Page 1

DUAL FUEL RANGE

COS-DFR304

COS-DFR366

COS-DFR486G

Installation & User Manual

IMPORTANT: Read and save these instructions.

NOTICE:

Installer: Leave this guide with the homeowner

Homeowner: Keep this guide for future reference

Page 2

THANK YOU FOR YOUR PURCHASE

Thank you for your purchase. We know that you have many brands and

products to choose from and we are honored to know that you have decided

to take one of our products into your home and hope that you enjoy it.

COSMO Appliances are designed according to the strictest safety and

performance standard for the North American market. We follow the

most advanced manufacturing philosophy. Each appliance leaves the

factory after thorough quality inspection and testing. Our distributors and

our service partners are ready to answer any questions you may have

regarding how to install, use and care for your products. We hope that this

manual will help you learn to use the product in the safest and most effective

manner.

Before using this product, please read through this manual carefully. Keep this

manual in a safe place for future reference. Please ensure that other

persons using this product are familiar with these instructions as well.

If you have any questions or concerns, please contact the dealer from whom you

purchased it, or contact our Customer Support at:

1-888-784-3108.

2

Page 3

TABLE OF CONTENTS

SAFETY & WARNINGS ..........................................................4-5

General Safety & Warnings ......................................................4

Installation Safety & Warnings .................................................5

INSTALLATION MANUAL .....................................................6-20

Legs ........................................................................................6

Anti-Tip Device .........................................................................7

Range .......................................................................................8

Range Hood .............................................................................9

Electrical Connection .............................................................10

Power Cord Replacement ......................................................11

Dimension Diagram: DFR304 ................................................12

Dimension Diagram: DFR366 .................................................13

Dimension Diagram: DFR486G ..............................................14

Circuit Diagram: DFR304 ........................................................15

Circuit Diagram: DFR366 ........................................................15

Circuit Diagram: DFR486G .....................................................16

Gas Connection ................................................................17-18

Gas Conversion ................................................................19-20

Before Use: Installation Checklist ..........................................21

Before Use: Final Preparation ................................................21

USER MANUAL ..................................................................22-42

Operation & Safety Warnings ............................................22-23

Burner / BTU Diagrams ...........................................................24

Cooktop Surface Cooking .................................................25-27

Oven Cooking ..................................................................28-38

Before Use / Tips ....................................................................28

Oven Functions .......................................................................29

Bake ........................................................................................30

Convection Bake & Turbo ..................................................31-32

Baking Recommendations .................................................33-34

Broil / Convection Broil ......................................................35-36

Broil/Roasting Recommendations ..........................................37

Care & Maintenance ................................................................38

Troubleshooting .................................................................39-41

Location of Appliance Tags ....................................................42

WARRANTY & SERVICE ....................................................43-44

3

Page 4

SAFETY & WARNINGS

PLEASE READ AND FOLLOW THESE

IMPORTANT INSTRUCTIONS FOR THE SAFETY

OF YOUR HOME AND OF THE PEOPLE LIVING

IN IT.

Save this Manual for local electrical inspector's use.

Read and save these instructions for future

reference. Observe all governing codes, ordinances

and regulations. Installation and service must be

performed by a qualified installer, service agency or

the gas supplier.

WARNING: If the information in this manual

is not followed exactly, a fire or explosion

may result causing property damage,

personal injury, or death.

WARNING: Do not store or use gasoline or

other flammable substances in the vicinity

of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS:

• Do not light any appliance.

• Do not touch any electrical switch.

• Do not use any phone in your building.

• Immediately call your gas supplier from a

neighbor's phone. Follow the gas supplier's

instructions closely.

• If you cannot reach your gas suppliers, call the

fire department.

In Massachusetts: All gas products must be installed

by a "Massachusetts" licensed plumber or gasfitter.

A "T" handle type manual gas valve must be

installed in the gas line connected to this appliance.

WARNING: NEVER use this appliance as a space

heater to heat or warm the room. Doing so may

result in carbon monoxide poisoning and

overheating of the oven.

This appliance has been designed for nonprofessional, domestic use only.

Do not use this appliance to heat a room.

Do not place any pot or pan on the open oven door.

The door is made of glass and it can break if loaded

with a weight.

Before beginning installation, please read these

instructions completely and carefully.

Do not remove permanently affixed labels, warnings,

or plates from the product. This may void the

warranty. Please observe all local and national codes

and ordinances.

Please ensure the range is properly grounded.

The installer should leave these instructions with the

consumer who should retain for local inspector's use

and for future reference.

The plug should always be accessible.

Installation must conform with local codes or in the

absence of codes, the National Fuel Gas Code

NSIZ223.1/NFPA54. Electrical installation must be in

accordance with the National Electrical Code, ANSI/

NPA70 - latest edition and/or local codes. IN

CANADA: Installation must be in accordance with the

current CAN/CGA-fe 149.1 National Gas Installation

Code or CAN/CGA-B 149.2, Propane Installation

Code and/or local codes. Electrical installation must

be in accordance with the current CSA C22.1

Canadian Electrical Codes Part 1 and/or local codes.

Installation of any gas-fired equipment should be

made by a licensed plumber. A manual gas shut-off

valve must be installed in the gas supply line ahead of

the oven in the gas flow for safety and ease of

service.

WARNING: This range can tip over, causing

possible injury or death. Install the anti-tip

device shipped with the range. See Page 7

of this manual.

WARNING: Read this instruction booklet

before installing and using the appliance.

The manufacturer will not be responsible for

any damage to property or to persons

caused by incorrect installation or improper

use of the appliance. The manufacturer

reserves the right to make changes to its

products when considered necessary and

useful, without affecting the essential safety

and operating characteristics.

WARNING: This appliance shall not be

installed with a ventilation system that blows

air downward toward the range; this type of

ventilation system may cause ignition and

combustion problem with the gas appliance

resulting in a personal injury or unintended

operation.

WARNING: An air curtain or other overhead

range/cooktop hood, which operates by

blowing a downward airflow onto a range/

rangetop/cooktop, shall not be used/installed

in conjunction with this gas range.

4

Page 5

INSTALLATION SAFETY & WARNINGS

This appliance shall only be installed by an

authorized professional.

This appliance shall be installed in

accordance with the manufacturer's

installation instructions.

This appliance must be installed in accordance

with the standards of the country where it will

be installed. The installation of this appliance

must conform to local codes and ordinances. In

the absence of local codes, Installations must

conforms to American National Standards,

National Fuel Gas Code ANSI Z223.1 - latest

edition/NFPA 54 or B 149.1.

The appliance, when installed, must be

electrically grounded in accordance with local

codes or, in the absence of local codes, with

the National Electrical Code, ANSI/NFPA 70.

If local codes permit, a flexible metal appliance

connection with the new AGA or CGA certified

design, max. 5 feet (1,5 m) long, 3/4" I.D. is

recommended for connecting this appliance to

the gas supply line. Do not bend or damage the

flexible connector when moving the appliance.

This appliance must be used with the pressure

regulator provided. The regulator shall be

properly installed in order to be accessible

when the appliance is installed in its final

location. The pressure regulator must be set for

the type of gas to be used. The pressure

regulator has 3/4" female pipe thread. The

appropriate fitting must be determined based

on the size of your gas supply line, the flexible

metal connector and the shutoff valve.

WARNING! Do not use aerosol sprays in

the vicinity of this appliance while

it is in operation.

ROOM VENTILATION

An exhaust fan may be used with the appliance;

in each case it shall be installed in conformity

with the appropriate national and local standards.

Exhaust hood operation may affect other vented

appliances; in each case it shall be installed in

conformity with the appropriate national and local

standards.

TYPE OF GAS

This appliance is shipped from the factory for use

with natural gas. Propane Conversion Kit must

be purchased separately. For use with propane

LP gas please follow the conversion procedure

described on pg. 17.

GAS PRESSURE

The maximum inlet gas supply pressure

incoming to the gas appliance pressure regulator

is 34 PSI (13,8 w.c. pr 3,5 kPa).

The minimum gas supply pressure for checking

the regulator setting shall be at least 1" w.c. (249

Pa) above the inlet specified manifold pressure

to the appliance (this operating pressure is 4"

w.c. (1.00 kPa) for Natural Gas and 11" w.c.

(2.75 kPa for LP Gas).

The appliance must be isolated from the gas

supply piping system by closing its individual

manual shutoff valve during any pressure

testing of the gas supply piping system at test

pressures equal to or less than 34 PSI (13,8

w.c. pr 3,5 kPa).

All opening and holes in the wall and floor, back

and under the appliance shall be sealed before

installation of the appliance.

