neutral (white) wires

(of the range cable) using a UL listed wire connector.

.

4

Connect the 2 red wires g together using a UL listed wire connector.

. Install junction box cover.

5

4-WIRE CONNECTION (UNGROUNDED NEUTRAL)- U.S.A. ONLY

4-Wire Cable from Home Power Supply

IMPORTANT: Use the 4-wire cable from home power supply in the U.S. where

local codes do not allow grounding through neutral, New Branch circuit

installations (1996 NEC), mobile homes and recreational vehicles, new

construction and in Canada.

. Disconnect power.

1

a

b together using a UL listed wire connector.

c and the ground (green or bare) wire d

U

ngrounded Neutral

i

b

h

c

g

f

e

d

a Junction Box

b Black Wires

c Neutral (White)

Wires

b

c

d

e

d Ground (Green or

Bare) Wire

e Cable from Range

f UL Listed Conduit

Connector

h

g

f

g Red Wires

h UL Listed Wire Connectors

i House Electrical Supply

20 21

a Junction Box

b Black Wires

c Red Wires

d Cable from Range

2

.

Connect the 2 black wires b together using a UL listed wire connector.

.

3

Connect the 2 red wires

. Untwist white wire from green (or bare) ground wire coming from the range.

4

.

5

Connect the 2 neutral (white) wires

wire connector.

6

.

Connect the ground (green or bare) wire

ground (green or bare) wire (in the junction box) using a UL listed wire

connector.

. Install junction box cover.

7

e UL listed or CSA

Approved Conduit

Connector

f Ground (Green or

Bare) Wires

c together using a UL listed wire connector.

h together using a UL listed

f from the oven cable to the

g UL Listed Wire

Connector

h Neutral (White) Wires

i House Electrical Supply

Page 12

Installation Instructions

Installation Instructions

STEP 4 - MAKE GAS CONNECTION

WARNING

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shut-off valve.

Securely tighten all gas connections.

If connected to LP, have a qualified person make sure gas

pressure does not exceed 14" (36 cm) water column.

Examples of a qualified person include:

licensed heating personnel,

authorized gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion or fire.

TYPICAL FLEXIBLE CONNECTION

CONNECT BSPP TO NPT ADAPTER TO GAS REGULATOR:

1. Apply pipe-joint compound made for use with LP gas to the male threads of

adapter c.

2

.

Insert adapter c into outlet of the gas pressure regulator d, and then

tighten

regulator is pointing up toward the range gas inlet pipe.

.

3

Install washer b in female end of adapter c, and then connect adapter

c

N

using two 10" adjustable wrenches. Be sure flow arrow

to range gas inlet pipe a via compression fitting and tighten.

OTE: Washer b must be used to create a leak proof seal.

on

CONNECT GAS LINE FROM GAS PRESSURE REGULATOR TO GAS SUPPLY:

1. Apply pipe-joint compound made for use with LP gas to the tapered (NPT)

threads of both adapters

. Attach one adapter to the gas pressure regulator and the other to the

2

gas shutoff valve and tighten both.

N

OTE: Do Not rotate the gas pressure regulator.

3

.

Attach the flexible gas line c to adapters d, one adapter at each end.

IMPORTANT: All connections must be wrench tightened (requires two 10"

adjustable wrenches). Do not over-tighten the connections to the gas pressure

regulator. Overtightening may crack the regulator creating a leak.

supplied with gas line kit.

d

e

a

d

a Adapter (provided)

b Gas Pressure Regulator

c Gas Supply Line

b

c

d

COMPLETE CONNECTION

1. Open the manual shutoff valve in the gas supply line. The valve is open when the

handle is parallel to the gas pipe.

2

. Test all connections by brushing on an approved noncorrosive leak-

detection solution. If bubbles appear, a leak is indicated. Correct any leak

found.

. Plug in range or reconnect power.

3

d Adapters (From Gas

Supply Line Kit)

e Gas Shutoff Valve

a

b

c

d

a Gas Line from Range

b Washer (provided)

c Adapter (provided)

d Gas Pressure Regulator

(provided)

STEP 5 - INSTALL RANGE

IMPORTANT: If the range is moved to adjust the leveling legs, make sure

when you move the range back into its final location that the anti-tip bracket is

engaged by repeating steps 1 through 8.

1

2

22 23

. Slide range into final location, making sure rear leveling leg slides into anti-

tip bracket. Leave a 1" (2.5 cm) gap between the back of the range and the

back wall.

. Place the outside of your foot against the bottom front to keep the range

from moving, and then grasp the back of the range, as shown.

Page 13

3. Slowly attempt to tilt the range forward.

If you encounter immediate resistance, the range foot is engage

d in the

anti-tip bracket. Go to Step 9.

4

. If the rear of the range lifts more than 1/2" (1.3 cm) off the floor without

resistance, stop tilting the range and lower it gently back to the floor. The

range foot is not engaged in the anti-tip bracket.

I

MPORTANT: If there is a snapping or popping sound when lifting the range,

the range may not be fully engaged in the bracket. Check to see if there are

obstructions keeping the range from sliding to the wall or keeping the range

foot from sliding into the bracket. Verify that the bracket is held securely in

place by the mounting screws.

5

. Slide the range forward, and verify that the anti-tip bracket is securely

attached to the floor or wall.

6

. Slide range back so the rear range foot is inserted into the slot of the

anti-tip bracket.

7

. Repeat steps 1 through 3 to ensure that the range foot is engaged in the

anti-tip bracket.

If the rear of the range lifts more than

1/2" (1.3 cm) off the floor without

resistance, the anti-tip bracket may not be installed correctly. Do not

operate the range without anti-tip bracket installed and engage

d.

