Page 1

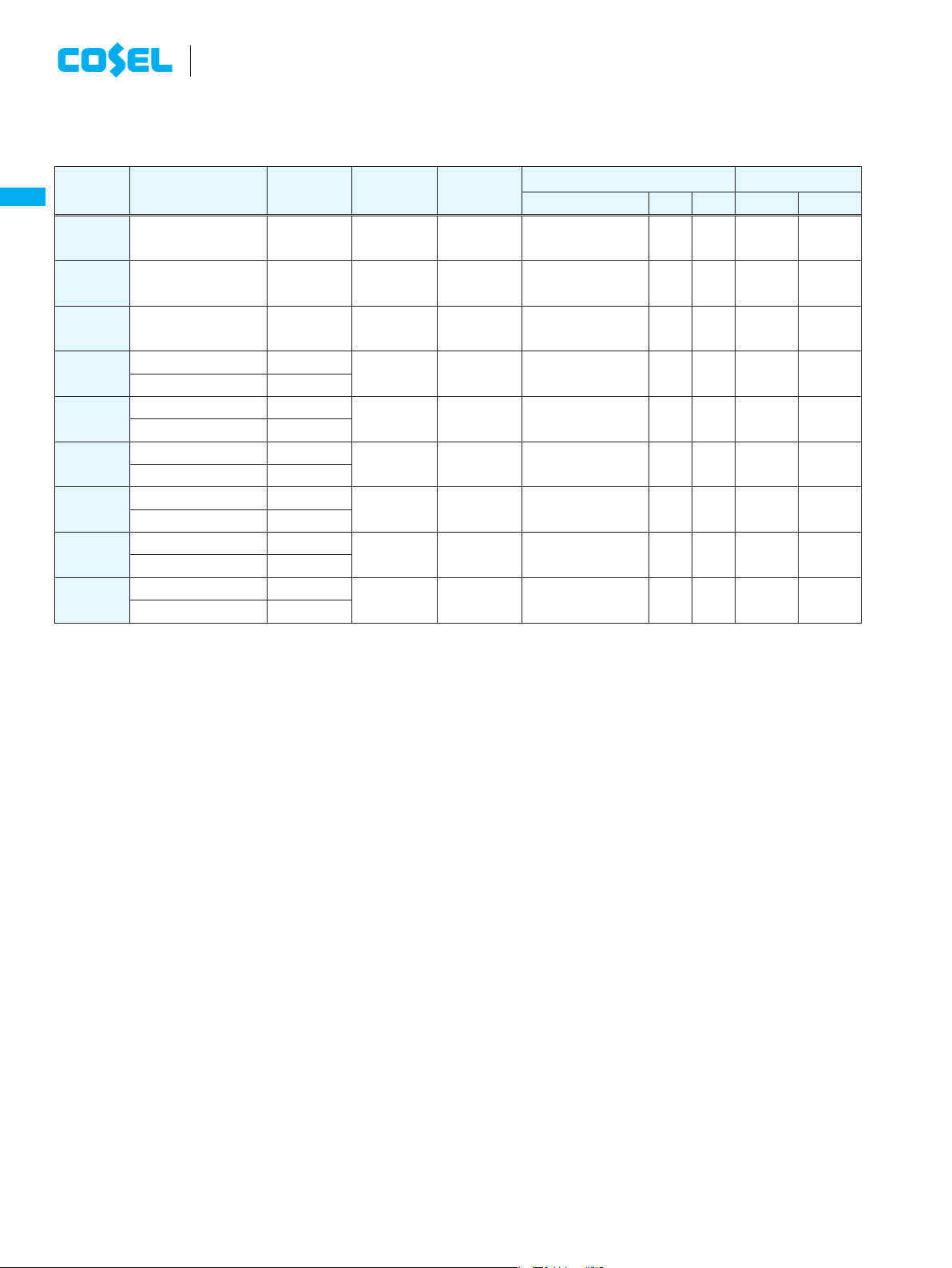

Basic Characteristics Data

Basic Characteristics Data

Inrush

current

protection

PCB/Pattern

Material

Single

sided

Double

sided

LFA

Model Circuit method

Switching

frequency

[kHz]

*1

Input

current

[A]

LFA10F Flyback converter 100 0.26 LF CEM-3 Yes Yes No

LFA15F Flyback converter 100 0.35 Thermistor CEM-3 Yes Yes No

LFA30F Flyback converter 130 0.65 Thermistor CEM-3 Yes Yes No

Series/Parallel

operation availability

Series

operation

Parallel

operation

*2

LFA50F

LFA75F

LFA100F

LFA150F

LFA240F

LFA300F

*1 The value of input current is at ACIN 100V and rated load.

*2 Refer to Instruction Manual 2.

