Page 1

,

COOKTOP

COS-DIC304

COS-DIC366

Cosmo is constantly making efforts to improve the quality and

performance of our products, so we may make changes to our

appliances without updating this manual. Visit

www.cosmoappliances.com to download the latest version of this manual.

To prevent harm to any person or damage to the

product, you must read all instructions supplied

before installing or using the appliance.

Page 2

IMPORTANT SAFETY INSTRUCTIONS

If the information in this manual is not followed exactly, a fire

or explosion may result causing property damage, personal

injury or death.

Do not store or use gasoline or other flammable vapors and

liquid in the vicinity of this or any other appliance.

WHAT TO DO IF YOU SMELL GAS

- Do not try to light any appliance.

- Do not touch any electrical switch.

- Do not use any phone in your building.

- Immediately call your gas supplier from a neighbor’s phone.

Follow the gas supplier’s instructions.

- If you cannot reach your gas suppliers, call the fire department.

Installation and service must be performed by a qualified

installer, service agency or the gas supplier.

!

WARNING

IMPORTANT:

SAVE FOR LOCAL ELECTRICAL INSPECTOR’S USE.

READ AND SAVE THESE INSTRUCTIONS FOR FUTURE

REFERENCE. OBSERVE ALL GOVERNING CODES AND

ORDINANCES.

The manufacturer will not be responsible for any damage to

property or to persons caused by incorrect installation or improper

use of the appliance.

The manufacturer reserves the right to make changes to its

products when considered necessary and useful, without affecting

the essential safety and operating characteristics.

This appliance has been designed for non-professional, domestic

use only.

2

Page 3

TABLE OF CONTENTS

3

IMPORTANT SAFETY INSTRUCTIONS

INSTALLATION GUIDE

USE GUIDE

CARE GUIDE

REFERENCE FIGURES

WARRANTY

—————— 2

—————— 3

—————— 12

—————— 15

—————— 17

——————20

Page 4

INSTALLATION GUIDE

4

This appliance shall only be installed by an authorized person.

This appliance shall be installed in accordance with the manufacturers

installation instructions,

IMPORTANT: this appliance must be installed in accordance with the

norms in force of the country concerned.

The installation of this appliance must conform to local codes and

ordinances. In the absence of local codes, Installations must conforms

to American National Standards, National Fuel Gas Code

ANSI Z223.1 – latest edition** or B149.1.

If local codes permit, a flexible metal appliance connection with the

new AGA or CGA certified design, max. 5 feet (1,5 m) long, 1⁄2” I.D.

recommended for connecting this cooktop to the gas supply line.

Do not bend or damage the flexible connector when moving the

cooktop. The pressure regulator has 1⁄2” female pipe thread.

You will need to determine the fitting required, depending on the

size of your gas supply line, the flexible metal connector and the

shutoff valve.

The appliance, when installed, must be electrically grounded in

accordance with local codes or, in the absence of local codes,

with the National Electrical Code, ANSI/NFPA 70.

The appliance and its individual shutoff valve must be disconnected

from the gas supply piping system any pressure testing of that system

at test pressure in excess of 1⁄2 psi (3,5 kPa).

The appliance must be isolated from the gas supply piping system by

closing its individual manual shutoff valve during any pressure testing

of the gas supply piping system at test pressures equal to or less than

1⁄2 psi (3.5 kPa).

For use with a pressure regulator. The regulator supplied must be

used with this appliance.

The gas appliance pressure regulator must be set for the gas with

which the appliance is used.

Page 5

5

INSTALLATION GUIDE

This appliance can be used with Natural Gas and LP Gas. It is shipped

from the factory adjusted for use with Natural Gas. Propane conversion

kits can be purchased separately.

The maximum inlet gas supply pressure incoming to the gas appliance

pressure regulator is 20’’ water column (5 kPa)

The minimum gas supply pressure for checking the regulator setting

shall be at least 1“ w.c. (249 Pa) above the inlet specified manifold

pressure to the appliance (this operating pressure is

4” w.c. (1.00 kPa) for Natural Gas and 10” w.c. (2.75 kPa) for LP Gas).