A manual valve shall be installed in an

accessible location in the gas line external to

the appliance for the purpose of turning on or

shutting off gas to the appliance

5

Page 6

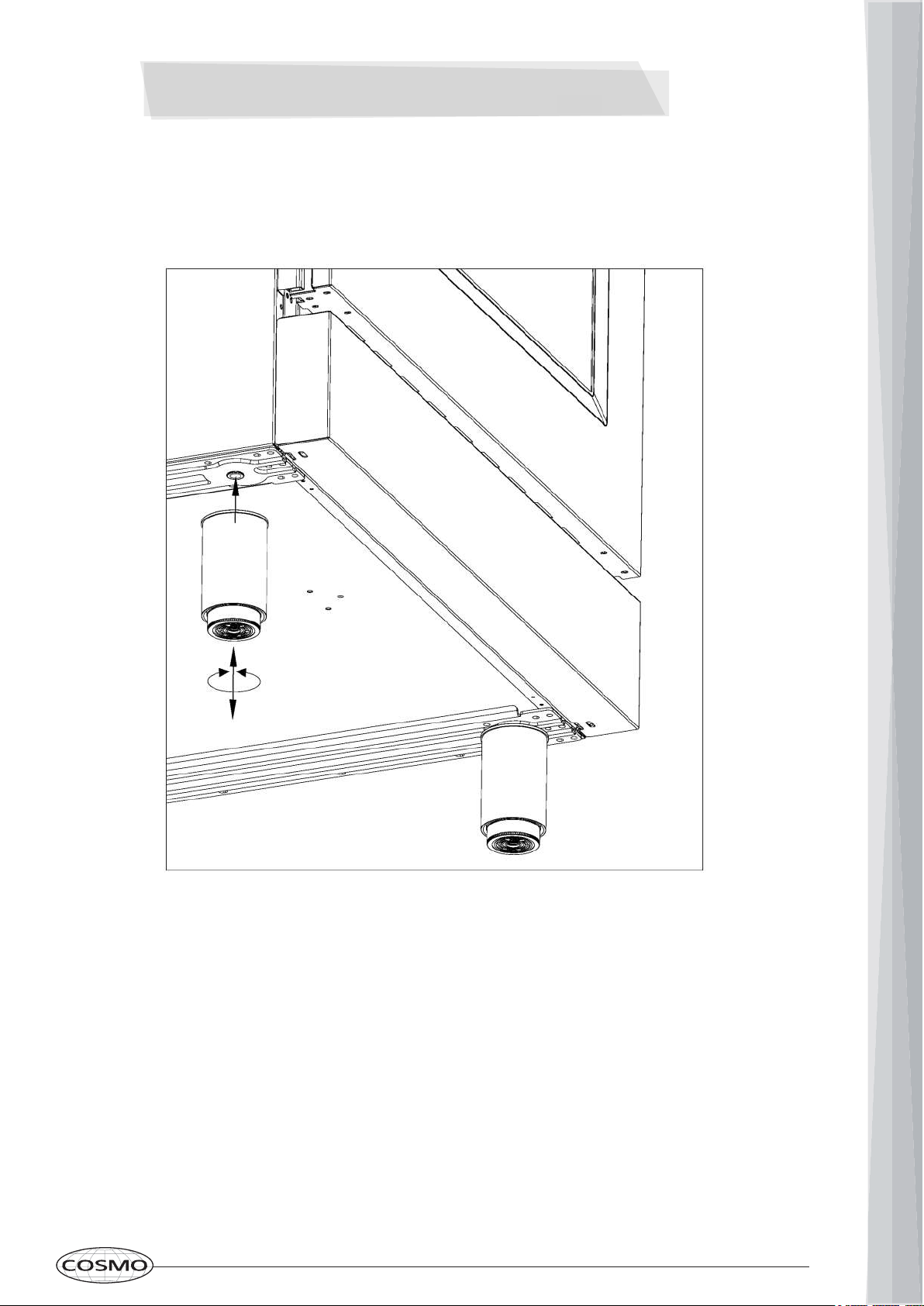

INSTALLATION: LEGS

The ranges must only be used with the legs properly installed.

Before installing the legs, position the appliance near its final location as the

legs are not suitable for moving the appliance over long distances.

Four height-adjustable legs are shipped with the range in the polystyrene

container situated over the appliance.

After unpacking the range, raise it enough

to insert the legs in the appropriate receptacles situated on the lower part of

the appliance. Lower the range gently to keep any undue strain from legs

and mounting hardware. If possible use a pallet or lift jack instead of tilting

the unit.

Adjust leg height to the desired level by twisting the inside portion of the leg

assembly until the proper height is reached. Check with a level device

to ensure the cooktop is perfectly level.

6

Page 7

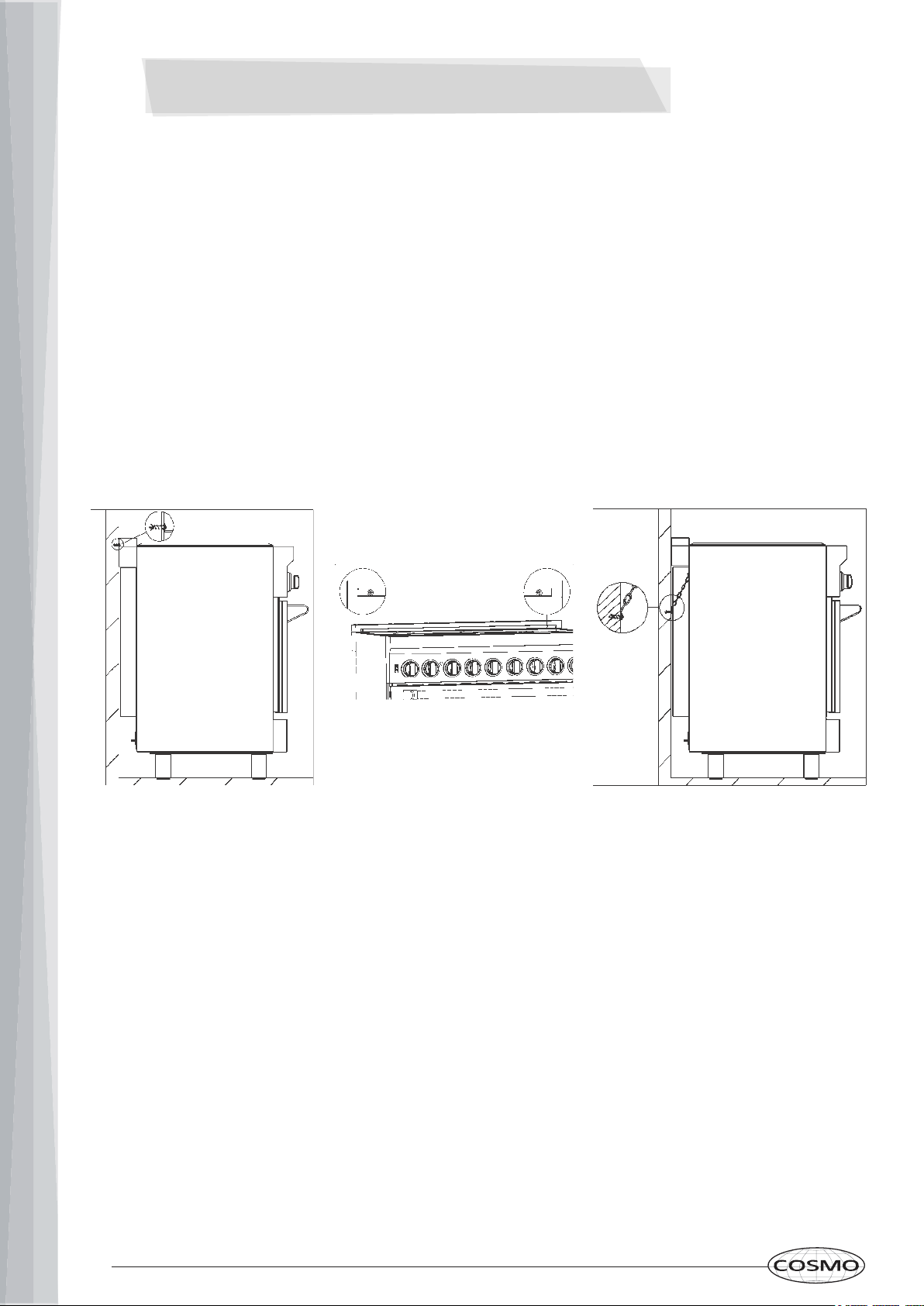

INSTALLATION: ANTI-TIP DEVICE

1.) The anti-tip bracket shipped with the range must be properly secured to the rear wall as

shown in the picture below. The height of the bracket from the floor must be determined after

the range legs have been adjusted to the desired height and after the range has been leveled.

Measure the distance from the floor to the bottom of the anti-tip bracket receptacle on the

back of the appliance. Position the two anti-tip brackets on the wall at the desired height plus

1/8" (0.32 cm). The brackets must be placed at 2 - 5/16" (6.0 cm) from each side of the range.

The distance between the two bracket is 25 - 1/4" (64.1 cm). Secure the brackets to the wall

with appropriate hardware. Slide the range against the wall until the brackets are fully inserted

into their receptacles on the back of the range.

Check to see that the Anti-Tip device is installed properly. Grasp the top rear edge of the

range and carefully attempt to tilt it forward. Verify that the Anti-Tip device is engaged.

2.) Or, use the anti-tip chain, and tighten up with fixed screw on the wall, and when the wall

not suitable for installation, the chain shall be fixed to the cabinet structure.