8

. Move the range into its final location, and check that the range is level by

placing a carpenter’s level on the bottom of the oven.

N

OTE: The range must be level for optimum cooking and baking

performance.

9

. If needed, use a wrench to adjust the height of the leveling legs until the

range is level from side to side and front to back.

Installation Instructions

Gas Conversion

WARNING

Explosion Hazard

Use a new CSA International approved gas supply line.

Install a shut-off valve.

Securely tighten all gas connections.

If connected to LP, have a qualified person make sure gas

pressure does not exceed 14" (36 cm) water column.

Examples of a qualified person include:

licensed heating personnel, authorized

gas company personnel, and

authorized service personnel.

Failure to do so can result in death, explosion or fire.

24 25

LP/PROPANE GAS CONVERSION

This appliance can be used with Natural Gas or LP/Propane gas. It is shipped

from the factory for use with natural gas.

be purchased separately.

When the cooktop is converted for liquid petroleum (LP) gas, the LP gas

supply is required to provide a minimum of 10" to a maximum of 14" water

column to the cooktop regulator.

The conversion must be performed by a qualified service technician in

accordance with the kit instructions and all local codes and requirements.

Failure to follow instructions could result in serious injury or property damage.

The qualified agency performing this work assumes responsibility for the

conversion.

A kit for converting to LP gas must

Page 14

Gas Conversion

Burner and Orifice Characteristic Table

Burner Position

Auxiliary Rear R 0.9 NG 4" 3500

Semi-Rapid Rear L and

Triple Front L 0.93 + 1.82 NG 4" 18000

Rapid Front R 1.6 NG 4" 11000

OTE: The triple burner has only two injectors, one injector mounted in the

N

center and one mounted below the cover plate. To access the second injector,

remove the two screws and the cover plate.

Center

Orifice Gas Pressure Rate

Diam. (mm) Type [i.w.c.] [BTU/h]

0.58 LP (Propane) 10" 3500

1.17 NG 4" 6000

0.75 LP (Propane) 10" 6000

1.14 + 0.56 LP (Propane) 10" 18000

1.03 LP (Propane) 10" 11000

Gas Conversion

STEP 1 - ADJUST THE GAS PRESSURE REGULATOR

IMPORTANT: Disconnect all electrical power, at the main circuit breaker or fuse

box. Shut off the gas supply to the range by closing the manual shut-off valve.

1

. Unscrew the regulator cap with the wrench.

a

a Regulator Cap

. Remove the retainer pin that is currently positioned for use with Natural Gas.

2

a

a

a Opening in grate for wok ring (provided) is located over left front burner.

ools Needed for Conversion:

T

Wrench

•

7 mm Nut Driver

•

Safety Glasses

•

Small Flat-head Screwdriver

•

. Turn the retainer pin upside down and replace it into the regulator cap. It is

3

. Screw the regulator cap back into the regulator.

4

26 27

a Retainer Pin

now positioned for use with LP gas.

a

a Retainer Pin

Page 15

Gas Conversion

Not Properly SeatedProperly Seated

STEP 3 - ADJUST BURNER

F

LAMES

NOTES:

•

Turn all burners on highest setting and check the flames. They should be

blue in color and may have some yellow tipping at the ends of the flame

when using LP gas. Foreign particles in the gas line may cause an orange

flame at first, but this will soon disappear.

•

Turn the cooktop burner knob to “LO” while observing the flame.

•

Adjustments must be made with two other burners in operation on a medium

setting. This prevents the upper row of flames from being set too low,

resulting in the flame being extinguished when other burners are turned on.

1

. Remove the knobs.

2

. Insert a screwdriver through the access hole in valve shaft as shown.

3

. Slowly turn the screw until the flame appearance is correct.

•

Open the valve more if the flames are too small or fluttered.

•

Close the valve more if the flames are too large.

Gas Conversion

STEP 4 - TESTING FLAME STABILITY

Test 1 - Turn the knob from “HI” to “LO” quickly. If the upper row of flames

goes out at this setting, increase the flame size and test again.

T

est 2 - With the burner on “LO”, open and close the cabinet door under

the cooktop. If the air currents created by the door moving extinguish

the flame, increase the flame height and test again.

STEP 5 - FLAME RE-CHECK

After the adjustment is made, turn all burners off. Ignite each burner individually.

Observe the flame at the “HI” position. Rotate the knob to the lowest setting and

be sure that the flame size decreases as the knob is rotated counterclockwise.

STEP 2 - CHANGE BURNER ORIFICES

IMPORTANT: Carefully read and observe each orifice label for correct location.

See the Burner Chart earlier in this section.

N

OTE: First remove all orifices and then start replacing them. This will help avoid

the possibility that some may not be replaced.

1

. Remove the burner grates, burner caps and burner heads.

. Using a 7mm nut driver, remove the burner orifices.

2

a Orifices

a

Triple Ring Burner

2 Orifices

3. Install the proper orifices in the exact locations as noted in the previous graphic.

4. Replace the burner bases, heads, caps and top grates. Make sure burner

caps are properly seated on the burner head.

a

Auxiliary Burner Semi-Rapid

Burner Rapid Burner

1 Orifice Each

28 29

Page 16

Gas Conversion

IMPORTANT: Once the conversion has been completed and has passed

testing, fill out the conversion sticker and include your name, organization

and the date conversion is made. Apply the sticker near the cooktop gas inlet

opening to alert others in the future that this appliance has been converted. If

converting back to Natural Gas, please remove the sticker so others know

that the appliance is set to use its original gas.

