Page 1

Basic Characteristics Data

Basic Characteristics Data

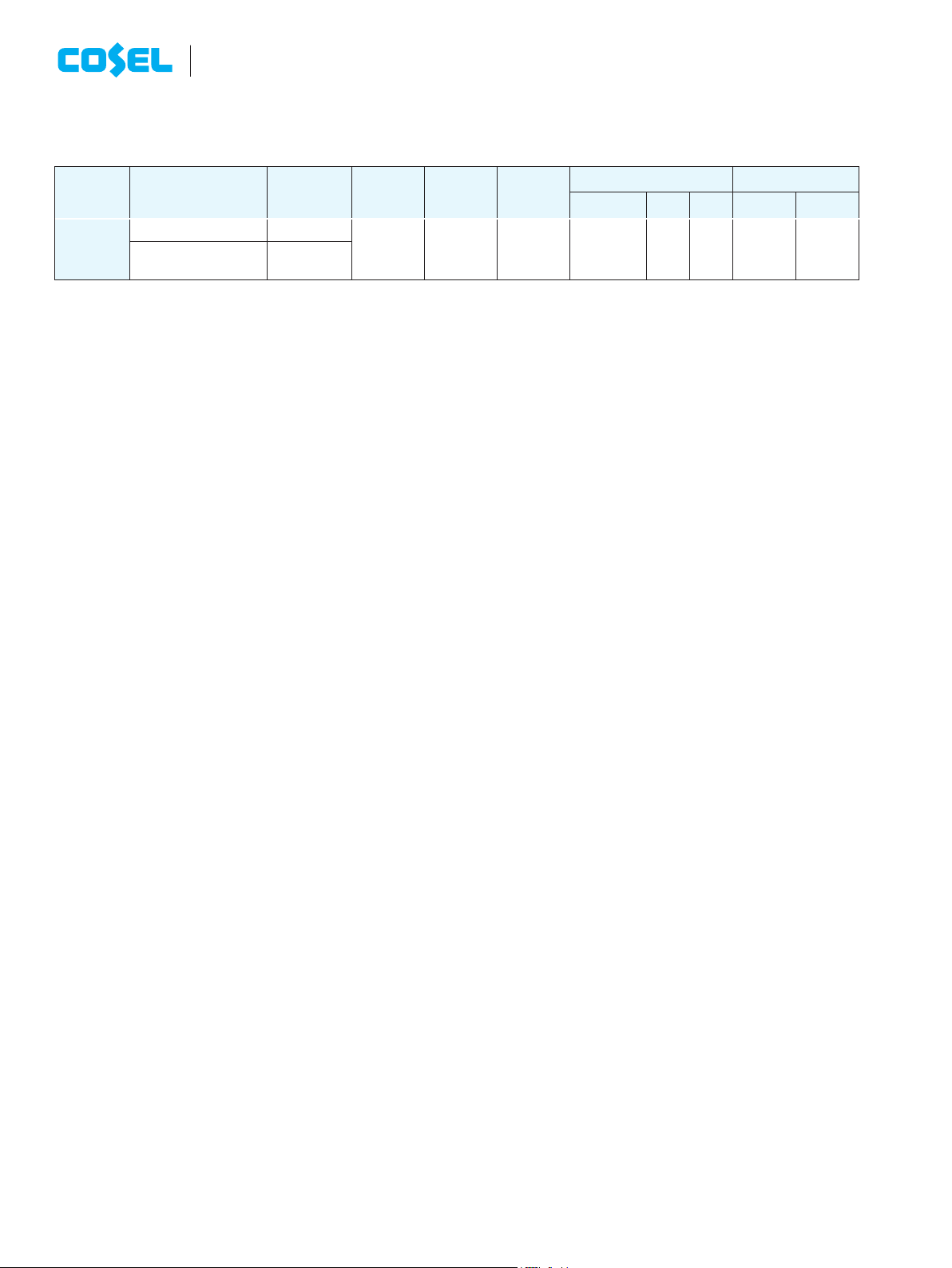

Switching

Model Circuit method

Active filter 47

FETA7000ST

Phase-shift Full-

bridge converter

* The value of input current is at ACIN 400V and rated load.

frequency

[kHz]

94

Input

current

[A]

