Page 1

I N S P I R I N G T H E W O R L D ’ S K I T C H E N

UNDER CABINET RANGE HOOD

COS-18U48

INSTALL & USER GUIDE

IMPORTANT SAFETY INSTRUCTIONS

Carefully read the following Important information redarding installation

safety and maintenance. Keep these instruction for future reference.

COS-18U48 INSTALL & USER GUIDE

Page 2

THANK YOU FOR YOUR PURCHASE

Thank you for your purchase. We know that you have many brands and

products to choose from and we are honored to know that you have decided

TABLE OF CONTENTS

to take one of our products into your home and hope that you enjoy it.

COSMO appliances are designed according to the strictest safety and performance

standard for the North American market. We follow the most advanced

manufacturing philosophy. Each appliance leaves the factory after thorough

quality inspection and testing. Our distributors and our service partners are

ready to answer any questions you may have regarding how to install, use and

care for your products. We hope that this manual will help you learn to use the

product in the safest and most effective manner .

If you have any questions or concerns, please contact the dealer from whom you

purchased it, or contact our Customer Support at:

1-888-784-3108.

SAFETY INSTRUCTIONS 4

STAINLESS STEEL BAFFLE FILTERS 5

DIMENSIONS DIAGRAM 6

PARTS DIAGRAM 7

INSTALLATION REQUIREMENTS 8

PRE-INSTALLATION REQUIREMENTS 9

INSTALLATION INSTRUCTIONS 10-15

OPERATION INSTRUCTIONS 16

MAINTENANCE 17-18

TROUBLESHOOTING 19

WARRANTY & SERVICE 20-21

2 3

Page 3

IMPORTANT SAFETY INSTRUCTIONS

STAINLESS STEEL BAFFLE FILTERS

Read all instructions before using this appliance. Save

these instructions for future references.

Approved for residential appliances. For residential use only.

Due to the weight and size of these vent hoods and to reduce the risk of personal injury or damage to the product

TWO PEOPLE ARE REQUIRED FOR PROPER INSTALLATION

CAUTION

FOR GENERAL VENTILATING USE ONLY. DO NOT USE TO

EXHAUST HAZARDOUS OR EXPLOSIVE MATERIALS OR

VAPORS.

CAUTION

To reduce risk of fire and to properly exhaust air, do

not vent exhaust air into spaces within walls,

ceilings, attics, crawl spaces, or garages.

WARNING

TO REDUCE THE RISK OF FIRE, USE ONLY METAL

DUCT WORK. Install this hood in accordance with all

requirements specified

WARNING

GROUNDING INSTRUCTIONS

This appliance must be grounded. In the event of an elec-trical

short circuit, grounding reduces the risk of electric shock

by providing an escape wire for the electric current. This

appliance is equipped with a cord having a grounding wire with a

grounding plug. The plug must be plugged into an outlet that is

properly installed and grounded.

WARNING - IMPROPER GROUNDING CAN

RESULT IN A RISK OF ELECTRIC SHOCK.

Consult a qualified electrician if the grounding instructions are

not completely understood, or if doubt exists as to whether the

appliance is properly grounded.

Do not use an extension cord. If the power supply cord is too

short, have a qualified electrician install an outlet near the

appliance.

WARNING

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK,

OR INJURY TO PERSONS, OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intended by the manufactur

er. If you have questio

2. Before servicing or cleaning the unit, switch power off

at service panel and lock service panel disconnecting means

to prevent power from being switched

the service disconnecting means cannot be locked, securely

fasten a prominent warning device, such as a tag, to the

service panel.

3. Installation Work and Electrical Wiring Must Be Done

By Quali ed Person(s) In Accordance With all Aplicable

Codes & Standards, Including Fire-ra

4. Suf cient air is needed for proper combustion an

exhausting of gases through the flue

burning equipment to prevent back- drafting. Follolow the

heating equipment manufacturers guideline and safety

standards such as those published by the National Fire

Protec

tion Ass

Heating, Refrigeration and Air Conditioning Engineers

(ASHRAE), and the local code authorities.