ABNORMAL OPERATION

ANY OF THE FOLLOWING ARE CONSIDERED TO BE ABNORMAL

OPERATION AND MAY REQUIRE SERVICING:

Yellow tipping of the hob burner flame.

•

Sooting up of cooking utensils.

•

Burners not igniting properly.

•

Burners failing to remain lit.

•

Burners extinguished by oven door.

•

Gas valves, which are difficult to turn.

•

I

N CASE THE APPLIANCE FAILS TO OPERATE CORRECTLY, CONTACT THE

UTHORIZED SERVICE PROVIDER IN YOUR AREA

A

THE BURNERS REQUIRE NO REGULATION OF THE PRIMARY AIR

Circuit Diagram

Low

Top Grill

Back grill

Bottom Grill

120 Therma l cut off

Cool fan

Cyc

High

Cool fan

M1

M2 M3

Lamp

Latch

fan

M4

85 Therma l cut off

Table des Matières

SÉCURITÉ DE LA CUISINIÈRE .................................................................................. 30

EXIGENCES D’INSTALLATION .................................................................................. 32

Outillage et pièces .....................................................................................................32

Exigences d’emplacement ........................................................................................33

Spécifications électriques .........................................................................................37

Exigences de l’alimentation en gaz ..........................................................................40

I

NSTRUCTIONS D’INSTALLATION .......................................................................... 43

Étape 1 - Déballage de la cuisinière ........................................................................43

Étape 2 - Installation de la bride antibasculement ...................................................44

Étape 3 - Raccordement électrique .........................................................................45

Étape 4 - Raccordement au gaz .............................................................................50

Étape 5 - Installation de la cuisinière ......................................................................52

C

ONVERSION POUR CHANGEMENT DE GAZ ....................................................... 53

Étape 1 – Réglage du détendeur ..............................................................................55

Étape 2 – Remplacement des orifices des brûleurs .................................................56

Étape 3 – Réglage des flammes des brûleurs ..........................................................57

Étape 4 – Test de la stabilité des flammes ...............................................................58

Étape 5 – Second test des flammes .........................................................................58

L1(RED)

N(WHITE)

L2(BLACK)

G(GREEN)

A68A67

L1

A53

A65

A10

A43

A12

A52

A66

A54A55

A42

L2

L2

L

L

L1

2

1

Latch2

GND

Latch_door1

Baffle

Latch1

DOOR

TO_DISP

UP_HT_CUT

L

L

a

PCB BOARD

MI

CA

down sensor

GA

CA

CA

CA

at

DOOR

tch1

GND

c

h2

up sensor

Latch_door2

CA

LN

POWER

TO_SW

GND

Probe

GND

Probe

GND

Baffle

probe_down probe_up

PCB BOARD

A Plug

B Plug

DISPLAY

Probe socket

30 31

Page 17

Sécurité de la Cuisinière

Votre sécurité et celle des autres est très importante.

Nous donnons de nombreux messages de sécurité importants

dans ce manuel et sur votre appareil ménager. Assurez-vous de

toujours lire tous les messages de sécurité et de vous y conformer.

Voici le symbole d’alerte de sécurité.

Ce symbole d’alerte de sécurité vous signale les

dangers potentiels de décès et de blessures graves

à vous et à d’autres. Tous les messages de sécurité

suivront le symbole d’alerte de sécurité et le mot

“DANGER”, “AVERTISSEMENT” ou “ATTENTION”.

Ces mots signifient :

Une situation de danger

DANGER

AVERTISSEMENT

ATTENTION

Tous les messages de sécurité vous diront quel est le danger

potentiel et comment réduire le risque de blessure et ce qui peut

se produire en cas de non-respect des instructions.

imminent. Vous courez le risque

d’un décès ou de blessures

graves si vous ne suivez pas

immédiatement les instructions.

Une situation potentiellement

dangereuse qui, si vous ne

l’évitez pas, peut provoquer la

mort ou des blessures graves.

Une situation potentiellement

dangereuse qui, si vous ne

l’évitez pas, peut entraîner des

blessures légères à modérées.

Sécurité de la Cuisinière

AVERTISSEMENT

Risque d'incendie

Si les informations figurant dans ce manuel ne sont pas suivies à

la lettre, il peut en résulter un incendie ou une explosion pouvant

causer des dégâts matériels, des blessures, voire un décès.

- Ne pas ranger et utiliser d’essence ou d’autres vapeurs et liquides

inflammables à proximité de cet appareil ou d’un autre appareil.

- QUE FAIRE SI VOUS SENTEZ UNE ODEUR DE GAZ

Ne pas essayer d’allumer un appareil.

•

Ne pas toucher d’interrupteur électrique.

•

Ne pas utiliser de téléphone dans votre bâtiment.

•

Faire évacuer tous les occupants de la pièce, du bâtiment ou

•

de la zone concernée.

Appeler immédiatement votre fournisseur de gaz depuis chez un

•

voisin. Suivre les instructions de votre fournisseur de gaz.

Si le fournisseur de gaz ne peut être rejoint, appeler les pompiers.

•

- L’installation et la maintenance doivent être confiées à un installateur

qualifié, à un réparateur agréé ou au fournisseur de gaz.

32 33

AVERTISSEMENT : L’odorat ne permet pas toujours la

détection d’une fuite de gaz.

Les distributeurs de gaz recommandent l’emploi d’un détecteur de

gaz (homologation UL ou CSA).

Pour d’autre information, contacter le fournisseur de gaz local.

En cas de détection d’une fuite de gaz, exécuter les instructions

“Que faire dans le cas d’une odeur de gaz”.

Page 18

•

Clé mixte de 7 mm

Sécurité de la Cuisinière

AVERTISSEMENT

Risque de basculement

Un enfant ou une personne adulte peut faire basculer la cuisinière

ce qui peut causer un décès.