Rated

input fuse

Inrush

current

protection

circuit

PCB/Pattern

Material

Single

sided

Double

sided

Series/Parallel

operation availability

Series

operation

operation

12.0 250V 30A Relay FR-4 Ye s Ye s Ye s

Parallel

FETA-6

Page 2

AC-DC Power Supplies Enclosed Type

Instruction Manual

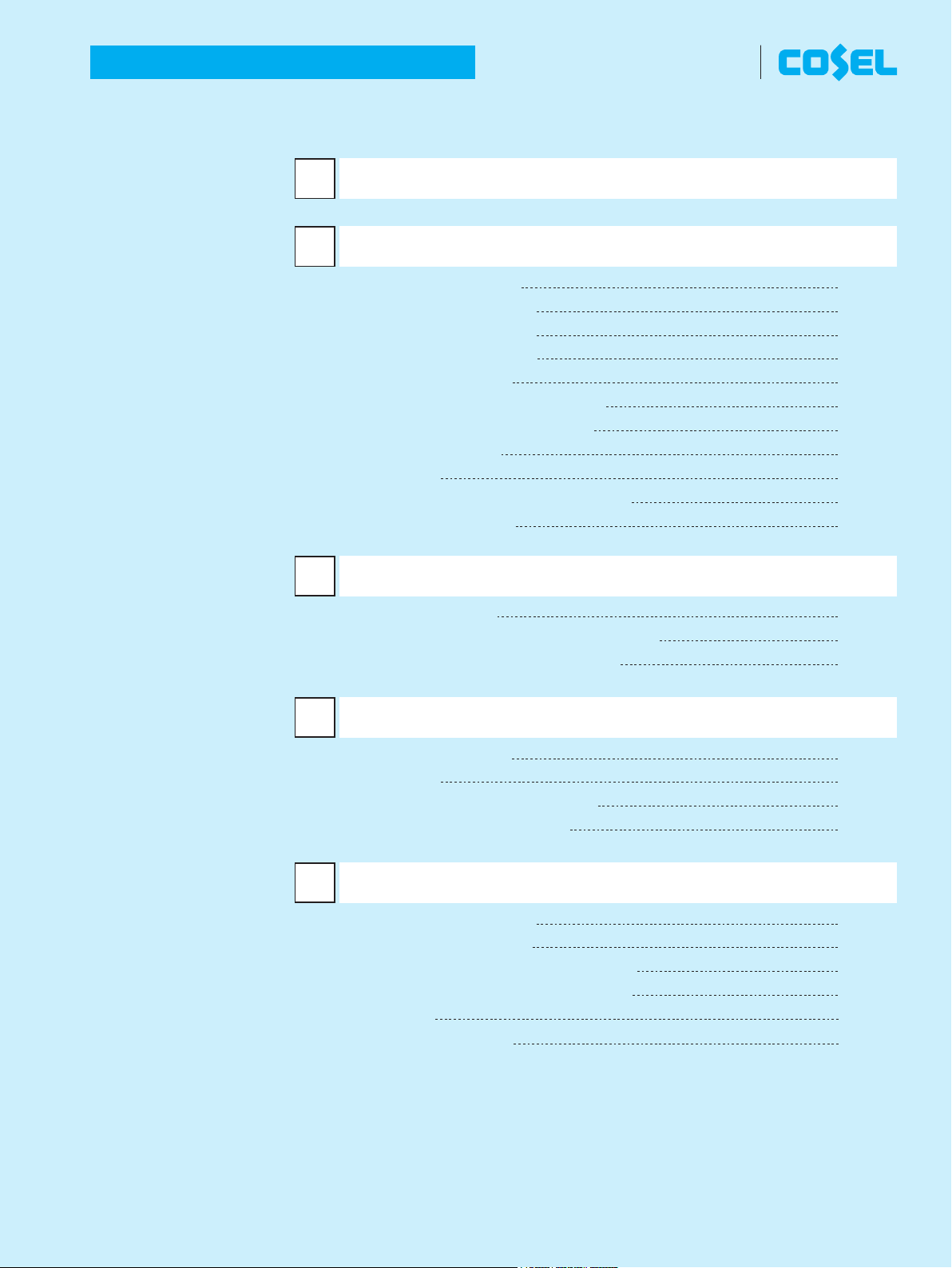

1 Terminal Blocks

2 Functions

2.1 Input Voltage Range

2.2 Inrush Current Limiting

2.3 Overcurrent Protection

2.4 Overvoltage Protection

2.5 Thermal Protection

2.6 Output Voltage Adjustment Range

2.7 Output Ripple and Ripple Noise

2.8 Remote ON/OFF

2.9 Isolation

2.10 Signal Output (LED / Warning / Alarm)

2.11 Sequence Diagram

3 Series/Parallel Operation

3.1 Series Operation

3.2 Parallel Operation/Master-slave Operation

3.3 N+1 Parallel Redundancy Operation

FETA-8

FETA-8

FETA-8

FETA-8

FETA-9

FETA-9

FETA-9

FETA-9

FETA-9

FETA-10

FETA-10

FETA-10

FETA-11

FETA-12

FETA-12

FETA-12

FETA-12

Assembling and Installation Method

4

4.1 Installation Method

4.2 Derating

4.3 Conditions of the safety approval

4.4 Expected Life and Warranty

5 Others

5.1 Output Current Monitor

5.2 Auxiliary Power (AUX)

5.3 Output Capacitive Load Considerations

5.4 External Component (EMI/EMC Filter)

5.5 Ground

5.6 Variable Speed Fan

FETA-13

FETA-13

FETA-14

FETA-14

FETA-14

FETA-15

FETA-15

FETA-15

FETA-15

FETA-15

FETA-15

FETA-15

FETA-7

Page 3

AC-DC Power Supplies Enclosed Type

Instruction Manual

1 Terminal Blocks

7

90å∫

AC (L3)

1

AC (L2)

2

AC (L1)

3

AC (N)

4

Frame ground (M5

5

+Output

6

-

Output

7

CN2

8

CN1

9

LED for output voltage conrmation (DC_OK)

0

LED for fault condition detection (ALARM)

å

Output voltage adjustable potentiometer

∫

Pin No. Pin Name Function

Table 1.2 Matching connectors and terminals on CN1, CN2

CN1

CN2

Input Terminals AC300-480V three phase four wire 47 - 63Hz

(M5)

)

Connectors

Table 1.1 Pin Conguration and Functions of CN1, CN2

1 AUXG Auxiliary power output (GND)

2 AUX Auxiliary power output

3 WRNG Warning signal (GND)

4 WRN Warning signal

5 PGG Alarm signal (GND)

6 PG Alarm signal

7 RCG Remote ON/OFF (GND)

8 RC Remote ON/OFF

9 COM Signal ground

10 TRM Adjustment of output voltage

11 VB Voltage Balance

12 CB Current Balance

Connector Housing Terminal Mfr.

S12B-PUDSS-1 PUDP-12V-S

8

Reel : SPUD-001T-P0.5

or SPUD-002T-P0.5

2 Functions

123456

J.S.T

2.1 Input Voltage Range

The input voltage range is AC300-480V (three phase four wire).