Active fi lter 60-440

Flyback converter 130

Active fi lter 60-440

Flyback converter 130

Active fi lter 60

Forward converter 140

Active fi lter 60

Forward converter 140

Active fi lter 60

Forward converter 140

Active fi lter 60

Forward converter 140

0.67 Thermistor CEM-3 Yes Yes No

1.0 Thermistor CEM-3 Yes Yes No

1.3 Thermistor CEM-3 Yes Yes No

2.0 Thermistor CEM-3 Yes Yes No

3.3 SCR CEM-3 Yes Yes No

4.1 SCR CEM-3 Yes Yes No

LFA-20

Page 2

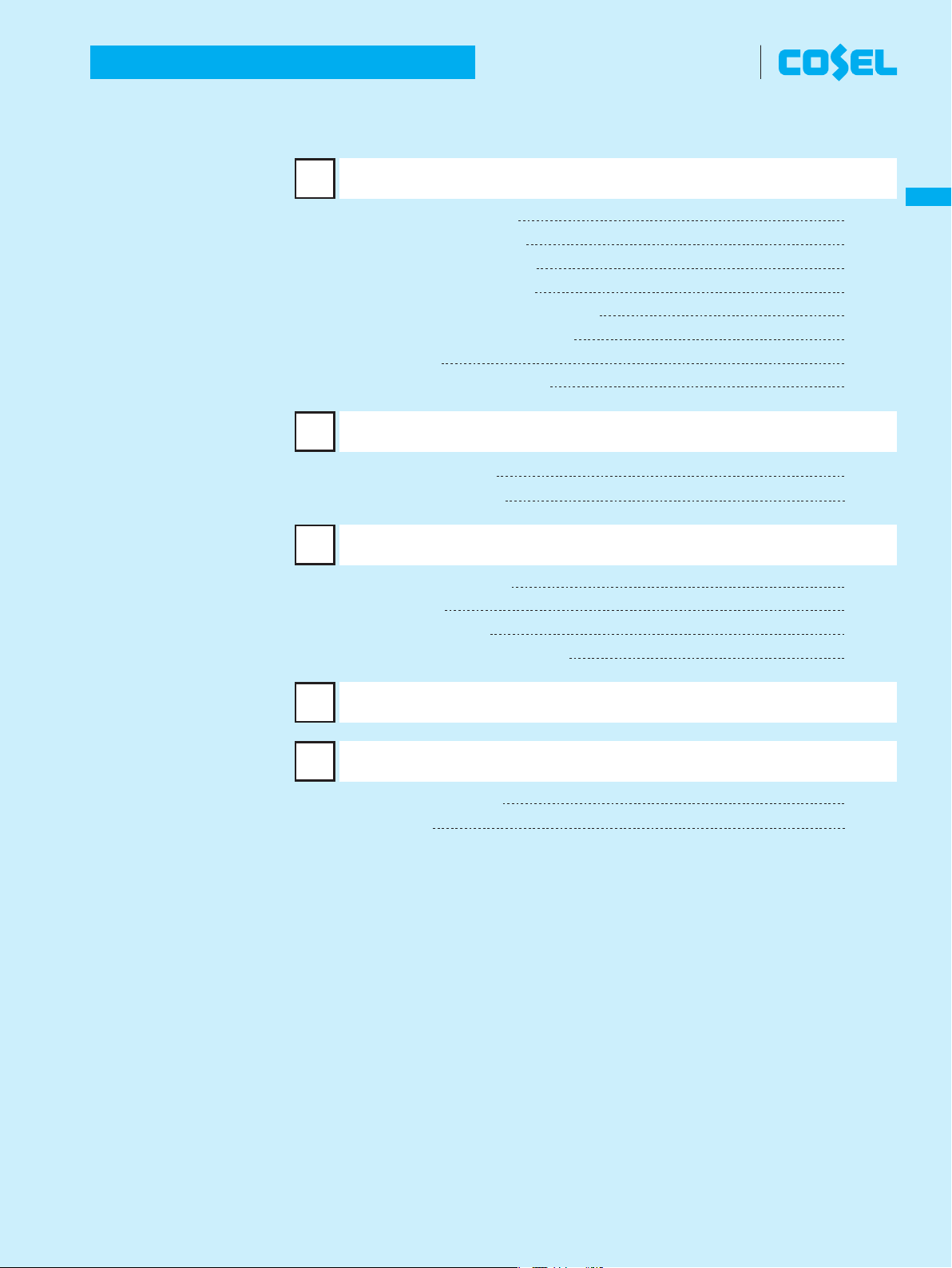

AC-DC Power Supplies Open Frame/ Enclosed Type

Instruction Manual

1 Function

1.1 Input voltage range

1.2 Inrush current limiting

1.3 Overcurrent protection

1.4 Overvoltage protection

1.5 Output voltage adjustment range

1.6 Output ripple and ripple noise

1.7 Isolation

1.8 Reducing standby power

2 Series Operation and Parallel Operation

2.1 Series Operation

2.2 Parallel Operation

3 Assembling and Installation Method

3.1 Installation method

3.2 Derating

3.3 Mounting screw

3.4 Expectancy life and warranty

LFA-22

LFA

LFA-22

LFA-22

LFA-22

LFA-22

LFA-22

LFA-23

LFA-23

LFA-23

LFA-23

LFA-23

LFA-24

LFA-24

LFA-24

LFA-24

LFA-28

LFA-28

4 Ground

5 Option and Others

5.1 Outline of options

5.2 Others

LFA-30

LFA-30

LFA-30

LFA-32

LFA-21

Page 3

AC-DC Power Supplies Open Frame/ Enclosed Type

1 Function

LFA

1.1 Input voltage range

The range is from AC85V to AC264V or DC120V to DC370V

¡

(please see SPECIFICATIONS for details).

In cases that conform with safety standard, input voltage range is

¡

AC100-AC240V (50/60Hz).

If input value doesn’t fall within above range, a unit may not oper-

¡

ate in accordance with specifi cations and/or start hunting or fail.

If you need to apply a square waveform input voltage, which is

commonly used in UPS and inverters, please contact us.

When the input voltage changes suddenly, the output voltage ac-

¡

curacy might exceed the specifi cation. Please contact us.

LFA10F, LFA15F, LFA30F

¿

A power factor improvement circuit (active fi lter) is not built-in. If

¡

you use multiple units for a single system, standards for input harmonic current may not be satisfi ed. Please contact us for details.

LFA10F, LFA15F, LFA30F, LFA50F, LFA75F,

¿

LFA100F, LFA150F, LFA240F, LFA300F

Operation stop voltage is set at a lower value than that of a stan-

¡

dard version (derating is needed).

-Use Conditions

LFA10F 5W (3W)

LFA15F 7.5W (5W)

LFA30F 10W (7.5W)

LFA50F 15W (10W)

LFA75F 25W (15W)

LFA100F 30W (20W)

LFA150F 50W (30W)

LFA240F 80W

LFA300F 100W (75W)

Input AC50V or DC70V

Duty 1s/30s

Please avoid using continuously for more than 1 second

*

under above conditions. Doing so may cause a failure.

Output ( ) 3.3V

Instruction Manual

LFA240F, LFA300F

¿

Thyristor technique is used in the inrush current limiting circuit.

¡

When you turn power ON/OFF repeatedly within a short period of

time, please have enough intervals so that the inrush current limiting circuit becomes operative.

When the switch of the input is turned on, the primary inrush cur-

¡

rent and secondary inrush current will be generated because the

thyristor technique is used for the inrush current limiting circuit.

1.3 Overcurrent protection

An overcurrent protection circuit is built-in and activated at 105%

¡

of the rated current or 101% of the peak current. A unit automatically recovers when a fault condition is removed.

Please do not use a unit in short circuit and/or under an overcurrent condition.

Intermittent Operation Mode

¡

Intermittent operation for overcurrent protection is included in a

part of series. When the overcurrent protection circuit is activated

and the output voltage drops to a certain extent, the output becomes intermittent so that the average current will also decrease.

1.4 Overvoltage protection

An overvoltage protection circuit is built-in. If the overvoltage pro-

¡

tection circuit is activated, shut down the input voltage, wait more

than 3 minutes and turn on the AC input again to recover the output voltage. Recovery time varies depending on such factors as

input voltage value at the time of the operation.

In option -R2, overvoltage protection is removed by toggling ON/

¡

OFF signal of remote control.

Remarks :

Please avoid applying a voltage exceeding the rated voltage to an

output terminal. Doing so may cause a power supply to malfunction or fail. If you cannot avoid doing so, for example, if you need

to operate a motor, etc., please install an external diode on the

output terminal to protect the unit.

1.5 Output voltage adjustment range

1.2 Inrush current limiting

An inrush current limiting circuit is built-in.

¡

If you need to use a switch on the input side, please select one

¡

that can withstand an input inrush current.

LFA10F

¿

Resistance for line fi lter is used for inrush current limiting.

¡

LFA15F, LFA30F, LFA50F, LFA75F, LFA100F,

¿

LFA150F

Thermistor is used in the inrush current limiting circuit. When you

¡

turn the power ON/OFF repeatedly within a short period of time,

please have enough intervals so that a power supply cools down

before being turned on.

LFA-22

Adjustment of output voltage is possible by using potentiometer.

¡

Please refer to instruction manual 5.1.

Option ”-Y” is recommended which can adjust the output voltage.