ATTENTION

A manual valve shall be installed in an accessible location in the gas

line external to the appliance for the purpose of turning on or shutting

off gas to the appliance

WARNING: Do not use aerosol sprays in the vicinity of this appliance

while it is in operation

INSERTING THE COOKTOP

After having removed the various loose parts from the internal and

external packing, make sure that the cooktop is not damaged and is

suitable for the specific gas usage. The gas type label is on the

underside of the cooktop base.

In case of doubt, do not use the appliance and contact skilled

personnel.

Keep all the packaging parts (polystyrene foam, cardboard, staples,

etc.) away from children.

Consider the critical dimensions of the appliance, before making an

opening in the top surface of the countertop. (relative measurements

as per Fig 1- 2).

Page 6

INSTALLATION GUIDE

6

ATTACHING THE COOKTOP

To prevent liquids from leaking accidentally into the underlying

storage space, the appliance is equipped with a special gasket.

To apply this gasket, carefully follow the instructions in Fig. 3. Lay out

the protective sealing strips along the edges of the opening in the

countertop and carefully overlap the strip end. (See Fig. 3). Insert the

cooktop into the countertop opening. With a screwdriver assemble

the brackets A to the cooktop bottom by means of the screws B.

(See Fig. 4). Slide the hooks into position and secure them with the

screws.Trim the part of the sealing strips which extend beyond the

hotplate base

GAS CONNECTION

Before connecting the appliance to the gas supply, first remove the

plastic plug on which is press- fitted into the gas inlet union; to

remove, just pull it off.

1. Check the ‘gas type’ sticker attached to the cooktop. Details of the

injector sizes used are recorded on the data plate located on the

base of the appliance.

2. This appliance shall be installed in accordance with installation

requirements of the local gas authority of the appropriate

installation code.

3. Before installing the cooktop consider the location of the gas

supply and routing the gas line.(Refer fig.6)

4. For LPG models: the gas supply is connected to the regulator

which is supplied loose. The inlet connection has a 1/2” B.S.P.

male thread. IT IS ESSENTIAL THAT THE ELBOW ON THE

APPLIANCE BE HELD FIRMLY WITH A SPANNER WHEN

CONNECTING THE SUPPLY. DO NOT OVER TIGHTEN.

The regulated pressure For LPG is 10” w.c. (See Fig. 5).

Page 7

INSTALLATION GUIDE

7

5. For NG models the gas supply is connected to the regulator

which is supplied loose. The inlet connection has a 1/2” B.S.P.

male thread. IT IS ESSENTIAL THAT THE ELBOW ON THE

APPLIANCE BE HELD FIRMLY WITH A SPANNER WHEN

CONNECTING THE SUPPLY. DO NOT OVER TIGHTEN. The

regulated pressure for NG is 4” W.C.

(See Fig. 5).

6. For gas inlet position of appliance refer Fig 5, 6 and 7. After

installing the gas supply and making all connections, check

thoroughly for possible leaks. Turn all control knobs on the unit

to ‘OFF’ position. Open the valve on the gas supply. Using a soap

and water solution check each gas connection one at a time, by

brushing the solution over the connection. Presence of bubbles will

indicate a leak. Tighten the fitting and re- check for leaks. If it is not

possible to correct the leak, replace fitting. Under no

circumstances should matches or flames be used for checking

leaks. It is essential that the gasket and the pressure test point

stopper are properly installed to avoid gas leakage

7. To checking inlet pressure at the appliance, perform the following:

a) Disconnect electric power before checking pressure.

b) Take off one of the gas burner cap and the relative flame

spreader in order to gain access to the burner injector.

c) Put the pressure detector directly on the burner injector.

Afterwards, open the relative burner knob at maximum position

keeping it pressed, then measure the outlet pressure from the

burner injector.

d) Once the pressure checking has been carried out, replace the

burner cap and flame spreader in the correct and original

position and re-connect electric power to the appliance.

8. Turn on appliance control and light each burner. Check for a

clear blue flame without yellow tipping. If burners show any

abnormalities, check that they are situated properly and in line with

the injector nipple.

Page 8

INSTALLATION GUIDE

8

9. Sometimes the burners will not ignite immediately and seem

to ‘blow’ slightly when they do ignite. This is usually due to air in

the gas lines, which will clear itself within minutes of use.

10. If after following the instructions given, satisfactory

performance cannot be obtained, contact your local gas authority

for advice and assistance.