¡

For the safety standard test, the input voltage range is AC346-

¡

415V (three phase four wire, 50/60Hz).

The current owing through the neutral line (N phase) increases

¡

when the AC input voltage is over AC456V three phase four wire

(18Amax). This does not affect product quality. Please select a

suitable wire gauge for the neutral line.

L1

AC300 - 480V

L2 L3

N

Three phase four wire system

Three phase three wire input voltage is not supported.

¡

The neutral line must be connected.

If the input voltage is not from three phase four wire connection or

out of the specied range, the unit will not operate properly and/or

may be damaged. If you need to apply a square wave form input

voltage, which is commonly used in UPS and inverters, please

contact us.

2.2 Inrush Current Limiting

An inrush current limiting circuit is built-in.

¡

If you need to use a switch on the input side, please select one

¡

that can withstand an input inrush current.

Relay technique is used in the inrush current limiting circuit. When

¡

you turn the power ON/OFF repeatedly within a short period of

time, please have enough intervals so that the inrush current limit-

ing circuit becomes operative.

When the switch of the input is turned on, the primary inrush cur-

¡

rent and secondary inrush current will be generated because the

relay technique is used for the inrush current limiting circuit.

FETA-8

11

12

1

2

1

2

Fig.1.1 Connector pin numbers

CN2CN1

11

12

Page 4

AC-DC Power Supplies Enclosed Type

Instruction Manual

2.3 Overcurrent Protection

An overcurrent protection circuit is built-in and activated at 105%

¡

or more of the rated current. A unit automatically recovers when a

faulty condition is removed.

Please do not use a unit in short circuit and/or under an overcur-

rent condition.

Output voltage shuts down when the output voltage continuously

¡

drops due to overcurrent protection.

Output voltage recovers from overcurrent protection by shutting

¡

down the input voltage and waiting more than 10 seconds then

turning on AC input again, or turning off the output voltage by re-

mote control.

2.4 Overvoltage Protection

When output voltage is increased to the overvoltage protection

¡

value, output voltage is shut down.

Output voltage recovers from overvoltage protection by shutting

¡

down the input voltage and waiting more than 10 seconds then

turning on AC input again, or turning off the output voltage by re-

mote control.