7

Page 8

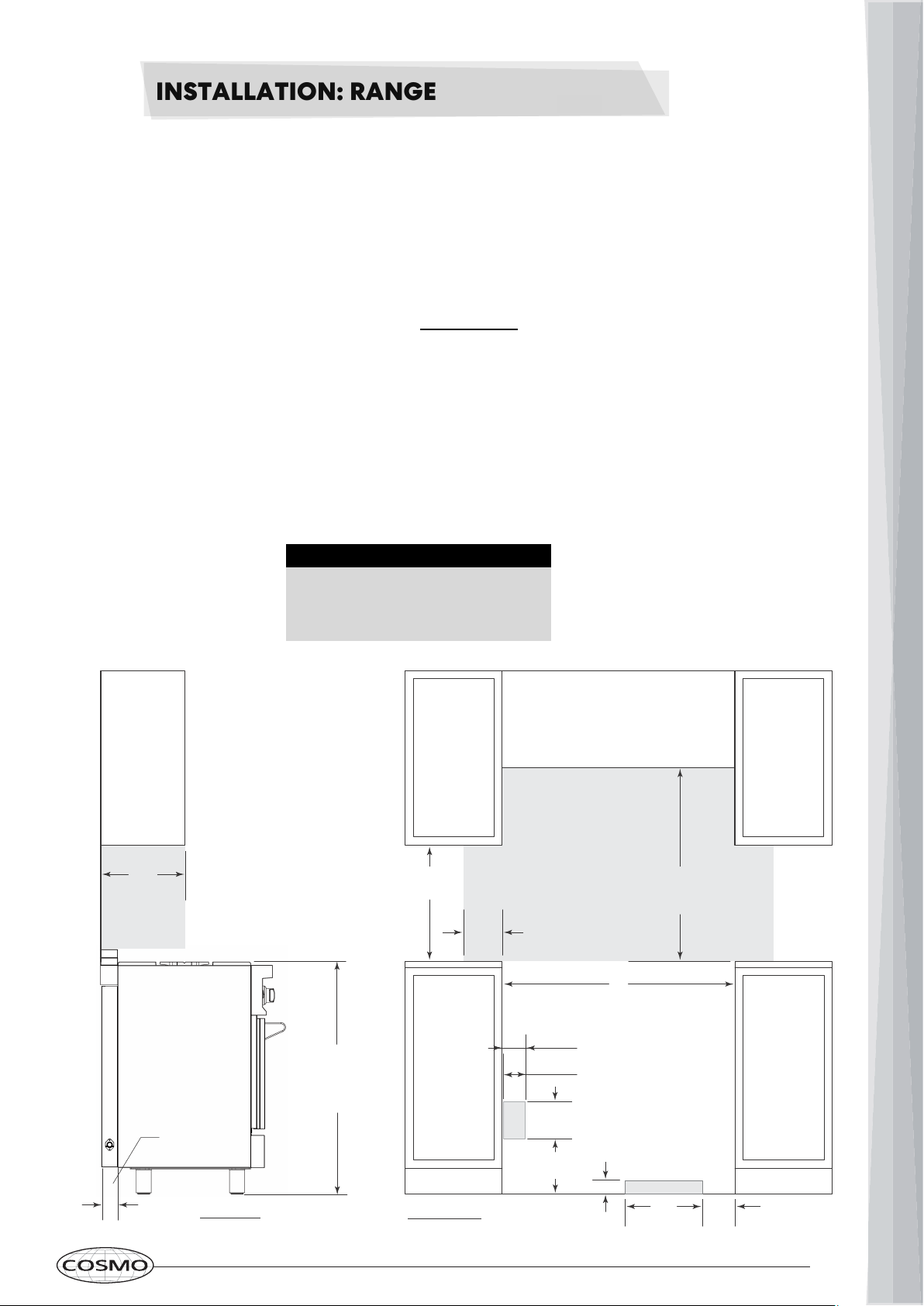

INSTALLATION: RANGE

E

.

G

"

ELECTRICAL REQUIREMENTS

A properly grounded and electrical

receptacle Type NEMA 14-50R should

be installed; refer to ELECTRICAL

CONNECTION section Page 10.

Check all local code requirements.

GAS REQUIREMENTS

An agency-approved, properly-sized

manual shut-off valve should be installed

no higher than 3" (7.6 cm) above the

floor and no less than 2" (5 cm) and no

more than 8" (20.3 cm) from the right

side (facing product).

To connect gas between shut-off valve

and regulator, use agency-approved,

properly sized flexible or rigid pipe.

Check all local code requirements.

COOKING RANGE WIDTH

30" Model

36" Model

48" Model

INSTALLATION ADJACENT TO KITCHEN

CABINETS

This range may be installed directly adjacent to

existing countertop high cabinets (36" or 91.5 cm

from the floor). For the best look, the worktop

should be level with the cabinet countertop. This

can be accomplished by raising the unit using the

adjustment spindles on the legs.

ATTENTION: The range CANNOT be installed

directly adjacent to kitchen walls, tall cabinets, tall

appliances, or other vertical surfaces above 36"

(91.4 cm) high. The minimum side clearance in

such cases is 6" (15.2 cm).

Wall cabinets with minimum side clearance must be

installed 30" above the countertop with countertop

height between 35 1/2" (90.2 cm) and 37 1/4" (94.6

cm). The maximum depth of wall cabinets above

the range shall be 13" (33.0 cm).

30"(757)

36"(910)

48"(1215)

13"

(330)

LOCATION OF GAS AND

ELECTRICAL EXTENDS

ON FLOOR

3

/5"

2

(65)

SIDE VIEW

3

/5"

36

T

COOKING

O

SURFACE

(930)

30"

(762)

(152)

FRONT VIEW

6"

OPENING WIDTH

(82)

3 23"

.

3 15"

(80)

53/4

(146)

93/4"

(250)

30" (762) TO 36"

(914) TO BOTTOM OF

VENTILATION HOOD*

W

(51)

2"

12"

(305) GAS

(127)

5"

8

Page 9

INSTALLATION: RANGE HOOD

To eliminate the risk of burns or fire by reaching over heated surface units, cabinet storage

space located above the surface units should be avoided. If cabinet storage is to be provided,

the risk can be reduced by installing a range hood. These hoods have been designed to work

in conjunction with the range and have the same finish for a perfect look.

For maximum performance, the height of the bottom of the hood from the worktop should be

between 30" (76.2 cm) and 36" (91.4 cm). This would typically result in the bottom of the

hood being 61 1/2" (156.2 cm) to 67 1/2" (171.5 cm) above the floor. These measurements

provide for safe and efficient operation of the hood.

Before installation of the exhaust hood, consult local or regional building and installation

codes for additional specific clearance requirements.

Refer to the range hood installation instructions provided by the manufacturer for additional

information.

9

Page 10

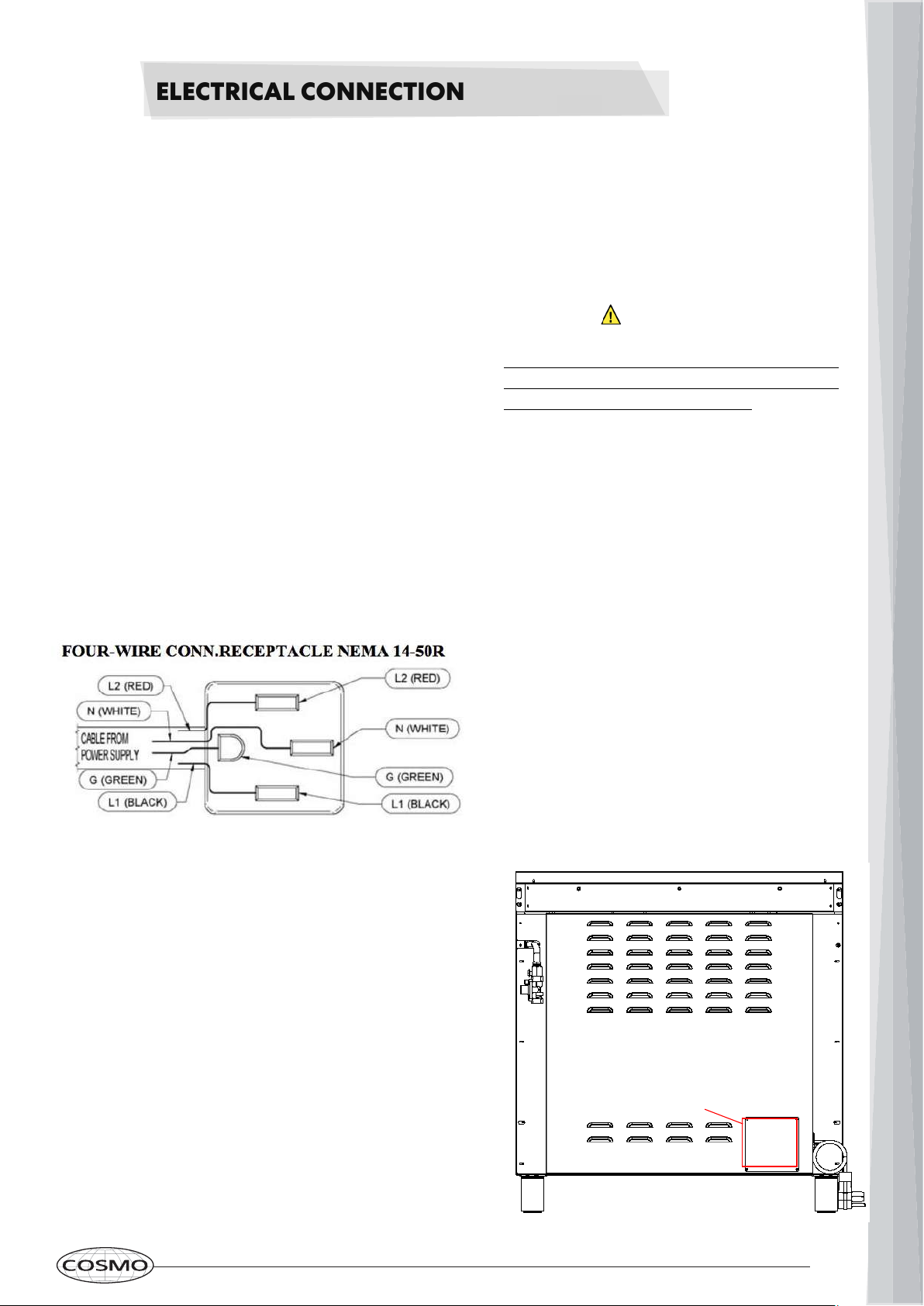

ELECTRICAL CONNECTION

The appliance shall be connected to a single

phase electric line rated at 120 208Vac or 120/

240Vac and 60Hz frequency.

ELECTRIC POWER RATING

• 120/208Vac: 10 A max

• 120/240Vac: 12 A max

HEATING ELEMENTS POWER RATING

• Oven bake element = 1500 Watt

• Oven circular element = 3200 Watt

• Oven broil element = 2850 Watt

Install a suitable electric power supply

receptacle connection type NEMA 14-50R able

to support a load of at least 30 A (per line)

according to local code requirements. For four

wires power supply connection system see

diagram below.

Check your local code for which of the options

below should be used in grounding the

receptacle power suppliy connections.

ELECTRICAL GROUNDING

This appliance is equipped with a fourprong plug for your protection against

shock hazard and should be plugged

directly into a properly grounded

receptacle, do not cut or remove the

prong from this plug.

WARNING

ELECTRICAL SHOCK HAZARD

Disconnect electrical power at the

circuit breaker box or fuse box before

installing the appliance. Provide

appropriate ground for the appliance.

Use copper conductors only. Failure to

follow these instructions could result

in serious injury or death.

DO NOT USE EXTENSION CORDS

WITH THIS APPLIANCE AS IT MAY

RESULT IN FIRE, ELECTRIC SHOCK

OR OTHER TYPE OF PERSONAL

INJURY.

FOUR WIRES CONNECTION

• Connect the L1 receptacle terminal to the

incoming BLACK electrical supply wire(L1-hot

wire)

• Connect the L2 receptacle terminal to the

incoming RED electrical supply wire (L2-hot

wire)

• Connect the NEUTRAL receptacle terminal to

the incoming NEUTRAL (WHITE) electrical

supply wire

• Connect the GROUND receptacle terminal to

the incoming GROUND (GREEN) electrical

supply wire

Label all wires prior to disconnecting

when servicing controls. Wiring errors

can cause improper and dangerous

operation. Verify proper operation after

servicing.

