Page 1

RANGE

GRP304

P366

Write important appliance information below:

Installer : _____________________

Serial Number Location

Located on oven door opening side, or

on the back of the unit.

Cosmo is constantly making efforts to improve the quality an

performance of our products , so we may make changes to our

appliances without updating this manua

www.cosmoappliances.com to download the latest version of this manual

l. Visit

To prevent harm to any person or damage to the product,

you must read all instructions supplied

before installing or using the appliance.

Page 2

Page 3

Thank You!

Thank you for your purchase. We

know that you have many brands

and products to choose from and

we are honored to know that you

have decided to take one of our

products into your home and hope

that you enjoy it.

Our appliances are designed

according to the strictest safety

and performance stan-dard for

the North American market. We

follow the most advanced

manufacturing philosophy. Each

We hope that this manual will

help you learn to use the product

in the safest and most effective

manner and care for it so that it

may give you the highes

satisfaction in cooking for years

to come.

If you have any questions or

concerns, please contact the

dealer from whom you

purchased it, or contact our

Customer Support at:

1-888-784-3108.

appliance leaves the factory after

thorough quality inspection and

testing. Our distributors and our

service partners are ready to

answer any questions you may

have regarding how to install, use

and care for your range hood.

The manual also includes

directions for the professional

installer that will install the

product in your home. We

recommend using trained

personnel for

professional installation.

Please keep this manual for future use.

Page 4

TABLE OF CONTENTS

IMPORTANT SAFETY INSTRUCTIONS .......................... 4

SPECIFICATIONS

INSTALL GUIDE

USE GUIDE ...................... ............................. ................ 28

CARE GUIDE

TROUBLESHOOTING GUIDE ..............

WARRANTY AND SERVICE

............................................................ 5

.............................................................. 12

.................................................................. 36

........................ 38

.............................................41

Page 5

IMPORTANT SAFETY INSTRUCTIONS

WARNING

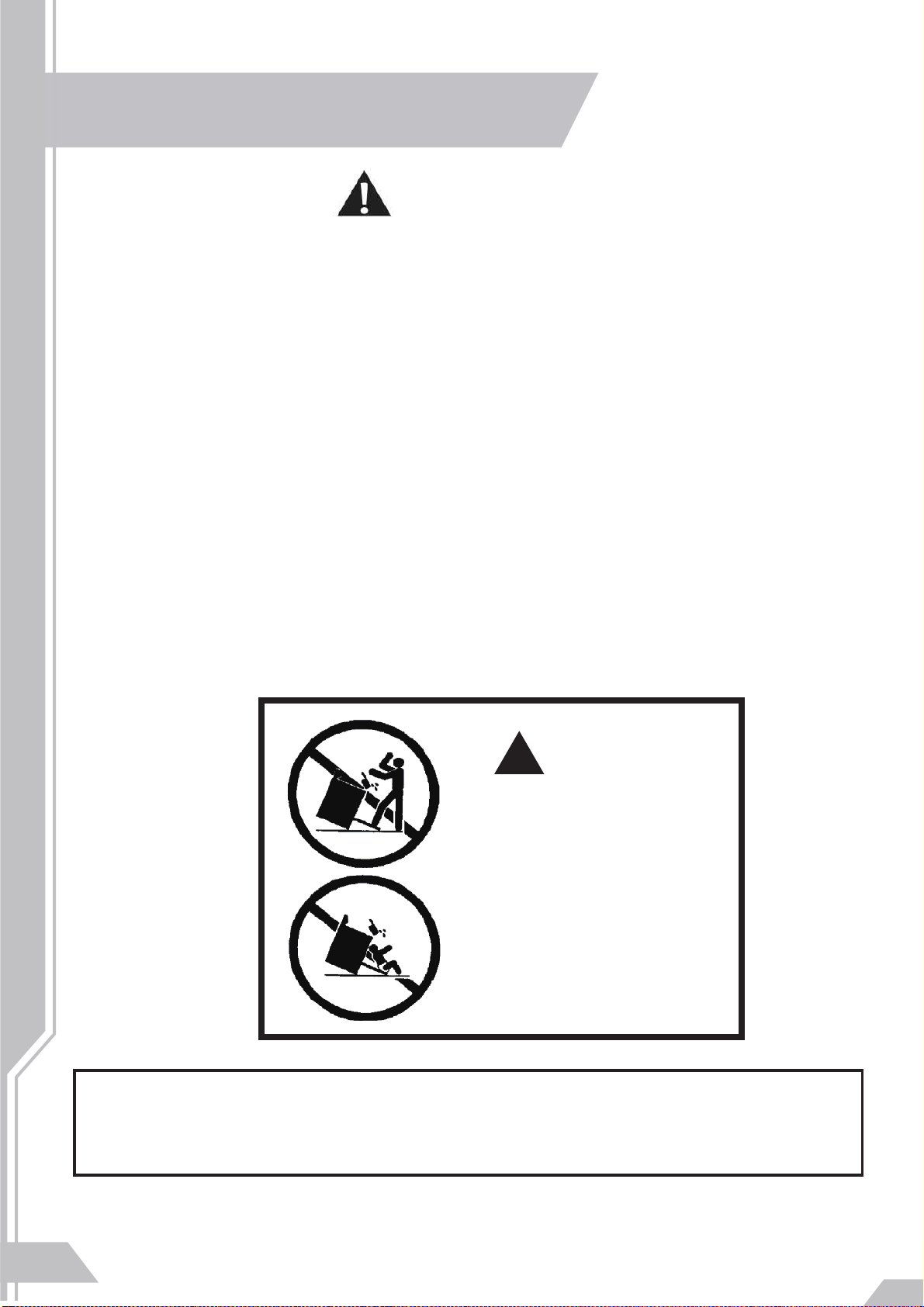

• A child or adult can tip the range and be killed. Re-engage

the anti-tip device if the range is moved . Do not operate

the range without the anti-tip device in place and engaged.

See installation instructions for details. Failure to do so can

result in death or serious burns to children or adults.

• This range must be secured and connected using the antitip device according to the installation instructions.

• Do not use the range if the anti-tip device has not been

properly installed and engaged.

• Failure to observe the information contained in the

installation instructions can lead to serious or fatal injuries for

children and adults.

ARNING

!

All ranges can tip

Injury to persons could result .

Install anti-tip devices packed

with range

See installation instructions

W

4

State of California Proposition 65 Warnings:

WARNING: This product contains one or more chemicals known to the State of California to cause cancer.

WARNING: This product contains one or more chemicals known to the State of California to cause birth defects or other

reproductive harm.