Note :

Please avoid applying a voltage exceeding the rated voltage to an

¡

output terminal. Doing so may cause a power supply to malfunc-

tion or fail. If you cannot avoid doing so, for example, if you need

to operate a motor, etc., please install an external diode on the

output terminal to protect the unit.

2.5 Thermal Protection

A thermal protection circuit is built-in.

¡

The thermal protection circuit may be activated under following

conditions and shut down the output.

When a current and a temperature continue to exceed the val-

1

ues determined by the derating curve.

When a fan stops or air ow weakens by intake port or exhaust

2

port is blocked.

Output voltage recovers from thermal protection by shutting down

¡

the input voltage and cooling down the inside of power supply ad-

equately then turning on AC input again, or turning off the output

voltage by remote control and cooling down the inside of power

supply adequately then turning on the output voltage by remote

control.

2.6 Output Voltage Adjustment Range

To increase an output voltage, turn the built-in potentiometer clock-

¡

wise. To decrease the output voltage, turn it counterclockwise.

The power supplies have an external output voltage control func-

¡

tion. The output voltage can be adjusted by changing the voltage

between the terminal TRM and the terminal COM on CN1/CN2.

You can decrease the voltage by drawing a current from the TRM

terminal.

You can calculate the output voltage in this case from formula 1

below.

Please do not apply +5V or more or negative voltage between

TRM and COM. Please contact us if you need accurate numbers.

Please do not apply negative Voltage to TRM terminal.

There is more than one method to adjust the output voltage, in-

cluding the methods to use external resistors and external power

supplies. Since each method has different characteristic, please

contact us for details.

The voltage between

Output voltage = Xrated output voltage

If the output voltage decreases to 60% or less of rated voltage,

output ripple may increase.

Table 2.1 Output voltage adjustment range

Model Output voltage adjustment range [V]

FETA7000ST-48 approximately 0 to 52.8

FETA7000ST-144 approximately 0 to 158.4

TRM and COM

2.5 [V]

--- 1

2.7 Output Ripple and Ripple Noise

Output ripple noise may be inuenced by measurement environ-

¡

ment, measuring method Fig.2.1 is recommended.

+Vout

1

C

+

-Vout

150mm

Oscilloscope

Bw:500MHz

1 :

C

Aluminum electrolytic capacitor 22μF

Fig.2.1 Measuring method of Ripple and Ripple Noise

Remarks :

When GND cable of probe with ux of magnetic force from power

supply are crossing, ripple and ripple noise might not measure

correctly.

Please note the measuring environment.

Bad example Good example

Fig.2.2. Example of measuring output ripple and ripple noise

Differential probe

Load

150mm

FETA-9

Page 5

AC-DC Power Supplies Enclosed Type

Instruction Manual

2.8 Remote ON/OFF

These models have a remote ON/OFF function.

¡

You can operate the remote ON/OFF function by sending signals

¡

to CN1/CN2. Please see Table 2.2 and Table 2.3 for specifica-

tions and Fig.2.3 for connecting examples.

Please note the following when using the remote ON/OFF func-

¡

tion.

The output stops when a current ows to RC.

1

The current own to RC is a 20mA max.

2

When the output voltage is turned off through the remote ON/OFF

3

circuit, the built-in fan slows down.

If the output voltage is turned off through the remote ON/OFF

4

circuit, the WRN signals and the PG signals keep ”Low”.

Description in this section is based on the assumption that you

5

will use one unit alone. If you are planning to use the units

in parallel operation or use multiple units for a single system,

please check necessary voltage and current values.

Please wire carefully. If done incorrectly, the internal components

¡

of the unit may be damaged.

Remote ON/OFF circuits (RC and RCG) are isolated from input,

¡

output, FG, AUX, WRN and PG.

Table 2.2 Specications of remote ON/OFF (RC-RCG)

Output voltage Between RC and RCG

ON L level (0 to 0.5V) or open

OFF H level (4.5 to 12.5V)

Table 2.3 Specications of remote ON/OFF (Case of Fig.2.3)

Connection method Fig.2.3 (a) Fig.2.3 (b) Fig.2.3 (c)

Power ON

Power OFF

SW open

(0.1mA max)

SW close

(3mA min)

Base pin RCG AUXG RCG, AUXG

(a)(b) (c)

AUXAUX AUX

Ri=780W Ri=780W Ri=780W

12V

typ

*1

Ra

RC RC RC

RCG

AUXG AUXG

12V

typ

Vcc

SW SW

RCG

12V

typ

Fig.2.3 Examples of connecting remote ON/OFF circuit

1 If the output of an external power supply is within the range of

*

4.5 - 12.5V, you do not need a current limiting resistor Ra. If

the output exceeds 12.5V, however, please connect the current

limiting resistor Ra.

