River Service

2

River 15

- cold water production (10°C): 15 litres per hour

- compressor: 1/10 HP

- condensation: Static

River 25

- cold water production (10°C): 25 litres per hour

- compressor: 1/6 HP

- condensation: Ventilated

River 50

- cold water production (10°C): 50 litres per hour

- compressor: 1/4 HP

- condensation: Ventilated

3

River 25 UP

- cold water production (10°C): 25 litres per hour

- compressor: 1/6 HP

- condensation: Ventilated

River 50 UP

- cold water production (10°C): 50 litres per hour

- compressor: 1/4 HP

- condensation: Ventilated

4

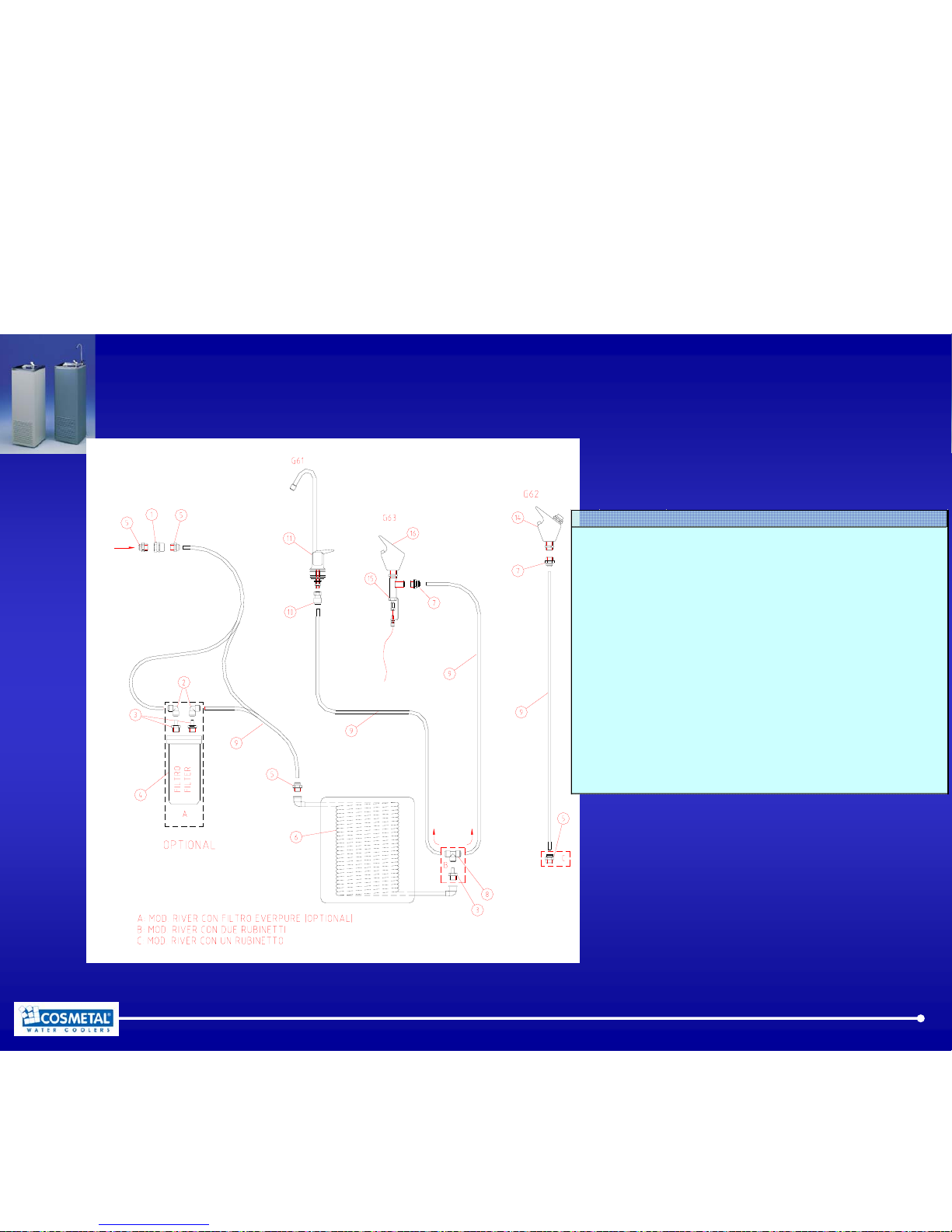

River - Hydraulic Circuit

N. CODICE DESCRIPTION

1

2521412 BULKHEAD CONNECT. NICKEL-PLATED 3/8F-1/2M

2

2521367 EQUAL ELBOW JG 8

3

2521363 STEM ADAPTOR JG 3/8M - 8

4

1501302 EVERPURE FILTER

5

2521360 STRAI GHT ADAPTOR JG 3/8M - 8

6

8150120 6 1 DIRECT COOLING SYSTEM RIVER 15

8110020 1 1 DIRECT COOLING SYSTEM RIVER 25

8110030 1 1 DIRECT COOLING SYSTEM RIVER 50

7

2521375 STRAIGHT ADAPTOR JG 1/8M - 8 FOR G62 TAP

8

2521364 EQUAL TEE JG 8

9

2801363 TUBE 8

10

2521366 STRAIGHT ADAPTOR JG FO R G61 TAP

11

2521705 G61 TAP

14

2521706 G62 TAP

15

2781193 MECHENICAL VALVE FOR G63 TAP

16

2521707 G63 TAP

5

Setting up the cooler at your premises

• Examine the packaging for sign of damage, report any damage to

the haulier

• Remove the carton and the plastic bag from the cooler

• Make a general inspection, ensuring that there are no marks or

damage to River and all accessories are present

• Sanitise the cooler

• Replace the plastic bag

• Replace the box over the cooler

• The River is ready for the transportation to the customer

6

Installation

• Place the cooler in the desired point of installation, away from

heat sources and protected from direct sunrays.

• Adjust foot to level the cooler correctly and to avoid irritating

noises caused by vibration.

• When handling and moving the cooler, use the handle recessed

into the cross support on the back of the unit.

• To ensure proper ventilation, position the River at a distance of at

least 6-7 cm from the wall.