Page 6

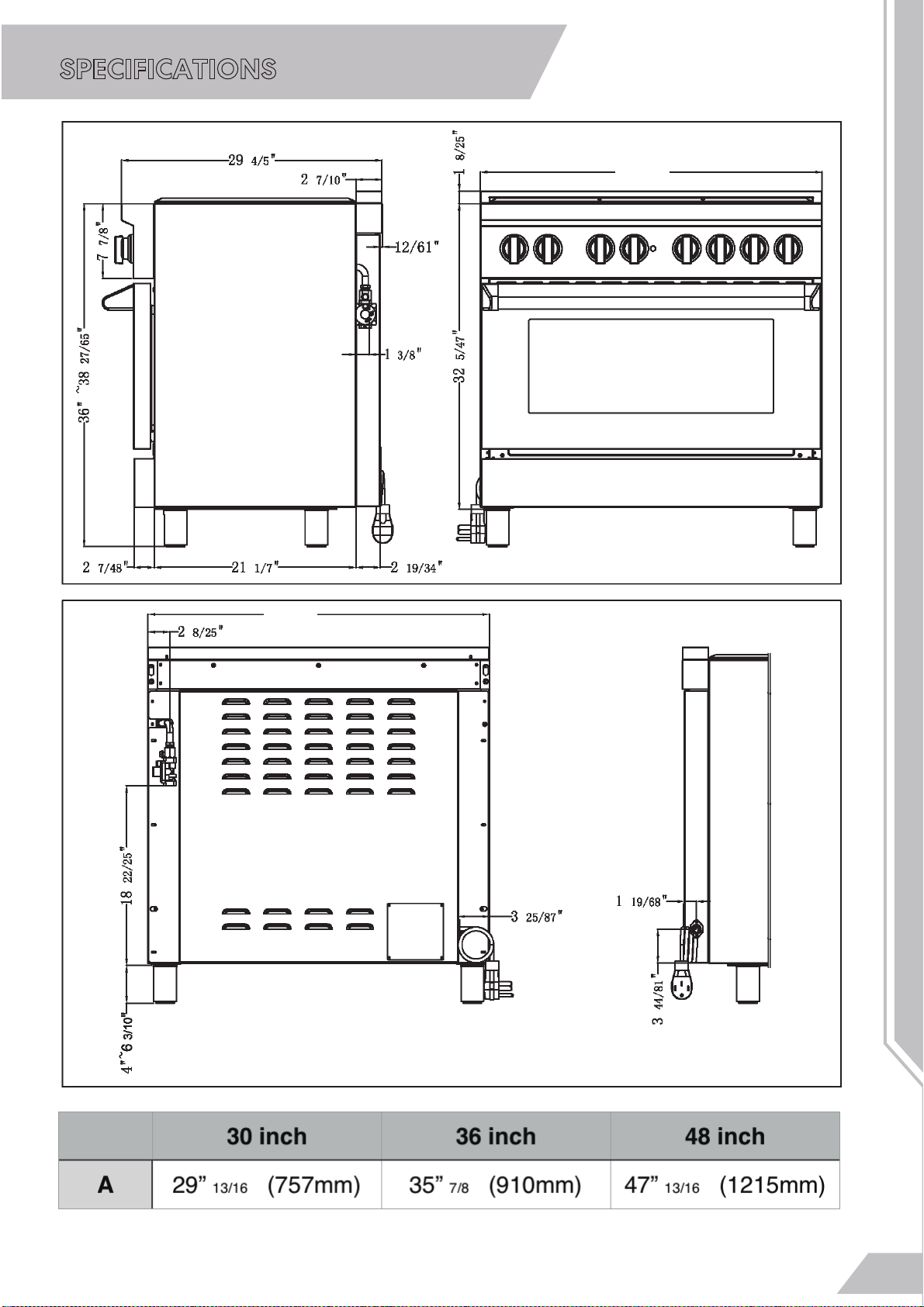

SPECIFICATIONS

A

A

5

Page 7

IMPORTANT SAFETY INSTRUCTIONS

ARNING

W

!

If the information in this manual is not followed exactly, a fire or

explosion may result causing property damage, personal

injury, or death.Dealer cannot be held liable for damage

occurring as a result of non-compliance with the instructions.

-Do not store or use gasoline or other flammable substances in

the vicinity of this or any other appliance.

-WHAT TO DO IF YOU SMELL GAS

•Do not light any appliance.

•Do not touch any electrical switch.

•Do not use any phone in your building.

•Immediately call your gas supplier from a neighbour's

phone. Follow the gas supplier's instructions.

•If you cannot reach your gas suppliers, call the fire department.

- Installation and service must be performed by a qualified

installer,

(In Massachusetts, installation must be performed by a

"Massachusetts" licensed plumber or gasfitter. A "T"

handle type manual gas valve must be installed in the gas

line connected to this appliance.)

- Theinstallationofappliance designed for manuafactured( mobile)

home installationmustconformwith the Manufactured Home

Construction and Safety Standard,Title 24CFR,Part 3280 I formerly

the Federal Standard for Mobile Home Construction and Safety,

Title 24,HUD(Part280) ] or with local codes where applicable..

service agency or the gas supplier.

6

– Note to the installer:

Please give these installation instructions to the consumer for the

local electrical/gas inspector.

Page 8

IMPORTANT SAFETY INSTRUCTIONS

When using the appliance, follow basic safety precautions,

including the following:

Read all instructions before installation and use of the range to

prevent accidents and machine damage.

W

ARNING

!

This appliance complies with current safety requirements.

Improper use of the appliance can lead to personal injury and

material damage.

Read all instructions before installing or using the oven for the

first time. Only use the appliance for its intended purpose.

Keep these operating instructions in a safe place and pass

them on to any future user.

The manufacturer reserves the right to make changes to its

products when considered necessary and useful, without

affecting the essential safety and operating characteristics.

This appliance has been designed for non-professional,

domestic use only.

Do not use this appliance to heat a room.

Do not place any pot or pan on the open oven door.

The door is made of glass and it can break if loaded with a

weight. Do not remove permanently affixed labels, warnings,

or plates from the product. This may void the warranty.

Please observe all local and national codes and ordinances.

Please ensure the range is properly grounded.

7

Page 9

IMPORTANT SAFETY INSTRUCTIONS

!

WARNING

Installation of any gas-fired equipment should be made by a

licensed plumber. A manual gas shut-off valve must be

installed in the gas supply line ahead of the oven in the gas

flow for safety and ease of service.

Make sure the appliance must be isolated from the gas

supply piping system and plug wire.

The plug should always be accessible.

Installation must conform with local codes or in the

absence of codes, the National Fuel Gas Code ANSIZ223.1/

NFPA54. Electrical installation must be in accordance with the

National Electrical Code ANSI/NFPA 70 - latest edition and/or

local codes.

IN CANADA: Installation must be in accordance with the current

CAN/CGA-fe 149.1 National Gas Installation Code or

CAN/CGA-B 149.2, Propane Installation Code and/or local codes.

Electrical installation must be in accordance with the current

CSA C22.1 Canadian Electrical Codes Part 1 and/or local codes.

This appliance shall not be installed with a ventilation system that

blow air downward toward the range/rangetop/cooktop; this type of

ventilation system may cause ignition and combustion problem with

the gas appliance resulting in a personal injury or unintended

operation

An air curtain or other overhead range/rangetop/cooktop hood, which

operates by blowing a downward airflow onto a

range/rangetop/cooktop, shall not be used/installedin conjunction

8

with this gas range.

Page 10

IMPORTANT SAFETY INSTRUCTIONS

Verify the type of gas being used at

the installation site . As shipped from

the factory , units are configured for

use with natural gas.