ELECTRICAL CONNECTION

The connection of the hobs to mains is effected via the flex and the

three pin plug located underneath the hotplate. The appliance

operates at a main voltage of 120V a.c., frequency: 60Hz. Electric

power absorption is about 1W for 5 gas burners version or 2W for 6

gas burners version.

WARNING: Electrical Grounding Instructions: This appliance is

equipped with a (three-prong) grounding plug for your protection

against shock hazard and should be plugged directly into a properly

grounded receptable. Do not cut or remove the grounding prong

from this plug.

WIRING DIAGRAMS (see Fig. 12.)

Wiring diagram description:

1. Cable terminal 2. Ignition switch 3. Spark generator

4. Ignition spark L. Black N. White T. Green (earth)

Page 9

INSTALLATION GUIDE

9

GAS CONVERSION

Before carrying out any maintenance work, disconnect

the appliance from the gas and electric supply.

Changing the burner nozzles

Lift up the burners and unscrew the nozzles ( Fig. 8)

using an adjustable wrench of 7 mm and change the

nozzles with those designed for the new gas supply

according to the information given in TABLE A shown

below.

TABLE A

CAUTION: Save the orifices removed from the appliance for future use

Page 10

INSTALLATION GUIDE

10

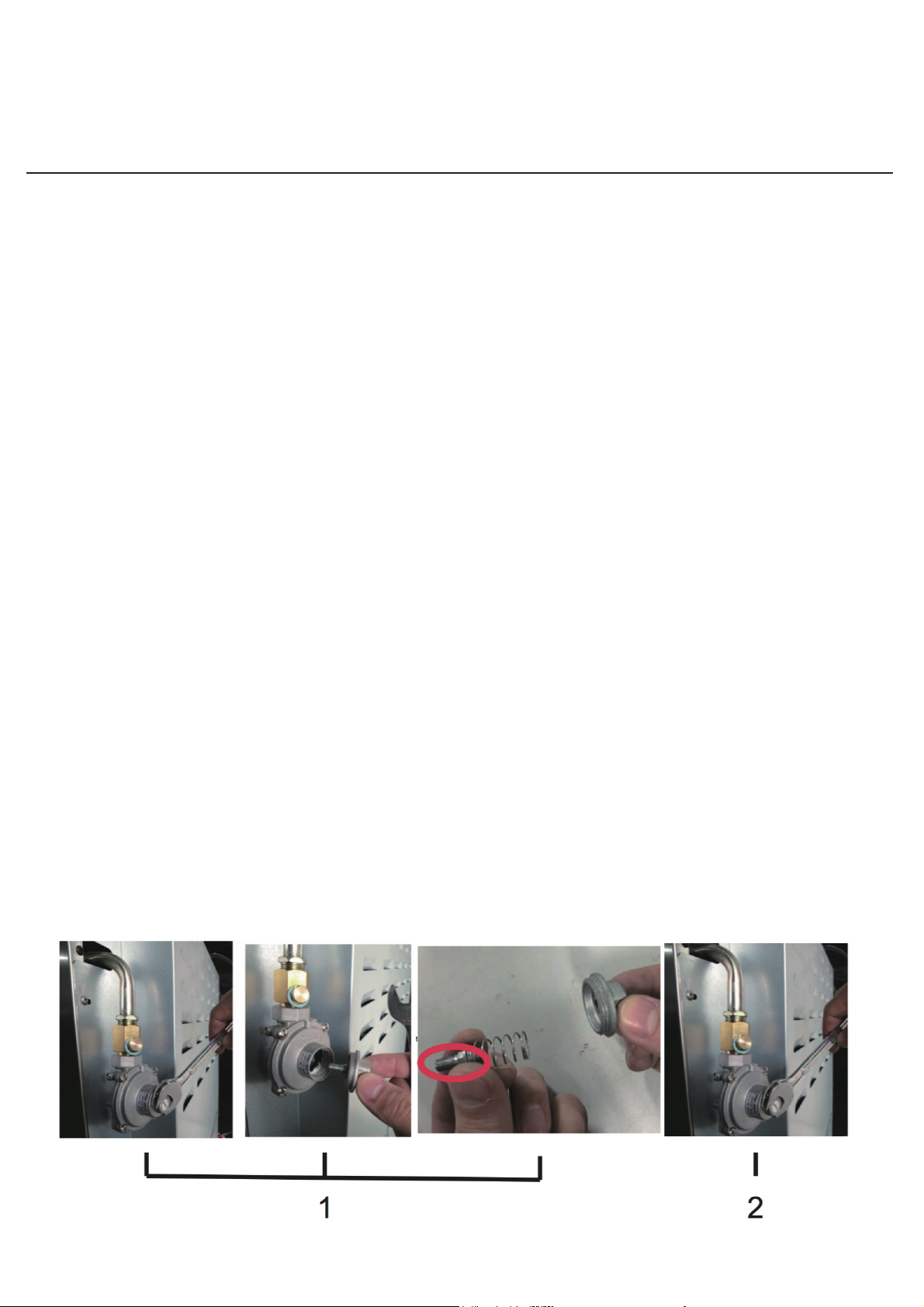

PRESSURE REGULATOR ADJUSTMENT FOR GAS CONVERSION:

The pressure regulator supplied with the appliance is a convertible

type pressure regulator for use with Natural Gas at a nominal outlet

pressure of 4” W.C. or LP gas at a nominal outlet pressure of 10” W.C.

and it is pre-arranged from the factory to operate with one of these

gas/pressure as indicated in the pre-arranging labels affixed on the

appliance, package and Instruction booklet.

Your cooktop is shipped from the factory set for use with natural gas.

It can be converted for use with propane gas by following steps

below. Note: The agency performing this work assumes responsiblity

for the conversion.

1)

Unscrew by hand the upper metal stopper of the regulator (Fig. 5)

2)

Unscrew by hand the white plastic piece screwed under the above

mentioned metal stopper. Afterward, screw in this part again in

opposite way under the metal stopper (for gas reference see the

written “LP” and “NAT” with relative indicating arrows on the white

piece).

3))

Screw again by hand the metal stopper in the original position on

the regulator.

Page 11

INSTALLATION GUIDE

11

REGULATION OF BURNER FLAME INTENSITY

To regulate the minimum flame on the burners, carry out the

following procedure indicated below:

1) Turn on the burner and put the knob onto position MINIMUM

( small flame ).

2) Remove the knob ( Fig. 9) of the tap which is set for standard

pressure. The knob is found on the shaft of the valve itself.

3) Beside the valve shaft, use a small screwdriver that fits the

gold colored screw found on the lower part of the tap (auxiliary,

semirapid, rapid Fig. 9) (dual fig.10) and turn the adjustment

clock-wise or counter clock-wise until the minimum flame

reaches a desired intensity level.

4) Make sure that that the flame does not go out when changing

the position quickly from MAXIMUM to the MINIMUM position. If

it does, the minimum flame intensity needs to be increased.

Page 12

USE GUIDE

12

WARNING:

Keep appliance area clear and free from combustible

materials, gasoline and other flammable vapors and liquid.

• Do not store dangerous or flammable material in the cabinet areas

above appliance; store them in a safe place in order to avoid

potential hazards.

• For safe use of appliance, do not use it for space heating.

• Do not use aerosol sprays in the vicinity of this appliance while it is

in operation For description of hotplates refer to installation

instructions.

• This product is intended for the cooking of food and must not be

used for other purposes.

• Unstable or deformed pans should not be placed on the burners

or hot plates in order to avoid accidents caused by spill over.

• Addeds care should be taken when cooking with oil or fat.

• Always ensure that the knobs are in the "O" Off or Stop position

when the appliance is not in use.

• Before maintenance and cleaning, disconnect the appliance and

allow cooling down.

• For reasons of hygiene and safety, this appliance must be

regularly cleaned and maintained.

• Ensure that air can circulate around the gas appliance. Poor

ventilation can result in lack of oxygen and extinguish the flame.

• The use of a gas cooking appliance produces heat and humidity

in the room where it is installed.

Page 13

USE GUIDE

13

• Ensure good ventilation of the room. Keep adequate natural

ventilation or install an extractor hood with a discharge tube.

In case of doubt, ask a professional installer for advice.

• Supply the appliance with the type of gas stamped on the

relevant label situated in the immediate vicinity of the gas

connection tube.

• To facilitate ignition, light the burners before placing pans on

the grid. Check that the flame is regular. Always lower the

flame or turn it off before removing the pan.

• Ensure burner caps are installed correctly (See instruction as

below.)