Joindre la bride antibasculement au pied arrière de la cuisinière.

Joindre de nouveau la bride antibasculement si la cuisinière

est déplacée.

Le non-respect de ces instructions peut causer un décès ou

des brûlures graves aux enfants et aux adultes.

Exigences d'installation

OUTILLAGE ET PIÈCES

Rassembler les outils et composants nécessaires avant d’entreprendre

l’installation. Lire et observer les instructions fournies avec chacun des outils de

la liste ci-dessous.

OUTILS NÉCESSAIRES

Mètre enrouleur

•

Tournevis à lame plate

•

Tournevis Phillips

•

Niveau

•

Perceuse électrique sans fil

•

Marteau

•

Clé ou pince

•

Clé à tuyauterie

•

Clés à molette de q0" (2)

•

Tourne-écrou de 3/8"

•

Pour conversions pour GPL / gaz naturel

Clé mixte de 1/2"

•

Tourne-écrou de 1/4"

•

Foret de 1/8" (3,2 mm) (pour

•

planchers en bois)

Marqueur ou crayon

•

Ruban adhésif de masquage

•

Composé d’étanchéité des raccords

•

filetés – résistant au GPL

Foret à maçonnerie à pointe carburée

•

de i/16" (4,8 mm) (pour planchers en

bétons céramique)

Solution non corrosive de détection

•

des fuites

Tourne-écrou de 7 mm

•

Exigences d'installation

PIÈCES FOURNIES

d

e

c

a Vis de 16 x 1 5/8” (2)

b La bride antibasculement

EMARQUE : Les brides antibasculement doivent être solidement fixées

R

au sous-plancher. La profondeur du plancher peut nécessiter des vis plus

longues pour l’ancrage de la bride dans le sous-plancher. Des vis plus

longues sont disponibles auprès de votre quincaillerie locale.

c Détendeur

d Adaptateur pour

conduite de gaz

avec rondelle

PIÈCES NÉCESSAIRES

Vérifier les codes locaux et consulter le fournisseur de gaz. Vérifier

l’alimentation en gaz et l’alimentation électrique existantes. Voir les sections

“Spécifications électriques” et “Spécifications de l’alimentation en gaz”.

Ensemble de conduite d’alimentation en gaz (conduite d’alimentation

•

et 2 adaptateurs)

EXIGENCES D’EMPLACEMENT

VENTILATION

IMPORTANT : Respecter les dispositions de tous les codes et

réglements en vigueur. Ne pas obstruer le flux de combustion et l’air de

ventilation.

C’est à l’installateur qu’incombe la responsabilité de respecter les

•

distances de séparation exigées, si spécifiées sur la plaque signalétique

de l’appareil. La plaque signalétique est située du côté gauche du cadre

du four. Ouvrir la porte du four pour lire l’étiquette. Consulter l’étiquette

située sur le panneau arrière de la cuisinière pour des données

supplémentaires et connaître la puissance nominale du four.

e Ensemble de

conversion au

gaz propane/

naturel

34 35

Page 19

Exigences d'installation

35

DIMENSIONS

Produit/ouverture

Les dimensions d’ouverture illustrées correspondent à une installation entre

des placards de 24" (61,0 cm) de profondeur, avec plan de travail de

25" (64,0 cm) de profondeur et de 36" (91,4 cm) de hauteur.

a

5,9" (15 cm)

Min.

b

c

ed

Dimension

a

30" (76 cm)

b

29 7/8" (75,9 cm)

c

25" (63,5 cm)

d

36" (91,4 cm)

e

37 3/4" (96 cm)

R

EMARQUE : La cuisinière peut être surélevée d’environ 1" (2,5 cm) en

ajustant les pieds de nivellement. L’avant de la porte et du tiroir peuvent

s’avancer davantage en fonction de l’agencement souhaité.

A

rrière de la cuisinière

a

b

c

a Panneau d’accès

au raccordement à

l’alimentation électrique.

b Ouverture pour le cordon

d’alimentation

c Zone d’encastrement

Exigences d'installation

Min. 24" (60.9 cm)

Max. 30" (77 cm)

a

a Plaque signalétique

TEMPÉRATURE

IMPORTANT : Les matériaux de certains placards et certains matériaux de

construction ne sont pas conçus pour résister à la chaleur générée par le four

durant la cuisson au four ou l’autonettoyage. Consulter le constructeur de la

maison ou le fabricant des placards pour déterminer si les matériaux utilisés

pourraient subir un changement de couleur, une déstratification ou d’autres

dommages.

Contacter un installateur de revêtement de sol qualifié, qui pourra déterminer si

•

le revêtement de sol peut résister à une température d’au moins 200 °F (93 °C).

Dans le cas de l’installation de la cuisinière par dessus un tapis, placer

•

sous la cuisinière une plaque d’appui isolée, ou une plaque de

contreplaqué de 1/4" (0,64 cm).

RENSEIGNEMENTS GÉNÉRAUX

La cuisinière doit être placée de manière à permettre une utilisation pratique

•

dans la cuisine.

Dans le cas d’une cuisinière encastrée, l’enceinte doit recouvrir

•

complètement les côtés et l’arrière de la cuisinière.

Afin de minimiser le risque de brûlures ou d’incendie au-dessus de la table

•

de cuisson, on doit éviter d’installer un placard mural. Si le rangement en

placard est envisagé, le risque peut être réduit par l’installation d’une hotte

de cuisinière ou un ensemble hotte/micro-ondes opérant horizontalement

sur un minimum de 5" (12,7 cm) au-delà du bas des placards.