7

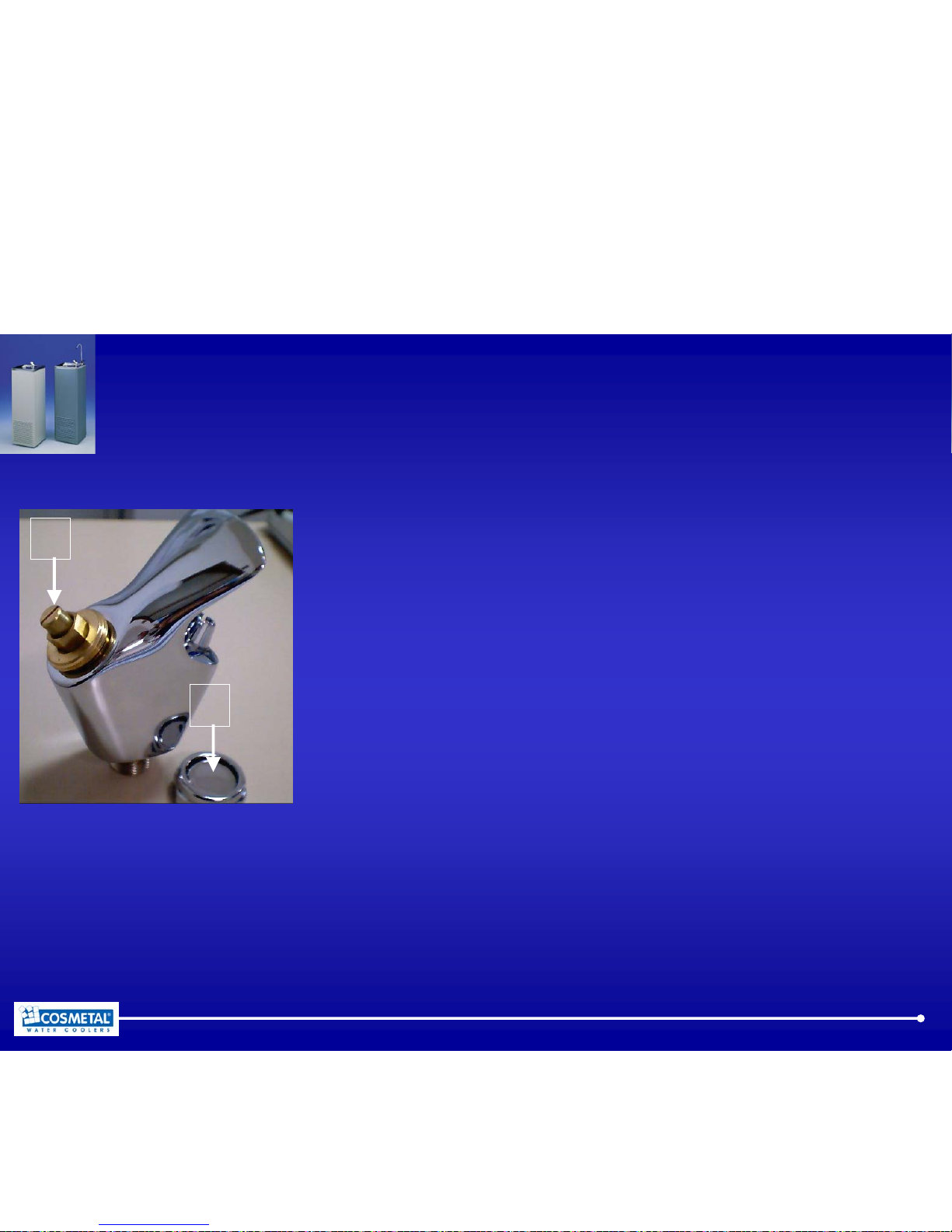

Assembly and adjustment of faucets 1

Faucet G61

Insert the lever and let it glide on the specific

guiding channel, attach the tube, and tighten it.

The water flow is pre-set by the manufacturer.

If it needs to be adjusted, manipulate ratchet N,

tighten it to increase the flow, loosen it to decrease

it.

Only carry out one revolution at a time.

N

8

Assembly and adjustment of faucets 2

Faucet G62

The faucets G62 are always assembled.

To regulate the water flow, remove ferrule G and

manipulate screw V.

Turning it clockwise will decrease the flow,

anticlockwise movement will in-crease it.

V

G

9

Assembly and adjustment of faucets 3

Faucet G63

The faucets G63 are always assembled.

This faucet is being controlled by a pedal, which

must be attached with a trigger device at the

predetermined location.

The water flow is regulated by manipulating screw S:

turning it clockwise will decrease the flow,

anticlockwise movement will increase it.

S

10

Water connection to the mains

• Before making the water connection, make sure the mains water

pressure is between 1 and 3 bars.

• If the mains water pressure exceeds 3 bars, predispose a pressure

reducer capable of reducing the latter to the 1-3 range.

• Connect the appliance to the water mains using the water inlet

fitting.

• The 3/8F connector or the fast coupling provided can be used for

the 8 mm diameter pipe.

• Predispose a stop tap on the water inlet pipe.

11

Connection on wastewater tube

• The wastewater is clean. It originates at the basin that collects

possible water drips during the distribution phase.

• Connect the wastewater tube (internal diameter 18 - external

