¡

ORDERING INFORMATION

ZUS61205

Output voltage

Input voltage

Output wattage

Single output

Series name

ZUS6

Thin profile

Isolated between input

-

output

Built

-

in overcurrent protection circuit

UL recognized, TÜV approved, CSA certified

Five

-

year warranty

ZU SERIES DC/DC CONVERTER

¶1 Rated input. 5V, 12V, 24V or 48V DC, Io=100%

¶2 The drift is a change at 25ª of ambient temperature and 30 minutes~8 hours after the input voltage applied at rated input/output.

¶3 Measured by 20MHz oscilloscope.

¶ Series/Parallel operation with other model is not possible.

VOLTAGE

CURRENT

EFFICIENCY

VOLTAGE

CURRENT

LINE REGULATION

LOAD REGULATION

RIPPLE ¶3

DRIFT

START-UP TIME

INPUT-OUTPUT

INPUT-CASE

OUTPUT-CASE

VIBRATION

IMPACT

AGENCY APPROVALS

[V]

[A]¶1

[%]¶1

[V]

[A]

[mV]

[mV]

[mVp-p]

[mVp-p]

[mV] ¶2

[ms]

[V]

[V]

STORAGE TEMP.,

HUMID. AND ALTITUDE

OPERATING TEMP.,

HUMID. AND ALTITUDE

OVERCURRENT

PROTECTION

TEMPERATURE

[mV]

REGULATION

-20˚C ~+55˚C

RIPPLE

NOISE

MODEL

ZUS60505

1.41 typ

71 typ

5

1.0

4.85~5.25

ZUS60512

1.63 typ

74 typ

12

0.5

11.40~12.60

ZUS60515

1.63 typ

74 typ

15

0.4

14.25~15.75

0.17 typ

78 typ

15

0.4

14.25~15.75

ZUS61205

0.69 typ

73 typ

5

1.2

4.85~5.25

ZUS61212

DC9~18

0.65 typ

78 typ

12

0.5

11.40~12.60

ZUS61215

0.65 typ

78 typ

15

0.4

14.25~15.75

ZUS62405

0.35 typ

73 typ

5

1.2

4.85~5.25

ZUS62412

DC18~36

0.33 typ

78 typ

12

0.5

11.40~12.60

ZUS62415

0.33 typ

78 typ

15

0.4

14.25~15.75

ZUS64805

0.18 typ

73 typ

5

1.2

4.85~5.25

ZUS64812

0.17 typ

78 typ

12

0.5

11.40~12.60

ZUS64815

DC4.5~9

INPUT

OUTPUT

ISOLATION

SAFETY

PROTECTION

CIRCUIT

ENVIRONMENT

SPECIFICATIONS

Works over 105% of rating and recovers automatically

AC500V, 1 minute. Cutoff current=10mA, DC500V, 50M

Ω min

(At Room Temperature)

AC500V, 1 minute. Cutoff current=10mA, DC500V, 50M

Ω min

(At Room Temperature)

AC500V, 1 minute. Cutoff current=10mA, DC500V, 50M

Ω min

(At Room Temperature)

-20~+71ª, 20~95%RH(Non condensing)(Refer to DERATING CURVE), 3,000m(10,000feet)max

-40~+85ª, 20~95%RH(Non condensing), 9,000m(30,000feet)max

10~55Hz, 98.0m/s

2

(10G), 3 minutes period, 60 minutes along X, Y and Z axis

490.3m/s

2

(50G), 11ms, once each X, Y and Z axis

UL1950, EN60950, CSA C22.2 No.950 Complies with IEC60950

OUTPUT VOLTAGE

SETTING

OUTPUT VOLTAGE

ADJUSTMENT RANGE

20max

40max

80max

120max

50max

20max

ZUS6053R3

0.94 typ

70 typ

3.3

1.0

3.20~3.47

20max

40max

80max

120max

50max

20max

48max

100max

120max

150max

150max

48max

60max

120max

120max

150max

180max

60max

20max

40max

80max

120max

50max

20max

48max

100max

120max

150max

150max

48max

60max

120max

120max

150max

180max

60max

20max

40max

80max

120max

50max

20max

48max

100max

120max

150max

150max

48max

60max

120max

120max

150max

180max

60max

20max

40max

80max

120max

50max

20max

ZUS6483R3

0.09 typ

73 typ

3.3

1.0

3.20~3.47

20max

40max

80max

120max

50max

20max

48max

100max

120max

150max

150max

48max

60max

120max

120max

150max

180max

60max

20max (Minimum input, lo=100%)

FIXED

R

¶3

DC 36~72

marked models are pending for safety approvals. Consult with us for delivery.