Toutes les ouvertures dans le mur ou le plancher de l’emplacement

•

d’installation de la cuisinière doivent être scellées.

Ne pas réaliser un scellement entre la cuisinière et les placards latéraux.

•

Une source d’électricité avec liaison à la terre est nécessaire. Voir la

•

section “Spécifications électriques”.

Une source de gaz adéquate doit être disponible. Voir la section

•

“Spécifications de l’alimentation en gaz”.

36 37

Page 20

Exigences d'installation

Alimentation électrique

IMPORTANT : Une prise électrique au plancher peut être soit encastrée soit

montée en surface, mais une prise électrique murale doit être encastrée pour

pouvoir effectuer le raccordement. Pour un câblage direct, le boîtier de

raccordement doit être monté sur le mur.

a

b

d

g

e

a 30" (76 cm)

b 111/2" (29.2 cm)

c 6" (15.2 cm)

d 71/4" (18.4 cm)

e 3" (7.6 cm)

EMARQUE : Distance de séparation minimale de 24" (61 cm) lorsque le fond

R

d’un placard de bois ou de métal est protégé par une planche ignifugée d’au

moins 1/4" (0,64 cm) recouverte d’une tôle d’acier d’épaisseur égale ou

supérieure au calibre 28 MSG, d’acier inoxydable de 0,015" (0,4 mm),

d’aluminium de 0,024" (0,6 mm), ou de cuivre de 0,020" (0,5 mm). Distance de

séparation minimale de 30" (76,2 cm) entre le dessus de la table de cuisson et le

fond d’un placard de bois ou de métal non protégé.

f 17

g Emplacement conseillé pour

la prise électrique

h Emplacement conseillé

c

h

f

1

/2" (44 cm)

pour le raccordement à

l’alimentation en gaz

Exigences d'installation

SPÉCIFICATIONS ÉLECTRIQUES

IMPORTANT : Utiliser un cordon d’alimentation à 3 fils, homologué UL, un

cordon d’alimentation de 30 ampères (queue de cochon); ou si les codes

locaux ne permettent pas la mise à la terre à travers le fil neutre, utiliser un

cordon d’alimentation à 4 fils, homologué UL, 30 ampères spécifié pour

une tension nominale de 250 volts et approuvé pour une utilisation avec

des cuisinières.

Si les codes locaux le permettent et un fil de terre séparé est utilisé, il est

recommandé qu’un électricien qualifié vérifie que le chemin de terre est

adéquat et que le calibre du fil de terre est conforme aux codes locaux.

Afin d’installer correctement votre cuisinière, vous devez déterminer le type

de connexion électrique que vous allez utiliser et suivre les instructions

indiquées ici.

La cuisinière doit être connectée à la tension électrique et fréquence

•

spécifiées sur le modèle / numéro de série de la plaque signalétique. Tous

les modèles sont conçus pour être raccordés soit à monophasée de

120/240V ou 120/208V CA, 60 Hz, 3 fils ou soit à une alimentation, 4 fils.

Tension et

fréquence

240V, 60 Hz 20A

208V, 60 Hz 17.4A

Lorsqu’une source d’électricité monophasée de 120/240 volts, 60 Hz/4

•

conducteurs (CA uniquement) est disponible, le circuit doit comporter

un dispositif de protection de 25 A maximum (ou 20 A si la source

d’électricité spécifiée sur la plaque signalétique est de 120/208 volts).

Pour les installations de fils directs, installer une boîte de dérivation

•

appropriée (non fournie). Un connecteur de conduit homologué UL de taille

appropriée doit être utilisé pour fixer correctement le conduit à la boîte de

dérivation.

MPORTANT Les codes locaux peuvent varier; les raccordements

I

électriques d’installation et de mise à la terre doivent être conformes à tous

les codes locaux applicables.

Si les codes locaux permettent la mise à la terre à travers le neutre de

l’alimentation électrique, connecter le fil neutre blanc et le fil de terre vert de la

cuisinière au fil neutre blanc de l’alimentation électrique.

Ampères Circuit exigé

25 Amp Circuit

20 Amp Circuit

38 39

Page 21

Exigences d'installation

EXIGENCES ÉLECTRIQUES - ÉTATS-UNIS UNIQUEMENT

Ne pas utiliser de câble de rallonge.

S’assurer que la connexion électrique et le calibre des fils sont appropriés et

en conformité avec le National Electrical Code, ANSI / NFPA n° 70 - dernière

édition et avec tous les codes et règlements locaux.

On peut obtenir un exemplaire de la norme ci-dessus auprès de :

National Fire Protection

Association One Batterymarch

Park

Quincy, MA 02269

AVERTISSEMENT

Risque de choc électrique

Exigences d'installation

EXIGENCES ÉLECTRIQUES - CANADA UNIQUEMENT

AVERTISSEMENT

Risque de choc électrique

Déconnecter la source de courant électrique avant l'intervention.

Brancher sur une prise de terre.

Ne pas utiliser de câble de rallonge.

Le non-respect de cette instruction pourrait causer un décès,

un incendie ou un choc électrique.

L’alimentation électrique du circuit du branchement du four doit

être coupée lorsque les connexions des lignes sont mises en place.

Ne pas utiliser pas de rallonge avec cet appareil.

Une mise électrique à la terre est nécessaire pour cet appareil.

L’extrémité libre du connecteur vert (le connecteur de mise à la

terre) doit être connectée à la masse appropriée. Ce connecteur

doit rester branché à la masse au four.

Si un tuyau d’eau froide est interrompu par du plastique, des joints

non métalliques, des raccords union ou d’autres matériaux isolants,

NE PAS L'UTILISER pour la mise à la terre.