diameter 24 mm) to a siphoned water discharge system.

• If necessary, cut the tube to avoid bending or an interruption of

downward flow.

12

Electricity Connection 1

• Connection to the mains electricity supply is carried out by

connecting the plug to a mains socket

• The supply socket must be equipped with an efficient earth plate

and it must be sized for the load of the appliance (see technical

characteristics).

• Make sure that the mains voltage corresponds with what is

specified on the data plate.

• Make sure that there is an omnipolar switch above the socket with

a minimum contact break of 3 mm protected by fuses of suitable

amperage for the absorption of the appliance itself (see technical

characteristics and data plate).

13

Electricity Connection 2

• Turn the screw of the cold water regulator to the maximum

position

• The thermostats make the appliance start.

14

Hygienic Cleaning

15

Hygienic Cleaning 1

• WARNING! Given that the products used for the hygienic cleaning

procedure contain corrosive acidic and alkaline substances,

disposable gloves and protective eyewear should be worn at all

times.

• When performing the hygienic cleaning procedure, please keep to

the product reaction times, sanitising liquid percentages and

quantities of water for rinsing.

• The hygienic cleaning should be performed before installing the

appliance and each time:

- components of the hydraulic cycle are replaced,

- you encounter or suspect there is contamination,

- the appliance is installed.

16

Hygienic Cleaning 2

• Warning: If a filtering kit is fitted on the appliance, it should be

excluded from the hygienic cleaning process.