5. When cutting or drilling into wall or ceiling, do not

damage electrical wiring and other hidden utilities.

Ducted systems must always be vented to the outdoors.

6.

ociation

FPA), the American Socie

(N

ns, contac

t the manufacture

on acci-dentally. When

(Chimney) of fuel

ted Construction.

d

ty for

r.

TO REDUCE THE RISK OF INJURY TO PERSONS, IN THE

EVENT OF A RANGE TOP GREASE FIRE, OBSERVE THE

FOLLOWING:

• SMOTHER FLAMES with a close-fitting lid, cookie sheet,

or metal tray, then turn off the burner. BE CAREFUL TO

PREVENT BURNS. If the flames do not go out immediate-ly,

EVACUATE AND CALL THE FIRE DEPARTMENT.

• NEVER PICK UP A FLAMING PAN – You may be burned.

• DO NOT USE WATER, including wet dishcloths or towels –

a violent steam ex-plosion will result.

• Use an extinguisher ONLY if:

1. You know you have a Class ABC extinguisher, and you

already know how to operate it.

2. The fire is small and contained in the area where it started.

3. The fire department is being called.

4. You can fight the fire with your back to an exi

Always leave safety grills and lters in place.Without these

components, operating blowers could catch onto hair, ngers and

loose clothing.

The manufacturer declines all responsibility in the event

of failure to observe the instructions given here for

installation,maintenance and suitable use of the product. The

manufacturer further declines all responsability for injury due to

negligence and the warranty of the unit automatically expires due

to improper maintenance.

WARNING

WARNING

To Reduce The Risk Of Fire Or Electric Shock, Do Not Use

This Hood With Any External Solid State Speed Control

Device.

WARNING

Unplug or disconnect the appliance from the power

supply before servicing.

WARNING – TO REDUCE THE RISK OF A RANGE TOP

GREASE FIRE:

A. Never leave surface units unattended at high settings.

Boilovers cause sm

Heat oils slowly on low or medium settings.

B. Always turn hood ON when cooking at high heat or when

flaming food (i.e. Crepes Suzette, Cherries Jubilee Peppercorn

Beef Flambe).

C. Clean ventilating fans frequently. Grease should not be

allowed to accumulate on fan or filte .

D. Use proper pan size. Always use cookware appropriate for

the size of the surface element.

oking and greasy spillovers that may ignite.

About Your New Filters

Stainless Steel Baffle Filters do not need linings or mesh inside of

the filters and are completely constructed out of stainless steel. The

stainless steel construction allows them to be used again and

again after being cleaned or going through the dishwasher.

How do Permanent Filters work?

They function by forcing the grease filled air to quickly and

continuously change direction as it passes through the filter.

The grease is unable to change direction as fast as the air

carrying them, they end up getting caught on the metal

blades and then trapped into the filter tray.

These filters are both efficient and require less maintenance.

Additional Filters can be purchased from:

www.cosmoappliances.com

4 5

Page 4

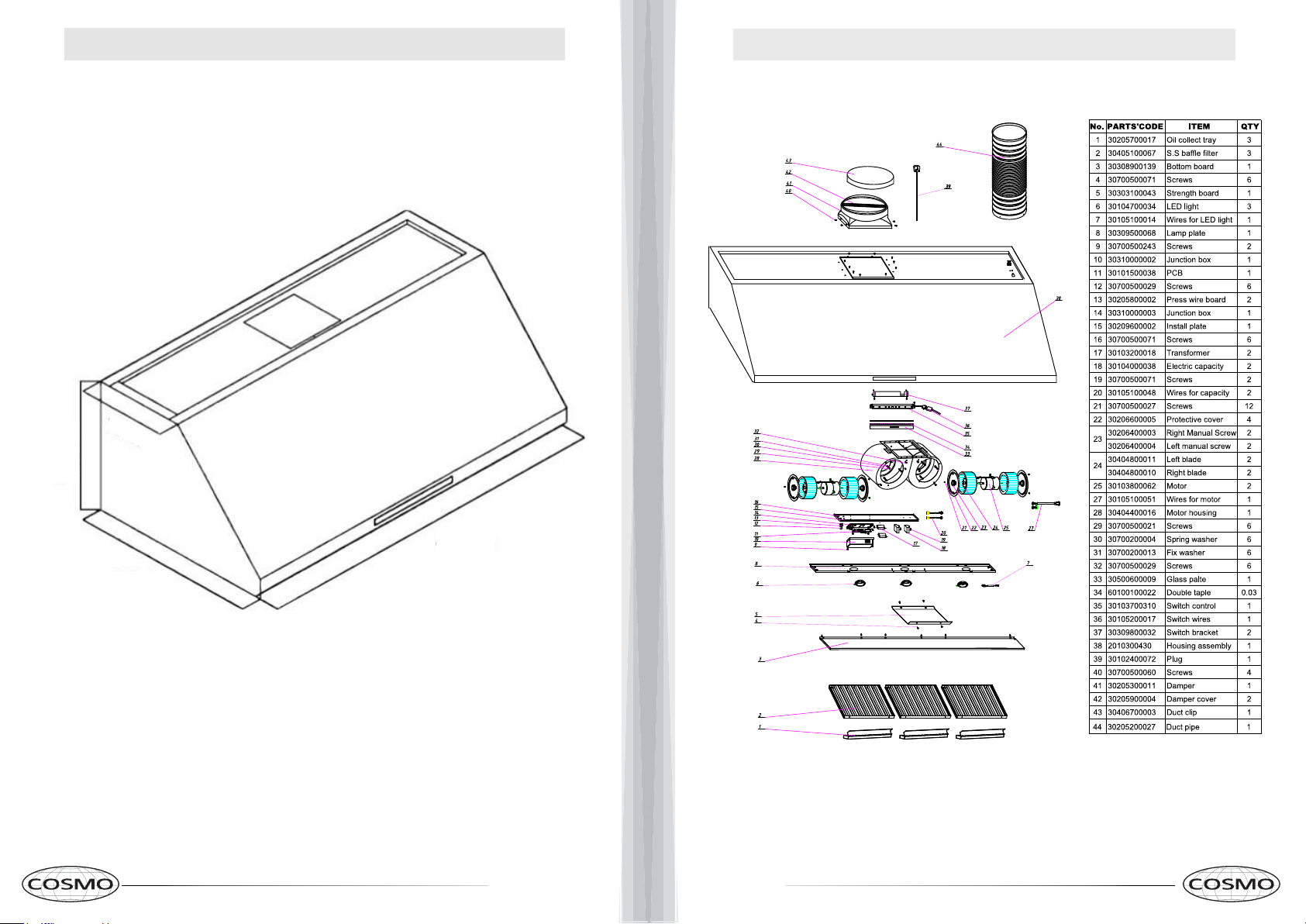

12 in.

17.9 in.

DIMENSIONS DIAGRAM

PARTS DIAGRAM

25 in.

COS-18U48

47.9 in.

6 7

Page 5

INSTALLATION REQUIREMENTS

PRE-INSTALLATION INSTRUCTIONS

Sufficient air is needed for proper combustion and exhausting of gases

through the chimney of fuel burning equipment to prevent backdrafting.

Follow the cooking equipment manufacturers guideline and safety

standards such as those published by the National Fire Protection

Association (NFPA), the American Society for Heating, Refrigeration

and Air Conditioning Engineers (ASHRAE), and local code.

When cutting or drilling into wall or ceiling, do not damage electrical

wiring and other hidden utilities. Ducted systems must always be

vented outdoors.