Make certain the range matches the

type of gas available at this location .

This range can be converted for use

with propane gas (LP ) and the

process is explained later in the manual.

For installation of the appliance at high

altitude , please consult your local gas

company for their recommen -dation

of the correct orifice sizes and any

other necessary adjustments that will

provide proper gas combustion at

specified altitudes.

CAUTION

When connecting unit to propane

gas , make certain the propane

gas tank is equipped with its own

high pressure regulator in addition

to the pressure regulator supplied

with the appliance. The pressure of

the gas supplied to the appliance

regulator must not exceed 14" (

37mb) water column.

• A manual

installed external to the appliance, in an

accessible location from the front, for the

purpose of shutting off the gas supply. The

supply line must not interfere with the back

of the unit. Make sure the gas supply is

turned off at the manual shut-off valve

before connecting the appliance.

• The range is supplied with its own pressure

regulator that has been permanently

mounted within the range body.

• The

• Always use pipe dope or Teflon® tape on

• Turn on gas and check supply line

gas supply connections should be made

by a competent technician and in accordance

with local codes or ordinances. In the

absence of a local code, the installation must

conform to the National Fuel Gas Code ANSI

Z223.1, Current Issue.

the pipe threads, and be careful not to apply

excessive pressure when tightening the

fittings.

connections for leaks using a soap solution

. Do not use a flame of any sort to check

for leaks.

gas shut-off valve must be

Natural Gas Requirements:

Supply Pressure: 6" to 14" water column. )

Propane Gas Requirements:

Supply Pressure: 11" to 14" water column.)

For Massachusetts Installations:

1.

Shut-off valve must be a “T” handle gas cock.

2.

Flexible gas connector must not be longer

than 36 inches.

3. Not approved for installation in a bedroom

or a bathroom unless unit is direct vent.

9

Page 11

IMPORTANT SAFETY INSTRUCTIONS

Do not carry or lift the range by the

W

!

ARNING

oven door handle or the control panel!

W

ARNING

!

Heating elements may be hot even though they are not

glowing. Interior surfaces of an oven become hot enough to

cause burns. External parts of the oven such as the door glass,

vents, and the control panel can become hot. During and after

use, do not touch, or let clothing or other flammable materials

come into contact with heating elements or interior surfaces of

the oven until they have had sufficient time to cool.

ARNING

W

!

Never pour cold water onto hot surfaces in a hot oven.The steam

10

created could cause serious burns or scalding and the sudden

change in temperature can damage the enamel in the oven

Page 12

IMPORTANT SAFETY INSTRUCTIONS

!

WARNING for Children

- As with any appliance, close supervision is necessary when the oven is

used by children.

- Do not leave children unattended: Children should not be alone or

unsupervised in the area where the appliance is installed. Do not allow

them to sit or stand on the appliance.

- As with any appliance, close supervision is necessary when used

by children.

- Children 8 years and older may only use the oven unsupervised if they

have been shown how to use it safely and recognize and understand the

consequences of incorrect operation.

- Children must not be allowed to clean or maintain the appliance

unsupervised.

- Children should not be left alone or unattended in an area where

an oven is in use. Never allow children to operate, sit or stand on any part of

the oven. Caution: Do not store items of interest to children in cabinets

above an oven. Children climbing on the oven to reach these items could

be injured.

- Danger of burns. The oven gets hot at the oven door glass, the vapor

handle and the operating controls. Children's skin is more sensitive to high

temperatures than that of adults.

Do not allow children to touch or play in, on or near the oven.

- Burn Hazard - Do not allow children to use the oven. Failure to do

so can result in severe burns or serious injury.

- Burn hazard!

Keep the spaces above and behind the range clear of any items that could

draw the attention of children . Otherwise , they can be tempted into climbing

onto the appliance.

- Danger of injury. Never allow children to hang or lean on any part of the

appliance

vent, the

11

Page 13

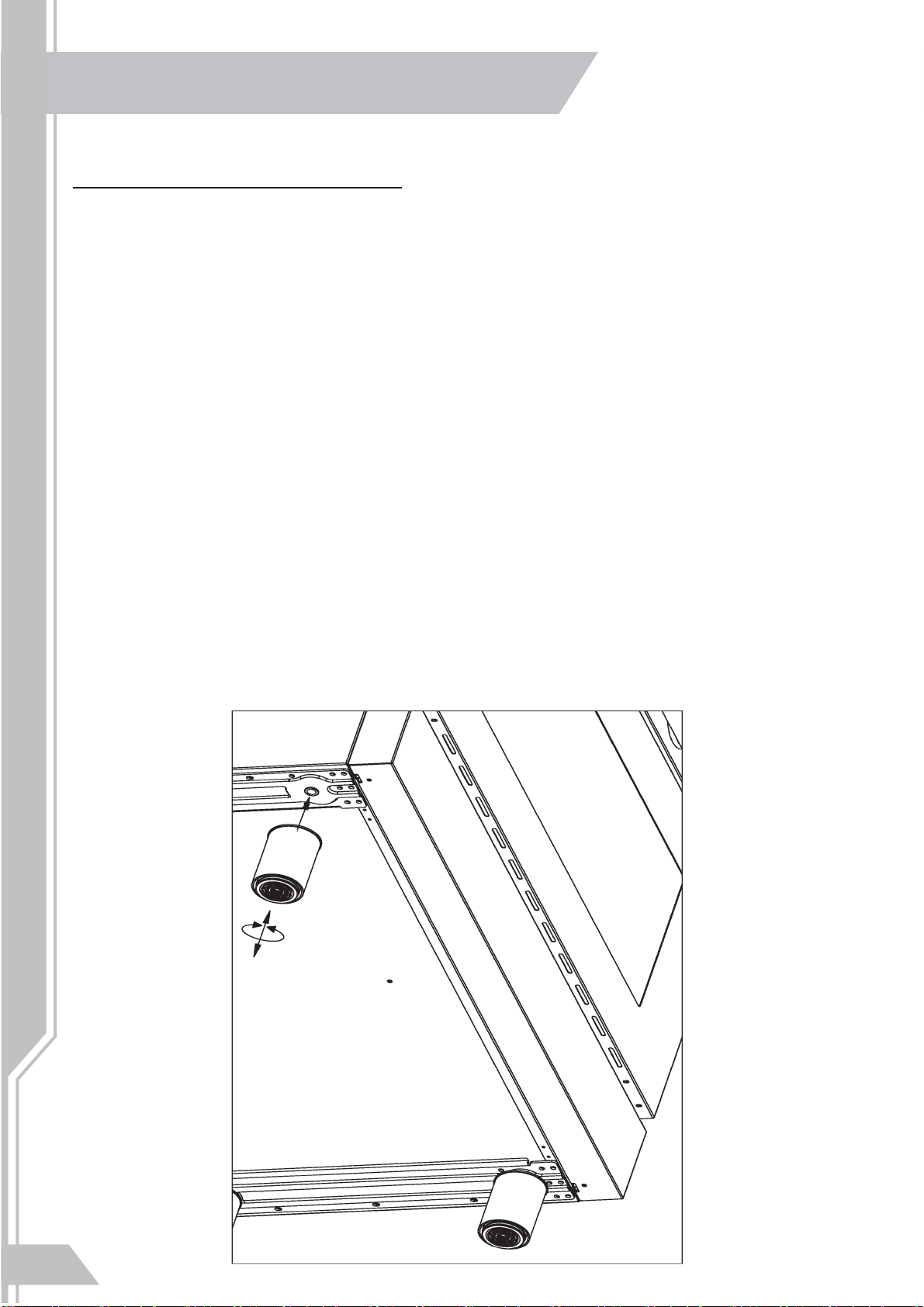

INSTALL GUIDE

INSTALLING THE LEGS

The ranges must be used only with the legs properly installed. Four heightadjustable legs are shipped with the range in the polystyrene container