BURNER CONTROLS

To light each burner, push the knob and turn it counter-clockwise to

maximum setting, and hold it for 3 to 5 seconds. The igniter will

spark and ignite the flame. At this position the gas supply is at the

maximum and the flame also at its maximum.

You can reduce the flame size by turning the knob in counterclockwise to your desired flame height. Should the burner fail to

light up, turn the knob to its original position and try again.

.

NOTE : When first used, the gas burner will not ignite immediately.

Hold the knob pressed down for an extended time for the gases to

fully fill the operating system.

Page 14

Burner Recommended pan size inches (mm)

Auxiliary 3%"-51/2"(90 -140)

Semi Rapid 51/2"-101/4"(140 - 260)

Rapid 71/8"-101/4" (180-260)

Dual burner 82/3"-101/4" (220 - 260)

DO NOT USE AN OPEN FLAME WHEN CHECKING FOR LEAKS!

!

WARNING

USE GUIDE

14

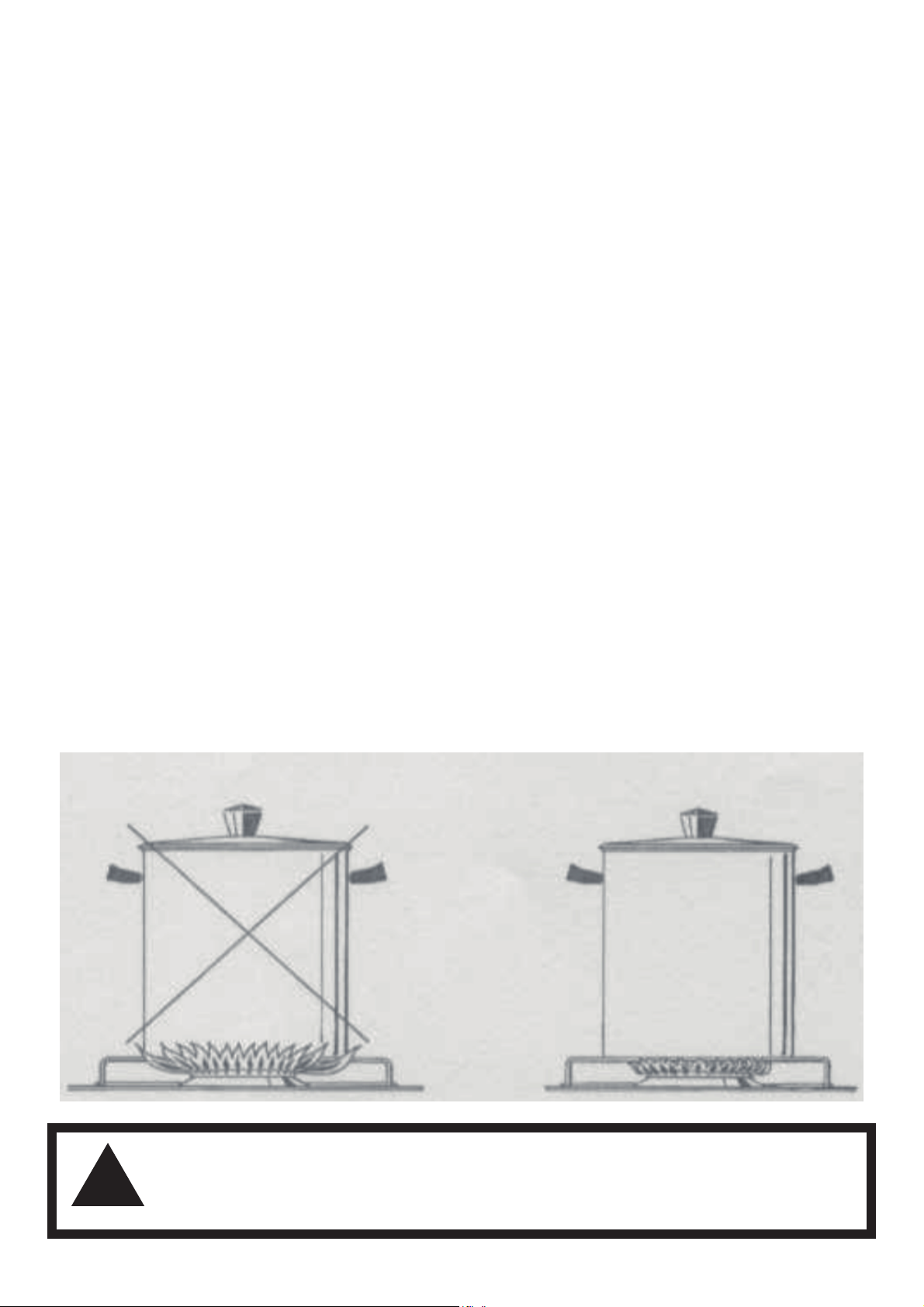

TIPS FOR USING PANS CORRECTLY

Always ensure that bottom and handles of pans do not protrude

from the worktop. When cooking with flammable fat such as oil, do

not leave the range unattended.Use pots of the appropriate size on

each burner following the indication of the diagram below.

When boiling liquids, turn the knob to the MINIMUM position once

boiling is reached to avoid overflow. Always use pots with matching

lid. Dry the bottom of pans before operation. Use pots with a flat,

thick bottom (except for wok cooking).

WOK COOKING: Always use the wok adapter supplied with the

range. Wok pan external diameter shall not be smaller than

10" (25cm) and larger than 16" (40cm).

Page 15

CARE GUIDE

15

Cleaning the worktop: Periodically clean the burner heads, the cast

iron pan supports and the burner caps using warm water. Remove

burned food and fat residues with a rubber spatula . If food residue

prevent the smooth operation of the control knobs,

call the customer service hotline to schedule service by a

factory-trained professional.

Cleaning stainless steel: For best results use a stainless steel cleaner

product with a soft sponge or wipe. Alternatively use a soft sponge or

cloth with a warm soap and water solution. Never use abrasive

powders or liquids!

Cleaning the burner caps: Lift the burner caps from the burner heads

and wash them in a warm soap and water solution. Dry thoroughly

before using them again. Before reinstalling them on the burner