BEFORE YOU BEGIN

Read these instructions completely and carefully.

●

IMPORTANT – Save these instructions for local inspector’s usage.

●

Note to installer – Be sure to leave these instructions with the Consumer.

●

Note to Consumer – Keep these instructions for future reference.

●

Skill Level – Installation of this vent hood requires basic mechanical and

electrical skills.

Proper installation is the responsibility of the installer.

●

CAUTION:

Due to the weight and size of these vent hoods and to reduce the

risk of personal injury or dam-age to the product, TWO PEOPLE

ARE REQUIRED FOR PROPER INSTALLATION.

WARNING

To reduce the risk of the fire or electrical shock, do not use this range

hood with any external solid-state speed control device. Any such

alteration from original factory wiring could result in damage to the unit

and/or create an electrical safety hazard. TO REDUCE THE RISK OF

THE FIRE, USE ONLY METAL DUCTWORK. These vent hoods are

designed to be installed onto a wall or beneath a cabinet.

:

Please read the instructions carefully. Unpack the Range Hood and check that all

•

functions are working before installing.

Ensure that the voltage (V) and the frequency (Hz) indicated on the sticker match

•

the voltage and frequency at the installation site.

Check that the area behind the installation surface to be drilled is clear of any

•

electrical cables or pipes, etc.

The stainless steel surfaces of the Range Hood are very easily damaged during

•

installation if scratched or bumped by tools. Please take care to protect the

surfaces during installation.

Protect the cooktop surface below with cardboard, or the like, to prevent

•

damage occurring during installation.

The manufacturer shall not be held liable for consumer’s failure to observe and

•

follow all pre-installation procedures and safety regulations.

The vertical distance from the cooking surface to the bottom of the range hood

•

should be at least 24 in. to 36 in. for best performance.

Determine if your installation will be top venting or back venting, and ensure

•

that the openings in the cabinet or wall are in the appropriate locations and

appropriate size.

If this is a new installation, choose the venting method that suits your needs. Cut

•

out openings for the damper and for power access in the cabinet bottom or

exterior wall, depending on the installation method chosen.

DUCTWORK PLANNING

These vent hoods are equipped for 8" round ductwork. This hood may be vented

•

vertically through upper cabinet or ceiling. A duct transition piece is supplied for

vertical exhaust. You may use elbows (sold separately) to vent horizontally

through the rear wall.

Determine the exact location of the vent hood.

•

Plan the route for venting exhaust to the outdoors.

•

Use the shortest and straightest duct route possible. For satisfactory

•

performance,duct run should not exceed 12.5 feet. equivalent length for any duct

configurations.

Use metal ductwork only.

•

WALL FRAMING FOR ADEQUATE SUPPORT

These vent hoods are heavy. Adequate structural support must be provided.

Actual length of straight duct plus duct fitting must equivalent. Equivalent

*

lengths of duct pieces are based on actual tests conducted by Evaluation

Engineering and reflect requirements for good venting performance with any

ventilation hood.

IMPORTANT:

Plug the Unit in and Test all Functions Before Installing.

8 9

Page 6

INSTALLATION INSTRUCTIONS INSTALLATION INSTRUCTIONS

24” (610 mm) Min / 36” (914 mm) Max

CAUTION: HOOD MAY HAVE VERY SHARP EDGES; PLEASE WEAR

PROTECTIVE GLOVES WHENEVER IT IS NECESSARY TO REMOVE ANY

PARTS FOR INSTALLING, CLEANING OR SERVICING.

IMPORTANT:

•

System must vent to the outside (roof or side wall).

• DO NOT vent system into an attic or other enclosed

area.

• DO NOT use laundry-type wall caps.

• Use metal/aluminum vent only. A rigid metal/aluminum vent is recommended.

DO NOT use a plastic vent.

•

• Always keep the duct clean to ensure proper airflow.