¡

Page 4

AC-DC Power Supplies Open Frame/ Enclosed Type

Instruction Manual

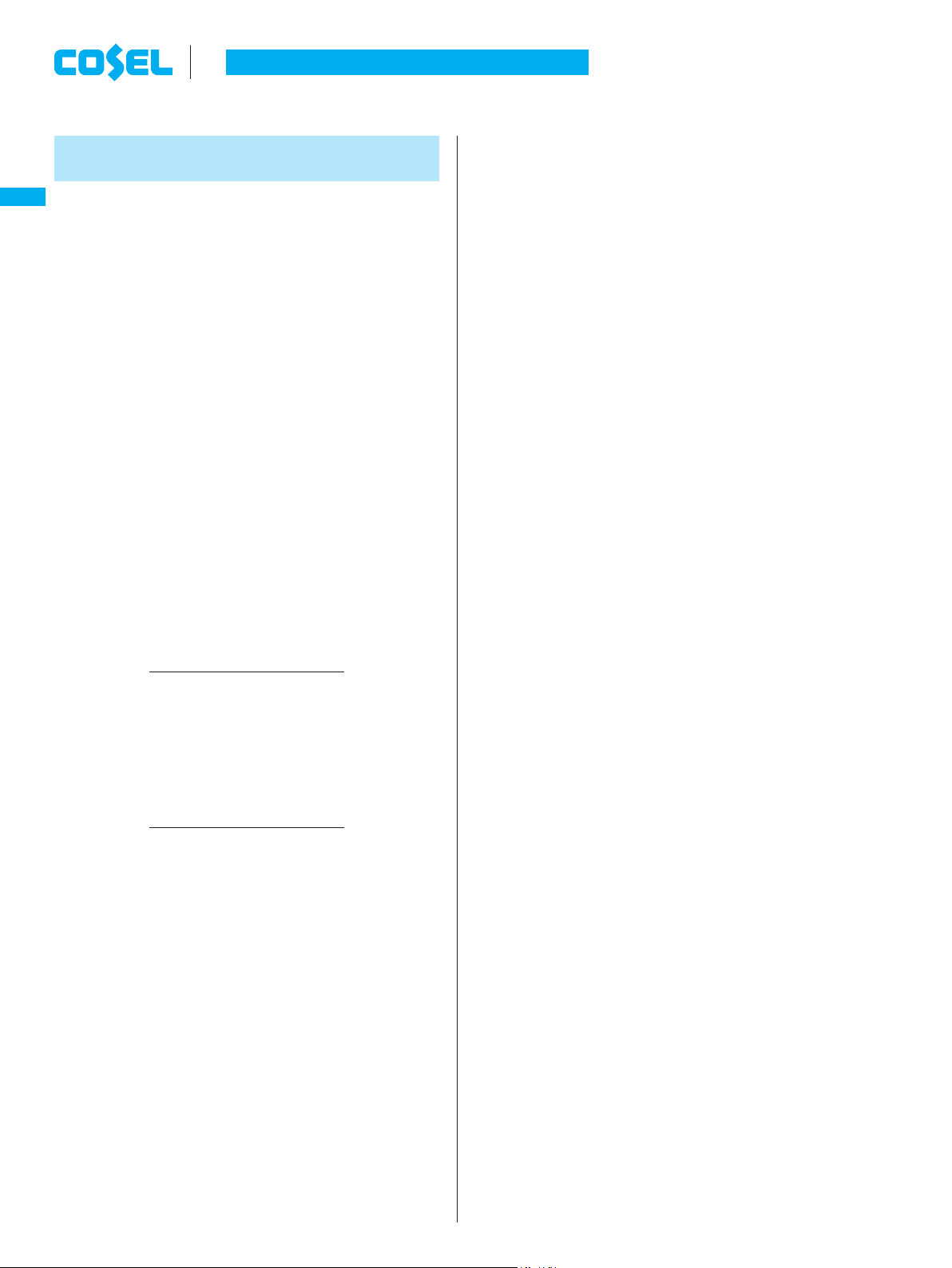

1.6 Output ripple and ripple noise

Output ripple noise may be infl uenced by measurement environ-

¡

ment, measuring method fi g.1.1 is recommended.

+Vout

2

C

1

C

+

-Vout

Osiloscope/

Ripple noise meter

Bw:20MHz

1 :

Film capacitor 0.1μF

C

2 :

Aluminum electrolytic capacitor 22μF

C

Fig.1.1 Measuring method of Ripple and Ripple Noise

Remarks :

When GND cable of probe with fl ux of magnetic force from power

supply are crossing, ripple and ripple noise might not measure

correctly.

Please note the measuring environment.

150mm

Differential probe

Load

LFA100F, LFA150F, LFA240F, LFA300F

¿

As for option -R2, reducing standby power is possible by OFF sig-

¡

nal of the remote control.

Please refer to instruction manual 5.1.

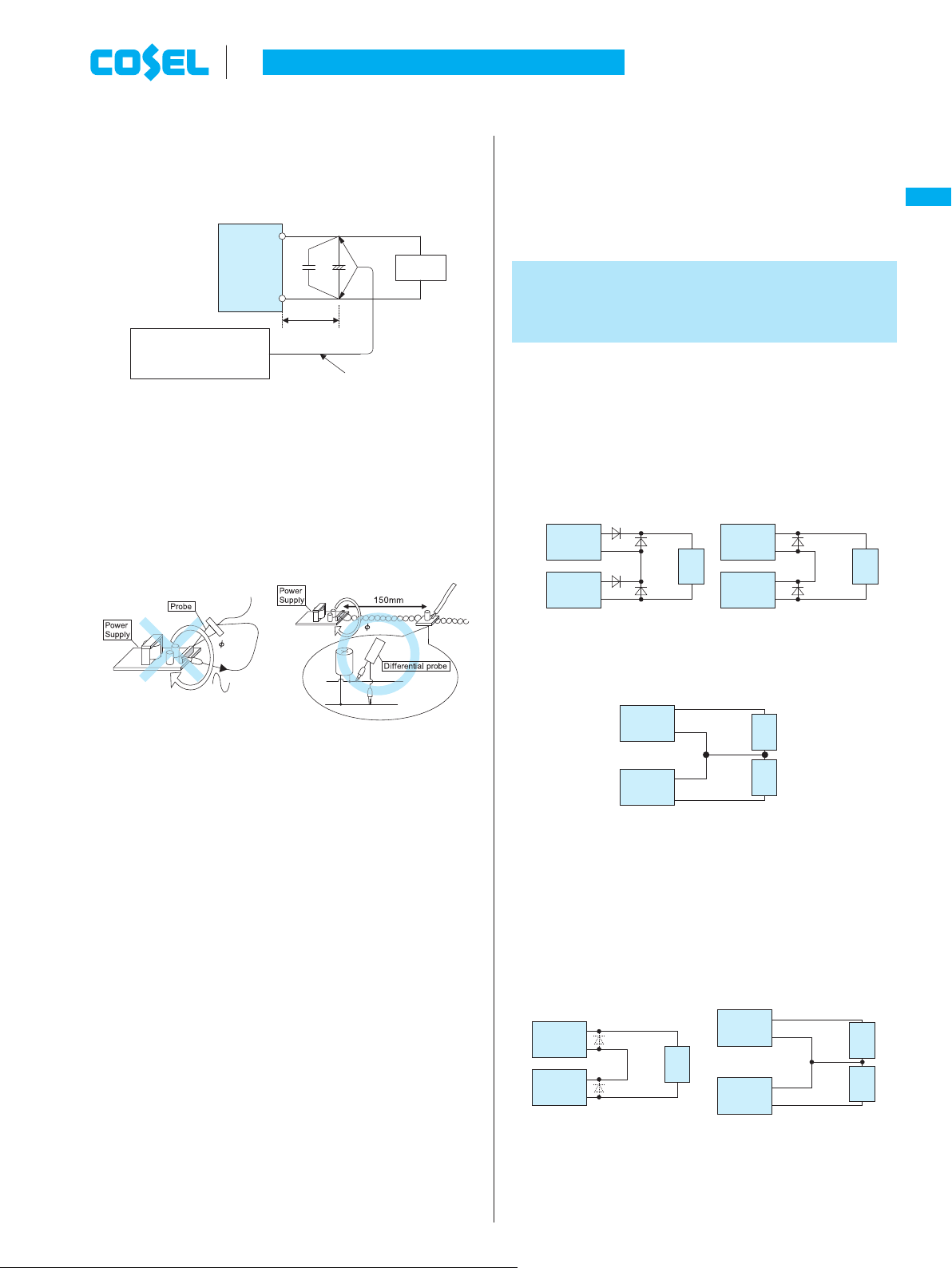

2 Series Operation and

Parallel Operation

2.1 Series Operation

LFA10F, LFA15F, LFA30F, LFA50F, LFA75F

¿

Series operation is available by connecting the outputs of two or

¡

more power supplies with the same output voltage, as shown below. Output current in series connection should be lower than the

lowest rated current in each unit.

12V or less 15V or more

Power

+

Supply

-

Power

+

-

Supply

D1-D4 : Use a schottky barrier

diode with low forward

voltage.

Fig.2.1 Examples of connecting in series operation (a)

D1

D3

D2

D4

Power

+

Supply

Load

Power

Supply

D1,D2 : Use a schottky barrier

D1

-

+

D2

-

diode with low forward

voltage.

LFA

Load

Bad example Good example

Fig.1.2. Example of measuring output ripple and ripple noise

1.7 Isolation

For a receiving inspection, such as Hi-Pot test, gradually increase

¡

(decrease) the voltage for the start (shut down). Avoid using HiPot tester with the timer because it may generate voltage a few

times higher than the applied voltage, at ON/OFF of a timer.

1.8 Reducing standby power

LFA10F, LFA15F

¿

A circuit reducing standby power is built in LFA10F and LFA15F.

¡

(standby power : 0.5W typ)

The load factor: Io=0-35%, the internal switch element is intermit-

tent operated, and the switching loss is decreased.

The specification of the Ripple/Ripple Noise changes by this

intermittent operation. The value of the ripple/ripple Noise when

intermittent operates changes in the input voltage and the output

current.

Please contact us for details.