situated over the appliance. Before installing the legs, position the appliance

near its final location as the legs are not suitable for moving the appliance

over long distances. This next part requires 2 people. After unpacking the

range, tilt the range enough to insert the legs in the appropriate receptacles

situated on the lower part of the appliance. Lower the range gently to keep

any undue strain from legs and mounting hardware. If possible use a pallet or

lift jack instead of tilting the unit. Adjust leg height to the desired level by

twisting the inside portion of the leg assembly until the proper height is

reached. Check with a level that the cooktop is perfectly level.

12

Page 14

INSTALL GUIDE

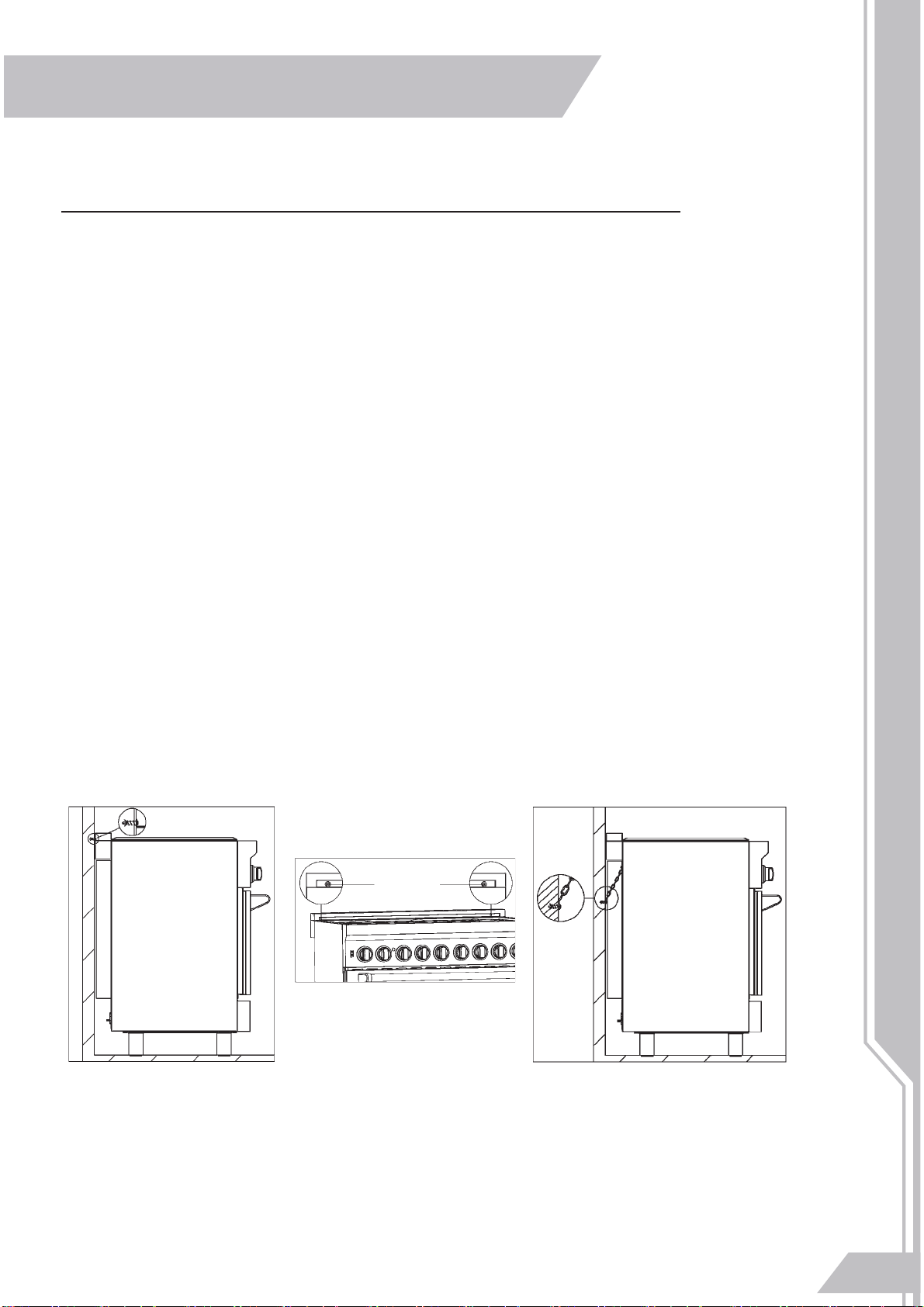

INSTALLING THE ANTI-TIP STABILITY DEVICE

The anti-tip bracket shipped with the range must be properly secured to

1)

the rear wall as shown in the picture below.The height of the bracket

from the floor must be determined after the range legs have been

adjusted to the desired height and after the range has been levelled.

Measure the distance from the floor to the bottom of the anti-tip bracket

receptacle on the back of the appliance.

Position the two anti-tip brackets on the wall at the desired height

plus 1/8" (0.32 cm). The brackets must be placed at 2 - 5/16" (6.0 cm)

from each side of the range. The distance between the two bracket

is 25 - 1/4" (64.1 cm). Secure the brackets to the wall with appropriate

hardware. Slide the range against the wall until the brackets are fully

inserted into their receptacles on the back of the range.

Check to see that the Anti-Tip device is installed properly. Grasp the top

rear edge of the range and carefully attempt to tilt it forward. Verify that

the Anti-Tip device is engaged.

2) Or, use the anti-tip chain, and tighten up with fixed screw on the wall,

and when the wall not suitable for installation, the chain shall be fixed to

the cabinet structure.

13

Page 15

INSTALL GUIDE

CABINETS

This range may be installed directly adjacent to existing countertop high

cabinets (36" or 91.5 cm from the floor).For the best look, the cooktop should be

level with the cabinet countertop. This can be accomplished by raising the unit

using the adjustment spindles on the legs.

ATTENTION: the range CANNOT be installed directly adjacent to kitchen

walls, tall cabinets, tall appliances , or other vertical surfaces above 36"(91.4

cm) high. The minimum side clearance in such cases is 6" (15.2 cm).Wall

cabinets with minimum side clearance must be installed 18" (45.7 cm) above

the countertop with countertop height between 35 1/2" (90.2 cm) and 37 1/2"

(94.6 cm). The maximum depth of wall cabinets above the range shall be 13"

(33.0 cm)

14

Page 16

INSTALL GUIDE

ELECTRICAL REQUIREMENTS

o reduce the risk of fire, electric shock, or personal injury:

T

WARNING

• Do not use an extension cord or adapter plug with this range.