To calculate a current limiting resistance value, please use the

following equation.

Ra[W]=

Vcc-(1.1+RiX0.005)

0.005

SW close

(0.5V max)

SW open

(0.1mA max)

Rb=1kW

RCG

AUXG

SW

2.9 Isolation

When you run a Hi-Pot test as receiving inspection, gradually in-

¡

crease the voltage to start. When you shut down, decrease the

voltage gradually by using a dial. Please avoid a Hi-Pot tester

with a timer because when the timer is turned ON or OFF, it may

generate a voltage a few times higher than the applied voltage.

2.10 Signal Output (LED/Warning/Alarm)

Functions of LED indicators and Output of Warning/Alarm are

¡

shown below. LED indicators and Output of Warning/Alarm are

signals to check the presence/absence of voltage at the output

terminal of a power supply and to detect warning/fault conditions.

The timing of signals might be vary depending on input and load

conditions. Please evaluate thoroughly.

Table 2.4 Description of LED indicator

LED indicator Condition Output voltage

OFF Input power not present OFF

Green - ON Normal condition ON

Green - Blinking DC OFF by RC signal OFF

Amber - Blinking

Amber - ON

Table 2.5 Description of the Warnings (WRN signal)

The WRN signals are ”Low”

when the power supply oper-

ates normally.

The signals turn ”High” when

AC input voltage is over

AC456V three phase four

WRN

wire system* or AC input

voltage is out of specifica-

tion or DC output voltage is

wrong(DC output voltage is

out of voltage adjustment

range.) or fan alarm/thermal

warning is detected.

This does not affect product quality. The current owing through

*

the neutral line (N phase) increases when AC input voltage is

over AC456V three phase four wire (18Amax). Select a suitable

wire gauge for the neutral line.

Warning condition

(refer to Table.2.5)

Fault condition

(refer to Table.2.6)

ON

OFF

Warning Output of Warning

Open collector method

Good : L level

(0 to 0.5V at 10mA)

Bad : H level or Open

(35Vmax)

FETA-10

Page 6

: Indeterminate

AC

AC

AC-DC Power Supplies Enclosed Type

Instruction Manual

Table 2.6 Description of the alarms (PG signal)

Alarm Output of Alarm

The PG signals are ”Low”

when the power supply oper-

ates normally.

The signals turn ”High” when

the fan stops or the power

supply stops as a result of

PG

output voltage decrease/stop,

Open collector method

Good : L level

(0 to 0.5V at 10mA)

Bad : H level or Open

(35Vmax)

activation of thermal protec-

tion, overvoltage protection,

overcurrent protection func-

tions or wrong input voltage

is applied.

100kW0.1mF

Fig.2.4 Internal circuit of PG/WRN

PG / WRN

PGG / WRNG

2.11 Sequence Diagram

(1)Turn ON/OFF by Remote ON/OFF control

ON

OFF

0V

0V

NG

OK

NG

OK

AC

Input

Events

AC INPUT

RC

Output

Voltage

AUX

WRN

PG

Fig.2.5 Sequence time chart by Remote ON/OFF control

(2)Turn ON/OFF by AC Input / Loss

Events

Input

1700ms max

signal inhibit

time

300ms max

500ms max

RC

ON

10-100ms

RC

OFF

Loss

AC

Loss

10ms max

20ms min

100ms min

: Indeterminate

Please note the followings when you use the warnings (WRN sig-

¡

nal) and the alarms (PG signal).

1 The time it takes until the WRN signals and the PG signals turn

”High” vary depending on conditions.

2 If the output voltage is turned off through a remote ON/OFF cir-

cuit, the WRN signals and the PG signals keep ”Low”.

The WRN signal (Warning) circuit and the PG signal (Alarm) cir-

¡

cuit are isolated from input, output, FG, RC and AUX.

AC INPUT

RC

Output

Voltage

AUX

WRN

PG

ON

OFF

0V

0V

NG

OK

NG

OK

1700 msmax

300ms max

500m s max

10-100ms

Fig.2.6 Sequence time chart by AC Input / Loss

10ms-10S

20ms min

1ms min

100m s min

FETA-11

Page 7

AC-DC Power Supplies Enclosed Type

3 Series/Parallel

Operation

Instruction Manual

3.2 Parallel Operation/Master-slave Operation

You can use the power supplies in parallel operation by connect-

¡

ing units as shown in Fig.3.2.