NE PAS brancher la masse à une canalisation de gaz.

Le circuit du NEUTRE ou de LIAISON A LA TERRE NE DOIT PAS

contenir de fusible. Un fusible dans le circuit du neutre ou de

liaison à la terre pourrait entraîner une électrocution.

L'utilisateur doit consulter un électricien qualifié s'il n'est pas sûr

que l'appareil est correctement relié à la terre.

Le non-respect de cette instruction peut causer un décès, un

incendie ou un choc électrique.

Vérifier que le raccordement à la source d’électricité et le calibre des

conducteurs sont conformes aux prescriptions de la plus récente édition de la

norme CSA C22.1, partie 1 - Code canadien de l’électricité, et de tout code ou

règlement local en vigueur.

On peut obtenir un exemplaire de la norme ci-dessus auprès de :

Canadian Standards

Association 178 Rexdale Blvd.

Toronto, ON M9W 1R3

CANADA.

En cas de doute quant à la qualité de la liaison à la terre de la cuisinière,

•

consulter un électricien qualifié.

Cette cuisinière est dotée d’un cordon d’alimentation (homologation CSA

•

International) destiné à être branché sur une prise de courant murale

standard 14-50R. Veiller à ce que la prise de courant murale soit placée à

proximité de l’emplacement définitif de la cuisinière.

Ne pas utiliser de câble de rallonge.

•

40 41

Page 22

Exigences d'installation

Exigences d'installation

EXIGENCES DE L’ALIMENTATION EN GAZ

AVERTISSEMENT

Risque d'explosion

Utiliser une canalisation neuve d'alimentation en gaz approuvée

par la CSA International.

Installer un robinet d'arrêt.

Bien serrer chaque organe de connexion des raccordements au gaz.

En cas de connexion au GPL, demander à une personne

qualifiée de s'assurer que la pression de gaz ne dépasse pas 36

cm (14 po) de la colonne d'eau.

Par personne qualifiée, on comprend :

le personnel autorisé de chauffage,

le personnel autorisé d'une compagnie de gaz,

et le personnel d'entretien autorisé.

Le non-respect de ces instructions peut causer un décès,

une explosion ou un incendie.

Observer toutes les prescriptions des codes et règlements en vigueur.

I

MPORTANT : L’installation doit satisfaire aux critères de tous les codes et

règlements locaux. En l’absence de code local, l’installation doit satisfaire aux

prescriptions de la plus récente édition du code national en vigueur : National

Fuel Gas Code ANSI Z223.1 (American National Standard), ou CAN/CGA

B149.

I

MPORTANT : Les tests de fuite de la cuisinière doivent être effectués

selon les instructions du fabricant.

TYPE DE GAZ

Gaz naturel:

La conception de cette cuisinière a été homologuée par CSA International

pour l’alimentation au gaz naturel, ou pour l’alimentation au GPL après

conversion adéquate.

Cette cuisinière a été configurée à l’usine pour l’alimentation au gaz naturel.

•

Voir la section “Conversions pour changement de gaz”. La plaque

signalétique des numéros de modèle et de série située sur le côté droit de la

garniture de la porte du four indique les types de gaz utilisables. Si le type

de gaz disponible n’est pas mentionné sur la plaque signalétique, consulter

le fournisseur de gaz local.

Conversion au GPL :

IMPORTANT : L’opération de conversion doit être exécutée par un

technicien qualifié.

Consulter le fournisseur de gaz avant toute conversion de l’appareil pour

l’utilisation d’un type de gaz qui n’est pas mentionné sur la plaque signalétique.

Voir la section “Conversions pour changement de gaz”.

CANALISATION DE GAZ

Installer une canalisation de gaz rigide de 3/4" (1,9 cm) jusqu’à l’emplacement

d’installation de la cuisinière. L’emploi d’une canalisation de plus petit

diamètre ou plus longue peut engendrer une déficience du débit

d’alimentation. On doit utiliser un composé d’étanchéité des tuyauteries

résistant à l’action du gaz de pétrole liquéfié. Pour l’alimentation au GPL, le

diamètre des canalisations doit être de 1/2" (1,3bcm) ou plus. Généralement,

le fournisseur de GPL détermine les matériaux à utiliser et le diamètre

approprié.

R

obinet d’arrêt du gaz :

La canalisation d’alimentation en gaz doit comporter un robinet d’arrêt manuel.

•

Le robinet d’arrêt manuel doit être séparé de la cuisinière, mais doit se

trouver dans la même pièce en un endroit où il sera facilement accessible

pour les manoeuvres d’ouverture/fermeture. Ne pas entraver l’accès au

robinet d’arrêt manuel. Le robinet d’arrêt manuel est prévu pour ouvrir ou

fermer l’alimentation en gaz de la cuisinière.

a b c

R

accord métallique flexible :

Si les codes locaux le permettent, on peut utiliser pour raccorder la cuisinière à

•

la canalisation de gaz un raccord métallique flexible neuf (homologation

CSA) de 4 à 5 pi (122 à 152,4 cm) de longueur, de diamètre interne de

1/2" (1,3 cm) ou 3/4" (1,9 cm).

Un raccord avec filetage mâle de 1/2" (1,3 cm) est nécessaire pour la

•

connexion sur le raccord à filetage femelle à l’entrée du détendeur de

l’appareil.