head, check that the gas flow holes are not clogged with food

residues or cleaning product residues.

ATTENTION: For further details about cleaning of the appliance,

please contact your appliance retailer.

SERVICE & MAINTENANCE INSTRUCTIONS

Service and maintenance only to be carried out by an authorized

person

To replace parts such as burners, valves and electric components,

the cooktop must be removed from the countertop by releasing the

attachment hooks, loosening the attachment screws of each burner,

unscrewing the cooktop attachment nuts which are visible at the

bottom of the surface, removing the cooktop stainless steel top, and

finally replacing the defective parts.

Page 16

CARE GUIDE

Note: If the valves must be replaced, first disassemble the ignition

1. Disassemble the valve body by loosening the two screws located

on the body of the valve. (See Fig. 13).

2. Extract and clean the seal cone and its housing with a rag soaked

with thinners.

3. Lightly grease the cone with a special grease.

4. Insert the cone, moving it several times, remove it again, remove

the excess grease and make sure that the gas passage ways

are unobstructed.

5. Replace all the pieces in reverse order and check that the valve o

perates correctly.

16

switches wires.

It is recommended to replace the valve gaskets each time the valve

is replaced, thus ensuring a perfect seal between the body and the

gas manifold.

WARNING: Disconnect power before servicing unit.

For the location of the wall receptacle for the three-prong grounded

plug of the appliance, see Fig. 1- 2.

WARNING: After first installation of the appliance or after any service

intervention concerning main gas parts of the appliance, perform

leak test using water with soap on the gas connections in order to

verify proper installation. Do not use fire for gas leak testing.

GREASING THE VALVES

If it becomes difficult to operate the valve, it should be greased

immediately by following the steps below:

Page 17

Fig. 1

Table n. 1

17

Page 18

Fig. 2

Fig. 3

Fig. 4

Fig. 5 Fig. 6

Fig. 7 Fig. 8 Fig. 9

18

30" MODEL : W = 30" , D= 21"

36" MODEL : W= 36", D = 21"

A = 1.29"

B = 1.73"

A = 3.7"

B = 1.72"

E = 6.25"

F = 1.76"

Page 19

Fig. 10 Fig. 11

Fig. 12 Fig. 13

Fig. 14

Fig. 15

19

Page 20

WARRANTY AND SERVICE

20

For full warranty details or registering warranty

on this product, please visit:

www.cosmoappliances.com/warranty

Loading...

Loading...