• This range must be properly grounded.

• Check with a qualified electrician if you are in doubt as to whether your range

is properly grounded.

• Do not modify the plug provided with your range—if it doesn¡¯t fit the outlet,

have a proper outlet installed by a qualified electrician.

• All wiring and grounding must be done in accordance with local codes or, in

the absence of local codes, with the National Electrical Code, ANSI/NFPA No.

70 – Latest Revision (for the U.S.) or the Canadian Electrical Code CSA C22.1

– La est Revisions and local codes and ordinances.

• Wiring diagram is located on the back of the range. (Inside of the cover back

wire)

• This range is equipped with an electronic ignition system that will not operate

if plugged into an outlet that is not properly polarized.

• All gas models ar

e equipped with a power cord with an equipment-grounding

conductor and a grounding plug.

• A 120-Volt, 60-Hz, AC, approved electrical service with or 20-amp circuit

breaker or time-delay fuse is required for all U.S. and Canadian models.

• Do not reuse a power supply cord from an old range or other appliance.

• The power cord electric supply wiring must be retained at the range cabinet

with a suitable UL-listed strain relief.

• A time-delay fuse or circuit breaker is also recommended.

ounding

Gr

• All r

• All gas models have a power cord with an equipment-

anges must be grounded for personal safety.

grounding conductor

and a grounding plug.

• The plug must be firmly plugged into a three-prong outlet

that is properly installed and grounded in accordance with

all local codes and ordinances. In the event of a malfunction

or breakdown, grounding will increase the risk of electrical

shock by not providing a path for the electric current.

e proper

Ensur

ground

and firm

connection

before use.

15

Page 17

INSTALL GUIDE

• Do not use a damaged power plug or loose wall outlet.

• Do not use an extension cor

d or adapter with this appliance.

• Do not, under any circumstances, cut, modify, remove, or otherwise defeat

the grounding (third) prong from the power cord. If the plug and the outlet

do not match or you have any doubt, have a qualified electrician install the

proper outlet.

The customer should have the wall receptacle and circle checked by a

qualified electrician to make sure the receptacle is properly grounded.

Ground Fault Circuit Interrupters(GFCIs) are not required ot recommended for

gas range receptacles.

• NEVER connect ground wire to plastic plumbing lines, gas lines, or water

pipes.

Failure to follow these instructions can result in death, fire, or electrical

CAUTION

GAS

An agency-approved, properly-sized manual shut¬off valve should be

shock.

installed no higher than 3" (7.6 cm) above the floor and no less than

2" (5 cm) and no more than 8" (20.3 cm) from the right side (facing product).

To connect gas between shut-off valve and regulator, use agency-approved

, properly sized flexible or rigid pipe. Check all local code requirements.

EXHAUST HOOD INSTALLATION

This range will best perform when used with exhaust hoods. These hoods have

been designed to work in conjunction with the range and have the same finish

for a perfect look. For maximum performance, the height of the bottom of the

hood from the cooktop should be between 30" (76.2 cm) and 36" (91.4 cm).

This would typically result in the bottom of the hood being 61 1/2" (156.2 cm)

to 67 1/2" (171.5 cm) above the floor. These measurements provide for safe

and efficient operation of the hood. Before installation of the exhaust hood,

consult local or regional building and installation codes for additional specific

clearance requirements. Refer to the range hood installation instructions

provided by the manufacturer for additional information.

16

Page 18

INSTALL GUIDE

WIRING DIAGRAM

36 INCH MODEL

CAUTION

Label all wires prior to disconnecting when servicing controls. Wiring

errors can cause improper and dangerous operation. Verify proper

operation after servicing

17

Page 19

INSTALL GUIDE

WIRING DIAGRAM

18

30 INCH MODEL

CAUTION

Label all wires prior to disconnecting when servicing controls.

Wiring errors can cause improper and dangerous operation. Verify

proper operation after servicing

Page 20

INSTALL GUIDE

GAS CONNECTION

All gas connections must comply with national and local codes. The gas supply

line (service) must be the same size or greater than the inlet line of the

appliance. This range uses a 1/2" NPT inlet

(see drawing below for details of gas connection). On all pipe joints use

appropriate sealant resistant to gas.

This range can be used with Natural or LP/Propane gas. The range is

shipped from the factory for use with natural gas.

For LP/propane household installation, the appliance must be converted by a

licensed installer, qualified licensed plumber, or gas service company. Gas

conversion is important for safe and effective use of the appliance. It is the

responsibility of the consumer and his/ her installer of the range to perform the

appropriate gas conversion following the directions of this manual

THE GAS CONVERSION PROCEDURE IS DESCRIBED

IN THIS MANUAL. THE GAS CONVERSION KIT MUST

BE PURCHASED SEPARATELY.

Please provide the service person with this manual before work is started

on the range.

DO NOT USE AN OPEN FLAME WHEN

!

!

Leak testing of the appliance shall be conducted according to the

manufacturer's instructions. Before placing the oven into operation, always

check for leaks with soapy water solution or other acceptable method. Check

for gas leakage with soapy water solution or other acceptable methods in all

gas connections installed between inlet gas pipe of the appliance, gas

WARNING

CHECKING FOR LEAKS!

regulator, and the manual shut-off valve.

19

Page 21

INSTALL GUIDE

MANUAL SHUT-OFF VALVE

THIS VALVE IS NOT SHIPPED WITH THE APPLIANCE AND MUST BE

SUPPLIED BY THE INSTALLER.

The manual shut-off valve must be installed in the gas service line between the

gas hook-up on the wall and the appliance inlet, in a position where it can be

reached quickly in the event of an emergency.

In Massachusetts: A T handle type manual gas valve must be installed in the

gas supply line to this appliance.

FLEXIBLE CONNECTIONS

In case of installation with flexible couplings and /or quick - disconnect fittings

, the installer must use a heavy-duty, AGA design-certified commercial

flexible connector of at least 1/2" (1.3 cm) ID NPT

(with suitable strain reliefs) in compliance with ANSI Z21.41 and Z21.69

standards.

In Massachusetts: The unit must be installed with a 36" (3-foot) long flexible gas

connector.

In Canada: use CAN 1-6.10-88 metal connectors for gas appliances and CAN 1-6.

9 M79 quick disconnect device for use with gas fuel.

PRESSURE TEST-POINT STOPPER VALVE

To avoid gas leaks, the pressure test-point stopper valve and gasket supplied

with the range must be installed on the gas fitting at the back of the range

according to the diagram below

20

Page 22

INSTALL GUIDE

PRESSURE REGULATOR

Since service pressure may fluctuate with local demand, every gas

cooking appliance must be equipped with a pressure regulator on

the incoming service line for safe and efficient operation.

The pressure regulator shipped with the appliance has two female

threads 3/4" NPT. The regulator shall be installed properly in order to be

accessible when the appliance is installed in its final position.