Please parallelly connect VB, CB and COM of each power supply

in parallel operation.

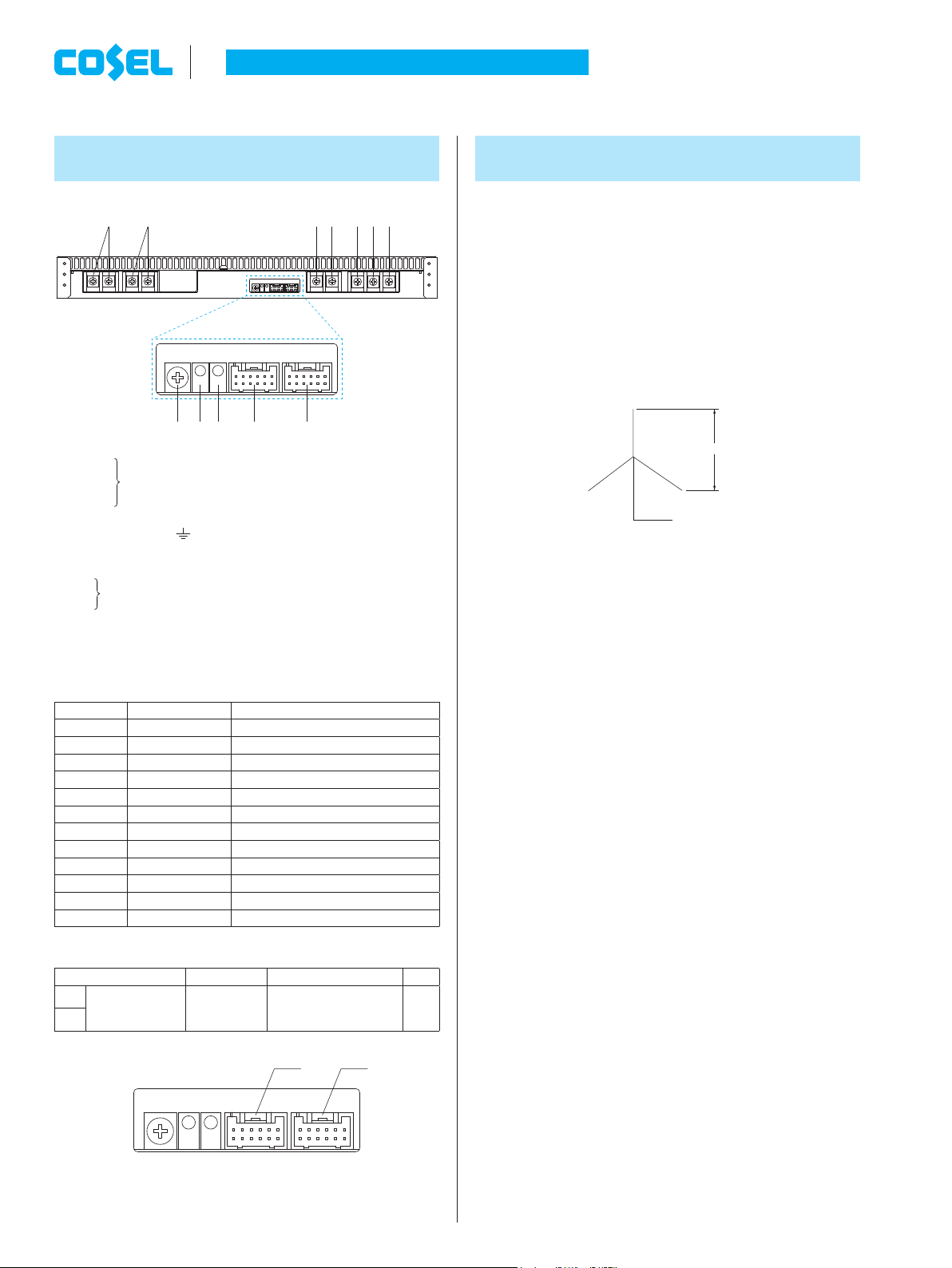

3.1 Series Operation

It is possible to connect multiple output voltages in series in order

¡

to obtain higher output voltage. However, care should be taken as

follows:

Notes of (a) and (b) :

Please note that the maximum current available to the load is

1

equal to the current of the lowest rated supply in the string.

2 In case of malfunction (Failure or protection circuit activation),

please stop the operation and replace the failed power supply.