Veiller à ne pas déformer/écraser/endommager le tube métallique flexible

•

lors d’un déplacement de la cuisinière.

a Canalisation de gaz

b Robinet d’arrêt manuel - position

d’ouverture

c Conduite de gaz flexible/rigide

vers la cuisinière

42 43

Page 23

Raccordement par un ensemble rigide :

On doit utiliser une combinaison de raccords pour réaliser un raccordement

rigide entre la cuisinière et la canalisation de gaz. Le tuyau rigide doit être aligné

que le raccord de connexion de la cuisinière. On doit veiller à ne soumettre les

sections de canalisation d’alimentation à aucun effort de traction ou flexion,

pour que la cuisinière soit d’aplomb et correctement alignée.

DÉTENDEUR DE GAZ

Le détendeur fourni avec cette cuisinière doit être utilisé. Pour un fonctionnement

correct, la pression d’alimentation du détendeur doit être comme suit :

G

az naturel:

Pression minimum : 5" (colonne d’eau)

Pression maximum : 14" (colonne d’eau)

G

PL :

Pression minimum : 11" (colonne d’eau)

Pression maximum : 14" (colonne d’eau)

En cas d’incertitude quant à la pression d’alimentation à établir, contacter le

fournisseur de gaz local.

D

ébit thermique des brûleurs

Les débits thermiques indiqués sur la plaque signalétique correspondent à

une altitude d’utilisation inférieure à 2000 pi (609,6 m).

Lorsque l’appareil est utilisé à une altitude supérieure à 2000 pi (609,6 m), on

doit réduire le débit thermique indiqué de 4 % pour chaque tranche de 1000 pi

(304,8 m) au-dessus du niveau de la mer (pas applicable au Canada).

TESTS DE PRESSURISATION DE LA CANALISATION DE GAZ

Pressurisation à une pression supérieure à ½ lb/po² (14" - colonne d’eau)

Lors de tout test de pressurisation de ce système à une pression supérieure à

1/2 lb/po² (3,5 kPa), on doit déconnecter la cuisinière et son robinet d’arrêt

individuel de la canalisation de gaz.

P

ressurisation à une pression inférieure à ½ lb/po² (14" - colonne d’eau)

Lors de tout test de pressurisation de la canalisation de gaz à une pression

égale ou inférieure à 1/2 lb/po² (3,5 kPa), on doit isoler la cuisinière de la

canalisation de gaz par fermeture de son robinet d’arrêt manuel individuel.

Exigences d'installation

Instructions d'installation

IMPORTANT : Cet appareil doit être installé uniquement par des personnes

autorisées et en conformité avec les instructions d’installation du fabricant,

les règlements locaux en matière de raccordement au gaz, les codes du

bâtiment municipaux, les règlements spécifiques au câblage électrique, les

règlements d’approvisionnement en eau locaux.

ÉTAPE 1 - DÉBALLAGE DE LA CUISINIÈRE

AVERTISSEMENT

Risque du poids excessif

Utiliser deux personnes ou plus pour déplacer et installer la

cuisinière.

Le non-respect de cette instruction peut causer une blessure au dos

ou d'autre blessure.

1. Ôter les matériaux d’emballage, le ruban adhésif et la pellicule protectrice

de la cuisinière. Garder la base de carton sous la cuisinière. Ne rien jeter

avant d’avoir complètement terminé l’installation.

. Retirer les grilles de four et le sachet de pièces du four et les

2

matériaux d’emballage.

. Pour retirer le fond en carton, prendre d’abord les 4 coins en carton de la

3

caisse. Empiler l’un des coins sur un autre. Répéter avec les 2 autres coins.

Les disposer sur le plancher dans le sens de la longueur derrière la

cuisinière, à titre de support de la cuisinière lorsque celle-ci est placée sur

sa partie postérieure.

4

. À l’aide d’au moins deux personnes, saisir fermement la cuisinière et la

déposer délicatement sur sa partie postérieure, sur les coins de protection.

. Retirer le fond en carton.

5

REMARQUES :

Les pieds de nivellement peuvent être réglés pendant que la cuisinière repose

•

sur sa partie postérieure.

Pour relever la cuisinière en position verticale, placer un carton ou un

•

panneau de fibres dur au sol devant la cuisinière pour protéger le plancher. À

deux personnes au moins, redresser la cuisinière et la placer sur le carton ou

le panneau de fibres dur.

44 45

Page 24

Instructions d'installation

Instructions d'installation

ÉTAPE 2 - INSTALLATION DE LA BRIDE

A

NTIBASCULEMENT

AVERTISSEMENT

Risque de basculement

Un enfant ou une personne adulte peut faire basculer la cuisinière

ce qui peut causer un décès.

Joindre la bride antibasculement au pied arrière de la cuisinière.

Joindre de nouveau la bride antibasculement si la cuisinière

est déplacée.

Le non-respect de ces instructions peut causer un décès ou

des brûlures graves aux enfants et aux adultes.

IMPORTANT : Une trousse de support antibasculement est incluse avec la

cuisinière. La bride antibasculement utilise le pied de nivellement droit ou

gauche afin de fixer la cuisinière au plancher.

1. Ôter la bride antibasculement fixée par du ruban adhésif à l’intérieur du four ou

du tiroir de remisage.

2

. Déterminer et marquer l’axe central de l’ouverture.

R

EMARQUE : On peut installer la bride antibasculement du côté gauche ou

droit de l’ouverture.

3

. Placer la bride antibasculement sur le sol de sorte que les distances à

partir du centre de la bride à l’axe central et au mur soient correctes par

rapport au modèle à installer.

Centre de l’ouverture jusqu’au centre de la bride : 131/2" (34,3 cm)

•

Mur jusqu’au dessus de la bride : 35/.6" (8, cm)

•

4

. Percer deux trous de 1/8" (3 mm) à travers les orifices de montage sur la

bride antibasculement et dans le plancher.