+

Power

Supply

-

Power

+

Supply

-

Fig.2.2 Examples of connecting in series operation (b)

LFA100F, LFA150F, LFA240F, LFA300F

¿

You can use a power supply in series operation. The output cur-

¡

rent in series operation should be lower than the rated current of a

power supply with the lowest rated surrent among power supplies

that are serially connected. Please make sure that no surrent exceeding the rated current fl ows into a power supply.

Power

+

Supply

Power

Supply

Only LFA300F -3R3 and -5.

*

Use a schottky barrier diode

with low forward voltage.

*

-

+

*

-

(a) (b)

Fig.2.3 Examples of connecting in series operation

Load

Power

Supply

Power

Supply

Load Load

+

-

LoadLoad

+

-

LFA-23

Page 5

AC-DC Power Supplies Open Frame/ Enclosed Type

2.2 Parallel Operation

Parallel operation is not possible.

¡

Redundancy operation is available by wiring as shown below.

¡

LFA

I1 I3

Power

Supply

+

-

Instruction Manual

There is a possibility that it is not possible to cool enough when

¡

the power supply is used by the sealing up space as showing in

Figure 3.2.

Please use it after confi rming the temperature of point A and point

B of Instruction Manual 3.2.

Case

I

2

Power

Supply

Fig.2.4 Example of redundancy operation

Even a slight difference in output voltage can affect the balance

¡

between the values of I

Please make sure that the value of I

current of a power supply.

+

-

and I2.

1

does not exceed the rated

3

[ the rated current value

I

3

Load

3 Assembling and

Installation Method

3.1 Installation method

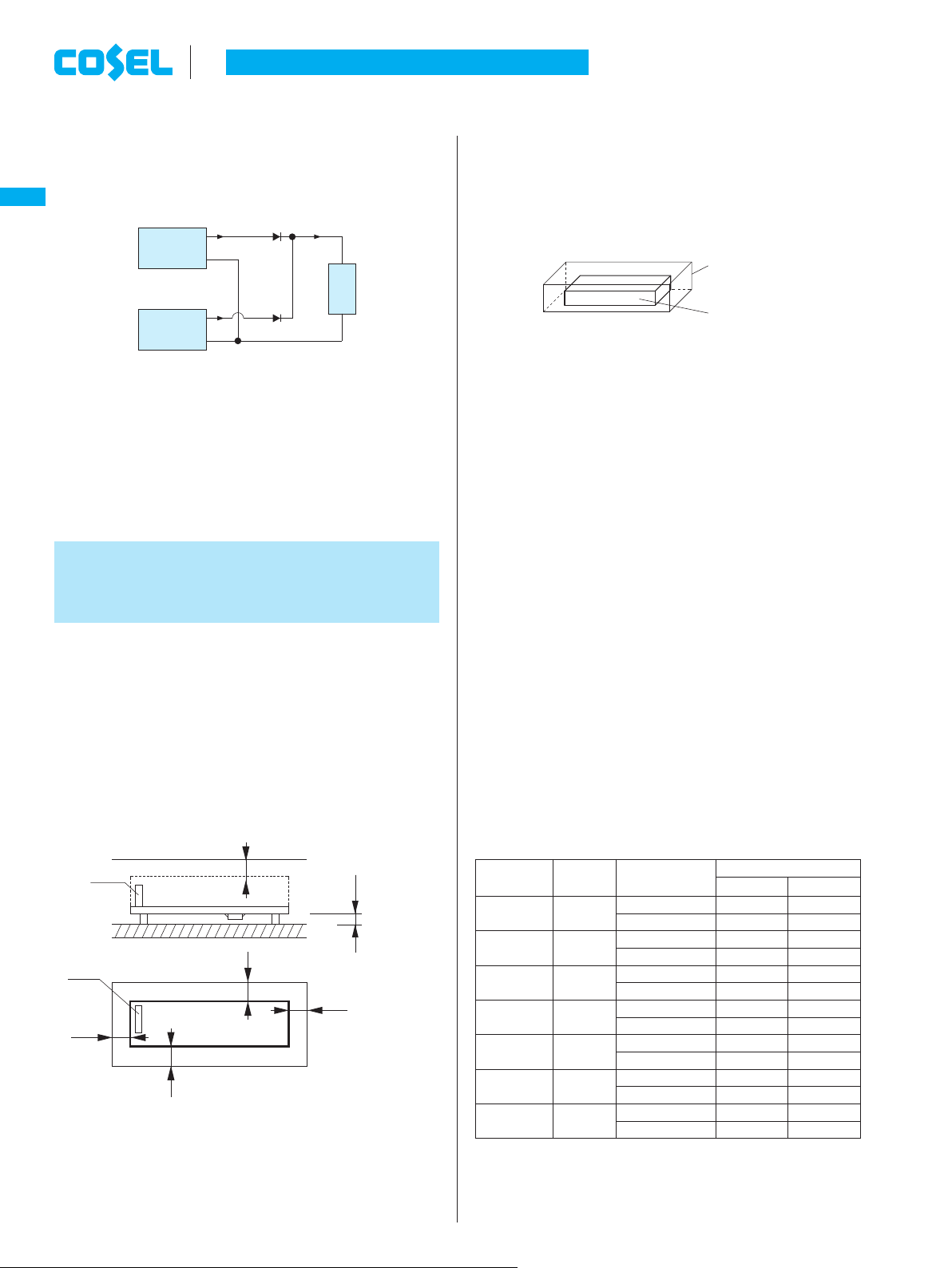

This power supply is manufactured by SMD technology.

¡

The stress to P.C.B like twisting or bending causes the defect of

the unit,so handle the unit with care.

In case of metal chassis, keep the distance between d

¡

insulate between lead of component and metal chassis, use the

spacer of 8mm or more between d

the insulation sheet between power supply and metal chassis.

. If it is less than d1 & d2, insert

1

& d2 for to

1

Power supply

Fig.3.2 Installation example

3.2 Derating

Environment to use it and Installation environment

¡

When using it,it is necessary to radiate heat by the heat of the pow-

er supply.

Table 3.1 - 3.9 shows the relation between the upper limit tempera-

ture (Point A and Point B) and load factors.

Please consider the ventilation so that the convection which is

enough for the whole power supply is provided.

And temperature of Point A and Point B please become lower than

upper limit temperature.

The expectancy life in the upper bound temperature (Point A and

Point B) is three years or more.

Please refer to External View for the position of Point A and Point B.

In case of with Chassis and Cover, please contact our sales offi ce

for getting more information.

Remarks:

Please be careful of electric shock or earth leakage in case of

*

temperature measurement, because Point A and Point B is live

potential.

Please refer to 3.4 if you want to extend the longevity of the ex-

*

pectancy life.

CN1

d

LFA-24

2

CN1

d

2

d

2

d2

Fig.3.1 Installation method

d2

=4mm min

d2

=8mm min

d1

Table 3.1 Temperatures of Point A, Point B LFA10F-

Mounting

Method

A

B

C

D

E

F

A,B,C,D,E,F Forced air

Cooling

Method

Convection

Convection

Convection

Convection

Convection

Convection

Load factor

20%<Io[100% 70 84

Io[20% 75 79

20%<Io[100% 70 81

Io[20% 73 77

20%<Io[100% 76 80

Io[20% 76 77

20%<Io[100% 70 78

Io[20% 75 77

20%<Io[100% 73 84

Io[20% 76 79

20%<Io[100% 74 80

Io[20% 76 78

70%<Io[100% 75 75

Io[70% 75 75

Max temperature

Point A[C] Point B[C]