392

ZU/ZT

MAX OUTPUT

WATTAGE

DC OUTPUT

VOLTAGE

DC OUTPUT

CURRENT

ZUS6

5V

ZUS6

3.3W

3.3 V

1.0 A

ZUS6

6W

12V

0.5A

ZUS6

6W

15V

0.4A

0505

053R3 483R3

5W

1.0A

1205 2405

6W

1.2A

4805 0512 1212 2412 4812 0515 1215 2415 4815

¡

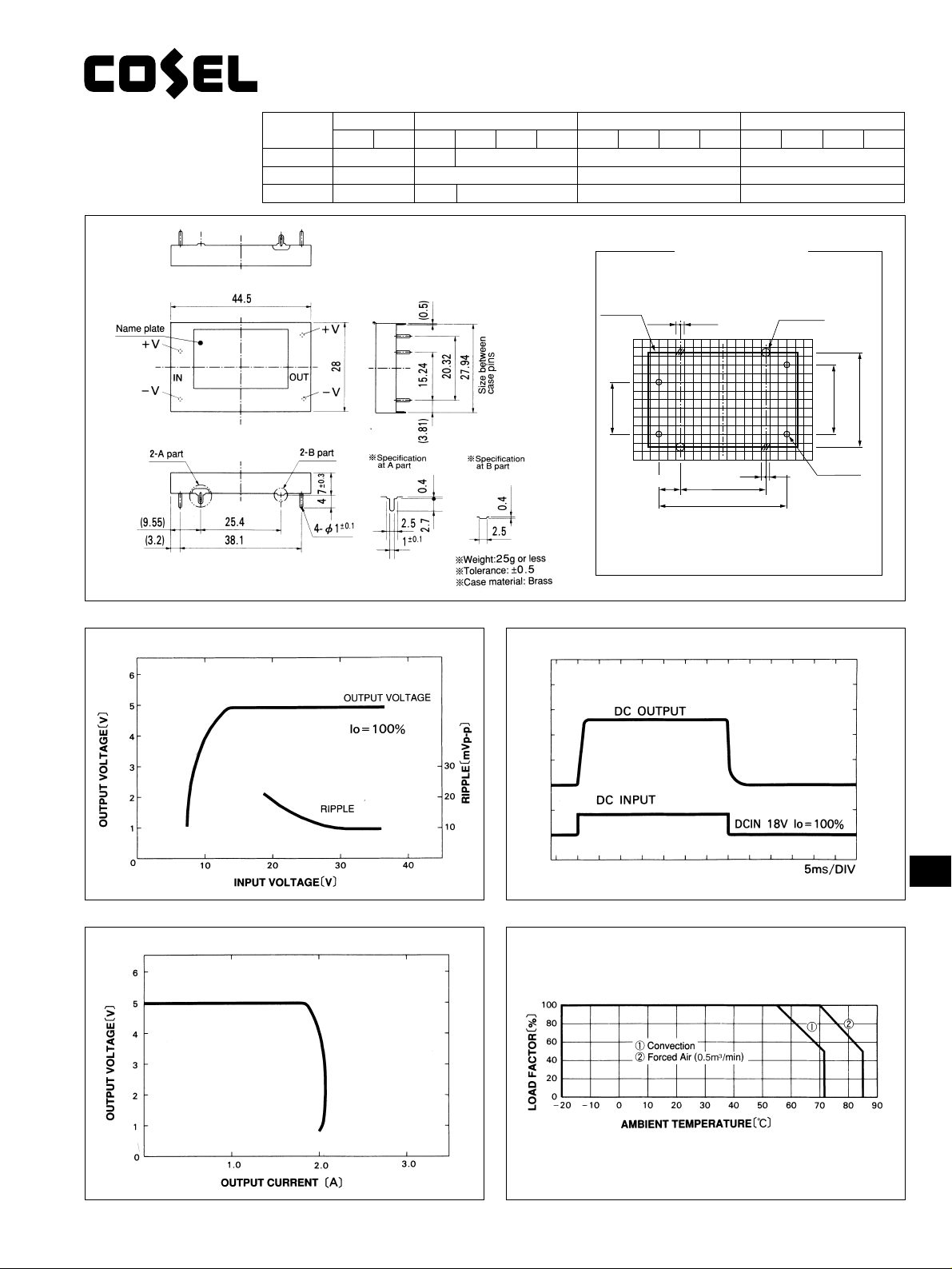

EXTERNAL VIEW

¡

DERATING CURVE

¡

RISE TIME & FALL TIME

(

ZUS62405

)

¡

OVERCURRENT CHARACTERISTICS

(

ZUS62405

)

¡

STATIC CHARACTERISTICS

(

ZUS62405

)

DC/DC CONVERTER

(SINGLE OUTPUT)

Outline

¶

Recomended size for

processing PCB

(TOP VIEW)

15.24

20.32

27.94

(1.25)

(1.25) (1.25)

(1.25)

4-

º

1.5

2-

º

1.6

38.1

25.4

6.35

¶Dimensions in mm

The converter is in contact with the

slanted area of the P.C.B. To keep

isolation, adequate wiring on the

mounted side is required.