When working with electrical

connection, please refer to the rating

label, the rating label is located near the

entrance of power supply cord.

Rating Label

10

Page 11

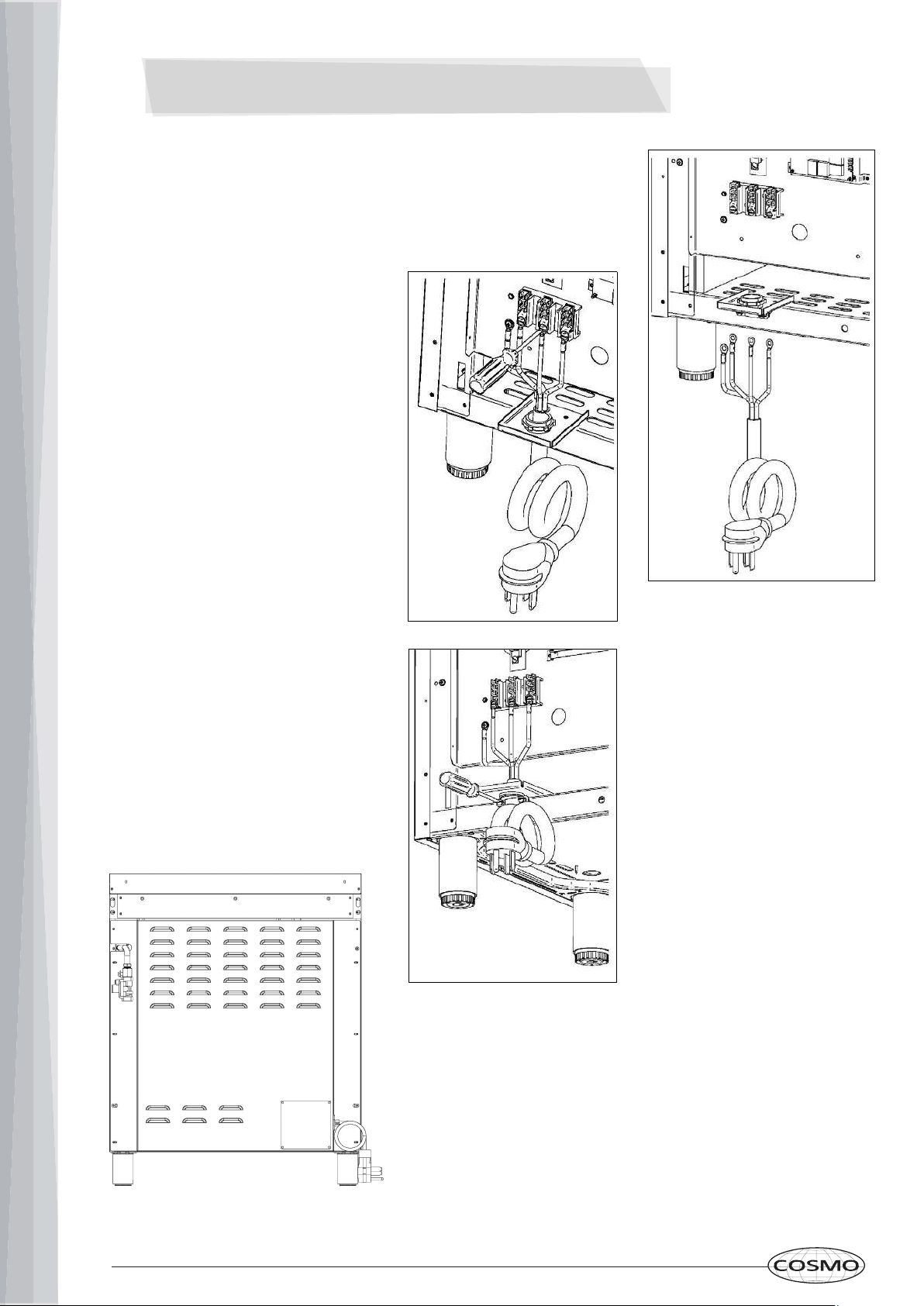

POWER CORD REPLACEMENT

DO NOT USE EXTENSION

CORDS WITH THIS APPLIANCE

AS IT MAY RESULT IN FIRE,

ELECTRIC SHOCK OR OTHER

TYPE OF PERSONAL INJURY.

The appliance is equipped at

the factory with an electric

supply cord set 4 wires type

with ring terminals (L1, L2, N,

Ground) suitable for range use

UL/CSA listed type SRDT/DRT

2x6AWG (L1, L2)+2x8AWG (N,

G) rated 300V, 40 or 50A with

fused plug type NEMA 14-50P;

cable length 1.5m in case the

supply cord set must be replaced,

it must be replaced with an

identical set having the save

technical specifications and

installed using the following

directions:

1.) Disconnect appliance from

electrical power supply receptacle

2.) Slide out the appliance from

the installation place to access

the back enclosure

3.) Remove back enclosure panel

by removing the 6 screws as

shown below.

4.) Loose strain relief

by unscrewing two

strain relief's screws in

diagram

5.) Remove damaged

supply cord set by taking off

the 4 electrical connection

screws (block L1, N, L2 and

Ground screw, see

diagram)

6.) Insert the new supply

cord set in the strain relief

and lock it with two strain

relief’s screws in suitable

position

7.) Fix well the ring

terminals G, L1, N, L2 of

the new supply cord set, as

shown in diagram with its 4

screws

8.) Reinstall the back

enclosure panel with 6

screws

9.) Slide the appliance back

into its proper location

10.) Reconnect the

appliance to the electrical

power

11

Page 12

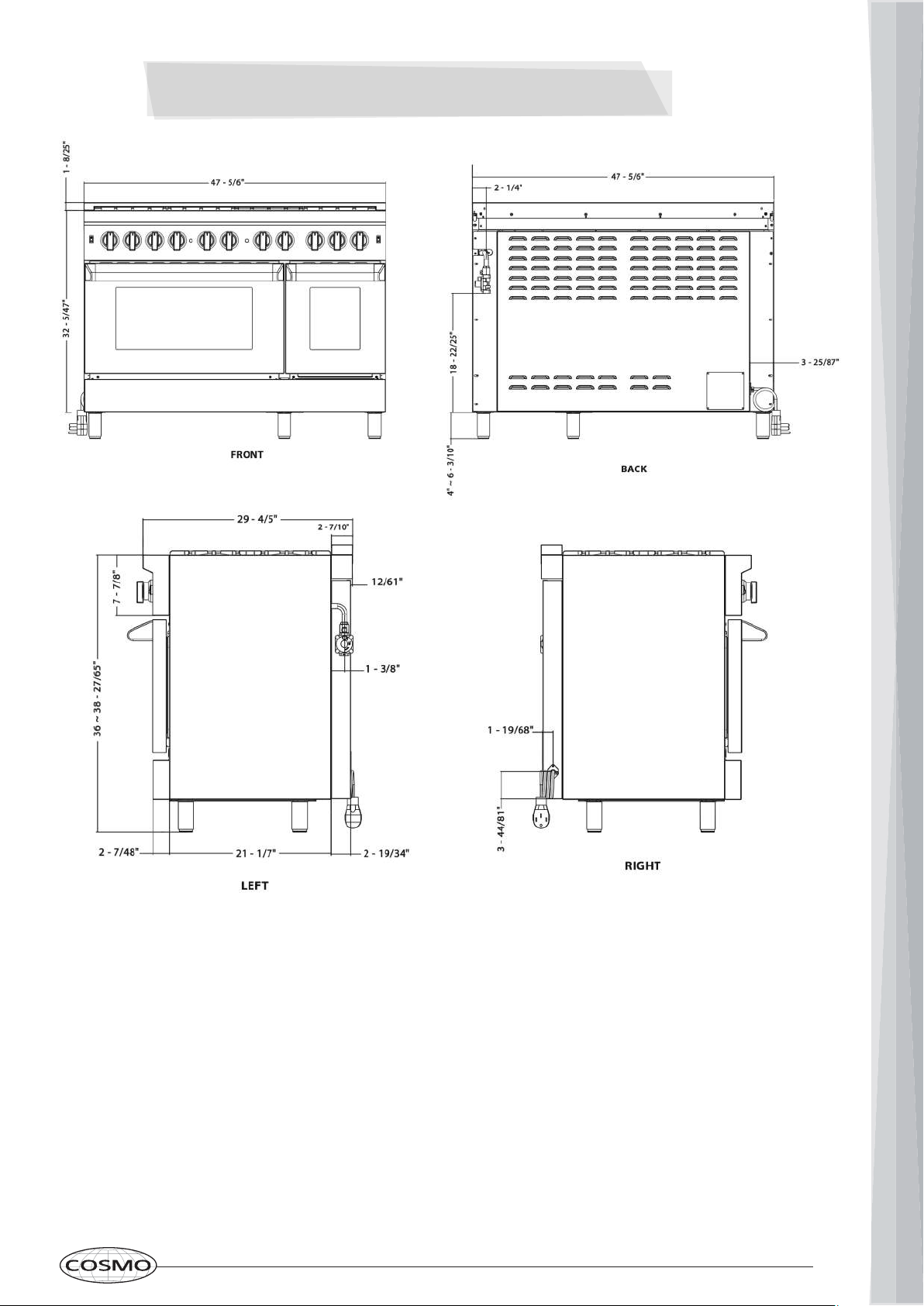

DIMENSION DIAGRAM: DFR304

12

Page 13

DIMENSION DIAGRAM: DFR366

13

Page 14

DIMENSION DIAGRAM: DFR486G

14

Page 15

CIRCUIT DIAGRAMS

DFR304

DFR366

15

Page 16

DFR486G

CIRCUIT DIAGRAMS

16

Page 17

GAS CONNECTION

All gas connections must comply with

national and local codes. The gas supply line

(service) must be the same size or greater

than the inlet line of the appliance. This

range uses a 1/2" NPT inlet (see drawing

below for details of gas connection). On all

pipe joints use appropriate sealant resistant

to gas.

This range can be used with Natural or LP/

Propane gas. The range is shipped from the

factory for use with natural gas.

For LP/propane household installation, the

appliance must be converted by the dealer,

by a factory-trained professional or by a

qualified licensed plumber or gas service

company.