R

EMARQUE : Contacter un installateur de revêtements de sol qualifié au

sujet des meilleures méthodes de perçage des trous de montage à

travers le revêtement de sol existant.

5. Au moyen des deux vis fournies, fixer la bride antibasculement au sol.

EMARQUE : Un des pieds arrière de la cuisinière sera centré avec la

R

bride antibasculement une fois déplacé à son emplacement final.

ÉTAPE 3 - RACCORDEMENT ÉLECTRIQUE

Après avoir lu les spécifications de chaque méthode de raccordement,

suivre les instructions de raccordement électrique se rapportant à votre

situation.

CORDON D’ALIMENTATION - CANADA SEULEMENT

AVERTISSEMENT

Risque de choc électrique

Brancher sur une prise de terre.

Ne pas utiliser de câble de rallonge.

Le non-respect de cette instruction pourrait causer un décès,

un incendie ou un choc électrique.

1. Brancher dans une prise murale reliée à la terre 14-50R.

2

. Passer à l’ÉTAPE 4 - RACCORDEMENT AU GAZ.

46 47

Page 25

Instructions d'installation

RACCORDEMENT DIRECT - É.-U. SEULEMENT

AVERTISSEMENT

Instructions d'installation

CONNEXION À 3 FILS (NEUTRE MIS À LA TERRE) - É.U.

EULEMENT

S

Risque de choc électrique

Déconnecter la source de courant électrique avant l’intervention.

Un raccordement incorrect du câblage en aluminium du domicile au

câblage en cuivre de l'appareil peut créer un risque électrique ou

déclencher un incendie. Si le domicile est doté d'un câblage en

aluminium, n'utiliser que des connecteurs conçus et homologués

UL pour raccorder le cuivre à l’aluminium et suivre rigoureusement

la procédure recommandée par le fabricant. Les raccordements du

cuivre à l'aluminium doivent être conformes aux codes locaux.

Utiliser des conducteurs en cuivre de calibre 10 ou en aluminium.

Raccorder l’appareil à la terre.

Le non-respect de cette instruction peut causer un décès, un

incendie ou un choc électrique.

Assurez-vous que votre installation est correctement installée et reliée à la terre

par un technicien qualifié. Demandez à votre revendeur de vous recommander

n technicien qualifié ou un centre de service de réparation agréé.

u

Le câblage d’alimentation de cette cuisinière comporte un conducteur

neutre (blanc) et un conducteur vert (ou nu) de liaison à la terre connecté à la

caisse; ces deux conducteurs sont torsadés.

Après vous être assuré qu’il n’y a plus de courant, branchez le conduit flexible

depuis le four jusqu’au boîtier de raccordement en utilisant un connecteur de

conduit homologué UL. Les graphiques suivants pour Neutre mis à la terre et

Neutre

non mis à la terre et les instructions fournies indiquent la façon la plus courante

de raccorder les cuisinières. Vos codes et règlements locaux sont évidemment

prioritaires sur ces instructions. Effectuez les raccordements électriques

conformément aux codes et règlements locaux.

AVERTISSEMENT

Risque de choc électrique

Le raccordement à la terre par le conducteur neutre est interdit

pour les nouvelles installations à circuit de dérivation (Code

national de l'électricité 1996), les résidences mobiles et les

véhicules de loisirs, ainsi que dans toute région où les codes

locaux interdisent le raccordement à la terre par le conducteur

neutre. Pour les installations où le raccordement à la terre par le

conducteur neutre est interdit, se reporter au schéma Neutre non

relié à la terre.

Pour raccorder l’appareil à la terre, utiliser le conducteur ou la

borne de mise à la terre.

Connecter de la manière habituelle le conducteur ou la borne

neutre au neutre du circuit de dérivation.

Le non-respect de cette instruction peut causer un décès, un

incendie ou un choc électrique.

Câble à 3 conducteurs depuis le point de distribution du domicile - É.-U.

eulement

s

IMPORTANT : Utiliser le câble à 3 conducteurs depuis l’alimentation

électrique du domicile lorsque les codes locaux autorisent un tel

raccordement.

. Déconnecter la source de courant électrique.

1

48 49

Page 26

Instructions d'installation

Neutre mis à la terre

a

b

c

d

e

i

h

g

f

Instructions d'installation

CONNEXION À 4 FILS (NEUTRE NON MIS À LA TERRE) - É.U.

EULEMENT

S

Câble à 4 conducteurs depuis l’alimentation électrique du domicile

IMPORTANT : Utiliser le câble à 4 conducteurs provenant de l’alimentation

électrique du domicile aux États-Unis lorsque les codes locaux ne permettent

pas la mise à la terre par l’intermédiaire du conducteur neutre, en cas de

nouvelle installation avec alimentation par un circuit de dérivation (1996 NEC),

dans les résidences mobiles et les véhicules récréatifs, dans les nouvelles

constructions, et au Canada.

. Déconnecter la source de courant électrique.

1

eutre non mis à la terre

N

a

b

i

h

a Boîtier de

connexion

b Fils noirs

c Fils (blancs)

neutres

.

2

Connecter ensemble les 2 conducteurs noirs

de fils (homologation UL).

3

.

Connecter les 2 conducteurs neutres (blancs)

nu) de liaison à la terre

de fils (homologation UL).

.

4

Connecter ensemble les 2 connecteurs rouges

de fils (homologation UL).

. Installer le couvercle du boîtier de connexion.

5

d Conducteur de liaison

à la terre (vert ou nu)

e Câble du cuisinière

f Connecteur de

conduit

(homologation UL)

(du câble du cuisinière) avec un connecteur

d

g Fils rouges

h Connecteurs de fils

(homologation UL)

i Alimentation électrique du

domicile