¶Div.: 0.1inch

MODEL

393

ZU/ZT

393

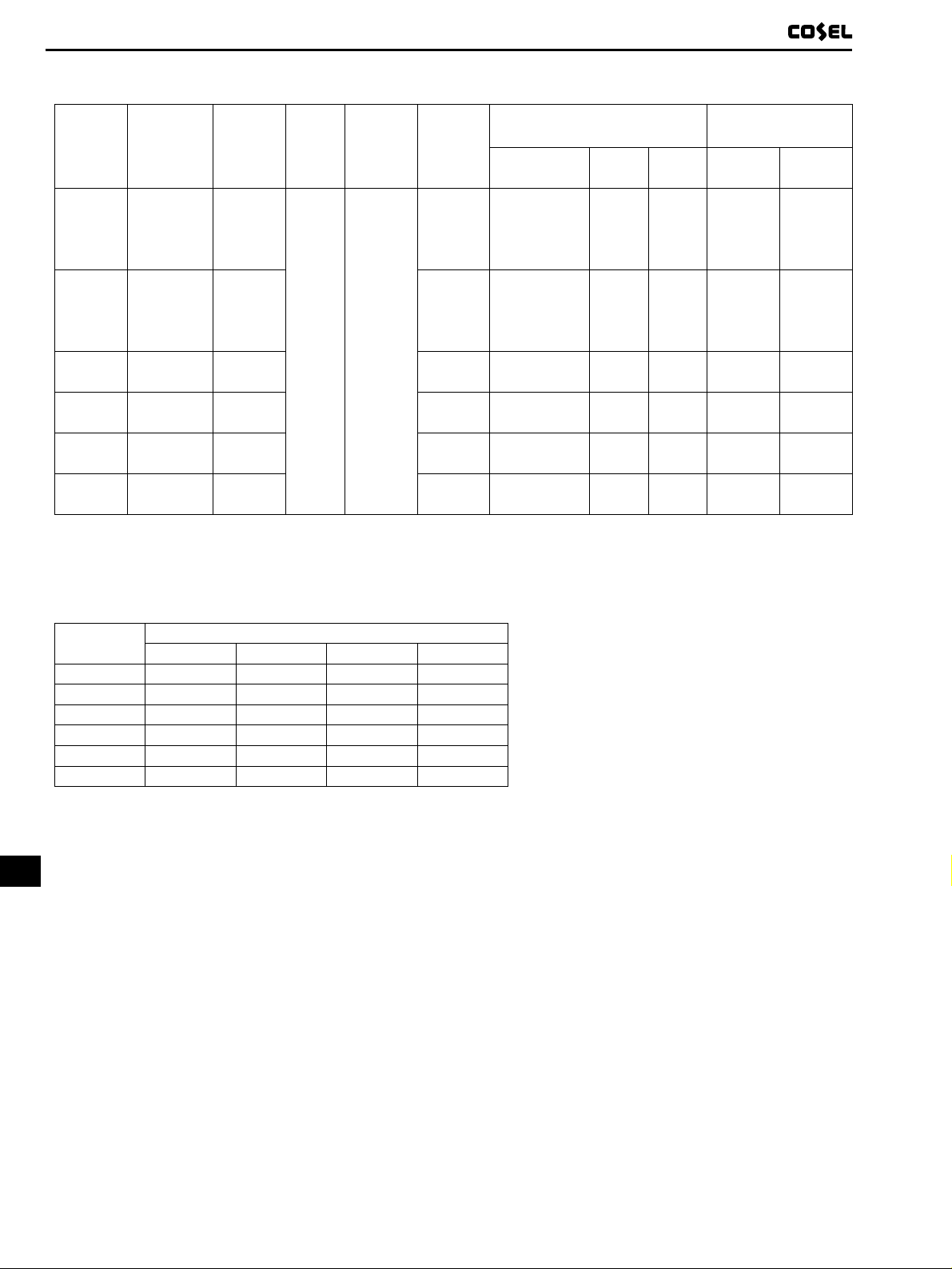

Basic characteristics data

Model

310~1600 -

-

-

-

-

-

200~1600

150~1600

100~ 200

330~ 400

330~ 400

*1

Refer to

table No.1

Yes

Yes

Yes

Yes

Yes

Yes

*2

*2

*2

Yes

Yes

Yes

*2

*2

*2

*2

*2

*2

PCB/PatternCircuit

method

Switching

frequency

[kHz]

Series/Parallel

operation availability

*1 Refer to Specification.

*2 Refer to Instruction Manual.

Input

current

[A]

Rated

input fuse

Material Single

sided

Flyback

converter

Flyback

converter

Flyback

converter

Flyback

converter

Single ended

forward converter

Single ended

forward converter

glass fabric base,

epoxy resin

glass fabric base,

epoxy resin

glass fabric base,

epoxy resin

glass fabric base,

epoxy resin

glass fabric base,

epoxy resin

glass fabric base,

epoxy resin

ZUS1R5

ZUW1R5

ZTS1R5

ZTW1R5

ZUS3

ZUW3

ZTS3

ZTW3

ZUS6

ZUW6

ZUS10

ZUW10

ZUS15

ZUW15

ZUS25

ZUW25

Series

operation

Parallel

operation

Double

sided

Inrush

current

protection

Table 1. Rated Input Fuse

Output Power

Input Voltage

5V

1.5W

3 W

6 W

10 W

15 W

25 W

72V

72V

72V

125V

125V

125V

1.2A

2.0A

4.0A

6.3A

8.0A

10.0A

12V

72V

72V

72V

125V

125V

125V

0.8A

1.2A

2.0A

3.5A

5.0A

6.3A

24V

72V

72V

72V

125V

72V

125V

0.8A

0.8A

1.2A

2.0A

2.0A

3.15A

48V

72V

72V

72V

125V

72V

125V

0.8A

0.8A

0.8A

1.0A

2.0A

2.0A

420

ZU/ZT

ZU/ZT

421

Instruction Manual

Pin Connection. . . . . . . . . . . . 422

Function . . . . . . . . . . . . . . . . . . . . 422

2.1 Input voltage . . . . . . . . . . . . . . . . . . . . . . . .422

2.2 Overcurrent protection . . . . . . . . . . . . . . . 422

2.3 Isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . .422

Wiring to Input/Output Pin

. . 423

Series Operation and Parallel Operation

. . 423

4.1 Series operation . . . . . . . . . . . . . . . . . . . . .423

4.2 Parallel redundancy operation . . . . . . . . . 424

Assembling and Installation Method

. . 424

5.1 Installation method . . . . . . . . . . . . . . . . . . 424

5.2 Derating . . . . . . . . . . . . . . . . . . . . . . . . . . . 425

Input Voltage/Current Range

. .425

Cleaning. . . . . . . . . . . . . . . . . . . . .425

Soldering. . . . . . . . . . . . . . . . . . . .425

Input/Output Pin. . . . . . . . . . .426

Peak Current (Pulse Load)

. . 426

10

9

8

7

6

5

4

3

2

1

Pin Connection . . . . . . . . . . . . 427

Function . . . . . . . . . . . . . . . . . . . . 427

2.1 Input voltage . . . . . . . . . . . . . . . . . . . . . . . .427

2.2 Overcurrent protection . . . . . . . . . . . . . . . 427

2.3 Overvoltage protection . . . . . . . . . . . . . . . 427

2.4 Adjustable voltage range . . . . . . . . . . . . . 428

2.5 Remote ON/OFF . . . . . . . . . . . . . . . . . . . .428

2.6 Isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . .428

Wiring to Input/Output Pin

. . 429

Series Operation and Parallel Operation

. . 429

4.1 Series operation . . . . . . . . . . . . . . . . . . . . .429

4.2 Parallel redundancy operation . . . . . . . . . 430

Assembling and Installation Method

. .430

5.1 Installation method . . . . . . . . . . . . . . . . . . .430

5.2 Derating . . . . . . . . . . . . . . . . . . . . . . . . . . . .430

Input Voltage/Current Range

. .431

Cleaning. . . . . . . . . . . . . . . . . . . . .431

Soldering. . . . . . . . . . . . . . . . . . . .431

Input/Output Pin. . . . . . . . . . .432

Peak Current (Pulse Load)

. . 432

10

9

8

7

6

5

4

3

2

1

ZU1R5 • ZU3 • ZU6 • ZU10

Pin Connection . . . . . . . . . . . 433

Function . . . . . . . . . . . . . . . . . . . . 433

2.1 Input voltage . . . . . . . . . . . . . . . . . . . . . . . .433

2.2 Overcurrent protection . . . . . . . . . . . . . . . .433

2.3 Isolation . . . . . . . . . . . . . . . . . . . . . . . . . . . .433

Wiring to Input/Output Pin

. . 434

Series Operation and Parallel Operation

. . 434

4.1 Series operation . . . . . . . . . . . . . . . . . . . . .434

4.2 Parallel redundancy operation . . . . . . . . . 435

Assembling and Installation Method

. . 435

5.1 Installation method . . . . . . . . . . . . . . . . . . 435

5.2 Derating . . . . . . . . . . . . . . . . . . . . . . . . . . . .435

Input Voltage/Current Range

. .435

Cleaning. . . . . . . . . . . . . . . . . . . . .436

Soldering. . . . . . . . . . . . . . . . . . . .436

Input/Output Pin. . . . . . . . . . .436

Peak Current (Pulse Load)