• Preparation of the hygienic cleaning solution, take five litres of

water in a bucket or pan.

• Add to it 5% of hydrogen peroxide 130 volumes; for the dosage,

use a graduated measuring cup or a common syringe.

• N.B.: when using commercial hygienic cleaning solutions, keep to

the instructions provided by the manufacturer and included in the

packaging.

• Using a pump P, connect the appliance water inlet to the bucket

filled with the disinfectant solution.

17

Hygienic Cleaning 3

• Start the pump, allowing the disinfectant to enter the appliance,

then turn on the taps to enable the hygienic cleaning solution to

flow throughout the entire hydraulic circuit, right through to the

water dispensing spout.

• Before you run out of disinfectant solution, turn the pump off and

stop the water dispensing.

• Leave the disinfectant solution to act for 20 minutes.

• Reconnect the appliance to the water mains.

• Allow for at least 15 litres of water to flow out of the taps so that

the water system is rinsed thoroughly, before using the appliance

again.

18

Troubleshooting

19

Troubleshooting cold water system 1

No cold water and compressor not running

1 Check voltage received by cooler

2 Check cold thermostat

3 Check wires

4 Check compressor relay

5 Check compressor overload

6 Check compressor

No cold water and compressor running

1 Check voltage

received by cooler.

2 Check for a refrigerant leak

3 Check capillary line

4 Check compressor

20

Troubleshooting cold water system 2

Too much noise coming from the cooler

1 Check for vibration at refrigeration pipes

2 Check for vibration

caused by adjustable feet

Cold water comes out slowly or not at all

1 Check water inlet pressure

2 The water is frozen. Check cold thermostat

3 Check water filter

21

Repairs & Solutions

22

Voltage

Checking the Voltage

• Is the electric cord plugged in?

Plug in the cooler

• Is the switch controlling the outlet in the OFF position?

Switch ON, verify with an electric appliance if the outlet is good.

For voltage problem the customer must to contact the utility company

23

Cold thermostat

On all Cosmetal cooler the cold thermostat is the same.

• Check if it’s in OFF position or set to the minimum

• Check for continuity

Unplug the electric cord, with a ohm meter control the thermostat continuity

If it exists the thermostat is good

• Check the wires connected on its terminals

• For change a thermostat it is important measuring the length of

capillary tube inserted in to the copper tube. In the faulty thermostat

place a piece of masking tape around the capillary tube at the point the

tube enters in the copper tube well.

24

Wires

Check the electrical wires

• Is any wire disconnected from terminal?

• Is any terminal loose?

Replace any defective wires, terminal, or connectors

25

Relays

The starting relay is located in the compressor electric box

• Check the continuity of the starting relay

With a ohm meter control the thermostat continuity.

If it exists the relay is good

• Check the PTC relay (Rio “RI” P.O.U.)

For to test a PTC relay it’s necessary change it with a known good one

Overload

Overload is a compressor self protection, It is possible to replace a faulty

overload, it’s in the compressor electric box

26

Compressor

• The compressor runs but does not cool the water (It may be low

on refrigerant)

• The compressor runs a short time and shuts off, then repeats the

pattern several times (the refrigerant lines may be restricted)

Change the compressor.

A specialised refrigerant repairman may do the substitution.

27

Refrigerant leak

• Is refrigerant leaking?

Check the temperature of condenser when the compressor running, if the

condenser is quit warm, there is a refrigerant leaking.

Normally when the compressor running, the condenser temperature is

50-55°C.

A specialised refrigerant repairman may do the service.

28

Capillary line

• Visually check to see that lines are not bent

A specialised refrigerant repairman may do the service.

29

Vibration

• Is a section of the pipes line vibrating against another cooler part?

Eliminate vibrations by moving tubing away from other cooler parts.

• Is the P.O.U. levelled?

Level the cooler using the adjustable feet.

30

Inlet pressure

• Is there a minimum pressure in the main water line?

Verify if there is an hand valve close or some tubes are bent.

• Check the mechanical filter fixed on the inlet metal connection.

Clean the mechanical filter or change it.

31

Faucet

• Is some drops of water come trough the water tap?

Some dirty is going to inside the valve. It’s necessary to disassemble the

valve and remove the dirty

32

Filters

• Is the water filter obstructed?

Change the filter cartridge

Loading...

Loading...