Gas conversion is important for safe and

effective use of the appliance. It is the

responsibility of the dealer and the owner of

the range to perform the appropriate gas

conversion following the directions of the

manufacturer.

MANUAL SHUT-OFF VALVE

THIS VALVE IS NOT SHIPPED WITH THE

APPLIANCE AND MUST BE SUPPLIED BY THE

INSTALLER.

The manual shut-off valve must be installed in the

gas service line between the gas hook-up on the

wall and the appliance inlet, in a position where it

can be reached quickly in the event of an

emergency.

In Massachusetts: A T handle type manual gas

valve must be installed in the gas supply line to

this appliance.

FLEXIBLE CONNECTIONS

In case of installation with flexible couplings and/

or quick-disconnect fittings, the installer must use

a heavy-duty, AGA design-certified commercial

flexible connector of at least 1/2" (1.3 cm) ID NPT

(with suitable strain reliefs) in compliance with

ANSI Z21.41 and Z21.69 standards.

In Massachusetts: The unit must be installed

with a 36" (3-foot) long flexible gas connector.

THE PROPER GAS CONVERSION

PROCEDURE IS DESCRIBED IN THIS

MANUAL. REPLACEMENT NOZZLES

CAN BE PURCHASED FROM

COSMOAPPLIANCES.COM.

Please provide the service person with this

manual before work is started on the range.

WARNING: DO NOT USE AN OPEN

FLAME WHEN CHECKING FOR LEAKS.

Leak testing of the appliance shall be

conducted according to the manufacturer's

instructions. Before placing the oven into

operation, always check for leaks with soapy

water solution or other acceptable method.

Check for gas leakage with soapy water

solution or other acceptable methods in all

gas connections installed between inlet gas

pipe of the appliance, gas regulator, till to the

manual shut-off valve.

In Canada: use CAN 1-6.10-88 metal connectors

for gas appliances and CAN 1-6.9 M79 quick

disconnect device for use with gas fuel.

PRESSURE TEST-POINT STOPPER VALVE

To avoid gas leaks, the pressure test-point

stopper valve and gasket supplied with the range

must be installed on the gas fitting at the back of

the range according to the diagram below.

17

Page 18

GAS CONNECTION

PRESSURE REGULATOR

Since service pressure may fluctuate with local demand, every gas cooking appliance must

be equipped with a pressure regulator on the incoming service line for safe and efficient

operation.

The pressure regulator shipped with the appliance has two female threads 34" NPT. The

regulator shall be installed properly in order to be accessible when the appliance is installed

in its final position.

Manifold pressure should be checked with a manometer and comply with the values

indicated below:

• Natural Gas: 4.0" W.c.P.

• LP / Propane: 10.0" W.C.P

Incoming line pressure upstream from the regulator must be 1" W.c.P. higher than the

manifold pressure in order to check the regulator.

The regulator used on this range can withstand a maximum input pressure of 1/2 PSI (13.8"

w.c. or 3,5 kPa) If the line pressure exceeds that amount, a step-down regulator is required.

The appliance, its individual shut-off valve, and the pressure regulator must be disconnected

from the gas line during any pressure testing of that system at pressures in excess of 1/2 PSI

(13.8" w.c. or 3,5 kPa).

The individual manual shut-off valve must be in the OFF position during any pressure testing

of the gas supply piping system at test pressures equal to or less than 1/2 PSI (13.8" w.c. or

3,5 kPa).

APPLIANCE SERVING

Before carrying any service, disconnect the appliance from gas appliance from final install

have access to the appliance for proper servicing intervention.

18

Page 19

GAS CONVERSION

WARNING! Before carrying out this operation,

disconnect the appliance from gas and electricity.

Gas conversion shall be conducted by a trained professional. Call customer service to identify

a trained professional near your home. The gas conversion procedure for this range includes 3

steps:

1.) Pressure regulator

2.) Surface burners

3.) Adjustment of minimum setting

The conversion is not completed if all 3 steps have not been concluded properly.

The replacement nozzles are sold separately and can be purchased from

cosmoappliances.com. Before performing gas conversion, obtain the proper nozzle for your

range.

STEP 1: PRESSURE REGULATOR

The pressure regulator supplied with the appliance is a convertible type pressure regulator for

use with Natural Gas at a nominal outlet pressure of 4" w.c. or LP gas at a nominal outlet

pressure of 11" w.c. and it is pre-arranged from the factory to operate with one of these gas /

pressure as indicated in the labels affixed on the appliance, package and Instruction booklet.

To convert the regulator for use with other liquid propane LP gas:

1.) Unscrew by hand the upper cap of the regulator, remove the silver plastic attachment from

the cap, reverse its direction and screw it again firmly against the cap. Once reversed, the

spring should be facing out, as shown below.

2.) Screw by hand the metal cap in the original position on the regulator

LP GAS

POSITION

19

Page 20

GAS CONVERSION

STEP 2: SURFACE BURNERS

To replace the nozzles of the surface burners, lift up the burners and unscrew the nozzles

shipped with the range using a 7mm socket wrench.

Replace nozzles using the conversion kit. Contact Cosmo Customer Service at 1-888-784-

3108, or go to www.cosmoappliances.com to purchase a conversion kit. Each nozzle has a

number indicating its flow diameter printed on the body.

STEP 3: ADJUSTMENT OF MINIMUM FLAME SETTING

WARNING: These adjustments should be made only for use of the appliance with

natural gas. For use with liquid propane gas, the choke screw must be fully turned in a

clockwise direction.

SURFACE BURNERS

1.) Light one burner at a time and set the to the MINIMUM position(small flame).

2.) Remove the knob.

3.) The range is equipped with a safety valve. Using a small-size slotted screwdriver, locate

the choke valve on the valve body and turn the choke screw to the right or left until the burner

flame is adjusted to desired minimum.

4.) Make sure that the flame does not go out when switching quickly from the MAXIMUM to the

MINIMUM position.

20

Page 21

BEFORE USING RANGE HOOD

INSTALLATION CHECKLIST

1.) Is the range mounted on its legs?

2.) Is the back guard securely connected?

3.) Has the anti-tip device been properly

installed?

4.) Does the clearance from the side cabinets

comply with the manufacturers directions?

5.) Is the electricity properly grounded?

6.) Is the gas service line connected following

the directions of the manufacturer?

7.) Have all the proper valves, stoppers and

gasket been installed between the range and

the service line?

8.) Has the gas connection been checked for

leaks?

FINAL PREPARATION

All stainless steel body parts should be

wiped with hot, soapy water and with a

liquid stainless steel cleanser.

If build-up occurs, do not use steel wool,

abrasive cloths, cleaners, or powders! If it

is necessary to scrape stainless steel to

remove encrusted materials, soak with hot,

wet cloths to loosen the material, then use

a wood or nylon scraper. Do not use a

metal knife, spatula, or any other metal

tool to scrape stainless steel! Scratches

are almost impossible to remove.

Before using the oven for food

preparation, wash the cavity thoroughly

with a warm soap and water solution to

remove film residues and any dust or

debris from installation, then rinse and

wiped dry.

9.) Has the range been set for the type of gas

available in the household?

10.) Does the flame appear sharp blue, with

no yellow tipping, shooting or flame lifting?

11.) Has the minimum setting for all burners

been adjusted?

21

Page 22

OPERATING SAFETY & WARNINGS

• Remember to set all cooktop / oven / broiler burners control knob to OFF position when not

in use.

• Be sure your appliance is properly installed and grounded by a qualified technician.

• Children should not be left alone or unattended in area where appliance is in use.

• Children should never be allowed to sit or stand on any part of the appliance.

• Do not store items of interest to children in cabinets above a range or on the back

guard of a range; children climbing on the range to reach items could be seriously injured.

• Wear proper apparel. Loose-fitting or hanging garments should never be worn while using

the appliance.

• Do not repair or replace any part of the appliance unless specifically recommended in

the manual. All other servicing should be referred to a qualified technician.

• Use only dry potholders. Moist or damp potholders on hot surfaces may result in burns

from steam. Do not let potholder touch hot heating elements.

• Do not use a towel or other bulky cloth.

• Do not to cover the holes inside the oven with aluminum foil.

• Do not to cover the worktop with aluminum foil.

• Do not store any flammable object or objects under pressure in the storage compartment.

• Keep the area of operation of the range free from combustible materials, gasoline and

other flammable vapors and liquid.

• Do not store dangerous or flammable materials in the cabinets above the appliance, since

this may result in a potential fire hazard.

• Do not use the appliance for space heating.

• Never use your appliance for warming or heating the room.

• Do not use aerosol sprays in the vicinity of the appliance while cooking.

• Do not sit or step on the oven door.

• Do not use oven for storage.

• Use care when opening door.

• Allow hot air or steam escape before removing or replacing food.

• Do not heat unopened food containers. Build-up of pressure may cause container to burst

and result in injury.

• Keep oven vent ducts unobstructed.

Continued on next page

22

Page 23

OPERATING SAFETY & WARNINGS

• Always place oven racks in desired location when oven is cool. If rack must be moved while

oven is hot, do not let potholder contact hot heating element in oven.

• Do not clean oven door gasket. The door gasket is essential for a good seal. Care should be

taken not to rub, damage, or move the gasket.

• Do not use oven cleaning products. No commercial oven cleaner or oven liner protective

coating of any kind should be used in or around any part of the oven.

• Clean only parts listed in manual.

• Before cleaning the oven, remove racks and any other contents inside the oven.

• Do not use water on grease fires. Smother fire or flames or use dry chemical or foam-type

extinguisher.

• The cooktop and surfaces facing the cooktop may be hot even though they are dark in

color. Areas near these may become hot enough to cause burns. During and after use, do

not touch, or let clothing or other flammable materials contact the cook-top and surfaces

facing the cook-top until they have had sufficient time to cool.

• WARNING: DO NOT TOUCH HEATING ELEMENTS OR INTERIOR SURFACES OF

OVEN. Heating elements may be hot even though they are dark in color. Interior surfaces of

an oven become hot enough to cause burns. During and after use, do not touch, or let

clothing or other flammable materials contact heating elements or interior surfaces of oven

until they have had sufficient time to cool. Do not touch any surface of the oven until they

have had sufficient time to cool, as some surfaces become hot enough to cause burns,

included: oven vent openings and surfaces near these openings, oven doors, and windows

of oven doors.