. . 437

10

9

8

7

6

5

4

3

2

1

ZT1R5 • ZT3

ZU15 • ZU25

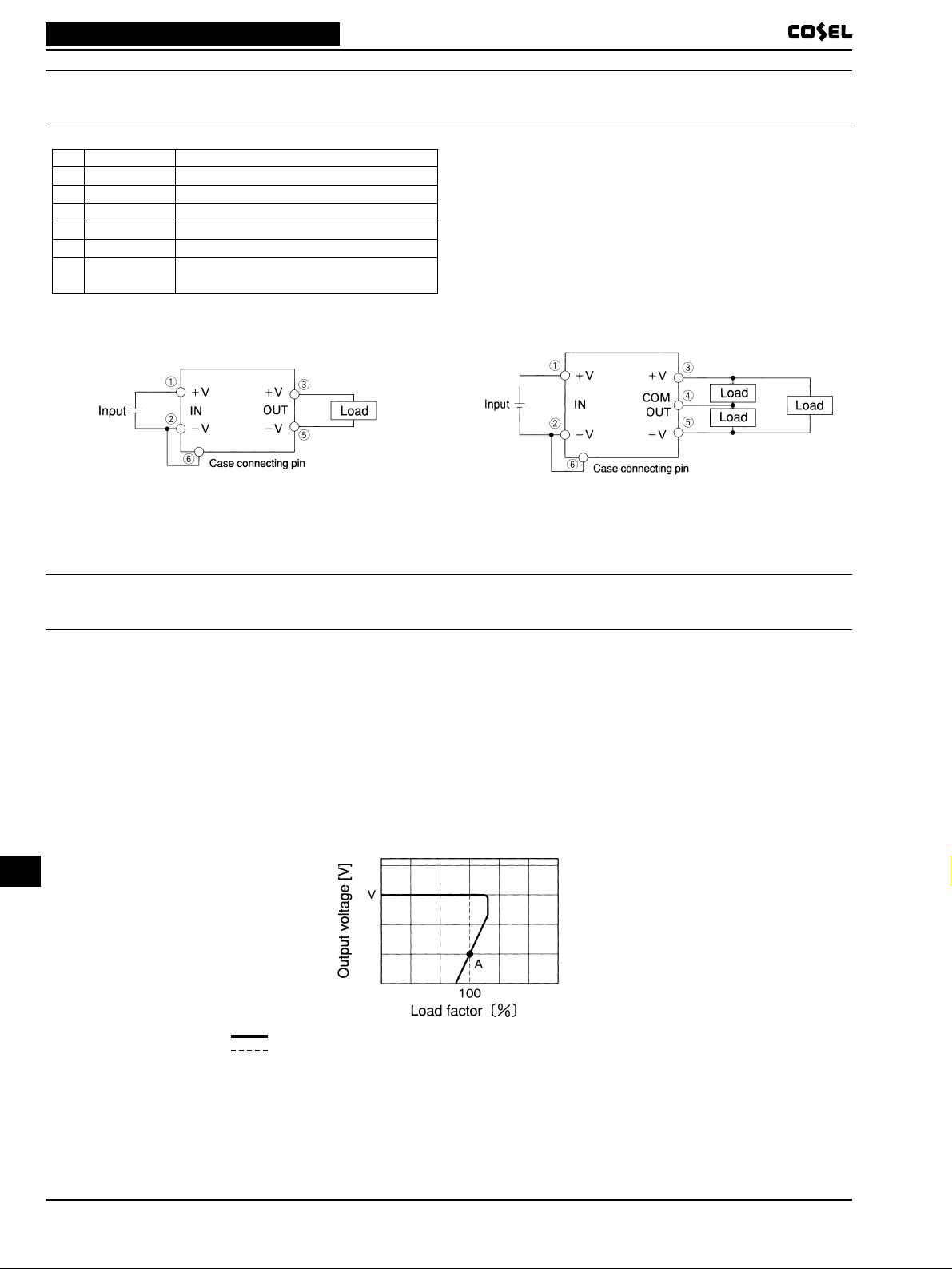

1. Pin Connection

¿

Single Output

¿

Dual(±)Output

¿

connecting pin

Case connecting pin is available. By connecting this pin to

-side of input, the radiation noise from main body can be

reduced.

2. Function

2.1 Input voltage

¡

If the wrong input is applied, the unit will not operate properly and/or may be damaged.

2.2 Overcurrent protection

¡

Overcurrent protection circuit is built-in and comes into effect at over 105% of the rated current.

Overcurrent protection prevents the unit from short circuit and over current condition of less than 20 sec. The unit automatically recovers

when the fault condition is cleared.

¡

The power supply which has a current foldback characteristics may not start up when connected to nonlinear load such as lamp, motor or

constant current load. See the characteristics below.

Fig. 2.1 Current foldback characteristics

2.3 Isolation

¡

For a receiving inspection, such as Hi-Pot test, gradually increase(decrease)the voltage for the start(shut down). Avoid using Hi-Pot

tester with the timer because it may generate voltage a few times higher than the applied voltage, at ON/OFF of a timer.

422

ZU1R5 • ZU3 • ZU6 • ZU10

ZU/ZT

No.

q

w

e

r

t

Pin connection Function

+DC INPUT

-DC INPUT

+DC OUTPUT

COMMON

-DC OUTPUT

Case connecting

pin

If connected to -side of input, the case potential can be

fixed and the value of radiation noise can be reduced.

+Side of input voltage

-Side of input voltage

+Side of output voltage

GND of output voltage(Only applicable for Dual output)

-Side of output voltage

y

: Load characteristics of power supply

: Characteristics of load (lamp, motor, constant current load, etc.)

Note: In case of nonlinear load, the output is locked out at A point.