• Calculate the following figures before installation:

1. Distance from the floor to the ceiling

2. Distance between the floor and the countertop/

stove

3. A distance of 24” to 36” is recommended

between stove top and the bottom of range hood.

30” minimum is required for gas stove tops.

4. Height of hood and duct cover.

Height and Clearance

For the most efficient and quiet operation:

• It is recommended that the range hood be vented

vertically through the roof through at least 10” round metal/

aluminum vent work.

• Use no more than three 90° elbows.

•

Make sure there is a minimum of 24” of straight vent between the elbows if more than one elbow is used.

•

The length of vent system and number of elbows should

be kept to a minimum to provide efficient performance.

• The vent system must have a damper.You may remove

damper flaps from damper to increase air flow.

•

Use silver tape or duct tape to seal all joints in the vent

system.

•

Use caulking to seal exterior wall or roof opening

around the cap.

CAUTION: HOOD MAY HAVE VERY SHARP EDGES; PLEASE WEAR

PROTECTIVE GLOVES WHENEVER IT IS NECESSARY TO REMOVE

PARTS FOR INSTALLING, CLEANING OR SERVICING.

A 47.75" x 2" x 4" wooden support (sold separately) is

required to properly install this Range Hood.

Install Wood Support

1. Locate at least two vertical studs at the wood mounting location by tapping drywall or by using a stud finder.

2. Position the supplied wood support

the support, drywall and into the studs.

3. Secure the wood support to two or more vertical studs with wood screws (not provided).

4. Use threaded drywall anchors when mounting the hood onto sheet rock. Mounting the hood into wall studs or

lumbars is highly recommended.

” ( mm) below the cabinet and drill 1/8” (3.175 mm) pilot holes through

0.5”

(12.7mm)

Wood Support

10 11

Page 7

INSTALLATION INSTRUCTIONS

Keyhole

Keyhole

INSTALLATION INSTRUCTIONS

Install Range Hood Mounting Screws

1. Mark the screw holes onto the bottom of cabinet by

Remember to compensate for the size of the

wooden support frame.

You will need to cut the holes for the power cord and the damper hole under the cabinet.

3.Install the range hood mounting screws, leaving the

clearance for mounting the range hood.

Top View

Keyhole Locations

0.69 in.

7.09 in.

17.5mm

0.69 in.

1. Lift the range hood and place over the protruding mounting screws; the keyhole slots on the top of the range

hood should engage with the protruding mounting screws.

2. Gently slide the range hood backwards until it cannot

2-1/8 in.

2.75 in.

19.82 in.

8.27 in.

3.61 in.

47.9 in.

2.41 in.

slide back any further. Finish screwing in the mounting screws.

measuring the holes located on top of the unit.

screws protruding a 1/4” (6.3 mm) to allow

0.69 in.

2-1/8 in.

2-1/8 in.

19.82 in.7.44 in.

2.75 in.

17.5mm

7.09 in.

17.5mm

0.69 in.

Secure Back of Range Hood

Using the wood screws, secure the back of the range hood into the wood support through the

keyhole slots in the rear of the range hood body.

Keyhole

1.18”

2.38”

15.75 “

31.5”

17.95”

12 13

Page 8

INSTALLATION INSTRUCTIONS

INSTALLATION INSTRUCTIONS

Install Damper

1.

Position the damper over the damper adapter and secure using the screws provided.

f DAMPER

f WALL

f DAMPER ADAPTER

INSTALLING THE EXHAUST DUCTING

Important:

Remove the packaging tape on the damper (located at the top of the unit) and make sure the flaps are

1.

able to move freely.

Use HVAC foil tape to wrap all the duct joints for an airtight seal

2.

Connect to AC Outlet

•

Connect AC plug into a grounded AC outlet having 120V,

60Hz. Place the outlet at a maximum distance of

33-1/2” (851 mm) from where the cord exits on the hood.