• Do not use an extension cord to connect this appliance. If the power supply cord is too

short, have a qualified electrician or serviceman install an outlet near the appliance.

• WARNING: Do not operate the range without the anti-tip device in place and engaged;

a child or adult can tip the range and be killed. Verify the anti-tip device has been properly

installed and engaged. Ensure the anti-tip device is re-installed when the range is moved;

failure to do so can result in death or serious burns to children or adults.

• ROOM VENTILATION: The use of a gas cooking appliance generates heat and

humidity in the room where it is installed. Proper ventilation in the room is needed. Make

sure the kitchen is equipped with a range hood of appropriate power (400 CFM minimum).

Activate the exhaust fan/range hood when possible. Intensive and continuous use of the

appliance may require additional ventilation, for example by opening a window.

23

Page 24

BURNER BTU DIAGRAMS

SURFACE BURNER LAYOUT

DFR304 DFR366

BURNERS

• Left Front: 18000 BTU

• Left Rear: 4200 BTU

• Right Front:13000 BTU

• Right Rear: 8500 BTU

DFR486G

BURNERS

• Left Front: 18000 BTU

• Left Rear: 13000 BTU

• Center Front: 8500 BTU

• Center Rear: 8500 BTU

• Right Front: 13000 BTU

• Right Rear: 4200 BTU

BURNERS

• Left Front: 18000 BTU

• Left Rear: 8500 BTU

• Center Front: 4200 BTU

• Center Rear: 13000 BTU

• Griddle: 13000 BTU

• Right Front: 18000 BTU

• Right Rear: 8500 BTU

24

Page 25

OPERATING INSTRUCTIONS

COOKTOP SURFACE COOKING

IMPORTANT: Remember to set all cooktop / oven / broiler burners control knob

to OFF position when not in use.

• Burner Position

Example showing Front right burner

• Maximum Temperature Setting

Recommended control knob

position for burner ignition

• Minimum Temperature Setting

(*) Appliance with worktop gas

valves alternative type

SURFACE BURNER OPERATION

Electric Ignition

To activate the electric ignition, simply turn the control knob counter-clockwise to maximum

power (*position). Press the knob to start the flow of gas and the ignition spark. The spark will

released at the metal tip of the white ceramic pin located on the side of the burner. Once the

flame is on, release the control knob gently.

If the flame turns off, repeat the above procedure.

ATTENTION: Do not ignite burners if the black burner cap is not installed or not

centered. The flame will be irregular.

Manual Ignition

Manual ignition is always possible even when the power is cut off or in the event of power

failure. Turn the control knob counter-clockwise to the MAXIMUM position. Light the flame

with a kitchen lighter or with a match.

25

Page 26

OPERATING INSTRUCTIONS

TIPS FOR USING BURNERS CORRECTLY

WARNING: KEEP CHILDREN AT A SAFE DISTANCE FROM THE APPLIANCE

DURING OPERATING. DO NOT ALLOW CHILDREN TO OPERATE THE

APPLIANCE.

IMPORTANT: Remember to set all cooktop / oven / broiler burners control knob

to OFF position when not in use.

1.) Always check that the burner caps are properly installed before operation.

2.) Verify that the flame of the worktop burners be completely blue and with regular aspect as

shown below.

3.) Always adjust the burner flame so it does not extend beyond the edge of the pan.

26

Page 27

OPERATING INSTRUCTIONS

TIPS FOR USING PANS CORRECTLY

ATTENTION: Always ensure that bottom and handles of pans do not

protrude from the worktop. When cooking with flammable fat such as oil,

do not leave the range unattended.

Use pots of the appropriate size on each burner following the below chart:

Burner Recommended Pan Size

Small

Medium

Large

Dual Burner

• When boiling liquids, turn the knob to the MINIMUM position once boiling is reached to

avoid overflow.

• Always use pots with matching lid.

• Dry the bottom of pans before operation.

• Use pots with a flat, thick bottom (except for wok cooking).

Wok Cooking

Always use the wok adapter supplied with the range. Wok pan external diameter shall

not be smaller than 10" (25cm) and larger than 16" (40cm).

inches (mm)

3 1/2" - 51/2" (90 -140)

5 1/2"-10 1/4" (140 - 260)

7 1/8" - 10 1/4" (180-260)

8 2/3" - 10 1/4" (220 - 260)

27

Page 28

OPERATING INSTRUCTIONS

OVEN COOKING

BEFORE USE: When using the oven for the first time it should be operated for 15-30

minutes at a temperature of about 500°F without cooking anything inside in order to

eliminate any moisture and odors from the internal insulation.

IMPORTANT: In case of electric power failure, set oven/broiler controls in off position

and do not attempt to use oven/broiler until electric power has been restored.

TIPS

• Use care when opening the oven door. Let hot air or steam escape before removing or

replacing food.

• Do not heat unopened food containers. Buildup of pressure may cause container to burst

and result in injury.

• Keep oven vent ducts unobstructed.

• To keep the oven as clean as possible, cook on the tray.

• When available, always follow recipe book directions. Personal experience will help to

determine any variations in the values reported in the table. In any case, it is recommended

to follow the instructions of the specific recipe being used.

• The ranges are equipped with commercial grade shelves and an enamel cooking tray.

Shelves are mounted on the appropriate guides situated on the sides of the oven

compartment. Insert the shelf between top and bottom guide in any of the 5 positions

available.

28

Page 29

OPERATING INSTRUCTIONS

OVEN FUNCTIONS

The oven has 5 functions defined for the following operations:

BAKE - Broiler + Bottom heating

elements, to be used with oven

temperature from 100° to 500°F

BROIL - Broiler heating element, to

be used with temperature selector at

500°F for broiling

TURBO - Circular + Bottom heating

elements + fan, to be used with

oven temperature from 100° to 500°F

CONVECTION BROIL - Broiler heating

element + fan, to be used with

temperature selector at 500°F for

convection broiling

CONVECTION BAKE - Circular heating

element + fan, to be used with oven

temperature from 0 to 500°F

OVEN LIGHT

The appliance is equipped with two oven lamps that light up when the oven door is opened

or each time the oven is in operation. They are turned off during the cleaning cycle.

COOLING FANS

The appliance is equipped with two cooling fan motors that activate when the oven is in

operation for cooking or cleaning, except in case of DEHYDRATE and PROOFING

functions. In stand-by condition (both selector in OFF position), the cooling fan motors

operate if oven temperature exceeds approximately 430°F (220°C) and stop automatically

when oven temperature drops below approximately 285-360°F (140- 180°C).

FRONT INDICATOR LIGHT

This appliance is equipped with an indicator light on the front panel;the indicator light will be

lit when the oven is heating. Once the oven reaches set temperature, the light will dim. The

light will be completely OFF when both the oven temperature selection knob and the oven

function selector knob are in the "OFF" position.

29

Page 30

OPERATING INSTRUCTIONS

BAKE

Preheating

Preheat the oven before baking. The oven does not need to be preheated for large pieces of

meat or poultry. See your recipe for preheating recommendation. Preheating time depends

on the temperature setting and the number of racks in the oven.

Tips for Getting the Best Results

• Minimize opening the door.

• Choose the right size bake ware.

• Use the bake ware recommended in the recipe. Store the any other cookware, pans,

etc. outside the oven: extra pans without food affect the browning and cooking.

• Browning can depend from the type of pan used:

◦ For tender, golden brown crusts, use light non-stick anodized or shiny metal pans.

◦ For brown crisp crusts, use dark non-stick/anodized or dark, dull metal utensils or

glass bake ware. These may require lowering the bake temperature 25°F.

Bakeware Type

Metal bake ware (with or without a non-stick finish), heat-proof glass, glass ceramic, pottery,

or other utensils are suitable for the oven. Suitable cookie sheets have a small lip on one

side only. Heavy sheets or those with lips on more than one side may affect the baking time.

Bake Rack Positions

Rack level positions in the oven are numbered as in the diagram on Page 28.

One Rack Baking

The Bake mode is best for baking on one rack with rack level 3 and 4 used for most baked

items. When baking tall items, rack level 4 may be used. Pies are best baked on rack level 4

or 5 to ensure the bottom of the crust is done without over-browning the top. When large

pieces of meat or poultry are roasted such as a prime rib of beef or a turkey, rack level 4 is

the preferred rack.

Two Rack Baking

Rack levels 3 and 5 may be used when baking on two levels. Cookies and biscuits can be

cooked properly using these two racks. Casserole dishes may al so be baked using these

two levels.

30

Page 31

OPERATING INSTRUCTIONS

COOKING WITH CONVECTION

There are many advantages to cooking with convection. In the convection system, a fan in

the back of the oven moves heated air evenly around the oven. The moving air provides even

heat so foods can be placed on any rack level with consistent results and without having to

rotate the pans. Convection also enables cooking simultaneously on multiple racks.

Low, shallow bake ware should be used with convection cooking. This allows the heated air

to properly move around the food. Pans with high sides or pans that are covered are not

suitable for convection cooking because high sides or lids prohibit the warm air from

circulating around the food.

Any food cooked uncovered will brown evenly and form a nice crust. Foods in covered dishes

(casseroles, pot roast) or delicate custards are not suitable for convection cooking.

CONVECTION BAKE & TURBO

Time can be saved by baking an entire batch of cookies at the same time. The cookies will

bake evenly and be done all at once. The baking time may be shorter due to the warm

circulating air. For small items such as cookies, check to see if they are done one to two

minutes before the recipe time. For larger baked items such as cakes, check five to six

minutes before the time indicated on the recipe.

Convection cooking of meat and poultry will result in foods that are brown and crispy on the

outside and moist and juicy on the inside. Large meat or poultry items may cook up to 30

minutes less than the suggested time so check them so they will not be over baked. A meat

thermometer or an instant read thermometer will provide more accurate results than the

"minute per pound" method. The larger the piece of meat or poultry, the more time you will

save.