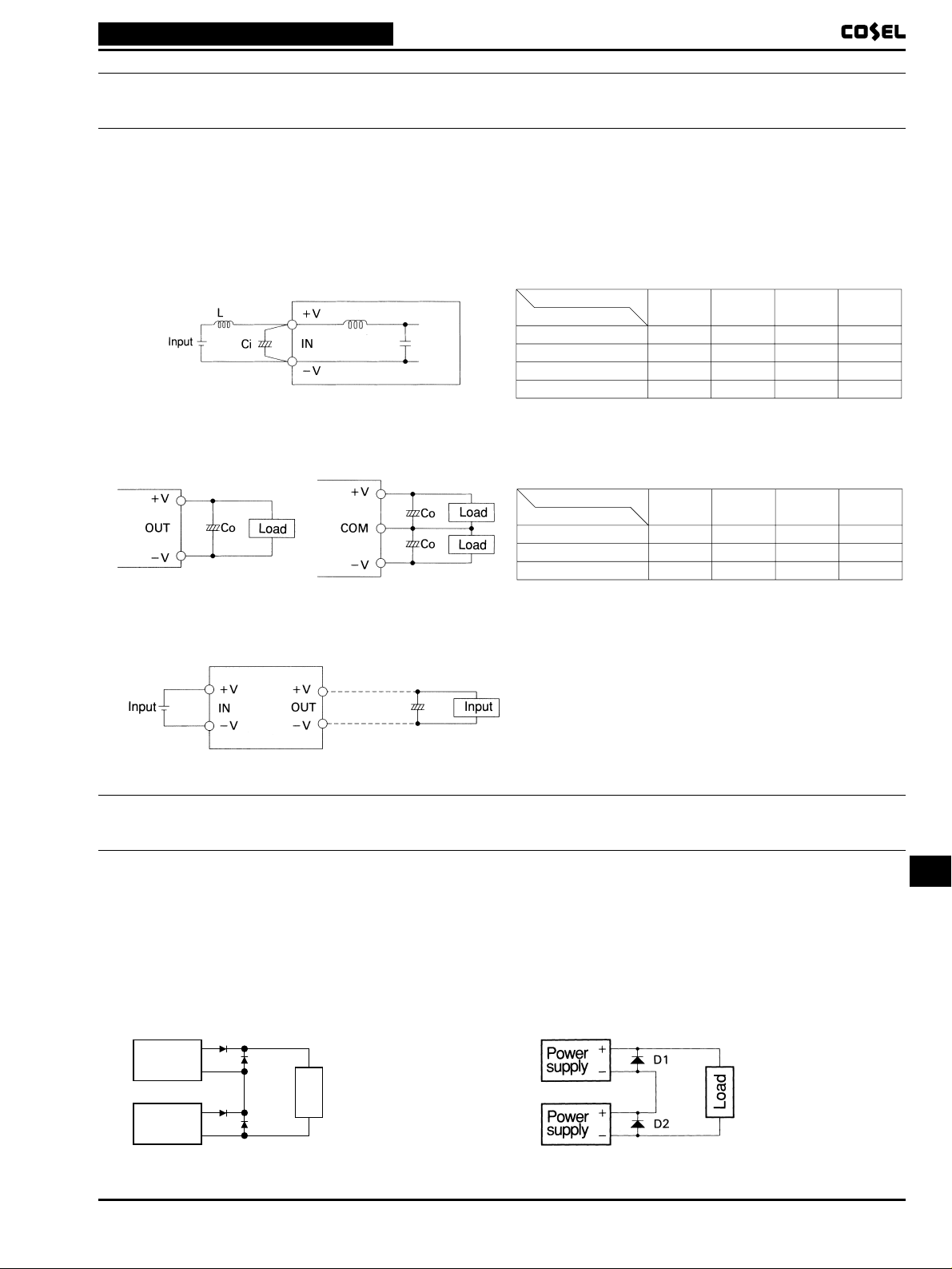

3. Wiring to Input/Output Pin

¡

Input filter is built

-

in. A capacitor Ci, if installed near the input terminal, will lower the input conducted noise from converter due to the

formation of the π type filter.

¡

When the distance from the DC line to the unit is greatly extended, it makes the input feedback noise much higher and the input voltage

several times higher than the normal level when turned ON. If this happens, the output power also becomes unstable. In order to prevent

the unit form failing in this way; please connect Ci to the input terminal. In addition, when the filter with "L" is used, please Ci to the input

terminal.

Capacity of external capacitor at input terminal: Ci[

µ

F]

Fig. 3.1 Connecting method of capacitor at input terminal

¡

To lower the output ripple voltage further, install an external capacitor Co at output terminal as shown below.

Capacity of external capacitor at output terminal: Co[

µ

F]

ZUS ZUW

Fig. 3.2 Connecting method of external capacitor at output terminal

¡

When the distance between load and DC output is long, please install capacitor at load as shown below.

Fig. 3.3 Connection method of capacitor at load

4. Series Operation and Parallel Operation

4.1 Series operation

¿

ZUS1R5/ZUW1R5 • ZUS3/ZUW3 • ZUS6/ZUW6

¡

Series operation is available by connecting the outputs of two or more power supplies, as shown below. Output currents in series

connection should be lower than the lowest rated current in each unit.

But at series operation with same output voltage, diode is not required to attach even if at (a).

When the output voltage is less than 5V. When the output voltage is more than 12V.

D1~D4: Please use Schottky Barrier Diode. D1 · D2: Please use Schottky Barrier Diode.

423

ZU1R5 • ZU3 • ZU6 • ZU10

ZU/ZT

Model ZUSIR5

ZUWIR5

100

47

33

10

ZUS3

ZUW3

220

100

47

22

ZUS6

ZUW6

470

220

100

47

ZUS10

ZUW10

470

220

100

47

5

12

24

48

Input voltage(V)

Model ZUS1R5

ZUW1R5

100

100

100

ZUS3

ZUW3

220

100

100

ZUS6

ZUW6

220

100

100

ZUS10

ZUW10

220

100

100

3, 5

12

15

Output voltage(V)

Power

supply

+

-

Power

supply

+

-

Load

D1

D2

D4

D3

¿

ZUS10/ZUW10

¡

Series operation is available by connecting the outputs of two or more power supplies as shown below. Output currents in series

connection should be lower than the lowest rated current in each unit.

(c) (d)

4.2 Parallel redundancy operation

¡

Parallel redundancy operation is available by connecting the units as shown below.

I

1, I2 the rated current value

5. Assembling and Installation Method

5.1 Installation method

¡

The unit can be mounted in any direction. Position them with proper intervals to allow enough air ventilation. Ambient temperature around

each power supply should not exceed the temperature range shown in derating curve.