O

Page 6

AC-DC Power Supplies Open Frame/ Enclosed Type

Instruction Manual

Table 3.2 Temperatures of Point A, Point B LFA15F-

Mounting

Method

A

B

C

D

E

F

A,B,C,D,E,F Forced air

Table 3.3 Temperatures of Point A, Point B

Mounting

Method

A

B

C

D

E

F

A,B,C,D,E,F Forced air

Table 3.4 Temperatures of Point A, Point B

Mounting

Method

A

B

C

D

E

F

A,B,C,D,E,F Forced air

Cooling

Method

Convection

Convection

Convection

Convection

Convection

Convection

Cooling

Method

Convection

Convection

Convection

Convection

Convection

Convection

Cooling

Method

Convection

Convection

Convection

Convection

Convection

Convection

Load factor

40%<Io[100% 72 80

Io[40% 77 81

40%<Io[100% 68 73

Io[40% 74 78

40%<Io[100% 75 84

Io[40% 78 81

40%<Io[100% 71 77

Io[40% 76 79

40%<Io[100% 70 79

Io[40% 76 81

40%<Io[100% 71 78

Io[40% 76 80

70%<Io[100% 75 75

Io[70% 75 75

Load factor

70%<Io[100% 73 73

Io[70% 79 77

60%<Io[100% 73 74

Io[60% 80 82

70%<Io[100% 80 77

Io[70% 83 80

70%<Io[100% 72 70

20%<Io[70% 80 77

Io[20% 79 80

70%<Io[100% 73 79

20%<Io[70% 79 85

Io[20% 77 81

70%<Io[100% 73 75

Io[70% 79 79

70%<Io[100% 75 75

Io[70% 75 75

Load factor

70%<Io[100% 86 68

Io[70% 86 77

70%<Io[100% 72 65

Io[70% 77 70

50%<Io[100% 78 71

Io[50% 84 77

50%<Io[100% 83 68

Io[50% 85 72

50%<Io[100% 76 75

Io[50% 83 81

50%<Io[100% 80 78

Io[50% 84 76

70%<Io[100% 75 75

Io[70% 75 75

Max temperature

Point A[C] Point B[C]

LFA30F-O

Max temperature

Point A[C] Point B[C]

LFA50F-O

Max temperature

Point A[C] Point B[C]

O

Table 3.5 Temperatures of Point A, Point B

Mounting

Method

A

B

C

D

E

F

A,B,C,D,E,F Forced air

Table 3.6 Temperatures of Point A, Point B

Mounting

Method

A

B

C

D

E

F

A,B,C,D,E,F Forced air

Table 3.7 Temperatures of Point A, Point B

Mounting

Method

A

B

C

D, F

E

A,B,C,D,E,F Forced air

Cooling

Method

Convection

Convection

Convection

Convection

Convection

Convection

Cooling

Method

Convection

Convection

Convection

Convection

Convection

Convection

Cooling

Method

Convection

Convection

Convection

Convection

Convection

Load factor

70%<Io[100% 85 70

Io[70% 86 76

70%<Io[100% 77 65

Io[70% 81 71

70%<Io[100% 81 68

Io[70% 83 72

70%<Io[100% 78 58

10%<Io[70% 80 63

Io[10% 84 72

70%<Io[100% 73 66

10%<Io[70% 83 68

Io[10% 83 79

70%<Io[100% 74 59

Io[70% 83 71

70%<Io[100% 75 75

Io[70% 75 75

Load factor

70%<Io[100% 85 74

50%<Io[70% 88 79

Io[50% 88 83

70%<Io[100% 77 72

50%<Io[70% 87 82

Io[50% 88 86

70%<Io[100% 87 82

Io[70% 88 85

70%<Io[100% 80 70

Io[70% 85 80

70%<Io[100% 74 85

Io[70% 80 88

70%<Io[100% 79 71

50%<Io[70% 88 77

Io[50% 88 79

70%<Io[100% 75 75

Io[70% 75 75

Load factor

60%<Io[100% 79 75

20%<Io[60% 86 85

Io[20% 87 87

70%<Io[100% 75 70

30%<Io[70% 85 78

Io[30% 86 81

60%<Io[100% 81 75

30%<Io[60% 86 81

Io[30% 87 83

70%<Io[100% 73 67

30%<Io[70% 83 76

Io[30% 84 77

70%<Io[100% 73 75

30%<Io[70% 82 83

Io[30% 83 84

70%<Io[100% 75 75

Io[70% 75 75

LFA75F-

LFA100F-

LFA150F-

O

Max temperature

Point A[C] Point B[C]

LFA

O

Max temperature

Point A[C] Point B[C]

O

Max temperature

Point A[C] Point B[C]

LFA-25

Page 7

AC-DC Power Supplies Open Frame/ Enclosed Type

Instruction Manual

Table 3.8 Temperatures of Point A, Point B LFA240F-

Mounting

Method

LFA

A

Cooling

Method

Convection

Load factor

Max temperature

Point A[C] Point B[C]

75%<Io[100% 75 70

50%<Io[75% 82 79

Io[50% 86 85

75%<Io[100% 63 61

B

Convection

50%<Io[75% 73 73

Io[50% 81 83

75%<Io[100% 76 73

C

Convection

50%<Io[75% 81 79

Io[50% 87 85

75%<Io[100% 66 55

D

Convection

50%<Io[75% 74 65

Io[50% 84 78

75%<Io[100% 62 62

E

Convection

50%<Io[75% 73 74

Io[50% 81 84

75%<Io[100% 68 62

F

Convection

50%<Io[75% 77 73

Io[50% 84 83

A,B,C,D,E,F Forced air

70%<Io[100% 75 75

Io[70% 75 75

Table 3.9 Temperatures of Point A, Point B, Point C, Point D LFA300F-

Mounting

Method

A,B,C,D,E and F

(3.3V/5V/12V/15V)

A,B,C,D,E and F

(24V/30V/36V/48V)

A

B

C

D

E

F

Cooling

Method

Convection

Convection

Convection

Convection

Convection

Convection

Forced air

Forced air

Load factor

80%<Io[100%

60%<Io[80%

Io[60%

80%<Io[100%

60%<Io[80%

Io[60%

80%<Io[100%

60%<Io[80%

Io[60%

80%<Io[100%

60%<Io[80%

Io[60%

80%<Io[100%

60%<Io[80%

Io[60%

80%<Io[100%

60%<Io[80%

Io[60%

50%<Io[100%

Io[50%

50%<Io[100%

Io[50%

Max temperature

Point A[C] Point B[C] Point C[C] Point D[C]

70 86

75 88

79 89

57 68

62 71

71 79

69 75

74 75

83 82

58 62

64 66

75 75

57 80

63 83

74 88

61 68

68 71

76 80

75 75 85 85

75 75 85 85

75 75 85 85

75 75 85 85

O

The operative ambient temperature is different by with / without

¡

chassis cover or mounting position. Derating curve is shown below.

Note: In the hatched area, the specification of Ripple, Ripple

Noise is different from other area.

LFA10F

¿

(B), (C)mounting(A), (D), (E), (F)mounting

11

(A) ~ (F)

60 [50

]

2

mounting

]

100

80

60

40

35

20

Load factor [%]

0

-10 70 [60

1

Convection

2

Forced air (0.5m3/min

20100

Inside[ ] is with case cover

*

4030

)

]

50 [40

[C]Ambient temperature

Fig.3.3 Ambient temperature derating curve (refer to Table 3.1)

LFA15F

¿

(A), (B), (C), (D)mounting(E), (F)mounting

11

(A) ~ (F)

60 [50

]

2

mounting

]

100

80

O

60

40

35

20

Load factor [%]

0

-10 70 [60

1

Convection

2

Forced air (0.5m3/min

20100

Inside[ ] is with case cover

*

)

]

50 [40

[30]4030

[C]Ambient temperature

Fig.3.4 Ambient temperature derating curve (refer to Table 3.2)

LFA30F

¿

(A), (C)mounting(D), (E)mounting

(F)mounting

100

80

60

40

20

Load factor [%]

0

-10 70 [60

1

1

Convection

2

Forced air (0.5m3/min)

20100

Inside[ ] is with case cover

*

40 [30

30

11

(B)mounting

1

]

]

[C]Ambient temperature

50 [40

60 [50

(A) ~ (F)

2

mounting

]

]

Fig.3.5 Ambient temperature derating curve (refer to Table 3.3)

LFA50F

¿

(D)mounting

1

(C), (E)mounting

1

(F)mounting

100

80

60

40

20

Load factor [%]

0

-10 70 [50

1

1

Convection

2

Forced air (0.5m3/min)

20100

Inside[ ] is with case cover

*

30 [10]