PRESSURE REGULATOR

Manifold pressure should be checked with a manometer and

comply with the values indicated below:

Natural gas -> 4. 0" W.c.P.

LP/Propane -> 10.0" W.c.P.

Incoming line pressure upstream from the regulator must be 1" W.c.P.

higher than the manifold pressure in order to check the regulator. The

regulator used on this range can withstand a maximum input pressure

of 1/2 PSI (13.8" w.c. or 3.5 kPa) If the line pressure exceeds tha

amount, a step-down regulator is required .

The appliance, its individual shut-off valve, and the pressure

regulator must be disconnected from the gas line during any

pressure testing of that system at pressures in excess of 1/2 PSI

(13 .8" w.c. or 3.5 kPa). The individual manual shut-off valve must be

in the OFF position during any pressure testing of the gas supply

piping system at test pressures equal to or less than 1/2 PSI (13.8"

w.c . or 3.5 kPa)..

21

Page 23

INSTALL GUIDE

APPLIANCE SERVICING

Before carrying any servicing operation disconnect the

appliance from gas and electric supply and extra appliance

from final installation place in order to have access to the

appliance for proper servicing intervention.

GAS CONVERSION

WARNING: Before carrying out this operation, disconnect

the appliance from gas and electricity.

Gas conversion shall be conducted by a licensed and

certified professional.

The gas conversion procedure for this range includes 3

steps:

1.

Pressure regulator configuration

2.

Burner nozzle replacement

3.

Minimum flame adjustment

The conversion is not completed if all 3 steps have not

been concluded properly.

IMPORTANT: Each nozzle has a number indicating its flow

diameter printed on the body. Consult the table on step 2

for matching nozzles to burners.

Save the original nozzles removed from the range for future

use.

22

Page 24

INSTALL GUIDE

STEP 1: PRESSURE REGULATOR CONFIGURATION

The pressure regulator supplied with the appliance is a

convertible type pressure regulator for use with Natural

Gas at a nominal outlet pressure of 4" w.c. or LP gas at a

nominal outlet pressure of 10" w.c. and it is pre-arranged

from the factory to operate with Natural Gas. It can be

converted for use with propane gas by following these

steps:

a. Unscrew by hand the upper metal cap of the regulator.

b. Unscrew by hand the silver plastic piece screwed under

the above mentioned metal cap. The silver plastic piece

has arrows indicating the position for natural gas (NAT)

and LP gas (LP). Reverse its direction and screw it back

firmly against the cap.

c. Screw by hand the metal cap in the original position on

the regulator.

STEP 1a

STEP 1b

STEP 1c

23

Page 25

INSTALL GUIDE

STEP 2: BURNER NOZZLE REPLACEMENT

To replace the nozzles of the surface burners : lift up the

burners and unscrew the nozzles shipped with the range

using a 7 mm (socket wrench). Replace nozzles using the

conversion set. Each nozzle has a number indicating its flow

diameter printed on the body. Consult below figures for

matching nozzles to burners :

LP:

0.65

NG: 1.04

LP: 0.95

NG: 1.55

LP: 1.08

NG: 1.79

LP: 0.95

NG: 1.55

LP: 0.65

NG: 1.04

LP: 1.27

NG: 2.30

3

LP: 1.08

NG: 1.79

0”

LP: 1.27

NG: 2.30

Bottom Bake Burner: NG: 2.38 / LP: 1.27

Top Broiler Burner: NG: 1.79 / LP: 1.08

LP: 0.95

NG: 1.55

36”

LP: 1.08

NG: 1.79

24

Page 26

INSTALL GUIDE

STEP 3: MINIMUM FLAME ADJUSTMENT

These adjustments should be made only for use of the

appliance with natural gas. For use with liquid propane gas, the

choke screw must be fully turned in a clockwise direction.

Light one burner at a time and set the knob to the MINIMUM

a.

position (small flame).

Remove the knob.

b.

The range is equipped with a safety valve. Using a small-

c.

size slotted screwdriver, locate the choke valve on the valve

body and turn the choke screw to the right or left until the

burner flame is adjusted to desired minimum.

Make sure that the flame does not go out when switching

d.

quickly from the MAXIMUM to the MINIMUM position when

knob is re-installed.

25

Page 27

INSTALL GUIDE

PLACEMENT OF COOKTOP BURNERS AND GRATES

CAUTION

1.

Do not operat

Position surface burner heads on top of the surface burner

e the surface burners without all burner parts in place.

bases as shown at right. The electrodes will fit into the slot in

the bottom of the heads. Make sure the surface burner heads

are flat and parallel with the cooktop.

2.

Place the matching size caps on top of each surface burner

head.

3.

CA

UTION

Always keep the burner caps and burner heads in place whenever the

surface burners are in use. Do not allow spills, food, cleaning

agents or any other material to enter the gas orifice holder

openings.

Place the left, center, and right surface burner grates on the

cooktop. The edges of the grates should match up with the porcelain

edges of the cooktop.

To prevent flare-ups and avoid creation of harmful by-products, do not

use the cooktop without all burner caps properly installed to insure proper

ignition and gas flame size.

Check and be sure the size of each burner cap matches the size of the

burner head. Check and be sure that all round style burner caps are

correctly in place on round burner heads.

Burner cap

Burner cap lip

Correct burner cap placement

26

Incorrect burner cap placement

Page 28

INSTALL GUIDE

INSTALLATION Checklist

1. Is the range mounted on its legs?

2. Is the back guard securely connected?

3. Has the anti-tip device been properly installed?

4.

Does the clearance from the side cabinets comply with the manufacturers

directions?

5. Is the electricity properly grounded?

6.

Is the gas service line connected following the directions of the manufacturer?

7.

Have all the proper valves, stoppers and gasket been installed between the

range and the service line?

8. Has the gas connection been checked for leaks?

9.

Has the range been set for the type of gas available in the household?

10. Does the flame appear sharp blue, with no yellow tipping,

shooting or flame lifting?

11. Has the minimum setting for all burners been adjusted?

12. Have you recorded the model # and serial # of your unit incase of need

for service? (Located on box label or back of the unit)

WARNING

!

USING THE OVEN FOR THE FIRST TIME

We recommend that before you cook in your new cooker you heat the oven to 380°F for

2hrs to run in BAKE mode. This is to burn off the residue from production. Please make

sure to open all windows and doors in the kitchen during this time to allow for proper

ventilation. After the oven cools wipe it out with hot water and a mild detergent. We also

recommend cleaning the racks and shelves before use.

When using the cooker for the first time you may notice the following......

There may be a smell. This is quite normal when the cooker is first heated as residual

oil from production of parts will be burnt off quickly.

There may be noises. This is also quite normal as new parts move and settle into place

during the initial heating process.

27

Page 29

USE GUIDE

This product is intended for the cooking of food and must not be used for other

purposes.

Unstable or deformed pans should not be placed on the burners or hot plates in

order to avoid accidents caused by spill over. Particular care should be taken

when cooking with oil or fat.

Always ensure that the knobs are in the "O", Off, or Stop position when the

appliance is not in use.