¡

Avoid placing the DC input line pattern layout underneath the unit because it will increase the line conducted noise. Make sure to leave an

ample distance between the line pattern layout and the unit. Also, avoid placing the DC output line pattern underneath the unit because it

may increase the output noise. Lay out the pattern away from the unit.

Fig. 5.1 Pattern wiring

424

ZU1R5 • ZU3 • ZU6 • ZU10

ZU/ZT

YES

NO

5.2 Derating

¡

By derating the output current, it is possible to operate the unit from -20ª~+71ª (-20ª~+85ª at forced air cooling).

¡

When unit mounted any way other than in drawings below, it is required to consider ventilated environments by forced air cooling or

temperature/load derating. For details, please consult our sales or engineering department.

6. Input Voltage/Current Range

¡

When a non-regulated source is used as a front end, make sure that the voltage fluctuation together with the ripple voltage will not exceed

the input voltage range.

¡

Select the converter that is able to handle the start

-

up current(Ip).

Fig. 6.1 Input current characteristics

7. Cleaning

¡

Cleaning is possible by below listed conditions.

Cleaning method

¡

During cleaning to drying (the condition that cleaning liquid is soaked into the ink of name plate), do not touch on the surface of name

plate.

¡

After cleaning, dry them enough.

8. Soldering

¡

Flow soldering : 260ª less than 15 seconds.

¡

Soldering iron : 450ª less than 5 seconds.

425

ZU1R5 • ZU3 • ZU6 • ZU10

ZU/ZT

No.

Classification

1

2

3

4

Cleaning agents Cleaning method

Liquid Temp.

Pine Alpha ST–100S(ARAKAWA CHEMICAL CO.)

Clean Through 750H(KAO Corporation)

IPA

Asahiklin AK–225AES(ASAHI GLASS CO.)

Varnishing or Ultra

sonic wave

Less than

60˚C

Period

Within 5

minutes

Within 2

minutes

–

Varnishing,Ultra sonic

wave, Vapor

Water type

Solvent type

9. Input/Output Pin

¡

When too much stress is applied on the input/output pins of the unit, the internal connection may be weakened. As below Fig. 9.1, avoid

applying stress of more than 19.6N(2kgf) on the pins horizontally and more than 39.2N(4kgf) vertically.

¡

The input/output pins are soldered on PCB internally, therefore, do not pull or bend them with abnormal forces.

¡

When additional stress is expected to be put on the input/output pins because of vibration or impacts, fix the unit on PCB (using silicone

rubber or fixing fittings) to reduce the stress onto the input/output pins.

Fig. 9.1 Stress onto the pins

10. Peak Current (Pulse Load)

¡

It is possible to supply the pulse current for the pulse load by connecting the capacitor externally at the output side.

¡

The average current Iav of output is shown in below formula.

¡

The required electrolytic capacitor C is found by below formula.

426

ZU1R5 • ZU3 • ZU6 • ZU10

ZU/ZT

Iav = Is +

(Iop - Is)t

T

C =

(Iop - Iav)t

∆Vo

1. Pin Connection

¿

Single Output

¿

Dual (±) Output

2. Function

2.1 Input voltage

¡

If the wrong input is applied, the unit will not operate properly and/or may be damaged.

2.2 Overcurrent protection

¡

Overcurrent protection circuit is built

-

in and comes into effect at over 105% of the rated current.

Overcurrent protection prevents the unit from short circuit and over current condition of less than 20 sec.

The unit automatically recovers when the fault condition is cleared.

Fig. 2.1 Overcurrent protection characteristics

2.3 Overvoltage protection

Single Output

¡

The overvoltage protection circuit is built-in and comes into effect at 115~140% of the rated voltage. The DC input voltage should be

shut down if overvoltage protection is in operation. The minimum interval of DC recycling for recovery 2 to 3 minutes(*).

* The recovery time depends on input voltage.

Multiple Output

¡

By detecting overvoltage condition between +V and -V, overvoltage protection circuit comes into effect at 115~140% of the rated

voltage.The DC input voltage should be shut down if overvoltage protection is in operation. The minimum interval of DC recycling for

recovery 2 to 3 minutes(*).

* The recovery time depends on input voltage.

Remarks:

Please note that unit's internal components may be damaged if excessive voltage(over rated voltage)is applied to output terminal of

power supply. This could happen when the customer tests the overvoltage performance of the unit.

427

ZU15 • ZU25

ZU/ZT

No.

q

w

e

r

t

y

u

Pin connection Function

+DC INPUT

-DC INPUT

RC

+DC OUTPUT

COMMON

-DC OUTPUT

TRM

+Side of input voltage

-Side of input voltage

Remote ON/OFF

+Side of output voltage

GND of output voltage(Only applicable for Dual output)

-Side of output voltage

Adjustment voltage range

2.4 Adjustable voltage range

¡

The output voltage is adjustable by external potentiometer.

¡

When the output voltage adjustment is not used, open the TRM pin.

¡

The over voltage protection circuit comes into effect when the output voltage is set too high.

¡

Output voltage is increased by turning potentiometer clockwise and is decreased by turning potentiometer counterclockwise.

¡

The wiring to the potentiometer should be as short as possible and connected to the remote sensing pins (+S and -S).

The temperature coefficient varies depending on the type of resistor and potentiometer.

It is recommended that the following types be used.

Resistor .............. Metal film type. coefficient of less than ±300ppm/ª

Potentiometer........ Cermet type, coefficient of less than ±100ppm/ª

Fig. 2.2 Connection devices outside the power supply

Table 2.1 Devices outside the power supply (Adjustable ±5%)

2.5 Remote ON/OFF

¡

The ground terminal of remote ON/OFF circuit is connected with -V input terminal.

Between RC and -V input: Output voltage is ON at “Low” level or short circuit(0~1.2V)

Between RC and -V input: Output voltage is OFF at “High” level or open circuit(2.4~5.5V)

(Connection example)

or or

Transistor IC Relay

When RC terminal is “Low” level, fan out current is 1mA typ. When Vcc is applied, use 5V

Vcc 24V. When remote ON/OFF function

is not used, please short between RC and -V input.

2.6 Isolation

¡

For a receiving inspection, such as Hi-Pot test, gradually increase(decrease)the voltage for the start(shut down). Avoid using Hi-Pot

tester with the timer because it may generate voltage a few times higher than the applied voltage, at ON/OFF of a timer.

428

ZU15 • ZU25

ZU/ZT

No.