Converting Conventional Baking to Convection Cooking

To convert most recipes for baked items (cookies, cakes, pies, etc.), reduce the oven

temperature by 25°F. For meats and poultry, use the temperature recommended in recipes

and cooking charts.

throughout the oven cavity for all uses. Multiple rack use is possible for baking large amounts

of food. When roasting, cool air is quickly replaced -searing meats on the outside and

retaining more juices and natural flavor on the inside with less shrinkage.

CONVECTION BAKE

Full power heat is radiated from the bake element in the bottom of the oven and partial power

is radiated from the top element. Air is circulated by the fan in the rear of the oven.

TURBO BAKE

The rear and bottom elements operate at full power. Air is circulated by the fan for even

heating. Use this setting to reduce pre-heating time of the oven or for recipes which require

uniform cooking with strong heat from bottom such as pizza and focaccia bread.

31

Continued on next page

Page 32

OPERATING INSTRUCTIONS

CONVECTION BAKE & TURBO (Continued)

Preheating

Preheat the oven before baking. The oven does not need to be preheated for large pieces of

meat or poultry. See your recipe for preheating recommendation. Preheating time depends on

the temperature setting and the number of racks in the oven.

Temperature Setting

When using Convection Bake, reduce the temperature recommended in the recipe by 25°F.

When roasting meats, check internal temperature prior to time recommended by recipe to

prevent over cooking. When roasting meats in convection mode, do not reduce temperature

setting.

Condensation

It is normal for a certain amount of moisture to evaporate from the food during any cooking

process The amount depends on the moisture content of the food. The moisture will condense

on any surface cooler than, the inside of the oven, such as the control panel.

Rack Positions

Large Main Oven One Rack Baking When baking on one rack, best results are obtained in the

bake mode (see Bake). When roasting a turkey or a large piece of meat, convection bake may

be used. Rack 4 is the most appropriate rack.

Two Rack Baking

Racks 4 and 2 are most appropriate when using the convection bake mode. Round cake pans

should be staggered on racks 4 and 2. Rectangular (9 x 13) cake pans and cookie sheets

should be placed on rack 4 directly under the one on rack 2. This may be used for cakes,

cookies, biscuits and other foods for which two rack baking is desirable. When several

casseroles, frozen pies or cakes are to be baked, use racks 4 and 2. These two racks can also

be used for a large oven meal.

Bakeware Type

Aluminum bake ware gives the best browning results. Cookie sheets with only two sides give

the best results. Aluminum commercial half-sheets or professional cooking utensils may be

used but baking times may be increased.

Placement

For better browning, utensils such as cookie sheets. Rectangular baking pans should be

placed crosswise on the rack with the shorter side facing right and left to allow better air flow.

When baking on more than one rack, cookie sheets and rectangular (9 x 13) cake pans should

not be staggered; round cake pans should be staggered.

Settings for BAKE/CONVECTION and BAKE/CONVECTION/TURBO Cooking Modes

These cooking modes are for baking, roasting or warming using one or two racks.

1.) Select BAKE/CONVECTION or BAKE/CONVECTION/TURBO using the Selector

switch.

2.) Set the oven temperature using the oven temperature control knob (not over the

maximum 500°F position). If using CONVECTION, set the oven control knob 25°F below

the temperature suggested in the recipe. Do NOT change recipe temperature if roasting

meats or poultry.

32

Page 33

OPERATING INSTRUCTIONS

FOOD PAN

SIZE

CONTROL

TEMPERATURE

SETTING

TOTAL

SUGGESTED

COOKING

TIME

Cookies

12„X15'

Cookie

Sheet

375*

8 to 12 minutes

Layer

Cakes

8"or

9'Round

350*

25 to 35

minutes

Sheet

Cakes

9'x13”

Pan

350*

30 to 40

minutes

Bunt

Cakes

12 Cup 325*

60 to 75

minutes

Brownies or

Bar Cookies

9"x9"

Pan

325*

20 to 25

minutes

Biscuits

12"x15"

Cookie

Sheet

425* or Package

Directions

10 to 15

minutes

Quick

Bread

8"x4" Loaf

Pan

350*

55 to 70

minutes

Muffins

12 cup

Muffin Pan

425*

14 to 19

minutes

425*

35 to 45

minutes

Fruit

Cobblers

9"x9"

Pan

Yeast

Bread,

Loaves

8Hx4” Loaf

Pan

375*

25 to 30

minutes

Dinner

Rolls

9”x13"

Pan

400*

12 to 18

minutes

Cinnamon

Rolls

9”x13”

Pan

375

25 to 30

minutes

Yeast

Cotter and

Cake

12"x15“

Cookie

Sheet

400*

20 to 30

minutes

BAKING RECOMMENDATIONS

Fruit Pies

9“

Diameter

33

'400*

25 to 30

minutes

Page 34

OPERATING INSTRUCTIONS

BAKING RECOMMENDATIONS (continued)

FOOD

Fruit

Apples

Bananas

Cherries

Orange peels and slices

Pineapple rings Towel dried

Strawberries

Vegetable

Peppers

Dipped in 1/4 cup lemon juice and 2

Dipped in 1/4 cup lemon juice and 2

1/4" slices of orange, orange part of

PREPARATION

clips water; 1/4" slices

cups water; 1/4" slices

Wash and towel dry. For fresh

cherries, remove pits

skin thinly peeled from oranges

Wash and towel dry. Sliced 1/2"

thick, skin (outside) down on rack

Wash and towel dry. Remove

membrane of peppers, coarsely

chopped about 1" pieces

APPROXIMATE DRYING

TIME (hrs)

11-15 Slightly pliable

10-15 Soft, pliable

10-15 Pliable, leathery, chewy

PeeIs: 2-4 Slices: 12-16

Canned: 9-13 Fresh: a-12

12-17

16-20

TEST FOR DONENESS

Orange peel: dry and brittle.

Orange slices: skins are dry and brittle,

fruit is slightly

Sott and pliable

Dry, brittle

Leathery with no moisture inside

Mushrooms

Tomatoes

Herbs

Oregano, Sage, Parsley,

Thyme, Fennel

Basil

Wash and towel dry. Cut off stem

end. Cut into 1/8" slices

Wash and towel dry. Cut thin slices,

1/6" thick, drain well.

Rinse and dry with paper towel

Use basil leaves 3 to 4 inches from

top. Spray with water, shake off

moisture and pat dry

7-12 Tough and leathery, dry

16-23

3-5 Cnsp and brittle

3-5

Dry, brick red Colour

Crisp and brittle

34

Page 35

OPERATING INSTRUCTIONS

BROIL / CONVECTION BROIL

Preheating

Broiling requires constant exposure to high, intense heat. Only the upper element heats in

the BROILER mode. It is recommended that you preheat the broil element before starting to

cook. Preheat until the "PRE-HEATING" light turns off (about 5-6 minutes).

Tips for Getting the Best Results

• Defrost food before broiling.

• Keep oven door closed during broiling.

• Steaks should be more than 1" thick if rare meat is desired. Use convection broil if

steaks are over 1-1/2 inches thick. Turn food over once after half cooking time. It is not

necessary to turn very thin food (ham slices, fillets of fish, etc.). Liver slices must be

turned over regardless of thickness.

• Use a timer. Set it for the minimum time and check the food.

• Center food directly under the broiling element for best browning.

Rack Positions

Before turning on the oven, place the rack in the desired position. After preheating the broiler,

center the broil pan under the broil element.

• Position 2: Use this rack position when broiling beef steaks, ground meat patties, ham

steak and lamb chops 1 inch or less thick. Also use when browning food.

• Position 3: Use this rack position when broiling meat 1 1/8 inches or more thick, fish,

poultry, pork chops,

ham steaks 1 inch or more thick.

• Position 3 or 4: Use this rack when broiling chicken quarters or halves.

Utensils

• Use metal or glass-ceramic bake ware when browning casseroles, main dishes, or

bread.

• DO NOT use heat-proof glass or pottery. This type of glassware cannot withstand the

intense hear of the broil element.

Broiling Using Meat Thermometer

To more accurately define the preparation of thick steaks or chops (at least 1 1/2 inches

thick), use a meat thermometer. Insert the point of the thermometer into the side of the meat

reaching the center of the steak or chop.

For rare steaks, cook the first side to 90°F. For medium or well done steaks, cook the first

side to 100°F. Turn and cook the second side to desired internal temperature.

35

Continued on next page

Page 36

OPERATING INSTRUCTIONS

BROIL / CONVECTION BROIL (Continued)

Setting BROILER or CONVECTION BROILER

Select CONVECTION BROIL to brown food slightly also on the bottom side. This mode is

preferred for browning food on both side that is too delicate for turning such as fish. The

degree of browning of each side might be different.

Set Oven to BROIL or CONVECTION BROIL

1.) Place oven rack in desired position.

2.) Set Selector Switch to BROIL or CONVECTION BROIL.

3.) Set oven temperature control knob to BROILER or CONVECTION BROILER setting

corresponding to 500° fixed BROILER setting (not over maximum temperature 500°F or

under 450°F)

4.) Wait until PRE-HEATING light turns off, after approximately 5-6 minutes.

5.) Place food in oven at desired rack position as referenced on Page 28.

36

Page 37

OPERATING INSTRUCTIONS

FOOD ITEM

RACK

OVEN MODE

FUNCTION

SELECTOR

CONTROL

TEMPERATURE

SETTING

SELECTOR

APPROXIMATE

SPECIAL

INSTRUCTIONS AND

TIPS

BEEF

Ground Beef

Patties, Vt thick

2

Broiler or convection

Broiler

500°

15 to 20 minutes

Broil until no pink in

center

T-Bone Steak

2

Broiler or convection

Broiler

12 to 20 minutes

Time depends on

rareness of steak

Flank Steak

2

Broiler or convection

Broiler

12 to 20 minutes Rare to Medium Rare

Eye of Round

Roast

3

20 to 25 min/lb

Small roasts take more

minutes per pound;

reduce time by using

Convection Bake

PORK Loin Roast

3

Bake or Convection

bake

20 to 25 min/lb

Cook until juices are

clear

POULTRY Boneless

Skinless Chicken

Breasts

2

Broiler or convection

Broiler

20 to 25 minutes

Cook until juices are

clear

Chicken Thighs

3

Broiler or convection

Broiler

25 to 30 minutes

Remove skin; Cook until

juices are clear

Half Chickens

3

Broiler or convection

Broiler

30 to 45 minutes

Turn with tongs; Cook

until juices are clear

Roast Chicken

4

Bake or Convection

bake

350°

75 to 90 minutes

Do not stuff; reduce time

by using Convection

Bake

Turkey

4

Bake or Convection

bake

325°

20 to 25 min/lb

Do not stuff; reduce time

by using Convection

Bake

500°

500°

Bake or Convection

bake

500°

500°

500°

325°

325°

BROILING & ROASTING RECOMMENDATIONS

BROILING AND ROASTING RECOMMENDATIONS

37

Page 38

CARE & MAINTENANCE

REPLACING OVEN LIGHT BULBS

WARNING! Disconnect power before servicing unit.