•

SEE IMPORTANT INSTRUCTIONS BELOW

IMPORTANT:

•

Observe all governing codes and ordinances.

•

It is the customer’s responsibility to contact a qualified electrical installer.

•

If codes permit and a separate ground wire is used, it is recommended that a qualified electrician

determine that the ground path is adequate. A 120-Volt, 60 Hz, AC-only, fused electrical supply is

required on a separate 15-amp circuit, fused on both sides of the line.

•

DO NOT ground to a gas pipe.

•

Check with a qualified electrician if you are not sure that the range hood is properly grounded.

•

DO NOT have a fuse in the neutral or ground circuit.

IMPORTANT: Save this Installation Guide for electrical inspector’s use.

GROUNDING INSTRUCTIONS:

•

This appliance must be grounded. In the event of an electrical short-circuit, grounding reduces the risk of

electric shock by providing an escape wire for the electric current.

•

This appliance is equipped with a cord having a grounding wire with a grounding plug. The plug must be

plugged into an outlet that is properly installed and grounded.

WARNING: Improper grounding can result in a risk of electric shock.

•

Consult a qualified electrician if the grounding instructions are not completely understood, or if doubt

exists as to whether the appliance is properly grounded. DO NOT use an extension cord. If the power

supply cord is too short, have a qualified electrician install an outlet near the appliance.

3-Pronged Plug

Ground Plug

3-Prong Receptacle

Important:

To provide extra support and to reduce the vibration, the appliance must fix onto the concrete wall

•

Important:

Install ductwork, making connection in direction of airflow as illustrated.

Secure joints in ductwork with sheet metal screws.

Wrap all duct joints with HVAC foil tape for an airtight seal.

14 15

Page 9

OPERATING INSTRUCTIONS

MAINTENANCE

Using the Fan

Press to begin low

speed. Screen will display

u

F1.

Press to increase speed

suction. Screen will display

increments as F2, F3, F4.

Press again to decrease

suction. Screen will display

00.

Press to begin high

v

speed suction. Screen will

display F3.

Press again to begin

high speed suction to F4.

Press again to stop

suction. Screen will display 00.

Using the Time Delay Function

u

v

w

x

to activate the Press

Time Delay Function.

Screen will display “15

minutes”.

Press to increase or to

decrease the time period

for the Time Delay

Function.

to cancel the Press

Time Delay Function.

The light will turn off at the end of the set time period if

Time Delay Function is activated while the light is on.

Turning the Light On of Off

Press

u

to turn light on

and again to turn light

off.

Care and Cleaning

The metal baffles channel grease

released by foods on the cook top into the

drip trays. The baffles also help prevent

flaming foods on the cook top

from damaging the inside of the hood. For

this reason, the baffles must ALWAYS be

in place when the hood is used.The

grease baffles and drip trays should be

cleaned once a month, or as needed.

To clean the grease baffles and drip

trays:

Drain and wipe all excess grease with a

dry paper towel, Soak them and then

swish them around in hot water and

detergent. Don’t use ammonia or

ammonia products because they will

darken the metal. Do not use abrasives

or oven cleaners. Rinse, shake and let

them dry before replacing. They may

also be cleaned in an automatic

dishwasher.

To remove:

Grasp the filter handles and pull them up,

forward and out. Grasp the drip tray and

carefully lift it up and out of the hood

track.

To replace the drip trays:

1. Place and seat the drip tray

into the hood rack.

2. Slide them left and right until

all trays are side-by-side in

place in the track

To replace the baffles filters:

1. Hold the baffle filter by the two handles.

2. Place the up end of the baffle

against the inside front of the

hood.

3. Slide it up and push the

bottom end back until it firmly

seats into place

16 17

Page 10

MAINTENANCE

TROUBLESHOOTING

CAUTION: NEVER PUT YOUR HAND INSIDE OF THE UNIT WHILE ITS OPERATING. FOR

THE BEST PERFORMANCE CLEAN YOUR

RANGE HOOD REGULARLY.