Output

voltage

1

2

3

4

5

3.3V

5V

12V

±12V

±15V

VR

1K

1K

5K

5K

5K

R1

470

100

270

10K

10K

The constant value of devices outside the power supply

(Unit: Ω)

R2

150

270

2.7K

3.9K

2.7K

3. Wiring to Input/Output Pin

¡

The input filter is built

-

in. A capacitor(Ci),if installed near the input terminal, will lower the input conducted noise from converter due to the

formation of the π type filter.

¡

When the distance from the DC line to the unit is greatly extended, it makes the input feedback noise much higher and the input voltage

several times higher than the normal level when turned ON. If this happens, the output power also becomes unstable. In order to prevent

the unit form failing in this way; please connect Ci to the input terminal. In addition, when the filter with "L" is used, please connect Ci to the

input terminal.

Capacity of external capacitor at input terminal: Ci[

µ

F]

Fig. 3.1 Connection method of capacitor at input terminal

¡

To decrease the ripple voltage further, install an external capacitor Co at output terminal as shown below.

Capacity of external capacitor at output terminal: Co[

µ

F]

ZUS ZUW

Fig. 3.2 Connecting method of external capacitor at output terminal

¡

When the distance between load and DC output is long, please install capacitor at load as below.

Fig. 3.3 Connection method of capacitor at load

4. Series Operation and Parallel Operation

4.1 Series operation

¡

Series operation is available by connecting the outputs of two or more power supplies, as shown below.

Output currents in series connection should be lower than the lowest rated current in each unit.

(a) (b)

429

ZU15 • ZU25

ZU/ZT

Model ZUS15

ZUW15

ZUS25

ZUW25

330

150

68

33

470

220

100

47

5

12

24

48

Input voltage(V)

Model ZUS15

ZUW15

ZUS25

ZUW25

220

100

100

220

100

100

3, 5

12

15

Output voltage(V)

4.2 Parallel redundancy operation

¡

Parallel redundancy operation is available by connecting the units as shown below.

¡

Values of I

1 and I2 become unbalanced by a slight different of the output voltage. Make sure that the output voltage of units is of equal

value and the output current from each power supply does not exceed the rated current.

I

1, I2

the rated current value

¡

Use external potentiometer is recommended which can adjust the output voltage.

5. Assembling and Installation Method

5.1 Installation method

¡

The unit can be mounted in any direction. Position them with proper intervals to allow enough air ventilation. Ambient temperature around

each power supply should not exceed the temperature range shown in derating curve.

¡

Avoid placing the DC input line pattern layout underneath the unit because it will increase the line conducted noise. Make sure to leave an

ample distance between the line pattern layout and the unit. Also, avoid placing the DC output line pattern underneath the unit because it

may increase the output noise. Lay out the pattern away from the unit.

Fig. 5.1 Pattern wiring

5.2 Derating

¡

By derating the output current, it is possible to operate the unit from -20ª~+71ª (-20ª~+85ª at forced air cooling).

¡

When unit mounted any way other than in drawings below, it is required to consider ventilated environments by forced air cooling or

temperature/load derating. For details, please consult our sales or engineering departments.

Fig. 5.2 Derating curve

430

ZU15 • ZU25

ZU/ZT

YES

NO

¡

The temperature increase of case surface at full load is shown by below table as referenced data.

Temperature increase on surface of case (ZU series) (Unit: deg)

6. Input Voltage/Current Range

¡

When a non-regulated source is used as a front end, make sure that the voltage fluctuation together with the ripple voltage will not exceed

the input voltage range.

¡

Select the converter that is able to handle the start-up current(Ip).

Fig. 6.1 Input current characteristics

7. Cleaning

¡

Cleaning agents :

¡

Cleaning period : The total time of varnishing, ultrasonic wave and vaper should be within 2 minutes. In case of ultrasonic wave cleaning,

the ultrasonic should be less than 15kw/m

3

. During cleaning to drying (the condition that cleaning liquid is soaked into

the ink of name plate), do not touch on the surface of name plate.

¡

After cleaning, dry them enough.

8. Soldering

¡

Flow soldering : 260ª less than 15 seconds.

¡

Soldering iron : 450ª less than 5 seconds.

431

ZU15 • ZU25

ZU/ZT

Input Voltage Output Voltage

3V, 5V

12V

±12V

±15V

5V

12V

±12V

±15V

5V

12V

±12V

±15V

3V, 5V

12V

±12V

±15V

30

36

39

38

28

34

36

35

31

38

34

27

21

23

24

26

38

42

39

40

36

42

43

45

32

38

36

35

28

25

31

31

15W 25W

5V

12V

24V

48V

No.

Classification

Cleanig agents

1

2

3

4

Pine Alpha ST-100S(ARAKAWA CHEMICAL CO.)

Clean Through 750H(KAO Corporation)

IPA

Asahiklin AK-225AES(ASAHI GLASS CO.)

Water type

Solvent type

9. Input/Output Pin

¡

When too much stress is applied on the input/output pins of the unit, the internal connection may be weakened. As below Fig. 9.1, avoid

applying stress of more than 19.6N(2kgf)on the pins horizontally and more than 39.2N(4kgf)vertically.

¡

The input/output pins are soldered on PCB internally, therefore, do not pull or bend them with abnormal forces.

¡

When additional stress is expected to be put on the input/output pins because of vibration or impacts, fix the unit on PCB (using silicone

rubber or fixing fittings) to reduce the stress onto the input/output pins.

Fig. 9.1 Stress onto the pins

10. Peak Current (Pulse Load)

¡

It is possible to supply the pulse current for the pulse load by connecting the capacitor externally at the output side.

¡

The average current Iav of output is shown in below formula.

¡

The required electrolytic capacitor C is found by below formula.

432

ZU15 • ZU25

ZU/ZT

Iav = Is +

(Iop - Is)t

T

C =

(Iop - Iav)t

∆Vo

433

ZU/ZT

1. Pin Connection

¿

Single Output

¿

Dual(±)Output

¿

Case Connectiong Pin

Case connecting pin is available. By connecting the pin to -side

of input, the radiation noise from main body can be reduced.

2. Function

2.1 Input voltage

¡

If the wrong input is applied, the unit will not operate properly and/or may be damaged.

2.2 Overcurrent protection

¡

Overcurrent protection circuit is built-in and comes into effect at over 105% of the rated current.