Before maintenance and cleaning, disconnect the appliance and allow cooling

down. For reasons of hygiene and safety this appliance must always be kept

clean.

Take care when using cleaning products in spray form. Never direct the spray

onto the electrical wiring, thermostat and bulb

When placing food in the oven, or when removing a large quantity of oil, juice,

etc., any spills onto the bottom of the oven must be cleaned before starting to

cook to avoid unpleasant smoke and also the possibility of these substances

catching fire.

Ensure that air can circulate around the gas appliance. Poor ventilation can

result in lack of oxygen and extinguish the flame.

The use of a gas cooking appliance produces heat and humidity in the room

where it is installed.

Ensure good ventilation of the room, keep adequate natural ventilation or

install an extractor hood with a discharge tube.

Supply the appliance with the type of gas stamped on the relevant label

situated in the immediate vicinity of the gas connection tube.

Ensure that the oven grids are inserted correctly. (See instruction as below.)

28

Page 30

USE GUIDE

NEVER cover any slots, holes or passages in the oven

bottom or cover an entire rack with materials such as aluminum

foil. Doing so blocks air flow through the oven and may cause

carbon monoxide poisoning. Aluminum foil linings may also trap

heat, causing a fire hazard.

NEVER use this appliance as a space heater to heat or warm

the room. Doing so may result in carbon monoxide poisoning

and overheating of the oven.

USING THE COOKTOP BURNERS

The knobs for the gas burners of the cooker are found on the

control panel. There are indication marks on each knob to

indicate the necessary knob positions for maximum (MAX) and

minimum (MIN) flame settings.

TO LIGHT A BURNER

1. Push and hold the knob corresponding to the burner and turn it

counter-clockwise to MAX.

2. Hold it for 3 to 5 seconds. The ignition will spark, gases will

flow, and the burner will ignite. The burner is at its maximum

size.

You can reduce the flame size by turning the knob counter

- clockwise to your desired setting.

If the burner fails to light, turn the knob to its OFF position and

repeat steps 1-2.

The burner flame should be blue.

NOTE : On first use, it will be required to hold onto

the knob at MAX position for 20-30 seconds to

allow the gases to completely fill the operating

system's inner piping.

29

Page 31

3. Check that the flame is regular.

If you suspect that the flame is irregular, ensure burner

caps are installed correctly (See instructions below.)

Burner cap

Burner cap lip

Correct burner cap placement

Incorrect burner cap placement

TIPS FOR USING PANS CORRECTLY

ATTENTION!

Always ensure that bottom and handles of pans do not protrude

from the worktop. When cooking with flammable fat such as oil, do

not leave the range unattended. Use pots of the appropriate size

on each burner following the indication of the diagram below.

Recommended pan size inches (mm)

Burner

Auxiliary

Semi Rapid

Rapid

3"- 5-1/2" (90 -140)

5 -1/2" -10- 1/4" (140 - 260)

7- 1/8" -10- 1/4" (180-260)

8 - 2/3"-10 - 1/4" (220 - 260)

Dual burner

30

Page 32

USE GUIDE

WHEN BOILING LIQUIDS:

Turn the knob to the MINIMUM position once boiling is

reached to avoid overflow. Always use pots with matching

lid. Dry the bottom of pans beforoperation. Use pots with

a flat, thick bottom (except for wok cooking).

WOK COOKING:

Always use the wok adapter supplied with the range. Wok

pan external diameter shall not be smaller than 10" (25cm)

and larger than 16" (40cm). SIMMERING: use the simmer

ring supplied with the range.

31

Page 33

USE GUIDE

USING THE GAS OVEN

Our oven functions allow the user to have flexibility in the

method of cooking and provide heating alternatives to

suit a wide variety of dishes.

HEATING

INDICATOR

TIMER

TEMPERATURE SETTING

LIGHT

To PRE-HEAT:

Set TIMER to ON. Set TEMPERATURE SETTING knob to desired preheat temperature. Heating Indicator Light will stay lit until oven has

reached set pre-heat temperature. Oven flame may turn on and off to

maintain set temperature until either knob is set to OFF.

BAKE

Heat comes from bottom heating elements. Suitable for cakes, muffins,

pizzas,and delicate egg dishes.

To use:

32

Turn the temperature setting knob to desired bake temperature. If bake

time is required, set the timer to desired baking duration. Oven will stop

heating once time expires. Otherwise, if TIMER is in ON position, oven

will heat until temperature setting knob is turned to OFF.

Page 34

USE GUIDE

CONVECTION BAKE

Heat comes from bottom elements combined with convection fan

air circulation for faster, more even, cooking. Suitable for dish

temperature from 0 to 500°F.

To use:

Turn the temperature setting knob to desired bake temperature.

Turn the Convection Fan switch on. If bake time is required, set

the timer to desired baking duration. Oven will stop heating once

time expires. Otherwise, if TIMER is in ON position, oven will

heat until temperature setting knob is turned to OFF. Once timer

reaches end time, the oven will stop heating.

BROIL

Heat comes from top grill elements which direct radiant heat

onto the food. Used for grilling or browning meats.

To use:

Turn the temperature setting knob to BROIL. If broil time is

required, set the timer to desired baking duration. Oven will stop

heating once time expires. Otherwise, if TIMER is in ON position,

oven will heat until temperature setting knob is turned to OFF.

CONVECTION BROIL

Heat comes from top grill elements which direct radiant heat onto

the food. Used for delicately grilling or browning meats, particularly

thinner meats.

To use:

Turn the temperature setting knob to BROIL. Turn the Convection

Fan switch on. If broil time is required, set the timer to desired

baking duration. Oven will stop heating once time expires.

Otherwise, if TIMER is in ON position, oven will heat until

temperature setting knob is turned to OFF.

33

Page 35

USE GUIDE

USING THE OVEN LIGHT

The light can be switced on/off using the switch on the left

side of the control panel.

COOKING TIMES

Cooking times can vary according to the type of food, its

density and its size.

34

Page 36

USE GUIDE

35

Page 37

CARE GUIDE

REPLACING THE OVEN LIGHT BULBS

WARNING!

Disconnect power before servicing unit.

To replace the oven light bulb, unscrew the protection glass

cover that projects out inside the oven.

NOTE: Touching the bulb with fingers may cause

burns to the skin. Always use protective glove or use

a cloth to remove the bulb.

CLEANING YOUR RANGE

ATTENTION!

During cleaning operation never move the appliance from its

foreseen original installation position.

ATTENTION!

Never use abrasive cleaners!

Scratches on the stainless steel surfaces are permanent.

Do not clean the range when it is hot!

Cleaning after installation: use a stainless steel cleaning

product or wipe to eliminate the residues of the

protection film after removal.

36

Page 38

CARE GUIDE

Cleaning the cooktop: periodically clean the burner heads, the

cast iron pan supports and the burner caps using warm water.

Remove burned food and fat residues with a rubber spatula .

If food residue prevent the smooth operation

knobs, call the customer service hotline to schedule service by a

factory-trained professional.

Cleaning stainless steel: for best results use a stainless steel

cleaner product with a soft sponge or wipe. Alternatively use a

soft sponge or cloth with a warm soap and water solution.