40 [20

[C]Ambient temperature

(B)mounting

1

(A)mounting

1

]

]

50 [30

60 [40

(A) ~ (F)

2

mounting

]

]

Fig.3.6 Ambient temperature derating curve (refer to Table 3.4)

LFA-26

Page 8

AC-DC Power Supplies Open Frame/ Enclosed Type

Instruction Manual

LFA75F

¿

(C)mounting(D)mounting

40 [20

11

(A), (B)mounting

1

(A) ~ (F)

2

mounting

]

]

]

]

50 [30

60 [40

(E), (F)mounting

100

80

60

40

20

Load factor [%]

0

-10 70 [50

1

1

Convection

2

Forced air (0.5m3/min)

20100

0 [10]3

[C]Ambient temperature

Inside[ ] is with case cover

*

Fig.3.7 Ambient temperature derating curve (refer to Table 3.5)

LFA100F

¿

(D), (E), (F)mounting

1

100

80

75

60

50

40

20

Load factor [%]

0

-10 7060 50400 3554535

1

Convection

2

Forced air (0.5m3/min)

(C)mounting

1

20100

(A)mounting

1

1

(B)mounting

2 (A) ~ (F)

mounting

[C]Ambient temperature

Fig.3.8 Ambient temperature derating curve (refer to Table 3.6)

LFA100F-O-SN

¿

(D), (E)mounting

1

100

80

75

60

40

20

Load factor [%]

10

0

-10 60 50400 3

1

Convection

2

Forced air (0.5m3/min)

1

20100

(C)mounting

2 (A) ~ (F)

mounting

4535

(B)mounting

1

(A)mounting

1

[C]Ambient temperature

Fig.3.9 Ambient temperature derating curve

LFA150F

¿

(B)mounting

(D), (E), (F)mounting

100

80

70

60

40

30

2

0

Load factor [%]

0

-10 7060 50400 3

1

1

Convection

2

Forced air (0.5m3/min)

(C)mounting

1

255654535250100

1

(A)mounting

1

2 (A) ~ (F)

mounting

[C]Ambient temperature

Fig.3.10 Ambient temperature derating curve (refer to Table 3.7)

LFA240F

¿

(B)mounting

(D), (F)mounting

1

(E)mounting

100

80

60

40

2250

Load factor [%]

0

-10 7060 50400 3

1

1

Convection

2

Forced air (0.5m3/min)

(C)mounting

1

2011500

1

(A)mounting

1

2 (A) ~ (F)

mounting

[C]Ambient temperature

Fig.3.12 Ambient temperature derating curve (refer to Table 3.8)

LFA240F-O-SN

¿

(B)mounting

(D)mounting

1

(E)mounting

100

80

70

60

40

25

20

Load factor [%]

10

0

-10 60 50400 3

1

1

Convection

2

Forced air (0.5m3/min)

15

5

(C)mounting

1

25

20100

1

(A)mounting

1

2 (A) ~ (F)

mounting

[C]Ambient temperature

Fig.3.13 Ambient temperature derating curve

LFA300F

¿

(B), (C)mounting

1

100

80

60

50

40

20

Load factor[%]

0

-10 7060 50400 3

1

Convection

2

Forced air

(1.0m

(0.5m3/min)

3

/min)

(E), (F)mounting

(D)mounting

1

:3.3V/5V/12V/15V

:24V/30V/36V/48V

25

20100

1

(A)mounting

1

2 (A) ~ (F)

mounting

[C]Ambient temperature

Output

voltage

Output power[W]

1Convection 2Forced air

3.3V 132.0 198.0

5V 200.0 300.0

12V 204.0 324.0

15V 210.0 330.0

24V 300.0 336.0

30V 300.0 330.0

36V 302.4 338.4

48V 302.4 336.0

Fig.3.14 Ambient temperature derating curve (refer to Table 3.9)

LFA

LFA150F-O-SN

¿

(D), (E)mounting

100

80

70

60

50

40

30

20

Load factor [%]

0

-10 50400 3

1

1

Convection

2

Forced air (0.5m3/min)

Fig.3.11 Ambient temperature derating curve

201500

(C)mounting

1

(B)mounting

1

(A)mounting

1

2 (A) ~ (F)

mounting

554525

[C]Ambient temperature

LFA-27

Page 9

AC-DC Power Supplies Open Frame/ Enclosed Type

(A)(

)(C)

Derating curve depending on input voltage

¡

Derating curve depending on input voltage is shown in Fig.3.8.

LFA10F, LFA15F

¿

8

Instruction Manual

LFA

[%]

100

80

Load factor

[AC V]

Fig.3.17 Derating curve depending on input voltage

Mounting method

¡

CN1

Standard

Position

(D) (E) (F)

CN1

(F) mounting is not possible when unit is with case cover, but if

¡

need to operate unit by (F) positioning with case cover, temperature / load derating is necessary. For more details, please contact

our sales or engineering departments.

85 90

B

CN1

CN1

CN1

Fig.3.18 Mounting method

3.3 Mounting screw

The mounting screw should be M3. The hatched area shows the

¡

allowance of metal parts for mounting.

If metallic fi ttings are used on the component side of the board,

¡

ensure there is no contact with surface mounted components.

This product uses SMD technology.

¡

Please avoid the PCB installation method which includes the twisting stress or the bending stress.

Recommendation to electrically connect FG to metal chassis for

*

reducing noise.

CN1

8

CN1

8

8

Fig.3.19 Allowance of metal parts for mounting

(LFA10F, LFA15F)

LFA30F, LFA50F, LFA75F, LFA100F,

¿

LFA150F

88

CN1

8

8

Fig.3.20 Allowance of metal parts for mounting

(LFA30F, LFA50F, LFA75F, LFA100F, LFA150F)

LFA240F, LFA300F

¿

88

CN1, TB1

8

8

8

8

Fig.3.21 Allowance of metal parts for mounting

(LFA240F, LFA300F)

3.4 Expectancy life and warranty

Expectancy Life.

¡

Table 3.10 Expectancy Life (LFA10F-

Mounting

Method

A, D , E , F Convection

B, C

A,B,C,D,E,F

Cooling

Method

Convection

Forced air

Average ambient

temperature (year)

Ta = 40C or less

Ta = 50C

Ta = 45C or less

Ta = 55C

Ta = 60C

Table 3.11 Expectancy Life (LFA15F-O)

Mounting

Method

A, B, C, D Convection

E , F Convection

A,B,C,D,E,F

Cooling

Method

Forced air

Average ambient

temperature (year)

Ta = 40C or less

Ta = 50C

Ta = 35C or less

Ta = 45C

Ta = 60C

O

)

Expectancy Life

Io[75%

6years 6years

5years 3years

6years 6years

5years 3years

5years 3years

Expectancy Life

Io[75%

6years 6years

5years 3years

6years 6years

5years 3years

5years 3years

Unit [mm]

88

8

8

Unit [mm]

88

8

8

Unit [mm]

75%<Io[100%

75%<Io[100%

LFA-28

Page 10

AC-DC Power Supplies Open Frame/ Enclosed Type

Instruction Manual

Table 3.12 Expectancy Life (LFA30F-O)

Mounting

Method

A, B, C Convection

D, E, F Convection

A,B,C,D,E,F

Cooling

Method

Forced air

Average ambient

temperature (year)

Ta = 40C or less

Ta = 50C

Ta = 35C or less

Ta = 45C

Ta = 60C

Table 3.13 Expectancy Life (LFA50F-O)

Mounting

Method

B , D Convection

C, E

A,B,C,D,E,F

Cooling

Method

A Convection

Convection

F

Convection

Forced air

Average ambient

temperature (year)

Ta = 40C or less

Ta = 50C

Ta = 35C or less

Ta = 45C

Ta = 30C or less

Ta = 40C

Ta = 25C or less

Ta = 35C

Ta = 60C

Table 3.14 Expectancy Life (LFA75F-O)

Mounting

Method

A, B Convection

E, F

A,B,C,D,E,F

C

D

Cooling

Method

Convection

Convection

Convection

Forced air

Average ambient

temperature (year)