Overcurrent protection prevents the unit from short circuit and over current condition of less than 20 sec. The unit automatically recovers

when the fault condition is cleared.

¡

The power supply which has a current foldback characteristics may not start up when connected to nonlinear load such as lamp, motor or

constant current load. See the characteristics below.

Fig. 2.1 Current foldback characteristics

2.3 Isolation

¡

For a receiving inspection, such as Hi-Pot test, gradually increase(decrease)the voltage for the start(shut down). Avoid using Hi-Pot

tester with the timer because it may generate voltage a few times higher than the applied voltage, at ON/OFF of a timer.

ZT1R5 • ZT3

q-Vw

+V

r+Vt

NC

COM

y

-V

e

S

IN OUT

No.

q

w

e

r

t

y

Pin connection Function

-DC INPUT

+DC INPUT

+DC OUTPUT

NC(Single output)

COM(Dual output)

-DC OUTPUT

If connected to -side of input, the case potential can be

fixed and the value of radiation noise can be reduced.

-Side of input voltage

+Side of input voltage

+Side of output voltage

No Connection

GND of output voltage(Only applicable for Dual output)

-Side of output voltage

Case Connecting

Pin

: Load characteristics of power supply

: Characteristics of load (lamp, motor, constant current load, etc.)

Note: In case of nonlinear load, the output is locked out at A point.

434

3. Wiring to Input/Output Pin

¡

Input filter is built

-

in. A capacitor Ci, if installed near the input terminal, will lower the input conducted noise from converter due to the

formation of the π type filter.

¡

When the distance from the DC line to the unit is greatly extended, it makes the input feedback noise much higher and the input voltage

several times higher than the normal level when turned ON. If this happens, the output power also becomes unstable. In order to prevent

the unit form failing in this way; please connect Ci to the input terminal. In addition, when the filter with "L" is used, please Ci to the input

terminal.

Capacity of external capacitor at input terminal: Ci[

µ

F]

Fig. 3.1 Connecting method of capacitor at input terminal

¡

To lower the output ripple voltage further, install an external capacitor Co at output terminal as shown below.

Capacity of external capacitor at output terminal: Co[

µ

F]

ZTS ZTW

Fig. 3.2 Connecting method of external capacitor at output terminal

¡

When the distance between load and DC output is long, please install capacitor at load as shown below.

Fig. 3.3 Connection method of capacitor at load

4. Series Operation and Parallel Operation

4.1 Series operation

¡

Series operation is available by connecting the outputs of two or more power supplies, as shown below. Output currents in series

connection should be lower than the lowest rated current in each unit.

But at series operation with same output voltage, diode is not required to attach even if at (a).

When the output voltage is less than 5V. When the output voltage is more than 12V.

D1~D4: Please use Schottky Barrier Diode. D1, D2: Please use Schottky Barrier Diode.

ZU/ZT

ZT1R5 • ZT3

Model ZTSIR5

ZTWIR5

100

47

33

10

ZTS3

ZTW3

220

100

47

22

5

12

24

48

Input voltage(V)

Model ZTS1R5

ZTW1R5

100

100

100

ZTS3

ZTW3

220

100

100

5

12

15

Output voltage(V)

Power

supply

+

-

Power

supply

+

-

Load

D1

D2

D4

D3

435

4.2 Parallel redundancy operation

¡

Parallel redundancy operation is available by connecting the units as shown below.

I

1, I2

the rated current value

5. Assembling and Installation Method

5.1 Installation method

¡

The unit can be mounted in any direction. Install the device, with proper intervals to allow enough air ventilation.

5.2 Derating

¡

Ambient temperature around each power supply should not exceed

the temperature range shown in derating curve.

6. Input Voltage/Current Range

¡

When a non-regulated source is used as a front end, make sure that the voltage fluctuation together with the ripple voltage will not exceed

the input voltage range.

¡

Select the converter that is able to handle the start-up current(Ip).

Fig. 6.1 Input current characteristics

ZU/ZT

ZT1R5 • ZT3

100

50

13

4

0

-

20 0 102030405060

(71) (85)

70 80 90

-

10

Load factor [%]

Ambient temperature [ª]

¶1 ZTS30512, ZTS30515

ZTW30512, ZTW30515

1

Convection[¶1 models]

2

Convection[Other models]

3

Forced air(500R/min)[¶1 models]

4

Forced air(500R/min)[Other models]

2

436

7. Cleaning

¡

Cleaning is possible by below listed conditions.

Cleaning method

¡

During cleaning to drying (the condition that cleaning liquid is soaked into the ink of name plate), do not touch on the surface of name

plate.

¡

After cleaning, dry them enough.

8. Soldering

¡

Flow soldering : 260ª less than 15 seconds.

¡

Soldering iron : 450ª less than 5 seconds.

9. Input/Output Pin

¡

When too much stress is applied on the input/output pins of the unit, the internal connection may be weakened. As below Fig. 9.1, avoid

applying stress of more than 9.8N(1kgf) on the pins horizontally and more than 19.6N(2kgf) vertically.

¡

When additional stress is expected to be put on the input/output pins because of vibration or impacts, fix the unit on PCB (using silicone

rubber or fixing fittings) to reduce the stress onto the input/output pins.

Fig. 9.1 Stress onto the pins

ZU/ZT

ZT1R5 • ZT3

No.

Classification

1

2

3

4

Cleaning agents Cleaning method

Liquid Temp.

Pine Alpha ST–100S(ARAKAWA CHEMICAL CO.)

Clean Through 750H(KAO Corporation)

IPA

Asahiklin AK–225AES(ASAHI GLASS CO.)

Varnishing or Ultra

sonic wave

Less than

60˚C

Period

Within 5

minutes

Within 2

minutes

–

Varnishing,Ultra sonic

wave, Vapor

Water type

Solvent type

Less than

9.8N(1kgf)

Less than

9.8N(1kgf)

Less than 19.6N(2kgf)

A part

A

437

10. Peak Current (Pulse Load)

¡

It is possible to supply the pulse current for the pulse load by connecting the capacitor externally at the output side.

¡

The average current Iav of output is shown in below formula.

¡

The required electrolytic capacitor C is found by below formula.

ZU/ZT

ZT1R5 • ZT3

Iav = Is +

(Iop - Is)t

T

C =

(Iop - Iav)t

∆Vo

Loading...

Loading...