Never use abrasive powders or liquids!

Cleaning the burner caps: lift the burner caps from the burner

heads and wash them in a warm soap and water solution. Dry

thoroughly before using them again. Before reinstalling them

on the burner head, check that the gas flow holes are not

clogged with food residues or cleaning product residues.

Cleaning Enamel: enamelled parts should be cleaned

frequently with warm soap and water solution applied with

soft sponge or wipe. Never use abrasive powders or liquids!

of the

control

a

Do not leave acid or alkaline substances on the enamelled

parts (such as vinegar, lemon juice, salt, tomato sauce, etc.).

Use a rubber spatula to remove fat residues.

Cleaning glass door: clean the glass using a non- abrasive

sponge or wipe with a warm soap and warm water solution.

Use a rubber spatula to remove fat residues.

ATTENTION: while cleaning the door, avoid spillage of food

residues and cleaning products in the venting holes situated

on the top side of the door. To clean the inside of the oven

door, call a professional.

37

Page 39

TROUBLESHOOTING GUIDE

Baking Pr

Food br

Food too brown on bottom

Food is dry or has shrunk

excessively

Food is baking or roasting too

slowly

owns unevenly

oblem Cause

Oven no

•

Aluminum f

•

Baking utensil t

•

Pans t

•

Oven no

•

Using glass

•

Incorrect rack position

•

Pans t

•

Oven temper

•

Baking time t

•

Oven door opened fr

•

Pan si

•

Oven temper

•

Oven no

•

t preheated

oil on oven rack or oven bottom

ouching each other or oven walls

t preheated

, dull or darkened metal pans

ouching each other or oven walls

ature too high

oo long

ze too large

ature too low

t preheated

oo large for recipe

equently

Pie crusts do not brown on

bottom or crust is soggy

Cakes pale, at and may not be

done inside

Cak

es high in middle with crack

on top

Oven door opened fr

•

T

ightly sealed with aluminum foil

•

Pan si

•

Baking time no

•

Using shin

•

Inc

•

Oven temper

•

Oven temper

•

Inc

•

Cak

•

Oven door opened t

•

Pan si

•

Oven temper

•

Baking time t

•

Pans t

•

ze too small

t long enough

y steel pans

orrect rack position

ature is too low

ature too low

orrect baking time

e tested too soon

ze may be too large

ature too high

oo long

ouching each other or oven walls

equently

oo often

38

Pie crust edges too brown

Inc

•

•

•

•

orrect rack position

Pan si

Oven temper

E

ze too small

dges of crust too thin

ature too high

Page 40

TROUBLESHOOTING GUIDE

PROBLEM

Burner will

not ignite

Burner

will not

operate

Gases not

flowing.

Burner

Flames are

uneven,

yellow and/

or noisy

POSSIBLE CAUSE SOLUTION

There is no power to

the cooktop

First time use. Air

still in the gas line.

Control knob is not

set correctly.

The burner port is

clogged.

Improper

installation.

Burner port(s) are

clogged.

Burner caps are not

positioned properly.

Propane gas is being

used.

Plug into a grounded 3 prong outlet. Replace

fuse or reset circuit breaker.

Turn on any one of the surface burner knobs

to release air from the gas lines.

Push in knob before turning to a setting.

Clean burner port opening using a sti, nylon

toothbrush or a straightened paper clip.

Turn the manual gas shut-off valve on.

Installer should make sure regulator is

correctly oriented (arrow towards unit).

Clean burner port opening using a sti, nylon

toothbrush or a straightened paper clip.

Place burner caps so that the alignment pins

are properly aligned with the slots.

The range should be converted to LP gas by

a qualied technician.

Burner

ame is too

high or too

low

Burner

makes

popping

noises

Excessive

heat

around

cookware

on cooktop

Cooktop gas supply

is not correct.

The gas pressure is

not correct.

The burner is wet. Allow the burner to dry before using.

The burner cap and/

or gas spreader

is not positioned

correctly.

The cookware is not

the proper size for

the burner.

Ensure the range is set for the correct

gas type. It is factory set for natural gas. If

connected to LP gas the burners should be

converted to LP gas with the orice/injector

kit supplied and the pressure regulator

converted to the LP gas setting by a qualied

technician.

Make sure the pressure regulator is installed

correctly and the gas line pressure is correct.

See Installation Instructions.

Place burner caps so that the alignment pins

are properly aligned with the slots.

Use cookware with a bottom surface

approximately the same size as the cooking

area and burner. Cookware should not

extend more than 1” (2.5 cm) outside the

cooking area. Adjust the ame so that it

does not come up around the cookware.

39

Page 41

TROUBLESHOOTING GUIDE

OBLEM POSSIBLE CAUSE SOLUTION

PR

Oven is not

heating

Oven is not

ooking evenly

c

Broil does

not work.

ooling fan

C

continues to

run after oven

is turned o

Oven light is

not working

properly

Oven light

stays on

No power to the

oven

Oven control not

turned on

Not using the correct

bake ware or oven

rack position

Knob settings are not

in the correct

positions.

The electronic

components have

not yet cooled

suciently

Light bulb loose or

burned-out.

Door is not closing

completely

Reset the circuit breaker or replace the

fuse in the electrical box to your oven.

Make sure the oven temperature has

been selected and timer is not "OFF".

Refer to cook charts for recommended

rack position. Always reduce recipe

temperature by 25 °F (15 °C) when

baking with Convention Bake mode.

Make sure oven temperature

selection knob is set to " BROIL" and

timer is not set to "OFF"

The fan will turn o automatically

when the electronic components have

cooled suciently.

Reinsert or replace the light bulb.

Touching the bulb with ngers may

cause the bulb to burn out.

Check for obstruction in oven door.

Check to see if hinge is bent or door

switch broken.

Cannot remove

lens cover

Heat blowing out

from the front

of oven.

essive

Exc

Moisture

Porcelain Chips

Soil build-up around

the lens cover.

Oven cavity

ventilation on

Porcelain interior

is bumped by oven

racks

Wipe lens cover area with a clean, dry

towel prior to attempting to remove

the lens cover.

The oven cavity ventilation is

operating until the oven is sufficiently

cooled. This is normal.

When using bake mode, preheat

the oven rst. Convection Bake and

Convection Roast will eliminate any

moisture in the oven.

When removing and replacing oven

racks, always tilt racks upward and do

not force them to avoid chipping the

porcelain.

FOR MORE HELP, VISIT OR CALL THE CUSTOMER

SUPPORT LINE AT 1-888-784-3108.

40

Page 42

WARR

ANTY AND SERVICE

TO RECEIVE W

BE REGISTERED. TO REGISTER, VISIT:

WWW.COSMOAPPLIANCES.COM/WARRANTY

FOR FULL WARRANTY DETAILS ON THIS PRODUCT PLEASE VISIT :

WWW.COSMOAPPLIANCES.COM/WARRANTY

ARRANTY SERVICE, YOUR PRODUCT MUST

WWW.COSMOAPPLIANCES.COM

Page 43

Page 44

Loading...

Loading...