+

Power

Supply

-

Remote ON/OFF

circuit (OFF signal)

+

Power

Supply

-

(a)

+

Power

Supply

-

Remote ON/OFF

circuit (OFF signal)

+

Power

Supply

-

(b)

+

Power

Supply

-

+

Power

Supply

-

(c)

Fig.3.1 Examples of connecting in series operation

Load Load

Alarm signal

detect circuit

Output voltage

monitor circuit

Load Load

+V

Power supply

Power supply

Power supply

Fig.3.2 Example of parallel connection

Differences in the output current values among the power sup-

¡

plies in parallel connection are 5% at most. Please make sure

that the sum of the output current values does not exceed a value

obtained from the following equation.

(Output current in parallel operation)

= (Rated current per unit) X (Number of units) X0.95

When the number of units in parallel operation increases, the in-

¡

put current also increases. Please design input circuitry (including

circuit pattern, wiring and current capacity for equipment) carefully.

Please make sure that the wiring impedance of a load from each

¡

power supply becomes even. Otherwise, the output current bal-

ance circuit may become inoperative.

The maximum number of unit in parallel operation is 3.

¡

You can adjust the output voltage in parallel operation by adjusting

¡

the potentiometer of just one power supply.

To do so, select one power supply as the master unit and turn the

potentiometers of the other (slave) power supplies clockwise to

the end.

Once you have done this, you can adjust the output voltage by

turning the potentiometer of the master unit.

Parallel connection with other products is not allowed.

¡

VB

CB

COM

+V

VB

CB

COM

+V

VB

CB

COM

-V

-V

-V

Load

3.3 N+1 Parallel Redundancy Operation

You can have N+1 redundancy operation for improved system reli-

¡

ability.

N+1 redundancy operation is possible by connecting units as

¡

shown in Fig.3.3.

VB, CB and COM are also connected together between all units

in parallel.

The output voltage gap of paralleled units must be adjusted within

¡

+/-600mV for 144V type, and +/-200mV for the other output mod-

els.

Output current calculation is required based on following equation.

¡

The current has to be more over normal operation current even if

FETA-12

Page 8

-V

Chassis of

30mm min30mm min

AC-DC Power Supplies Enclosed Type

Instruction Manual

one power supply fails.

Maximum output current [ Rated current per unit X Numbers of

normal operated units X 0.95

If you add one extra power supply in parallel operation, even if

¡

one of the power supplies in your system fails, the remaining non-

failed power supplies continue to sustain the system. If one of the

power supplies stops operating, the output voltage may change

about 5%.

Parallel with other products is not allowed.

¡

Please shut off the input voltage when you replace a failed power

¡

supply.

After replacement, please make sure that all wirings are complet-

¡

ed correctly, before re-applying input voltage.

Hot-swap or Hot-plug is not available.

¡

2 or more power supplies failures may cause the output voltage to

¡

decrease, lending the application system to shut down. Immediate

replacement is recommended when a power supply has failed.

+V

Power supply Load

Power supply

VB

CB

COM

+V

VB

CB

COM

-V

-V

Chassis of

customer system

Mounting Screw

Fig.4.1 Mounting screw

Table 4.1 Max penetration length

Size a (Max penetration length)

M3 10mm max

M4 15mm max

The power supplies have a built-in forced cooling fan. Do not

¡

block ventilation at the suction side and its opposite side.

If you use a power supply in a dusty environment, it can cause a

¡

failure. Please consider taking such countermeasures as install-

ing an air lter near the suction area of the system to prevent a

failure.

Exhaust opening

FETA7000ST

a

Air flow

+V

Power supply

Fig.3.3 Example of N+1 redundancy operating connection

If you have any questions about series, parallel and N+1 redun-

¡

dancy operations, please contact us.

VB

CB

COM

4 Assembling and

Installation Method

4.1 Installation Method

Screw mounting requires considering the product weight for safety

¡

xtures.

To keep enough insulation distance between screws and internal

¡

components, length of the mounting screw should not exceed rec-

ommendation as shown in Table4.1.

Air flow

Intake opening

(a) Front side (b) Rear side

Fig.4.2 Location of intake port and exhaust port

Intake

opening

Fig. 4.3 Clearance of intake port and exhaust port

When mounting the power supply with screws, it is recommended

¡

that this be done as shown in Fig.4.4. If other methods are used,

be sure the weight of the power supply is taken into account.

FETA7000ST

Exhaust

opening

FETA-13

Page 9

[AC V]

Load [%]

0

100

Load factor [%]

Ambient temperature [C]

Life expectancy of fan [H]

Ambient temperature[C]

500,000

AC-DC Power Supplies Enclosed Type

Instruction Manual

-V +V Input

Fixed screw (6 pcs.) Fixed screw (6 pcs.)