CLEANING

1. Clean the Range Hood assembly once every 6 months.

2. DO NOT clean the motor or electrical components with water or

any other liquid

REPLACING LIGHT BULBS

CAUTION: LAMP UNIT MAY BE HOT! WAIT UNTIL THE UNIT IS COOL. BEFORE

ATTEMPTING TO REP LACE THE LED LAMPS MAKE SURE THE UNIT IS POWERED OFF AND

UNPLUGGED.

Note: Individual LED bulbs cannot be replaced, only entire LED lamps.

1. Remove the baffle filters

2. Find the wire connection of the lamp inside the unit and unplug.

3. Remove old LED lamp by pushing it out of its hole from the inside.

4. Plug in new LED lamp.

5. Reinstall the baffle filters.

CAUTION: ALWAYS UNPLUG UNIT FROM POWER BEFORE SERVICING

PROBLEM

My range hood is

noisy

My range hood has

poor performance..

My range hood shakes.

A. The range hood and cook top

B. There are too many open

C. The motor performance has

D. Check and make sure the

A. The installation is not secure.

B. The fan is broken or not

C. The motor is loose. Check

SOLUTION

A. Check inside the range

hood for any loose debris and

remove.

are too far away from each

Optimal distance is 24” to 36”

other.

windows or doors in the area.

Close some doors or

windows.

decreased due to wear.

Replace motor.

tape holding down the

damper flaps at the vent hole

are removed before use.

Check again and make sure

the installation hardware is

securely mounted.

balanced. Realign or replace

fan.

and make sure the motor is

solidly mounted to the unit.

TOOLS

Phillips Screwdriver

Phillips Screwdriver

Phillips Screwdriver

18 19

The motor no

longer runs.

Light bulbs went out.

A. Replace control panel or

circuit board.

B. Replace with new motor

assembly.

A. Replace with a new LED

lamp assembly.

Phillips Screwdriver

Phillips Screwdriver

Page 11

WARRANTY AND SERVICE

For full warranty details on this product please visit:

http://www.cosmoappliances.com/warranty

TO RECEIVE WARRANTY SERVICE, YOUR

PRODUCT MUST BE REGISTERED. TO REGISTER, VISIT:

WWW.COSMOAPPLIANCES.COM/WARRANTY

IMPORTANT

Do Not Return This Product To The Store If

you have a problem with this product, please contact

Cosmo Customer Support at

+1(888)784-3108

DATED PROOF OF PURCHASE, MODEL #, AND SERIAL #

REQUIRED FOR WARRANTY SERVICE

IMPORTANT

Ne pas Réexpédier ce Produit au Magasin

Pour tout problème concernant ce produit, veuillez contacter

le service des consommateurs Cosmo Customer Support au

+1(888) 784-3108

UNE PREUVE D’ACHAT DATEE EST REQUISE POUR BENEFICIER DE

LA GARANTIE.

SCAN TO REGISTER

Si tiene algún problema con este producto, por favor contacte el

NECESITA UNA PRUEBA DE DE COMPRA FECHADA, NÚMERO DE

20 21

IMPORTANTE

No regrese este producto a la tienda

AYUDA AL CLIENTE COSMO al

+1(888)784-3108

(Válido solo en E.U.A).

MODELO Y DE SERIE PARA EL SERVICIO DE LA GARANTÍA

Correct Disposal of this product:

This marking indicates that this appliance should not

be disposed with other household wastes. To prevent

possible harm to the environment or human health

from uncontrolled waste disposal, recycle it responsibly to

promote the sustainable reuse of material resources.

Page 12

Cosmo is constantly making efforts to improve the quality and

performance of our products, so we may make changes to our

appliances without updating this manual.

Electronic version of this manual is available at:

www.cosmoappliances.com

Loading...

Loading...