Ta = 40C or less

Ta = 50C

Ta = 35C or less

Ta = 45C

Ta = 30C or less

Ta = 40C

Ta = 20C or less

Ta = 30C

Ta = 60C

Table 3.15 Expectancy Life (LFA100F-O)

Mounting

Method

B, C Convection

D, E , F Convection

A,B,C,D,E,F

Cooling

Method

A Convection

Forced air

Average ambient

temperature (year)

Ta = 40C or less

Ta = 50C

Ta = 35C or less

Ta = 45C

Ta = 35C or less

Ta = 45C

Ta = 60C

Table 3.16 Expectancy Life (LFA150F-O)

Mounting

Method

D, F Convection

A,B,C,D,E,F

Cooling

Method

A Convection

B Convection

C Convection

E Convection

Forced air

Average ambient

temperature (year)

Ta = 30C or less

Ta = 40C

Ta = 25C or less

Ta = 35C

Ta = 25C or less

Ta = 35C

Ta = 25C or less

Ta = 25C or less

Ta = 60C

Expectancy Life

Io[75%

6years 6years

5years 3years

6years 6years

5years 3years

5years 3years

Io[75%

6years 6years

5years 3years

6years 6years

5years 3years

6years 6years

5years 3years

6years 6years

5years 3years

5years 3years

Io[75%

6years 6years

5years 3years

6years 6years

5years 3years

6years 6years

5years 3years

6years 6years

5years 3years

5years 3years

Io[75%

6years 6years

5years 3years

6years 6years

5years 3years

6years 6years

5years 3years

5years 3years

Io[75%

6years 6years

6years 5years

6years 6years

6years 6years

6years 6years

6years 5years

6years 6years

6years 5years

5years 5years

75%<Io[100%

Expectancy Life

75%<Io[100%

Expectancy Life

75%<Io[100%

Expectancy Life

75%<Io[100%

Expectancy Life

75%<Io[100%

Table 3.17 Expectancy Life (LFA240F-O)

Mounting

Method

B, C Convection

D, F

A,B,C,D,E,F

Cooling

Method

A Convection

Convection

E

Convection

Forced air

Average ambient

temperature (year)

Ta = 30C or less

Ta = 40C

Ta = 20C or less

Ta = 30C

Ta = 20C or less

Ta = 15C or less

Ta = 60C

Table 3.18 Expectancy Life (LFA300F-O)

Mounting

Method

B, C

E, F

A,B,C,D,E,F

Warranty

¡

Table 3.19 Warranty

Mounting

Method

A, D , E , F Convection

B , C Convection

A,B,C,D,E,F

Cooling

Method

A Convection

Convection

D

Convection

Convection

Forced air

Cooling

Method

Forced air

Average ambient

temperature (year)

Ta = 30C or less

Ta = 40C

Ta = 20C or less

Ta = 30C

Ta = 25C or less

Ta = 20C or less

Ta = 50C

(

LFA10F-O)

Average ambient

temperature (year)

Ta = 40C or less

Ta = 50C

Ta = 45C or less

Ta = 55C

Ta = 60C

Table 3.20 Warranty (LFA15F-O)

Mounting

Method

A, B , C , D Convection

E , F Convection

A,B,C,D,E,F

Cooling

Method

Forced air

Average ambient

temperature (year)

Ta = 40C or less

Ta = 50C

Ta = 35C or less

Ta = 45C

Ta = 60C

Table 3.21 Warranty (LFA30F-O)

Mounting

Method

A, B, C Convection

D, E, F Convection

A,B,C,D,E,F

Cooling

Method

Forced air

Average ambient

temperature (year)

Ta = 40C or less

Ta = 50C

Ta = 35C or less

Ta = 45C

Ta = 60C

Expectancy Life

Io[75%

6years 6years

5years 3years

6years 6years

5years 3years

6years 5years

6years 5years

5years 3years

Io[75%

6years 6years

5years 3years

6years 6years

5years 3years

6years 5years

6years 5years

5years 3years

Io[75%

5years 5years

5years 3years

5years 5years

5years 3years

5years 3years

Io[75%

5years 5years

5years 3years

5years 5years

5years 3years

5years 3years

Io[75%

5years 5years

5years 3years

5years 5years

5years 3years

5years 3years

75%<Io[100%

Expectancy Life

75%<Io[100%

Warranty

75%<Io[100%

Warranty

75%<Io[100%

Warranty

75%<Io[100%

LFA

LFA-29

Page 11

AC-DC Power Supplies Open Frame/ Enclosed Type

Instruction Manual

Table 3.22 Warranty (LFA50F-O)

Mounting

Method

LFA

B , D Convection

C, E Convection

A,B,C,D,E,F

Cooling

Method

A Convection

F Convection

Forced air

Table 3.23 Warranty (LFA75F-O)

Mounting

Method

A, B Convection

E, F Convection

A,B,C,D,E,F

Cooling

Method

C Convection

D Convection

Forced air

Average ambient

temperature (year)

Ta = 40C or less

Ta = 50C

Ta = 35C or less

Ta = 45C

Ta = 30C or less

Ta = 40C

Ta = 25C or less

Ta = 35C

Ta = 60C

Average ambient

temperature (year)

Ta = 40C or less

Ta = 50C

Ta = 35C or less

Ta = 45C

Ta = 30C or less

Ta = 40C

Ta = 20C or less

Ta = 30C

Ta = 60C

Warranty

Io[75%

5years 5years

5years 3years

5years 5years

5years 3years

5years 5years

5years 3years

5years 5years

5years 3years

5years 3years

Io[75%

5years 5years

5years 3years

5years 5years

5years 3years

5years 5years

5years 3years

5years 5years

5years 3years

5years 3years

75%<Io[100%

Warranty

75%<Io[100%

Table 3.26 Warranty (LFA240F-O)

Mounting

Method

B, C Convection

D, F Convection

A,B,C,D,E,F

Cooling

Method

A Convection

E Convection

Forced air

Average ambient

temperature (year)

Ta = 30C or less

Ta = 40C

Ta = 20C or less

Ta = 30C

Ta = 20C or less

Ta = 15C or less

Ta = 60C

Table 3.27 Warranty (LFA300F-O)

Mounting

Method

B, C Convection

E

A,B,C,D,E,F

Cooling

Method

A Convection

D Convection

,

F Convection

Forced air

Average ambient

temperature (year)

Ta = 30C or less

Ta = 40C

Ta = 20C or less

Ta = 30C

Ta = 25C or less

Ta = 20C or less

Ta = 50C

Warranty

Io[75%

5years 5years

5years 3years

5years 5years

5years 3years

5years 3years

5years 3years

5years 3years

Io[75%

5years 5years

5years 3years

5years 5years

5years 3years

5years 3years

5years 3years

5years 3years

75%<Io[100%

Warranty

75%<Io[100%

Table 3.24 Warranty (LFA100F-O)

Mounting

Method

B, C Convection

D, E, F Convection

A,B,C,D,E,F

Cooling

Method

A Convection

Forced air

Average ambient

temperature (year)

Ta = 40C or less

Ta = 50C

Ta = 35C or less

Ta = 45C

Ta = 25C or less

Ta = 35C

Ta = 60C

Table 3.25 Warranty (LFA150F-O)

Mounting

Method

D, F Convection

A,B,C,D,E,F

Cooling

Method

A Convection

B Convection

C Convection

E Convection

Forced air

Average ambient

temperature (year)

Ta = 30C or less

Ta = 40C

Ta = 25C or less

Ta = 35C

Ta = 25C or less

Ta = 35C

Ta = 25C or less

Ta = 25C or less

Ta = 60C

Warranty

Io[75%

5years 5years

5years 3years

5years 5years

5years 3years

5years 5years

5years 3years

5years 3years

Io[75%

5years 5years

5years 5years

5years 5years

5years 5years

5years 5years

5years 3years

5years 5years

5years 3years

5years 3years

75%<Io[100%

Warranty

75%<Io[100%

4 Ground

When installing the power supply with your unit, ensure that the

¡

input FG terminal of CN1 or mounting hole FG is connected to

safety ground of the unit.

5 Option and Others

5.1 Outline of options

Please inquire us for details of specifi cations and delivery timing.