(a) (b)

Fig.4.4 Installation method

4.2 Derating

Input Voltage Derating Curve

¡

Input voltage derating curve is shown in Fig.4.5.

100

85

-V +V Input

Fixed screw

(6 pcs.)

Fixed screw

(6 pcs.)

4.3 Conditions of the safety approval

To apply for safety standard using this power supply, the following

¡

conditions must be met.

This unit must be used as a component of the end-use equip-

1

ment.

This unit must be provided with overall enclosure.

2

The FG terminal must be connected to safety ground of the end-

3

use equipment, as required for class I equipment.

50A circuit breaker must be externally installed on the input side.

4

Altitude of operation is up to 3,000 m.

5

4.4 Expected Life and Warranty

Expected life

¡

Please see the following tables for expected life.

Table.4.2 Expected lifetime

Mounting

All

direction

This lifetime includes a built-in fan lifetime.

*

Life expectancy (R(t)=90%) of fan depends on use conditions as

¡

Cooling

method

Forced air cooling

(internal fan)

Average ambient

temperature

Ta = 40

C

Ta = 60

C

shown in Fig 4.7.

Expected lifetime

[years]

Io = 50% Io = 100%

7 5

4

-

300 320

Fig.4.5 Input voltage derating curve

Ambient Temperature Derating Curve

¡

Derating curve depending on an ambient temperature is shown in

Fig.4.6.

Specications for ripple and ripple noise changes in the shaded

*

area.

80

60

40

20

0

7040 60- 10 210 30 5000

8

Fig.4.6 Ambient temperature derating curve

100,000

10,000

Warranty

¡

Warranty is 3 years.

Io=50%

Io=100%

3020 40 50 60 70

Fig.4.7 Life expectancy of fan

FETA-14

Page 10

AC-DC Power Supplies Enclosed Type

5 Others

5.1 Output Current Monitor

You can monitor an output current by measuring a voltage be-

¡

tween the terminal CB and COM.

Fig.5.1 shows the relationship between the voltage of the terminal

¡

CB and the output current.

The output current shown in Fig.5.1 should be used only as a

guide.

5

4

3

2

Voltage of CB [V]

1

0

020406080 100

Load factor [%]

Load factor :

Fig.5.1 Load factor conversion graph

Note:

Careful wire connection is needed to avoid a malfunction caused

¡

by noise.

Use a measuring instrument which has 500kW input impedance

¡

or more.

Do not short between CB and COM because of possibility of fail-

¡

ure.

5.2 Auxiliary Power (AUX)

The power supplies can generate an auxiliary power (AUX: 12V

¡

0.15A) from CN1/CN2 to provide for remote ON/OFF and attached

circuits.

AUX circuit is isolated from other (input, output, FG, RC, WRN

¡

and PG) circuits.

Please do not draw a current of 0.15A or higher from the auxiliary

¡

power because doing so could damage the internal circuits or

cause malfunction.

When you connect a DC-DC converter, a current a few times

higher than normal current may ow at start-up. Please check the

current.

Output current

Rated current

Instruction Manual

5.3 Output Capacitive Load Considerations

Please see Table 5.1 for maximum value of external output capac-

¡

itance.If the external output capacitance exceeds the value shown

in Table 5.1, please contact us for details.

Table. 5.1 Maximum value of external output capacitance

Model

FETA7000ST-48 22,000

FETA7000ST-144 7,500

5.4 External Component (EMI/EMC Filter)

FETA7000ST can comply with FCC Part 15 class A and CIS-

PR32-A, EN55032-A, VCCI-A by connecting an external EMI/

EMC Filter.

Recommended EMI/EMC Filter:

FN3280H-25-32 (schaffner), B84131-M3-A116 (EPCOS) or equiv-

alent product.

300

-

480VAC

(3

f

4-Wire)

L3

L2

EMI/EMC

L1

N

FG

FILTER

Fig.5.2 Connecting EMI/EMC Filter

5.5 Ground

When installing the power supply with your unit, ensure that the

¡

input FG terminal is connected to safety ground of the unit.

5.6 Variable Speed Fan

The power supply has built-in variable speed cooling fan. The fan

¡

speed is a function of load and ambient temperature.

Maximum value of external output

L3

L2

L1

N

FG

capacitance [μF]

DC OUT +

FETA7000ST

DC OUT -

LOAD

FETA-15

Loading...

Loading...