To replace the oven light bulb, unscrew the protection cap that projects out inside the oven.

NOTE: Touching the bulb with fingers may cause the bulb to burn out. Always use protective

glove or use a cloth to remove the bulb.

CLEANING YOUR RANGE

ATTENTION: During cleaning operation never move the appliance from its

foreseen original installation position.

• Never use abrasive cleaners. Scratches on the stainless steel surfaces are permanent.

• Do not clean the range when hot.

Cleaning After Installation

Use a stainless steel cleaning product or wipe to eliminate the glue residues of the blue

protection film after removal.

Cleaning the Cooktop

Periodically clean the burner heads, the cast iron pan supports and the burner caps using

warm water. Remove burned food and fat residues with a rubber spatula . If food residue

prevent the smooth operation of the control knobs, call the customer service hotline to

schedule service by a factory-trained professional.

Cleaning Stainless Steel

For best results, use a stainless steel cleaner product with a soft sponge or wipe. Alternatively

use a soft sponge or cloth with a warm soap and water solution. Never use abrasive powders

or liquids.

Cleaning the Burner Caps

Lift the burner caps from the burner heads and wash them in a warm soap and water solution.

Dry thoroughly before using them again. Before reinstalling them on the burner head, check

that the gas flow holes are not clogged with food residues or cleaning product residues.

Cleaning Enamel

Enamelled parts should be cleaned frequently with warm soap and water solution applied with

a soft sponge or wipe. Never use abrasive powders or liquids. Do not leave acid or alkaline

substances on the enamelled parts (such as vinegar, lemon juice, salt, tomato sauce, etc.).

Use a rubber spatula to remove fat residues.

Cleaning the Glass Door

Clean the glass using a non-abrasive sponge or wipe with a warm soap and warm water

solution. Use a rubber spatula to remove fat residues.

ATTENTION: While cleaning the door, avoid spillage of food residues and

cleaning products in the venting holes situated on the top side of the door. To

clean the inside of the oven door, call a qualified professional. If you have any

further questions regarding cleaning the appliance, please contact your

appliance retailer.

38

Page 39

TROUBLESHOOTING

CauseBaking Problem

Food browns unevenly

Food too brown on bottom

Food is dry or has shrunk

excessively

Food is baking or roasting too

slowly

Oven not preheated

•

Aluminum foil on oven rack or oven bottom

•

Baking utensil too large for recipe

•

Pans touching each other or oven walls

•

Oven not preheated

•

Using glass, dull or darkened metal pans

•

Incorrect rack position

•

Pans touching each other or oven walls

•

Oven temperature too high

•

Baking time too long

•

Oven door opened frequently

•

Pan size too large

•

Oven temperature too low

•

Oven not preheated

•

Oven door opened frequently

•

Pie crusts do not brown on

bottom or crust is soggy

Cakes pale, at and may not be

done inside

Cakes high in middle with crack

on top

Tightly sealed with aluminum foil

•

Pan size too small

•

Baking time not long enough

•

Using shiny steel pans

•

Incorrect rack position

•

Oven temperature is too low

•

Oven temperature too low

•

Incorrect baking time

•

Cake tested too soon

•

Oven door opened too often

•

Pan size may be too large

•

Oven temperature too high

•

Baking time too long

•

Pans touching each other or oven walls

•

Incorrect rack position

•

39

Pie crust edges too brown

Pan size too small

•

Oven temperature too high

•

Edges of crust too thin

•

Page 40

TROUBLESHOOTING

PROBLEM POSSIBLE CAUSE

Burner will

not ignite

Burner

will not

operate

Gases not

flowing.

Burner

Flames are

uneven,

yellow and/

or noisy

There is no power to

the cooktop

First time use. Air

still in the gas line.

Control knob is not

set correctly.

The burner port is

clogged.

Improper

installation.

Burner port(s) are

clogged.

Burner caps are not

positioned properly.

Propane gas is being

used.

SOLUTION

Replace fuse or reset circuit breaker.

Turn on any one of the surface burner knobs

to release air from the gas lines.

Push in knob before turning to a setting.

Clean burner port opening using a sti, nylon

toothbrush or a straightened paper clip.

Turn the manual gas shut-off valve on.

Installer should make sure regulator is

correctly oriented (arrow towards unit).

Clean burner port opening using a sti, nylon

toothbrush or a straightened paper clip.

Place burner caps so that the alignment pins

are properly aligned with the slots.

The range should be converted to LP gas by

a qualied technician.

Burner

ame is too

high or too

low

Burner

makes

popping

noises

Excessive

heat

around

cookware

on cooktop

Cooktop gas supply

is not correct.

The gas pressure is

not correct.

The burner is wet. Allow the burner to dry before using.

The burner cap and/

or gas spreader

is not positioned

correctly.

The cookware is not

the proper size for

the burner.

Ensure the range is set for the correct

gas type. It is factory set for natural gas. If

connected to LP gas the burners should be

converted to LP gas with the orice/injector

kit supplied and the pressure regulator

converted to the LP gas setting by a qualied

technician.

Make sure the pressure regulator is installed

correctly and the gas line pressure is correct.

See Installation Instructions.

Place burner caps so that the alignment pins

are properly aligned with the slots.

Use cookware with a bottom surface

approximately the same size as the cooking

area and burner. Cookware should not

extend more than 1” (2.5 cm) outside the

cooking area. Adjust the ame so that it

does not come up around the cookware.

40

Page 41

TROUBLESHOOTING

POSSIBLE CAUSE SOLUTIONPROBLEM

Oven is not

heating

Oven is not

cooking evenly

Broil does

not work.

Cooling fan

continues to

run after oven

is turned o

Oven light is

not working

properly

No power to the

oven

Oven control not

turned on

Not using the correct

bake ware or oven

rack position

Knob settings are not

in the correct

positions.

The electronic

components have

not yet cooled

suciently

Light bulb loose or

burned-out.

Reset the circuit breaker or replace the

fuse in the electrical box to your oven.

Make sure the oven temperature has

been selected and timer is not "OFF".

Refer to cook charts for recommended

rack position. Always reduce recipe

temperature by 25 °F (15 °C) when

baking with Convention Bake mode.

Make sure oven temperature

selection knob is set to " BROIL" and

timer is not set to "OFF"

The fan will turn o automatically

when the electronic components have

cooled suciently.

Reinsert or replace the light bulb.

Touching the bulb with ngers may

cause the bulb to burn out.

Oven light

stays on

Cannot remove

lens cover

Heat blowing out

from the front

of oven.

Excessive

Moisture

Porcelain Chips

Door is not closing

completely

Soil build-up around

the lens cover.

Oven cavity

ventilation on

Porcelain interior

is bumped by oven

racks

Check for obstruction in oven door.

Check to see if hinge is bent or door

switch broken.

Wipe lens cover area with a clean, dry

towel prior to attempting to remove

the lens cover.

The oven cavity ventilation is

operating until the oven is sufficiently

cooled. This is normal.

When using bake mode, preheat

the oven rst. Convection Bake and

Convection Roast will eliminate any

moisture in the oven.

When removing and replacing oven

racks, always tilt racks upward and do

not force them to avoid chipping the

porcelain.

FOR MORE HELP, VISIT COSMOAPPLIANCES.COM

OR CALL COSMO CUSTOMER SUPPORT: 1-888-784-3108.

41

Page 42

LOCATION OF APPLIANCE TAGS

The rating tag shows the model and serial number of your range. It is located under the front

edge of the range cooktop, and is visible when the oven door is open (see illustration)

A= Rating tag(s) located under front edge of cooktop

B= Wiring / schematic diagram placed behind backside panel and on Pages 15-16

42

Page 43

WARRANTY AND SERVICE

For full warranty details on this product please visit:

http://www.cosmoappliances.com/warranty

TO RECEIVE WARRANTY SERVICE, YOUR

PRODUCT MUST BE REGISTERED. TO REGISTER, VISIT:

WWW.COSMOAPPLIANCES.COM/WARRANTY

SCAN TO REGISTER

43

Page 44

IMPORTANT

Do Not Return This Product To The Store If

you have a problem with this product, please contact

Cosmo Customer Support at

+1(888)784-3108

DATED PROOF OF PURCHASE, MODEL #, AND SERIAL #

REQUIRED FOR WARRANTY SERVICE

IMPORTANT

Ne pas Réexpédier ce Produit au Magasin

Pour tout problème concernant ce produit, veuillez contacter

le service des consommateurs Cosmo Customer Support au

+1(888) 784-3108

UNE PREUVE D’ACHAT DATEE EST REQUISE POUR BENEFICIER DE

LA GARANTIE.

IMPORTANTE

No regrese este producto a la tienda

Si tiene algún problema con este producto, por favor contacte el

AYUDA AL CLIENTE COSMO al

+1(888)784-3108

(Válido solo en E.U.A).

NECESITA UNA PRUEBA DE DE COMPRA FECHADA, NÚMERO DE

MODELO Y DE SERIE PARA EL SERVICIO DE LA GARANTÍA

Correct Disposal of this product:

This marking indicates that this appliance should not

be disposed with other household wastes. To prevent

possible harm to the environment or human health

from uncontrolled waste disposal, recycle it responsibly to

promote the sustainable reuse of material resources.

44

Page 45

NOTE:

Page 46

Cosmo is constantly making efforts to improve the quality and

performance of our products, so we may make changes to our

appliances without updating this manual.

Electronic version of this manual is available at:

www.cosmoappliances.com

Loading...

Loading...