*

You can combine multiple options. Some options, however, can-

*

not be combined with other options. Please contact us for details.

-C

¿

Option -C units have coated internal PCB for better moisture

-

resistance.

LFA-30

Page 12

AC-DC Power Supplies Open Frame/ Enclosed Type

Instruction Manual

-G

¿

Option -G units are low leakage current type.

-

Differences from standard versions are summarized in Table 5.1.

-

Table 5.1 Low leakage current type

Leakage Current

(AC240V 60Hz)

Conducted Noise N/A

Output Ripple Noise

This is the value that measured on measuring board with capaci-

*

tor of 22μF at 150mm from output connector.

Measured by 20MHz oscilloscope or Ripple-Noise meter (Equivalent

to KEISOKU-GIKEN:RM-103).

-H (LFA100F-24, LFA150F-24, LFA240F-24,

¿

Please contact us for details about

0.15mA max

Ripple Noise

LFA300F-24/30/36/48-TY)

Option -H units can output the peak current.

-

Peak load is possible to draw as below.

-

l

p

: peak current

l

ave

: average current

Output current [A]

t

1

t

2

Fig.5.1 Peak current

Input voltage is AC90V to AC264V.

t1[10[sec]

lp[rated peak current

lave[rated output current

t1

Duty =

t1+t2

In case of LFA300F duty is depended on peak wattage.

Please contact us about the detail.

Remarks:

There is possibility that an internal device is damaged when the

*

specifi cation is exceeded.

-J (LFA300F)

¿

Option -J units, the input and output connector are changed to

-

EP connectors (Mfr. Tyco Electronics).

The appearance in option -J units is defferent from the standard

-

untis. Please contact us about the detail.

-J1

¿

Option -J1 units, the Input and Output connector is VH connec-

-

tors (Mfr. J.S.T.).

LFA300F appearance of option -J units is defferent from the

-

standard appearance. Please contact us about the detail.

100[%] [35%

X

-S--SN

¿

-S indicates a type with chassis, and -SN indicates a type with

-

chassis and cover (Refer to external view). Refer to “Derating

Curves”in Section 3.2.

Please contact us about the detail of LFA300F.

-

-SNF (LFA300F-5/12/24-TY)

¿

In option -SNF, the cover, chassis and cooling fan are added.

-

The appearance of option -J units is defferent from the of stan-

-

dard appearance. Please contact us about the detail.

Oil and other chemical liquid splashing environment may cause

-

the performance degradation and failure.

-Y

¿

Option -Y units can adjust the output voltage by the potentiom-

-

eter is attached .

Refer to the adjustable range to the table 5.2 and table 5.3.

-

LFA10F, LFA15F, LFA30F, LFA50F, LFA75F

¡

Table 5.2 Output voltage adjustment range

Output voltage Output voltage adjustment range[V]

3.3V*

5V 4.5 to 5.5

12V 10.8 to 13.2

15V 13.5 to 16.5

24V 21.6 to 26.4

36V 32.4 to 39.6

48V 43.2 to 52.8

Some of the product, -Y is standard equipment.

*

(LFA10F-3R3-Y,LFA15F-3R3-Y,LFA30F-3R3-Y,

LFA50F-3R3-Y,LFA75F-3R3-Y)

LFA100F, LFA150F, LFA240F, LFA300F

¡

Table 5.3 Output voltage adjustment range

Output voltage Output voltage adjustment range[V]

3.3V*

5V*

12V 10.8 to 13.2

15V 13.5 to 16.5

24V 21.6 to 27.5

30V (LFA300F) 27.0 to 33.0

36V 32.4 to 39.6

48V 39.6 to 52.8

Some of the product, -Y is standard equipment.

*

(LFA100F-3R3-Y, LFA100F-5-Y,

LFA150F-3R3-Y, LFA150F-5-Y, LFA300F-O-TY)

To increase an output voltage, turn a built-in potentiometer

-

clockwise.

To decrease the output voltage, turn it counterclockwise.

-

Please take care when you adjust output voltage by potenti-

-

ometer, because there is possibility of electric shock and the

breakdown as contacting to other internal circui by telectrically

conductive tool.

2.85 to 3.63

2.85 to 3.63

4.5 to 5.5

LFA

LFA-31

Page 13

AC-DC Power Supplies Open Frame/ Enclosed Type

Instruction Manual

-R (LFA100F, LFA150F, LFA240F, LFA300F)

¿

You can control output ON/OFF remotely in Option -R units. To

-

LFA

do so, connect an external DC power supply and apply a voltage to a remote ON/OFF connector, which is available as option.

Built-in

Model Name

LFA100F, LFA150F,

LFA240F, LFA300F

External Power

Source

Remote ON/OFF connector (Optional)

Fig.5.2 Example of using a remote ON/OFF circuit

Dedicated harnesses are available for your purchase. Please

-

see Optional Parts for details.

1 If the output of an external power supply is within the range

*

of 4.5 - 12.5V, you do not need a current limiting resistor R. If

the output exceeds 12.5V, however, please connect the current limiting resistor R.

To calculate a current limiting resistance value, please use the following equation.

Vcc-(1.1+RiX0.005)

R[W]=

Please wire carefully. If you wire wrongly, the internal components

*

of a unit may be damaged.

Remote ON/OFF circuits (RC+ and RC-) are isolated from input,

¡

output and FG.

Resistor

Ri [ W ]

Input Current

0.005

Voltage between RC (+)

and RC (-) [V]

Output ON Output OFF

780 4.5 - 12.5 0 - 0.5 20max

Inside of a Power

(+)

(-)

1

2

Supply

SW

*1

R

RC

RC

Ri

Input

Current

[mA]

-T (LFA240F, LFA300F)

¿

Option -T units have vertically positioned screws on a terminal

-

block.

Please contact us for details about appearance.

-

FG

AC (N)

AC (L)

Fig.5.3 Example of option -T

The screw can be held to terminal block by inserting and lifting the

¡

screwdriver from the side of terminal block.

+ screwdriver

screw

terminal block

f5.5MAX

Fig.5.4 lifting method

-T1 (LFA300F)

¿

Option -T units have horizontally positioned screws on a termi-

-

nal block.

Please contact us for details about appearance.

-

FG

AC (N)

AC (L)

-V

+V

-V

+V

-R2 (LFA100F, LF A150F, LF A240F, LF A300F)

¿

The usege is the same as option -R, please refer to Option -R.

-

Reducing standby power is possible by OFF signal of the re-

-

mote control.

Start up time by ON signal in remote control is 350ms(typ).

-

The latch condition in overvoltage protection is removed by tog-

-

gling ON/OFF signal of remote control.

Standby power

-

LFA100F,LFA150F,LFA240F

0.2Wtyp (AC100V), 0.7Wtyp (AC200V)

LFA300F

0.25Wtyp (AC100V), 1.1Wtyp (AC200V)

LFA-32

Fig.5.5 Example of option -T1

5.2 Others

This power supply is the rugged PCB type. Do not drop conduc-

¡

tive objects in the power supply.

At light load, there remains high voltage inside the power supply

¡

for a few minutes after power OFF.

So, at maintenance, take care about electric shock.

This power supply is manufactured by SMD technology. The

¡

stress to PCB like twisting or bending causes the defect of the

unit, so handle the unit with care.

Tighten all the screws in the screw hole.

-

Install it so that PCB may become parallel to the clamp face.

-

Avoid the impact such as drops.

-

Page 14

AC-DC Power Supplies Open Frame/ Enclosed Type

While turning on the electricity, and for a while after turning off,

¡

please don’t touch the inside of a power supply because there are

some hot parts in that.

When a mass capacitor is connected with the output terminal

¡

(load side), the output might become the stop or an unstable operation. Please contact us for details when you connect the capacitor.

LFA10F, LFA15F

¿

When these power supplies are connected to the input terminal in

¡

parallel, the total capacitance between line and line becomes big.

Therefore, the electrical discharge resistance on the safety stan-

dard might become necessary.

Please contact us for details when safety standard is necessary at

multiple units usage.

Instruction Manual

LFA

LFA-33

Loading...

Loading...